Abstract

Kappaphycus alvarezii is being introduced in several countries and in some of them there is a need to adapt this cultivation to periods with lethal temperatures, such as the 16–18 °C that occurs in the winter in southern Brazil. Moreover, there is the need to maintain the seedlings during this lethal temperature period. Considering the promising results obtained with the commercial powder extract of Ascophyllum nodosum (Acadian marine plant extract powder—AMPEP) treatment in the cultivation of K. alvarezii in vitro and in the sea allowing more resistance to epiphytes and increasing the growth rate and carrageenan yield, it was hypothesized that seedlings previously subjected to an AMPEP treatment could be more resilient to lethal temperatures. The daily growth rate and carrageenan yield and gel quality (gel strength and gel viscosity) of K. alvarezii in vitro previously treated with AMPEP were analyzed under temperature stress. The daily growth rates and the gel strengths of the AMPEP-treated samples were increased. In spite of the lower carrageenan yield and lower gel viscosity, the values were within the ones accepted by the carrageenan industry. Thus, the treatment of the seedlings of the K. alvarezii with AMPEP solution can be used as an alternative to lower temperature effects on crops as a preventive action for the cultivation of the seedlings in tanks and in the sea in periods of low temperatures at sea.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Kappaphycus alvarezii Doty (Doty) ex P.C. Silva is the main source of raw material for the carrageenan industry (Bindu and Levine 2011; Bixler and Porse 2011). To meet the Brazilian demand for carrageenan, this species was initially introduced in Brazil in the late 1990s for experimental purposes, followed by the introduction of commercial farms. However, there was a need to adapt K. alvarezii cultivation techniques to some different environmental factors not suited to the culture of this species in this new environment. A solution for Brazilian cultivation of K. alvarezii was applying a floating rafts system made with PVC and the use of a tubular net technique in places with muddy bottoms and greater water movement. This cultivation system has spread all along the area allowed for commercial cultivation of K. alvarezii by the Brazilian Government in the southeastern coast (Góes and Reis 2011).

Hayashi et al. (2011) had success with experimental cultivation of K. alvarezii in the southern Brazil, Florianópolis, Santa Catarina state, using the same technique. However, during winter, the water temperatures (16–18 °C) in their sampling area were lethal to the cultivated samples. For the feasibility of the cultivation of K. alvarezii in this area, there is the need to allow the growth of this species in low temperatures. Hayashi (personal communication) commented that the better way to do this is to cultivate this alga in tanks during the months with low temperatures. Another option that could be established in sites with low temperatures consists of getting healthy seedlings to be cultivated once the cold season ends. Moreover, assuming that the loss of seedlings will make future cultivation attempts futile, there will be a need to translocate seedlings from other crops, increasing costs. To prevent the introduction of organisms accompanying the translocated seedlings, which despite being considered native organisms for the Brazilian coast, they could be treated as exotic at places in which the translocation of seedlings took place according to Brazilian environmental laws. A quarantine process would be required although to date no proper protocol has been established, which would delay the planting season and cultivation cycle.

Based on the promising results obtained with the use of a commercial powder, an extract of Ascophyllum nodosum Mont. (Acadian marine plant extract powder—AMPEP) in K. alvarezii in vitro and in the sea, where the samples based with the extract solution, became more resistant to epiphytes and had increased growth rate and carrageenan yield (Hurtado et al. 2009; Loureiro et al. 2010; 2012; Borlongan et al. 2011; Yunque et al. 2011). It was hypothesized that seedlings previously subjected to an AMPEP solution treatment could be more resilient to temperatures considered lethal.

To test this hypothesis, we evaluated the effect of the use of the AMPEP solution in the seedlings of K. alvarezii in vitro at the low temperatures that occur in southern Brazil between autumn and spring (Hayashi et al. 2011). The parameters chosen to evaluate K. alvarezii production and development under temperature stress were daily growth rate, carrageenan yield, and gel quality (gel strength and gel viscosity).

Material and methods

Laboratory conditions

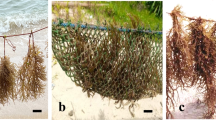

K. alvarezii seedlings were obtained in a commercial cultivation at Paraty Mirim, Rio de Janeiro state, Brazil (23°14′52′ S and 44°39′09′ W). The samples were then cleaned of epiphytes and acclimatized for 30 days in 5 L glass tanks (water temperature, 22 ± 2 °C; irradiance, 130 ± 10 μmol photons m−2 s−1; photoperiod, 12:12 h; 35 ± 1 salinity (PSU) and pH 8.1 ± 0.3).

