Abstract

Kappaphycus and Eucheuma species have been successfully cultivated in Southeast Asia since the early 1970s. The increasing global demand for carrageenan in processed foods and thereby the need for industrial-scales of biomass to be provided to feed an extraction industry, exceeded wild stock availability and productivity and commercial demands could only be achieved through extensive cultivation of selected carrageenophytes . This unprecedented situation led to the introduction of carrageenophyte species and cultivars around the world; combined production of Eucheuma and Kappaphycus is one of the largest for seaweed biomass in the world.

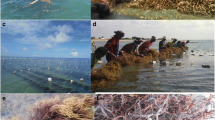

The activity of, and economic benefits accrued from, seaweed farming are indeed responsible for significant changes in rural, coastal communities in a number of important countries. Such activities generating new activity and income are often the only source of cash to some of the farmers. However, in spite of the enormous size and value of the industry the techniques applied to cultivation of carrageenophytes has remained almost unchanged in the commercial farms. Seedlings (or vegetatively propagated fragments of older, larger, mature thalli) are still most commonly planted along ropes held in various configurations, in most of the major production centers, e.g. mostly classified as simple stakes in the ground (off-bottom planting to floating rafts of various design). Some technological developments have been made in Brazil and India with the implementation of tubular nets for planting, which allows a degree of mechanization on the farms; both countries are developing mechanical harvesters. Further to co-production of biomass and harvesting, the drying process is still a limiting problem for production, and drying costs are high, in countries with high rainfall, this segment of the process is discussed in detail by Ali et al. Chap. 8). Diseases such as “ice-ice” and blooms of epiphytes and endophytes (see Chap. 6 by Loureiro et al.), as well as present and impending climate change effects (see Chap. 7 by Largo et al.) are also very big challenges.

In general, the production of carrageenophytes in tropical and sub-tropical regions is very dependent on the weather: as in prevailing conditions during the dry and wet seasons or surface seawater temperatures (SSTs) during “cold” winters and/or “hot” summers. For the future, efforts need to be made to increase the productivity and resistance of the selected strains of carrageenophyte seedlings against environmental instabilities.

Access provided by CONRICYT-eBooks. Download chapter PDF

Similar content being viewed by others

Keywords

4.1 Introduction

Seaweed farming has been increasing in economic significance over recent years, and at the time of writing, is considered the second largest production in aquaculture. FAO usually includes seaweeds in the group called “aquatic plants”, of which in 2014, 27.3 million MT were produced, with a value of US$5.6 billion. Seaweeds were responsible for almost 98% of this production, the remaining 2% being represented by microalgal biomass and other aquatic plants (FAO 2016). According to Porse and Rudolph (2017), the major sources of carrageenan are Kappaphycus (170,000 MT, dwt), followed by Eucheuma (4,500 m MT, dwt), Gigartina radula and G. skottsbergii (14,000 MT, dwt) and finally, Chondrus crispus and others (3,200 MT, dwt). Kappaphycus and Eucheuma are mainly cultivated in the Southeast Asian region and Tanzania and only small volumes are produced in the Latin American countries, while the rest of the carrageenophytes are produced in temperate countries.

Eucheumatoids (which include the Kappaphycus and Eucheuma genera, with multiple species and varieties), have been given names of convenience by industry, viz. the commercial names: “cottonii ” and “spinosum”, respectively are the main cultivated stocks. In only 4 years, the production of these changed from 5,629 million MT (2010) to 10,992 million MT (2014). The main producers, the Philippines, were subsequently overtaken by Indonesia. However, due to the success of cultivation and value of the biomass they are now being farmed in more than 50 countries (FAO 2016). Figure 4.1 presents the main countries involved in commercial cultivation .

Both genera are predominantly cultivated in tropical and sub-tropical waters. They are the major raw material sources of kappa and iota carrageenans traditionally used for their rheological properties as emulsifiers, binders and for suspension or stabilization in a wide range of processed food products, pharmaceutical carriers and the cosmetic industries (Bixler and Porse 2011).

The cultivation of Kappaphycus and Eucheuma displaced wild-gathered Chondrus crispus as a major source of kappa carrageenan , since it was commercially grown in the Philippines and other tropical countries, mainly because of the lower cost of labor. From the beginning of commercial cultivation in early 1970s until 2008, the Philippines was the major supplier of Kappaphycus species. In 2008, Indonesia expanded their seaweed farms and, because they have more geographic area, became the largest producer at the time of writing.

Seaweed farming became a complementary income for fisheries where commercial cultivation was established, changing the social profile mainly in small villages in Africa. Tanzania, especially the Zanzibar Islands, are good examples of successful commercial production from seedlings introduced from the Philippines and now commercial farms are spread along the Eastern African coast and India.

The recent increase in demand for carrageenan (particularly kappa for its rheological properties) promoted the development of these cultivation activities, mainly in the tropics. Southeast Asian Countries and Pacific Islands are trying to achieve the same success modelled after the Philippines and Indonesia. Similarity in environmental conditions makes all such regions very promising for the expansion of seaweed farms.

On the Caribbean coast of México and Central America , including the Caribbean Islands , wild stocks of Eucheuma (viz. Eucheuma isiforme) had been sporadically exploited, particularly for local consumption – as a vegetable. Depletion of natural stocks and insufficient volumes for commercial extraction from local species led to the introduction of non-native Eucheuma/Kappaphycus varieties to be tested in research, pilot-farms from approximately 1981 in this region. In South America, the lack of success into the research for valorization of local (indigenous) species which could be commercialized, stimulated the introduction of varieties of both genera in 1994. However, until recently there was no officially permitted, commercial cultivation . We present some of the past and recent experiences on the use and cultivation of Eucheuma and Kappaphycus around the world, including an assessment of socio-economic benefits for coastal communities and future , potential development.

4.2 Cultivation in Tropical and Sub-tropical Waters

4.2.1 Southeast Asia and China

The geographical locations of the Philippines, Indonesia and Malaysia, within the Coral Triangle, where natural populations of Kappaphycus and Eucheuma are found, are also well suited to open-water, extensive, commercial cultivation of these seaweeds. These areas provide multitudes of shallow reef areas and also access to deeper, off-shore areas with cooler, surface seawater temperatures; sandy to coral debris bottom substrata; clear and clean water and also moderate to strong water movement. Such conditions favor robust and luxuriant growth of eucheumatoid seaweeds. The absence of tropical cyclones in Indonesia and Malaysia are a bonus to the stability of farming operations there and furthermore contributed to high production rates. The geographic location of the Philippines is unfortunately often beset with many weather disturbances including super typhoons which can cause havoc for farming rigs (anchors, floats, lines and nets).

4.2.1.1 The Philippines

Marine Colloids, Inc., a USA seaweed-processing firm, established the first Kappaphycus (“cottonii ” type; originally called Eucheuma) cultivation research program in the Philippines in 1969. This initiative was later joined by the Bureau of Fisheries and Aquatic Resources (BFAR, formerly called the Philippine Fisheries Commission), and the University of the Philippines. The late Dr. Maxwell S. Doty, Vicente Alvarez, and Dr. Gavino C. Trono Jr. were pioneer academic practitioners in advancing Kappaphycus cultivation in the Philippines and later around the world (Doty 1973; Trono 1977; Ricohermoso and Deveau 1979; Doty and Alvarez 1981).

Intensive field surveys and collection of data were conducted during 1967–1970 in order to assess the best cultivation sites. Though the first cultivation trials were made in Panagatan Is., Caluya, Antique, and Ilin Is. Occidental Mindoro, Philippines, in 1969, it was a satellite cultivation trial in Tapaan Is., Siasi, Sulu in 1971 which provided the most promising indications for suitability of farming, with an average growth rate of 1.5–5.5% day−1 (Doty 1973; Parker 1974). Experimental cultivation sites in Caluya, Antique and Occidental Mindoro were later abandoned due to frequent typhoons and poor management. Other areas such as Sacol Is., Zamboanga City and Garza Is. and Occidental Mindoro, started to cultivate Kappaphycus in 1971–1972. The first commercial quantities of Kappaphycus (then called Eucheuma and ‘cottonii ’ – a source of kappa carrageenan ) were harvested from the cultivation areas in 1972. Since then, commercial cultivation of Kappaphycus has been successfully introduced, not only in Mindanao, but also the Visayas and Luzon, as seen in Fig. 4.2 (BAS 2001).

