Abstract

Kappaphycus is one of the most significant, economically valuable red seaweeds, cultivated in tropical and subtropical waters. This alga demands a relatively high market value globally, due to applications of the kappa carrageenan colloid that is industrially extracted from the biomass. Carrageenan is widely used in food, pharmaceuticals, and nutraceuticals and for aquaculture applications. The first successful commercial cultivation of Kappaphycus (previously called Eucheuma) was recorded from the southern Philippines in the late 1960s using the line and stake method. Dramatic production increases were achieved, with the Philippines being the leading producer of Kappaphycus for more than 30 years, until it was overtaken by Indonesia (in approximately 2008). By 1988, Kappaphycus farming became widespread in Indonesia, and efforts have been undertaken to spread Kappaphycus farming to more than 30 countries worldwide. Since 2008 Kappaphycus production steadily rose in Indonesia, but production from the Philippines has tended to decline since 2011. Research and development (R&D) initiatives focusing on Kappaphycus in the Philippines emphasized the means to increase productivity and solutions to issues causing declining production. R&D focusing on Kappaphycus cultivars in the Philippines was made through the National Seaweed R&D Program. Several institutions and research centers took major steps to achieve these objectives. There were significant and relevant results obtained in studies of molecular taxonomy, factors affecting sporulation, tissue culture and mutagenesis, protoplast isolation, strain selection, mitigation of ‘ice–ice’ malaise and Neosiphonia infestations. A recent development in Kappaphycus farming was the discovery that use of an extract from a brown seaweed acts as a biostimulant to improve tolerance of cultivars to abiotic stresses. Problems and challenges encountered in the production of Kappaphycus, even after more than 40 years of farming, but which needed to be overcome, are discussed.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Among those red seaweeds commercially cultivated worldwide, Kappaphycus and Eucheuma held the highest levels of production between 2000 and 2010 (Fig. 1). Kappaphycus is predominantly cultivated in tropical and subtropical waters. It is a major source of kappa carrageenan used as an emulsifier or binder or for suspension and stabilization in a wide range of products in the food processing, pharmaceutical, and cosmetic industries (Bixler and Porse 2011).

Cultivated Kappaphycus displaced wild-gathered Chondrus crispus as a major source of kappa carrageenan since it was commercially grown in the Philippines and other tropical countries, mainly because of the lower cost of labor. The geographical location of the Philippines, Indonesia, and Malaysia within the Coral Triangle where natural populations of Kappaphycus and Eucheuma are found favored robust and luxuriant growth of these seaweeds when in cultivation from shallow to deep water areas. The countries mentioned are major producers of cultivated Kappaphycus and Eucheuma (Fig. 2). Warm, clean, and clear seawater and good weather further bolstered the farming of carrageenan-bearing seaweeds in the region. However, among the three countries within the Coral Triangle, it is only the Philippines which is frequently visited by cyclones, being bordered to the east by the Pacific Ocean where cyclones originate. Hence, production is greatly affected in the Philippines as compared to Indonesia. The former had an annual seaweed production of 0.7–1.5 Mt fwt from 2000 to 2013 (Fig. 3a) with Palawan, Tawi-Tawi, Sulu, Bohol, and Zamboanga Sibugay as the leading producing provinces (Fig. 3b) (BAS 2014).

The successes of, and challenges to, carrageenan seaweed farming in the Philippines, after more than four decades and including several research and development (R&D) programs, training courses, and other initiatives, are discussed in this paper, highlighting the major activities of different stakeholders of the carrageenophyte seaweed industry.

Early years of commercial farming

Marine Colloids, Inc., a US seaweed-processing firm established the first Kappaphycus (“cottonii” type; originally called Eucheuma) cultivation research program in the Philippines in 1969. This initiative was later joined by the Bureau of Fisheries and Aquatic Resources (BFAR, formerly called the Philippine Fisheries Commission), and the University of the Philippines. The late Dr. Maxwell S. Doty, Vicente Alvarez, and Dr. Gavino C. Trono Jr. were pioneer academic and practitioners in advancing Kappaphycus cultivation in the Philippines and later around the world.

Intensive surveys and collection of data were conducted in the period 1967–1970 to assess the best cultivation sites. Though the first cultivation trials were made in Panagatan Is., Caluya, Antique, and Ilin Is. Occidental Mindoro, Philippines, in 1969, it was in the satellite cultivation trial in Tapaan Is., Siasi, Sulu in 1971 which was the most promising, with an average growth rate of 1.5–5.5 % day−1 (Doty 1973; Parker 1974). Experimental cultivation sites in Caluya, Antique, and Occidental Mindoro were abandoned later due to frequent typhoons and poor management. Other areas such as Sacol Is., Zamboanga City, and Garza Is., Occidental Mindoro, started to cultivate Kappaphycus in 1971–1972. At present, its commercial cultivation has been expanded to several areas of the Philippines.

The successful cultivation of Kappaphycus in the Philippines was later transferred to neighboring Southeast Asian countries notably Indonesia (Neish 2013) and Malaysia as early as 1975 and 1978 (Hurtado et al. 2014). Today, this seaweed is cultivated commercially in almost 30 countries, e.g., Solomon Is. (Kronen 2013), Mexico (Robledo et al. 2013), India (Krishnan and Narayanakumar 2013), and Tanzania (Msuya 2013).

Developments in R & D toward production technology

Systematics and taxonomy

The earliest identification of kappa-producing seaweed was called Eucheuma cottonii (Kraft 1970). However, this identification was changed by Doty in 1985. In the same year, he identified three new varieties of Eucheuma, namely, (1) Eucheuma alvarezii var. alvarezii in honor of Vicente Alvarez, (2) Eucheuma alvarezii var. tambalang, in honor Mr. Tambalang, and (3) Eucheuma alvarezii var. ajak-assi in honor of Sampayani Ajak and Assi. These identifications were based from the external and internal morphology of the vegetative and reproductive structures of each variety. Three years later, Doty (1988) changed all the three identifications to Kappaphycus alvarezii var. alvarezii, Kappaphycus alvarezii var. tambalang, and Kappaphycus alvarezii var. ajak-assi, respectively. At the present time, only Kappaphycus alvarezii var. tambalang is predominantly used by the farmers for commercial cultivation, primarily because it is a faster growing species and has better carrageenan quality as compared to Kappaphycus striatum (Hurtado et al. 2012).

Since the start of cultivating Kappaphycus and Eucheuma in the Philippines, a lot of strains bearing different color morphotypes were adopted. Naming each strain according to the native tongue of the locality added more confusion to the scientific nomenclature. However, advances in taxonomy and systematics made the identification of seaweeds more reliable and accurate using genetic markers. Zuccarello et al. (2006) made the first report on the genetic distinction between K. alvarezii, K. striatum, and Eucheuma denticulatum from 137 samples (wild and cultivated) analyzed from Hawaii, Indonesia, Madagascar, the Philippines, Tanzania, Venezuela, and Vietnam using mitochondrial cox2-3 and plastidal RuBisCo spacers. The same authors claimed that all cultivated K. alvarezii, at that time, around the world had a similar mitochondrial haplotype. However, these markers did not distinguish all the morphotypes known in cultivated K. alvarezii as confirmed by the reports of Tan et al. (2012) and Lim et al. (2013) who studied several samples of Kappaphycus and Eucheuma in the Southeast Asian region. The authors further reported that the molecular data gathered affirmed the higher species diversity in the region derived from morphological plasticity. The discovery of Kappaphycus malesianus J. Tan, P. E. Lim, and S. M. Phang as a new species by Tan et al. (2014) is an additional name to the Kappaphycus list as a potential cultivar for commercial propagation. The authors claimed that this new species is genetically distinct from its Kappaphycus congeners. The holotype of K. malesianus was found in a seagrass bed in the Celebes Sea, west of the Karindingan Is., Sabah, Malaysia; however, this same species has been commercially cultivated in Sitangkai, Tawi-Tawi, Philippines, since early 2000 to the present (Romero, personal communication).

