Abstract

Biodiesel production is a fast-growing industry. Biodiesel is obtained through transesterification of different kinds of oils with methanol. This process results in a formation of substantial amounts (up to 10% of a total product mass) of the by-product fraction that mainly contains glycerol but also some toxic contaminations (spent catalyst, salts after neutralization, residual methanol, methyl esters, and free fatty acids), and that is therefore called crude glycerol. Efficient utilization of this fraction is imperative to the sustainability of the biodiesel industry. This review describes different methods of valorization of the crude glycerol fraction with the focus on biotechnological processes conducted by yeasts. In particular, production of organic acids, polyols, ethanol, microbial oil, carotenoids, γ-decalactone, sophorolipids, heterologous proteins, and biomass is discussed.

Access provided by Autonomous University of Puebla. Download chapter PDF

Similar content being viewed by others

Keywords

- Biodiesel

- Crude glycerol

- Yarrowia lipolytica

- Pichia pastoris

- Oleaginous yeasts

- Citric acid

- Erythritol

- SCO

- Ethanol

- Carotenoids

12.1 Biodiesel as an Emerging Sustainable Biofuel

Global warming (caused by increased carbon dioxide emissions), environmental pollution, and the threat of exhaustion of world resources of fossil fuels are some of the many concerns that had arisen in twentieth century and followed humanity into the new millennium. The 2030 Agenda for Sustainable Development, adopted by all United Nations Member States in 2015, is a call for action to fight major global issues. At its heart are the 17 Sustainable Development Goals, among them goal #7 (ensure access to affordable, reliable, sustainable and modern energy for all) and goal #13 (take urgent action to combat climate change and its impacts) (https://sustainabledevelopment.un.org/?menu=1300).

Search for “green”, renewable energy resources that can be used instead of fossil fuels brought to humankind attention among others such options as biogas, bioethanol, and biodiesel. These biofuels are produced from renewable biological material and after combustion generate an acceptable level of emissions gases (Quispe et al. 2013).

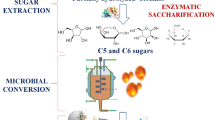

Biodiesel is a liquid biofuel obtained by transesterification (Fig. 12.1) of triglycerides from vegetable oils or animal fats with an alcohol (Fukuda et al. 2001). Biodiesel can be used in diesel engines alone or blended with diesel oil.

Biodiesel production by transesterification of triglycerides from vegetable oils with methanol. (Adapted from Smirnov et al. 2018)

First vegetable oil-powered engine was produced by the French company Otto and presented at the Paris Exhibition in 1900. Rudolph Diesel also experimented with castor oil and animal oils as a possible fuel for locomotive engines (Radley 2016). But due to the success of petroleum and diesel oil as the cheap fuels, these studies did not gain further attention until early 1980 when the study with the sunflower oil was conducted in South Africa prompted by diesel oil embargo (Ma and Hanna 1999) and the National Program of Vegetable Oils for Energy Purposes (PRO-OIL) started to gain momentum in Brazil. But vegetable oils contain, besides triacylglycerols, some additional compounds (free fatty acids, phospholipids, sterols, etc.) that complicate its direct usage as a fuel for engines (Kegl 2008). These problems can be overcome with the chemical modifications of vegetable oil, such as cracking, esterification, and transesterification. The process of fatty acids transesterification was developed to obtain a mixture of long-chain monoalkylic esters (biodiesel). In Europe, biodiesel is produced on an industrial scale since 1992 (Quispe et al. 2013). Stimulated by tax exemptions and other governmental incentives, world’s biodiesel production increases every year and is expected to reach 110,000 ML in 2020 (Rodrigues et al. 2017).

Such drastic increase in production was supported by the fact that biodiesel fuel has a lot of advantages over the petroleum and diesel oil: it has a higher flash point and flammability point which ensures safer storage, loading/unloading, and handling of this material by the drivers and operators (Knothe et al. 2005); it degrades more rapidly than diesel fuel, minimizing the environmental consequences in case of accidental spills; after combustion, it produces less emissions of contaminants (carbon monoxide, particulate matter, polycyclic aromatic hydrocarbons, aldehydes, carcinogenic substances) and has no jeopardy due to emissions of sulfur dioxide (SO2); and it has good lubricating properties (Romano and Sorichetti 2011). Unfortunately, there are several aspects in which biodiesel is inferior to petroleum diesel: it has the lower calorific value, which causes slightly higher fuel consumption; it has slightly higher emissions of nitrous oxide; it is less stable than diesel fuel and therefore it has short shelf life (up to 6 months); and in pure form, it may degrade equipment made from plastic or natural rubber; it may dissolve the deposits of sediments from diesel fuel in storage tanks and fuel lines and flushed them into the car engine (Romano and Sorichetti 2011). Also, biodiesel has a high freezing point – at low temperatures, it tends to quickly lose fluidity that may lead to clogging of filters and damage to the starting system of the engine (Munoz et al. 2012). Biodiesel exhibits more corrosive behavior than diesel oil due to the following factors: it is more hygroscopic and captured water can itself act on the corrosion or cause the hydrolysis of biodiesel or promote microbial growth; the presence of impurities like methanol, free glycerol, free fatty acid, and catalyst residues (Na and K) also promotes metallic corrosion; and biodiesel dissolves more metallic parts than diesel due to its good lubricity, and these trace metals in solution enhance biodiesel degradation and therefore corrosion (Haseeb et al. 2011; Singh et al. 2012). The intensity of biodiesel self-oxidation and its corrosive behavior depends on the amount of the double bonds in unsaturated fatty acids, so the oils with high concentrations of polyunsaturated fatty acids are undesirable for biodiesel production (Borsato et al. 2012). All mentioned disadvantages are significantly reduced when biodiesel is used in blends with diesel fuel (Romano and Sorichetti 2011). Blends with diesel fuel are designated as “B∗,” where “∗” is the number reflecting the percentage of biodiesel in the blend. For example, “B2” indicates a blend with 2% biodiesel and 98% petroleum diesel (Romano and Sorichetti 2011). In Brazil, government initiates increase in biodiesel percentage in the blends almost every year. For example, in 2008, all diesel blends sold had to be at least B3; in 2009, B4; and in 2010, B5 (Mota et al. 2009). B20, a mixture of 20% biodiesel and 80% diesel, is scheduled for introduction in 2020 (Pousa et al. 2007).

Theoretically, biodiesel can be produced from any source containing oil, but not all sources produce biodiesel that complies with strict international standards for the quality fuel. The most commonly used vegetable oils are rapeseed (in European Union), soybean (in United States of America, Brazil, Argentina), palm (in Asian and Central American countries), and sunflower oils (Romano and Sorichetti 2011) (Fig. 12.2). Latest advantages in bioengineering even allowed the obtaining of oilseed crops with high content of specific fatty acids (e.g., high omega-7 monounsaturated fatty acid), which improved ignition quality and oxidative stability of produced biodiesel (Beaudoin et al. 2014). But there are some issues in using oilseed plants: for their cultivation, productive agricultural lands are used that can be otherwise exploited to obtain more food. That’s why attempts have been made to produce biodiesel from nonedible feedstock (second-generation biodiesel). Nonedible, drought-tolerant oil plants (e.g., jojoba, Jatropha) that were grown on nonused land can be considered as such feedstock. Another good example can be waste cooking oil – a residue from cooking process of industries, restaurants, and bars. Although it was shown to be somewhat inferior in comparison with virgin vegetable oils due to the high content of free fatty acids that can be converted to soaps during transesterification process (Thompson and He 2006), after some adjustments (e.g., changing the catalysis from basic to acidic), it can be used for biodiesel production. Finally, very promising source of oils is microalgae which were included in the so-called third-generation biofuels group (Rodrigues et al. 2017). Being fast-growing, autotrophic microorganisms (Yang et al. 2011), they produce 200 more oil per unit of area than the best-performing oil plants (Demirbas 2009).

The most common process of biodiesel production is the transesterification (also called alcoholysis) of vegetable oil (or animal fat) with short-chain alcohols, including methanol, ethanol, butanol, and amylic alcohol. This reaction results in the formation of a mixture of esters of the fatty acids and glycerol (Meher et al. 2006). The glycerol layer is denser than the ester one; therefore, it deposits at the bottom of the reactor and can be removed by simple decantation. Methanol (CH3OH) and ethanol (C2H5OH) are the most widely used alcohols for biodiesel production. Most of the production facilities prefer methanol as it offers easier ester phase separation from glycerol, better alcohol recovery, and higher reaction speed (Munoz et al. 2012). Some enterprises consider ethanol route as more ecologically friendly, though in ethanolysis the mixture of esters and glycerol is more stable, complicating the separation and purification of biodiesel fraction (Meher et al. 2006). Important parameter of transesterification reaction is alcohol/oil ration. The stoichiometry of the reaction requires three molecules of alcohol for each molecule of triacylglycerides; however, as the reaction is reversible, excess amount of one of the reagents is required to drive the process to completion. So the most biodiesel facilities use at least 6 to 1 M ratio of methanol to oil. In case of ethanol, molar ratio between 9:1 and 12:1 gave the best results (Sinha et al. 2008). The majority of the excess alcohol (up to 80%) ends up in the crude glycerol fraction after the reaction, so producers tend to recover the alcohol by distillation and reuse it (Miesiac 2003).