4.2.1.2 Indonesia

The first attempt to farm ‘spinosum’ (now known as Eucheuma denticulatum (Burman) Collins et Harvey, a source of iota carrageenan ) in Indonesia was made at Thousand Islands, Pulau Pari by Soerjodinoto and Hariadi Adnan in 1967; however, it did not progress further. Prompted by insufficient and unsustainable supplies of wild stocks, the True Blue Expedition was initiated in order to further focus on seeking additional sites suitable for cultivation. This was organized by Auby (Sanofi), Copenhagen Pectin (CP Kelco), Marine Colloids Inc. (MC) and the Indonesian Fisheries, LPPL. The CP Kelco and MC farming projects at Pulau Samaringa, Sulawesi and Riau Islands in 1975–1977 were inconclusive, hence the project moved to Bali. From 1978–1984, CP Kelco continued farming in Bali and success was eventually achieved at Nusa Lembongan (Neish 2013).

Free seedlings and farm materials were provided to fishermen and the resulting production of “spinosum” biomass (for iota carrageenan ) steadily increased to commercial levels. From 1985–1986, CP Kelco initiated farms in Indonesia to supplement those initiated by Marine Colloids Inc. and Sanofi (now Cargill). Commercial ‘cottonii ’ seaweed farming finally arrived in Indonesia in 1985 (Neish 2013).

From 1985–2009, Indonesian seaweed farm development was driven by the farmers themselves and local trader/collectors in a reflective, “bottom-up” manner. A market need for raw material for processing was made known to the prospective seaweed farmers by value-chain stakeholders on the demand side; farmers were exposed to the initially very simple technology that was required for growing these eucheumatoid seaweeds and, with facilitation from a variety of development organizations, i.e. the Australian Agency for International Development (AusAID), Canadian International Development Agency (CIDA) and the International Finance Corporation (IFC), to name a few, local seaweed farmers were able to build their businesses within the context of village norms, mores and structures (Neish 2013). Seaweed farming became integrated into the social fabric of the farmer/villagers to the point where it now appears to be a traditional, economic activity – even though it did not begin until the “relatively recent” mid-1980s, as further asserted by Neish (2013). Seaweed farming in Indonesia was also seen as being complementary to, and compatible with, other economic activities in the coastal villages, such as fishing and farming land crops. Ready cash from seaweed farming also had a noticeable multiplier effect in the local economies. Shops, support services for seaweed farming and village infrastructure all benefited notably from the cash derived from seaweed activities flowing through the local, village economies.

In 2007, Indonesia became the world’s number one producer of Kappaphycus production by volume (i.e. 1.7 M MT fwt), when it overtook the Philippines (1.5 M MT fwt, FAO 2010). Almost all of the Indonesian islands (Fig. 4.3) are currently planted with different strains or varieties of either Kappaphycus and Eucheuma using fixed-off bottom, hanging long-line and various raft methods, involving tens of thousands of coastal families (Neish 2013; Hurtado et al. 2014).

4.2.1.3 Malaysia

A carrageenophyte farming industry was introduced to Malaysia in 1978; Sabah is the state producing the commercial volumes (Sade et al. 2006; Fig. 4.4). Farming was introduced in Semporna, east coast of Sabah by the Bajau and the Suluk peoples from Tawi-Tawi, Philippines (Eranza et al. 2015) and operated at the commercial scale by Aquatic Resources Limited (an American company). Since 1980, the management of the seaweed farming project on Semporna was solely under the responsibility of the Department of Fisheries, Sabah (DOFS). In the 1990s, support was extended to further seaweed cultivation as the new economic engine for local development with several initiatives receiving government support. The private sector was invited to participate in this development. In early 2000, a Seaweed Industrial Zone (SIZ), listing seaweed as a high-value product from aquaculture was established by the National Aquaculture Program. In 2010, the Seaweed Commercial Project Approach (SCPA) was established and further accompanied by a New Innovation Technology and Environment (NITE) strategy under the auspices of the Government Transformation Program (GTP) to strengthen Research and Development and Commercialization (RDC; Azhnar 2016).

For decades, Malaysia worked on several continuous economic plans each of which was intended to help the local economy and eradicate poverty. Seaweed farming was one of the National Key Economic Activities (NKEA) of the 10th Malaysia Plan. Unfortunately annual production of eucheumatoids was low, as compared to neighboring countries such as the Philippines and Indonesia. This was in spite of the existence of extensive, favorable farming areas for Kappaphycus (approximately 38,500 ha). The recent report of Eranza et al. (2015) claimed that there were three major issues which beset the Malaysian seaweed industry which had to be addressed, namely: (1) seaweed farming activities between Malaysian islanders and immigrant seaweed farmers (Hussin and Khoso 2017); (2) seaweed farmers and the middlemen; and (3) seaweed quality, pricing and semi-refinery companies. The dilemma is now that less progressive seaweed farming methods in Semporna have resulted in Malaysia no longer being one of the main global producers (Eranza et al. 2015). The same author concluded that although the economic returns from the industry through farming, harvesting and post-harvest handling to the refining stages can be profitable, Malaysia has some major issues to resolve before this can become a reality.

4.2.1.4 Vietnam

Kappaphycus alvarezii has been reported as having been introduced from the Philippines to the south of Ninh Thuan province in Vietnam by the Institute of Applied Material Technology in Nha Trang and the Fisheries Extension Department in Ninh Thuan, via Kochi University, Japan in 1993 (Ohno et al. 1995, 1996). The first experimental evaluation was undertaken by Ohno et al. (1996) in ponds, lagoons, inlets and off-shore. The authors reported that the best daily growth rate (DGR) of plants grown in the lagoon areas was 9–11% day−1 in May–June (i.e. the cold season); those grown in inlets ranged from 7–9% day−1 in June; and those grown in ponds ranged from 5–6% day−1 in January–July, but decreased to less than 4% day−1 in August (i.e. the hot season). Grazing by fish was observed to occur in the areas thereby reducing productivity. These values were similar to those obtained from K. alvarezii cultivated in the Philippines and Indonesia.

Three years after its introduction, commercial farming of Kappaphycus started in the central and southern regions (Nang and Dinh 1998; Tsutsui et al. 2005) and it was regarded as an important resource for the coastal fishery (Le 2011; Fig. 4.5). However, after 2003, productivity declined, allegedly because of the deteriorating quality of the seedling material (i.e. after the old stock had been used continuously for vegetative production for over 10 years).

Dung and Nhan (2001) reported on the successful experimental cultivation of K. alvarezii in Haiquan Lagoon and Cat Ba Bay, Vietnam utilizing open-water, floating rafts and tie-tie with plastic cultivation lines. The growth rates observed from the open sea were higher than those achieved in the sheltered bays and ranged from 5.2–9.8% day−1 and 5.3–7.9% day−1, respectively. In 2003, Kappaphycus was also introduced to Khanh Hoa Province, in Bich Dam on Hon Tre Island (facing the Hon Mun Marine Protected Area). This attempt was however abandoned because of pressure from fish predation, a problem that can largely be mitigated only by technical options such as cages, which were not known in Vietnam at that time. In Cam Ranh and Van Phong bays, located in the same province, Kappaphycus and Eucheuma were found to grow well and the area occupied had been expanding there (Dung and Nhan 2001).

K. alvarezii is considered a highly efficient cultivar , the cultivation of which can generate jobs and supplemental income for poor Vietnamese coastal areas (Nang 2005). Additionally, the nutrient extraction capacity of the cultivated biomass can also provide significant contributions to the ecological balance and bioremediation of eutrophic coastal areas. In this region, cultivation frames were set on the bottom of shallow areas during the cool season, with rapid water movement, high winds and waves; during the warm season there were sunny conditions but with limited water movement, minimal winds and wave energy. The cultivation of Kappaphycus led to reductions in the concentrations of ammonia , nitrite, nitrate, phosphate and phosphorus which widely ranged from 10–80% (Nang 2005). However, the quality of Vietnamese cultivated Kappaphycus remained high, meeting the required standards for sustainable commercial cultivation , particularly in southern Vietnamese waters.

4.2.1.5 Cambodia

The first company to plant Kappaphycus in Cambodia was the Korean-owned, Star Private, which was established in 1999 (The Cambodia Today 2005). Seedlings from Malaysia were first planted in Kampot. Several years later, production was high in 2003 and 2004 at 6,000 MT and 16,000 MT, fwt, respectively. However, by 2006, only 6,800 MT fwt were harvested. In 2007, the farmers were demotivated as to why their seaweeds were not growing as well as the previous years. As a result, production declined even further to almost nothing. The farmers allegedly blamed the construction of a nearby seaport for pollution which led to the poor growth of the seaweed (The Phnom Penh Post 2008). Three companies were engaged in farming, namely, Kampot-Star Private Enterprise, Cambodia Seaweed and Kampot Seaweed operating on 9,000 ha. In 2007, Kampot-Star Private Enterprise was purchased by the Enviro Corporation and later relocated its farming areas to Koh Khong. No reported production of seaweed has occurred since 2006 (Lang 2015; Fig. 4.5).

