Abstract

Despite of its success, the carrageenan industry has had to cope with difficulties due to epiphyte infestations and diseases known as ice-ice. Some promising results in respect of biomass production, carrageenan yield, and protection epiphytes were obtained using a powdered extract of the brown alga Ascophyllum nodosum in Kappaphycus alvarezii seedling production. This study focused on the effects of the A. nodosum extract on the treatment of K. alvarezii cultivated on commercial floating rafts not only to evaluate improvements demonstrated in vitro but also the effects on the quality of the carrageenan. The seedlings were treated in an A. nodosum extract solution and placed alongside their controls on commercial floating rafts using the tubular net technique. Daily growth rate, carrageenan yield, gel strength, and gel viscosity were obtained over 20 and/or 40 days. After 20 days, daily growth rates showed no significant difference (p = 0.44), while the carrageenan yield was higher in samples that were treated with the A. nodosum solution (p < 0.001). After 40 days, both daily growth rate (p = 000.7) and carrageenan yield (p = 0.009) were higher in treated samples; however, gel strength was higher in control samples (p = 0.03) as viscosity was also highest in the samples which had not been treated (p < 0.001). The use of the A. nodosum extract treatment on the cultivation in situ of K. alvarezii was positive since after 40 days when the daily growth rate and carrageenan yield increased. In spite of the negative effect on the quality of the semi-refined carrageenan, the values were within commercial standards.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Eucheumatoid is a general name for certain species that produce carrageenans which includes species of the genera Betaphycus Doty in Silva, Basson, Kappaphycus Doty, and Moe, and Eucheuma J. Agardh (Doty 1988, 1995). The last two species are valuable cultivated commodities for the hydrocolloid industry and collectively contribute to as much as 88 % of the worldwide production of carrageenan. Among eucheumatoids, Kappaphycus alvarezii (Doty) Doty ex. P.C. Silva is the most productive source of raw material for the industry, as it is farmed in more than twenty countries (Bindu and Levine 2011).

In spite of its success, K. alvarezii cultivation has endured a number of agronomically-related issues that are common in any land crop (i.e., infestations and diseases) and which are a major concern to seaweed farming. Epiphytism is mainly caused by a small number of red filamentous macroalga and other species, e.g., Neosiphonia savatieri (Hariot) M.S. Kim and I.K. Lee, Neosiphonia apiculata (Hollenberg) Masuda and Kogame, Ceramium sp. Roth, Acanthophora sp. J.V. Lamouroux, Ulva sp. Linnaeus, and Centroceras sp. Kützing. Its effects alter biomass production once it compromises the cortical portion of the thalli opening wounds, allowing bacterial infections that cause tissue necrosis (Vairappan 2006; Vairappan et al. 2008).

Additional problems, which begin with changing environmental factors that result in a condition called “ice-ice,” indicated by the whitening of the thallus lead to lower biomass and carrageenan production. Mendoza et al. (2002) also observed a depolymeralization of the carrageenan in the apical tips of the thalli, decreasing the overall quality of the carrageenan (lowering the viscosity and gel strength).

Reports of these occurrences have been more dominant in the Philippines and Indonesia, with recent accounts in east Africa, but crop losses appear to be an increasing phenomena, mainly due to increased epiphytism, on the account of them being hard to mitigate or manage once they are established (Vairappan et al. 2008; Hurtado et al. 2009; Schaffer et al. 2011). The complete removal of the cultivars and the destruction of the seedlings are the currently accepted methods to quickly address those problems (Mendoza et al. 2002; Hurtado et al. 2006; Vairappan 2006).

Efforts have been made using a commercial extract from the brown macroalga Ascophyllum nodosum (Linnaeus) Le Jolis, named Acadian Marine Plant Extract (AMPEP), in cultivated K. alvarezii seedlings. AMPEP increases daily growth rate and carrageenan yield of K. alvarezii as well as mitigated the damaging effects of epiphytes (Hurtado et al. 2009; Loureiro et al. 2010; Borlongan et al. 2011; Yunque et al. 2011). The use of AMPEP on K. alvarezii has been very promising and a “vaccine-like effect” was proposed by Loureiro et al. (2012) in an attempt to clarify the biochemical pathways involved in the observed positive responses. However, none of the in situ and in vitro studies have analyzed the effects of AMPEP on the quality (rheological properties such as gel strength and gel viscosity) of the carrageenan obtained from K. alvarezii.