Experimental design

After the acclimatization period, the samples were bathed for 1 h in containers with 12 L of a solution of AMPEP (20 g L−1 of filtered seawater, 0.45 μm) under constant aeration. Samples that were not bathed in an AMPEP solution were characterized as controls. Each sample consisted of apical tips of K. alvarezii (5 cm in length for a total of 5 g wet mass) and was cultured in an Erlenmeyer with 500 mL filtered seawater (0.45 μm) under constant aeration. Eight replications of AMPEP and control samples (n = 8) underwent three temperature treatments: t1 (16 ± 1 °C), t2 (19 ± 1 °C), and t3 (22 ± 1 °C). Temperatures t1 and t2 were considered lethal to K. alvarezii, and temperature t3 corresponded to those occurring in successful commercial cultivations of K. alvarezii in southern Rio de Janeiro state (Góes and Reis 2011, 2012). Temperatures were kept constant with coolers (fans; BAYO FS-120) in shallow plastic containers containing the Erlenmeyer flasks. The experiment lasted 20 days.

K. alvarezii daily growth rate and carrageenan yield and gel quality

The growth of the samples was estimated as daily growth rate (DGR), corresponding to the DGR (% day−1) = [(M t / M 0)1/t − 1] × 100 % where M 0 is the initial wet mass, M t is the final wet mass, and t is days of cultivation (Yong et al. 2013).

To calculate the carrageenan yield of the K. alvarezii samples, semi-refined carrageenan was obtained by an alkaline transformation process. In this process, the samples remained in a 6 % KOH solution in a water bath (80 °C) for 2 h, then was washed in water and maintained in 0.06 % NaClO solution for 30 min at room temperature (25 °C). The samples were then washed in water to remove any residue and finally dried in an oven (60 °C) to obtain a constant dry mass. The pH 8.4 was maintained throughout the procedure (Góes and Reis 2011; 2012; Loureiro et al. 2012).

The carrageenan yield (CY) of each K. alvarezii sample (n = 8) was estimated by calculating the percentage of semi-refined carrageenan obtained in relation to the dry mass of the sampled alga (Góes and Reis 2011, 2012) by the formula CY = (Mc / Ms) × 100, where Mc is the semi-refined dry carrageenan mass and Ms is the initial dry mass of the K. alvarezii sample.

The quality of the carrageenan gel produced by K. alvarezii samples was estimated by gel strength and gel viscosity from eight gel samples (n = 8). To prepare the gel of the semi-refined carrageenan, each sample was macerated in a ball mill (Mixer Mill MM 400, Retsch) and mixed in 100 mL distilled water to a 1.5 % proportion. This solution was kept for 1 h at room temperature (25 °C) and heated (80 °C) for 10 min under constant agitation and subsequently cooled (7 ± 2 °C) for 24 h.

The gel viscosity was analyzed using a cone Rheometer DV-III Ultra (Brookfield Engineering Labs, Inc.) at 75 °C with a CP-40 spindle. The gel strength was measured using the Texturometer, TexturePros CT (Brookfield Engineering Labs Inc.) with a cylindrical probe and a sample flask of 2.5 cm width and 5 cm height.

Statistical analysis

The assumptions of normality (Shapiro–Wilk test) and homogeneity of variance (Cochran test) of the data were previously tested and parametrical tests could be used to analyze carrageenan yield and gel strength of the K. alvarezii samples. The difference in the daily growth rate and in the gel viscosity of the K. alvarezii samples (AMPEP and control) cultivated at three temperatures (t1, t2, and t3) were analyzed by Kruskal–Wallis ANOVA since they did not meet the requirements for parametric testing even when they were transformed. The statistically significant different medians were identified using multiple comparisons p values (two-tailed).

Statistical differences in carrageenan yield and gel strength of the K. alvarezii samples at three temperatures were obtained by one factor analysis of variance (one-way ANOVA), and the differences were distinguish using the least significant difference (LSD) Fisher test. The analyses were run with Statistica Program, 6.0, StatSoft Inc. and used the confidence interval of 95 % (p < 0.05), using eight replicas per treatment (n = 8). Data were expressed as mean ± standard deviation.