4.2.1.6 China

A two-year study of K. alvarezii introduced to Hainan Island (Fig. 4.5), from the Philippines in 1985, showed promising results. The average daily growth in weight reached 10% day−1 at a favorable SST of about 26 °C. Experimental results indicated that timely cutting of the growing seaweed biomass was an effective way to obtain new vegetative cuttings (seedlings) for cultivation which also accelerated growth (Wu et al. 1989). New cuttings (0.05 kg) were suggested to be suitable as “seeds” and that the remaining parts of the old plant were then to be harvested. Cultivation with a type of underwater raft designed for places where there was a strong, prevailing wind was used to expand cultivation to more regions within Hainan Province. The status of Kappaphycus farming in Hainan supports a substantial local carrageenan industry (Pang, personal communications)

Sullivan et al. (2001) reported a prototype model to illustrate the importance of integrating seaweed cultivation activities with management and maintenance of the health of coastal embayments, a model which was explored for Xincun Bay, southeastern Hainan Province. The nutrient extraction capacity of Kappaphycus cultivated in Xincun Bay was reported to be able to remove 53.8 MT of nitrogen and 3.7 MT of phosphorus during the 1999–2000 growing season.

4.2.1.7 Myanmar

Kappaphycus seedlings were brought to Myanmar from Cambodia in 2008 and reportedly originated from Vietnam (Ohno, personal communications) The Mergui Archipelago was the major site of seaweed farming (Fig. 4.6). MSC Korea, a private company engaged in agar and carrageenan processing, established seaweed farms in the locality using single bamboo rafts and later adopting the hanging long-line method (Kim, personal communications). Monsoon rains from May–October limited production, this was in addition to the annual occurrence of ‘ice-ice’ and also endo-epiphytism. It was only during the period November–April when farming was found to be favorable, however, production has remained at a very limited level (Ohno, personal communications).

4.2.2 The Pacific Islands

A history of introductions of Kappaphycus to the Pacific has been described by several authors such as Solly and Booth 1977; Why 1985; Luxton et al. 1987; Nelson 1988; Adams and Foscarini 1990; Smith 1991; Ram 1991; McLachlan 1992; South 1993; Eldredge 1994; Luxton and Luxton 1999; Ask et al. 2003a, b.

Carrageenophyte farming areas, as introduced in the Pacific Islands, are shown in the Fig. 4.7. Amongst the islands in the Pacific, Kiribati, Papua New Guinea and the Solomon Islands were described as having suitable sites available for eucheumatoid farms. However, there were no local nor national markets for the raw materials grown, there was however an increasing demand from international markets (i.e. demand in US and Europe; Table 4.1). The Solomon Islands was a candidate for good, commercial viability, providing high export earnings, together with a good livelihood for the farmers and thereby alleviation of their poverty. Kiribati had the same potential to adopt and be successful at commercial farming (Table 4.2).

4.2.2.1 The Cook Islands

Kappaphycus alvarezii was introduced to the Islands of Aitutaki in the late 1980s from Fiji (Eldredge 1994), but never progressed to a successful mariculture activity. A second attempt at re-kindling interest was made in 2001 when 700 kg of seaweed was brought from Tabuaeran Lagoon in Kiribati destined for Tongareva, Rakahanga and Pukapuka. However, in Tongareva Islands, this activity was refused by the Island Council at the last moment for fear of inadvertently introducing unwanted foreign marine organisms along with the seedlings, a fear which was used to protect the local pearl oyster industry.

Seaweed farming was tested in Pukapuka and Penrhyn but unfortunately it did not take off. It is likely that labor availability was a limiting factor and/or too expensive and that the costs of freight and farming equipment were also too expensive for the modest volumes that could be produced in the Northern Islands. Palmerston was considered the better location because of existing, established transportation/trade links due to parrot fish (Luxton 2001). However, despite a second attempt in 2001, the introduction of Kappaphycus farming to the Cook Islands was unsuccessful.

4.2.2.2 The Fiji Islands

Kappaphycus farming was introduced to Fiji in 1976 (Ram 1991), when Kappaphycus seedstocks were brought from the Philippines (Solly and Booth 1977). Field cultivation trials were carried out and maintained for more than two years at Telau Island, near Suva (Prakash 1990). Sadly, these farms failed due to their destruction by a cyclone in 1980 (Ram 1991).

Kappaphycus was reintroduced in 1984 by the Fiji Fisheries Division with the cooperation of Coast Biologicals (NZ) Ltd., with funding support from the Commonwealth Fund for Technical Cooperation (CFTC). K. alvarezii seedstock was imported from Tonga and trials were conducted successfully at Tavua, Rakiraki and Verata in Tailevu (Ram 1991; South 1993). The first commercial production began in 1986 at Tavua, Rakiraki, Kaba, Kiuva and Rewa. Considerable expansion took place in 1987, with farms established in new areas such as: Moturiki, Ovalau, Bua, Batiki, Vanuabalavu, Fulaga and Ogea (Ram 1991; South 1993). However, there were several set-backs for Kappaphycus farming in these areas due to the effects of bad weather on cultivation and crop losses due to damage by cyclone-induced, high tides and heavy swells (Pickering 2005).

In 2005, there were four sites under cultivation: two were in the Lau Group, on the islands of Ono-i-Lau and Namuka-i-Lau; one was in Kadavu, near Kabariki Village and one was at Vanua Levu, near Namuka Village. Whilst commercial production is still carried out in these areas, the volumes are very small (i.e. less than 20 MT). It was projected that production would be around 100 MT (Lal and Vuki 2010).

4.2.2.3 The Kiribati Islands

Kiribati is regarded as having enormous marine fishery resources and extensive biological diversity (Adams and Foscarini 1990; Ram 1991). The economic and social development of the islands have been directly dependent on the availability and sustainability of marine resources. Developments in marine aquaculture such as seaweed farming, have been encouraged in order to minimize fishing pressure especially on the outer islands and villages with approximately 300 villagers.

K. alvarezii and Eucheuma denticulatum from Hawaii, which originally came from the Philippines, were first introduced to Kiritimati (Christmas) Island in 1977 by Dr. Maxwell Doty (Why 1985; Uan 1990; South 1993; Luxton and Luxton 1999) and to Tabuaeran (Fanning Is., also from the Hawaiian seedstock) by Russell in 1977 (Luxton and Luxton 1999). Its commercial production began in 1986 on six of the Gilbert Group of islands namely: Tarawa, Butaritari, Aranuka, Abemama, Abaiang and Beru. Production peaked in 1991 at 1,020 MT, fwt, however, this declined to 400 MT in 1993. The reasons for the decline were cited mostly to be as a result of adverse weather conditions associated with the ‘El Niño’ effect which induced strong westerly winds and destroyed many farms. Other important reasons contributing to the decline in activities were late payments to farmers, lack of production inputs and weak production and marketing management (Bergschmidt 1997).

The Atoll Seaweed Company (ASC), owned by the Government of Kiribati, purchased seaweed from the farmers and shipped it to the capital of Tarawa, where it was pressed into bales for onward shipping to New Zealand and Europe. A number of institutions such as the Atoll Seaweed Company (ASC) Ltd., the European Development Fund (EDF), Central Pacific Producers Ltd. (CPPL) and some private companies, e.g. CP Kelco, Dragon World, the Asil Group Ltd., Honjin Intl. Ltd. and Betio Mini Mart Ltd., were involved in purchasing and marketing dried seaweed produced by the farmers in Kiribati (Komarudin and Hussein 2015). In 2008–2009, the Ministry of Fisheries Kiribati distributed seedlings to farmers in Abaiang; these originated from the same island and Onoto Island. In 2010, six villages , or about 300 households, were involved in farming seaweeds and contributed to the national production which increased to more than 400 MT from 2010 to early 2011. Since 2011, seaweed production decreased further; it was not because of the price, but rather due to technical, biological and environmental issues. The seedstock no longer continued to prosper in the local conditions in Abaiang, possibly due to continued vegetative propagation and loss of strain vigour.

Family-based farming was the norm in Kiribati; whole families were involved together in all farming-related activities. Men usually went to the seashore for planting, maintenance and harvesting, whilst women and children had the responsibility of drying, binding seedlings and sorting the dried seaweed.

