Abstract

The application of macroalgae for food and feed has been increasing continuously due to their nutritional and health-promoting properties. Efficient post-harvest drying is needed to remove moisture content from macroalgal biomass without negatively affecting its nutritional value. We hypothesized that low-temperature oven drying would preserve most of the nutrients and polyphenols in macroalgae. The polyphenol-rich brown macroalga, Fucus vesiculosus, was exposed to one of the following treatments: freeze-drying (FD; for 72 h), oven drying at 40 ℃ (OD40; for 24 h), and oven drying at 80 ℃ (OD80; for 24 h). The concentration of total fatty acids and the sum of saturated, mono-, and polyunsaturated fatty acids exhibited a decreasing trend with higher drying temperatures (FD > OD40 > OD80), indicating the sensitivity of fatty acids to a high drying temperature. However, the sum of total or essential amino acids was significantly higher (p < 0.05) in OD80 compared to OD40 and FD biomass. In this study, the average N-protein-conversion factor for dried F. vesiculosus remained relatively stable (~ 4.64) across drying treatments. The total polyphenol content remained unaffected by the drying treatment, although it tended to decrease with increasing drying temperature. Targeted metabolomics revealed three classes of phenolic compounds: phenylpropanoids, flavones, and flavonols. A low-temperature oven drying appears to be a suitable method to preserve nutrients and polyphenols in brown macroalgae. Future studies are needed to evaluate the impact of drying methods on other bioactive compounds and to understand the economic sustainability of oven drying.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

The global cultivation of macroalgae, also called seaweeds, is consistently increasing, driven by its diverse applications such as food, animal feed, fertilizer, biogas, and cosmetics (Araújo et al. 2021). Macroalgae are perceived as a valuable resource for human and animal nutrition due to the presence of basic nutrients and other health-promoting ingredients such as dietary fiber, polyunsaturated fatty acids (PUFAs), vitamins and minerals, and secondary bioactive metabolites, including polyphenols (Holdt and Kraan 2011; Morais et al. 2020). Moreover, macroalgae do not require freshwater to grow and can be cultivated sustainably with a low carbon footprint (Duarte et al. 2022). Hence, the use of macroalgae as food and feed may improve food security and enhance environmental sustainability in the future. However, the fresh macroalgae biomass contains high levels of moisture making it highly perishable and quick to deteriorate after harvesting. Thus, fresh biomass needs stabilizing before further application of macroalgae. Drying is the most widely used post-harvest method for stabilizing macroalgae, as it removes moisture, reduces the weight and volume of biomass, thereby minimizing storage space and transportation costs and also effectively inhibits microbial growth, (Tello-Ireland et al. 2011). It is thus important to evaluate how post-harvest stabilization, particularly different drying methods, influences the concentration or properties of key nutritional components and bioactive compounds in macroalgae biomass (Stévant et al. 2018).

Various drying methods, such as sun-drying, oven-drying, freeze-drying, vacuum-drying, etc., can be used to remove moisture from harvested macroalgae (Kadam et al. 2015; Ling et al. 2015). Each drying method possesses unique advantages and bottlenecks regarding cost, duration, and effects on the nutritional and physiochemical attributes of dried biomass, necessitating careful evaluation when selecting a particular drying method (Cruces et al. 2016; Stramarkou et al. 2017). For example, sun drying is the cheapest and least energy-intensive method. However, macroalgal biomass dried using this method is highly susceptible to airborne contamination, UV radiation, oxidation, and unpredicted weather conditions (Fudholi et al. 2014; Ringeisen et al. 2014) that could affect the quality of the final product. On the other hand, freeze-drying can protect against the degradation of heat-sensitive essential nutrients and secondary bioactive compounds in the dried products (Kandasamy and Naveen 2022). Unlike other drying methods that rely on heat, freeze-drying works with the principle of sublimation, a way of dehydrating frozen biomass via a process that transforms ice into vapor. For example, the freeze-dried brown macroalga, Sargassum hemiphyllum, exhibited higher levels of total amino acids, total polyunsaturated fatty acids, and total vitamin C compared to sun-dried and oven-dried samples (Chan et al. 1997). However, freeze-drying has higher production costs than other methods due to higher energy consumption and longer processing time (Ratti 2001; Hsu et al. 2003;, limiting its industrial application. Post-harvest drying of macroalgal biomass, particularly through freeze-drying followed by oven drying, has also been identified as the primary contributor to the carbon footprint that could reduce the sustainability of the seaweed supply chain (van Oirschot et al. 2017; Koesling et al. 2021; Thomas et al. 2021), highlighting the need for low-temperature oven drying.

Oven drying is one of the most common drying techniques that can efficiently and quickly remove moisture content from macroalgae. However, it is crucial to use the appropriate oven drying temperature to dry macroalgal biomass, considering both the quality of the dried biomass and energy consumption. The use of high temperatures over extended durations during oven drying can adversely affect the content and activity of heat-sensitive bioactive compounds and nutrients (Kadam et al. 2015). Drying seaweed at low temperatures (< 45 °C) has been shown to preserve bioactive compounds (Moreira et al. 2016). For instance, the total polyphenol content (TPC) and its antioxidant activity in Fucus vesiculosus extracts decreased with increasing drying temperatures (35 > 40 > 60 > 75 °C) (Moreira et al. 2016). In contrast, Gupta et al. (2011) found that drying edible Irish brown macroalga, Himanthalia elongata, for 24 h at 25 °C resulted in a 49% reduction in TPC and a 51% reduction in total flavonoid content, however, the reduction declined at the drying temperature of 40 °C. Fucus vesiculosus, one of the brown macroalgae species that is commonly available on the Norwegian sea coast, is rich in various nutritional and phenolic compounds (Catarino et al. 2018; Obluchinskaya et al. 2022). While a few studies have examined the impact of oven-drying temperatures on the product quality (coloration and pigmentation) of F. vesiculosus (Silva et al. 2019), there has been limited research on how different oven-drying temperatures affect both the nutritional and phenolic compounds of whole F. vesiculosus biomass, as well as the potential consequences on nutrient digestibility. This knowledge is important because previous studies show that post-harvesting processing can influence the nutritional composition, in vitro organic matter, and crude protein digestibility of brown macroalgae (Pandey et al. 2023). Thus, we hypothesized that a low-temperature oven-drying would preserve most of the nutrients and polyphenols in the brown macroalga, F. vesiculosus.

Materials and methods

Seaweed sampling

The fresh macroalga, F. vesiculosus, used in this study was harvested manually during low tides from the upper intertidal zone near Hoøya, Steinkjer, Trøndelag, Norway (coordinates 64°01′12.4" N 11°22′16.7" E) on 23 September 2021. After harvesting, the fresh biomass was first washed with seawater to remove any possible phytoplankton, mollusks, and sand. Then, the algal samples were transported to the laboratory of Nord University, Steinkjer, Norway (within an hour) and washed thoroughly three times with fresh water to remove the remaining impurities. Then, the washed biomass samples were subjected to three different drying treatments, as described below.