Cultivation techniques

The only commonly applied method of commercially propagating Kappaphycus and Eucheuma since it was introduced in 1969 is still vegetative cutting. The thallus is cut into 100–150-g pieces selecting only the younger and more robust branches as propagules (=seedling) for planting purposes.

During the experimental years of cultivating Kappaphycus, the team of Doty tried several cultivation techniques to grow the ‘cottonii’ (BFAR 1969, unpublished data), such as (1) fixed off-bottom—consisting of stakes and lines made from monofilament nylon cord and soft plastic ‘tie-tie’, to tie the propagules to the cultivation lines, (2) the net method—propagules were tied at the intersections of the net using soft plastic ‘tie-tie’ and the four corners anchored by stakes driven in to the substratum, (3) the tubular method—made of fish net in a cylindrical shape where propagules were distributed inside, and (4) the cage method—made of fish net divided into rectangular compartments where propagules were evenly distributed. All these cultivation techniques (Doty 1973; Parker 1974; Doty and Alvarez 1981; Ricohermoso and Deveau 1979) were undertaken in shallow waters with the lowest mean tide level ranging from 25 to 100 cm. Later, the bamboo floating raft technique was introduced (Trono and Valdestamon 1994; Trono 1998). Commercial cultivation of Kappaphycus was no longer limited to shallow waters but introduced to deeper waters which required more support structures and higher initial capital investment and operating expenses (Hurtado and Agbayani 2002; Hurtado 2013; Valderrama et al. 2013). These new techniques included the hanging long line, free swing, multiple-raft long line, spider web, triangular (Hurtado et al. 2014), and vertical long lines (Capacio, personal communication). Of the four original “cottonii” cultivation techniques, only the fixed–off-bottom method continues to be commonly used among the farmers.

Micro-propagation technology

The quest to increase both productivity and production of Kappaphycus and Eucheuma cultivars in the Philippines was made through the National Seaweed R&D Program. The Department of Science and Technology through the Philippine Council for Agriculture, Aquatic and Natural Resources Research Development was the leading government agency which supported the seaweed R&D programs of the state universities (Marine Science Institute—University of the Philippines and Mindanao State University) and a few private universities (De La Salle University, Silliman University, University of Santo Tomas, and University of San Carlos). Likewise, the Department of Agriculture–Bureau of Fisheries and Aquatic Resources (DA-BFAR) and the Southeast Asian Fisheries Development Center—Aquaculture Department (SEAFDEC-AQD) initiated several R&D programs too. Several international organizations and multinational corporations based in the Philippines (Asian Development Bank (ADB), Australian Agency International Development (AusAID), Cargill Texturizing Solutions, Canada International Development Agency (CIDA), FMC Biopolymer, Deutsche Gesellschaft fur Internationale Zusammenarbeit GmbH (GTZ), International Finance Corporation (IFC), and US Agency International Development (USAID), in collaboration with local non-government organizations such as the Partnership for Development Assistance Programme, Inc. (PDAP), formerly known as Philippine Development Assistance Programme, Inc., and the Integrated Services for the Development of Aquaculture and Fisheries (ISDA), to name a few, made major steps in achieving the above-cited objectives.

Scarcity of raw materials due to impoverishment of natural seaweed populations became evident in the late 1980s. As early as 1990, signs of the deteriorating quality of Kappaphycus and Eucheuma cultivars, brought on by slow growth and the perennial occurrence of ‘ice–ice’, were observed because of continuous vegetative propagation; hence, the need to improve the productivity and production of said cultivars was deemed to be necessary. Alternative methods of generating “new” and “improved” Eucheuma and Kappaphycus were then pursued, namely, as follows.

Tissue culture

Micro-propagation using tissue culture techniques was applied to produce a large number of plants, genetically identical to the mother plant, as well as one another. The earliest work of Dawes and Koch (1991) demonstrated that enriched seawater media ranging from Erd schreibers seawater (ESS) and SWMD-1 to inexpensive soil extract (Erdschreiber’s), or holding in sterile seawater for up to three weeks, were successful. The micro-propagation of Kappaphycus and Eucheuma resulting in clonal propagation from axenic explants was achieved within 4–8 weeks, and these were then used as young propagules for outplanting purposes. The authors also reported that callus development and branch regeneration had also been induced in the two forms of each species. The same authors further reported that results of their initial field trials indicated that culture facilities in the farming areas of the Philippines could maintain high-yielding and rapidly growing seed-stock for the seaweed farmers.

The successful micro-propagation of Kappaphycus and Eucheuma in the laboratory of Dawes and Koch (1991) was followed by two studies that included growth performance in the laboratory and outplanting in the field (Dawes et al. 1993, 1994). These authors reported that the highest growth rates (4.48 % day−1) were found using inexpensive enrichments such as soil water and coconut water supplemented with 0.7 mM N and 13 μM P and a liquid fertilizer, Algafer. Laboratory-grown branches of both K. alvarezii and E. denticulatum, when transplanted to rafts in the field, showed daily growth rates of 4.4–8.9 % day−1, as high, or higher than, as other reported growth rates.

Ten years after the first report on the micro-propagation of Kappaphycus and Eucheuma, Hurtado and Cheney (2003) reported the successful propagule using vitamin mix, plus 1 ppm of plant growth hormone (zeatin + phenol acetic acid) with prior treatment of an antibiotic mixture (E3) which led to the formation of calli, that eventually regenerated to plantlets after few months. The plantlets were further grown in floating net cages to obtain good-quality propagules for commercial cultivation. Growth performance of the plantlets grown in floating net cages ranged from 5.8 to 7.2 % day−1, comparable with the results obtained by Dawes et al. (1994) using floating rafts. The growth rates of the plants produced through tissue culture reported by Hurtado and Cheney (2003) suggested that such plants grew at rates as good as, if not better than, those of ‘seedlings’ produced by the traditional method in the commercial cultivation of E. denticulatum.

Micro-propagation using tissue culture techniques was also undertaken in three color morphotypes of K. alvarezii var. “adik-adik.” True calli were formed after 29–35 days following dense formation of filaments or undifferentiated round cells at the medullary and inner cortical layers of the section using ESS/2 + plant growth hormone (zeatin + phenol acetic acid) (Hurtado and Biter 2007). Plantlets (2–3 mm long) were able to regenerate after 98, 150, and 177 days in vitro among the red, green, and brown morphotypes, respectively. This study established successful methods for the production and regeneration of tissue explants of K. alvarezii var. adik-adik which was a possible application to mass produce “new” cultivars for land- and sea-based nurseries as sources for commercial farming.

A deviation from the application of culture media (inorganic elements/compounds) to produce plantlets of Kappaphycus was reported by Hurtado et al. (2009). The authors reported the use of Acadian marine plant extract powder (AMPEP), a seaweed extract from the brown seaweed Ascophyllum nodosum, as a culture medium + plant growth hormones (zeatin and phenyl acetic acid (PAA) at 1 ppm) as used in the successful regeneration of young plants from different Kappaphycus varieties. Extract from A. nodosum is extensively studied and traded globally for agricultural farming purposes. There are several reports on the direct benefits from the application of A. nodosum and other seaweed extracts on land plants and crop performance, and these include (1) enhanced root vigor (Crouch and van Staden 1992), (2) increased leaf chlorophyll content (Blunden et al. 1996), (3) an increase in the number of leaves (Rayirath et al. 2008), (4) improved fruit yield (Arthur et al. 2003; Kumar and Sahoo 2011; Kumari et al. 2011), (5) heightened flavonoid content (Fan et al. 2011), and (6) enhanced vegetation propagation (Leclerc et al. 2006). However, the more substantial improvements associated with application of seaweed extracts involve the improved tolerance toward abiotic stresses, such as those brought on by drought (Spann and Little 2011; Zhang and Ervin 2004), ion toxicity (Mancuso et al. 2006), freezing (Rayirath et al. 2009), and high temperature (Zhang and Ervin 2008). Application of this extract for seaweeds was reported by Hurtado et al. (2009, 2012), Loureiro et al. (2010, 2012, 2013, 2014), Yunque et al. (2011), Borlongan et al. (2011), and Kumar et al. (2013).