This study evaluated the effect on the daily growth rate, carrageenan yield, gel strength, and viscosity of K. alvarezii samples treated with AMPEP in order to clarify its effects on K. alvarezii samples rheology as well as to test its effectivness in the sea.

Materials and methods

Study area and experimental design

In Brazil, the species being cultivated is K. alvarezii (Barros-Barreto et al. 2013). The voucher material was deposited in the herbarium of Botanical Garden of Rio de Janeiro (RB 515835, 515836, 515837). Sampling was conducted from May 2011 to June 2012. The sampling domain was composed of three productive commercial farms at Sepetiba Bay, on the south coast of Rio de Janeiro state, Brazil: Prainha (22°57′17″ S–43°54′31″ W), Jardim (22°56′25″ S–43°55′08″ W), and Praia Leste (22°56′01″ S–43°52′20″ W) in order to include different cultivation sites under diverse environmental conditions. This bay has a tropical climate (i.e., rainy summers and dry winters) with higher irradiances in summer and decreasing in the winter (Góes and Reis 2011).

The floating rafts used in the experiment were owned by the commercial farms. They all used the tubular net technique since it is the main cultivation technology used in Brazilian farms (Góes and Reis 2011). Each raft was composed of 10 to 15 modules (3 × 5m), where each module was made from two 100-mm (diam) PVC tubes (closed ends) connected to each other by 6-mm (diam) polypropylene cables.

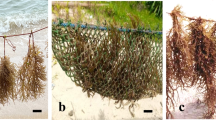

From all of the commercial floating rafts in each cultivation site (15–20 floating rafts per site), eight were randomly selected from a grid chart of the location. Four rafts received the AMPEP treatment, while the others acted as controls. From each commercial floating raft (composed of 10 to 15 modules), one module was randomly chosen. Four tubular nets were placed per module, two to be removed at 20 days, and two at 40 days. Each tubular net held eight K. alvarezii seedlings (Fig. 1).

Graphic representation of one floating raft with 15 modules used in the commercial cultivation of Kappaphycus alvarezii in Brazil and the experimental design that used seedlings treated with AMPEP (AMPEP) and seedlings not treated with AMPEP (control) that used one module of each commercial raft for each sample treatment

The AMPEP treatment consisted of bathing K. alvarezii samples (single individuals, 100 ± 10 g each) in a solution of 20 g L−1 of the extract with seawater for 1 h adapting the protocol used by Loureiro et al. (2010). To ensure full coverage of the thalli, the samples were placed inside hardened plastic containers with a 60-L capacity with the solution. The end period of 40 days was chosen since it is similar to the 45-day production cycle commonly used in Brazil (Góes and Reis 2011, 2012).

Daily growth rate of K. alvarezii

At the end of each cultivation period, the growth of the samples was estimated as daily growth rate (DGR) and calculated according to the formula: DGR = 100 × [(ln (M f/M i)/t], where M f is the final dry mass and M i is the initial dry mass and t is the time of cultivation (Góes and Reis 2011, 2012).

Semi-refined carrageenan and carrageenan yield

Twelve samples, for each treatment, were taken to the laboratory in order to obtain semi-refined carrageenan from K. alvarezii by an alkaline transformation with 6 % KOH solution in a water bath (80 °C) for 2 h with successive washing with fresh water. The samples were then maintained in 0.06 % NaClO solution for 30 min (25 °C) and washed with fresh water to remove residues. They were then dried in the oven at 60 °C until constant mass; pH 8.4 was maintained during the procedure (Loureiro et al. 2010; Góes and Reis 2011, 2012).

The carrageenan yield of K. alvarezii (CY) was expressed as the percentage of carrageenan relative to the algal dry mass (Góes and Reis 2011, 2012), derived from the formula: CY = (M c/M s) × 100, where M c is the carrageenan dry mass (oven dried at 60 °C to constant mass) and M s is the seaweed dry mass (oven dried at 60 °C to constant mass).

Rheology of K. alvarezii

To prepare gel of the semi-refined carrageenan, each sample was macerated into a ball mill (Mixer Mill MM 400, Retsch) and mixed in 100 mL of distilled water to a 1.5 % proportion of carrageenan (1.5 g of semi-refined carrageenan powder to 98.5 mL of distilled water). This solution was kept for 1 h at room temperature (25 °C), then heated (80 °C) for 10 min under constant agitation, and subsequently cooled (7 ± 2 °C) for 24 h.

