Abstract

Xylitol is commercially used in chewing gum and dental care products as a low calorie sweetener having medicinal properties. Industrial yeast strain of S. cerevisiae was genetically modified to overexpress an endogenous aldose reductase gene GRE3 and a xylose transporter gene SUT1 for the production of xylitol. The recombinant strain (XP-RTK) carried the expression cassettes of both the genes and the G418 resistance marker cassette KanMX integrated into the genome of S. cerevisiae. Short segments from the 5′ and 3′ delta regions of the Ty1 retrotransposons were used as homology regions for integration of the cassettes. Xylitol production by the industrial recombinant strain was evaluated using hemicellulosic hydrolysate of the corn cob with glucose as the cosubstrate. The recombinant strain XP-RTK showed significantly higher xylitol productivity (212 mg L−1 h−1) over the control strain XP (81 mg L−1 h−1). Glucose was successfully replaced by glycerol as a co-substrate for xylitol production by S. cerevisiae. Strain XP-RTK showed the highest xylitol productivity of 318.6 mg L−1 h−1 and titre of 47 g L−1 of xylitol at 12 g L−1 initial DCW using glycerol as cosubstrate. The amount of glycerol consumed per amount of xylitol produced (0.47 mol mol−1) was significantly lower than glucose (23.7 mol mol−1). Fermentation strategies such as cell recycle and use of the industrial nitrogen sources were demonstrated using hemicellulosic hydrolysate for xylitol production.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Xylitol is a polyol which has several applications as a low calorie sweetener and for prevention of dental cavities [33]. Microbial production of xylitol is desirable due to the high cost of the current industrial process based on chemical hydrolysis and hydrogenation [24]. Natural xylose metabolising microorganisms including yeasts such as Candida [32] have been studied for fermentation of xylose to xylitol. Microbial conversion of xylose to xylitol is carried out by a cofactor (NADPH or NADH) dependent enzyme xylose reductase (XR). Xylitol is further metabolized to xylulose by the enzyme xylitol dehydrogenase (XDH) present in the xylose metabolising microorganisms. Xylulose can then enter pentose phosphate pathway (PPP) where majority of the cofactor NADPH is regenerated [39]. However, application of the natural xylose metabolizing organisms for xylitol production is limited due to the poor efficiency and yield of xylitol on consumed xylose in pretreated hemicellulosic hydrolysates [7, 45].

For improvement in the xylitol production, synthetic biology approach has been used and genetically engineered bacteria [49] or yeasts such as C. tropicalis with deleted XDH gene and S. cerevisiae strains over-expressing heterologous XR have been developed. Synthetic biology is an excellent tool for design and construction of novel biological constructs to produce the desired products from various platform substrates or feed stocks [34]. Various approaches including DNA assembly tools, introduction of the DNA into the cells and identification of targets for pathway optimization have been employed to develop more efficient xylose fermenting strains [25]. Though considerable advancement has been made using the recombinant strains, development of industrial strains and using hemicellulosic hydrolysates is an important area for improvement in xylitol production [16, 30].

Saccharomyces cerevisiae is a Generally Regarded As Safe (GRAS) organism, and is a preferred host for the industrial fermentation processes. Saccharomyces cerevisiae demonstrates natural tolerance against the fermentation and metabolic inhibitors such as HMF and furfural by the virtue of elevated function of the PPP and oxidoreductase enzymes [14]. The early research efforts were focused on the use of laboratory strains of S. cerevisiae to express xylose reductase genes, due to availability of auxotrophic markers required for cloning gene cassettes [22]. The industrial strains are less amenable to genetic modifications due to varied ploidy levels and adaptations acquired making them robust to withstand the industrial process environments [40].

Although S. cerevisiae does not grow on xylose as the sole carbon source, it carries a gene GRE3, encoding a non-specific NADPH dependent aldose reductase, which converts xylose to xylitol [23]. It is expressed in the stress responses for hypoxia, osmotic or heat shock, etc. [10]. Overexpression of the endogenous GRE3 gene in S. cerevisiae has been shown to facilitate xylose fermentation [18, 21, 22]. Saccharomyces cerevisiae is dependent on the HXT group of sugar transporters for xylose uptake. Expression of the SUT1 gene encoding a xylose transporter from P. stipitis has been reported to improve xylose uptake in S. cerevisiae [12, 17, 46]. Though integration in high copy number is desirable for stable overexpression of the cloned gene, it requires iterative transformation of the cassette with different markers. The long terminal repeat sequences (LTR) of the retrotransposons have been previously reported for stable integration of multiple copies of the gene cassette in S. cerevisiae [20, 37].

In the present study, an industrial strain of S. cerevisiae was genetically engineered to carry stable integrated overexpression cassettes of the genes GRE3 and SUT1 in the genome. The gene cassettes were assembled and double crossover homologous recombination was facilitated by the flanking delta or long terminal repeat (LTR) regions of the Ty1 retrotransposon. It is desirable to use the industrial strains due to their high fermentation efficiency and ability to withstand diverse stress conditions prevailing in the biorefinery processes [5, 47]. Xylitol production was evaluated using glucose as co-substrate in fed batch fermentation by the recombinant industrial strain. For the first time, glycerol has been demonstrated as cosubstrate to replace glucose in xylitol production by the recombinant S. cerevisiae. Xylitol production was evaluated with different cell densities and cell recycle fermentation using glycerol as cosubstrate. Finally, xylitol production has been evaluated with recombinant industrial strain using hemicellulosic hydrolysate of corn cob.