4.2.2.4 The Marshall Islands

E. denticulatum and K. alvarezii were introduced into Mil and Likiep in Majuro Lagoon in 1990 (Eldredge 1994). There is no other information available relating to those early trials. In 2002, the Marshall Islands began a new seaweed farming project with seedlings imported from Kiribati under the expertise of Mr. James Uan from Kiribati. The Food and Agriculture Organization (FAO), Marshall Islands Marine Resources Authority (MIMRA), Marshall Islands Development Bank (MIDB) and the College of Marshall Islands (CMI) supported this initiative with the training of staff and community members. This resulted in the establishment of trial farms on several of the atolls. However, farming activities did not progress that much; the latest country report made by Hambrey Consulting group in 2011a (www.hambreyconsulting.co.uk) reported the following opportunities and constraints:

Opportunities

-

1.

Trials suggested a number of locations to provide adequate conditions for farming.

-

2.

Dried produce not so susceptible to unreliable shipping

-

3.

Simple, low-cost technology, relatively suited to rural farmers

-

4.

There was an established international market for dried seaweed for processing into a range of natural gels

Constraints

-

1.

A number of technical issues remained to be resolved in terms of site selection and husbandry including the control of grazing and negative impacts on sharks affected by grazing control measures.

-

2.

Biosecurity concerns relating to the introduction of non-native seedlings

-

3.

Comparative disadvantage related to large-scale and well-organized production in other production centres such as Indonesia.

-

4.

RMI production would be minute on an international scale and it would be difficult to ensure that a reasonable market value was paid for relatively small volumes of local product.

4.2.2.5 Papua New Guinea

In 2010 a new venture was established by a Malaysian Company at Milne Bay Province. There were initial problems with rapid SST fluctuations at one site, but with a change of locations to Suau Island and Trobriand Islands, the imported seedlings were reportedly growing well (www.hambreyconsulting.co.uk). The company invested significantly in supplying materials and providing technical assistance to the farmers through the provision of Malaysian technicians living on site.

There appeared to be fair opportunities for cash generation which could then be used for poverty alleviation. Foreign exchange earnings were expected to flow through seaweed cultivation as an activity in favorable locations around Papua New Guinea. Reasons cited for the optimism included: a reasonable infrastructure for transportation; suitable environmental conditions; limited alternative income generating opportunities; low labor costs and positive economic ambitions of the coastal fisherfolks. Investments by a Malaysian company in Milne Bay Province suggested that there was both a strong market demand and a significant role for the private sector to play in facilitating the start-up of family/community-based production (Hambrey 2011b, see www.hambreyconsulting.co.uk). The economics of carrageenophyte cultivation appeared to be favorable, although the cost of local freight (i.e. from the growing site to local collection/shipping center) were suggested to be relatively high. The outcome of this enthusiasm remains unknown.

4.2.2.6 The Solomon Islands

Carrageenophyte farming was tested by the UK ODA (Overseas Development Agency) in the late 1980s in Munda, Vona Vona and Rarumana, but suffered from rabbit fish grazing and low prices/low volumes produced and was ultimately abandoned in the early 1990s (Hambrey 2011c, see www.hambreyconsulting.co.uk). At that time, product was shipped to Fiji before being forwarded to the Philippines. Under the EU Rural Fisheries Development (RDF) project in the 1990s and early 2000s, fisheries centers were upgraded in several locations and opportunities for diversification and increased use were explored. As a result, carrageenan -bearing seaweed production was re-started at Rarumana using residual stocks from the previous initiative; 19 MT, fwt was produced in 2001–2002. This aroused the interest of a local trading company (traditionally engaged mainly in collecting copra) which began to buy and export seaweed, with an exclusive license. Production was then extended to Wagina – supported/facilitated by the Fisheries Department, the Nature Conservancy and private sector traders.

In 2010, four additional trading companies obtained licenses to export ‘cottonii ’ seaweed, and this, along with more favorable international markets, saw beach prices rise significantly from US$ 3–4 kg−1 to US$ 5–6 kg−1, generating significantly increased interest and activity in several locations. Seaweed cultivation became a relatively well-established enterprise at Wagina, with smaller amounts also produced in Rarumana, Buena Vista (by the Sandfly Group). Production in 2010 amounted to “several hundred (metric) tons”. This represented a significant income to the communities involved and in some cases, smaller groups or individuals involved.

Prices for Kappaphycus or Eucheuma are relatively good and artisanal seaweed farming was shown to be clearly economically viable, with a potential to make significant positive contributions to poverty alleviation, gross domestic product (GDP) and foreign exchange. Good sites were known to be available in the island grouping (e.g. good access, shelter, water exchange, with a lack of grazers), however, testing new sites was a time consuming and risky activity. Switching activities and efforts between seaweed cultivation, bêche-de-mer, other fishery products and copra, each according to their price and availability was a characteristic of the innovative and adaptable coastal village economies. Mechanisms were badly needed in order to maintain eucheumatoid seedstock during periods of relatively low prices and reduced activity (Hambrey 2011c, see www.hambreyconsulting.co.uk)

Kronen (2013) reported a brief, but comprehensive, history of Kappaphycus farming on the Solomon Islands with the following milestones:

-

1988 – First trials undertaken by the Overseas Development Agency (ODA) of the United Kingdom at Vona Vona Lagoon and Rarumana village in the Western Province, in cooperation with the Ministry of Fisheries and Marine Resources (MFMR). The one-year project demonstrated good growth for Kappaphycus alvarezii seedlings imported from Fiji (Tiroba and McHugh 2006) however, most trials were negatively affected by fish grazing.

-

2000 – The Aquaculture Division of the MFMR was established and started collecting seedstock remaining from the 1988 growth trials in Vona Vona Lagoon.

-

2001 – The Aquaculture Division carried out growth trials in Rarumana and after 2 years, 600 kg of dried seaweed was produced in this area.

-

2002 – The Rural Fishing Enterprise Project (RFEP) funded by the European Union (Member Organization) became involved in seaweed farming. In cooperation with the Secretariat of the Pacific Community (SPC) and MFMR, the RFEP conducted a seaweed training workshop in November, targeting 30 fisheries officers. Successful growth trials under the RFEP at Rarumana were completed in 2003.

-

2003 – The remaining funds (SBD1.5 million, EU STABEX funds) from the RFEP project were allocated to provide further support in the framework of a one-year seaweed farm development project. The project provided farm materials, outboard motors and a warehouse in Rarumana ; and the first PFnet (broadband, e-mail) system was set up to ensure communication between producers and buyers.

-

2004 – In July, a warehouse was built in Wagina where the second PFnet was set up. A feasibility study for further support from the European Union (Member Organization) was carried out.

-

2005 – By early 2005, there were about 130 farmers in Rarumana and the Shortland Islands (Western Province) plus 300 farmers in Wagina, Choiseul Province; seaweed farming had also expanded to Malaita and Makira-Ulawa. About seven export licenses were approved; however, only one exporter (Solomon Seaweed) renewed its license in 2006. Agents were paid a commission based on production. Export of seaweeds was tax-free.

-

2005 – In July 2005, a 3-year SBD15 million seaweed commercialization project (CoSPSI) funded by the European Union (Member Organization; STABEX funds) began, which was extended until January 2009, with a focus on sites in Ontong Java Atoll, Reef Islands, Malaita. The project also supported continued seaweed farming development at Wagina and Rarumana.

-

2005 – With assistance from CoSPSI, the International Waters Project (IWP; Global Environmental facility, SPREP) established a seaweed farming operation in the eastern Marovo Lagoon, within the framework of its community development approach, which remained one of the major producers.

-

2006 – May, the farm-gate price for seaweed dropped from SBD 2.00 kg−1 to SBD 1.50 kg−1, due to increased fuel prices, which in turn increased national and international freight costs.

-

2007 – A severe earthquake and associated tsunami on April 2, resulted in the loss of some of the best seaweed farming areas in the Western Province (Rarumana), and an estimated loss of 20–30% of production within the CoSPSI project.

-

2008 – In July, the farm-gate price for carrageenophyte biomass increased to SBD 3.10 kg−1.

-

2009 – The remaining CoSPSI funds were used to support a seaweed farming adviser based at the MFMR for 1 year (April 2009–March 2010).