Results

Significant differences in daily growth rates of AMPEP treatment and control were found at different temperatures (H = 43.83, p < 0.001, Fig. 1a). The highest daily growth rates of K. alvarezii were obtained from samples treated with AMPEP, when compared to their controls at all temperatures (p < 0.05, multiple comparisons p values). At temperature t1 (16 ± 1 °C), the control samples showed whitening of the thallus, while bleaching was not observed in samples treated with AMPEP under the same temperature conditions.

a–d: Daily growth rate (a), carrageenan yield (b), gel viscosity (c), and gel strength (d) of K. alvarezii samples in vitro submitted to the AMPEP treatment (AT) or not (CT, control treatment), under three temperatures (t1 = 16 ± 1 °C; t2 = 19 ± 1 °C and t3 = 22 ± 1 °C). Square represents the mean, rectangle the ± standard error, line the ± standard deviation, and circle the outliers

Moreover, significant differences in carrageenan yield of K. alvarezii between AMPEP and control samples were observed (F = 271.94, p < 0.001, Fig. 1b). When AMPEP samples were compared with their control samples, the results at temperatures t1 (16 ± 1 °C) and at t2 (19 ± 1 °C) were different from the ones cultivated under temperature t3 (22 ± 1 °C). The highest yields were obtained by control samples (p < 0.001, LSD test), while at temperature t3 (22 ± 1 °C) the carrageenan yield of AMPEP samples was higher than the control (p < 0.001, LSD test).

Similar results were observed with the gel viscosity of K. alvarezii cultivated under different temperatures (H = 33.30, p < 0.001, Fig. 1c), with higher gel viscosity obtained by the control samples cultivated at temperatures t1 and t2 and similarly gel viscosity (AMPEP and control) in samples cultivated in temperature t3. Differently, the gel strength of the K. alvarezii cultivated under different temperature conditions (F = 65.67, p < 0.001, Fig. 1d) showed different results from daily growth rates, carrageenan yield, and gel viscosity, where the control samples presented lower gel strengths in temperatures t1 and t2 and no significant difference in temperature t3 when compared to AMPEP samples.

Discussion

The daily growth rate of the seedlings submitted to the AMPEP solution and cultivated in low temperatures are within the range of values for commercial cultivation at Rio de Janeiro state (Góes and Reis 2011; 2012) and within the range found in other studies on the effect of AMPEP on this species in cultivations in vitro and in situ (Loureiro et al. 2010; 2012; Borlongan et al. 2011; Yunque et al. 2011).

High daily growth rates for K. alvarezii seedlings were obtained at all temperatures when subjected to AMPEP treatment, even at suboptimal temperatures with adverse effects on growth of the species (Ohno et al. 1994; Hayashi et al. 2011). This might perhaps be due to the presence of betaines that promote protection of the disruption of electron transport by the photosystem II and degradation of pigments as described by Mackinnon et al. (2010). Moreover, the presence of cytokinin could also play a role as an elicitor activity in the AMPEP extract and its antioxidant properties (Reitz and Trumble 1996; Khan et al. 2009). Studies that utilized higher plants as test subjects showed that the A. nodosum extract administered in the soil or as foliar sprays proved to be an effective antioxidant in combating pests or protecting the samples from adverse effects caused by long exposure to their own defense response (reactive oxygen species) (Jayaraj et al. 2008; Khan et al. 2008; 2009; Parys et al. 2009; Jayaraman et al. 2011).

The beneficial effects of using AMPEP in other organisms (higher plants) that were submitted to a temperature stress already showed promising results. Rayirath et al. (2009) observed the efficiency of this extract on aiding the survival of Arabidopsis thaliana (L.) Heynh. in vitro (−7.5 °C) and in situ (−5.5 °C). This positive effect was attributed to the presence of lipophilic compounds (LPCs) and the direct action of those lipophilic fractions on cold response genes COR15A, RD29A, and CBF3 which are likely to be present in red macroalgae due to the genes evolutionary paths.

Nair et al. (2012) also found a positive effect of the A. nodosum extract in A. thaliana at low temperatures and commented that the expression of genes showed the accumulation of proline, which was mediated by an increased expression of genes for proline (P5CS1 and P5CS2) and the reduction in gene expression of proline dehydrogenase (PRODH). Proline is known to play many roles in frost tolerance; such as a mediator of osmotic adjustments, stabilizer of proteins and membranes, inducer of osmotic stress-related genes, and source of reduction equivalents during stress recovery (Nair et al. 2012; Yoshiba et al. 1997; Rudolph et al. 1986) which proves to also take place in similar ways in macroalgae. Moreover, the elevated presence of LPCs significantly increased the concentration of soluble sugars in the cytosol in response to freezing stress, showing the mode of action of LPCs in protecting the tested samples at low temperatures and their effects in addition to priming cold response genes.