Materials and methods

Evaluation of glycerol utilization by S. cerevisiae strains

Cultures of the S. cerevisiae BY4741, S. cerevisiae Ethanol Red (ER) and S. cerevisiae XP strains were stored in the form of glycerol stocks at −80 °C. The stocks were inoculated in 50 mL YPD medium in 250 mL flasks and cell growth was allowed to revive the culture. The overnight grown cells were transferred to the 50 mL medium containing 10 g L−1 yeast extract, 20 g L−1 of peptone and glycerol each (YPG) in 250 mL flask at an initial OD600nm of about 0.4 and were incubated at 30 °C and shaken 150 rpm. The OD600nm of the cultures was recorded at regular intervals to monitor the cell growth.

Recombinant strain development

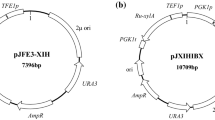

In our previous report, we reported cloning of the genes GRE3 and SUT1 in the vectors p426TEF and pD1211, respectively, under the strong and constitutive TEF1 promoter. The recombinant plasmids were maintained in the E. coli TOP10F’cells grown in LB medium with 80 ppm ampicillin [21]. The expression cassettes were PCR amplified from the respective purified plasmids using the primers 1 and 2 for the GRE3 and 3, 4 for SUT1 as enlisted in the Table S1. The KanMX cassette providing resistance to G418 was used as selection marker in the recombinant yeast strain. The marker cassette was obtained from the vector pJET1.2-B-KanMXP. The overexpression cassettes were used as templates for PCR amplification of the segments G-GRE3 (~1.6 kb) (primers 5, 6), G-SUT1 (2.3 kb) (primers 7, 8) and G-KanMX (~1.6 kb) (primers 9, 10) using Q5 High-Fidelity DNA polymerase (0491S, NEB, UK). These segments were designed to carry overlapping regions for assembly of the recombinant vector pUCδRTKδ which is shown in Fig. S1. The 5′ (primer 5) and 3′ (primer 10) delta regions were flanking the segments G-GRE3 and G-KanMX, respectively. Amplified segments were purified by gel extraction as per kit protocol (28704, Qiagen Netherlands). The vector pUC19 was used for cloning and maintenance of the construct in E. coli. Purified plasmid vector pUC19 was double digested using restriction enzymes SacI and SalI and linearized vector was then purified by gel extraction. The gene cassettes and the linearized vector were assembled to construct the circular plasmid pUCδRTKδ as shown in Fig. S1, using the Gibson Assembly Cloning Kit (E5510S, NEB, UK) as per kit protocol. The construct was transformed into the E. coli competent cells (NEB 5-alpha, C2987, UK) using heat shock and transformants were selected on LB medium containing 80 ppm ampicillin. The transformants were verified for the presence of plasmid pUCδRTKδ and selected recombinants were maintained in the selective LB medium as glycerol stocks at −80 °C. The details of the primers, plasmids and the strains used in this study have been provided in Tables S1, S2 and S3, respectively.

The plasmid pUCδRTKδ was purified from E. coli cells and digested using the PsiI enzyme. The 5.8 kb linear segment δRTKδ containing the flanking homology regions (40–45 bp each) and overexpression cassettes of GRE3, SUT1 and KanMX, was purified by gel extraction for transformation in S. cerevisiae. The S. cerevisiae strain XP is a diploid industrial strain isolated from molasses-based distillery in India. S. cerevisiae cells were grown till mid exponential phase in the medium containing 10 g L−1 yeast extract, 20 g L−1 peptone with 20 g L−1 glucose (YPD). Electroporation was performed in (BioRad Micropulser ™) at 1.5 kV, 25 μF capacitance and resistance of 200 Ω. The purified linear construct δRTKδ was transformed using 0.2 mm electroporation cuvette, maintained on ice. The transformants were selected on YPD plates containing 400 ppm of the antibiotic G418 and verified by PCR. Selected transformants of the recombinant industrial strain S. cerevisiae (XP-RTK) were grown and maintained in YPD medium with G418 as glycerol stocks at −80 °C. Up to 150 recombinant colonies were re-patched on the YPD plates containing G418 at concentrations of 400–4000 ppm for screening for the degree of resistance to the antibiotic G418.

Preparation of corn cob hemicellulosic hydrolysate

Corn cob having total solid content of 92% on the weight basis was subject to mechanical shear to obtain particle size of 20–40 mm, and soaked in water for nearly 30 min. The feed containing 30% solids was constantly supplied with steam, 2% sulphuric acid and 1% oxalic acid on the basis of the solid content for pre-treatment. The pre-treatment was performed in the continuous digester for 20 min at high pressure and temperature of 6 bars and 160 °C, respectively, maintained using the acids and steam. The pretreated slurry of the hemicellulosic hydrolysate of corn cob thus generated, contained about 18–20% solids [36]. Partial detoxification and concentration of the xylose stream was achieved by nanofiltration system having spiral wound membrane in the first stage. The membrane having a filtration area was 0.37 m2 and molecular weight cutoff of 150–300 Da was selected based on the molecular weight of xylose (150 g M−1). The operating conditions were maintained at 30 °C and 30 bar pressure. In the second stage, the xylose stream was passed through anion exchange resin BF100 (Ion Exchange, India) column for detoxification [8]. The composition of the non-detoxified and detoxified hemicellulosic hydrolysate of corn cob used in fermentation trials has been provided in Table 1.