Different catalysts can be used for transesterification reaction: basic or acidic, homogeneous or heterogeneous, and chemical or biological. The most commonly used process of biodiesel production driven by basic catalysis is faster than in case of acidic catalysis, and the end product has less corrosive properties (Ma and Hanna 1999). Substances used for basic catalysis are the alkoxides (Schwab et al. 1987) and hydroxides (Aksoy et al. 1990) of sodium or potassium. The alkoxides of alkali cations such as potassium methoxide (CH3ONa) are the most reactive catalysts, but the hydroxides (KOH and NaOH) are more accessible in price, so they are being used more (Munoz et al. 2012). KOH is more expensive than NaOH; however, there is less soap formation using KOH (Fukuda et al. 2001). The excessive amounts of basic catalyst can decrease the acidity index of biodiesel, but it can also cause the formation of soaps, hampering the separation of glycerol from esters. That’s why the base catalysis is preferable when the oils do not contain a lot of water and free fatty acids. In case of high free fatty acids content, a pretreatment by saponification or the acid catalysis for previous esterification of these acids is recommended (Marchetti et al. 2007). Heterogeneous acid catalysts have many advantages: they simultaneously promote alcoholysis of triglycerides and esterification of free fatty acids, reduce the number of needed purification steps, and, as it forms the insoluble phase, give the possibility to recover and reuse the catalyst in a continuous process (Munoz et al. 2012). The biological or enzymatic catalysis is also a very perspective option as it is more specific, does not promote side reactions, and allows the simple recovery of glycerol, the total esterification of free fatty acids, and the use of mild conditions in the process. The main drawbacks of this technology are the high cost of enzyme production, extraction, and purification as well as their instability in solution (Singh and Singh 2010). These problems can be partially resolved by the immobilization of enzymes, which allows their reuse. Many processes of biodiesel production using immobilized lipases have been developed (Shieh et al. 2003).

Although transesterification is the most important step in biodiesel production, additional steps are required to obtain a quality product (Meher et al. 2006). As was already mentioned, the mix of two components (esters and glycerol) should be separated after the completion of the transesterification reaction, and esters fraction should be purified from the excess of catalyst, water, and alcohol.

There are some other technological processes that can be used for biodiesel production, for example, the esterification catalyzed by the sulfonic or sulfuric acids. This reaction is quite slow and requires temperatures above 100 °C for over 3 hours and a large alcohol excess, but the obtained esters yield is very high (99%) (Al-Widyan and Al-Shyoukh 2002; Fukuda et al. 2001).

12.2 Crude Glycerol as a by-Product of Biodiesel Industry

The by-products of biodiesel production are glycerol, biodiesel washing wastewaters, methanol, and solid residues (Varanda et al. 2011). As was already mentioned, glycerol is a major by-product of transesterification reaction that can and has to be removed from biodiesel as it can promote the formation of deposits and sediments, reducing the engine life (Munoz et al. 2012). The fraction which is being removed after the transesterification reaction contains not only glycerol but many other compounds. It is most commonly referred to as crude glycerol. Crude glycerol makes up to 10% of a total product mass, so 1 kg of crude glycerol is produced per 12.6 L of biodiesel (Dobroth et al. 2011). Due to rapid increase in biodiesel production, by 2020, global annual crude glycerol production is expected to reach of 4200 ML (Okoye and Hameed 2016). In fact, the global market is flooded with excessive crude glycerol, which led to a drastic decrease in its price from $400 per ton in 2001 to less than $100 per ton in 2011 (Quispe et al. 2013). Large-scale biodiesel producers refine obtained crude glycerol to a chemically pure substance and sell it to the food, pharmaceutical, or cosmetics industries. However, the process of crude glycerol purification is quite expensive and inaccessible for small- to moderate-scale biodiesel producers (Thompson and He 2006). As more and more crude glycerol is generated, its disposal starts to be a problem. Biodiesel producers together with researchers must seek alternative applications for crude glycerol. Some of them have already been developed – e.g., using crude glycerol as a cheap organic solvent, as a raw feedstock for the production of value-added compound, as building block to biomaterial synthesis, etc. (Yang et al. 2012).

Utilization of unpurified crude glycerol as a feedstock in industrial processes is hampered by the inconsistent nature of this fraction: its content varies strongly, depending on the kind of oil and the process employed for biodiesel synthesis. It can be in liquid or solid (Nanda et al. 2014) state and generally has high pH (above 10) and low density. The main contaminants in crude glycerol are water, ash (mainly originated from the KOH catalyst), calcium, magnesium, phosphorous, sulfur, methanol (or other alcohol that was used for biodiesel production), soaps (products of reaction between free fatty acids from oil and basic catalyst), free fatty acids (FFA), methyl esters of fatty acids (FAME), and glycerides. Glycerides, soaps, FFA, and FAME are sometimes generally named nonglycerol organic matter (NGOM). Methanol can be partially eliminated from crude glycerol fraction by biodiesel producers; that’s why its content varies from 0.5% up to 20–30% when such process did not take place. Glycerol content in crude glycerol samples also differs significantly, ranging from 20 to 80 wt% (Hu et al. 2012a). Thompson and He analyzed 7 types of crude glycerol produced from different feedstock and found out that all of them have more or less similar chemical composition except of the crude glycerol produced from waste cooking oil which had much more soaps and dissolved unreacted glycerides and esters (Thompson and He 2006). In contrast to these findings, when Hansen et al. analyzed 11 crude glycerol samples from different biodiesel plants in Australia, the substantial differences between these samples were demonstrated (Hansen et al. 2009).

The impurities in crude glycerol may significantly affect its implementation in industrial processes. It was shown that soap and methanol inhibit the production of docosahexaenoic acid from crude glycerol by algae (Pyle et al. 2008) and the high content of Na or K can substantially suppress the microbial activity during the anaerobic digestion of crude glycerol for production of biogas (Santibanez et al. 2011). Interestingly, some studies showed that certain impurities in crude glycerol can actually benefit the production of certain compounds such as bio-oil (Xiu et al. 2010) and polyurethane foams (Hu et al. 2012b). It is necessary to analyze the composition of crude glycerol to develop the right way of its application.

12.3 Potential Applications of Crude Glycerol

12.3.1 Crude Glycerol Purification

As was already mentioned, successful utilization of crude glycerol adds to biodiesel industry profitability. The most obvious application of crude glycerol is to refine it to high-purity glycerol which can be used by food, cosmetic, and pharmaceutical industries. Three types of refined glycerol can be distinguished based on their purity: (1) “technical grade” glycerol that can be used as a reagent for chemical synthesis but not in food or pharmacy; (2) United States Pharmacopeia (USP), glycerol appropriate for food and pharmaceutical products; and (3) Food Chemicals Codex (FCC), glycerol appropriate for use in food (Quispe et al. 2013).

The choice of the refining process for crude glycerol should be based on its chemical composition and the desired level of purity of the final product. The typical refining process includes three stages: acidification/neutralization, a vacuum evaporation to remove methanol (or ethanol) and water, and the final refining to achieve high purity. On the first stage, a strong acid (e.g., phosphoric acid, hydrochloric acid, or sulfuric acid) is added followed by neutralization of solution with, for example, NaOH. Several reiterations of these two steps can be performed (Javani et al. 2012). Acid reacts with soaps and convert them into free fatty acids, which results in a formation of a cloudy solution. After settling for some time, this solution separates into three phases: top fatty acid phase, middle phase with glycerol and methanol (or ethanol), and bottom phase with the inorganic salts (Rodrigues et al. 2017). Nanda et al. compared the performance of hydrochloric acid, sulfuric acid, and phosphoric acid in the purification process and found out that phosphoric acid was superior to the others as it provided reduction of the time period required for phases separation, the formed precipitates were found to be easily separated by filtration, and the obtained phosphates could be directly used as a fertilizer and as buffer solution (Nanda et al. 2014).

On the second stage, residual alcohol (methanol or ethanol) is removed by a vacuum distillation that prevents glycerol decomposition caused by higher temperatures. Alcohol is removed in order to be used again in transesterification reaction. But sometimes biodiesel producers even do not perform the recovery of methanol as using new methanol is more cost-effective (Bohon et al. 2011). Obtained after the second stage of purification, glycerol can be used as “technical grade” raw material, whereas the attainment of a “food grade” glycerol requires the third stage of purification. Final purification can be achieved, for example, through ion exchange, activated carbon absorption, or membrane separation technology (MST) (Rodrigues et al. 2017).

The overall process of crude glycerol purification is cumbersome, energy-consuming, and expensive, thus prohibitive for small- and average-scale producers who must develop other feasible uses for this feedstock.

12.3.2 Production of Heat and Energy from Crude Glycerol

At present, more than 2000 uses for glycerol are known, but most of them require purified glycerol (Quispe et al. 2013). Potential applications for nonpurified crude glycerol are heat and energy production (e.g., by combustion, production of H2 or syngas through steam reforming, production of electricity with microbial fuel cells, production of biomethane by anaerobic digestion), implementation as an addition to a compost or an animal feed, and thermochemical or biological conversions for value-added products (Claude 1999).

