Abstract

Microalgae and especially green algae are microorganisms that are used in a wide range of industrial applications of high economic interest, such as fish farming, food, cosmetics, pharmaceuticals, and biofuel. In this study, the green microalga Chlorella vulgaris was examined as raw material for the recovery of bioactive compounds and the production of multifunctional extracts. Firstly, the drying of raw biomass, which is a crucial pre-treatment stage, was examined with freeze-drying having the best performance. Ultrasound assisted extraction (UAE) applying various solvent systems was studied under optimized conditions. For the untreated microalgal biomass, ethanol was indicated as the preferable solvent, whereas on dried samples, water was a more suitable solvent. UV-Vis spectrometry and high-performance liquid chromatography (HPLC) were used for the determination of total carotenoid, chlorophyll, and protein content in the raw materials, extracts, and extraction residues. Moreover, the suitability of drying technique and extraction solvent system was evaluated according to the obtained antiradical activity of the relevant treated biomass and extraction samples using the DPPH method.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Nowadays, the exploitation of marine resources is a pillar of the EU bioeconomy. Microalgae are a marine resource, which exhibits large industrial interest, presenting a wide range of applications. Apart from fish farming, pharmaceutical, cosmetic, and biofuel industries show great interest in the exploitation of the unique characteristics of microalgal. The nutrition industry, though, seems to be the sector that benefits more from their exploitation. Microalgae are a particularly attractive source of high-value molecules, such as proteins, fatty acids, and vitamins. However, their high content in natural pigments that act as antioxidants, such as chlorophylls and carotenoids, is the feature that gives microalgae high commercial value (Vigani et al. 2015).

One of these microalgae is Chlorella vulgaris, a unicellular, eukaryotic organism, which contains a notable natural source of a broad spectrum of novel compounds (Kwang et al. 2008). Specifically, it contains high concentrations of proteins, vitamins, chlorophyll a and b, and primary carotenoids, such as lutein and β-carotene (Kwang et al. 2010; Plaza et al. 2012). These carotenoids, along with chlorophylls and other chemical compounds of Chlorella, such as phenolic compounds, can scavenge free radicals (Wu et al. 2005; Plaza et al. 2012). The most common applications of C. vulgaris in the human nutrition sector are as food supplement or additive, colorant and emulsifier. These products can be found in different forms such as capsules, tablets, extracts, and powders (Safi et al. 2014; Champenois et al. 2015). Japan owns the first place in consuming and producing Chlorella for human consumption, in view of its various health benefits, that have been determined by clinical studies (Plaza et al. 2012). The benefits reported are related to Chlorella’s immune-modulating, antitumor, antibacterial, and antiinflammatory properties, as well as the antiproliferative effects on cancer cells (Kwang et al. 2010; Safi et al. 2014).

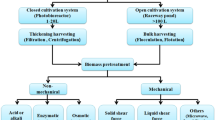

Chlorella vulgaris is an optimum alga for biomass production, as it is considerably resistant against unfavorable growth conditions, showing also fast growth rates. However, its biochemical composition varies and depends on cultivation and production processes (Ahn et al. 2016; Aremu et al. 2016). Therefore, several growth techniques, such as autotrophic cultivation, including open pond systems and closed photobioreactors, heterotrophic, and mixotrophic cultivation, have been implemented (Görs et al. 2010; Doucha and Lívansky 2012; Abreu et al. 2012; Safi et al. 2014). After harvesting, the microalgal biomass has an extremely high moisture content of up to 90%. This fact makes the handling and logistics of C. vulgaris very expensive, difficult, and unstable. Since bioactive content, prolonged preservation and extended shelf life are dependent on the microalgal biomass treatment after harvesting process; in the present study, several drying treatments of C. vulgaris were evaluated (Viswanathan et al. 2012; Orikasa et al. 2014).

Dehydration represents an essential process in food industries. The main objectives of food product drying are the minimization of microbial growth, the avoidance of the deterioration due to oxidative reactions, and weight and volume reduction, which leads to a decrease of storage and transportation costs (Krokida et al. 2003; Oliveira et al. 2010). However, microalgae, and especially C. vulgaris, represent foodstuffs with high nutritional value, containing heat-sensitive compounds which might be altered by the drying treatment (Ryckebosch et al. 2011). In addition, drying is an energy consuming and expensive step that increases the overall production cost of microalgal products (Chen et al. 2015). The industrially used techniques for microalgae are greenhouse drying and spray-drying. However, these methods can lead to damage of the heat-labile functional pigments, because of thermal breakdown and complexation (Molina Grima et al. 2013). Therefore, techniques able to adjust the drying temperature, such as conventional hot-air drying, and techniques avoiding thermal degradation, such as freeze-drying (lyophilization), are suggested. Conventional hot-air drying is the most widespread drying process in food industries, as long as it is cost-effective, despite the considerable nutrient degradation it causes (Krokida et al. 2003; Ryckebosch et al. 2011; Orikasa et al. 2014). On the other hand, freeze-drying is the gentlest dehydration method and effectively maintains the sensory and nutritive value of microalgae. Nevertheless, this technique requires high energy and expensive equipment (Ratti 2001).