Drying treatments

After draining the excess water, F. vesiculosus biomass was exposed to three different drying treatments: freeze drying (FD), oven-drying at 40 ℃ for 24 h (OD40), and oven-drying at 80 ℃ for 24 h (OD80). Freeze drying of F. vesiculosus biomass was performed using a laboratory freeze dryer (Labconco, USA) at -50 ℃ (< 0.4 mbar vacuum pressure) for 72 h. For oven drying, ~ 300 g of the algal biomass was placed in a perforated aluminum tray and dried in a laboratory drying oven for 24 h by setting the speed of the air valve fan to 10 (Termaks AS, Norway). Then, all dried samples were ground to a particle size of 2 mm using a cutter mill (CT Cyclotex TM 193 TM, FOSS, Denmark), which were later subjected to chemical analyses. Drying and further chemical analyses of F. vesiculosus biomass were carried out in triplicates (n = 3).

Chemical analysis

The dry matter (DM), organic matter (OM), ash, and protein contents of the samples were analyzed through gravimetric methods following the guidelines of the Association of Official Analytical Chemists (AOAC), with adjustments based on Horwitz (2010). Dry matter was calculated by desiccating the ground algal powder (2 to 3 g) from each drying treatment at 105 °C for 24 h. The ash content was determined by weighing the residual material post-incineration of samples at 530 °C overnight, while the organic matter was calculated as the dry matter weight minus the ash weight in the dry matter. Nitrogen content (N) was quantified using the Kjeldahl method (Kjeltec 8400, FOSS, Denmark), crude protein (CP) content was calculated using a conversion factor of the common Jone’s factor 6.25, and true protein (TP) was calculated using a specific N-protein conversion factor (Kp) based on the amino acid. Average Kp values were calculated from the ratio of the sum of AA residue (anhydrous or water-corrected AA) to total nitrogen content as calculated by Janssen et al. (2017). Neutral detergent fiber (NDF) was analyzed using the filter bag technique (Ankom200 Fiber Analyzer, USA) with a neutral detergent solution, heat-stable alpha-amylase (Ankom Technology, USA), and sodium sulfite (Ankom Technology). Crude fat content was assessed through extraction with a mixture of 80% petroleum ether and 20% acetone using an Accelerated Solvent Extractor (ASE200; Dionex, USA) as described previously (Pandey et al. 2023). The gross energy content of the samples was determined using a PARR 6400 Bomb Calorimeter (Parr Instruments, USA).

In vitro organic matter digestibility in monogastric animals

In vitro fecal digestibility of the organic matter (OM) was analyzed following a procedure described by Boisen and Fernández (1997). Briefly, a three-step incubation procedure was followed, where samples were incubated at 39 °C with pepsin (porcine, 2000 FIP U g−1) for 75 min and subsequently with pancreatin solution containing 50 mg pancreatin (Porcine, grade IV, Sigma -1750) for 3.5 h. Then, samples were mixed with EDTA solution followed by a mixed multi-enzymatic complex comprised of arabinase, cellulase, β-glucanase, hemicellulase, xylanase, and pectinase (Viscozyme L, Sigma-Aldrich V2010). After washing with ethanol and acetone, the undigested materials were dried at 105 °C overnight and weighed for DM. Finally, dried samples were incinerated in a muffle furnace at 500 °C for 3 h and OM content was calculated. The in vitro total tract digestibility of OM was calculated by the difference between the OM of the initial samples and the undigested residue after correction for the blank.

Fatty acids composition

The modified method for analyzing fatty acid (FA) composition was used as described by O'Fallon et al. (2007). Initially, 0.3 g dry alga sample was weighed directly into test tubes and then methanol (MeOH) was added in a scaled volume of 4.25 mL. The next step involved the addition of the internal standard (C13:0) with a concentration of 0.5 mL. Following this, 10 N KOH was introduced (0.56 mL) and the tubes were vigorously shaken on a vortex mixer for 1 min before being placed in a water bath at 55 °C for 1.5 h. Throughout the incubation, the tubes underwent periodic vigorous shaking 5 times every 20 min. Subsequently, the tubes were cooled, and 24 N H2SO4 (0.465 mL) was added. The final steps involve cooling, the addition of heptane (2.4 mL), shaking for at least 1.5 min on a vortex mixer, and centrifugation for 5 min at room temperature at 1600 × g. Then about 1.5 mL of the heptane layer was carefully transferred to 2 mL gas chromatography (GC) vials with lids. Finally, the fatty acid composition was analyzed in a Trace GC Ultra system with an auto-injector (Thermo Scientific) using an Rt-2560 GC Capillary Column, 100 m, 0.25 mm ID, 0.20 um df (RESTEK, Cat # 13,198), and the Chromeleon Chromatography Management Software (Dionex Ltd, UK).

Amino acids composition

The amino acids (AA) contents were analyzed according to Commission Regulation (EC) No 152/2009 (Commission 2009). The concentrations of AA in dried macroalga samples were analyzed by ion-exchange chromatography on a lithium high-performance column (Biochrom Ltd, UK) in an automated AA analyzer (Biochrom 30, Biochrom Ltd), using lithium-based eluents and post-column derivatization with ninhydrin (Physiological Fluid Chemical Kit, Biochrom Ltd). Quantification of eighteen standard amino acids was performed based on standard curves established using amino acid standard (Pickering Laboratories, USA) and the Chromeleon Chromatography Management Software (Dionex Ltd).

Total polyphenol extraction and quantification

Total polyphenol was determined following the method by Pandey et al. (2022). Initially, 1 g of dried macroalga was mixed with a 1:1 (v/v) mixture of methanol and water (MeOH–water) in a 50 mL tube. The pH of the mixture was adjusted to ∼ 2, and the tube was shaken (VWR Advanced Digital Shaker, VWR International LLC, USA) for 2 h at 200 rpm at room temperature. After this, the tube was centrifuged at 12,000 × g for 10 min and the liquid portion (supernatant) was collected. The residue was further treated with a 7:3 mixture of acetone and water, followed by another round of shaking and centrifugation with the same configuration. Then, supernatants were pooled, and filtered (Whatman TM Grade 597 ½ Qualitative Folded Filter Paper, cytiva, Europe GmbH, Germany), and the extract was stored overnight at -20 °C for quantification.

For quantification of TPC in the pooled extract, 50 mg phloroglucinol (calculated as anhydrous) was dissolved in 100 mL distilled water and used as a stock solution (500 μg mL−1) to make serial dilutions and obtain the standard solution at the concentration of 500, 250, 125, 62.5, 31.25, 15.625 and 0 μg mL−1. The algal extract was then diluted 10 times (1:10) in distilled water. In the analysis, both sample solutions and standard solutions were loaded into a 96-well microplate in triplicates. Subsequently, 100 µL of Folin-Ciocalteu reagent was added to each well, followed by the addition of 80 µL of a 7.5% sodium carbonate solution. The microplate was covered and kept in a dark room for 2 h to allow the reactions to occur. After this incubation period, the absorbance of the mixture was measured at a wavelength of 750 nm using a spectrophotometric microplate reader (BIO-RAD, iMark Microplate Reader, USA). The mean TPC was calculated in milligram of phloroglucinol equivalents (mg PGE) per g of DM using the provided formula.