Renewable energy can be produced from crude glycerol by means of thermochemical (e.g., pyrolysis and gasification) or biological processes (e.g., biological fuel cells, hydrogen generation, and anaerobic digestion) (Plácido and Capareda 2016).

Johnson and Taconi reported that the combustion of crude glycerol is a viable strategy for its disposal, though not for the large producers of biodiesel (Johnson and Taconi 2007). The heat of combustion of the crude glycerol obtained after transesterification of first-use vegetable oils is higher than that of pure glycerol (Lide 1999), and for crude glycerol obtained from waste cooking oil, this value is even higher (Thompson and He 2006). Co-combustion of the crude glycerol with other biomass may proffer good results (Thompson and He 2006). But still crude glycerol is considered to be cheap, low-quality fuel due to its drawbacks: relatively low heating value, high self-ignition temperature, and high emissions and salt content. Also, crude glycerol combustion causes the formation of highly toxic acrolein, though its emission can be brought to the acceptable levels (Rodrigues et al. 2017). Therefore, it is better to process crude glycerol in order to obtain more valued fuels – e.g., hydrogen or biomethane.

Hydrogen can be produced from glycerol through thermochemical or biological reactions. Examples of thermochemical reactions are pyrolysis and gasification, steam reforming (Sánchez et al. 2010), supercritical water reforming (Byrd et al. 2008), or aqueous phase reforming (Tuza et al. 2014).

Pyrolysis is a process of chemically decomposing organic materials at elevated temperatures (>300 °C) in the absence of oxygen and, typically, under pressure. This process results in a formation of a gas phase (syngas, the mixture of hydrogen and carbon monoxide), liquid phase (bio-oil), and a solid phase (biochar). In several studies, crude glycerol was used as an auxiliary compound to pyrolyze different types of feedstocks (swine manure, lignite, olive kernel, corn straw, etc.), and the addition of crude glycerol has been found to increase hydrogen and light hydrocarbons concentrations in syngas and the quality of bio-oil (Cheng et al. 2014; Delgado et al. 2013; Manara and Zabaniotou 2013; Skoulou et al. 2012). These observations reveal the possibility to use crude glycerol as a co-substrate for pyrolysis at the thermal conversion plant which can use other agricultural residues of biodiesel production (plants’ stems, leafs, pressed seeds, etc.) as main substrate (Plácido and Capareda 2016).

Glycerol steam reforming (GSR) provides a possibility to produce high amounts of hydrogen using existing steam reforming units. But direct application of crude glycerol as a feedstock for steam reforming arises some issues connected with difficulties in purification of the formed hydrogen and the high deposition of carbon and coke during the process which eventually leads to catalyst inactivation (Rodrigues et al. 2017).

Biological processes that can be employed for hydrogen production from glycerol are dark fermentation and photofermentation (Ghosh et al. 2012b; Rossi et al. 2011). Dark fermentation is performed by anaerobic or facultative anaerobic microorganisms such as Enterobacter aerogenes (Sarma et al. 2013), Escherichia coli (Gonzalez et al. 2008), Klebsiella sp. (Chookaew et al. 2014), and Clostridium pasteurianum (Lo et al. 2013). The efficiency of this process can be improved by modifying the microorganisms using selection (Varrone et al. 2013) or genetic engineering (Gonzalez et al. 2008), by determining the optimal composition of the culture media and the optimal reactor conditions (Ngo et al. 2011), and by reducing the inhibitor (e.g., methanol and saponified free fatty acids) concentrations (Sarma et al. 2014).

Photofermentation is the process of hydrogen production from organic feedstock (usually, organic acids) in the presence of light. Certain purple non-sulfur photosynthetic bacteria can directly transform glycerol into bio-hydrogen (Ghosh et al. 2012a; Sabourin-Provost and Hallenbeck 2009). For example, this process can be efficiently carried out by bacterium Rhodopseudomonas palustris (Ghosh et al. 2012a), which can use also crude glycerol although its growth is inhibited by saponified free fatty acids from this feedstock (Pott et al. 2013). Alleviation of this inhibition can be achieved by the pH adjustment and the precipitation of saponified free fatty acids with calcium salts (Pott et al. 2014).

Biogas (mixture of methane, carbon dioxide, and other gases) can be generated in the process called anaerobic digestion, during which microorganisms break down biodegradable material in the absence of oxygen. Crude glycerol could be employed as the main (Hutnan et al. 2013) or an additional carbon source (Siles Lopez et al. 2009) during anaerobic digestion. Crude glycerol has been co-digested with waste compounds such as sewage sludge, manure, and food wastes, which has improved the methane yield from these raw materials (Alvarez et al. 2010; Nartker et al. 2014). This implies that crude glycerol can be sold to anaerobic digestion plants or the biodiesel producers can equip their facilities with anaerobic digestion reactors to process crude glycerol together with the other organic wastes left from their main activity (Plácido and Capareda 2016).

Also, it was shown that crude glycerol can be used as substrate for microbial fuel cells, which produce electricity (Feng et al. 2011).

12.3.3 Using Crude Glycerol in Agriculture

It has been suggested that crude glycerol can be composted (Brown 2007) and used in fertilizers or as an animal feed supplement (Chung et al. 2007).

It was attempted to add crude glycerol to the ration of dairy cows (Chung et al. 2007; DeFrain et al. 2004), pigs (Kijora et al. 1995), broiler chickens (Cerrate et al. 2006), and laying hens (Lammers et al. 2008). Thompson and He showed that crude glycerol obtained from the first-use oil samples can be used as a source of carbohydrates whereas the crude glycerol from waste cooking oil can be used as a fat supplement in animal feed (Thompson and He 2006). At the same time, scientists express concerns about crude glycerol implementation as an animal food additive as there is no information about long-term impact of impurities present in crude glycerol (e.g., methanol).

12.3.4 Production of Chemical Compounds from Crude Glycerol

Glycerol can be used as a building block for production of chemical compounds through thermochemical or biological processes. Some of this processes can employ crude glycerol as well, although impurities in crude glycerol often cause undesirable side reactions, products of which as well as impurities themselves contaminate end product. Here, we will recount a few compounds that can be obtained from glycerol and then concentrate our attention on the possible implementation of crude glycerol as a feedstock for bioconversion using yeasts.

Crude glycerol can be thermochemically converted into propylene glycol (Chiu et al. 2006; Dasari et al. 2005), acetol (Chiu et al. 2006), biopolyols and polyurethane foams (Hu et al. 2012b; Luo et al. 2013), acrolein (Cheng et al. 2013), etc. Hydrothermal electrolysis of crude glycerol in alkaline biodiesel wastewater at high temperatures and pressures produces lactic acid (Yuksel et al. 2011). Crude glycerol can be used for glycerolysis of castor oil methyl esters to achieve monoglycerides and diglycerides which can be used in the plastic industries (Echeverri et al. 2013). Glycerol carbonate can be produced from crude glycerol through transesterification with dimethyl carbonate (Plácido and Capareda 2016). It is a valuable compound that can be used for production of polyesters, polycarbonates, polyurethanes, polyamides, surfactants, lubricating oils, cosmetics, and electrolytic carriers in lithium ion batteries (Ochoa-Gómez et al. 2009; Okoye and Hameed 2016) and as a substitute for ethylene or propylene carbonate. Also crude glycerol can be converted to mono-, di-, and triacetylesthers in the process of acetylation via esterification (Dosuna-Rodríguez and Gaigneaux 2012; Gonçalves et al. 2008). Triacetin (triacetylated glycerol esther) can be used in the cosmetic, pharmaceutical, tobacco, and food industries or as a fuel additive. Mono- and diacetin have uses as cryogenics and as feedstocks for the production of biodegradable polyesters (Rodrigues et al. 2017).

But not all processes that use glycerol as a building block can successfully employ crude glycerol. For example, when succinic acid-based polyesters were synthesized using crude glycerol, they didn’t show rubbery behavior at room conditions due to incorporation of impurities from the glycerol source to the polymer backbone, whereas polymers synthesized from pure or “technical grade” glycerol possessed desired properties (Valerio et al. 2015).

Biological crude glycerol transformation has several advantages compared to chemical conversion. It is more specific in terms of produced products, has higher tolerance to impurity, and is more environmentally friendly (Clomburg and Gonzalez 2013). There are a number of microorganisms which can metabolize glycerol, such as representatives of the genera Escherichia, Klebsiella, Enterobacter, Gluconobacter, Clostridium, Candida, Aspergillus, etc. (Solomon et al. 1995). Though when impurities in crude glycerol reach high concentrations, they can inhibit growth of the microorganisms. For example, the salts, methanol, and fatty acids present in crude glycerol were reported to inhibit C. pasteurianum growth (Venkataramanan et al. 2012), and the fermentation behavior of the bacteria was only restored when fatty acids were removed by acid precipitation. Similarly, crude glycerol was found to significantly inhibit growth and production of 1,3-propanediol by Citrobacter freundii due to the high concentrations of free fatty acids and free methyl esters (Anand and Saxena 2012).