The created dried products show great interest thanks to their content of proteins, carotenoids, and chlorophylls, which exhibit significant antioxidant activity. Proteins are one of the most important constituents of microalgal biomass. Specifically, C. vulgaris reaches 42–58% proteins per dry weight of biomass and differs according to growth conditions. The amino acid profile of this microalga fits perfectly to the standard profile for human nutrition. Chlorella’s proteins show significant emulsifying capacity, which is better than commercial ingredients (Safi et al. 2014). In addition, Chlorella’s carotenoids have multiple therapeutic properties and may lower the risk of cardiovascular diseases and specific cancer types (Kwang et al. 2008). Furthermore, the abundant photosynthetic pigment in Chlorella, chlorophyll a, which can reach 1–2% of dry weight, and its derivatives, such as pheophytin, have been largely examined for their biological activities (Kwang et al. 2008, 2010; Safi et al. 2014). Apart from the dried biomass, rich extracts can be recovered, using green and food grade solvents, such as ethanol and water, in combination with ultrasound-assisted extraction (UAE). Ultrasound-assisted extraction can achieve a significant reduction of extraction time, as well as an increase of the extraction yield, by not altering the physical and chemical properties of the extract (Plaza et al. 2012), as well as the remaining biomass, promoting the holistic exploitation of the microalga. The holistic exploitation includes the valorization of the extraction residues in other applications, such as animal feed and aquaculture. This is achieved with the use of green, environmentally friendly, non-toxic, and compatible for food application solvents.

In the present study, the effect of pretreatment on the recovery of functional compounds from C. vulgaris biomass was evaluated. Specifically, a comparison of the bioactive content and antioxidant activity of the untreated raw biomass to freeze-dried and hot-air-dried biomass was performed. The applied extraction technique was ultrasound-assisted extraction (UAE) using water and ethanol as solvents. The extracts, as well as the biomass pellets produced, were evaluated on their total carotenoid, chlorophyll a, antioxidant activity, and protein content using ultraviolet-visible (UV-Vis) spectrophotometric assays and high-performance liquid chromatography (HPLC).

Materials and methods

Materials and chemicals

Chlorella vulgaris biomass cultivated at flat panel photobioreactors was donated By MEDBIO S.A. (Chios, Greece). The biomass was stored at −30 °C immediately to avoid any microbial spoilage and degradation. Solvents and reagents used in the extraction experiments were of analytical grade, while for the HPLC analysis, solvents of HPLC grade were used. Water, ethanol, and acetone were purchased Fisher Scientific (UK). 2,2-Diphenyl-picrylhydrazyl (DPPH) reagent was from Sigma-Aldrich.

Drying treatment

Chlorella vulgaris was delivered wet containing 70.38 ± 2.90% moisture, and freeze-drying method, as well as hot-air drying method, was applied in order to determine the effect of drying on the physicochemical properties of the biomass. The water loss and the moisture content were measured during the drying processes.

For freeze-drying, samples of C. vulgaris were frozen at −30 °C for 72 h, in a Sanyo MDF-236 freezer (Osaka, Japan), and afterwards were dehydrated for 12 h in a Leybold-Heraeus GT 2A freeze-dryer (Germany) under the effect of high vacuum (3 mbar).

During the hot-air drying, a laboratory oven (Binder ED 115, 230V, 1.6 KW) was used at 60 °C for 12 h. Thin layers of 1–5 mm of C. vulgaris wet biomass were placed in the oven on non-stick baking paper.

Color characterization

The CIELab system was applied for the color determination of the freeze-dried and hot-air-dried samples using a portable spectrophotometer (MiniScan XE, Hunter Associates Laboratory Inc., USA), equipped with a 4-mm measuring head. The dried samples were compared with the reference sample, which was wet C. vulgaris that was dried in the atmosphere placed in a dark and dry place until its moisture content came in equilibrium with the atmosphere.

In the CIELab color model, the lightness of the samples L and the chromatic indicators a and b were determined. L takes values from 0, which represents black, to 100, which represents a perfect reflecting diffuser. The parameter a represents the difference between red (+a) and green (−a), and the parameter b describes the difference between yellow (+b) and blue (−b). Hue (h) was also calculated using Eqs. 1a–1f. The units of h are in the forms of degrees (o), where 0° represent red, 90° represent yellow, 180° green, and 270° blue (Papadaki et al. 2014).