Barros et al. (2006), when subjecting K. alvarezii to freezing stress, observed the exudation of H2O2 (preventing effective action of catalase—CAT and the induction of ascorbate peroxidase gene—APX). It was suggested that this exudation is a physiological strategy of the red alga to handle the scale and rapid production of the highly toxic H2O2 in their tissues. Loureiro et al. (2012) observed the same results when they induced the production of H2O2 in K. alvarezii samples in order to evaluate the effects of AMPEP under such conditions.

It is therefore suggested that the gradual (but constant) H2O2 accumulation may be responsible for the delay in responses appropriate to CAT and APX, as suggested by Barros et al. (2006), which guarantees an acclimatization in the long term, permitting K. alvarezii to increase its growth rate (i.e., biomass increment) under adverse environmental conditions combined with favorable compounds present in AMPEP and its antioxidant action.

The carrageenan yields of the K. alvarezii seedlings (AMPEP and control samples) under the three tested temperatures were within the range considered ideal by the industry, around 30 % (Hayashi et al. 2007; Hung et al. 2009; Góes and Reis 2011; 2012). Probably, the highest values observed in samples under low temperature stress (t1 and t2) when compared with temperature t3 were caused by the known increase in production of polysaccharide (agar, carrageenan, and alginate) as the first line of defense of macroalgae that disposes of this resource in response to abiotic stresses (Craigie and Wen 1984; Knutsen et al. 2001). The chlorophyll content that is known to decrease under low temperature conditions (Dawes et al. 1999) seemed to be unharmed of less affected on AMPEP treated samples since their daily growth rate results were higher when compared to their respective controls. Nair et al. (2012) attests that the AMPEP extract has a positive effect (70 % less of chlorophyll damage due to low temperature) on reducing the expression of chlorophyllase under chilling stress.

The gel strength and gel viscosity of the samples of K. alvarezii were independent of the temperature range that they were cultivated at or the effect of treatment and are within the range values found in other studies made with K. alvarezii cultivated at Sepetiba bay at Rio de Janeiro state (Góes and Reis 2011; 2012) and elsewhere (Ohno et al. 1994; Hayashi et al. 2007). Also, values are within what is expected by the carrageenan industry, gel strength superior to 200 g cm2 and gel viscosity between 30 and 800 cP (Góes and Reis 2011).

Craigie and Wen (1984) reported that algae subjected to low temperature stress have higher gel strength. This was in agreement with results of this study, regardless if the samples were treated with the AMPEP solution or not. Furthermore, the carrageenan gel strengths of AMPEP samples grown at low temperatures (t1 and t2) were higher than their controls; this was possibly caused by the extract's abundance of soluble potassium (17–22 %) in its composition (Hurtado et al. 2009; Loureiro et al. 2012). Kappa-carrageenan is sensitive to potassium ions allowing it to produce more rigid gels when the samples were previously exposed to aqueous solutions rich in soluble potassium. The temperature also affects the proportion of sulfate and 3,6-anhydro-galactose in the final carrageenan conformation, a fact that is directly responsible for the rheological properties of the polysaccharide. Moreover, it also affects the disulfide bond in proteins, as a result of the chilling stress, promoting additional final carrageenan conformational shifts.

At lower temperatures, the concentration of sulfate in the carrageenan is lessened when compared to 3,6-anhydro-galactose. This molecular configuration provides greater rigidity to the gel when compared to gels obtained from samples cultivated in higher temperature conditions (Craigie 1990; Craigie and Wen 1984).

Negative changes in the molecular weight of carrageenan caused by stress factors (low temperatures in this study) also avoid the correct formation of hydrogen bonds, which are responsible for the formation of the double helix that increases the gelling power of the polysaccharide. This deficiency causes low gel viscosity (Mendonza et al. 2002). In this experiment, this pattern was observed only with the samples treated with AMPEP.

In conclusion, the use of the commercial extract powder of A. nodosum, AMPEP, in K. alvarezii samples in vitro at low temperatures acted as a remedial to stress, increasing the daily growth rates and the gel strength of the treated samples. In spite of the lower carrageenan yield and lower gel viscosity obtained using AMPEP, the values were within the ones used in the industry. Thus, the treatment of the seedlings of the K. alvarezii with AMPEP solution can be an alternative as a preventative action for the cultivation of the seedlings in tanks and in the sea in periods of low temperatures.