At the time of writing, the Solomon Islands was the biggest, single producer of non-edible seaweed in the Pacific region (Algae World News 2015), mainly because of the strong support provided by the local government (MFMR, Ministry of Fisheries and Marine Resources), as seen from the following factors: (1) Training of 609 seaweed farmers and 25 seaweed buying agents; (2) Writing and distribution of a training manual for all seaweed farmers; and (3) Assessment of 15 new seaweed farming sites and development of another 15 new seaweed farms; and provision of seaweed farming material including canoes, outboard motors and water tanks to seaweed farmers. The MFMR added that the total production of seaweed in 2014 was 1,520 MT, worth about SBD$5.6 Million to the seaweed farmers (Algae World News 2015).

4.2.3 Western Indian Ocean

In the Western Indian Ocean Region, although seaweed farming was documented in 1970s and further experimented in mid-1980s, it was not until 1989 that commercial farming started (Fig. 4.8). Commercial farming of Eucheuma and Kappaphycus in Tanzania was initiated by private entrepreneurs from Denmark and the Philippines in 1989 using an imported strain of the then Eucheuma genus (which was a collective name given to Eucheuma and Kappaphycus species and variants) from the Philippines. It was necessary to import seedstock because the local, indigenous strain could not provide the yield required by the need for cultivated, commercial volumes (Msuya 2013). Private entrepreneurs situated the first farms on the East Coast of the Zanzibar Islands, in the villages of Paje and Jambiani.

To ensure the largest biomass production (it is interesting to note that the quality of the carrageenan produced was not considered at that time), varieties of Eucheuma and Kappaphycus were imported from the Philippines, under strict quarantine regulations. The first exports of dried carrageenophyte seaweeds from the Western Indian Ocean was in 1990 (one year after the first commercial farms were established) when 808 MT dry were exported from Zanzibar (Msuya 2013).

4.2.3.1 Tanzania

The success of seaweed farming in the two pilot villages on Zanzibar Island triggered the rapid expansion of farming practices to other areas including the sister island of Pemba (Lirasan and Twide 1993), as well as nearby areas of the mainland, such as Tanga and Bagamoyo (between 1992–1994). In 1995, it was found necessary to begin seaweed farming in the southern part of mainland Tanzania. This was executed by Dr. Flower Msuya of the University of Dar es Salaam, Institute of Marine Sciences who was contracted by a project called: “Rural Integrated Project Support (RIPS)”, funded by the Finnish International Development Agency (FINNIDA) to farm the first seaweed seedlings at Mtwara, Lindi and Kilwa Districts. A feasibility study was undertaken and nursery farms were established in 1995 (Msuya 1995); in 1996 farming expanded to more than ten villages (Msuya 1996). The chronology from the beginnings to expansion of seaweed farming from Zanzibar to other parts of Tanzania has been documented by multiple authors, viz. Eklof et al. (2012), Msuya (2010), Msuya (1995, 1996) and URT (2005). By 1997, carrageenophytes were farmed in all coastal areas of Tanzania. From the first export of 808 MT recorded in 1990, seaweed production continued to rise maximizing at 15,000 MT in 2012. In the ensuing years, production fluctuated between 11,000–13,000 MT annually.

4.2.3.2 Madagascar

From Tanzania, eucheumatoid farming expanded to other countries in the Indian Ocean. The first country to pick up commercial farming was Madagascar starting in 1997. Support for commercial production in Madagascar came from a project aimed to improve the income of coastal communities (Améliorationdes Revenus des Populations Littorales), this was funded by the European Development Fund (EDF) and implemented by the Food and Manufacturing Company (FMC) of USA, working with local institutions (Msuya et al. 2014). In 1998, strains of two cultivars were imported from Zanzibar to Madagascar – for exactly the same reasons that Zanzibar had imported seedstocks – the indigenous species could not produce enough volume to sustain a commercial business (Randriambola and Rafalimanana 2005).

4.2.3.3 Mozambique

After Madagascar, it took some time for other Indian Ocean countries to begin commercial farming of carrageenan -bearing seaweeds. In 2002, farming operations commenced in Mozambique. Cultivation began in Pemba, in 2002 and expanded to Nampula, both sites located in northern Mozambique.

4.2.3.4 Kenya

Kenya also joined the industry of producing carrageenophyte biomass for processing, starting commercial farming in 2010 on the southern coast. Efforts to support commercial production were made by a number of organizations such as ACT Kenya, SUDRA, and East African Wildlife Society (EAWS). In some instances the self-help groups system was used. Since 2014, commercial farming has been supported by the Kenya Coastal Development Project (KCDP), funded by the World Bank. At the time of writing (Jan 2017), there was commercial production in three villages; FAO supported commercial production in Kenya under a Technical Cooperation Project with the Kenyan Government. Kenya also had a local buyer, a company called East African Seaweeds. This solved the problem of dependency on buyers from Tanzania ; there is potentially a bright future for commercial seaweed farming in Kenya.

4.2.3.5 India

Cultivation of commercial carrageenophytes began in India in 2000 when Pepsi Foods Ltd. (a subsidiary of Pepsico India Holdings Ltd.) became interested in the cultivation of Kappaphycus alvarezii. The economic viability of open-sea cultivation was proven and the technology of commercial cultivation was transferred to PepsiCo, India Holdings Ltd., in 2001 who then initiated pilot-scale farming along the Palk Bay side of the Mandapam coast (Eswaran et al. 2002). The cultivation business rights for K. alvarezii were transferred by Pepsi Foods Ltd. to Aquagri Processing Pvt. Ltd., a company formed by a group of entrepreneurs led by a former PepsiCo executive, Mr. Abhiram Seth – as a tripartite agreement in August 2008. This company was successful in expanding cultivation activities to Tamil Nadu.

The farming systems in India was seen to evolve in concert with innovations in biomass processing. The bio-economic analysis for individual and artisanal culture of K. alvarezii in India reported a positive, net-present value only 6-months after inception of the business, with an internal rate of return at 210% (Jara and Riffo 2016). This analysis further endorsed the added benefits that K. alvarezii farming could lead the diversification of coastal livelihoods where opportunities were known to be sorely limited. The socio-economic impact of K. alvarezii farming in India was investigated in depth as a part of the study sponsored by FAO (Krishnan and Narayanakumar 2010).

4.2.3.6 Sri Lanka

In 2008, the Sewalanka Foundation, a leading Sri Lankan NGO, in collaboration with Abeysinghapura-Panama Fisheries Cooperative Society and the United Deep Sea Fisheries Cooperative Society in Pottuvil, started a pilot assessment of Kappaphycus (alvarezii) using a cage method at Panama and Ullei (in Pottuvil) on Sri Lanka’s east coast. There was initial success with good growth, however, grazing, drying and marketing were perceived as problems (Samarakoon 2009). Though the Foundation envisioned this aquaculture activity to bring economic benefits to the coastal communities, they also believed that an ecological impact assessment was required in order to prevent potential, future degradation of the marine ecosystem.

The germplasm of K. alvarezii was imported to Sri Lanka in 2011 from Malaysia, following procedures for introduction and quarantine. Material was acclimated to Sri Lankan waters by maintaining trial plots in various locations of the Kilinochi and Jaffana regions. Commercial farming of K. alvarezii began in 2012 after carrying out thorough feasibility studies using floating bamboo raft and off-bottom, mono-line methods (Shanmugam et al. 2016). The average daily growth rate ranged between 4.0–5.5% day−1, a good indication that commercial farming was indeed viable. As of 2017, only 50–60 seaweed farmers were still engaged in this activity, with a total production of 120 MT for 2014–2016. The possibility for the expansion of K. alvarezii cultivation to other coastal parts of Sri Lanka remained promising; Shanmugam et al. (2016) claimed that engagement in the activity could create an alternative livelihood for a large number of coastal people, which could also earn foreign exchange through either the export of dried seaweed biomass or by adding value through products such as agricultural biostimulants and production of the processed food additive carrageenan .

Since 2014, Sri Lanka’s Hayleys Aquagri has been active in promoting seaweed cultivation in the western part of the country, i.e. Vallaipadu and Eranamatha Nagar in the Mannar Sea Basin by supplying propagules, rafts, drying frames, training to the families and assistance in the marketing of the dried seaweed. In June 2015, the same company and the United Nations Development Programme (UNDP) agreed to collaborate in expanding seaweed farming to the islands of Analaitivu, Eluvaitivu and Nainaitivu in order to provide livelihood opportunities for 40 families, eight of which were households with women at their head. This project encouraged communities to diversify livelihood opportunities in an environmentally sustainable manner, based on a: ‘Community-Based Aquaculture for Livelihood Diversification’ strategy. As of 2017, Sri Lanka had vigorously adopted Kappaphycus farming in suitable areas .