Saturation or chroma (C) calculation was based on the following equation. High values of C indicate pure color.

The total color difference (ΔE) between the different types of samples and the reference sample was calculated using the following equation (Papadaki et al. 2014).

where ΔL = L sample − L atmospheric, Δa = a sample − a atmospheric, and Δb = b sample − b atmospheric.

MC determination and drying kinetics

The moisture content of wet and dried biomass was performed according to Official Methods of Analysis, AOAC (Cunniff 1998) and was determined in a Sanyo Gallenkamp PLC vacuum oven (England) at 70.00 ± 0.20 °C. Experiments were conducted in triplicate. The moisture content was calculated based on the following equation when the samples reached constant weight

where MC—the moisture content on wet basis (kg kg−1), W w—the wet weight (kg), and W d—the dried weight of the sample (kg).

For the determination of drying kinetics, the weight of the samples was measured regularly during drying. Examining the drying processes, a first-order kinetic model was considered for the description of the moisture transfer

where X—material MC on dry basis (d.b.) during drying (kg water kg−1 dry solids), X e —equilibrium MC of dehydrated material (kg water kg−1 dry solids), k—drying rate (min−1), and t—processing time (min) (Kyriakopoulou et al. 2013).

Drying kinetics were calculated as the slope of the rate-drying curve at reduced drying rate. The MC (d.b.) of the dry biomass X (kg water kg−1 dry solids) is equal to X i at zero time, and Eq. 6 is integrated as follows

Extraction experiment

Samples of untreated or dried C. vulgaris were extracted under ultrasounds in a XO-SM50 Ultrasonic Microwave Reaction System (Nanjing Xianou Instruments, China) operating at 25 kHz, at 450 W, and at 20 °C for a total duration of 5 min. The samples were placed in a beaker with 50 mL in a solid to solvent ratio 1:20 g dry weight per mL solvent (ethanol or water). The specific solvents were selected based on the bioactive content of C. vulgaris.

The extraction yields (EY) of the extracts and pellets were calculated based on the following equation.

Determination of pigments

Total carotenoid and chlorophyll contents

The total carotenoid and chlorophyll a contents were estimated according to Jeffrey et al. (1997), using 90% acetone as solvent. Equation 8 was used for chlorophyll a determination and Eq. 9 for total carotenoids.

The qualitative evaluation of total carotenoid content was done using HPLC analysis.

Characterization of carotenoid-rich extracts

HPLC analysis was performed with an HPLC Shimandzu HP 1100 Series (USA) equipped with a diode array detector and an automatic Agilent 1200 Series injector. Carotenoid compounds were analyzed with an YMC C30 (Germany) analytical column (5 m, 250 × 4.6 mm I.D.). The solvents consisted of methanol, t-butylmethylether, and 1% phosphoric acid aqueous solution, and the flow rate was 1 mL min−1. The linear gradient, as adapted from Fuji Chemical Industry Co., Ltd., for t-butylmethylether was as follows: 0 min, 15%; 15 min, 30%; 23 min, 80%; 27 min, 80%; 27.1 min, 15%; and 35 min, 15% while concentration of 1% phosphoric acid solution was constant at 4%. Detection of carotenoids was accomplished using a diode array system at a wavelength of 480 nm. Carotenoids were identified by comparison to external standard (β-carotene standard) and quantified by use of standard curve.

Protein content

The concentration of total protein in the extracts was measured using the Bradford protein assay (Bradford 1976) as proposed by Stoscheck (1990). Furthermore, the concentration of total protein in the raw material and extraction residues was measured using the Kjeldahl method (Sáez-Plaza et al. 2013).

Determination of antiradical activity

The AAR was evaluated with the 2,2-diphenyl-1-picrylhydrazyl (DPPH) radical (Kyriakopoulou et al. 2013). Chlorella vulgaris extracts (0.1 mL) were added to 3.9 mL of DPPH (0.03 mg mL−1) in methanol. A Bel Photonics UV-M51 spectrophotometer (Piracicaba, Brasil) was used for the determination of the absorbance at 515 nm after 60 min. Changes in the absorbance of appropriately diluted samples were measured at 25 °C, and using a calibration curve, the percentage of the DPPH inhibition was calculated as described in Eq. 10

Statistical analysis

One-way and factorial analysis of variance (ANOVA) was used to analyze the differences between the three biomass types (wet, freeze dried, and hot-air dried) and the two solvent systems (ethanol and water) with respect to the total carotenoid, chlorophyll a, and protein content, as well as the extraction yield and the antiradical activity. Tukey’s range test was applied, and all the statistical tests were performed with STATISTICA (StatSoft).