Evaluation of glucose as cosubstrate in fed batch fermentation of xylose

The inoculums of the XP and XP-RTK cultures were prepared in YPD medium (pH 5.5) shaken at 150 rpm at 30 °C, for 24 h to achieve the OD600nm of about 20. The fermentation medium containing 10 g L−1 yeast extract and 20 g L−1 peptone (referred as YP and prepared as 10× stock) and 50 g L−1 of glucose solution were sterilized separately. The corn cob hemicellulosic hydrolysate was heated at 80 °C for 10 min before inoculation. The concentrated stocks along with the hemicellulosic hydrolysate were added just before inoculation to the bioreactor to prepare 400 mL fermentation medium (YPD) containing nearly 40 g L−1 xylose. Fermentation was initiated by inoculating 15% v/v of seed culture. The pH of medium was maintained at 5.5 using 4 N NaOH or 4 N HCl. The fermentation was performed in 1 L fermenter (BioFlo/CelliGen 115, New Brunswick, USA) at temperature 30 °C, agitation of 150 rpm and at 0.2 vvm aeration. Process was operated in batch mode for first 24 h after inoculation. Once the initial glucose was completely consumed, glucose stock solution (300 g L−1) was continuously fed at a flow rate of 2.5 mL h−1. Antifoam was added as per requirement. All the chemicals were purchased from HiMedia (India).

Mitotic stability estimation

The mitotic stability of the recombinant strain was assessed as the relative viability count of the recombinant cells in fermentation broth. Sample of broth at beginning and the end of the fermentation was spread onto plates of non-selective (YPD) and selective medium with 400 ppm G418 to estimate the fraction of recombinant cells that could retain the antibiotic resistance.

Xylose fermentation with glycerol as co-substrate at different initial cell densities

For the batch fermentation study at different initial cell densities, the seed cultures of the strains XP and XP-RTK were grown in bulk in 2 L flasks each containing 400 mL of YPD medium. Cells were harvested at 24 h by centrifugation at 8000 rpm for 5 min and the pellets were resuspended to attain initial biomass concentration of 2, 4, 8, 12, 18, 24 g L−1 DCW in the fermentation medium. Batch fermentation of xylose was performed in 50 mL medium containing 40 g L−1 glycerol and xylose each (YPGX) 250 mL shaken flask at 150 rpm agitation and 30 °C.

Cell recycle in batch fermentation of xylose with glycerol

Cell recycle studies were performed in batch fermentation of xylose using YPGX medium. Cells were harvested by centrifugation after 144 h of each batch of fermentation since glycerol was nearly completely consumed (Fig. 4c). The cells were inoculated to the fresh medium at 4 g L−1 DCW. After each batch the biomass production and xylitol productivity were monitored.

Xylitol production using alternative nitrogen sources

Xylitol production was studied while using alternative low cost sources of nitrogen with glycerol as co-substrate. The industrial nitrogen sources, corn steep liquor (CSL), urea and diammonium phosphate (DAP) were used in combinations, which contained the total nitrogen content equivalent to laboratory medium consisting of yeast extract and peptone (YP). Seed cultures of XP and XP-RTK grown in YPD medium were harvested by centrifugation and inoculated at 4 g L−1 DCW to initiate fermentation. The fermentation media contained 40 g L−1 of glycerol and xylose each. Batch fermentation of xylose was performed in 50 mL medium in 250 mL shaken flask at 150 rpm agitation and 30 °C.

Xylitol production using detoxified hemicellulosic hydrolysate of corn cob

Preparation of the seed culture and the fermentation medium containing glycerol (40 g L−1) and CSL (4.2 g L−1) was similar as described earlier. Three different media combinations containing yeast extract and peptone or CSL as nitrogen source and pure xylose or detoxified hemicellulosic hydrolysate of corn cob were prepared. The synthetic xylose stock solution (400 g L−1) or detoxified corn cob hemicellulosic hydrolysate (dHHCC) were sterilized separately. Xylose or the hemicellulosic hydrolysate was then added to obtain the xylose concentration of nearly 40 g L−1 in 50 mL volume of medium. The pH of the fermentation media was adjusted to 5.5 with 4 N HCl and then cells were inoculated at 4 g L−1 DCW. Xylitol production using the hemicellulosic hydrolysate and pure xylose were compared in the batch fermentation by the recombinant S. cerevisiae XP-RTK strain.

Specific xylose reductase activity measurement

Fermentation samples were centrifuged at 8000 rpm for 5 min to harvest 50 mg cells and were washed with distilled water. Crude cell-free extract was prepared by treating cells with 200 µL Y-PER™ Yeast Protein Extraction Reagent (Thermo Scientific, USA) and 4 µL Protease Inhibitor Cocktail (Sigma Aldrich, USA) and then centrifugation at 13,000 rpm for 10 min. The supernatant or crude cell free extract was immediately used for the enzyme assay and protein measurement or stored at −80 °C. The specific XR activity was estimated by the method reported earlier [44]. The assay reaction contained 150 µM NADPH, 500 mM Potassium phosphate buffer having pH 6, 200 µM xylose and diluted crude cell free extract in a total assay volume of 1 mL. Reaction mixture was allowed to stand on ice for 10 min and absorbance was read at 340 nm using the spectrophotometer (Schimadzu UV2450, Japan). One unit of XR activity is defined as the amount of enzyme required to oxidize 1 µM NADPH in 1 min. Protein content was determined by the standard method [26]. The specific XR activity was calculated by dividing the XR activity by the protein concentration in the samples.

Mitotic stability measurement

The recombinant strains exhibited loss of vector during growth on non-selective media in fermentation studies. The stability of the recombinant strains was measured as the relative viability count. The fermentation broth was diluted appropriately and spread onto plates of selective (YPD with 400 ppm G418) and non-selective (YPD) media to estimate the fraction of recombinant cells that could retain the integrated segment.

Analytical methods

The fermentation samples were analyzed for estimating concentrations of glucose, glycerol, xylose, xylitol, ethanol and other byproducts by HPLC (1100 system, Agilent Technologies, USA). Separation was done using the Aminex HPX-87H column (300 × 7.8 mm i.d.) (Bio-Rad, USA) at a column temperature of 55 °C. Sulfuric acid (5 mM) was used as mobile phase at a flow rate of 0.6 mL min−1 and the compounds were detected using the refractive index detector. For estimation of the dry cell weight the fermentation samples were centrifuged at 8000 rpm for 5 min. The cell pellet was washed with distilled water. The cells were resuspended in 1 mL water and allowed to dry in a glass plate in the vacuum oven at 60 °C. The dry cell weight (DCW) was calculated in g L−1 from the observed weight.