4.2.4 Central America

For this chapter, we use the term “Central America ” not in its purest geographical sense, but to delimit those countries sharing a common coast with the Caribbean Sea, from México to Panama and also including the Caribbean Islands . At present, there is no facility for the industrial extraction of phycocolloids in the Caribbean. In this region, the history of utilization of seaweeds, particularly members of the genus Eucheuma, is relatively recent in comparison to other geographical areas. Eucheuma isiforme received much attention as being the main genus providing biomass for the commercial production of iota carrageenan . This alga can be found naturally occurring throughout the Caribbean where it is locally abundant (Cheney 1988) and commonly found seasonally, as beach-cast material during the north winds. Seaweeds have been cultivated for food in the Caribbean, this is a tradition dating back to the first half of the nineteenth century. These activities began in St. Lucia using techniques and methods of cultivation developed by the Fisheries Management Unit/International Development Research Centre: ‘Seamoss Project’ (Smith 1992). Various species of Gracilaria were grown successfully, but their susceptibility to epiphytism and poor agar qualities made their further utilization impossible. In 1991, preliminary results with E. isiforme, which originated from Belize, showed higher growth rates (i.e. doubling time of 10–12 days, Allan Smith unpublished data) and provided more resistant seaweeds. Therefore, commercial farmers in St. Lucia began to use it on their farms. By 2000, E. isiforme became the principal farmed crop. With the exception of E. isiforme, no other domestication of a seaweed species was undertaken in the region. The native species, had been harvested only for local consumption on some of the Caribbean Islands. However, after 1991, select carrageenophytes were introduced by people aware of their potential benefits and relative ease of cultivation in several countries including Mexico (Muñoz et al. 2004), Panama (Batista de Vega 2009) and several Caribbean Islands (Fig. 4.9).

Here we review the published information available for countries where native and introduced species of Kappaphycus and Eucheum a have been studied so far.

4.2.4.1 The Caribbean Islands

Until the 1980s, “sea moss” was marketed almost exclusively in a dried, bleached form. In English-speaking islands and a few Central American locations, including Honduras and Panama, various red algae were harvested for the preparation of traditional drinks and puddings (Smith 1997). Seaweeds and their drinks were already known in most Caribbean Islands as “sea moss”, as well as “Irish Moss” (but not Chondrus) in Jamaica, or simply as “seaweed” in Belize. It was sold locally, or exported to the more populous islands of the region where wild stocks had been depleted due to un-restricted, over-harvesting. After 2001, processing facilities were established or expanded on a number of islands, including Jamaica, Barbados, Grenada, Antigua and Barbuda, Trinidad and Tobago, St. Vincent and the Grenadines, St. Lucia, and Dominica. As a result, a wide variety of packaged and bottled “sea moss” products became available. However, the supply of commercial species from wild stocks also declined over the same period and this limited the output from the smaller processing facilities which existed on many islands. Jamaica rose to be the region’s largest processor of sea moss products and imported an average of 13 MT of K. alvarezii per year from the Philippines to meet the demand (Smith and Rincones 2006). Given the shortage of raw material for processed products in the region there was an evident potential for further expansion of seaweed mariculture. The development of cultivation to provide raw materials to the extract industry was limited to those areas with a depressed economy, with very low incomes; due to the value afforded raw material, it is unlikely that production for the phycocolloid industries would ever be viable in the countries where seaweeds are already used for food.

4.2.4.2 Guadeloupe and Martinique

The first introduction of carrageenophytes from the Indo-Pacific into the Neo-tropical Realm, in a natural environment , occurred in Guadeloupe, French West Indies, in 1981 (Areces et al. 2014). Olivier Barbaroux reported the introduction of two Eucheuma species (e.g. E. denticulatum and E. cottonii ) in Guadeloupe (Barbaroux and Perez 1983). Barbaroux et al. (1984) further described cultivation trials in the West Indies where a raft system was developed, providing an effective surface area of 2,500 m2 consisting of a flexible rope framework, which operated at depths greater than 10 m. Nylon culture ropes would be seeded with 19,000–22,000 plants. The net suspension technique was also used, taking an idea from Amat (1981); a small mesh net (3 cm) was maintained 1 m below the surface by polystyrene floats. The yield was comparable to the raft method, except there were effectively no losses, whereas the floating unit had approximately 16–20% loss of plants over the cultivation period. It should be noted that this method has also been utilized with great success in Brazil (Goes and Reis 2011). Growth rates recorded from the Guadeloupe pilot-project were however low, when compared to other sites of commercial cultivation (viz. 1.5–2% day−1 for E. denticulatum and 4% day−1 for E. cottonii ). Perez et al. (1992) concluded that the economic return on effort for the cultivation of the carrageenophytes would be too low for the biomass production and hence not competitive with Asian sources of raw materials.

4.2.4.3 Santa Lucia and Barbados

In the mid-1990s, a program was conducted in St. Lucia to identify sea moss species suitable for the market that would be less susceptible to the seasonal appearance of epiphytes, which reduced the quality of the common Gracilaria spp. produced in many areas. Preliminary results with Eucheuma isiforme from Belize showed that under cultivation conditions, plants remained completely free of silt and epiphytes and furthermore maintained high and stable growth rates. Accordingly, E. isiforme had already replaced Gracilaria spp. as the principal farmed crop for sale in a dried, bleached form. Coastal communities on the east coast of St. Lucia formed the Praslin Seamoss Farmers Association and also established a processing and bottling facility aimed at both local and export markets (Brown 1999). Although processing produced traditional concentrates and beverages, business developed informally and there were no accurate records of the quantities involved. However, the dried, bleached seaweeds commanded high prices and the harvest and local processing was viewed as being economically important to many coastal communities (Smith 1998).

4.2.4.4 Antigua and Barbuda

E. isiforme was also harvested commercially in Antigua and Barbuda until the 1980s, primarily from the Codrington Lagoon on Barbuda. It was used locally and exported for traditional food applications in the region, however this enterprise was discontinued because of severe over-harvesting. The most widespread use of seaweeds in this Caribbean region was for food, as in other Caribbean Islands (Smith 1998).

4.2.4.5 St Vincent and Grenadines

Both Eucheuma isiforme and Kappaphycus alvarezii were the focus of sea moss producers on Union Island, St. Vincent and the Grenadines. The project: “Developing the Economic Viability, Human Capacity, and Environmental Sustainability of a Seamoss Cooperative” on Union Island, St. Vincent and the Grenadines, funded by GEF-PNUD Small Grant Program (2010–2012), was intended to improve the viability of the “sea moss” industry through cultivation of both of these genera. The potential was thoroughly investigated by research and experimentation, capacity development, improved monitoring of human impacts on the marine environment and improvement of community awareness of the connections between environmental pollution and livelihoods. The project had the expected outcome of creating a sustainable sea moss industry in the area.

4.2.4.6 Belize

Eucheuma isiforme was harvested commercially in Belize; approximately 800 kg (air-dry weight) were exported annually to the USA for use in health-food applications during the 1990s (Smith 1998). Unfortunately, this exportation ceased, but harvesting continues to supply local consumption. Natural E. isiforme populations grew close to the mainland; they were however, severely depleted making the scarce biomass even more “valuable”. Seaweed farms off the shore of the Twin Cayes in the South Water Caye Marine Reserve were supported by a non-profit group called the: “Dangriga Development Initiative” (DDI). The project was also supported by the Belize Fisheries Department with the intention to provide a supplementary source of income for the residents and fishermen surrounding the South Water Caye Marine Reserve. Potentially, the large-scale production of this product was a feasible option since dried seaweed was already sold at the central market in Dangriga Town. Clean, dry and bleached sea moss fetched relatively high prices locally, commonly retailing for around US$8 kg−1 (Smith 1998). The establishment of marine protected areas which included existing harvesting sites on the Belize Barrier Reef led to renewed interest in cultivation in order to provide alternative sources of economic activity and income. The project entitled: “Sustainable and Environmentally Responsible Production of Seaweed (Eucheuma isiforme and Gracilaria spp.)” in the marine areas adjacent to Placencia Village, was supported through GEF UNDP Small Grant Program to revitalize the Placencia Cooperative. By establishing 10 sustainable seaweed farms near Placencia they attempted to resolve two problems: the decline of commercial fishing stocks in and around the Southern Belize Barrier Reef System World Heritage Site (Gladden Spit & Silk Cayes Marine Reserve and Laughing Bird Caye National Park) and the reduced productivity of the Placencia Producers Co-operative. The outcome of these initiatives remain unknown at the time of writing.