Results

Effect of drying treatment on physicochemical characteristics of CV biomass

A comparison between the freeze drying, hot-air drying, and untreated CV biomass was performed, taking into account the moisture content, the drying kinetics, the color change, and the bioactive content variation.

Moisture content and drying kinetics

The initial moisture content of C. vulgaris was decreased from 70.38 ± 2.90 to 0.88 ± 0.05% (w.b.) and 3.58 ± 0.19% (w.b.) for freeze drying and hot-air drying, respectively, after 4.5 h of treatment. The equilibrium moisture contents of C. vulgaris dried by freeze drying and hot-air drying were determined by Eq. 4.

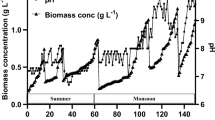

Since drying kinetics are the most significant information required for the design and simulation of dryers, their calculation was made based on experimental curves given in Fig. 1. The prediction of the drying constants k was as follows: k = 2.19 × 10−6 min−1 and k = 1.61 × 10−6 min−1 for FD and HAD, respectively.

Color characterization

Wet C. vulgaris samples were in the form of a paste and had intense green color, which after drying exhibited significant changes. In the case of FD, the samples were collected as powder, which had intense green color and was easily crushed. On the contrary, after HAD at 60 °C, the samples had a dark brown color and they were in the form of thin flakes. Observing the two samples, significant changed in the texture also occurred arguing on the presence of a hardening effect.

The differences between the drying methods were also visible through the discoloration of the samples compared to reference sample dried in atmospheric conditions. The color difference was determined by the CIELab Color Space System and the results are shown in Table 1. FD resulted in lighter color indicated by higher L values, while the green color was increased (indicated by negative a value and H value close to 180°). The samples showed four times higher C values, compared to hot-air dried, which validates their color intensity. The a and h values of hot-air-dried samples indicated browning during heating.

Beyond the quality characteristics, however, it is useful to study the effects of the two drying methods on the bioactive content of CV, and specifically on the content of total carotenoid and chlorophyll a, as well as of proteins.

Total carotenoid and chlorophyll a content

The wet CV biomass prior to any treatment exhibited the highest concentration of total carotenoids (197.17 ± 3.22 mg total carotenoids g−1 dry biomass) (Fig. 2). Total carotenoids are heat-sensitive and highly susceptible to the drying temperature and time. Comparing the two drying methods, FD performed better in retaining the carotenoid content compared to AD. However, the loss of total carotenoids noted in this case was significant, reaching up to 57.12 ± 3.74%. Regarding HAD, the applied temperature of 60 °C leads to overheating of the surface, contributing to the marked carotenoid degradation (up to 91.06 ± 2.37%).

In addition, FD is preferred to HAD, giving a final chlorophyll a content higher by 60% approx. (Fig. 2). However, the chlorophyll a loss that occurs, when wet and freeze-dried biomass are compared, is significant. This means that although chlorophyll a, is not as heat-sensitive as carotenoids, it is oxidized and affected much easier during the drying process. The chlorophyll a concentration in the fresh biomass was 82.02 ± 2.34 mg g−1 dry biomass, while the respective concentration in the freeze-dried biomass was 17.67 ± 0.55 mg g−1 dry biomass and in the hot-air-dried biomass was 10.97 ± 0.53 mg g−1 dry biomass.

Protein content

Total protein degraded over long drying times (>3 h) even in low temperature, however not as significantly (Fig. 3). At relatively higher drying temperature (60 °C), a minor decrease in protein content was observed. The protein concentration in freeze-dried biomass was 16.12 ± 0.61%, while the corresponding concentration in the hot-air-dried biomass was 15.35 ± 1.09%.

Pigments recovery

Assuming that the recovery of bioactive compounds in wet biomass is 100%, the dried biomass samples were evaluated accordingly (Fig. 4). HAD showed 90% approximately pigment losses. Specifically, this drying technique achieves 8.95 ± 0.37% total carotenoid recovery and 13.38 ± 0.59% chlorophyll a recovery. The high drying temperatures, as well as the hot-air stream that dehydrates and overheats the surface of the samples, are the main reasons for the massive degradation of nutrients. On the other hand, FD maintained a high percentage of biological value and pigments content. For example, the recovery of total carotenoids accomplished by this method was 42.88 ± 2.10%. However, chlorophyll a showed a different behavior, reaching recovery rates of 21.54 ± 0.70%.