Statistical analysis

The data was collected from at least three different and biologically independent experiments. The statistical analysis was done using student’s t test null hypothesis and represented as mean ± standard error (SE).

Results and discussion

Evaluation of glycerol utilization by S. cerevisiae strains

Glycerol is a non-fermentative and non-repressive carbon source and it plays a significant role in osmoregulation in S. cerevisiae [4, 33]. Glycerol is an abundantly available, low cost carbon source hence it is favourable as a cosubstrate for growth, hence it has attained importance in development of industrially relevant bioprocesses by various microorganisms [27, 31]. Other co-substrates such as glucose, ethanol or cellobiose have been studied for NADPH regeneration during xylose metabolism by recombinant S. cerevisiae. Though sugars are abundantly available and can be readily metabolized by yeasts, they exhibit certain demerits as co-substrates. Glucose exhibits catabolite repression and it is required in significantly higher amounts for xylose fermentation [28]. While utilization of ethanol resulted in lower rates of xylose fermentation than glucose [11, 29], cellobiose is a costly substrates [48]. Glycerol can be used to overcome the limitations of other co-substrates for production of various biochemicals at potentially higher yields [27, 31]. However, poor consumption and growth rate of S. cerevisiae on glycerol has been reported to restrict its use as a co-substrate [11, 45]. We compared the maximum specific growth rates (µ max) of different strains of S. cerevisiae on glycerol. The µ max of different laboratory and industrial strains of S. cerevisiae on glycerol were measured and the highest µ max of 0.26 h−1 was obtained by the industrial strain XP (Table 2). Intraspecies diversity in growth characteristics on glycerol as sole carbon source has been reported earlier with S. cerevisiae isolates. The genetic diversity in the isolates was used as a tool to develop superior S. cerevisiae strain for improved glycerol metabolism [41, 42]. Based on maximum growth rate on glycerol, strain XP was selected for genetic modification to facilitate fermentation of xylose.

Genome integration of gene cassettes

Earlier we have reported that overexpression of the genes GRE3 and SUT1 showed higher xylitol productivity in S. cerevisiae as compared to other xylose reductase genes [21]. In present study, we focused on genetically modifying the industrial diploid strain S. cerevisiae XP for the production of xylitol. The cassettes for overexpression of the genes GRE3 (~1.6 kb), SUT1 (2.3 kb) and the antibiotic marker KanMX (~1.6 kb) were synthesized by PCR from the respective plasmids. The 5′ and 3′ delta homology regions from Ty1 retrotransposon were incorporated using PCR flanking the cassettes of GRE3 and KanMX, respectively. Recombinant circular plasmid pUCδRTKδ was assembled and maintained in E. coli (Fig. S1). The plasmid DNA was purified and assembly was verified by PCR amplification and DNA sequencing of the construct (1st Base Laboratories, Malaysia). The linear construct δRTKδ consisting of the expression cassettes of the genes GRE3, SUT1 and selectable antibiotic marker KanMX, was generated by digestion with PsiI and purified using gel extraction. The segment δRTKδ was then transformed into the electro-competent cells of the industrial strain S. cerevisiae XP and the transformants were selected on YPD medium containing antibiotic G418. The integration of the δRTKδ segment into the genome of recombinant S. cerevisiae XP was verified by PCR. Genome integration of the DNA assembly comprising multiple gene cassettes was achieved using the short (~45 bp) segments of the delta homology regions of the Ty1 retrotransposon of S. cerevisiae. The complete Ty1 elements or only delta segments of Ty1 exist in S. cerevisiae strains at the maximum frequency as compared to the other classes of retrotransposons. Also, the integration using Ty1 delta region has been reported to be more stable as compared to the homology regions from other members of Ty family [9, 19]. The plasmid based recombinant laboratory strains often show heterogeneous gene expression levels which is not desirable in industrial processes [34]. Plasmid based gene cloning results in segregational instability in the absence of selection pressure resulting in lower expression levels. The integration vectors using the auxotrophic markers for recombination allow a single or low copy number of the cloned gene. In our study, the S. cerevisiae XP transformants were selected on increasing concentrations of antibiotic G418 for selection of multicopy integrant. Selection of transformants with higher resistance to antibiotic has been reported to be correlated with high copy number integration using Ty delta homology regions [37]. After electroporation, 150 recombinant colonies were randomly selected among the transformants obtained on the plate containing 400 ppm G418 for further screening. The colonies were serially selected on the plates with 500, 600, 800, 1000, 1500, 2000, 3000 and 4000 ppm G418 concentration and the number of colonies that could grow were 138, 127, 79, 39, 13, 6, 2 and 2, respectively. The transformant showing resistance up to tenfold higher G418 concentration than the minimum inhibitory concentration (MIC) was referred to as strain XP-RTK and it was used for xylose fermentation studies.