Conversion of crude glycerol by microorganisms can be used for the production of the wide range of chemicals: oxalic and docosahexaenoic acid (Ethier et al. 2011), polyhydroxyalkanoate (PHA) and polyhydroxybutyrate (PHB) (Dobroth et al. 2011), 1,3-propanediol (Casali et al. 2012), 2,3-butanediol (Biebl et al. 1998), dihydroxyacetone (Liu et al. 2013b), surfactants (Sousa et al. 2012), eicosahexanoic acid (Athalye et al. 2009), ethanol (Oh et al. 2011), glyceric acid (De Ley and Frateur 1970), n-butanol (Jensen et al. 2012), propanoic acid (Bertleff et al. 2005), trehalose (Ohtake and Wang 2011), single-cell oil (Chatzifragkou et al. 2011; Garlapati et al. 2016), amino acids (Meiswinkel et al. 2013), organic solvent-tolerant lipase (Volpato et al. 2008), lignoceric acid (Habe et al. 2008), and many others. Despite such impressive list of compounds that can be produced from crude glycerol, at present, an industrial process using crude glycerol does not exist, mainly due to the high cost of product recovery (Plácido and Capareda 2016). We can almost apply for this situation a paraphrased old industry proverb about lignin: “You can make anything out of crude glycerol, except money.” Hopefully, with the improvement of technologies of crude glycerol conversion, they would be finally industrialized.

12.4 Crude Glycerol as a Feedstock for Biotechnological Processes Using Yeasts

12.4.1 Glycerol Intake and Conversion by Yeasts

12.4.1.1 Transport of Glycerol Through the Plasma Membrane

Since glycerol is fairly common in the environment, it is not surprising that many yeasts can use it as a source of carbon and energy. For that glycerol should be first transported inside the yeast cell. The molecular mechanisms of glycerol movement through the plasma membrane were best investigated in the yeast Saccharomyces cerevisiae, for other yeasts information on this subject is fragmentary. Previously, it was deemed that glycerol is able to penetrate S. cerevisiae membrane by diffusion (Gancedo et al. 1968; Heredia et al. 1968), passive transport through the channel formed by protein Fps1 (Luyten et al. 1995; Sutherland et al. 1997), and active transport through the channels formed by proteins Gup1 and Gup2 (Holst et al. 2000). It all turned out to be not the case as it was discovered that glycerol is imported through the glycerol/H+-symporter Stl1 (Ferreira et al. 2005). The deletion of the STL1 gene completely abolished the active transport of glycerol, and the corresponding deletion strain of S. cerevisiae was incapable of growing on glycerol as the sole source of carbon nutrition. Similar H+ and Na+-glycerol symporters have been described for the halotolerant yeast Debaryomyces hansenii (Lucas et al. 1990), Pichia sorbitophila (Lages and Lucas 1995), and Zygosaccharomyces rouxii (van Zyl et al. 1990).

In many non-Saccharomyces yeasts, glycerol import into the cells may actually be performed by facilitated diffusion through the membrane facilitator proteins – homologues of Fps1 protein. For example, it has been established (Liu et al. 2013a) that expression of the FPS2 gene from yeast Pachysolen tannophilus in S. cerevisiae complements the deletion of the STL1 gene, whereas the expression of its own FPS1 gene does not provide growth restoration on glycerol. The same effect was achieved by expression of the homologues of the FPS1 gene from different types of nonconventional yeasts (Candida jadinii, Pichia pastoris[sometimes referred to as Komagataella pastoris or Komagataella phaffii], and Yarrowia lipolytica) in S. cerevisiae stl1Δ mutant (Klein et al. 2016). This high level of growth persists even after deletion of the STL1 gene (Klein et al., 2016). However, in order to finally confirm the role of these transporters in the glycerol import, scientists should perform their deletion and overexpression in the yeast species from which they originate.

12.4.1.2 Ways of Catabolism of Glycerol in Yeast

Catabolism of glycerol in the yeast cells is carried out through glycerol-3-phosphate (phosphorylation pathway) or dihydroxyacetone (oxidative pathway of glycerol utilization) (Fig. 12.3). Obtained in this process, dihydroxyacetone phosphate can either be included into the central metabolism through conversion to glyceraldehyde-3-phosphate under the action of a triose phosphate isomerase or may be a substrate for the synthesis of lipids. The conversion of glycerol through glycerol-3-phosphate is catalyzed by the enzymes glycerol kinase and FAD-dependent glycerol-3-phosphate dehydrogenase. In S. cerevisiae, glycerol kinase is encoded by the gene GUT1 (GlycerolUpTake) (Pavlik et al. 1993; Sprague and Cronan 1977), and glycerol-3-phosphate dehydrogenase is encoded by the gene GUT2 (Ronnow and Kielland-Brandt 1993). This pathway seems to be the only way of glycerol conversion in S. cerevisiae as gut1Δ and gut2Δ mutants are incapable to utilize glycerol (Sprague and Cronan 1977). This pathway also has been identified in many other yeasts, such as D. hansenii (Adler et al. 1985), Z. rouxii (Pribylova et al. 2007), and Candida glycerinogenes (Wang et al. 2000).

Glycerol metabolism and ethanol production in S. cerevisiae. Abbreviations: G-6-P glucose-6-phosphate, F-6-P fructose-6-phosphate, F-1,6-P fructose-1,6-biphosphate, DHAP dihydroxyacetone phosphate, DHA dihydroxyacetone, GAP glyceraldehyde-3-phosphate, Gly-3-P glycerol-3-phosphate, 1,3-P-glyc 1,3-phosphoglycerate, PEP phosphoenolpyruvate, Ac-CoA acetyl coenzyme A, TCA tricarboxylic acid cycle, Tpi1 triose phosphate isomerase, Adh1-5 alcohol dehydrogenases, Pdc1,5,6 pyruvate decarboxylases, Ald3 aldehyde dehydrogenase, Gpd1, Gpd2 cytosolic glycerol-3-phosphate dehydrogenases, Gpp1, Gpp2 glycerol-3-phosphate phosphatases, Gut1 glycerol kinase, Gut2 glycerol-3-phosphate dehydrogenase, Gcy1 glycerol dehydrogenase, Dak1, Dak2 dihydroxyacetone kinase, Hxt, Stl1, Fps1 membrane transporters (Semkiv et al. 2017)

But many other yeast species convert glycerol through dihydroxyacetone. The first step in this pathway is the oxidation of glycerol to dihydroxyacetone with glycerol dehydrogenase, which is encoded by the gene GCY1. The second step is the phosphorylation of dihydroxyacetone to dihydroxyacetone phosphate with dihydroxyacetone kinase, which is encoded by genes DAK1 and DAK2. The mentioned genes are present in the S. cerevisiae genome (Jung et al. 2012; Norbeck and Blomberg 1997), but the corresponding enzymes are rather involved in regulation of the concentration of glycerol during hyperosmotic stress (Blomberg 2000), than in glycerol utilization as a carbon source. At the same time, in other yeasts, this pathway is more important.

There is not much information available about the role of one or another pathway of glycerol utilization in particular yeast species. Tani and Yamada divided the studied yeast species into three groups: (1) yeast that converts glycerol through glycerol-3-phosphate (e.g., Candida boidinii), (2) yeast that converts glycerol through dihydroxyacetone (e.g., Hansenula ofunaensis), and (3) yeast that can use both pathways (e.g., Candida valida) (Tani and Yamada 1987). However, these observations were based on the presence of certain enzymes activities, and not on the analysis of the deletion mutants, and therefore cannot be considered as a final proof. Convincing evidence of the predominant function of the dihydroxyacetone pathway of glycerol utilization was obtained after analysis of Schizosaccharomyces pombe mutant with the deletion of the gene GLD1 which encodes glycerol dehydrogenase (Matsuzawa et al. 2010).

It must be mentioned that most strains of the conventional yeast S. cerevisiae exhibit rather poor growth on the medium containing glycerol as a sole carbon source (Swinnen et al. 2013). Some other yeasts grow on glycerol much better. For example, when the ability of 42 different types of yeast to grow on glycerol was tested, Pichia jadinii and Pichia anomala revealed the highest growth rate – about three-fold higher than in S. cerevisiae (Lages et al. 1999). Also nonconventional yeasts Y. lipolytica, P. pastoris, and P. tannophilus have good ability to grow on glycerol, so pure and crude glycerol can be used as a feedstock for biotechnological processes which employ these yeasts (Klein et al. 2017).