Effect of extraction solvents on the recovery of bioactive compounds

Extraction yield of extracts and pellets

The drying treatment and the nature of solvent were determining factors that affected significantly the extraction yields and extract bioactivity. The selection of an efficient solvent was required due to the presence of different compounds with varied chemical characteristics and polarities (Bampouli et al. 2015). As a result, two solvents with different polarities (water and ethanol) were tested to evaluate the influence of these solvent characteristic on bioactive compounds extraction from the microalga. The results of the extraction yields are presented in Figs. 5 and 6.

In the case of the extracts obtained, as regards the effect of solvents, biomass yields extracted with water were high (Fig. 5). Specifically, the yield for the raw biomass was 63.74 ± 2.97%, while for the FD biomass, the yield was 45.00 ± 1.76% and for the HAD biomass 29.17 ± 0.93%. Although ethanol is a common solvent for C. vulgaris extraction (Kwang et al. 2008, 2010), this solvent demonstrated lower yields.

Regarding the pellets, according to Fig. 6, the greater the yield of the extract was the lower the yield of the extraction residue obtained. Comparing the different remaining residues, pellets of ethanol extraction showed significantly higher yields. This indicates that although the extracts of the biomass exhibited high bioactive content, the remaining biomass after treatment can also give high extraction yields. Among wet and dried pellets, wet biomass treated with water exhibited the lowest yields, which was also a result of the difficulty in handling of the biomass due to its nature (sticky paste).

Total carotenoid content

As shown in Fig. 7, ethanol was the suitable solvent for the extraction of wet biomass, achieving 427.10 ± 22.67 mg total carotenoids g−1 dry biomass, and water was the optimum solvent for the extraction of freeze-dried and hot-air-dried biomass, achieving 104.66 ± 1.71 and 30.21 ± 0.87 mg total carotenoids g−1 dry biomass, respectively.

Concentration of total carotenoids in water and ethanol extracts of wet, freeze-dried (FD), and hot-air-dried (HAD) Chlorella vulgaris biomass after ultrasound sonication at 25 kHz, 450 W, and 20 °C for 5 min (expressed in mg total carotenoids g−1 dry biomass). Number of replicates (N) = 3; the error bars show the standard deviation

Selected extracts, specifically, the ethanolic of the wet and freeze-dried biomass, were evaluated using HPLC. The chromatogram of the ethanolic extract of wet biomass obtained at 480 nm (Fig. 8) showed that the presence of eight pigments and the corresponding HPLC-UV-DAD spectra are presented in the online supplementary material (Fig.8b). The bioactive compounds detected were as follows: luteoxanthin, loroxanthin, lutein/siphonaxanthin, β-zeacarotene, canthaxanthin, β-carotene, astaxanthin, and phaeophytin a. All the spectroscopic properties of the most important compounds found in C. vulgaris wet biomass are summarized in Table 2.

a High-performance liquid chromatogram (HPLC) of the ethanolic extract of Chlorella vulgaris wet biomass. Detection 480 nm. Column 30 μm. Solvents: methanol, t-butylmethylether, and 1% phosphoric acid aqueous solution. Flow rate 1 mL min−1. Peaks: 1 luteoxanthin, 2 loroxanthin, 3 lutein/siphonaxanthin, 4 β-zeacarotene, 5 canthaxanthin, 6 β-carotene, 7 astaxanthin, and 8 phaeophytin a. b HPLC-UV-DAD spectra of the chromatographic peaks for the ethanolic extract of C. vulgaris wet biomass (numbers correspond to the peak numbering of a)

As far as the ethanol extract of freeze-dried biomass was concerned, its chromatogram demonstrated the presence of only three pigments: β-carotene at 10.797 min (33.05% of total identified carotenoids), canthaxanthin at 13.730 min (20.73% of total identified carotenoids), and astaxanthin at 14.464 min (46.22% of total identified carotenoids). The chromatogram of the abovementioned extract shows a significantly decreased compound content, with the heights of peaks being less than 30 mAU.

In the case of pellets evaluated with the UV-Vis method, Fig. 9 shows that through the 5 min extraction, a significant proportion of carotenoids is left in the extraction residues, while the objective was to recover quite rich extracts. However, choosing appropriate solvents, such as ethanol for the treatment of wet Chlorella, this objective is achieved (only 58.43 ± 3.00 mg total carotenoids g−1 dry biomass remained). In addition, since the purpose was the implementation of procedures in the food industry, fast and economical methods are needed, so the 5-min UAE seems to be an appropriate short extraction treatment. Moreover, water generally exhibits satisfactory results concerning not only the extracts, but also the remaining pellets. The fact that the pellets were still containing some bioactive compounds is considered important, since they can be available for other uses, such as aquaculture.