4.2.4.7 Cuba

After trials with native species (i.e. Gracilaria domingensis and Bryothamnion triquetrum ), the introduction of Kappaphycus striatum, K. alvarezii and E. denticulatum was made to Cuba, from the Philippines, in 1991. Cultivation trials on the coast north west of Havana were conducted in order to determine if the appropriate environmental conditions for cultivation were present (Areces and Céspedes 1992). With the exception of E. denticulatum, the other two introductions were found to adapt successfully to Caribbean conditions. In field tests, two long-line approaches were used for farming with ropes placed at either, or near, to the surface, or along the bottom. When the experimental farming was extended at pilot-scale, only the raft techniques were used over a two-year continuous cycle of Kappaphycus production. Harvesting and re-seeding of the lines occurred every 45 or 60 days; daily growth rates for both Kappaphycus species exceeded 6% day−1 (Serpa-Madrigal et al. 1997; Serpa-Madrigal and Areces 1998). Cuba also conducted tests to evaluate the potential ecological risks of these introduced species Many of the studies by Cuban researchers into quarantine procedures and the ecological impacts of introductions remain unpublished. A summary of research results on the development of guidelines for quarantine procedures and site testing was published by Areces et al. (2014). As a result of the recommendations, Kappaphycus remains banned from cultivation in Cuba, the reasons are unknown at time of writing, but likely due to political/environmental concerns, reasons rather than the potential to cultivate.

4.2.4.8 Panama

In Panama, around the Province of Colon, as in other parts of the Caribbean, the harvesting and use of sea moss seaweeds has been part of the daily tradition and diet of the local Afro-Antillan communities. The “pearl moss” ( Chondrus crispus ) from Europe was exported to the Caribbean by soldiers who went to the Panama Canal Zone in order to support the efforts of the First and Second World Wars. Chondrus was also called “Isinglass”, from the Dutch word meaning fish gelatin. At the time of writing (March, 2017), at least two ethnic Panamanian groups continue to consume seaweed: the Gunas and the West Indians (Batista de Vega and Connor 1990). A total of 37 species of seaweed were recorded as being commonly used by the Gunas people for medicinal and cultural purposes (Batista de Vega 2006).

A seaweed program of the Institute of Tropical Research, Smithsonian Institution (SI) operated at the Galeta Point Marine Laboratory from 1979–1982 and reported a list of nearly 1,500 species, some of commercial importance (Hay 1981). Amongst the species selected for culture, Gracilaria sp. was used to establish the first experimental farm in Central America within the community of La Playita, in the city of Colon. In 1995, an experimental seaweed farm around the District of Colon, at the northern entrance of the Panama Channel was established. In 1996, after the introduction of Kappaphycus alvarezii, Gracilarias de Panama S.A. involved Guna Indians and Afro-descendant communities of the surrounding areas to expand the cultivation practices. The seaweed cultivation project was organized into 14 farms called “polygons” by the Maritime Authority of Panama (MAP) and monitoring was provided by the Ministry of Environment (MiAmbiete), the autonomous entity of Panama with a responsibility for natural resources in conjunction with the Aquatic Resources Authority of Panama (ARAP). The area chosen for these activities remained one of the most monitored areas in the tropics, with more than 80 years of data collected by the Panama Channel Authority and long-term monitoring projects by SI (http://www.stri.si.edu/sites/esp/data_access_policy.htm). Fourteen environmental parameters were recorded directly at the farming sites, e.g. seawater temperature (both at the surface and depth), salinity, pH, velocity and direction of the currents, were part of the evaluation since they could be directly correlated to growth and the quality of the carrageenan obtained from the cultivated biomass . These data were analyzed by Contreras and Rosenthal (2003). Monitoring from 1999–2009, by the Heltmholtz-Zentrum Geesthacht Center for Material and Costal Research in Germany was undertaken, they also installed an oceanographic buoy in Bahia Las Minas, near the seaweed farms which further contributed to the collection of data.

Experiments with K. alvarezii were initiated with indigenous material donated by fishermen from around La Playita and these were conducted within a lagoon open to the sea, surrounded by mangrove ecosystems, with a sandy bottom. A rectangular , semi-fixed structure constructed from wooden stakes, secured into the substratum and ropes alternating with buoys to form a grid and fixed structures constructed using PVC pipes, were all evaluated for farming purposes. In situ growth rates were measured for a series of experiments in order to establish the effects of various environmental parameters and seasonality on the daily growth rate. These studies were also conducted in relation to planting structures (fixed vs. semi-fixed); the presence or absence of epiphytes and initial seeding density (e.g. 50 and 100 g). Daily growth rates were compared in five weather conditions during the annual seasonal cycles of the area, viz. “dry season” (December 15–March 15); “dry to wet season” (March15–July 28); “very wet season” (July 28–August 15); “wet season” (August 15–October 15) and “wet to dry season” (October 15–December 15). Significant differences in the growth rates were observed between seasons and by site. Moreover, significant differences between daily growth in relation to current direction were also found, as well as in relation to the fixed structures used; the study period was extended from 2005–2008 and was also conducted at multiple sites. The percentage yield of carrageenan derived from the cultivated biomass was found to vary in relation to the duration of the cultivation (i.e. number of days since planting). The molecular weight of the extracted carrageenan was found to increase in relation to culture duration. These results allowed the farmers to extend the cultivation model to other places, with the intention of planting at lower cost with a greater production (Batista, own obs).

Kappaphycus farming in Panama evolved into another successful commercial endeavor called: Panama Sea Farms (PSF), which was a company working in Bocas del Toro with Indian communities. Gracilarias de Panama S.A. and PSF joined forces to make carrageenophyte seaweeds an export product which could generate a cash income for the inhabitants of coastal areas; encouragingly, with the potential great social impact and also revenue for the country. Both Gracilarias de Panama and PSF worked locally to improve the drying process, transforming the wet alga from 92 to 32% moisture content, which was stable point for storage and handling. At the time of writing (April, 2017), these two companies purchased all production available from local producers and export the dried seaweed to Malaysia (Teejoy Marine Company, in partnership with PSF) in order to produce semi-refined carrageenan (SRC). Despite the high demand for carrageenans, Panamanian seaweed scientists, farmers, buyers and processors still lack access the tools required to accurately and inexpensively assess the carrageenan content of their own seaweed crops throughout all stages of growth and refining. A recent technique capable of measuring and characterizing the carrageenan content in vitro, using confocal laser scanning microscopy was published to identify and broaden the knowledge of the carrageenan content located in the cell wall of K. alvarezii (Batista de Vega et al. 2016).

4.2.4.9 Mexico

In Mexico, the most studied carrageenophyte has been E. isiforme, both in terms of the carrageenan content, seasonality and chemical characteristics (Robledo 2006); further research is also underway. A biomass assessment at the Campeche Banks, west coast of the Yucatan Peninsula, dates to the late 1970s and reported a density of E. isiforme at approximately 6.7 kg m−2, with an estimated total biomass of 35,794 MT fresh weight. Thereafter, an incipient exploitation of Agardhiella sp. and E. isiforme occurred from 1977–1980 in some locations of the Campeche coast and the material was exported to Denmark to produce ι-carrageenan .