Evaluation of glucose as cosubstrate in fed batch fermentation of xylose

Fed batch fermentation of xylose to xylitol by the recombinant industrial S. cerevisiae strain XP-RTK was studied using glucose as cosubstrate. Xylose was obtained from the hemicellulosic hydrolysate of corn cob, which also contained sugars glucose in negligible amounts and the inhibitory compounds generated during pretreatment. Glucose was fed continuously for regeneration of the cofactor NADPH for the enzyme xylose reductase [13]. Glucose was fed at a growth limiting rate of 2.2 g L−1 h−1, to avoid catabolite repression of xylose metabolism. The recombinant strain produced xylitol with near theoretical yield, showing that xylitol could not be metabolized further. The overall xylose consumption by the recombinant strain XP-RTK (82%) was threefold higher than the control strain XP which showed 26% xylose consumption. Xylitol production was observed in the control strain due to expression of endogenous copy of the GRE3 gene (Fig. 1a, b). The specific XR activity was compared in the recombinant strain, as well as the control strain using cells harvested from the fermentation broth. The specific activity in the cells of the recombinant strain XP-RTK (0.37 U mg−1) was found to be nearly twofold higher over the control strain (Table 3). The higher xylitol productivity by the strain XP-RTK could be attributed to the presence of multiple copies of the expression cassette integrated into the genome. During the batch phase, biomass growth occurred on glucose and the xylose consumption was not observed. In xylose fermentation phase, the specific xylitol productivity of 11 mg g−1 h−1 was shown by the recombinant XP-RTK strain. The specific productivity was maintained throughout fermentation, showing that the recombinant strain could stably retain δRTKδ expression cassette over the xylose fermentation phase (Fig. 2). Stable genome integration could be facilitated using the short segments of the 5′ and 3′ delta regions.

Xylose fermentation with glycerol as co-substrate at different initial cell densities

Xylose fermentation was performed using glycerol as co-substrate by the strains XP and XP-RTK at different initial cell densities (Fig. 3). Glycerol does not exhibit catabolite repression and could be co-metabolized with xylose. The aerobic metabolism of glycerol in S. cerevisiae involves the gene GCY1 encoding the enzyme glycerol dehydrogenase that converts glycerol to dihydroxyacetone while regenerating NADPH. The NADPH pool can be utilized for the activity of the enzyme xylose reductase for conversion of xylose to xylitol.

The strain XP-RTK showed a significant increase in xylitol productivity with increasing cell densities as shown in Fig. 3. After 144 h, xylitol productivity of 166, 208 and 271 mg L−1 h−1 were achieved at 2, 4 and 8 g L−1 DCW, respectively, and the highest xylitol productivity of 318 mg L−1 h−1 was obtained at 12 g L−1 DCW. Up to 12 g L−1 biomass concentration, the yield of xylitol on the consumed glycerol (Yxylitol/glycerol) increased due to overall higher xylose reductase activity. The metabolism of glycerol led to increase in biomass concentration; which augmented the overall xylitol productivity. The control strain also showed highest xylitol productivity of 111 mg L−1 h−1 due to expression of endogenous copy of the GRE3 gene at 12 g L−1 DCW inoculum. However, the maximum xylitol produced (21 g L−1) by the control strain XP was significantly lower than the recombinant strain. At cell densities beyond 12 g L−1, decrease in xylitol productivity and the biomass formation were observed. This could be attributed to the limitation in aeration required for glycerol metabolism at increased cell densities in shake flask cultures. Higher cell densities lead to anaerobic conditions in the shake flask cultures shifting glycerol metabolism through the enzymes GUT1 and GUT2 which are independent of NADPH [33]. It was observed that equivalent biomass of nearly 20 g L−1 DCW was produced by the control and the recombinant strains on glycerol as a cosubstrate. Though the glycerol consumption was similar at different cell densities, xylitol productivity improved with the increasing initial cell densities.

The final xylitol titre of 47 ± 2.7 g L−1 obtained in the batch fermentation was fourfold higher than the titre (12 g L−1) achieved in fed batch process with glucose. One of the major advantages of glycerol as cosubstrate include xylose fermentation in batch mode as compared to the fed batch fermentation in glucose based process. Dilution of the broth during the fed batch process resulted in lower final titre of xylitol. The recombinant strain overexpressing GRE3 gene required continuous regeneration of the cofactor NADPH which is provided by metabolism of the co-substrate. Assuming that the entire glucose is metabolized through PPP and completely oxidized to carbon dioxide, theoretically cells can regenerate 12 mol NADPH per 1 mol glucose consumed [3]. The amount of glucose fed to regenerate NADPH during fermentation of xylose was found to significantly exceed the theoretical requirement. In our studies, the molar yield of xylitol obtained on glucose was 23.7 mol mol−1. The poor efficiency of cofactor regeneration with glucose as co-substrate can be explained by the consumption of glucose through the fermentation pathway apart from PPP, to produce ethanol and biomass [6]. Alternatively, glycerol is metabolized by the enzyme glycerol dehydrogenase under aerobic conditions to regenerate 1 mol of NADPH per mole of glycerol. The molar yield of xylitol on glycerol was found to be 0.47 mol mol−1, which was closer to the theoretical requirement. This is the first report on xylitol production by industrial recombinant strain of S. cerevisiae using glycerol as co-substrate.

Cell recycle in batch fermentation of xylose with glycerol

The stability of the recombinant strain was studied during the cell recycle fermentation using non-selective media (YPGX) and xylitol productivity was evaluated. The control and the XP-RTK strain showed specific xylitol productivity of 7.9 and 16 mg g−1 h−1, respectively. The recombinant strain showed nearly twofold higher and stable specific xylitol productivity over nearly 12 generations during four cells recycles (Fig. 4). The glycerol consumption and biomass produced by both the control and the recombinant strain were similar. However, during glycerol metabolism, the reducing power generated in the form of NADPH was efficiently utilized by the recombinant strain as a cofactor for xylitol production. The stable xylitol productivity was achieved by sustained expression of the GRE3 gene. The stability of the strain during cell recycles also supported the selection of Ty1 retrotransposon delta segments for integration of the expression cassette.