Concentration of total carotenoids in the water and ethanol pellets of wet, freeze-dried (FD), and hot-air-dried (HAD) Chlorella vulgaris biomass after ultrasound sonication at 25 kHz, 450 W, and 20 °C for 5 min (expressed in mg total carotenoids g−1 dry biomass). Number of replicates (N) = 3; the error bars show the standard deviation

Chlorophyll a content

The trend of chlorophyll a was identical to that of total carotenoids, with ethanol being the solvent which produces the highest recovery of chlorophyll a in the extracts (351.01 ± 18.06 mg g−1 dry biomass) (Fig. 10). As expected also, the concentration of chlorophyll a in pellets (Fig. 11) was similar to that of carotenoids.

Concentration of chlorophyll a in the extracts of wet, freeze-dried (FD), and hot-air-dried (HAD) Chlorella vulgaris biomass after ultrasound sonication at 25 kHz, 450 W, and 20 °C for 5 min, using water and ethanol as solvents (expressed in mg chlorophyll a g−1 dry biomass). Number of replicates (N) = 3; the error bars show the standard deviation

Concentration of chlorophyll a in the pellets of wet, freeze-dried (FD), and hot-air-dried (HAD) Chlorella vulgaris biomass after ultrasound sonication at 25 kHz, 450 W, and 20 °C for 5 min, using water and ethanol as solvents (expressed in mg chlorophyll a g−1 dry biomass). Number of replicates (N) = 3; the error bars show the standard deviation

Protein content

According to Fig.12, water enhanced the recovery of proteins in the extracts. For example, the water extract of wet biomass shows a concentration of 0.49 ± 0.02 mg proteins mL−1 extract, whereas the ethanolic extract of the same type of biomass recovered only 0.08 mg protein mL−1 extract. The high protein content in the pellets (Fig. 13) was dependent on the removal of the extractable part of the biomass. Specifically, the ethanol samples showed higher protein content, as long as the ethanolic extracts were poor in protein, resulting to an enriched extraction residue. Protein levels were found to increase under the drying treatment. This effect is not likely real, but an artifact of increased cell digestibility and therefore increased signal when quantified (Nelson 2015).

Concentration of proteins in the extracts of wet, freeze-dried (FD), and hot-air-dried (HAD) Chlorella vulgaris biomass after ultrasound sonication at 25 kHz, 450 W, and 20 °C for 5 min, using water and ethanol as solvents (expressed in mg proteins mL−1). Number of replicates (N) = 3; the error bars show the standard deviation

Concentration of proteins in the pellets of wet, freeze-dried (FD), and hot-air-dried (HAD) Chlorella vulgaris biomass after ultrasound sonication at 25 kHz, 450 W, and 20 °C for 5 min, using water and ethanol as solvents (expressed in % of dry biomass). Number of replicates (N) = 3; the error bars show the standard deviation

Antioxidant activity

As shown in Fig. 14, the antioxidant activity of the water extracts was higher. For example, wet biomass extracted with water presented 24.13 ± 0.79% DPPH inhibition, while when extracted with ethanol only 2.89 ± 0.15%. In addition to this, it was observed that after HAD, the antioxidant activity of water extracts was increased (49.37 ± 1.41%), compared to those after FD (11.64 + 0.19%). On the other hand, as shown in Fig. 15, pellets underperform in antioxidants due to the efficient extraction and recovery of compounds with antioxidant properties, which were in the extractable fraction of biomass.

Antioxidant activity of the extracts of wet, freeze-dried (FD), and hot-air-dried (HAD) Chlorella vulgaris biomass after ultrasound sonication at 25 kHz, 450 W, and 20 °C for 5 min, using water and ethanol as solvents (expressed in % biomass). Number of replicates (N) = 3; the error bars show the standard deviation

Antioxidant activity of the pellets of wet, freeze-dried (FD), and hot-air-dried (HAD) Chlorella vulgaris biomass after ultrasound sonication at 25 kHz, 450 W, and 20 °C for 5 min, using water and ethanol as solvents (expressed in % biomass). Number of replicates (N) = 3; the error bars show the standard deviation

Discussion

Chlorella vulgaris is a microalga rich in total carotenoids, chlorophyll a, and proteins. Two industrially used drying techniques, specifically freeze drying and hot-air drying, were applied in order to evaluate their effect and compare them, taking into account four significant parameters: the moisture content, the drying kinetics, the color change, and the degradation of the bioactive content. Based on the first parameter, comparing the two treatments, the achieved final moisture content of hot-air-dried biomass was greater than that of the freeze-dried biomass. The samples treated with HAD showed faster dehydration of the surface of the material, while, despite the thin layer of the sample, below the surface there is some remaining moisture. The intensive drying creates a hard dry shell on the surface does not allow the diffusion of the rest of the moisture towards the upper surface and eventually the air (Giri and Prasad 2007; Oliveira et al. 2010).