12.4.2 Bioconversion of Crude Glycerol to Value-Added Compounds by Yeasts

12.4.2.1 Production of Organic Acids

Citric (CA) and Isocitric (ICA) Acids

Crude glycerol can be used as a feedstock for the production of organic acids, in particular, citric acid (CA) and isocitric acid (ICA). Being tricarboxylic acid (TCA) cycle intermediates, both these acids play a central role in metabolism of aerobic organisms and can be produced in excessive amounts and excreted by certain fungi, bacteria, and yeasts in specific growth conditions (Fig. 12.4). CA is of interest for many industrial applications due to its nontoxic, acidulant, buffering, and chelating properties (Rzechonek et al. 2019). For example, CA is used as an acidity regulator, preservative, and flavor enhancer in the food and beverage industry, as an antioxidant or a buffering system for improving stability of pharmaceuticals, as a detergent component in dishwasher cleaners, and as a cross-linker in the production of biodegradable polymers in cosmetic, metallurgy, textile, and other industries (Karaffa and Kubicek 2003). Annual world CA production exceeded two million tons in 2015, growing at 3–5% per year (Ciriminna et al. 2017).

CA, ICA, PA, KGA, and SA production in Y. lipolytica. Modified from (Gao et al. 2016a). PDH pyruvate dehydrogenase, CS citrate synthase, ACO aconitase, IDH isocitrate dehydrogenase, α-KGDH α-ketoglutarate dehydrogenase, SCS succinyl-CoA synthetase, SDH succinic dehydrogenase, FUM fumarase, MDH malate dehydrogenase, PYC pyruvate carboxylase, ICL isocitrate lyase, MS malate synthase

For the first time, CA was isolated from citrus fruits. Currently, it is commercially produced by fermentation of beet or cane molasses as well as glucose syrup by the mycelial fungus Aspergillus niger (Karaffa and Kubicek 2003). This method offers high product yield but has several disadvantages: molasses need to be treated with toxic ferrocyanides to remove the excess of trace elements which are harmful to A. niger, production is associated with the accumulation of significant amounts of heavy metal-contaminated wastewater and solid waste gypsum (about 16 tons waste/ton CA), possible substrate spectrum for A. niger is quite narrow, etc. (Kamzolova et al. 2015). That is why during the last decades, some yeast species have been considered as a substitute of A. niger for CA production. These yeasts have broader substrate range, lower sensitivity to heavy metals and oxygen limitations, and CA yield comparable to A. niger (Kamzolova et al. 2011). In particular, some yeast species can use pure and crude glycerol as a carbon substrate for CA production.

When forty yeast species were tested concerning their growth in crude and commercial glycerol, four yeast strains (Lindnera saturnus UFLA CES-Y677, Y. lipolytica UFLA CM-Y9.4, Rhodotorula glutinis NCYC 2439, and Cryptococcus curvatus NCYC 476) were found to be able to grow in these conditions, and among them, Y. lipolytica had shown the highest level of glycerol intake (Souza et al. 2014).

When organic acids formation was tested for 66 yeast strains of different genera (Candida, Pichia, Saccharomyces, Torulopsis, and Yarrowia) in the medium containing pure glycerol as a carbon source, 41 strains belonging mainly to species Y. lipolytica produced acids in contrast to 25 strains of the genera Debaryomyces, Candida, Pichia, Saccharomyces, and Torulopsis (Kamzolova et al. 2011). All in all, Y. lipolytica seems to be one of the best candidates for crude or pure glycerol conversion to CA (and other valuable compounds; see next paragraphs).

Y. lipolytica is widely known for its ability to produce lipids (Groenewald et al. 2014), polyols, and organic acids (Kamzolova et al. 2015; Rymowicz et al. 2010) from the wide range of substrates, including unspecific carbon sources such as fatty acids, alkanes, plant oils, fats, waste cooking oil, or crude glycerol (Mironczuk et al. 2016). In particular, crude glycerol is easily utilized by the yeast Y. lipolytica despite its highly contaminated nature (Papanikolaou et al. 2002a).

Y. lipolytica is able to secrete high amounts of intermediate organic acids, such as pyruvic, citric, isocitric, or 2-oxoglutaric acids, into the medium under the conditions of excessive amounts of carbon source and limited amounts of some of the other growth factors (e.g., N-source, thiamine, or by the mineral salt components P, S, or Mg). Nitrogen limitation causes the secretion of CA and ICA mixture (Holz et al. 2009). Secretion of ICA was previously considered to be undesirable side process of CA production with Y. lipolytica due to the fact that ICA has an inferior buffer capacity and chelating ability compared to CA, and the crystallization of CA during the purification process is disturbed by ICA contaminations >5% (Forster et al. 2007). Therefore, previously, researchers mainly aimed to decrease ICA production (Finogenova et al. 2002; Forster et al. 2007). But recently, the development of the reliable method of CA/ICA separation via methyl esterification has risen the interest in ICA production (Heretsch et al. 2008). ICA is much more expensive compared to CA and can be used as a chiral building block for chemical synthesis of complex natural products; as a useful pharmaceutical, food, and beverage additive; and in cosmetics and detergents (Heretsch et al. 2008). Also, monopotassium salt of ICA has been used in several biochemical analyses (assays of aconitate hydratase, NAD-isocitrate dehydrogenase, NADP-isocitrate dehydrogenase, isocitrate lyase) (Kamzolova et al. 2011). Due to this emerging areas of ICA application, researchers started to consider the switch of the CA/ICA ratio toward the ICA production to be a favorable outcome (Holz et al. 2009; Rzechonek et al. 2019).

The CA/ICA ratio formed by Y. lipolytica mainly depends on the substrate, cultivation conditions (air saturation, intracellular iron and zinc content, etc.), and the strain used (Forster et al. 2007). Wild-type strains secrete mainly CA and about 8–16% ICA on carbohydrates or glycerol as sole carbon source and approximately 50–65% CA and 35–50% ICA on the gluconeogenetic substrates alkanes and the renewable triglycerides, ethanol or acetate (Finogenova et al. 2005). Interestingly, when crude glycerol was used for Y. lipolytica fermentation, CA/ICA pattern was shifted more toward ICA in comparison with the fermentation on the medium with pure glycerol as carbon source (Kamzolova et al. 2011; Rzechonek et al. 2019). This may be caused by the contaminants present in crude glycerol, e.g., free fatty acids.

Y. lipolytica utilizes glycerol through glycerol-3-phosphate (phosphorylation pathway) (Makri et al. 2010), and activities of enzymes connected with oxidative pathway of glycerol utilization were not detected (Morgunov et al. 2013). Therefore, during assimilation of glycerol from the cultivation medium, Y. lipolytica cells possess high activities of glycerol kinase, NAD-dependent glycerol-3-phosphate dehydrogenase, and (in some Y. lipolytica strains) FAD-dependent glycerol-3-phosphate dehydrogenase (Morgunov et al. 2004). During assimilation of the crude glycerol, induction of glyoxylate cycle enzymes isocitrate lyase and malate synthase was also observed. This induction was probably associated with the active assimilation of fatty acids from glycerol-containing wastes (Morgunov et al. 2013). Glycerol kinase activity in Y. lipolytica cells was found to be affected by pH and salt presence – low pH or high amounts of salts in the cultivation medium inhibit glycerol kinase and decrease overall velocity of glycerol assimilation (Tomaszewska et al. 2014a).

As was already mentioned, CA production by Y. lipolytica requires specific cultivation conditions. Acid formation does not occur in the exponential growth phase but is very active in the stationary growth phase (Kamzolova et al. 2015). Yeast growth limitation has to be achieved through the restriction of mineral components in the medium, such as nitrogen, phosphorus, sulfur, or magnesium (Imandi et al. 2008). It was shown that when yeast growth was limited with phosphorus or sulfur, a significant amount of ICA was produced; therefore, nitrogen limitation is more preferable for CA production (Kamzolova et al. 2011). Optimal pH for CA production in Y. lipolytica is 4.5–6.5. Lower pH triggers polyols synthesis (Egermeier et al. 2017) although recombinant Y. lipolytica with overexpression of the genes GUT1 (encoding glycerol kinase) and GUT2 (encoding glycerol-3-phosphate dehydrogenase) were shown to be able to produce CA at pH 3 (Rzechonek et al. 2019). The optimal temperature for CA production is about 28 °C, and the optimal dissolved oxygen concentration (pO2) 50% (of air saturation) (Morgunov et al. 2013). Less active aeration during the process causes an undesirable decrease in the activity of some mitochondrial enzymes (citrate synthase, aconitase, malate dehydrogenase, and NADP-dependent isocitrate dehydrogenase) involved in the synthesis of CA (Kamzolova et al. 2011). Addition of exogenous CA in a moderate amount at early stage of CA production stimulates the biosynthesis of endogenous CA by the yeast cells (Kamzolova et al. 2015). Different studies report either increase (Morgunov et al. 2013) or decrease (Kamzolova et al. 2011) in CA production when crude glycerol was used as carbon source instead of a pure glycerol. Also, crude glycerol may enable either increase in yeast growth due to the presence of contaminants that can be used as nutritional elements by yeasts or (in higher concentrations) growth inhibition due to high concentration of toxic compounds (Souza et al. 2014). Besides optimization of the culture conditions, over the years, Y. lipolytica mutants with improved CA production or modified CA/ICA ratio were obtained by UV irradiation combined with negative selection on acetate-containing medium, selection on fluoroacetate, genetic engineering, etc. (Forster et al. 2007; Holz et al. 2009; Morgunov et al. 2013; Tomaszewska et al. 2014a).