According to the report of Hurtado et al. (2009), a shorter duration for shoot formation and regeneration was observed when the explant was treated with AMPEP + plant growth regulator (PGR = PAA + zeatin at 1 mg L−1) as compared to AMPEP when used singly. However, the four explants, namely, K. alvarezii (kapilaran, KAP), tambalang purple (PUR), adik-adik (AA), and one variety of K. striatum var. sacol (green sacol (GS)) responded differently to the number of days required for shoot formation. The KAP variety took 46 days to form shoots at 3–4 mg L−1 AMPEP + PGR, while PUR required 21 days at 3–5 mg L−1 AMPEP and 3–4 mg L−1 AMPEP + PGR. AA required 17 days at 3–5 mg L−1 AMPEP and AMPEP + PGR and GS 25 days at 1 mg L−1 AMPEP + PGR. The authors reported further that among the four explants used, PUR and AA initiated shoot formation with the use of AMPEP only at higher concentrations (3–5 mg L−1) after a shorter period. The use of AMPEP alone and/or in combination with PGR as a culture medium in the propagation of micro-plantlets using this culture technique was highly encouraging.

The use of AMPEP to improve the production of Kappaphycus plantlets was further reported by Yunque et al. (2011) using five color morphotypes of K. alvarezii and one color morphotype of K. striatum. Optimum media concentrations of AMPEP in combination with PGR (zeatin and PAA), pH–temperature combinations, and the ratio of explants, i.e., density/volume of medium, were tested to determine the shortest duration of shoot emergence. Each variety performed differently as to the number of days required before shoot emergence, as influenced by the concentration of AMPEP, pH–temperature combinations, and density/volume ratios. However, among the five varieties tested, the green and purple K. alvarezii showed the shortest number of days (nine) for shoot emergence. The rate of production of new and improved Kappaphycus plants for a commercial nursery stock was improved through the use of AMPEP with optimized culture media pH, temperature, and density conditions.

Spores and protoplasts

Though the results of micro-propagation of Kappaphycus and Eucheuma (1991–1994) were successful, the use of propagules generated from tissue culture techniques was not adopted by the farmers commercially. Hence, generating sporelings from carpospores was pursued in the hope that more viable plants could be developed as an alternative method of generating sporelings. In vitro and in situ release of carpospore and tetraspores and their subsequent germling development were then studied.

The recruitment of spores from K. alvarezii and Eucheuma, on a farm in Tawi-Tawi as an alternative method of generating sporelings for commercial cultivation, was first reported by Azanza-Corrales et al. (1996). It took 5 months after deployment to observe sporelings from Mactan stone blocks serving as a substratum for spore attachment, and this was influenced by current speed, number of days with low tide, and salinity. Significant recruitment was observed between September and December 1993 and January to February 1994 which indicated a seasonality of reproductive plants in the field.

According to Azanza and Aliaza (1999), the timing of collection of cystocarpic plants was crucial for the release of carpospores. Air drying before immersion in seawater showed the highest average, i.e., 279,000 carpospores g−1 wt of thallus from days 1 to 5. Nutrient enrichment showed little effect on spore release, while higher levels of nutrients (F/2, F/20) enhanced growth of contaminants and only reduced carpospore viability. On the other hand, low irradiance (7 μmol photons m−2 s−1) or low (25 ppt) or high salinity (e.g., 40 ppt) inhibited spore release and germling development. Germling growth was highest in the more enriched medium (F/2) (10.57 % growth day−1), when compared to F/20 medium (2.26 % growth day−1), Azanza and Aliaza (1999).

Though success was attained on the in vitro carpospore release of Kappaphycus in the report of Azanza and Ask (2003), it took 10 months to attain the best growth in the laboratory of 2.5 % day−1, which was comparatively low to that reported by Dawes and Koch (1991), Dawes et al. (1994), Hurtado and Cheney (2003), Hurtado and Biter (2007), Hurtado et al. (2009), and Yunque et al. (2011) in Kappaphycus and Eucheuma using tissue culture techniques.

Successful shedding of carpospores from wild K. striatum was reported by Luhan and Sollesta (2010). The authors claimed that growing the spores in a multistep culture method, i.e., from batch culture, aquaria, and tanks to the sea farm, was possible but dependent on photoperiod and temperature. Though it took almost 650 days to complete the cycle, it was the first report that described the development and growth of K. striatum from carpospores in the laboratory and in grow-out conditions in the wild, until they reached market size and maturity.

Carpospore progenies are diploid (2n) generations (tetrasporophytes) that are presumed to be more robust than the isomorphic haploids (n), based on the hypothesis that diploid (tetrasporophytes) are genetically superior to the haploid generation (cystocarpic and spermatangial generations). However, sourcing of reproductive explants (carposporophytes and tetrasporophytes) is highly seasonal, which limits the frequency of generating viable plantlets for commercial cultivation, as compared to micro-propagation where explants are available year-round.

An attempt to regenerate plantlets of different strains of K. alvarezii using protoplasts was met with little success (Salvador and Serrano 2005). Though they were able to isolate protoplasts and achieve subsequent germination using different combinations of enzymes under different culture conditions (culture media, temperature, photoperiods, and irradiance), no viable plantlets were regenerated.

Micro-propagation using tissue culture techniques, spore shedding and protoplast isolation, and germination were all investigated in order to produce improved qualities of cultivars that could possibly substitute for the repetitive use of vegetative “cuttings” as commonly used by the industry, in order to improve the productivity and production of Kappaphycus. However, to this date, none of the above techniques have been commercialized except for the tissue culture technology developed by SEAFDEC-AQD. A successful mass production of plantlets from the laboratory to the hatchery tanks was achieved. Several trials were made also in the field to test the efficacy and vigor of these plants as early as 2009 (Hurtado, unpublished data). Since 2013, young plants of K. alvarezii generated and developed from tissue culture have been distributed to the local industry for cultivation (Luhan, personal communication; Capacio, personal communication). However, the sustainability of these cultivars needs to be tested further. Moreover, the establishment of several, nationwide Seaweed Laboratory Centers by BFAR, in order to develop new and improved cultivars using the branch culture technique, will hopefully bolster a higher production of the Philippines in the near future.

Strain improvement

Over the years of vegetative propagation of Kappaphycus and Eucheuma, a large number of strains or varieties in varied color morphotypes have been observed and recorded (Trono et al. 2000; Hurtado et al. 2008a, 2008b, 2013). In situ growth performance of four varieties of K. alvarezii and four varieties of K. striatum was studied under three different culture periods (i.e., 30, 45, and 60 days) for a period of 1 year, in order to select the best “strain” of these two species for commercial cultivation (Hurtado 2008). Between the two species, K. alvarezii had the highest growth rate as compared to K. striatum. Among the K. alvarezii “strains,” tambalang purple ranked number one in terms of production when cultured for 30 and 60 days. Among the tambalang varieties, the highest production was recorded at 45-day duration of culture, except for tambalang purple which was at 60 days. Among the sacol varieties, the highest production was recorded at 30-day duration of culture, except for the green which was at 45 days. It has been observed that there was seasonality in growth rates between the two species having the highest growth rates from June to September, coinciding with lower water temperature and salinity. The occurrence of ‘ice–ice’ and Neosiphonia from March to April coincided with an elevated record of temperature; however, no subsequent occurrence of the “disease” was observed thereafter. K. alvarezii (tambalang purple) is widely cultivated in region of the Zamboanga Peninsula.

Improved crop management

Culture period manipulation

Seaweed farmers in the Philippines and elsewhere normally harvest Kappaphycus according to their economic needs. Based on observations (Hurtado, personal observation), K. striatum is grown for only 30 days, while K. alvarezii is grown for 45 days, or seldom for periods 60 or 90 days. Several studies have shown that the duration of culture impacted both growth rate and carrageenan characteristics, as influenced by culture technique (Hurtado et al. 2001, 2008c; Villanueva et al. 2011).