From the examination of the drying curves in Fig. 1, it is evident that freeze drying achieves faster dehydration compared to hot-air drying. The thin biomass layers applied results in high drying rates, allowing faster heat and water mass transfer through the samples. Both drying rates calculated decreased sharply in the last drying stages (60 min), where the material, depending on the treatment, exhibited different final moisture content. In the case of FD, the initial high rate of water loss under freeze drying conditions occurs because of the rapid removal of the unfrozen water in the early stages. In the case of HAD, water is being evaporated from the free surface and when there is no change in the drying temperature; the rate of removal of water is related to the rate of heat transfer to the material and mass transfer from the solid material to the ambient air (Pu and Sun 2017).

The different treatments, apart from the final moisture content, also presented significant sensorial changes. In general, the study on the deterioration of color during drying of high-value food products is significant for the evaluation of their outward aspect and because of the close relationship between antioxidant content and color (Ratti 2001). The determination of the color change of the samples shows that FD results in a lighter and more intense green color, arguing that this technique is a more appropriate process to preserve nutraceutical foods, while HAD alters the color to brown, which is the result of various reactions, including pigment degradation. High temperatures during drying exert a great influence in degrading the color (Ratti 2001). In addition, these high surface temperatures, as well as the migration of soluble solids to the surface and increase of such soluble materials at the surface as the water evaporates, are responsible for the hardening effect of HAD samples (Maskan 2001). Moreover, the cracking of the surface of HAD samples was visible, since tissue splits and ruptured internally due to the temperature rise in the sample, while at the same time, the moisture transfer was allowed with higher rate from the cracks formed (Maskan 2001).

Regarding the bioactive content of C. vulgaris biomass after drying, FD maintained a high percentage of the biological value and C. vulgaris pigment content, excluding chlorophyll a, the loss of which was significant. In general, the water removal induces a decrease of the nutritional value of foodstuffs (Oliveira et al. 2010). Starting with total carotenoids, they are heat-sensitive compounds, therefore treatments over 50 °C lead to significant content loses (Dey and Rathod 2013). As Sogi et al. (2015) mentioned, dryers operating at elevated temperatures show a decline in the concentration of total carotenoids. Overdrying of microalgae often leads in the loss of key elements, such as carotenoids and chlorophylls (Sofiyanti et al. 2015). In that respect, FD is considered a more appropriate method, because no heating is required. However, still a high loss of total carotenoids was observed. This is due to the larger porosity of freeze-dried products compared to those dehydrated by other techniques. This in fact may increase the oxidation of the samples, as a result of the exposure of a greater surface area (An-Erl King et al. 2001).

As far as the chlorophyll a content is concerned, since chlorophylls are not as heat-sensitive as carotenoids, oxidation is a more determining factor than temperature. The chlorophyll a concentration in the fresh biomass was as high as reported in different studies (Görs et al. 2010; Kwang et al. 2010). Chlorella biomass contains an above-average ratio of chlorophyll a per dry mass (Görs et al. 2010). Although, the rest of the pigments seemed to remain after FD, the chlorophyll a concentration is a lot lower than the untreated sample. As chlorophyll a has the tendency to be oxidized, C. vulgaris freeze-dried samples, which have an increased surface area, are expected to be exposed to oxygen and, thus extensive oxidation is caused. The most common mechanism of chlorophyll a degradation is the transformation into pheophytin (An-Erl King et al. 2001), which is due to the loss of Mg2+, an ion that is in the center of the chlorin ring of chlorophyll (Milenković et al. 2012).

However, the protein content in the three samples showed a different trend. The degradation of proteins after drying was low. In the case of FD, that was mainly due to the selection of low temperature treatment, while in the case of HAD heating seemed to favor the protease activity leading to high protein recovery (Nelson 2015).

The obtained C. vulgaris-dried biomasses, as well as the wet biomass, were extracted with two efficient solvents (water and ethanol), and the effect of the drying treatment in combination with the nature of solvent was determined taking into consideration three important parameters: the extraction yield, the bioactive content (total carotenoid, chlorophyll a and protein content), and the antiradical activity. Water extracts demonstrated higher biomass yields than ethanolic ones. Water is a polar solvent and represents a small molecule, which may easily penetrate C. vulgaris cells. It also enhances cell lysis and does not denature the extractable components. On the other hand, the molecular structure of ethanol prevents the effective penetration into C. vulgaris cells. The superiority of water against solvents of lower polarity is reported by Plaza et al. (2012) when water, ethanol, and hexane were compared and the highest yields were obtained with water. The ethanol extraction yield was increased in the case of wet biomass, where the internal moisture seems to acts as a co-solvent. In the case of water, the yields are significantly reduced when drying is applied and especially HAD. This is due to the high exposure of the surface to the warm air, resulting in a hard and cracking surface, which makes difficult the impregnation of the solvent during extraction (Lewicki 2006; Giri and Prasad 2007). On the contrary, FD creates a porous structure and gives a powder, thereby increasing the contact surface between the solvent and the cells. This resulted in a simultaneous improvement of the extraction process and better extraction yields.