Also, ability to produce high amounts of CA from crude glycerol under nitrogen-limiting conditions has been shown for some Candida species, such as strains Candida parapsilosis ATCC 7330 and Candida guilliermondii ATCC 9058 (West 2013). Unfortunately, despite all these developments, there is no large industrial process of CA production with yeasts at present, although there are indications for recent process developments using Y. lipolytica (Fickers et al. 2005).

Pyruvic Acid

Besides CA and ICA, Y. lipolytica can excrete pyruvic acid (PA) and α-ketoglutaric acid (KGA) under the conditions of excessive amounts of carbon source and limited amounts of thiamine in the cultivation medium. Y. lipolytica is a thiamine-auxotrophic yeast due to the inability to synthesize the pyrimidine structure of the thiamine molecule (Yin et al. 2012). When thiamine in the cultivation medium is depleted, activities of thiamine-dependent enzymes (pyruvate dehydrogenase, transketolase, α-ketoglutarate dehydrogenase) start to decrease, blocking the conversion of the corresponding substrates (Fig. 12.4). Big disadvantage of this process is the simultaneous production of PA and KGA because these acids are similar in physical and chemical properties which make the procedure of their separation quite tricky. That is why if production is directed toward PA, researches try to decrease the accumulation of KGA by Y. lipolytica and vice versa.

PA is used as a diet supplementary (Stanko et al. 1992) for the production of L-tryptophan (Nakazawa et al. 1972), L-tyrosine, and 3,4-dihydroxyphenyl alanine (Yamada et al. 1972) and as a substrate for enzyme activities assays in biochemistry and medicine. PA can be produced by chemical process or with the help of certain bacteria, basidiomycetes, or yeasts (Morgunov et al. 2004). For example, extensively studied PA producer is yeast Candida glabrata (former Torulopsis glabrata), selected strain of which is able to produce 67.8 g/L of PA from glucose (Yonehara and Miyata 1994). Y. lipolytica was found to produce PA not only from glucose but also from glycerol. When 18 strains of the genera Candida and Yarrowia were tested for their ability to produce PA using glucose or glycerol as carbon sources, seven efficient PA producers were identified, and Y. lipolytica strain 374/4 was the best among them (Morgunov et al. 2004). It produced 1.6-fold higher amount of PA in glycerol-containing medium than in case of the medium with glucose. Also, amount of accumulated KGA was 4 times lower than that of PA. In glycerol-containing medium with 2 μg/L of thiamine strain Y. lipolytica 374/4 accumulated 61.3 g/L of PA by the 78th hour of cultivation. It was confirmed that activities of thiamine-dependent enzymes, such as transketolase, pyruvate dehydrogenase, and α-ketoglutarate dehydrogenase, decreased substantially after the transition of yeast cells from the exponential growth phase to growth retardation phase caused by the exhaustion of thiamine in the medium.

The overexpression of the genes encoding α-ketoglutarate dehydrogenase complex is another possible approach to further increase the production of PA and restrict the accumulation of KGA in Y. lipolytica (Holz et al. 2011).

However, mentioned experiments with PA production by Y. lipolytica were performed in the defined medium with the addition of pure glycerol. When yeast was grown in complex polypeptone-containing medium, no PA production was observed, probably due to high thiamine content in this medium (Yonehara and Miyata 1994). To our knowledge, no attempts have been made to produce PA from crude glycerol, but it was successfully used for the production of KGA (Otto et al. 2012).

α-Ketoglutaric Acid

The α-ketoglutaric acid (KGA) is used as a dietary supplement, in the agrochemical and pharmaceutical industries, as a building block for the synthesis of heterocycles and elastomers, etc. (Sauer et al. 2008). Currently, KGA is synthesized chemically from diethyl succinate and diethyl oxalate or by transamination of glyoxylic acid with sodium glutamate and a copper catalyst (Otto et al. 2011), but these methods are ecologically harmful. KGA production via microbial fermentation has a potential to be more profitable and environmentally friendly. KGA can be produced by bacteria Pseudomonas fluorescens, Serratia marcescens, Bacillus ssp., Corynebacterium glutamicum, and Arthrobacter paraffineus or by yeasts Candida ssp., Pichia ssp., C. glabrata, and Y. lipolytica (Otto et al. 2011). Most studies on KGA production by yeasts concentrate on the last two species.

KGA production by these yeasts is triggered by the thiamine limitation and excess of carbon source and accompanied by the production of PA as a major by-product and fumarate, malate, and succinate as minor by-products (Otto et al. 2012). However, when n-alkanes, plant oils, fatty acids, or their derivatives are used as substrates for KGA production, PA is not accumulating due to the fact that substrate is degraded via acetyl-CoA omitting pyruvate (Finogenova et al. 2005).

KGA production from pure and crude glycerol is accompanied by PA accumulation, which needs to be minimized. In an attempt to decrease the by-product yield during KGA production from crude glycerol by Y. lipolytica, Otto et al. constructed recombinant Y. lipolytica strains with the overexpression of gene FUM1 (encoding fumarase), PYC1 (encoding pyruvate carboxylase), or both mentioned genes (Otto et al. 2012). Multicopy integration of the gene FUM1 into Y. lipolytica genome caused a significant reduction of the production of PA, fumarate, and malate during crude glycerol conversion to KGA. In contrast, the overexpression of PYC1 gene or both genes FUM1 and PYC1 caused an increased accumulation of the mentioned by-products (Otto et al. 2012). Besides that, the production of KGA decreased in the strain with the PYC1 gene overexpression in comparison to the initial Y. lipolytica strain. Interestingly, in other study, overexpression of the heterologous pyruvate carboxylase genes ScPYC1 from S. cerevisiae and RoPYC2 from Rhizopus oryzae in Y. lipolytica strain WSH-Z06 caused the increase of KGA yields by 24.5 and 35.3% and the decrease of PA yields by 51.9 and 69.8%, respectively (Yin et al. 2012). In a 3-L fermenter, the recombinant strain with RoPYC2 gene overexpression produced the highest amount of KGA – 62.5 g/L with a decrease in PA yield from 35.2 to 13.5 g/L (Yin et al. 2012).

The optimal pH for KGA production is around 3.5; therefore, a two-stage pH control strategy was developed for KGA synthesis from crude glycerol in the bioreactor. For the beginning of cultivation, pH was set on 5.0 and aeration rate at 50% (growth phase). Then for the KGA production phase, pH was reduced to 3.8 and pO2 to 10% (Otto et al. 2012). At the beginning of production phase, large amounts of by-product PA were synthesized, but as the glycerol in the medium was exhausted, cells started to reuptake PA and converted it to KGA. PA reduction in the engineered yeasts with overexpression of heterologous gene-encoding pyruvate carboxylase (ScPYC1or RoPYC2) was much faster than those in the initial Y. lipolytica strain WSH-Z06 (Yin et al. 2012).

Similar effect – decreased PA and increased KGA concentrations – was achieved for KGA and PA producing yeast C. glabrata by stimulation of pyruvate carboxylase activity by the increased supply of its cofactor biotin (Zhang et al. 2009).

Also KGA/PA ratio was increased in the recombinant C. glabrata strain with the overexpression of heterologous gene PDC1 (encoding pyruvate decarboxylase) from S. cerevisiae (Zhang et al. 2009). Further improvement in KGA production is possible by modifying the activities of NAD- and NADP-dependent isocitrate dehydrogenases (catalyzes the oxidation of isocitrate to KGA) and the mitochondrial α-ketoglutarate dehydrogenase complex (catalyzes the oxidative decarboxylation of KGA to succinyl-CoA) (Otto et al. 2012).

Succinic Acid

Succinic acid (SA) can be used as a precursor of many important chemicals in surfactant, food, and pharmaceutical industries (Yan et al. 2014). The US Department of Energy has listed SA among the top twelve potential bio-generated chemical building blocks for the future (White et al. 2004).

Currently, SA is mainly produced by petroleum-based chemical process, but efforts are made to implement bio-based methods of SA production from sustainable feedstock (Mazière et al. 2017). Many SA producers were found among bacteria (Sanchez et al. 2005), e.g., Actinobacillus succinogenes and A. succiniciproducens. Basfia succiniciproducens has been shown to convert crude glycerol to SA (Scholten et al. 2009). Yeasts are also considered as SA producers owing to their tolerance to high acidity. Glycerol is considered as one of the most promising feedstock for commercially feasible SA production (Tan et al. 2014).

It comes as no surprise that Y. lipolytica was proposed as a potential SA producer from crude glycerol. But wild-type strains of Y. lipolytica almost did not accumulate SA during cultivation. Previously, production of KGA by Y. lipolytica was combined with subsequent decarboxylation of KGA by hydrogen peroxide to obtain SA (Kamzolova et al. 2009).