When brown and green K. alvarezii morphotypes were grown on fixed, off-bottom line (FOB), hanging long line (HLL), and a combination of these two techniques (HLL-FOB) for durations of 60 and 90 days, the combination of the two techniques (HLL-FOB) was the most efficient and productive at 60 days of culture (Hurtado et al. 2001). There was no significant difference in growth rate (% day−1) and production (fresh wt kg m−1 line−1) between the two color morphotypes. The authors described that the seaweed was grown for the first 30 days on hanging long lines at 25–30 cm below the surface for a faster growth rate and then taken down to the mid-bottom of the highest tide, after 30 days of culture, thus exposing them to a compromised light intensity level (Doty 1973) and keeping them away from excessive exposure to strong waves and low salinity (<26 ppt) during rainy days. These factors demonstrated that the combination of HLL-FOB was the most efficient and productive technique for the cultivation of Kappaphycus.

When K. striatum var. sacol was grown at (1) two stocking densities (500 and 1000 g m−1 line−1) and (2) at four different depths (50, 100, 150, and 200 cm below the water surface), each for three different durations of culture (30, 45, and 60 days), growth rate, carrageenan content, and molecular weight were significantly affected (p < 0.01) as shown by Hurtado et al. (2008c). The authors reported the following results: (1) a decreasing growth rate at both stocking densities and at all four depths, as the duration of the culture period increased, (2) a lower stocking density (500 g m−1 line−1) showed a higher growth rate for the shortest durations, i.e., 30 days, as compared to those grown at a higher density, (3) a decreasing growth rate as depth increased, except at 50 cm after 60 days of culture, (4) a 45-day culture period produced the highest molecular weight of carrageenan at both stocking densities (500 g m−1 line−1 = 1079.5 ± 31.8 kDa and 1000 g m−1 line−1 = 1167 ± 270.6 kDa), and (5) ‘sacol’ grown for 30 days at 50 cm (1178 kDa) to 100 cm (1200 kDa) depth showed the highest values of molecular weight of carrageenan extracted. Their results suggested that K. striatum var. sacol was best grown at a stocking density of 500 g m−1 line−1, at a depth of 50–100 cm, and for duration of 30 days in order to provide the highest growth rate, carrageenan content, and molecular weight.

A mathematical formula was employed to derive a weekly optimization index (a metric incorporating several parameters or product attributes, viz., biomass, carrageenan yield, and gel strength) on four commercially farmed Kappaphycus varieties (K. alvarezii var. alvarezii, K. striatum var. sacol, Kappaphycus sp. “aring-aring,” and Kappaphycus sp. “duyan”) in order to determine the most appropriate time of harvest. The Kappaphycus species exhibited ca 300 % increase in biomass within 4–7 weeks of the initiation of culture (ca 150 g from an initial biomass of 50-g wet weight), and then a biomass plateau was observed. The carrageenan yield in all seaweeds fluctuated minimally (mean 55–58 ± 2–4 %); however, gel strength peaked at 8–9 weeks of culture. The highest optimization index was obtained during week 8 for K. alvarezii var. alvarezii and week 9 for the rest of the cultured seaweeds (K. striatum var. sacol, Kappaphycus sp. “aring-aring,” and Kappaphycus sp. “duyan”) (Villanueva et al. 2011). The authors recommended harvest times for the respective seaweeds in order to obtain the best carrageenan quality.

A similar study was undertaken by Critcley et al. (2007) on K. alvarezii where five thalli were destructively harvested weekly for 6 weeks to assess growth rate, biomass increase, carrageenan yield, and molecular weight. The growth rate was linear at 2.5–5.2 % day−1, and significant differences were observed in growth rate and biomass increase between weeks (p < 0.05) and a positive correlation between growth rate and biomass (p < 0.01, two tailed). The author observed an increase in molecular weight from week 1 (639 Da) to week 5 (1,020,600 Da), but a decline in k-carrageenan content from week 1 (47.7 % of dry weight) to week 6 (26.5 % dry weight) which was possibly due to the presence of “ice–ice.” An increasing level of an iota carrageenan fraction was recorded from the first week (6.8 %) to the fourth week (14.5 %). It can be concluded that K. alvarezii demonstrated good growth rates and carrageenan characteristics after the sixth week of cultivation, which supported the industry practice.

Use of a biostimulant

The review of Craigie (2011) on seaweed extracts in plant science and agriculture comprehensively reported its many benefits. The use of seaweed extract as a soil conditioner and foliar spray has a long history as a supplement to land plant productivity and food production in various parts of the world. However, it was only recently that seaweed extract was also used as biostimulant to enhance the growth rate and increase tolerance to abiotic stresses such as extreme temperature, salinity, and light intensity in another seaweed. Below are few reports from the Philippines which marked the novel use of seaweed extract from A. nodosum, AMPEP, and in particular the cultivation of Kappaphycus.

Borlongan et al. (2011) showed that the use of AMPEP significantly (p < 0.05) increased the growth rate of the two Kappaphycus varieties (tungawan (TUNG) and giant tambalang (GTAM)) (Table 1) tested and also decreased the percentage occurrence of Neosiphonia sp. The percentage occurrence of Neosiphonia sp. infection (6–50 % at all depths) of both Kappaphycus varieties with AMPEP treatment was significantly lower than that of the controls (i.e., 10–75 % at all depths) (Fig. 4a, b). Both the growth rate of the cultivated seaweed and the percentage occurrence of the epiphytes decreased as the cultivation depth increased. Plants dipped in AMPEP and suspended at the surface had the highest growth rates (i.e., 4.1 %, TUNG; 3.1 %, GTAM) after 45 days; those without AMPEP dipping had the highest percentage occurrence of Neosiphonia infection (viz. 70–75 %). The occurrence of the Neosiphonia infestation was found to be correlated with changes in irradiance and salinity at the depths observed (Table 2). The results suggested that both varieties of K. alvarezii used in the study demonstrated the fastest growth rate when grown immediately at the water surface. On the other hand, in order to minimize damage caused by the occurrence of epiphytic Neosiphonia, K. alvarezii should be grown within a depth range of 50–100 cm. The findings of Borlongan et al. (2011) are important for the improved management of Kappaphycus for commercial farming with the use of AMPEP, especially in the reduction of the deleterious Neosiphonia sp. infections Fig. 5.

a Average percentage occurrence of Neosiphonia sp. on K. alvarezii var. giant tambalang grown at different depths from April to November. b Average percentage occurrence of Neosiphonia sp. on K. alvarezii var. tungawan grown at different depths from April to November (Borlongan et al. 2011)

The efficacy of AMPEP was further tested in order to optimize the growth rate of three color morphotypes of K. alvarezii (reddish brown, yellowish brown, and purple) in the field and the occurrence of macro-epiphytes, as influenced by the concentration of AMPEP (0.01, 0.1, and 1.0 g L−1 of seawater) and dipping time (30 and 60 min). The optimum concentration and duration were obtained at 0.1 g L−1 and 30 min, respectively. These optimum parameters were then further verified in a commercial nursery using the yellowish brown morphotype which demonstrated vigorous growth of multiple shoots, enhanced pigmentation, absence of macro-epiphytes, and faster growth rate (Hurtado et al. 2012). The same authors showed, in another experiment, that K. alvarezii (tambalang purple morphotype) and K. striatum (sacol green morphotype) with, and without, AMPEP dipping demonstrated almost the same trends in total antioxidant activity and phenolic content but differed monthly in iron chelating ability. The increased free radical scavenging ability and transition metal chelating ability of AMPEP-dipped Kappaphycus might be of interest from the point of view of resistance to pathogens and abiotic stresses—a phenomenon in the carrageenophyte seaweed industry elsewhere which presents as a major problem limiting productivity and production. The results of Hurtado et al. (2012) clearly showed the significance, as well as efficacy of AMPEP as a biostimulant in the cultivation of another seaweed.

Recently, the use of AMPEP in sea-based nurseries (BFAR-NFRDI, personal communication) and in commercial cultivation operations has been shown to be effective (de la Cruz, personal communication; Ferrer, personal communication; Capacio, personal communication). All claimed that Kappaphycus dipped in AMPEP at 0.1 g L−1 for 30–45 min was efficient to increase biomass by an average of greater than four to five times monthly. These observations are of paramount importance in improving and increasing the productivity and production of Kappaphycus.