References

Barros MP, Necchi O Jr, Colepicolo P, Pedersén M (2006) Kinetic study of the plastoquinone pool availability correlated with H2O2 release in seawater and antioxidant responses in the red alga Kappaphycus alvarezii exposed to single or combined high light, chilling and chemical stresses. Biochim Biophys Acta 1757:1520–1528

Bindu MS, Levine IA (2011) The commercial red seaweed Kappaphycus alvarezii—an overview on farming and environment. J Appl Phycol 23:789–796

Bixler HJ, Porse H (2011) A decade of change in the seaweed hydrocolloids industry. J Appl Phycol 23:321–335

Borlongan IAG, Tibudos KR, Yunque DAT, Hurtado AQ, Critchley AT (2011) Impact of AMPEP on the growth and occurrence of epiphytic Neosiphonia infestation on two varieties of commercially cultivated Kappaphycus alvarezii grown at different depths in the Philippines. J Appl Phycol 23:615–621

Craigie JS (1990) Cell walls. In: Cole KM, Sheath RG (eds) Biology of the Red Algae. Cambridge University Press, Cambridge, pp 221–225

Craigie JS, Wen ZC (1984) Effects of temperature and tissue age on gel stregth and composition of agar from Gracilaria tikhaviae (Rhodophyta). Can J Bot 62:1665–1670

Dawes CJ, Orduña-Rojas J, Robledo D (1999) Response of the tropical red seaweed Gracilaria cornea to temperature, salinity and irradiance. J Appl Phycol 10:419-425

Góes HG, Reis RP (2011) An initial comparison of tubular netting versus tie–tie methods of cultivation for Kappaphycus alvarezii (Rhodophyta, Solieriaceae) on the south coast of Rio de Janeiro State, Brazil. J Appl Phycol 23:607–613

Góes HG, Reis RP (2012) Temporal variation of the growth, carrageenan yield and quality of Kappaphycus alvarezii (Rhodophyta, Gigartinales) cultivated at Sepetiba Bay, southeastern Brazilian coast. J Appl Phycol 24:173–180

Hayashi L, Oliveira EC, Bleicher-Lhonneur G, Boulenguer P, Pereira RTL, von Seckendorff R, Shimoda VT, Leflamand A, Vallée P, Critchley AT (2007) The effects of selected cultivation conditions on the carrageenan characteristics of Kappaphycus alvarezii (Rhodophyta, Solieriaceae) in Ubatuba Bay, São Paulo, Brazil. J Appl Phycol 19:505–511

Hayashi L, Santos AA, Faria GSM, Nunes BG, Souza MS, Fonseca ALD, Barreto PLM, Oliveira EC, Bouzon ZL (2011) Kappaphycus alvarezii (Rhodophyta, Areschougiaceae) cultivated in subtropical waters in Southern Brazil. J Appl Phycol 23:337–343

Hung LD, Hori K, Nang HQ, Kha T, Hoa LT (2009) Seasonal changes in growth rate, carrageenan yield and lectin content in the red alga Kappaphycus alvarezii cultivated in Camranh Bay, Vietnam. J Appl Phycol 21:265–272

Hurtado AQ, Yunque DA, Tibudos K, Critchley AT (2009) Use of Acadian marine plant extract powder from Ascophyllum nodosum in tissue culture of Kappaphycus varieties. J Appl Phycol 21:633–639

Jayaraj J, Wan A, Rahman M, Punja ZK (2008) Seaweed extract reduces foliar fungal diseases on carrots. Crop Prot 27:1360–1366

Jayaraman J, Norrie J, Punja ZK (2011) Commercial extract from the brown seaweed Ascophyllum nodosum reduces diseases in greenhouse cucumber. J Appl Phycol 23:353–361

Khan W, Palanisamy R, Hankins SD, Critchley AT, Smith DL, Papadopoulos Y, Prithiviraj B (2008) Ascophyllum nodosum (L.) Le Jolis extract improves root nodulation in Alfalfa. Can J Plant Sci 88:728–728

Khan W, Rayirath UP, Subramanian UP, Jitesh MN, Rayorath P, Hodges DM, Critchley AT, Craigie JS, Norrie J, Prithiviraj B (2009) Seaweed extracts as biostimulants of plant growth and development. J Plant Growth Reg 28:386–39