To obtain Y. lipolytica strain directly producing SA, Gao et al. decided to block (Fig. 12.4) further SA metabolism in TCA cycle (Gao et al. 2016a). The succinate dehydrogenase complex oxidizes SA to fumaric acid with the simultaneous reduction of the ubiquinone to ubiquinol (Cecchini 2003). This complex consists of five subunits (SDH1–5), among them SDH1 and SDH2 are catalytic subunits, SDH3 and SDH4 perform a role of molecular anchors, and SDH5 is required for SDH complex stability and activity (Oyedotun and Lemire 2004). In the study of Gao et al., the gene-encoding SDH5 subunit (Ylsdh5) was deleted in Y. lipolytica strain Po1f to obtain recombinant strain PGC01003. This strain demonstrated a weak growth in glucose-containing medium in contrast to the sdh1 or sdh2 deletion strains which have been shown to lose their ability to grow in glucose (Yuzbashev et al. 2010). PGC01003 indeed accumulated and secreted enhanced amounts of SA. It also accumulated substantial amounts of acetic acid (approximately 6 g/L) due to the emerged imbalance between glycolysis and TCA cycle. When the cultivation media and conditions were optimized, strain PGC01003 produced 43 g/of SA from crude glycerol during batch cultivation and 160 g/L of SA during fed-batch cultivation (Gao et al. 2016a).

Using in situ fibrous bed bioreactor (isFBB) under the optimal conditions (20 g sugarcane bagasse as immobilization material, 120 g/L crude glycerol as carbon source, and 4 L min−1 of aeration rate), SA production by PGC01003 was increased to 53.6 g/L during batch cultivation and 209.7 g/L during fed-batch cultivation. Methanol was shown to inhibit the cell growth and SA production under described conditions when its initial concentration was more than 5 g/L (Li et al. 2018a). Obtained Y. lipolytica strain and developed isFBB have a great potential for industrial implementation.

Lactic Acid

Due to its chemical properties, lactic acid (LA) is of interest for many industrial applications, e.g., food, pharmaceutical, leather, textile, and chemical industries (Datta and Henry 2006). Also, L- and D-optical isomers of LA are the components used for the production of biodegradable polylactic acid that can be used in automobile, packaging, and cosmetic industries (Abdel-Rahman et al. 2013).

LA can be produced by homo- and heterofermentative lactic acid bacteria, fungi (e.g., genus Rhizopus), yeasts (Saccharomyces and Kluyveromyces genera), and microalgae (e.g., Scenedesmus obliquus) (Abdel-Rahman et al. 2013). Developed industrial processes use carbohydrates as a substrate for LA production. There have been reported bacteria and fungi with the efficient LA production from glycerol as a sole carbon source (Mazumdar et al. 2013; Vodnar et al. 2013). For example, the fungus R. oryzae was able to produce about 48 g/L of LA from 75 g/L of crude glycerol supplemented with lucerne green juice (Vodnar et al. 2013).

Yeasts are perspective microorganisms for LA production as they are robust, resistant to low pHs, and widely used for industrial bioprocesses (Sauer et al. 2010). The methylotrophic yeast P. pastoris can be used for crude glycerol conversion, as it efficiently utilizes glycerol and methanol as carbon sources and it is resistant to enhanced methanol concentrations (Looser et al. 2015). P. pastoris even accumulates more biomass when crude glycerol is used as a carbon source in comparison to the growth on the medium with pure glycerol (Anastacio et al. 2014).

When de Lima et al. had expressed the gene LDH encoding lactate dehydrogenase from Bos taurus under the control of the strong constitutive promoter GAP1 in P. pastoris, obtained recombinant strains produced only 10% of the theoretically possible LA amount (de Lima et al. 2016). Therefore, they additionally overexpressed in this strain heterologous gene-encoding LA transporter Jen1p from S. cerevisiae or homologous gene-encoding putative LA transporter PAS which was identified by amino acid sequence similarity with Jen1p. Performance of the obtained recombinant strains was evaluated in fed-batch fermentation which was composed of two phases. First phase of cellular growth was carried out under sufficient oxygen supply followed by LA production stage accompanied with a single-pulse addition of 4% crude glycerol and hypoxia conditions. Under such conditions, the strain containing homologous PAS transporter showed the highest LA yield of approximately 0.7 g/g of glycerol. Simultaneously, acetic acid formation by this strain was reduced by half. In conclusion, recombinant P. pastoris strain with LDH and PAS overexpression can be used for efficient LA production from crude glycerol in two-phase fed-batch fermentation (de Lima et al. 2016).

12.4.2.2 Production of Erythritol and Other Polyols

Erythritol

Polyols are noncyclic hydrogenated carbohydrates which can be used as low caloric sweeteners in food and beverages industry (Park et al. 2016). Such compounds as erythritol, glycerol, ribitol, arabitol, mannitol, xylitol, and sorbitol belong to this group. Chemical method of polyols production (catalytic hydrogenation of sugars under high temperature and pressure) is not very efficient, so production of polyols is chiefly carried out by microbial conversion of carbohydrates (Park et al. 2016). For the first time, production of polyols was observed by Röhr during citric acid fermentation by A. niger (Röhr et al. 1983). In yeasts, polyols chiefly play role of osmolytes, which protect yeast cells against osmotic stress, but they are also produced during yeasts growth under normal conditions (Kayingo et al. 2001).

Erythritol is one of the most important polyols, whose production by microorganisms is being extensively studied. Erythritol is a four-carbon polyol with no optical activity. It occurs naturally in alcoholic beverages, in mushrooms, and as a component of fruits such as pears, melons, and grapes (Bernt et al. 1996). Erythritol exhibits about 70% of the relative sweetness of sucrose, but its caloric value is very low and the majority of consumed compound is quickly excreted, so it is considered to be “zero-calorie sweetener” (Rzechonek et al. 2018). Also, erythritol is safe for diabetic patients, has no carcinogenic or teratogenic potential (Bernt et al. 1996), and does not contribute to tooth decay (Rzechonek et al. 2018). In fact, it was even suggested to prevent dental caries (Hashino et al. 2013) and improve endothelial function in patients with type II diabetes (Flint et al. 2014). However, as in the case of other polyols, the excessive consumption of erythritol may cause a laxative effect (Oku and Nakamura 2007). Due to its positive properties, erythritol ought to be widely used in food and pharmaceutics, but its application is somewhat restricted by its relatively high retail price.

Among the microorganisms capable of overproducing erythritol, there are osmophilic yeasts from the genera Pichia, Zygopichia, Candida, Debaryomyces, Moniliella, Torula, Torulopsis, Trigonopsis, Trichosporon, Trichosporonoides, Pseudozyma, and Ustilago (Jeya et al. 2009; Moon et al. 2010), some fungi and lactic acid bacteria (Veiga-Da-Cunha et al. 1992), etc. The mechanism of erythritol formation in osmophilic yeasts is not completely identified. It possibly proceeds through transketolase (TK) reaction between fructose-6-phosphate and glyceraldehyde-3-phosphate. Obtained in this reaction, erythrose-4-phosphate and xylulose-5-phosphate could be dephosphorylated and reduced to erythritol and arabitol as verified in C. magnoliae (Park et al. 2005). The gene-encoding enzyme responsible for erythrose-4 phosphate dephosphorylation has not yet been identified (Rzechonek et al. 2018). Erythrose is reduced to erythritol by NADPH-dependent enzyme erythrose reductase (ER) (Lee et al. 2010). ER has been identified and described in a few yeasts, such as Moniliella megachiliensis (Kobayashi et al. 2013), Candida magnoliae (Lee et al. 2010), and Y. lipolytica (Janek et al. 2017). TK and ER activities in some yeasts are strongly influenced by the presence of NaCl (Park et al. 2011; Sawada et al. 2009). On the whole, changes in osmotic pressure (caused by high-sugar concentration or salt addition) induce erythritol accumulation in yeast cells. Other factors that influence erythritol biosynthesis are pH and temperature of medium, type of substrate and its concentration, sources of nitrogen and phosphorus, and additional factors such as chloride, copper, and manganese ions (Jeya et al. 2009; Tomaszewska et al. 2014a).

Aureobasidium sp., Pseudozyma tsukubaensis (Tomaszewska et al. 2014a), Moniliella pollinis, M. megachiliensis, and recently also Y. lipolytica (Rzechonek et al. 2018) were implemented for industrial erythritol production. On the industrial scale, erythritol is predominantly obtained from glucose derived from wheat or cornstarch hydrolysates (Moon et al. 2010). Glycerol has been previously reported as not suitable for erythritol biosynthesis (Jeya et al. 2009), but soon it was found that yeast Y. lipolytica produced erythritol in the cultivation medium with glycerol as the sole carbon source at pH 3.0 even better than in the medium with glucose (Rymowicz et al. 2009). Even in the medium containing both glucose and glycerol, Y. lipolytica first utilizes glycerol (Papanikolaou et al. 2002b). As was already mentioned, Y. lipolytica produces mainly CA during glycerol fermentation at pH 4.5–6.5; however, at pH 3.0, CA concentration is very low as polyols production (Fig. 12.5) starts to prevail (Tomaszewska et al. 2014a). Low pH value during erythritol biosynthesis is an advantage, because it protects the culture against bacterial contamination and thereby supports the development of continuous fermentation procedures (Tomaszewska et al. 2012). Erythritol production from glycerol in Y. lipolytica is also stimulated by salt addition as it increases activities of TK and ER. Moreover, the presence of salt in the medium improved not only erythritol yield but also the selectivity of biosynthesis, decreasing the amount of by-product polyols. Crude glycerol contains salt contamination, which can additionally induce erythritol production. For example, notable increase in erythritol yield was observed for the Y. lipolytica strain Wratislavia K1 when crude glycerol was used instead of pure glycerol as carbon source for erythritol production (Tomaszewska et al. 2014a). Glycerol itself generates higher osmotic stress than glucose which is beneficial to erythritol production (Yang et al. 2016). Another advantage of glycerol as a substrate for erythritol production is the composition of by-products after fermentation. When sugars are used as a substrate, glycerol occurs as one of the main by-products of erythritol production, which is quite difficult to separate from erythritol (Rzechonek et al. 2018). When glycerol is used as carbon source, it can be completely depleted from the cultivation medium and the presence of other by-products may be reduced as well (Mironczuk et al. 2014; Mironczuk et al. 2015; Rymowicz et al. 2009). Therefore, using glycerol and especially cheap crude glycerol as a substrate could ensure cost-effective erythritol production by Y. lipolytica.