The gel viscosity was analyzed using a cone Rheometer DV-III Ultra (Brookfield Engineering Labs, Inc.) at 75 °C with a CP-40 spindle. The gel strength was measured using the Texturometer, TexturePro CT (Brookfield Engineering Labs, Inc.) with a cylindrical probe and a sample flask of 2.5 cm width and 5 cm height. Measurements were made after 40 days, which reflected a full cultivation cycle, allowing the investigation of any effects of AMPEP on K. alvarezii related to any possible molecular transformation of the carrageenan.

Statistical analyses

Data normality (Shapiro–Wilks test) and homogeneity of the variances (Levene test) were tested to use parametric or nonparametric analysis of the data. Differences between AMPEP and control samples at each given cultivation period (daily growth rate and carrageenan yield at 20 days and gel strength and gel viscosity) were tested using the Mann–Whitney test since even after transformation, the data did not meet the criteria for parametric testing. Daily growth rate and carrageenan yield at 40 days were analyzed using Student’s paired t test. Analyses were performed using Statistica 6.0, StatSoft, at the 95 % confidence level (p < 0.05). Data were expressed as (minimum) mean ± standard deviation (maximum) with twelve replicates for each experiment.

Results

After 20 days of cultivation, no significant differences were obtained between treatments (p = 0.44) of the daily growth rate; however, the carrageenan yield was higher in samples treated with AMPEP (p < 0.001). At 40 days, both daily growth rate and carrageenan yield of samples treated with AMPEP were higher when compared to their controls (p < 0.009).

The gel strength of the semi-refined carrageenan samples of K. alvarezii treated with AMPEP was lower than the control samples (p = 0.03), similar to the gel viscosity (p < 0.001) which was also lower in samples which received the AMPEP treatment. All the results of statistical differences can be referred in Table 1.

Discussion

Daily growth rates of K. alvarezii cultivated in the sea, under commercial cultivation during 20 and 40 days, were generally higher than what is normally expected for Sepetiba Bay. At the southern portion of Sepetiba Bay, Góes and Reis (2011, 2012) reported mean growth rates of K. alvarezii of 3.3 and 3.8 % day−1. The results obtained in this study were within the range obtained for K. alvarezii cultivated using floating rafts in Brazil and other countries, ranging between 0.8 to 7.2 % day−1 (Ohno et al. 1994; Muñoz et al. 2004; Hayashi et al. 2007a, b, 2011; Hung et al. 2009).

The results of the daily growth rate of K. alvarezii obtained in this study and in vitro (5.5 % day−1 AMPEP and 2.5 % day−1control samples) by Loureiro et al. (2010) using the same protocols to treat red algae samples with AMPEP solution can be considered promising results when compared to the results obtained by Borlongan et al. (2011). The authors examined the efficiency of AMPEP on two variants of K. alvarezii at different depths in the sea using a lower concentration of the extract (0.1 g L−1 of AMPEP) and exposing the samples of K. alvarezii to AMPEP in a shorter period of time (30 min). They also obtained positive results on growth improvement (1.3 to 4.1 % day−1 in samples treated with AMPEP and 0.9 to 3.0 % day−1 in the controls); however, when their results were compared with the ones obtained by this study, the growth rate obtained in the Brazilian coast was higher.

Yokoya et al. (2010) reported the presence of cytokinins in some red alga and discussed the importance of hormones in the physiology of the growth of red algae. Higher concentrations of AMPEP led to higher growth rates of K. alvarezii, which may be linked to stimulatory compounds present in the extract related to cytokinin synthesis (Khan et al. 2008, 2009) and the presence of certain betaines (Mackinnon et al. 2009) as observed in higher plants.

The carrageenan yield of K. alvarezii at 20 and 40 days (AMPEP and control samples) was within the range considered ideal by industrial standards, around 30 % (Hayashi et al. 2007a, b; Hung et al. 2009; Góes and Reis 2011, 2012).

Hayashi et al. (2007a), Reis et al. (2008), and Góes and Reis (2012) discussed the importance of environmental shifts as stress factors, such as changes in salinity and water movement, in the conformation of carrageenan, which consequently causes changes in its rheological properties as a preventive response to these stresses. AMPEP can act as an elicitor to K. alvarezii responses to stress conditions, prompting its defenses causing a greater production of carrageenan (Loureiro et al. 2012). This might explain the higher carrageenan yield results of K. alvarezii samples exposed to AMPEP as early as 20 days of cultivation when compared to the control samples.