Evaluation of industrial nitrogen sources for xylitol production

To improve the feasibility of the xylitol production by recombinant S. cerevisiae, industrial sources of nutrients were evaluated. The complex nitrogen sources such as yeast extract and peptone have been reported to enhance xylose metabolism in yeasts [2, 15, 43]. To replace the expensive components of the laboratory media such as yeast extract and peptone, alternative media components were evaluated for xylitol production by the recombinant strain to develop an industrially feasible process. Xylose fermentation was evaluated in media containing combinations of inorganic and organic nitrogen sources as shown in Fig. 5. The total nitrogen content in all the combinations was equivalent to the laboratory medium containing yeast extract and peptone. Among the different media combinations, CSL showed the highest productivity (232 mg L−1 h−1) of xylitol, which was comparable to that obtained using laboratory medium. The combination of DAP and urea as nitrogen source in the medium, led to significantly lower xylitol productivity of 159 mg L−1 h−1 by the recombinant strain. Utilization of CSL as a complex nitrogen source led to significant improvement of about 1.6-fold in the specific productivity of xylitol by the XP-RTK strain (16.2 mg g−1 h−1) over the control strain (9.6 mg g−1 h−1) inspite of similar biomass formation. CSL is a complex nitrogen source consisting of several other macro and micro-nutrients that intensify growth and fermentation by the yeast cells [2, 15].

Specific xylitol productivity using alternative nitrogen sources, YP (10 g L−1 yeast extract + 20 g L−1 peptone), Csl (4.2 g L−1 corn steep liquor), Csl-DU (2.5 g L−1 corn steep liquor + 5.7 g L−1 DAP + 1.3 g L−1 urea), DU (8.5 g L−1 DAP + 3.8 g L−1 urea) by the strains XP and XP-RTK. All fermentations were conducted with 40 g L−1 xylose and 40 g L−1 glycerol and initial cell density of 4 g DCW per liter

Xylitol production using detoxified corn cob hemicellulosic hydrolysate

Xylitol production was compared in pure xylose and hemicellulosic hydrolysate of corn cob to evaluate the feasibility of using recombinant strain on industrial feed stocks. Fermentation using non-detoxified hemicellulosic hydrolysate showed negligible consumption of xylose using glycerol as cosubstrate (data not shown). The inhibitory compounds in hemicellulosic hydrolysate such as furfural, hydroxymethyl furfural (HMF) and acetic acid have been reported to exhibit redox stress in the microorganisms. Various oxidoreductase enzymes in PPP are the targets for inhibition affecting growth and metabolism of the microorganisms [1, 14]. During detoxification of the hemicellulosic hydrolysate, nanofiltration partially reduces the level of acetic acid and further removal of acetic acid along with other inhibitors like furfural, HMF and phenolics is achieved by treatment with anion exchange resin. The composition of the detoxified stream has been provided in Table 1, and it was used to study xylitol production. The detoxified stream contained significantly lower or negligible amounts of the inhibitors as compared to the non-detoxified stream (Table 1). Xylitol productivity obtained by the strain XP-RTK using detoxified hemicellulosic hydrolysate (196 mg L−1 h−1) or pure xylose (217 mg L−1 h−1) were comparable using YP as nitrogen source. Use of CSL instead of YP for the fermentation of detoxified hemicellulosic hydrolysate also showed nearly similar xylitol productivity of 202 mg L−1 h−1 by the strain XP-RTK. The recombinant S. cerevisiae strain showed equivalent xylose fermentation rate with both, the industrial or laboratory sources of xylose and nitrogen used in the medium.

Conclusion

In this study, we showed that recombinant industrial strains having different genetic backgrounds can be utilized for improvement in fermentation efficiency of the microorganism. The overexpression cassettes of the endogenous GRE3 gene and SUT1 were integrated into the genome using the short segment of the delta homology regions of the Ty1 retrotransposons to attain stable recombination. This is the first report on fermentation of xylose using glycerol as co-substrate by the recombinant industrial strain of S. cerevisiae. Cell recycle strategy and low cost industrial nutrients were utilized for xylitol production using the recombinant strain. The industrial strain showed ability to metabolise glycerol, which could be beneficial for the bio-refineries. Other advantages of using glycerol include, its low cost and formation of negligible byproducts, making glycerol a desirable co-substrate for the industrial fermentation and downstream processes. Our lab is currently working on developing the S. cerevisiae strain having higher rates of glycerol metabolism in the presence of inhibitors arising in the pre-treatment of biomass to avoid the detoxification process.

References

Almeida JRM, Modig T, Petersson A, Hahn-Hagerdal B, Liden G, Gorwa-Grauslund MF (2007) Increased tolerance and conversion of inhibitors in lignocellulosic hydrolysates by Saccharomyces cerevisiae. J Chem Technol Biotechnol 82:340–349

Amartey S, Jeffries TW (1994) Comparison of corn steep liquor with other nutrients in the fermentation of d-xylose by Pichia stipitis CBS 6054. Biotechnol Lett 16(2):211–214. doi:10.1007/BF0102167

Berg JM, Tymoczko JL, Stryer L (2002) The metabolism of glucose-6-phosphate by the pentose phosphate pathway is coordinated with glycolysis. Biochemistry, Section 20.4, 5th edn. W H Freeman, New York

Blomberg A, Adler L (1989) Roles of glycerol and glycerol-3-phosphate dehydrogenase (NAD+) in acquired osmotolerance of Saccharomyces cerevisiae. J Bacteriol 171(2):1087–1092

Borgne SL (2012) Genetic engineering of industrial strains of Saccharomyces cerevisiae. Recombinant gene expression: reviews and protocols, 3rd edn. Methods Mol Biol Springer 824:451–465. doi:10.1007/978-1-61779-433-9_24