Earlier studies regarding the efficacy of AMPEP on disease resistance, on agricultural crops such as carrot (Jayaraj et al. 2008) and cucumber (Jayaraj et al. 2011), reported that the A. nodosum commercial extract enhanced disease resistance through the induction of plant defense genes or proteins. While this is entirely speculation as a mode of action in seaweeds, such as AMPEP-dipped Kappaphycus, this aspect should be further studied in commercially grown seaweeds since pathological studies will become increasingly important as many cultivated, commercial seaweeds are based on limited genetic resources, grown as monospecific crops—a perfect situation for the codevelopment of pest species. This is exactly what has happened in terrestrial plant production and can be entirely predicted/expected to occur in seaweed cultivation; in fact, it is perhaps more surprising that, in particular, carrageenophytes have been cultivated by vegetative propagation for so long with relatively few “health” issues, until relatively recently (Largo et al. 1995a, b; Critchley et al. 2004; Hurtado et al. 2006; Vairappan 2006; Vairappan et al. 2008; Tisera and Naguit 2009; Solis et al. 2010; Borlongan et al. 2011).

On-site training courses and information dissemination/technology transfer

Training is an important component in the transfer of R&D results to the seaweed farmers. Several hands-on training courses were conducted throughout the Philippines on appropriate cultivation techniques. It is very important that the seaweed farmers gain knowledge about the basic biology and ecophysiology of Kappaphycus and Eucheuma in order to fully understand the complex interrelationships of the seaweeds and their marine environment.

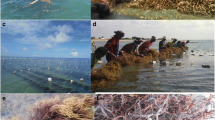

Several on-site, nationwide, hands-on training courses were conducted, to train not only current seaweed farmers but also newcomers to the industry, the latest of which is shown in Fig. 6. The success stories of some of the just out-of-school youths in three different ‘pondohans’ in Sitangkai, Tawi-Tawi, and in Marcilla, Coron, Palawan, are noteworthy. Positive results, as far as improved production and economic lifestyle, were experienced. The details of their success stories can be found in Hurtado (2013). This training was implemented by PDAP and ISDA, two local non-government organizations with financial support from international donors.

IFC-ADB not only funded the establishment of two nurseries in Zamboanga City but also more importantly provided training on technical issues such as disease and post-harvest management and development of entrepreneurial skills. Despite the success of these courses and the establishment of sea-based nurseries, the biggest setback was continuity of the project once the funding ended. Apparently, the seaweed farmers are far more inclined to operate as individual workers than belong to an organized group or cooperative working together.

Other training courses were conducted also by the senior author in the Visayas and Mindanao, especially on the establishment of sea-based nurseries. The use of a biostimulant (i.e., AMPEP) to promote faster growth and to improve tolerance to abiotic stresses of seedlings was adapted, and very encouraging results were achieved (Ferrer, personal communication).

The initiative of Cargill Texturizing Solutions (formerly Degussa Texturants) and PDAP in the dissemination of technology and information through the distribution of training brochures, flyers, and posters is highly commendable. The format, style, and language of these information brochures were specifically tailored to the seaweed farmers for ease of understanding.

Economic performance

A technology transferred to the stakeholders is nothing without considering the following: (1) technical feasibility, (2) economic viability, (3) environmental responsibility, and (4) social acceptability. There were several earlier reports on the technical feasibility and economic viability of Kappaphycus and Eucheuma farming, and these were documented by Doty (1986), Alih (1990), Samonte et al. (1993), Padilla (1994), Hurtado et al. (1996, 2001), and Hurtado and Agbayani (2002), to name a few. A recent study on the social and economic dimensions of carrageenan seaweed farming described six case studies across the major and emerging Kappaphycus–Eucheuma-producing countries in the world, i.e., India, Indonesia, Mexico, the Philippines, Solomon Is., and Tanzania (see Valderrama et al. 2013). A global synthesis was made by the contributing authors to provide a balanced assessment and comparison of the social and economic performance of carrageenan seaweed farming in different countries. The highlights of the study included as follows: (1) The technical and economic performance of a number of carrageenan seaweed farming cases was systematically evaluated and compared, (2) positive and negative social impacts of carrageenan seaweed farming were discussed, (3) issues related to governance and institutions in the sector were reviewed, (4) challenges and constraints faced by different countries in the future development of their seaweed industries were identified, and (5) a series of information and knowledge gaps were identified, in order to provide a clearer vision of carrageenan seaweed farming development in the future and facilitate evidence-based policy decision making and sector management. A brief summary of the economics of carrageenan seaweed farming in the Philippines, as one of the case studies, is presented in Table 3.

The above-cited economic analysis (Valderrama et al. 2013) is one of the six country case studies describing the “off-bottom” (i.e., FOB) and “floating” systems (i.e., HLL, multiple-raft long lines (MRLL) and the spider web (SW)) representing the three major areas of seaweed farming in the Philippines.

Based from the economic analyses, the productivity of the FOB system in Zamboanga was twice as high as that in Tawi-Tawi, while the productivity of the floating line systems in Tawi-Tawi (HLL) was almost three times as high as the FOB system in the same area. According to Valderrama et al. (2013), the productivity of the different culture systems in the Philippines, and other case studies, does not demonstrate any particular distinctive patterns, neither in terms of production per unit of cultivation line nor in terms of production per unit of farming area. This can be attributed to differences in farm locations (i.e., surface seawater temperature, movement, monsoons, salinity, and water quality) affecting growth rates of the seaweed and the number of cultivation cycles per year.

The economic efficiency (cost-effectiveness) of a farming system can be measured by its amortized capital cost, per unit of seaweed production. The FOB system in Tawi-Tawi and the HLL in Palawan had relatively low amortized capital costs because of the “free” and/or low-cost materials (stakes and floaters). A relatively low amortized capital cost simply indicated relatively high economic efficiency. HLL in Palawan also demonstrated the most economically efficient farming system, costing only US$ 3.6 for 1 t of dried seaweed produced, which was mainly due to the relatively high productivity and low amortized capital cost. However, among the floating systems adapted, SW in Zamboanga was the most expensive with the highest amortized capital cost per unit of seaweed production (US$ 111.1 t−1).

The most effective floating line system was the HLL, both in Tawi-Tawi and Palawan since it had the lowest total costs (per ton of dried seaweed production) as compared to other farming systems in the Philippines and indeed the other case studies examined in Valderrama et al. (2013). The floating line system (SW) was the most sophisticated technique used in deeper waters and had a lower capital cost and operating expenses than the floating raft system MRLL.

Among the farming systems adapted in the Philippines, net cash inflow in the first year was positive, except for the MRLL. This meant that these farms were able to recover their initial investments within 1 year. Use of the MRLL had a net cash outflow (i.e., negative net cash inflows) in the first year because of investments required in motorized boats. However, their positive net cash inflows in the second year were more than enough to cover the outflows in the first year, which implied that the payback periods of their investment were less than 2 years.

The summarized economic analysis of the Philippines’ carrageenophyte production indicated that when properly conducted, farming could be highly profitable and viable. Relying on “free” and/or low-cost materials and own labor, family farms using the HLL technique in Palawan and Tawi-Tawi could earn more than US$ 800 per year from 1 t of dried seaweed worth about US$ 1000 based on a capital cost of US$ 16–64 and operating expenses of US$ 89–203. In fact, there are countless lives that have been dramatically and positively changed because of seaweed farming, especially in the more remote islands of the Philippines (Hurtado et al. 2014).