Formula to calculate the TPC:

where, Mean TPC = average of the total polyphenol concentrations of triplicate samples obtained from the calibration curve, SV = volume of solvent used for extraction, and DF = dilution factor of the original extract during the quantification assay.

Polyphenols profiling using targeted metabolomics

The quantification of the multiple classes of phenolics in the dried F. vesiculosus samples was analyzed using the method described by Vrhovsek et al. (2012). Briefly, 2 g of dried alga powder was mixed with 5 mL of a water/methanol/chloroform mixture (20:40:40), followed by vortexing for 1 min. The samples were then subjected to orbital shaking for 15 min at room temperature. Subsequently, centrifugation at 1000 × g and 4 °C for 10 min separated the upper phase, constituting the aqueous methanol extract. This extract was filtered through a 0.2 μm PTFE (polytetrafluoroethylene) membrane filter before analysis using ultraperformance liquid chromatography coupled with mass spectrometry (UPLC/QqQ-MS). For setting up the UPLC/QqQ-MS instrument, method validation, and preparation of internal standard stock solutions, the specifications and protocol outlined by Vrhovsek et al. (2012) were used.

Statistical analysis

One-way Analysis of Variance (ANOVA) and Tukey’s Honestly Significant Difference (HSD) tests were performed using R Statistical Software (The R Foundation for Statistical Computing, v4.3.3; R Core Team 2021) to investigate potential differences in measured parameters across three distinct drying treatments. The chosen level of significance was established at p < 0.05. All data are presented as mean ± standard deviation (n = 3) unless otherwise stated. Principal Component Analysis (PCA) was conducted to explore patterns in amino acid and fatty acid concentrations under three drying treatments using the PCA function from the FactoMineR package (Lê et al. 2008). Data were centered and scaled to unit variance. The variance explained by the first two principal components (PC1 and PC2) was calculated using the get_eigenvalue function from the factoextra package (Kassambara 2016). A PCA biplot, displaying both the measured variables and individual observations, was generated with the fviz_pca_biplot function from the factoextra package. To evaluate the relationship between the studied parameters (of all treatments) of major nutrients (Ash, Total FA, Total AA, TPC, CF, CP) and in vitro total tract organic matter digestibility, a Pearson correlation matrix was created using Corrplot package in R.

Results

Proximate composition

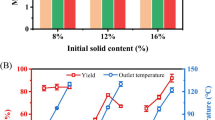

To identify the effects of different drying methods on basic macroalgal nutrients, we performed the proximate composition analyses of F. vesiculosus biomass exposed to three different drying treatments (Table 1). Oven drying at 80 °C (OD80) and FD demonstrated significantly higher concentrations of DM (p < 0.05), CP, and TP (% DM, p < 0.05) compared to the biomass exposed to OD40. A slight but significant lower in the N content (p < 0.05) was observed, with the N content being lower in OD40 samples compared to FD and OD80 samples. CP and TP were found to be lower (p < 0.05) in samples that dried at OD40 compared to those samples dried at OD80 and FD. The calculated average Kp was approximately 4.64 in F. vesiculosus, regardless of the drying treatments. An approximately 26 to 27% lower true protein content compared to CP, using a conversion factor of 6.25, was noted for all drying techniques. Crude fat content was reduced by twofold in samples exposed to OD40 (~ 2.1% DM) and OD80 (~ 2.3% DM) compared to the samples exposed to FD (~ 4.6% DM). OD40 led to a significantly lower concentration (~ 33% DM) of neutral detergent fiber (NDF) compared to FD (~ 42.2% DM). Neither the ash and the OM content nor the gross energy value of F. vesiculosus was significantly affected by any of the drying treatments, although ash and OM content tended to be slightly higher in OD80 compared to the other drying methods. The in vitro total tract organic matter digestibility of the dried F. vesiculosus was not affected by the drying treatments (p = 0.305; Fig. 1).

Effect of different drying treatments on the in vitro total tract organic matter digestibility of F. vesiculosus. Data are presented as mean ± standard deviation. FD, freeze drying (-50 ℃, 72 h, < 0.4 mbar); OD40, oven drying at 40 ℃ for 24 h; OD80, oven drying at 80 ℃ for 24 h; DM, dry matter; OM, organic matter; OMD, organic matter digestibility

Fatty acid composition

A total of 23 fatty acids were identified in F. vesiculosus: eight saturated fatty acids (SFA), six monounsaturated fatty acids (MUFA), and nine polyunsaturated fatty acids (PUFA) (Table 2). The total fatty acid content tended to be lower (p = 0.063) with an increase in the drying temperature. Myristic acid (C14:0), palmitic acid (C16:0), behenic acid (C22:0), cis-oleic acid (C18:1n9c), and linoleic acid (C18:2n6c) were the main fatty acids found, regardless of the method employed. The PCA-biplot showed the distribution of fatty acids among the three drying treatments (Fig. 2), with FD and OD40 showing similar fatty acid profiles, while OD80 exhibits a distinct pattern. The first two principal components PC1 and PC2 explained 71.35% and 28.65% of the total variance, respectively (Fig. 2).

PCA-biplot showing the fatty acids composition of F. vesiculosus exposed to three different drying methods. Data were centered and scaled to unit variance. The variance explained by the first two principal components (PC1 and PC2) was calculated using the get_eigenvalue function from the factoextra package. A PCA biplot, displaying both fatty acid variables and individual observations (FD, OD40, and OD80), was generated with the fviz_pca_biplot function from the factoextra package

Saturated fatty acids (SFA): Regardless of the drying treatment, the concentration of total SFA remained unaffected but a decreasing trend (p = 0.084) was observed with higher temperatures, resulting in a lower concentration of total SFA in OD80 (~ 27.6 g kg−1 DM) compared to OD40 (~ 29.4 g kg−1 DM) and FD (~ 31.6 g kg−1 DM). However, the composition of saturated fatty acids (SFA) was not significantly affected by the heat treatments except for behenic acid (C22:0). The concentration of behenic acid was significantly lower in OD80 (~ 6.9 g kg−1 DM) compared to FD (~ 8.2 g kg−1 DM) (p = 0.030) however no significant difference (p > 0.05) was observed between OD40 and FD.