However, in the long term, the eliciting factor is not harmful to K. alvarezii as the extract seems to carry a series of elicitors and protective molecules (specific isoforms of different antioxidant enzymes such as superoxide dismutase [Mn-SOD-1, ∼150 kDa], ascorbate peroxidase [APX-4, ∼55 kDa], glutathione peroxidase [GSH-Px-2, ∼55 kDa], and glutathione reductase [GR-1, ∼180 kDa] that specifically responded to AMPEP supplementation) that even under stress and the exposure to oxidative bursts (as a response to unfavorable conditions) are able to sustain and protect the samples even after a brief time of exposure (Loureiro et al. 2012; Kumar et al. 2013).

In addition to improving growth rate and carrageenan yield, AMPEP seemed to be effective in reducing some epiphytes (Loureiro et al. 2010). This factor was not tested, but it was observed in the seedlings that were treated with AMPEP. Since the experiment was made using floating rafts of commercial cultivations, when the modules of the rafts where the seedlings were treated with AMPEP were compared with the modules of the commercial rafts that were not used in the experiment, apparently the experimental modules had about 20 % less biofouling than the modules that were not used in the experiment (personal observation).

AMPEP is rich in soluble potassium (17–22 %) in its composition (Hurtado et al. 2009; Loureiro et al. 2010) and K. alvarezii in kappa carrageenan (Pereira et al. 2013). Since kappa carrageenan is known to be sensitive to potassium ions, the carrageenan extract from the AMPEP-treated samples should produce more rigid gels. This can be explained by the changes in the syneresis (spontaneous extrusion of water through the surface of gel when it is at rest) of the seedlings that were exposed to aqueous solutions rich in soluble potassium. Higher potassium concentrations would display higher syneresis resulting in higher gel strength results. However, the gel strength of K. alvarezii was higher in the control samples but was within the range obtained by Góes and Reis (2011, 2012) in crops at Sepetiba Bay and in other locations (Ohno et al. 1994; Hayashi et al. 2007a, b). This leads to the idea that the potassium available through AMPEP treatment that was absorbed by K. alvarezii, when the alga was cultivated in the sea, would not be significant enough to change the molecular structure of the extracted carrageenan.

Although the gel viscosity of the carrageenan derived from the K. alvarezii samples treated with AMPEP was lower when compared to the control samples, these values were similar to those recorded for Sepetiba Bay (Góes and Reis 2011, 2012). When evaluating carrageenan yield and quality of K. alvarezii, Mendoza et al. (2002) found that healthy samples provided an extract with better gel quality (higher gel strength and higher viscosity) as compared to stressed samples exhibiting “ice-ice” symptoms. Samples with “ice-ice” showed changes in molecular weight, preventing the correct formation of hydrogen bonds, reflecting directly on the ability to form the double helix that occurs in the regular gelling process. Carrageenan compromises alternating units of d-galactose and 3,6-anhydro-galactose, joined by α-1,3 and β-1,4-glycosidic bonds. Higher levels of ester sulfate in the powdered extract solution can result in lower gel strength and viscosity due to a change in the molecular weight (Craigie and Wong 1979; Craigie 1990; Knutsen et al. 2001). The results of the present study support previous results of Loureiro et al. (2012), where AMPEP acts as an elicitor to K. alvarezii own defenses.

In conclusion, the use of AMPEP treatment in the cultivation in the sea of K. alvarezii is recommended to improve the growth of K. alvarezii, as after 40 days the daily growth rate increased and was superior to the numbers already attained at the Sepetiba Bay region. Furthermore, a higher carrageenan yield was produced compared to the control samples. In spite of the negative effect on the quality of the semi-purified carrageenan, the values were within commercial standards.