Constraints and challenges

Despite several successful stories of carrageenan seaweed farming in the Philippines, even after more than four decades of cultivation, it has still many constraints and challenges to overcome. Every year, the country experiences an average of 24–25 typhoons (from weak to super typhoons), devastating the coastal areas and in particular seaweed farm structures. The super typhoon Haiyan, which visited the Philippines in November 2013, reduced the production of five major seaweed producing regions of the country from eastern to western Visayas and northern Palawan; thus, a tremendous reduction in the total production was recorded (SIAP, personal communication). To rehabilitate, the farm areas required considerable funds and time to recover the lost production and also to provide access to propagules for re-planting. The Moro National Liberation Front (MNLF) siege in Zamboanga City in September–October 2013 also contributed to the decreased production of the Zamboanga Peninsula, in particular, and the nation in general. Several families engaged in seaweed farming along the coast from Mariki to Arena Blanco, Zamboanga City, were displaced, which resulted in them abandoning their seaweed farms (Hurtado, personal observation), and as of July 2014, some families were still living in evacuation centers. Major technical problems in carrageenan seaweed farming are presented in Table 4.

There are three major challenges which face the industry of the Philippines including other countries of the Southeast Asian region, namely,

-

1.

Improvement of the genetic material that is available from clonal propagation

There is a continuing effort to select only the fast-growing and disease-resistant cultivars from micro-propagation. Once selected, clonally reproduced material has little opportunity to diversify by mutation. However, Kappaphycus as a food (guso) and raw material from which a food ingredient product (kappa carrageenan) is extracted should not be considered as a primary candidate for genetic modification (i.e., by the insertion of foreign DNA). This is to ensure that the extracts are used across their widest possible market base. Labeling of carrageenan as being derived from a GMO organism would create unnecessary resistance in the market place for the multiplicity of commodity and consumer goods. The natural variability of Kappaphycus across its extensive natural range has not been fully utilized, and it can be predicted that many morphotypes remain to be evaluated as strains for cultivation. It may also be that various strains/cultivars should have much smaller geographic distributions within seaweed farms. It is implicit that far more is known about the biology and phenology of the various strains. Early selection of the “best strains” for cultivation was perhaps a little haphazard. It is time that more concerted efforts were applied. This could be achieved by the establishment of a center for eucheumatoid research in the SE Asian region (i.e., Philippines) (along the lines of other important crop centers for potato, rice, banana, etc.). Bananas are a clonal crop plant which has a number of disease and cultivation challenges, and there are some parallels to be learned for clonal seaweeds perhaps.

-

2.

Preservation of the germplasm and seedling stocks that may help to provide access of propagules for re-planting in typhoon-devastated farms and other cultivable areas where propagules are unavailable

There is a need to provide the farmers with the strains that they have been growing preferably the fast-growing and “disease”-resistant strains, hence the need to establish “seed banks” in each region by the government, private sector, and local and international non-government organizations (NGOs). However, if the acquisition of materials and training of technicians that would allow tissue culture and cold/cryopreservation storage are unfeasible, the development of backup farms in areas that are historically safe is the best alternative. Those farms would have the sole purpose to provide propagules to the industry.

On the other hand, within time, there could be some collaboration and joint funding among the ASEAN countries that would result in the establishment of a Kappaphycus/Eucheuma research center to address this concern.

-

3.

Effect of changing climate and ocean acidification on seaweeds and seaweed farming and ecological impacts of human responses

The impact of global warming in the environment is mainly due to the absorbance of heat and carbon from the atmosphere by the oceans, thus changing the physical and chemical properties of the ocean. Seaweeds are directly affected by ocean warming. Increased surface seawater temperature will affect physiological processes altering phenology, growth rate, and ultimately the fitness of the cultivated seaweed in different ways (Harley et al. 2012). Seaweeds will have to acclimate or adapt to the new environmental conditions (Bellard et al. 2012; Viejo et al. 2011)

Strains of Kappaphycus/Eucheuma that have been selected for cultivation over the years were able to adapt to its environment as demonstrated from their “plastic” resiliency. For the past several years, the farmers have been growing the cultivars in shallow waters using the traditional FOB technique, but with the changing climate, they are gradually growing their cultivars in deeper waters using the hanging long-line, multiple raft long line, and the spider web techniques.

Conclusions

The impact of R&D in the carrageenan seaweed industry is being gradually felt, for example, some science-based technologies as follows: (1) Young plants developed from micro-propagation through tissue culture techniques are being used by the seaweed farmers as propagules for cultivation and (2) the introduction of AMPEP is being used to bolster growth and more importantly improve tolerance to abiotic stresses in order to reduce/or control secondary problems such as ‘ice–ice’ malaise and epiphytic and epiendophytic “ infections” (i.e., Neosiphonia spp.).

Ideally, the different stakeholders of the seaweed industry should work harmoniously without any reservations to sustain the seaweed-producing and allied industries in the Philippines and other producing countries. Innovations from farming and processing to product applications are the key to a successful, robust, and sustainable business model.

References

Alih EM (1990) Economics of seaweed Eucheuma farming in Tawi-Tawi Islands in the Philippines. In: Hirano R, Hanyu I (eds) The second Asian fisheries forum. Asian Fisheries Society, Manila, pp 245–249

Arthur GD, Stirk WA, van Staden J (2003) Effect of a seaweed concentrate on the growth and yield of three varieties of Capsicum annuum. S Afr J Bot 69:207–211

Azanza RV, Aliaza T (1999) In vitro carpospore release and germination in Kappaphycus alvarezii (Doty) Doty from Tawi-Tawi, Philippines. Bot Mar 42:281–284

Azanza RV, Ask E (2003) Kappaphycus alvarezii (Doty) Doty carposporeling growth and development in the laboratory. Int Seaweed Symp 17:95–99

Azanza-Corrales R, Aliaza TT, Montano NE (1996) Recruitment of Eucheuma and Kappaphycus on a farm in Tawi-Tawi, Philippines. Hydrobiologia 326(327):235–244

Bellard C, Bertelsmeier C, Leadley P, Thuiller W, Courchamp F (2012) Impacts of climate change on the future of biodiversity. Ecol Lett 15:365–377

Bixler HJ, Porse H (2011) A decade of change in the seaweed hydrocolloids industry. J Appl Phycol 23:321–335

Blunden G, Jenkins T, Liu YW (1996) Enhanced leaf chlorophyll levels in plants treated with seaweed extract. J Appl Phycol 8:535–543

Borlongan IAG, Tibubos KR, Yunque DAT, Hurtado AQ, Critchley AT (2011) Impact of AMPEP on the growth and occurrence of epiphytic Neosiphonia infestation on two varieties of commercially cultivated Kappaphycus alvarezii grown at different depths in the Philippines. J Appl Phycol 23:615–621

Bureau of Agricultural Statistics (2014). Fisheries Statistics Profile. http://countrystat.bas.gov.ph

Craigie JS (2011) Seaweed extract stimuli in plant science and agriculture. J Appl Phycol 23:371–393

Critcley AT, Hurtado AQ, Bleicher-L'honneur, GM, Leflamand A, Mazoyer J (2007) Observations on the duration of culture of Kappaphycus alvarezii var. tamblang. Internat. Seaweed Symp. 19 (Abstract)

Critchley AT, Largo D, Wee W, Bleicher-L’honneur G, Hurtado AQ, Schubert J (2004) A preliminary summary on Kappaphycus farming and the impact of epiphytes. Jap J Phycol 52:231–232

Crouch IJ, van Staden J (1992) Effect of seaweed concentrate on the establishment and yield of greenhouse tomato plants. J Appl Phycol 4:291–296

Dawes CJ, Koch EW (1991) Branch micropropagule and tissue culture of the red alga Eucheuma denticulatum and Kappaphycus alvarezii farmed in the Philippines. J Appl Phycol 3:247–257

Dawes CJ, Trono GC Jr, Lluisma AO (1993) Clonal propagation of Eucheuma denticulatum and Kappaphycus alvarezii for the Philippine seaweed farms. Hydrobiologia 260(261):379–383

Dawes CJ, Lluisma AO, Trono GC Jr (1994) Laboratory and field growth studies of commercial strains of Eucheuma denticulatum and Kappaphycus alvarezii in the Philippines. J Appl Phycol 6:21–24

Doty MS (1973) Farming the red seaweed, Eucheuma, for carrageenans. Micronesica 9:59–73