Two forms belonging to the genus Eucheuma, i.e. E. isiforme and E. isiforme var. denudatum, both native to the Gulf of Mexico and the Caribbean, were studied and cultivated on the southern coast of Florida (Dawes et al. 1974, 1977) and in the Yucatan Peninsula (Perez-Enriquez 1996a). The distribution and abundance of E. isiforme was characterized by its seasonality. Biomass availability of E. isiforme, over an annual cycle, ranged from 0.98–3.20 kg m−2. These data suggested that the populations were amenable to commercial exploitation in some areas. The largest E. isiforme standing stock occurred during the cold season (November–December) when high concentrations of nutrients and lower levels of light were to be found off the coast of Yucatan. This period also coincided with the largest yield of carrageenan (>40%; Freile-Pelegrin and Robledo 2006). The maximum growth of E. isiforme in the area occurred during October–April, with no growth during summer, when low densities were reported (approx. 20 g m−2) which were too low to be harvested for commercial purposes, suggesting that recruitment took place at the end of summer (Perez-Enriquez 1996b). These results should be taken into consideration for the management of natural populations, as well as for mariculture of this species. More recent results (Robledo and Freile-Pelegrín 2011) on their cultivation reported higher growths in April (1.2–3.8% day−1) being significantly affected by surface seawater temperatures (SST), whilst the carrageenan yields ranged from 34.8–37.1%. The seasonal variation in the biochemical compositions were similar to variations in carrageenan yield, suggesting that biochemical composition could be related to SST and hence to growth, while incident light and nutrients, influenced carrageenan quantity. In general, the carrageenan yield and viscosities found in E. isiforme were within the levels required for Eucheuma species for industrial applications, suggesting commercial/industrial potential. However, particularities in relation to the geographical location of raw material and extraction conditions are frequent. In this regard, the yield and physico-chemical properties of E. isiforme carrageenan was found to vary from 44.6% carrageenan content for “native” extraction, to between 31.8–35.3%, depending on the alkali concentration and time applied. Similar effects were seen for carrageenan viscosity values, with the lowest being for native extracts (e.g. 39–57.0 cPs), whilst alkali extractions with 1% KOH, for 3–4 h increased viscosity (e.g. 160.0–161.3 cPs). The yield and physico-chemical properties of native and alkali-treated carrageenans from Eucheuma isiforme was also found to depend upon the geographical origin of the harvested material, e.g. Eucheuma isiforme from Nicaragua produced higher yields, both with native (57.2%) and alkali treatments (43.5%), viscosities were also significantly different between the native (144.6 ± 3.3 cPs) and alkali-treated carrageenan (113.9 ± 2.6 cPs). In general, chemical and FTIR analysis of Eucheuma isiforme revealed a preponderantly iota-carrageenan extract. Commercial exploitation of E. isiforme off the Yucatan Coast, cannot be fully achieved without a management plan, or proven cultivation practices (Robledo and Freile-Pelegrín 2011). Unlike other Latin American countries, such as Brazil, to date, there have been no official initiatives to promote seaweed farming in Mexico. Techniques have been successfully tested in the region on different carrageenophyte species and varieties suited to various types of environment, however, practical experience on an adequate scale required to establish the costs and detailed activities of the operation are also of paramount importance (Dominguez-May et al. 2015). Recently, the domestication of E. isiforme was proven to be possible and cultivars were being produced in experimental IMTA systems (Robledo, unpublished data).

Although Kappaphycus alvarezii was not a native of the Gulf of Mexico, one species of the genus Eucheuma, previously described as E. inerme, from Campeche, was later transferred to the genus Kappaphycus (Ortega et al. 2001). Early laboratory experiments to observe the acclimation temperatures of Kappaphycus (Eucheuma) isiforme and Kappaphycus alvarezii, found that the former presented a greater capacity to acclimate to changes in parallel to the local, seasonal SST changes, which was attributed to the habitat characteristics (Dawes 1989). A commercial cultivar of K. alvarezii was first introduced to Mexico for evaluation in cultivation in 1999; the cultivar was provided by Dr. Edison J. de Paula, which had originated from the Philippines and was later cultured in the laboratory in Brazil. Whilst the technical viability to produce K. alvarezii was proven (Robledo et al. 2013), using a commercial, non-indigenous species, there were questions on its sustainability. Nevertheless, the carrageenan yield of the K. alvarezii biomass produced, i.e. 32–41% and harvesting time-management as a parameter that conditions both the carrageenan quality and its economic feasibility have been evaluated (Valderrama et al. 2015, Dominguez-May et al. 2015), suggesting that further efforts to support this activity in the area could bring social and economic benefits , if planned in a sustainable manner.

4.2.5 South America

Eucheuma and Kappaphycus were introduced in some South American countries to supply the national demand for carrageenan (Paula et al. 1999; Smith and Rincones 2006; Hayashi et al. 2007, 2011, 2014; Góes and Reis 2011; Leon and Tirado 2011; Reis et al. 2016).

Even with the long history of seaweed introductions, seaweed farming in South America (SA) is still incipient, despite the potential, with 29,199 km of coastline and a collective exclusive economic zone of 10.43 million km2, from ten countries. South America has different climatic zones, from tropical to polar, but for the most-part being tropical and warm-temperate (SEDAC 2016). Four main, warm ocean currents warm the South-American coastal zone: (a) South Equatorial Current, (b) Brazil Current, (c) Guyana Current, which warms almost all of the South America Atlantic coast of Colombia, Venezuela, Guyana, Suriname, French Guyana and most parts of the Brazilian coast, and d) Pacific Equatorial Counter-Current which warms the northwestern parts of the Pacific Coast – including Colombia and Ecuador. The similarities of the environmental and social characteristics in these warm water countries under-pins a similar history of eucheumatoid production.

As of 2017, more than 50% of the population of SA was reported to live in the coastal zone, there is a forecast of a 32% increase within 100 km of the shore by 2025 (Duedall and Maul 2005). A large number of these people live in traditional, coastal communities, comprising low-income, artisanal fisher-folk with low levels of formal education, high rates of illiteracy and other social barriers which make them most vulnerable to limitations of natural, resource-dependent activities, such as fishing (Salas et al. 2011). These similarities were, or are, shared with other countries where cultivation of eucheumatoid species has been successfully implemented, e.g. Southeast Asia and Africa, however, this success has not yet been achieved in South America (Reis et al. 2016). Regardless of many introductions being made from the 1990s onwards, commercial and experimental farming is only reported in Brazil, Venezuela, Colombia and Equador (Leon and Tirado 2011; Hurtado et al. 2014; FAO 2016; Fig. 4.10).

4.2.5.1 Brazil

In 1995, K. alvarezii and K. striatus were introduced to a sea farm in São Paulo State, Brazil, after 10 months of laboratory, quarantine conditions (Paula et al. 2002; Bulboa and Paula 2005; Bulboa et al. 2007; Oliveira 2006; Silva et al. 2010). The original seedlings were from the Philippines, but had also been cultivated in Japan (Silva et al. 2010). During the experimental period only K. striatus produced viable spores, K. alvarezii did not produce spores. As a result, the material was removed from the sea and its production forbidden in Brazil (Bulboa and Paula 2005; Silva et al. 2010). K. alvarezii produced spores but further studies concluded that they were not viable under normal, prevailing sea conditions (Paula et al. 1999). Neither spores nor sporangia were observed in other studies in the Brazilian South such as Santa Catarina State (Hayashi et al. 2011), Southeast Rio de Janeiro State (Castelar et al. 2009a, b) and the Northeast Region – Paraíba State (Araújo 2013) where the species were also introduced.

In 1998, a new introduction was reported to Brazil. After 4 months of quarantine, K. alvarezii from Venezuela was introduced to Ilha Grande Bay, Rio de Janeiro State, thereby starting the first commercial cultivation in Brazil (Castelar et al. 2009a, b). In 2004, the species was further introduced in Sepetiba Bay which became the largest Brazilian farm (see also Chap. 1). The farm facilities employed more than 100 workers and had approximately 120 floating rafts; each raft was 150 m long by 3 m. An average productivity of 39.3 g dw day−1 and an average daily growth rate of 3.8% day−1 were reported (Goes and Reis 2012; Reis et al. 2016). In 2008, seaweed rafts installed at Marambaia Bay were transferred to areas nearby at Itacuruçá City (Rio de Janeiro State; Alexandre Feder and Henrique Geromel de Góes, personal communications). However, in 2012, activities related to carrageenan processing from these farms were closed, it is presumed due to lack of profitability, but no reasons were apparent at the time of writing. Recently, another factory was opened, producing carrageenan from ten seaweed farms located in Sepetiba Bay and Ilha Grande Bay (Alexandre Feder, personal communication).

In 2008, K. alvarezii from São Paulo State was legally introduced in to Santa Catarina State (Silva et al. 2010) for experimental purposes. Santa Catarina is located in southern Brazilian, with sub-tropical conditions with the coolest SST occurring in winter. This was in contrast to São Paulo and Rio de Janeiro, where commercial cultivation was already allowed. Farming was successful in spring, summer and autumn, with growth rates close to 3.5% day−1. Also, since Santa Catarina was the main mollusc producer (responsible for 95% of Brazilian production), technologies which amalgamated mollusc and seaweed production were co-developed to minimize production costs and offer potential mechanisation and productivity benefits to the local farmers (Santos 2014). At the time of writing (April 2017), Santa Catarina State region was still undertaking experimental studies before scaling-up to commercial cultivation .

K. alvarezii was also introduced in to north-eastern Brazil, in Ceará, Rio Grande do Norte, Paraíba and Pernambuco States and possibly in Bahia State (Oliveira et al. 2009; Silva et al. 2010). These areas have been indicated as having high environmental risks by Castelar et al. (2015). Araújo (2013) reported on small rafts in Paraiba State. However, at the time of writing, things are reported to be changing rapidly, see elsewhere in this book (Neish et al. on Reflections on the commercial development of Kappaphycus chapter) for a further update on the cultivation and processing of carrageenophytes in Brazil.

4.2.5.2 Venezuela