Monosaturated fatty acids (MUFA): Except for cis-oleic acid (C18:1n9c), the composition of MUFA was also not altered by drying treatments. A significant difference was evident in the concentration of cis-oleic acid (C18:1n9c), with a 20% lower concentration observed after OD80 (~ 24.3 g kg−1 DM) compared to FD (~ 30.0 g kg−1 DM), while no significant differences were noted between OD40 and FD. Similarly, a comparable decrease in total MUFA concentration was noted. Specifically, the concentration after OD80 (~ 25.4 g kg−1 DM) was significantly lower (p = 0.046) than after FD (~ 31.2 g kg−1 DM), furthermore, no statistical difference was observed between OD40 and FD.

Polyunsaturated fatty acids (PUFA): Although the drying treatments did not significantly impact the concentration of total PUFA, a declining trend (p = 0.076) was evident with increasing temperature compared to FD. Compared to SFA and MUFA, more pronounced effects of drying treatments were observed in PUFA, where the concentration of four out of nine PUFAs was significantly influenced by the drying treatments. Oven drying at 80 ℃ (OD80) exhibited significantly lower concentrations of arachidonic acid (C20:4n6) and eicosapentaenoic acid (C20:5n3) compared to FD. In contrast, cis-11,14-eicosadienoic acid (C20:2) and cis-13,16-docasadienoic acid (C22:2) remained unaffected by either OD80 or FD. When comparing OD40 with FD, the concentration of cis-13,16-docasadienoic acid (C22:2) was significantly diminished in OD40 (~ 0.060 g kg−1 DM) compared to FD (~ 0.070 g kg−1 DM), despite being negligible in both cases. No differences were noted between OD40 and OD80.

Amino acid composition

The composition of amino acids analysis is displayed in Table 3. Aspartic acid, glutamic acid, and leucine were the major amino acids that were abundant in F. vesiculosus regardless of the drying methods. The sum of all amino acids analyzed ranged from ~ 36.5 to ~ 41.6 g kg−1 DM and was affected by the drying treatments where the total concentration was higher (p = 0.017) for OD80 than at OD40, however, no significant differences were observed when compared with FD. The PCA-biplot showed the distribution of amino acids among the three drying treatments (Fig. 3), with FD and OD80 showing similar amino acid profiles, while OD40 exhibits a distinct pattern. The first two principal components PC1 and PC2 explained 85.87% and 14.13% of the total variance, respectively (Fig. 3). None of the drying treatments affected the ratio of essential amino acid (EAA) to non-essential amino acid (NEAA) (p > 0.05).

PCA-biplot showing the amino acids composition of F. vesiculosus exposed to three different drying methods. Data were centered and scaled to unit variance. The variance explained by the first two principal components (PC1 and PC2) was calculated using the get_eigenvalue function from the factoextra package. A PCA biplot, displaying both amino acid variables and individual observations (FD, OD40, and OD80), was generated with the fviz_pca_biplot function from the factoextra package

Essential amino acid (EAA): Out of the nine EAAs studied, six showed significant changes due to the drying treatments. Overall, there were no noticeable differences between oven-dried samples (both OD40 and OD80) and freeze-dried (FD) samples. However, the concentration of EAAs was significantly higher in OD80 compared to OD40 for all the EAAs affected. This trend was consistent for total EAAs, with higher sums observed in OD80 (~ 17.3 g kg−1, DM) compared to OD40 (~ 15.1 g kg−1, DM), while no significant difference was observed compared to FD (~ 16.3 g kg−1 DM).

Non-essential amino acid (NEAA): The drying treatments affected four out of nine NEAAs. Briefly, aspartic acid and cystine levels were significantly lower in samples subjected to OD40 compared to FD samples and OD80. Moreover, the concentration of aspartic acid, glutamic acid, cysteine, and tyrosine levels subjected to OD40 was significantly lower than those subjected to OD80. No significant differences were observed in the levels of glutamic acid and tyrosine between oven-dried (OD40 and OD80) and freeze-dried samples. Similar to EAAs, the concentrations of NEAAs were significantly higher in OD80 compared to those dried at OD40, while no significant difference was observed between samples subjected to OD80 and FD.

Polyphenol and phenolic compounds

The concentration of the TPC and different phenolic compounds is displayed in Table 4. No significant difference was observed in TPC, but the tendency (p = 0.084) showed that its concentration decreases with an increase in drying temperature (~ 79.8 mg PGE g−1 DM, ~ 77.8 mg PGE g−1 DM, and ~ 69.9 mg PGE g−1 DM, respectively for FD, OD40, and OD80). Targeted metabolomics revealed phenolic compounds that fall into three different classes, i.e. phenylpropanoids, flavones, and flavonoles. Most of these phenolic compounds were retained when drying the macroalga using a freeze dryer. The caftaric acid was found to be significantly lower in OD40 (~ 0.24 mg kg−1) and OD80 (~ 0.17 mg kg−1) samples compared to FD (~ 0.40 mg kg−1) samples.

Correlation between the chemical composition and in vitro OM digestibility

The Pearson correlation matrix showed that the in vitro total tract organic matter digestibility (OMD) was negatively correlated with the TPC content (r =-0.78, p = 0.014) (Fig. 4). Although the crude fat content (r =-0.4, p > 0.05) and NDF (r =-0.15, p > 0.05) were inversely correlated with the organic matter digestibility, the effect was found to be insignificant. The OMD was positively correlated with CP (r = 0.23, p > 0.05) and total amino acid content (r = 0.34, p > 0.05) but the effects were not significant.

Correlation matrix showing the relationship between the selective main nutrients and the in vitro organic matter digestibility of dried F. vesiculosus. OMD, organic matter digestibility; CP, crude protein; AA, amino acids; CF, crude fat; NDF, neutral detergent fiber; FA, fatty acids; TPC, total polyphenol content

Discussion

We hypothesized that a low-temperature oven-drying following harvesting would preserve nutritional and phenolic compounds of F. vesiculosus while aiming for animal feed applications. The major findings of the present study were that: a) oven drying of F. vesiculosus at low or high temperatures differentially affects its nutritional composition; b) high drying temperature reduces total polyphenol and specific phenolic compounds in F. vesiculosus; and c) in vitro total tract OM digestibility of F. vesiculosus remains stable regardless of the drying treatments. In this study, the oven drying method (at low and high temperatures) was evaluated because this can be a cheaper and commercially more feasible drying option along with the advantages of shorter drying duration and low energy consumption compared to the freeze-drying technique (Zhang et al. 2010).

As high investment and operating costs are associated mainly with stabilizing and processing freshly harvested biomass, it is crucial to identify efficient strategies to reduce these financial barriers for the sustainability of the industry (Stévant and Rebours 2021). From the industrial perspective, freeze-drying and oven/cabinet drying have been more common than other stabilization methods in recent years. While entirely avoiding these two drying techniques is not feasible in the industry, both methods should incorporate bioenergy heat sources to mitigate overall environmental impacts from a life cycle perspective (Fridahl and Lehtveer 2018). Therefore, establishing standard strategies for the post-harvest processing of seaweed biomass, including large-scale drying methods, is necessary to produce various seaweed-based food and feed products.