Doty MS (1985) Eucheuma alvarezii sp. novum (Gigartinales, Rhodophyta) from Malaysia. In: Abbott IA, Norris JN (eds) Taxonomy of economic seaweeds: with reference to some Pacific and Caribbean species. California Sea Grant College Program, La Jolla, pp 37–45

Doty MS (1986) Estimating returns from producing Gracilaria and Eucheuma on line farms. Monogr Biol 4:45–62

Doty MS (1988) Prodomus Ad Systematica Eucheumatoideorum: a tribe of commercial seaweeds related to Eucheuma (Solieriaceae, Gigartinales). In: Abbott IA (ed) Taxonomy of economic seaweeds: with reference to some Pacific and Caribbean species. Volume II. California Sea Grant College Program, La Jolla, pp 159–208

Doty MS, Alvarez VB (1981) Eucheuma farm productivity. Int Seaweed Symp 8:688–691

Fan D, Hodges DM, Zhang JZ, Kirby CW, Ji XH, Locke SJ, Critchley AT, Prithiviraj B (2011) Commercial extract of the brown seaweed Ascophyllum nodosum enhances phenolic antioxidant content of spinach (Spinacia oleracea L.) which protects Caenorhabditis elegans against oxidative and thermal stress. Food Chem 124:195–202

Harley CDG, Anderson KM, Demes KW, Jorve JP, Kordas RL, Coyle TA, Graham MH (2012) Effects of climate change on global seaweed communities. J Phycol 48:1064–1078

Hurtado AQ (2008) In situ strain improvement of Kappaphycus. Terminal Report submitted to Cargill Texturizing Solutions. Cargill Texturizing Solutions, France, p 23

Hurtado AQ (2013) Social and economic dimensions of carrageenan seaweed farming in the Philippines. In D. Valderrama, J. Cai, N. Hishamunda, N. Ridler (eds) Social and economic dimensions of carrageenan seaweed farming. Fish Aqua Tech Paper 580. FAO, Rome, p 91–113

Hurtado AQ, Agbayani RF (2002) Deep sea farming of Kappaphycus using multiple raft long-line method. Bot Mar 45:438–444

Hurtado AQ, Biter AB (2007) Plantlet regeneration of Kappaphycus alvarezii var. adik-adik by tissue culture. J Appl Phycol 19:783–786

Hurtado AQ, Cheney DP (2003) Propagule production of Eucheuma denticulatum (Burman) Collins and Harvey by tissue culture. Bot Mar 46:338–341

Hurtado AQ, Agbayani RF, Sanares R, de Castro-Mallare MTR (2001) The seasonality and economic feasibility of cultivating Kappaphycus alvarezii in Panagatan Cays, Caluya Antique, Philippines. Aquaculture 199:295–310

Hurtado AQ, Critchley AT, Trespoey A, Bleicher-L’honneur G (2006) Occurrence of Polysiphonia epiphytes in Kappaphycus farms at Calaguas Is. Camarines Norte, Philippines. J Appl Phycol 18:301–306

Hurtado AQ, Critchley AT, Bleicher-L’honneur G (2008a) Kappaphycus ‘cottonii’ farming (revised ed.). Degussa Texturizing Solutions, Baupte

Hurtado AQ, Pactoran JE, Allaga AT, Faburada ES (2008b) Mga dapat alamin sa pagsasaka ng Kappaphycus ‘cottonii’. Philippine Development Assistance Program, Quezon City

Hurtado AQ, Critchley AT, Trespoey A, Bleicher-L’honneur G (2008c) Growth and carrageenan quality of Kappaphycus striatum var. sacol grown at different stocking densities, duration of culture and depth. J Appl Phycol 20:551–555

Hurtado AQ, Yunque DA, Tibubos KT, Critchley AT (2009) Use of Acadian marine plant extract powder from Ascophyllum nodosum in tissue culture of Kappaphycus varieties. J Appl Phycol 21:633–639

Hurtado AQ, Joe M, Sanares RC, Fan D, Prithiviraj B, Critchley AT (2012) Investigation of the application of Acadian Marine Plant Extract Powder (AMPEP) to enhance the growth, phenolic content, free radical scavenging, and iron chelating activities of Kappaphycus Doty (Solieriaceae, Gigartinales, Rhodophyta). J Appl Phycol 24:601–611

Hurtado AQ, Montaño MNE, Martinez-Goss MR (2013) Commercial production of carrageenophytes in the Philippines: ensuring long-term sustainability for the industry. J Appl Phycol 25:733–742

Hurtado AQ, Gerung GS, Yasir S, Critchley AT (2014) Cultivation of tropical red seaweeds in the BIMP-EAGA region. J Appl Phycol 26:707–718

Hurtado-Ponce AQ, Agbayani RF, Chavoso EAJ (1996) Economics of cultivating Kappaphycus alvarezii using fixed bottom line and hanging long line methods in Panagatan Cays, Caluya, Antique, Philippines. J Appl Phycol 105:105–109

Jayaraj J, Wan A, Rahman M, Punja ZK (2008) Seaweed extract reduces foliar fungal disease on carrot. Crop Prot 10:1360–1366

Jayaraj J, Norrie J, Punja ZK (2011) Commercial extract from brown seaweed Ascophyllum nodosum reduces fungal diseases in green house cucumber. J Appl Phycol 23:353–361

Kraft GT (1970) The algal genus Eucheuma in the Philippines. Hawaii Botanical Sci. Paper. No. 18. University of Hawaii, Honolulu, p 368

Krishnan M, Narayanakumar R (2013) Social and economic dimensions of carrageenan seaweed farming in India. In D. Valderrama, J. Cai, N. Hishamunda, N. Ridler (eds) Social and economic dimensions of carrageenan seaweed farming, Fish Aqua Tech Paper 580. FAO, Rome, p 163–185

Kronen M (2013) Social and economic dimensions of carrageenan seaweed farming in the Solomon Islands. In D. Valderrama, J. Cai, N. Hishamunda, N. Ridler. (eds) Social and economic dimensions of carrageenan seaweed farming. Fish Aqua Tech Paper 580. FAO, Rome, p 147–161

Kumar G, Sahoo D (2011) Effect of seaweed liquid extract on growth and yield of Triticum aestivum var. Pusa Gold J Appl Phycol 23:251–255

Kumar M, Reddy CRK, Jha B (2013) The ameliorating effect of Acadian marine plant extract against liquids-induce oxidative stress and DNA damage in marine macroalga Ulva lactuca. J Appl Phycol 25:369–378

Kumari R, Kaur I, Bhatnagar A (2011) Effect of aqueous extract of Sargassum johnstonii Setchell on growth, yield and quality of Lycopersicon esculentum Mill. J Appl Phycol 23:623–633

Largo DB, Fukami F, Nishijima T, Ohno M (1995a) Laboratory induced development of the ice-ice disease of the farmed red algae Kappaphycus alvarezii and Eucheuma denticulatum (Solieriaceae, Gigartinales, Rhodophyta). J Appl Phycol 7:539–543

Largo DB, Fukami F, Nishijima T (1995b) Occasional bacteria promoting ice-ice disease in the carrageenan-producing red algae Kappaphycus alvarezii and Eucheuma denticulatum (Solieriaceae, Gigartinales, Rhodophyta). J Appl Phycol 7:545–554

Leclerc M, Caldwell CD, Lada RR, Norrie J (2006) Effect of plant growth regulators on propagule formation in Hemerocallis spp. and Hosta spp. Hort Sci 41:651–653

Lim PE, Tan J, Phang SM, Nikmatullah A, Hong DD, Sunarpi H, Hurtado AQ (2013) Genetic diversity of Kappaphycus Doty and Eucheuma J. Agardh (Solieriaceae, Rhodophyta) in Southeast Asia. J Appl Phycol 26:1253–1272

Loureiro RR, Reis RP, Critchley AT (2010) In vitro cultivation of three Kappaphycus alvarezii (Rhodophyta, Areschougiaceae) variants (green, red and brown) exposed to a commercial extract of the brown alga Ascophyllum nodosum (Fucaceae, Ochrophyta). J Appl Phycol 22:101–104