Celton M, Goelzer A, Camarasa C, Fromion V, Dequin S (2012) A constraint-based model analysis of the metabolic consequences of increased NADPH oxidation in Saccharomyces cerevisiae. Metab Eng 14(4):366–379. doi:10.1016/j.ymben.2012.03.008

Choi JH, Moon KH, Ryu YW, Seo JH (2000) Production of xylitol in cell recycle fermentations of Candida tropicalis. Biotechnol Lett 22:1625–1628

De Mancilha IM, Karim MN (2003) Evaluation of ion exchange resins for removal of inhibitory compounds from corn stover hydrolyzate for xylitol fermentation. Biotechnol Prog 19(6):1837–1841

Dunn B, Richter C, Kvitek DJ, Pugh T, Sherlock G (2012) Analysis of the Saccharomyces cerevisiae pan-genome reveals a pool of copy number variants distributed in diverse yeast strains from differing industrial environments. Genome Res 22(5):908–924

Garay-Arroyo A, Covarrubias AA (1999) Three genes whose expression is induced by stress in Saccharomyces cerevisiae. Yeast 15:879–892

Hallborn J, Gorwa MF, Meinander N, Penttilä M, Keränen S, Hahn-Hägerdal B (1994) The influence of co-substrate and aeration on xylitol formation by recombinant Saccharomyces cerevisiae expressing the XYL1 gene. Appl Microbiol Biotechnol 42(2–3):326–333

Hamacher T, Becker J, Gardonyi M, Hahn-Hagerdal B, Boles B (2002) Characterization of the xylose-transporting properties of yeast hexose transporters and their influence on xylose utilization. Microbiology 148:2783–2788

Hector R, Mertens J, Bowman M, Nichols N, Cotta M, Hughes S (2011) Saccharomyces cerevisiae engineered for xylose metabolism requires gluconeogenesis and the oxidative branch of the pentose phosphate pathway for aerobic xylose assimilation. Yeast 28(9):645–660

Heer D, Heine D, Sauer U (2009) Resistance of Saccharomyces cerevisiae to high concentrations of furfural is based on NADPH-dependent reduction by at least two oxidoreductases. Appl Environ Microbiol 75:7631–7638. doi:10.1128/AEM.01649-09

Jeffries TW (1985) Effects of culture conditions on the fermentation of xylose to ethanol by Candida shehatae. Biotechnol Bioeng Symp 15:149–166

Karhumaa K, Hahn-Hägerdal B, Gorwa-Grauslund MF (2005) Investigation of limiting metabolic steps in the utilization of xylose by recombinant Saccharomyces cerevisiae using metabolic engineering. Yeast 22:359–368

Katahiraa S, Itoa M, Takemab H, Fujita Y, Taninob T, Tanakac T, Fukudac H, Kondo A (2008) Improvement of ethanol productivity during xylose and glucose co-fermentation by xylose-assimilating S. cerevisiae via expression of glucose transporter SUT1. Enzyme Microb Technol 43:115–119

Khattab S, Kodaki T (2014) Efficient bioethanol production by overexpression of endogenous Saccharomyces cerevisiae xylulokinase and NADPH-dependent aldose reductase with mutated strictly NADP+-dependent Pichia stipitis xylitol dehydrogenase. Process Biochem 49:1838–1842

Kim JM, Vanguri S, Boeke JD, Gabriel A, Voytas DF (1998) Transposable elements and genome organization: a comprehensive survey of retrotransposons revealed by the complete Saccharomyces cerevisiae genome sequence. Genome Res 8(5):464–478

Kim MD, Jeun YS, Kim SG, Ryu YW, Seo JH (2002) Comparison of xylitol production in recombinant Saccharomyces cerevisiae strains harboring XYL1 gene of Pichia stipitis and GRE3 gene of S. cerevisiae. Enzyme Microb Technol 31:862–866. doi:10.1016/S0141-0229(02)00192-8

Kogje A, Ghosalkar A (2016) Xylitol production by Saccharomyces cerevisiae overexpressing different xylose reductases using non-detoxified hemicellulosic hydrolysate of corncob. 3. Biotech 6(2):1–10. doi:10.1007/s13205-016-0444-4

Konishi J, Fukuda A, Mutaguchi K, Uemura T (2015) Xylose fermentation by Saccharomyces cerevisiae using endogenous xylose-assimilating genes. Biotechnol Lett 37:1623–1630. doi:10.1007/s10529-015-1840-2

Kuhn A, van Zyl C, Tonder AV, Prior BA (1995) Purification and partial characterization of an aldo-ketoreductase from Saccharomyces cerevisiae. Appl Environ Microbiol 61:1580–1585

Leathers TD (2003) Bioconversions of maize residues to value-added coproducts using yeast-like fungi. FEMS Yeast Res 3:133–140. doi:10.1016/S1567-1356(03)00003-5

Li M, Borodina I (2015) Application of synthetic biology for production of chemicals in yeast Saccharomyces cerevisiae. FEMS Yeast Res 15(1):1–12. doi:10.1111/1567-1364.12213

Lowry O, Rosenbrough N, Farr A, Randall R (1951) Protein measurement with the Folin phenol reagent. J Biol Chem 193(1):265–275

Mattam AJ, Clomburg JM, Gonzalez R, Yazdani SS (2013) Fermentation of glycerol and production of valuable chemical and biofuel molecules. Biotechnol Lett 35(6):831–842

Meinander NQ, Boels I, Hahn-Hägerdal B (1999) Fermentation of xylose/glucose mixtures by metabolically engineered Saccharomyces cerevisiae strains expressing XYL1 and XYL2 from Pichia stipitis with and without overexpression of TAL1. Bioresour Technol 68(1):79–87

Meinander NQ, Hahn-Hägerdal B (1997) Influence of cosubstrate concentration on xylose conversion by recombinant, XYL1-expressing Saccharomyces cerevisiae: a comparison of different sugars and ethanol as cosubstrates. Appl Environ Microbiol 63(5):1959–1964