Oven drying of F. vesiculosus at low or high temperatures differentially affects its nutritional composition

Preserving the nutritional and bioactive compounds of macroalgae is important for applications such as animal feed ingredients. Freeze drying is found to preserve the highest levels of nutrients and bioactive compounds in harvested macroalgae biomass (Subbiah et al. 2023). The low temperature and reduced oxygen level during freeze-drying prevent oxidation and minimize damage to cellular integrity, thereby helping retain nutrients in the dried products (Wong and Cheung 2001; Ullah et al. 2023). However, practical challenges associated with freeze drying such as technical requirements, high energy consumption, and increased operating costs make it difficult to implement at a commercial level, especially for large quantities of macroalgal biomass with an extremely high moisture content (Badmus et al. 2019). Thus, this study explored the possibility of preserving both nutrients and phenolic compounds in a polyphenol-rich brown macroalga, F. vesiculosus, through post-harvest oven drying at low and high temperatures.

Although the fat content in macroalgae is relatively low compared to terrestrial plants such as soy and sunflower (Swarnalatha 2018), the proportion of essential fatty acids and functional lipid fractions, namely omega-3 and omega-6 fatty acids is generally high in macroalgae (Hamid et al. 2015). A higher concentration of total unsaturated fatty acids (MUFA and PUFA) over total SFA in this study is in accordance with a previous study on green and brown macroalgae by Ortiz et al. (2006). In this study, both oven drying at 40 ℃ and 80 ℃ negatively affected the concentration of most of the total fatty acids, a low-temperature oven drying was found to be suitable for preserving specific fatty acids. In particular behenic acid, oleic acid, arachidonic acid, and eicosapentaenoic acid were preserved to a greater extent by applying a low-temperature oven drying (40 ℃). Saturated fatty acids appear to be more stable with heat treatment as the total SFA concentration was not significantly different between the drying treatments, which is in agreement with a previous study on F. serratus by Badmus et al. (2019). During thermal processing, greater unsaturation of fatty acids leads to more oxidative degradation in plants (Cao et al. 2014). This aligns with our findings, where the concentration of oleic acid, arachidonic and eicosapentaenoic acids, and total MUFA were particularly reduced by high-temperature oven drying (80 °C). Specifically, the total MUFA concentration of F. vesiculosus in this study was decreased by up to 19% during high-temperature oven drying compared to freeze drying, corroborating the results of Badmus et al. (2019) observed in F. serratus and F. spiralis. Hence, the drying temperature stands out as a critical factor impacting lipid oxidation thus reducing the lipid concentration in the dried macroalgae. Freezing the macroalgae samples during storage (-20 °C) and a low-temperature and oxygen level in the freeze-drying process have been found to lead to less lipid oxidation compared to other drying methods (Schmid et al. 2016). Overall, both oven-drying (at 40 ℃ and 80 ℃) treatments reduced crude fat contents of dried F. vesiculosus compared to freeze-drying, which could be related to the heat input mechanisms and prolonged exposure to high temperatures, causing lipid oxidation (Wells et al. 2017). Nevertheless, low-temperature oven drying (40 ℃) appears to be a favorable drying method when considering the concentration of health-promoting unsaturated fatty acids such as MUFAs and PUFAs.

Due to the presence of a considerable amount of non-protein nitrogen (NPN) and free amino acid present in the seaweed, the use of 6.25 as a N-to-protein conversion factor leads to an overestimation of their actual protein content (Diniz et al. 2011; Shuuluka et al. 2013; Janssen et al. 2017). Therefore, an accurate assessment of the true protein content requires a species-specific correction factor that includes total amino acid analyses and the independent determination of total N (Diniz et al. 2011). In this study, regardless of drying treatment, the N-to-protein conversion factor for F. vesiculosus was found to be relatively stable (~ 4.64). This conversion factor is slightly higher than the previously reported N-to-protein conversion factor of ~ 4.30 in the same species by Biancarosa et al. (2017), and lower than the proposed conversion value of 5 by Angell et al. (2016). These differences could be associated with potential differences in geographical location and different harvesting times between the studies.

Our data suggest that drying F. vesiculosus biomass at a high temperature (80 °C) is as effective as freeze-drying (72 h) for preserving major nutrients. In fact, the protein and total amino acid content were higher in the samples dried at high temperatures (80 ℃) compared to low temperatures (40 ℃), indicating the possibility of higher protein extractability at a high drying temperature. The macroalgal cell wall comprises polysaccharides that form a matrix with proteins, lipids, and other nutrients. The thermal applications result in a weakening of this complex structure facilitating the release of bound protein (Meade et al. 2005; Sharma et al. 2012). According to current findings, the high concentration of amino acids by oven drying at high drying temperatures supports the above reasoning on the release of protein by heat treatment. Similarly, most other nutrients were depleted or lost at high drying temperatures and the amino acid concentration thus increased. In addition, Duan et al. (2014) suggested that temperatures between 60 and 120 °C can inhibit enzyme activity, preventing protein destruction, which could improve the amino acid content in dried naked oats. Furthermore, the formation of polyphenol-protein complexes also results in the variable content of protein and amino acids (Wong and Cheung 2001; Harnedy and FitzGerald 2013). In our study, a negative correlation of the crude protein (r =-0.51) and total amino acid (r =-0.57) with the TPC was evident, supporting the previous finding by Wong and Cheung (2001) in other brown species. The higher CP content observed in this study with high-temperature oven drying (80°C) might be attributed to the lower concentration of total phenolic compounds (TPC) compared to samples dried at a lower temperature (40°C). Overall, exposing F. vesiculosus biomass to 40 °C temperature after harvesting can help preserve heat-sensitive fatty acids, whereas for certain nutrients such as protein and amino acids, a high temperature (80 °C) could be a more effective strategy.

High temperature reduces TPC and specific phenolic compounds in F. vesiculosus

Macroalgae, in particular brown algae, are rich in various bioactive compounds mainly polyphenols that have health-promoting and anti-methanogenic properties (Vissers et al. 2018; Cotas et al. 2020). F. vesiculosus is one of the brown macroalgae that have the highest polyphenol and phenolic compounds among the Fucus species (Obluchinskaya et al. 2022). Therefore, preservation of such bioactive and health-promoting compounds is crucial while processing the macroalgae for animal feed additives/ingredients. This study demonstrated that elevated temperature could reduce the concentration of TPC in F. vesiculosus, supporting the earlier findings by Cruces et al. (2016) and Moreira et al. (2016) who observed a decrease in TPC with increasing drying temperature (35 > 40 > 60 > 75 °C) in the same seaweed species. The reduction in phenolic compounds at higher drying temperatures was reported by earlier studies indicating that high temperatures favor the activation of oxidative enzymes, e.g., polyphenol oxidases and peroxidases, and degrade phenolic compounds over 40 °C (Le Lann et al. 2008; Gupta et al. 2011; Tello-Ireland et al. 2011; Badmus et al. 2019).