References

Barros-Barreto M, Marinho L, Reis R, Mata C, Ferreira P (2013) Kappaphycus alvarezii cultivated in Brazil: is it only one species? J Appl Phycol 25:1143–1149

Bindu MS, Levine IA (2011) The commercial red seaweed Kappaphycus alvarezii—an overview on farming and environment. J Appl Phycol 23:789–796

Borlongan IAG, Tibudos KR, Yunque DAT, Hurtado AQ, Critchley AT (2011) Impact of AMPEP on the growth and occurrence of epiphytic Neosiphonia infestation on two varieties of commercially cultivated Kappaphycus alvarezii grown at different depths in the Philippines. J Appl Phycol 23:615–621

Craigie JS (1990) Cell walls. In: Cole KM, Sheath RG (eds) Biology of the red algae. Cambridge University Press, Cambridge, pp 221–225

Craigie JS, Wong KF (1979) Carrageenan biosynthesis. Proc Int Seaweed Symp 9:369–377

Doty MS (1988) Prodromus ad systematica Eucheumatoideorum: a tribe of commercial seaweeds related to Eucheuma (Solieriaceae, Gigartinales). In: Abbott IA (ed) Taxonomy of economic seaweeds with reference to some Pacific and Caribbean species, vol II, California Sea Grant College Program. University of California, La Jolla, pp 159–207

Doty MS (1995) Betaphycus philippinensis gen. et sp. nov. and related species (Solieriaceae, Gigartinales). In: Abbott IA (ed) Taxonomy of economic seaweeds with reference to some Pacific and Caribbean species, V. California Sea Grant College Program. University of California, La Jolla, pp 237–245

Góes HG, Reis RP (2011) An initial comparison of tubular netting versus tie-tie methods of cultivation for Kappaphycus alvarezii (Rhodophyta, Solieriaceae) on the south coast of Rio de Janeiro State, Brazil. J Appl Phycol 23:607–613

Góes HG, Reis RP (2012) Temporal variation of the growth, carrageenan yield and quality of Kappaphycus alvarezii (Rhodophyta, Gigartinales) cultivated at Sepetiba bay, southern Brazilian coast. J Appl Phycol 24:173–180

Hayashi L, Oliveira EC, Bleicher-Lhonneur G, Boulenguer P, Pereira RTL, Seckendorff R, Shimoda VT, Leflamand A, Vallée P, Critchley AT (2007a) The effects of selected cultivation conditions on the carrageenan characteristics of Kappaphycus alvarezii (Rhodophyta, Solieriaceae) in Ubatuba Bay, São Paulo, Brazil. J Appl Phycol 19:505–511

Hayashi L, Paula EJ, Chow F (2007b) Growth rate and carrageenan analyses in four strains of Kappaphycus alvarezii (Rhodophyta, Gigartinales) farmed in the subtropical waters of São Paulo State, Brazil. J Appl Phycol 19:393–399

Hayashi L, Santos AA, Faria GSM, Nunes BG, Souza MS, Fonseca ALD, Barreto PLM, Oliveira EC, Bouzon ZL (2011) Kappaphycus alvarezii (Rhodophyta, Areschougiaceae) cultivated in subtropical waters in southern Brazil. J Appl Phycol 23:337–343

Hung LD, Hori K, Nang HQ, Kha T, Hoa LT (2009) Seasonal changes in growth rate, carrageenan yield and lectin content in the red alga Kappaphycus alvarezii cultivated in Camranh Bay, Vietnam. J Appl Phycol 21:265–272

Hurtado AQ, Critchley AT, Bleicher-Lhonneur G (2006) Occurrence of Polysiphonia epiphytes in Kappaphycus farms at Calaguas Is., Camarines Norte, Philippines. J Appl Phycol 18:301–306

Hurtado AQ, Yunque DA, Tubudos K, Critchley AT (2009) Use of Acadian marine plant extract powder from Ascophyllum nodosum in tissue culture of Kappaphycus varieties. J Appl Phycol 21:633–639

Khan W, Palanisamy R, Hankins SD, Critchley AT, Smith DL, Papadopoulos Y, Prithiviraj B (2008) Ascophyllum nodosum (L.) Le Jolis extract improves root nodulation in alfalfa. Can J Plant Sci 88:728–728

Khan W, Rayirath UP, Subramanian UP, Jitesh MN, Rayorath P, Hodges DM, Critchley AT, Craigie JS, Norrie J, Prithiviraj B (2009) Seaweed extracts as biostimulants of plant growth and development. J Plant Growth Regul 28:386–399

Knutsen SH, Sletmoen M, Kristensen T, Barbeyron T, Kloareg B, Potin P (2001) Arapid method for the separation and analysis of carrageenan oligosaccharides released by iota- and kappa-carrageenase. Carbohydr 331:101–106

Kumar M, Reddy CRK, Jha B (2013) The ameliorating effect of Acadian marine plant extract against ionic liquids-induced oxidative stress and DNA damage in marine macroalga Ulva lactuca. J Appl Phycol 25:369–378