Loureiro RR, Reis RP, Berrogain FD, Critchley AT (2012) Extract powder from the brown alga Ascophyllum nodosum (Linnaeus) Le Jolis (AMPEP): a “vaccine-like” effect on Kappaphycus alvarezii (Doty) Doty ex P.C. Silva. J Appl Phycol 24:427–432

Loureiro RR, Reis RP, Berrogain FD, Critchley AT (2013) Effects of a commercial extract of the brown alga Ascophyllum nodosum on the biomass production of Kappaphycus alvarezii (Doty) Doty ex P C. Silva and its carrageenan yield and gel quality cultivated in Brazil. J Appl Phycol 26:763–768

Loureiro RR, Reis RP, Marroig RF (2014) Effect of the commercial extract of the brown alga Ascophyllum nodosum Mont. on Kappaphycus alvarezii (Doty) Doty ex P.C. Silva in situ submitted to lethal temperatures. J Appl Phycol 26:629–634

Luhan MRJ, Sollesta H (2010) Growing the reproductive cells (carpospores) of the seaweed, Kappaphycus striatum, in the laboratory until outplanting in the field and maturation to tetrasporophyte. J Appl Phycol 22:579–585

Mancuso S, Azzarello E, Mugnai S, Briand X (2006) Marine bioactive substances (IPA extract) improve foliar ion uptake and water stress tolerance in potted Vitis vinifera plants. Adv Hort Sci 20:156–161

Msuya FE (2013) Social and economic dimensions of carrageenan seaweed farming in the United Republic of Tanzania. In D. Valderrama, J. Cai, N. Hishamunda, N. Ridler (eds) Social and economic dimensions of carrageenan seaweed farming, Fish Aqua Tech Paper 580. FAO, Rome, p 115–146

Neish IC (2013) Social and economic dimensions of carrageenan seaweed farming in Indonesia. In D. Valderrama, J. Cai, N. Hishamunda, N. Ridler (eds) Social and economic dimensions of carrageenan seaweed farming. Fish Aqua Tech Paper 580. FAO, Rome, p 61–89

Padilla EJ (1994) Economies of scale and factor elasticities in seaweed farming in the Philippines. TML Conference Proc 4:193–2007

Parker HS (1974) The culture of the red algal genus Eucheuma in the Philippines. Aquac 3:425–439

Rayirath P, Jithesh MN, Farid A, Khan W, Palanisamy R, Hankins SD, Critchley AT, Prithiviraj B (2008) Rapid bioassays to evaluate the plant growth promoting activity of Ascophyllum nodosum (L.) Le Jol. using a model plant, Arabidopsis thaliana (L.) Heynh. J Appl Phycol 20:423–429

Rayirath P, Benkel B, Hodges DM, Allan-Wojtas P, MacKinnon S, Critchley AT, Prithiviraj B (2009) Lipophilic components of the brown seaweed, Ascophyllum nodosum, enhance freezing tolerance in Arabidopsis thaliana. Planta 230:135–147

Ricohermoso MA, Deveau LE (1979) Review of commercial propagation of Eucheuma (Florideophyceae) clones in the Philippines. Int Seaweed Symp 9:525–531

Robledo D, Gasca-Leyva E, Fraga J (2013) Social and economic dimensions of carrageenan seaweed farming in Mexico. In D. Valderrama, J. Cai, N. Hishamunda, N. Ridler (eds) Social and economic dimensions of carrageenan seaweed farming. Fish Aqua Tech Paper 580. FAO, Rome, p 185–204

Salvador RC, Serrano AE (2005) Isolation of protoplasts from tissue fragments of Philippine cultivars of Kappaphycus alvarezii (Solieriaceae, Rhodophyta). J Appl Phycol 17:15–22

Samonte GPB, Hurtado-Ponce AQ, Caturao RD (1993) Economic analysis of bottom line and raft monoline culture of Kappaphycus alvarezii var. tambalang in Western Visayas, Philippines. Aquac 100:1–11

Solis MJL, Draeger S, dela Cruz TEE (2010) Marine-derived fungi from Kappaphycus alvarezii and K. striatum as potential causative agents of ice-ice disease in farmed seaweed. Bot Mar 53:587–594

Spann TM, Little HA (2011) Applications of a commercial extract of the brown seaweed Ascophyllum nodosum increases drought tolerance in container-grown ‘Hamlin’ sweet orange nursery trees. Hort Sci 46:577–582

Tan J, Lim PE, Phang SM, Hong DD, Sunarpi H, Hurtado AQ (2012) Assessment of four molecular markers as potential DNA barcodes for red algae Kappaphycus Doty and Eucheuma J. Agardh (Solieriaceae, Rhodophyta). PLoS One 7(12):e52905

Tan J, Lim PE, Phang SM, Rahiman A, Nikmatullah A, Sunarpi H, Hurtado AQ (2014) Kappaphycus malesianus sp. nov.: a new species of Kappaphycus (Gigartinales, Rhodophyta) from Southeast Asia. J Appl Phycol 26:1273–1285

Tisera WL, Naguit MR (2009) Ice-ice disease occurrence in seaweed farms in Bais Bay, Negros Oriental and Zamboanga del Norte. Threshold 4:1–16

Trono GC (1998) The seaweed resources of the Philippines. In: Critchley AT and Ohno M (eds). Seaweed Resources of the World. JICA, Japan 47–61

Trono GC, Valdestamon RG (1994) New aspects in the ecology and culture of Kappaphycus and Eucheuma. Kor J Phycol 9:205–216

Trono GC Jr, Lluisma AO, Montaño MNE (2000) Primer on farming and strain selection of Kappaphycus and Eucheuma in the Philippines. PCAMRD, Quezon City, p 33

Vairappan CS (2006) Seasonal occurrences of epiphytic algae on the commercially cultivated red alga Kappaphycus alvarezii (Solieriaceae, Gigartinales, Rhodophyta). J Appl Phycol 18:611–617

Vairappan CS, Chung CS, Hurtado AQ, Soya FE, Bleicher-L’honneur G, Critchley A (2008) Distribution and symptoms of epiphyte infection in major carrageenophyte-producing farms. J Appl Phycol 20:477–483

Valderrama D, Cai J, Hishamunda N, Ridler N (2013) Social and economic dimensions of carrageenan seaweed farming. FAO Fish Aqua Tech Paper 580. FAO, Rome, p 204

Viejo RM, Martinez B, Arrontes J, Astudillo C, Hernandez L (2011) Reproductive patterns in central and marginal populations of a large brown seaweed: drastic changes at the southern range limit. Ecography 34:75–84

Villanueva RD, Romero JB, Montaño MNE, de la Peña PO (2011) Harvest optimization of four Kappaphycus species from the Philippines. Biomass Bioenergy 35:1311–1316

Yunque DAT, Tibubos KR, Hurtado AQ, Critchley AT (2011) Optimization of culture conditions for tissue culture production of young plantlets of carrageenophyte Kappaphycus. J Appl Phycol 23:433–438

Zhang XZ, Ervin EH (2004) Cytokinin-containing seaweed and humic acid extracts associated with creeping bentgrass leaf cytokinins and drought resistance. Crop Sci 44:1737–1745

Zhang XZ, Ervin EH (2008) Impact of seaweed extract-based cytokinins and zeatin riboside on creeping bentgrass heat tolerance. Crop Sci 48:364–370

Zuccarello GC, Critchley AT, Smith JE, Sieber V, Bleicher-L’honneur G, West JA (2006) Systematics and genetic variation in commercial Kappaphycus and Eucheuma (Solieriaceae, Rhodophyta). J Appl Phycol 18:643–651

Acknowledgments

The senior author is thankful to the National Organizing Committee of ISAP 2014 for inviting her as one of the plenary speakers and also for all the assistance extended and also to Lynn Cornish and Dr. Rafael R. Loureiro for their constructive insights in the revision of this manuscript.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Hurtado, A.Q., Neish, I.C. & Critchley, A.T. Developments in production technology of Kappaphycus in the Philippines: more than four decades of farming. J Appl Phycol 27, 1945–1961 (2015). https://doi.org/10.1007/s10811-014-0510-4

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10811-014-0510-4