Total polyphenol in macroalgae represents a group of different phenolic compounds therefore, profiling of polyphenols is an important part of characterizing secondary metabolites present in the macroalgae. In this study, thirteen phenolic compounds were identified in F. vesiculosus regardless of the drying techniques applied, whereas six different phenolic compounds were quantified by Golshany et al. (2024) for the same species. This variable result in the identification of various phenolic compounds in F. vesiculosus could be attributed to the differences in the extraction and quantification method between the two studies, as well as differences in location and environmental parameters. In our study, caftaric acid appears to be specifically sensitive to drying temperature, as indicated by approximately 68% lower concentration in response to oven drying at 80 °C. Also, a similar trend (not significant though) was seen in other phenolic compounds identified, where either the concentration was decreased, or compounds were not detected with an increase in drying temperature, supporting the earlier findings of Curtasu and Nørskov (2023) in willow bark. The reduced or below-detection levels of phenolic compounds with an increasing temperature could be due to the influence of temperature on the extractability of the heat-sensitive compounds. To the best of our knowledge, no previous studies have reported on the effect of drying techniques on the composition of phenolic compounds in F. vesiculosus. For F. vesiculosus, freeze-drying allowed the highest recovery of the compounds followed by the low-temperature oven drying in this experiment, as most of the phenolic compounds appear to be heat-liable (Che Sulaiman et al. 2017).

Since brown macroalgae are rich in various bioactive compounds, future studies are needed to evaluate the effect of drying methods on other phenolic and bioactive compounds, pigments, phytosterols, and bioactive polysaccharides. Moreover, it is also equally important to scrutinize their potential influence on digestibility, particularly when the dried macroalgae are intended for animal feed applications as discussed below.

In vitro total tract OM digestibility of F. vesiculosus remains stable regardless of the drying treatments

In addition to nutrient and polyphenol content, the utilization or digestibility of the macroalgal biomass is also equally important for its optimal utilization as an animal feed component. Several components such as dietary fiber, phytic acids, polyphenolic substances, and enzyme inhibitors can negatively influence the digestibility of macroalgae in production animals (Salehi et al. 2019). Therefore, appropriate post-harvest processing techniques are required to improve the digestibility of the macroalgae. Different post-harvest macroalgae processing techniques such as blanching, drying, etc., can influence the OM and CP total tract digestibility in both monogastric and ruminants (Wong and Cheung 2001; Pandey et al. 2023). The in vitro total tract digestibility of F. vesiculosus in response to different drying methods has not been previously reported. Pandey et al. (2023) found that the in vitro total tract OM digestibility of F. vesiculosus in monogastric remained unaffected by low-temperature blanching (40 °C for 5 min) but decreased by 8% with high-temperature blanching (80 °C for 5 min). In this study, the in vitro total tract digestibility of OM in monogastric animals was not impacted by the drying treatments. This suggests that different post-harvest processing methods such as drying or blanching yield varying effects on macroalgae digestibility. Supporting the earlier studies by Bikker et al. (2020), a low overall digestibility of F. vesiculosus in this study could be associated with its high fiber content (up to 42%), as the fiber content is inversely associated with the in vitro OM total tract digestibility (r =-0.15). Another parameter identified in this study that also negatively influenced in vitro OM digestibility in monogastric (r =-0.78) was TPC, corroborating the earlier studies by Pandey et al. (2023) in blanched F. vesiculosus. However, future studies on the effect of feeding brown macroalgae exposed to different post-harvesting methods and temperatures using in vivo methods are required to evaluate the digestibility and animal performance better.

Conclusions

The present study showed a significant impact of drying treatments on the nutrients and phenolic composition of F. vesiculosus. Although freeze drying was identified as the superior drying technique, it is practically difficult to implement commercially for drying a large quantity of high moisture-containing algal biomass. In this context, we found that low-temperature (40 °C) drying could preserve most of the nutrients, including fatty acids and TPC, thus offering a cost-effective alternative solution to freeze drying. In this study, we determined the N-protein conversion factor of F. vesiculosus to be approximately 4.64, and it remained stable across the drying treatments. Employing a high drying temperature (80 °C) method may be advantageous specifically for protein and amino acids but can negatively influence the content of unsaturated fatty acids and phenolic compounds. Although oven drying temperatures can negatively influence specific nutrients or phenolic compounds, a low-temperature oven drying (40 °C) would be an advantageous strategy for drying F. vesiculosus for animal feed purposes considering nutritional composition, phenolic compounds, and digestibility into account. Careful attention should be paid while selecting appropriate methods for post-harvest drying, as nutrients and bioactive compounds in brown macroalgae can be differentially sensitive to different drying methods or temperatures. Future in vivo feeding trials are needed to evaluate the impacts of post-harvesting processing of macroalgal biomass to assess nutrient utilization, animal health and performance, and production parameters.

Data availability

Data generated during this study can be obtained from the corresponding author upon reasonable request.

References

Angell AR, Mata L, de Nys R, Paul NA (2016) The protein content of seaweeds: a universal nitrogen-to-protein conversion factor of five. J Appl Phycol 28:511–524

Araújo R, Vázquez Calderón F, Sánchez López J, Azevedo IC, Bruhn A, Fluch S, Garcia Tasende M, Ghaderiardakani F, Ilmjärv T, Laurans M (2021) Current status of the algae production industry in Europe: an emerging sector of the blue bioeconomy. Front Mar Sci 7:626389

Badmus UO, Taggart MA, Boyd KG (2019) The effect of different drying methods on certain nutritionally important chemical constituents in edible brown seaweeds. J Appl Phycol 31:3883–3897

Biancarosa I, Espe M, Bruckner C, Heesch S, Liland N, Waagbø R, Torstensen B, Lock E (2017) Amino acid composition, protein content, and nitrogen-to-protein conversion factors of 21 seaweed species from Norwegian waters. J Appl Phycol 29:1001–1009

Bikker P, Stokvis L, Van Krimpen M, Van Wikselaar P, Cone J (2020) Evaluation of seaweeds from marine waters in Northwestern Europe for application in animal nutrition. Anim Feed Sci Technol 263:114460

Boisen S, Fernández J (1997) Prediction of the total tract digestibility of energy in feedstuffs and pig diets by in vitro analyses. Anim Feed Sci Technol 68:277–286

Cao J, Zou X-G, Deng L, Fan Y-W, Li H, Li J, Deng Z-Y (2014) Analysis of nonpolar lipophilic aldehydes/ketones in oxidized edible oils using HPLC-QqQ-MS for the evaluation of their parent fatty acids. Food Res Int 64:901–907

Catarino MD, Silva AM, Cardoso SM (2018) Phytochemical constituents and biological activities of Fucus spp. Mar Drugs 16:249

Chan JC-C, Cheung PC-K, Ang PO (1997) Comparative studies on the effect of three drying methods on the nutritional composition of seaweed Sargassum hemiphyllum (Turn.) C. Ag. J Ag Food Chem 45:3056–3059