Loureiro RR, Reis RP, Critchley AT (2010) In vitro cultivation of three Kappaphycus alvarezii (Rhodophyta, Areschougiaceae) variants (green, red and brown) exposed to a commercial extract of the brown alga Ascophyllum nodosum (Fucaceae, Ochrophyta). J Appl Phycol 22:101–104

Loureiro RR, Reis RP, Berrogain FD, Critchley AT (2012) Extract powder from the brown alga Ascophyllum nodosum (Linnaeus) Le Jolis (AMPEP): A “vaccine-like” effect on Kappaphycus alvarezii (Doty) Doty ex P.C. Silva. J Appl Phycol 24:427–432

Mackinnon SL, Hiltz D, Ugarte R, Craft CA (2009) Improved methods of analysis for betaines in Ascophyllum nodosum and its commercial seaweed extracts. J Appl Phycol 22:489–494

Mendoza WG, Montaño EN, Gazon-Fortes ET, Villanueva RD (2002) Chemical and gelling profile of ice-ice infected carrageenan from Kappaphycus striatum (Schmitz) Doty “sacol” strain (Solieriaceae, Gigartinales, Rhodophyta). J Appl Phycol 14:409–418

Muñoz J, Freile-Pelegrín Y, Robledo D (2004) Mariculture of Kappaphycus alvarezii (Rhodophyta, Solieriaceae) color strains in tropical waters of Yucatán, México. Aquaculture 239:161–177

Ohno M, Largo BD, Ikumoto T (1994) Growth rate, carrageenan yield and gel properties of cultured kappa-carrageenan producing red alga Kappaphycus alvarezii (Doty) Doty in the subtropical waters of Shikoku, Japan. J Appl Phycol 6:1–5

Pereira L, Gheda SF, Ribeiro-Claro PJA (2013) Analysis by vibrational spectroscopy of seaweed polysaccharides with potential use in food, pharmaceutical and cosmetic industries. Int J Carbohydr Chem 2013:1–7

Reis RP, Yoneshigue-Valentin Y, Santos CP (2008) Spatial and temporal variation of Hypnea musciformis carrageenan (Rhodophyta-Gigartinales) from natural beds in Rio de Janeiro State, Brazil. J Appl Phycol 20:1–8

Schaffer D, Isten G, Asakawa T, Serra C (2011) Zanzibar Marine Institute of Science Report. In: TWAS (ed) Academy of Sciences for the Developing Countries, Tanzania pp 31-55

Vairappan CS (2006) Seasonal occurrences of epiphytic algae on the commercially cultivated red alga Kappaphycus alvarezii (Solieriaceae, Gigartinales, Rhodophyta). J Appl Phycol 18:611–617

Vairappan CS, Chung CS, Hurtado AQ, Flower ES, Lhonneur GB, Critchley AT (2008) Distribution and symptoms of epiphyte infection in major carrageenophyte-producing farms. J Appl Phycol 20:477–483

Yokoya NS, Stirk WA, van Staden J, Novák O, Turecková V, Pňnčík A, Strnad M (2010) Endogenous cytokinins, auxins and abscisic acid in read algae from Brazil. J Phycol 46:1198–1205

Yunque DAT, Tibudos KR, Hurtado AQ, Critchley AT (2011) Optimization of culture conditions for tissue culture production of young plantlets of carrageenophyte Kappaphycus. J Appl Phycol 23:433–438

Acknowledgments

Conselho Nacional de Desenvolvimento Científico e Tecnológico (CNPq), Coordenação de Aperfeiçoamento de Pessoal de Nível Superior (CAPES), and Fundação Carlos Chagas Filho de Amparo à Pesquisa do Estado do Rio de Janeiro (FAPERJ) supported this work. The authors would like to thank Acadian Seaplants Ltd. for providing the AMPEP, Henrique Geromél de Góes, from ALGAMAR Ltda. for providing K. alvarezii samples and Beatriz Castelar, and Rafael Marroig for the assistance on the experiments in the field.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Loureiro, R.R., Reis, R.P., Berrogain, F.D. et al. Effects of a commercial extract of the brown alga Ascophyllum nodosum on the biomass production of Kappaphycus alvarezii (Doty) Doty ex P. C. Silva and its carrageenan yield and gel quality cultivated in Brazil. J Appl Phycol 26, 763–768 (2014). https://doi.org/10.1007/s10811-013-0210-5

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10811-013-0210-5