Hypothetical pathways of glycerol conversion into polyols in Y. lipolytica (Tomaszewska et al. 2014a). 1 glycerol kinase, 2 glycerol-3-P dehydrogenase, 3 mannitol dehydrogenase, 4 hexokinase, 5 mannitol-1-P dehydrogenase, 6 mannitol-1-phosphatase, 7 transketolase, 8 transaldolase, 9 arabitol dehydrogenase, 10 erythrose reductase

Erythritol synthesis from glycerol could be improved in several directions: (a) optimization of the cultural medium composition, (b) optimization of fermentation setup, and (c) modification of the Y. lipolytica strains used in the biosynthesis by mutagenesis or genetic engineering.

When artificial neural network model and genetic algorithm were used to predict the optimal medium composition to maximize erythritol production from crude glycerol, it was found out that medium with 232.39 g/L crude glycerol, 1.57 g/L urea, and 31.03 g/L NaCl led to predictive maximum erythritol concentration of 110.7 g/L (Yang et al. 2016). In real experiment in such conditions, Y. lipolytica strain A16 produced 109.2 g/L of erythritol, which is approximately 2 times higher than the usual values obtained in batch fermentations (40 to 60 g/L) (Rywinska et al. 2015; Yang et al. 2016). Also it was found out that erythritol production can be improved by medium supplementation with Mn2+ (25 mg/L), Cu2+ (2.5 mg/L) (Tomaszewska et al. 2014b), thiamine, yeast extract (Rywinska et al. 2015), and surfactant Span 20 (Rakicka et al. 2016b).

In respect of the fermentation setup, improved productivity is obtained in fed-batch systems where the amount of substrate is renewed at least once or, sometimes, a few times (Rymowicz et al. 2009; Rywinska et al. 2015; Tomaszewska et al. 2014b; Yang et al. 2014a).

Another modification is repeated fed-batch cultures (RBC). In this system, after consumption of the substrate, fermentation medium is separated into a concentrated fraction of microorganisms and another fraction enriched with the fermentation product. Later, fresh substrate is added to the microorganism fraction and another cycle of the production begins. This may be repeated one or several times (Mironczuk et al. 2014). In such system, after replacing 30% of the working volume several times, researchers were able to obtain 224 g/L of erythritol with a 0.78 g/g product yield from pure glycerol (Rzechonek et al. 2018). In the RBC with crude glycerol, the average erythritol concentration oscillated from 81.3 to 180.8 g/L during the course of fermentation (Mironczuk et al. 2014). In the continuous fermentation performed in a chemostat, erythritol production from pure glycerol was 103.4 g/L with a productivity of 1.12 g/L h and a yield of 0.52 g/g. When crude glycerol was used as a substrate, these values were lower – 81.9 g/L of erythritol with productivity of 0.9 g/L h and yield of 0.4 g/g (Rakicka et al. 2016a).

Several modified Y. lipolytica strains with improved erythritol production were obtained. For example, Y. lipolytica strain Wratislavia K1 was isolated by two-stage selection: first, acetate-negative mutant incapable of growth on acetate as the sole carbon and energy source was isolated after exposure to UV irradiation, and then the most productive strain was isolated in the course of continuous citric acid production from glucose in nitrogen-limited chemostat at a dilution rate of 0.016 h−1 (Tomaszewska et al. 2014a). Strain Wratislavia K1 produced the highest amounts of erythritol among other acetate-negative mutants, probably due to its inability to reutilize this polyol. Rymowicz et al. reported that using crude glycerol (300 g/L) in a fed-batch system with Y. lipolytica Wratislavia K1 resulted in a production of 170 g/L of erythritol with a yield of 0.56 g/g and productivity of 1.0 g/L/h (Rymowicz et al. 2009).

Later, the strain Wratislavia K1 was genetically modified by overexpression of the native gene GUT1 and S. cerevisiae gene SUC2 gene (encoding sucrose hydrolyzing enzyme invertase). The obtained recombinant strain possessed ability to utilize sucrose and to assimilate glycerol faster than the initial strain (Rakicka et al. 2017). This strain was tested in two-stage fermentation: first, abundant biomass was accumulated during growth in the medium containing industrial raw molasses as a sole carbon source; then, stage of polyols production started after the addition of 4% NaCl and 150 g/L of crude glycerol. In such conditions, recombinant strain produced 100.65 g/L of polyols, with productivity of 1.09 g/L/h and yield of 0.67 g/g. This way, efficient polyol production from inexpensive raw materials was achieved (Rakicka et al. 2017).

Genes encoding the two first enzymes of glycerol assimilation (GUT1 and GUT2) have been overexpressed in Y. lipolytica strain A101. Overexpression of GUT2 gene did not improve erythritol production, and overexpression of GUT1 gene or co-overexpression of both genes caused a 24% or 35% increase in erythritol productivity, respectively (Mironczuk et al. 2016).

Also attempt has been made to hinder erythritol reutilization by Y. lipolytica. For that, the gene EYK1 encoding erythrulose kinase was identified and deleted in Y. lipolytica. Obtained recombinant strain was unable to use erythritol as a carbon source and revealed 26% improvement in erythritol productivity (Carly et al. 2017).

Another osmotolerant yeast, M. megachiliensis, has been found to be able to utilize nonrefined glycerol waste derived from palm oil or beef tallow and convert it to erythritol. When 200 g/L of crude glycerol was used as a carbon source for M. megachiliensis fermentation, the yield of erythritol was approximately 60% (Kobayashi et al. 2015).

Mannitol

Mannitol is a six-carbon polyol that can be used in the food, pharmaceutical, and medical industries. It has similar characteristics to other polyols: sweet taste; low caloric value; naturally found in fruits, vegetables, and mushrooms; etc. (Khan et al. 2009). Mannitol is industrially produced by catalytic hydrogenation of fructose and glucose mixture at high temperature and pressure, which requires a high purity of substrates. Microbial production of mannitol (Fig. 12.5) is an appealing alternative (Saha and Racine 2011). Mannitol can be produced by yeasts C. magnoliae, C. zeylanoides, the fungi Aspergillus, and bacteria, especially lactic acid bacteria (Saha and Racine 2011). Fructose- and glucose-containing media have been found to be the most suitable for the production of mannitol. Osmophilic yeast C. magnoliae has been shown to produce 209 g/L of mannitol from fructose/glucose mixture with an impressive yield of 83% (Song et al. 2002). C. magnoliae was reported to produce 213 g/L of mannitol from similar substrate in fed-batch fermentation (Lee et al. 2003). Fructose/glucose medium supplementation with Ca2+ and Cu2+ further increased the production of mannitol with C. magnoliae strain HH-01 reaching 223 g/L (Lee et al. 2007b).

There is not much information about mannitol production from glycerol. Mannitol is a major by-product during glycerol conversion to erythritol by Y. lipolytica. Some strains of Y. lipolytica produce mannitol as the only polyol in nitrogen-limited conditions. For example, Y. lipolytica LFMB strain 19 produced 19.4 g/L of mannitol from 90 g/L of glycerol (Chatzifragkou et al. 2011). When several Y. lipolytica were analyzed, strains A UV’1 and A-15 were found to be able to produce significant amounts (up to 27.6 g/L) of mannitol (Tomaszewska et al. 2012). NaCl salt addition to the medium improves erythritol biosynthesis and simultaneously inhibits mannitol formation by these strains. In the fed-batch process, the A UV’1 strain produced 91.6 g/L erythritol and 38.1 g/L mannitol from pure glycerol as a carbon source (Tomaszewska et al. 2012).

The resting cells of yeast C. magnoliae were found to be able to produce exclusively mannitol (up to 51 g/L) from pure glycerol. Mannitol yield in this process was as high as 50% (Khan et al. 2009).

Arabitol

Arabitol is a five-carbon polyol that can be used in similar manner as erythritol and mannitol, that is, as a natural sweetener, a dental caries reducer, and a sugar substitute for diabetic patients (Gare 2002). Besides usual polyols’ properties, arabitol can be transformed into several groups of chemicals like its enantiomer xylitol, arabonic/arabinoic acid, etc. (White et al. 2004).