Che Sulaiman IS, Basri M, Fard Masoumi HR, Chee WJ, Ashari SE, Ismail M (2017) Effects of temperature, time, and solvent ratio on the extraction of phenolic compounds and the anti-radical activity of Clinacanthus nutans Lindau leaves by response surface methodology. Chem Cent J 11:54

Commission E (2009) Commission Regulation (EC) No 152/2009 of 27 January 2009 laying down the methods of sampling and analysis for the official control of feed. Off J Eur Union 54:2–54

Cotas J, Leandro A, Monteiro P, Pacheco D, Figueirinha A, Gonçalves AM, da Silva GJ, Pereira L (2020) Seaweed phenolics: From extraction to applications. Mar Drugs 18:384

Cruces E, Rojas-Lillo Y, Ramirez-Kushel E, Atala E, López-Alarcón C, Lissi E, Gómez I (2016) Comparison of different techniques for the preservation and extraction of phlorotannins in the kelp Lessonia spicata (Phaeophyceae): assays of DPPH, ORAC-PGR, and ORAC-FL as testing methods. J Appl Phycol 28:573–580

Curtasu MV, Nørskov NP (2023) Comprehensive quantification of flavonoids and salicylic acid representative of Salix spp. using microLiquid Chromatography-Triple Quadrupole Mass Spectrometry: the importance of drying procedures and extraction solvent when performing classical solid-liquid extraction. J Chromatogr A:464139

Diniz GS, Barbarino E, Oiano-Neto J, Pacheco S, Lourenço SO (2011) Gross chemical profile and calculation of nitrogen-to-protein conversion factors for five tropical seaweeds. Am J Plant Sci 2:287–296

Duan X, Ren G-y, Liu L-l, Zhu W-x, Liu Y-h (2014) The influences of drying process on crude protein content of naked oat cut herbage (Avena nuda L.). Drying Technol 32:321–327

Duarte CM, Bruhn A, Krause-Jensen D (2022) A seaweed aquaculture imperative to meet global sustainability targets. Nat Sustain 5:185–193

Fridahl M, Lehtveer M (2018) Bioenergy with carbon capture and storage (BECCS): Global potential, investment preferences, and deployment barriers. Energy Res Social Sci 42:155–165

Fudholi A, Sopian K, Othman MY, Ruslan MH (2014) Energy and exergy analyses of solar drying system of red seaweed. Energy Build 68:121–129

Golshany H, Yu Q, Fan L (2024) Comparative extraction and antioxidant potential of bioactive compounds from Fucus vesiculosus: Kinetic modeling and UPLC-Q-TOF-MS phenolic profiling. Food Biosci 57:103575

Gupta S, Cox S, Abu-Ghannam N (2011) Effect of different drying temperatures on the moisture and phytochemical constituents of edible Irish brown seaweed. LWT- Food Sci Technol 44:1266–1272

Hamid N, Ma Q, Boulom S, Liu T, Zheng Z, Balbas J, Robertson J (2015) Seaweed minor constituents. In: Tiwari BK, Troy DJ (eds) Seaweed sustainability. Elsevier, Amsterdam, pp 193–242

Harnedy PA, FitzGerald RJ (2013) Extraction of protein from the macroalga Palmaria palmata. LWT- Food Sci Technol 51:375–382

Holdt SL, Kraan S (2011) Bioactive compounds in seaweed: functional food applications and legislation. J Appl Phycol 23:543–597

Horwitz W (2010) Official methods of analysis of AOAC International. Vol I, Agricultural chemicals, contaminants, drugs. AOAC International, Gaithersburg

Hsu C-L, Chen W, Weng Y-M, Tseng C-Y (2003) Chemical composition, physical properties, and antioxidant activities of yam flours as affected by different drying methods. Food Chem 83:85–92

Janssen RH, Vincken J-P, van den Broek LA, Fogliano V, Lakemond CM (2017) Nitrogen-to-protein conversion factors for three edible insects: Tenebrio molitor, Alphitobius diaperinus, and Hermetia illucens. J Agric Food Chem 65:2275–2278

Kadam SU, Álvarez C, Tiwari BK, O’Donnell CP (2015) Processing of seaweeds. In: Tiwari BK, troy dJ (eds) Seaweed sustainability. Elsevier, Amsterdam, pp 61–78

Kandasamy S, Naveen R (2022) A review on the encapsulation of bioactive components using spray-drying and freeze-drying techniques. J Food Process Eng 45:e14059

Kassambara A (2016) Factoextra: extract and visualize the results of multivariate data analyses. R package version 1

Koesling M, Kvadsheim NP, Halfdanarson J, Emblemsvåg J, Rebours C (2021) Environmental impacts of protein-production from farmed seaweed: Comparison of possible scenarios in Norway. J Clean Prod 307:127301

Le Lann K, Jégou C, Stiger-Pouvreau V (2008) Effect of different conditioning treatments on total phenolic content and antioxidant activities in two Sargassacean species: comparison of the frondose Sargassum muticum (Yendo) Fensholt and the cylindrical Bifurcaria bifurcata R. Ross. Phycol Res 56:238–245

Lê S, Josse J, Husson F (2008) FactoMineR: an R package for multivariate analysis. J Stat Softw 25:1–18

Ling ALM, Yasir S, Matanjun P, Abu Bakar MF (2015) Effect of different drying techniques on the phytochemical content and antioxidant activity of Kappaphycus alvarezii. J Appl Phycol 27:1717–1723

Meade SJ, Reid EA, Gerrard JA (2005) The impact of processing on the nutritional quality of food proteins. J AOAC Int 88:904–922

Morais T, Inácio A, Coutinho T, Ministro M, Cotas J, Pereira L, Bahcevandziev K (2020) Seaweed potential in the animal feed: A review. J Mar Sci Eng 8:559

Moreira R, Chenlo F, Sineiro J, Arufe S, Sexto S (2016) Drying temperature effect on powder physical properties and aqueous extract characteristics of Fucus vesiculosus. J Appl Phycol 28:2485–2494

Obluchinskaya ED, Pozharitskaya ON, Zakharov DV, Flisyuk EV, Terninko II, Generalova YE, Smekhova IE, Shikov AN (2022) The biochemical composition and antioxidant properties of Fucus vesiculosus from the Arctic region. Mar Drugs 20:193

O’Fallon JV, Busboom J, Nelson M, Gaskins C (2007) A direct method for fatty acid methyl ester synthesis: Application to wet meat tissues, oils, and feedstuffs. J Anim Sci 85:1511–1521

Ortiz J, Romero N, Robert P, Araya J, Lopez-Hernández J, Bozzo C, Navarrete E, Osorio A, Rios A (2006) Dietary fiber, amino acid, fatty acid and tocopherol contents of the edible seaweeds Ulva lactuca and Durvillaea antarctica. Food Chem 99:98–104