Menon V, Prakash G, Rao M (2010) Value added products from hemicellulose: biotechnological perspective. Glob J Biochem 1:36–67

Merico A, Ragni E, Galafassi S, Popolo L, Compagno C (2011) Generation of an evolved Saccharomyces cerevisiae strain with a high freeze tolerance and an improved ability to grow on glycerol. J Ind Microbiol Biotechnol 38(8):1037–1044. doi:10.1007/s10295-010-0878-3

Mohamad NL, Mustapa Kamal SM, Mokhtar MN (2015) Xylitol biological production: a review of recent studies. Food Rev Int 31(1):74–89. doi:10.1080/87559129.2014.961077

Nevoigt E, Stahl U, Van Z (1989) Osmoregulation and glycerol metabolism in the yeast Saccharomyces cerevisiae. FEMS Microbiol Rev 21(3):231–241

Nielsen J, Fussenegger M, Keasling J, Lee SY, Liao JC, Prather K, Palssonnature B (2014) Engineering synergy in biotechnology. Nat Chem Biol 10:319–322. doi:10.1038/nchembio.1519

Ochoa-Estopier A, Lesage J, Gorret N, Guillouet SE (2011) Kinetic analysis of a Saccharomyces cerevisiae strain adapted for improved growth on glycerol: implications for the development of yeast bioprocesses on glycerol. Bioresour Technol 102:1521–1527. doi:10.1016/j.biortech.2010.08.003

Pal S, Joy S, Kumbhar P, Trimukhe KD, Varma AJ, Padmanabhan S (2016) Effect of mixed acid catalysis on pretreatment and enzymatic digestibility of sugar cane bagasse. Energy Fuels 30(9):7310–7318

Parekh RN, Shaw MR, Wittrup KD (1996) An integrating vector for tunable, high copy, stable integration into the dispersed Ty δ sites of Saccharomyces cerevisiae. Biotechnol Prog 12:16–21

Raj AE, Kumar HS, Kumar SU, Misra MC, Ghildyal NP, Karanth NG (2002) High cell density fermentation of recombinant Saccharomyces cerevisiae using glycerol. Biotechnol Prog 18(5):1130–1132

Schwartz K, Wenger JW, Dunn B, Sherlock G (2012) APJ1 and GRE3 homologs work in concert to allow growth in xylose in a natural Saccharomyces sensu stricto hybrid yeast. Genetics 191:621–632. doi:10.1534/genetics.112.140053

Spencer JFT, Spencer DM (1983) Genetic improvement of industrial yeasts. Annu Rev Microbiol 37:121–142. doi:10.1146/annurev.mi.37.100183.001005

Swinnen S, Ho PW, Klein M, Nevoigt E (2016) Genetic determinants for enhanced glycerol growth of Saccharomyces cerevisiae. Metab Eng 36:68–79. doi:10.1016/j.ymben.2016.03.003

Swinnen S, Klein M, Carrillo M, McInnes J, Nguyen HT, Nevoigt E (2013) Re-evaluation of glycerol utilization in Saccharomyces cerevisiae: characterization of an isolate that grows on glycerol without supporting supplements. Biotechnol Biofuels 6(1):1

Van Zyl C, Prior BA, Kilian SG, Kock JL (1989) d-Xylose utilization by Saccharomyces cerevisiae. Microbiology 135(11):2791–2798

Verduyn C, Van Kleef R, Frank J, Schreuder H, Van Dijken J, Scheffers W (1985) Properties of the NAD(P)H-dependent xylose reductase from the xylose fermenting yeast Pichia stipitis. Biochem J 226(3):669–677

Walther T, Hensirisak P, Agblevor FA (2001) The influence of aeration and hemicellulosic sugars on xylitol production by Candida tropicalis. Bioresour Technol 76:213–220

Weierstall T, Hollenberg CP, Boles E (1999) Cloning and characterization of three genes (SUT1–3) encoding glucose transporters of the yeast Pichia stipitis. Mol Microbiol 31(3):871–883

Zaldivar J, Borges A, Johansson B, Smits H, Villas-Bôas S, Nielsen J, Olsson L (2002) Fermentation performance and intracellular metabolite patterns in laboratory and industrial xylose-fermenting Saccharomyces cerevisiae. Appl Microbiol Biotechnol 59:436–442

Zha J, Li B-Z, Shen M-H, Hu M-L, Song H, Yuan Y-J (2013) Optimization of CDT-1 and XYL1 expression for balanced co-production of ethanol and xylitol from cellobiose and xylose by engineered Saccharomyces cerevisiae. PLoS One 8(7):e68317. doi:10.1371/journal.pone.0068317

Zhang J, Zhang B, Wang D, Gao X, Hong J (2013) Xylitol production at high temperature by engineered Kluyveromyces marxianus. Bioresour Technol 152:192–201. doi:10.1016/j.biortech.2013.10.109

Acknowledgements

This work was funded by Praj Industries Ltd. We would like to thank Prof. J. Thevelein (VIB, Belgium) for his kind gift of the vector pJET1.2KanMXP. We also thank the Analytical Sciences Team at Praj Matrix for the support in analysis of metabolites during the study.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Ethical approval

This article does not contain any studies with human participants or animals performed by any of the authors.

Informed consent

Informed consent was obtained from all individual participants included in the study.

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Kogje, A.B., Ghosalkar, A. Xylitol production by genetically modified industrial strain of Saccharomyces cerevisiae using glycerol as co-substrate. J Ind Microbiol Biotechnol 44, 961–971 (2017). https://doi.org/10.1007/s10295-017-1914-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10295-017-1914-3