Knutsen SH, Sletmoen M, Kristensen T, Barbeyron T, Kloareg B, Potin P (2001) A rapid method for the separation and analysis of carrageenan oligosaccharides released by iota and kappa-carrageenase. Carbohydrates 331:101–106

Loureiro RR, Reis RP, Berrogain FD, Critchley AT (2012) Extract powder from the brown alga Ascophyllum nodosum (Linnaeus) Le Jolis (AMPEP): a vaccine-like effect on Kappaphycus alvarezii (Doty) Doty ex P.C. Silva. J Appl Phycol 24:427–432

Loureiro RR, Reis RP, Critchley AT (2010) In vitro cultivation of three Kappaphycus alvarezii (Rhodophyta, Areschougiaceae) variants (green, red and brown) exposed to a commercial extract of the brown alga Ascophyllum nodosum (Fucaceae, Ochrophyta). J Appl Phycol 22:101–104

Mackinnon SL, Hiltz D, Ugarte R, Craft CA (2010) Improved methods of analysis for betaines in Ascophyllum nodosum and its commercial seaweed extracts. J Appl Phycol 22:489–494

Mendonza WG, Montaño NE, Ganzon-Fortes ET, Villanueva RD (2002) Chemical and gelling profile of ice–ice infected carrageenan from Kappaphycus striatum (Schmitz) Doty sacol strain (Solieriaceae, Gigartinales, Rhodophyta). J Appl Phycol 14:409–418

Nair P, Kandasamy S, Zhang J, Ji X, Kirby C, Benkel B, Hodges MD, Critchley AT, Hiltz D, Prithiviraj B (2012) Transcriptional and metabolic analysis of Ascophyllum nodosum mediates freezing tolerance in Arabidopsis thaliana. BMC Genomics 13:643

Ohno M, Largo DB, Ikumoto T (1994) Growth rate, carrageenan yield and gel properties of cultured kappa carrageenan producing red alga Kappaphycus alvarezii (Doty) Doty in the subtropical waters of Shikoku, Japan. J Appl Phycol 6:1–5

Parys S, Kehraus S, Pete R, Kupper FC, Glombitza KW, Konig GW (2009) Seasonal variation of polyphenolics in Ascophyllum nodosum (Phaeophyceae). Eur J Phycol 44:331–338

Rayirath P, Benkel B, Hodges MD, Allan-Wojitas P, MacKinnon S, Critchley AT, Prithiviraj B (2009) Lipophilic components of the brown seaweed, Ascophyllum nodosum, enhance freezing tolerance in Arabidopsis thaliana. Planta 230:135–147

Reitz SR, Trumble JT (1996) Effects of cytokinin-containing seaweed extract on Phaseolus lunatus L.: influence of nutrient availability and apex removal. Bot Mar 39:33–38

Rudolph AS, Crowe JH, Crowe LM (1986) Effects of three stabilizing agents—proline, betaine, and trehalose on membrane phospholipids. Arch Biochem Biophys 245:134–143

Yong YS, Yong WTL, Anton A (2013) Analysis of formulae for determination of seaweed growth rate. J Appl Phycol DOI. doi:10.1007/s10811-013-0022-7

Yoshiba Y, Kiyosue T, Nakashima K, Yamaguchi-Shinozaki K, Shinozaki K (1997) Regulation of levels of proline as an osmolyte in plants under water stress. Plant Cell Physiol 38:1095–1102

Yunque DAT, Tibudos KR, Hurtado AQ, Critchley AT (2011) Optimization of culture conditions for tissueculture production of young plantlets of carrageenophyte Kappaphycus. J Appl Phycol 23:433–438

Acknowledgments

Conselho Nacional de Desenvolvimento Científico e Tecnológico (CNPq), Coordenação de Aperfeiçoamento de Pessoal de Nível Superior (CAPES), and Fundação de Amparo à Pesquisa do Estado do Rio de Janeiro (FAPERJ) supported this research. The authors would like to thank Acadian Seaplants Limited for providing the AMPEP and Henrique Geromél de Góes for providing K. alvarezii samples.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Loureiro, R.R., Reis, R.P. & Marroig, R.G. Effect of the commercial extract of the brown alga Ascophyllum nodosum Mont. on Kappaphycus alvarezii (Doty) Doty ex P.C. Silva in situ submitted to lethal temperatures. J Appl Phycol 26, 629–634 (2014). https://doi.org/10.1007/s10811-013-0085-5

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10811-013-0085-5