Pandey D, Hansen HH, Dhakal R, Aryal N, Rai SP, Sapkota R, Nielsen MO, Novoa-Garrido M, Khanal P (2022) Interspecies and seasonal variations in macroalgae from the Nordic region: Chemical composition and impacts on rumen fermentation and microbiome assembly. J Clean Prod 363:132456

Pandey D, Næss G, Fonseca AJ, Maia MR, Cabrita AR, Khanal P (2023) Differential impacts of post-harvest hydrothermal treatments on chemical composition and in vitro digestibility of two brown macroalgae (Fucales, Phaeophyceae), Ascophyllum nodosum and Fucus vesiculosus, for animal feed applications. J Appl Phycol 35:2511–2529

Ratti C (2001) Hot air and freeze-drying of high-value foods: a review. J Food Eng 49:311–319

Ringeisen B, Barrett DM, Stroeve P (2014) Concentrated solar drying of tomatoes. Energy Sustain Dev 19:47–55

Salehi B, Sharifi-Rad J, Seca AM, Pinto DC, Michalak I, Trincone A, Mishra AP, Nigam M, Zam W, Martins N (2019) Current trends on seaweeds: Looking at chemical composition, phytopharmacology, and cosmetic applications. Molecules 24:4182

Schmid M, Guihéneuf F, Stengel DB (2016) Evaluation of food grade solvents for lipid extraction and impact of storage temperature on fatty acid composition of edible seaweeds Laminaria digitata (Phaeophyceae) and Palmaria palmata (Rhodophyta). Food Chem 208:161–168

Sharma KD, Karki S, Thakur NS, Attri S (2012) Chemical composition, functional properties and processing of carrot—a review. J Food Sci Technol 49:22–32

Shuuluka D, Bolton JJ, Anderson RJ (2013) Protein content, amino acid composition and nitrogen-to-protein conversion factors of Ulva rigida and Ulva capensis from natural populations and Ulva lactuca from an aquaculture system, in South Africa. J Appl Phycol 25:677–685

Silva AF, Abreu H, Silva AM, Cardoso SM (2019) Effect of oven-drying on the recovery of valuable compounds from Ulva rigida, Gracilaria sp. and Fucus vesiculosus. Mar Drugs 17 (2):90

Stévant P, Indergård E, Ólafsdóttir A, Marfaing H, Larssen WE, Fleurence J, Roleda MY, Rustad T, Slizyte R, Nordtvedt TS (2018) Effects of drying on the nutrient content and physico-chemical and sensory characteristics of the edible kelp Saccharina latissima. J Appl Phycol 30:2587–2599

Stévant P, Rebours C (2021) Landing facilities for processing of cultivated seaweed biomass: a Norwegian perspective with strategic considerations for the European seaweed industry. J Appl Phycol 33:3199–3214

Stramarkou M, Papadaki S, Kyriakopoulou K, Krokida M (2017) Effect of drying and extraction conditions on the recovery of bioactive compounds from Chlorella vulgaris. J Appl Phycol 29:2947–2960

Subbiah V, Duan X, Agar OT, Dunshea FR, Barrow CJ, Suleria HA (2023) Comparative study on the effect of different drying techniques on phenolic compounds in Australian beach-cast brown seaweeds. Algal Res 72:103140

Swarnalatha G (2018) Comparison of nutritive value of seaweed with other terrestrial foods—a review. Int J Food Nutr Sci 7:61–70

Tello-Ireland C, Lemus-Mondaca R, Vega-Gálvez A, López J, Di Scala K (2011) Influence of hot-air temperature on drying kinetics, functional properties, colour, phycobiliproteins, antioxidant capacity, texture and agar yield of alga Gracilaria chilensis. LWT-Food Sci Technol 44:2112–2118

Thomas J-BE, Sodré Ribeiro M, Potting J, Cervin G, Nylund GM, Olsson J, Albers E, Undeland I, Pavia H, Gröndahl F (2021) A comparative environmental life cycle assessment of hatchery, cultivation, and preservation of the kelp Saccharina latissima. ICES J Mar Sci 78:451–467

Ullah MR, Akhter M, Khan ABS, Yasmin F, Hasan MM, Bosu A, Haque MA, Islam MM, Islam MA, Mahmud Y (2023) Comparative estimation of nutritionally important chemical constituents of red seaweed, Gracilariopsis longissima, affected by different drying methods. J Food Qual 2023:6623247

van Oirschot R, Thomas J-BE, Gröndahl F, Fortuin KP, Brandenburg W, Potting J (2017) Explorative environmental life cycle assessment for system design of seaweed cultivation and drying. Algal Res 27:43–54

Vissers AM, Pellikaan WF, Bouwhuis A, Vincken JP, Gruppen H, Hendriks WH (2018) Laminaria digitata phlorotannins decrease protein degradation and methanogenesis during in vitro ruminal fermentation. J Sci Food Agric 98:3644–3650

Vrhovsek U, Masuero D, Gasperotti M, Franceschi P, Caputi L, Viola R, Mattivi F (2012) A versatile targeted metabolomics method for the rapid quantification of multiple classes of phenolics in fruits and beverages. J Agric Food Chem 60:8831–8840

Wells ML, Potin P, Craigie JS, Raven JA, Merchant SS, Helliwell KE, Smith AG, Camire ME, Brawley SH (2017) Algae as nutritional and functional food sources: revisiting our understanding. J Appl Phycol 29:949–982

Wong K, Chikeung Cheung P (2001) Influence of drying treatment on three Sargassum species 2. Protein extractability, in vitro protein digestibility, and amino acid profile of protein concentrates. J Appl Phycol 13:51–58

Zhang M, Jiang H, Lim R-X (2010) Recent developments in microwave-assisted drying of vegetables, fruits, and aquatic products—drying kinetics and quality considerations. Drying Technol 28:1307–1316

Acknowledgements

The authors appreciate the members of the Khanal Laboratory (KLab) for scientific discussions.

Funding

Open access funding provided by Nord University. This work was supported by the Regional Research Fund (RFF) Trøndelag, Norway through the MicroSea project (Project no: 313553).

Author information

Authors and Affiliations

Contributions

SD: Conceptualization, Methodology, Formal analysis, Visualization, Writing—original draft. DP: Conceptualization, Methodology, Writing—review & editing. MEH: Methodology, Writing—review & editing. JVN: Methodology, Writing—review & editing. UV: Methodology, Data evaluation, Writing—review & editing. PK: Conceptualization, Methodology, Data evaluation, Writing—review & editing, Funding acquisition, Project administration, Major Supervision.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Dhakal, S., Pandey, D., van der Heide, M.E. et al. Effect of different drying methods on the nutritional composition and phenolic compounds of the brown macroalga, Fucus vesiculosus (Fucales, Phaeophyceae). J Appl Phycol (2024). https://doi.org/10.1007/s10811-024-03343-6

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10811-024-03343-6