However, despite the low extraction yields of ethanol (Fig. 5), this solvent was very selective on the recovery of total carotenoids and chlorophyll a. This result is in agreement with the experiments of Kwang et al. (2010), where the best results were obtained with 90% ethanol. The increased efficiency reported was a result of the high proportion of water-soluble contents in C. vulgaris. This means that ethanol, when in an aqueous environment (such as the raw biomass), can recover a great fraction of the contained carotenoids. On the contrary, water exhibited best results in combination with FD samples. Ice crystals, created in the tissue matrix during FD, disrupt the cell structure, thus promoting the solvent extraction and achieving high extraction of carotenoids (Sogi et al. 2015). In addition, the moisture content in freeze-dried biomass has been greatly reduced. Thus, the aqueous extraction of dry biomass is favored because of the better solvent impregnation and diffusion in the inner of biomass, as the solid-liquid extraction relies on diffusion phenomena.

The ethanolic extract of C. vulgaris wet biomass, which shows by far the highest concentration of pigments using the UV-Vis method, was evaluated also through the HPLC method. In general, the analysis of carotenoids is complicated due to the diversity and the presence of different isomeric forms of these compounds. HPLC is considered a reliable method for algal pigment analysis, and it has been proposed in several studies (Cha et al. 2010; Kwang et al. 2010; Plaza et al. 2012). However, the difficulty of the carotenoid identification based on their UV-Vis spectra should be taken into account because a lot of carotenoids possess very similar or identical spectra (Crupi et al. 2010). As a way to decrease misidentification, the analysis was based not only on the maximum wavelength absorption of the specific compounds but also in their spectral shape. The wavelengths of the maximum absorption (λ max), as well as the spectral shape, which indicates the relationship between the peak heights of the longest-wavelength absorption band (III) and the middle absorption band (II), calculated from the minimum between the two peaks (%III/II), were compared with those from pure standards (Young 2004). The life cycle and the illumination strongly influence the carotenoid pattern of C. vulgaris (Senger et al. 1993). Specifically, the compound of the first peak of the chromatogram was identified to be luteoxanthin, a carotenoid with λ max: 400, 422, and 448 nm and identical UV-Vis spectra (Young 2004). Based on the λ max and the spectral shape of the compound of the second peak, it is attributed to loroxanthin. Loroxanthin is a unique xanthophyll that is detected only in specific green algae (Chlorophyceae), including C. vulgaris (Aitzetmüller et al. 1969). The absorption spectrum of loroxanthin in ethanol, exhibits λ max at 446 and 474 nm and the degree of fine structure (%III/II) is 45% (Young 2004). Loroxanthin is identified as a hydroxy lutein and is spectroscopically similar to lutein (λ max of lutein: 422, 445, 474 nm), with the only difference in the spectral shape (lutein: %III/II 60) (Aitzetmüller et al. 1969; Young 2004). The third peak of the chromatogram shows a maximum absorption at 455 nm, presenting also λ max at 428 and 475 nm. In general, siphonaxanthin is a keto-carotenoid of green algae and presents a maximum absorption in 455 nm in ethanol (Young 2004; Sugawara et al. 2014). On the other hand, lutein, which is the predominant carotenoid in C. vulgaris, has λ max at 422, 445, and 474 nm. It is concluded that in the third peak, there is not a complete separation of lutein and siphonaxanthin and this is why the absorption spectra has this specific shape. β-Zeacarotene is an intermediate in the biosynthesis of β-carotene and other carotenoids and presents maximum absorption in ethanol at 406, 428, and 454 nm (Young 2004). Hence, it was presumed that the pigment in the fourth peak shows plausible characteristics of β-zeacarotene. Canthaxanthin is a secondary carotenoid, which is found in C. vulgaris, presents λ max at 474 nm in ethanol, and has the similar absorption spectra with the carotenoid of the fifth peak in the chromatogram (Gouveia et al. 1996; Young 2004). The absorption spectra of the sixth peak were a typical spectra of β-carotene. β-Carotene is an abundant carotenoid in C. vulgaris and has λ max in ethanol at 425, 450, and 478 nm and little fine structure (%III/II 25). In addition, astaxanthin is a secondary carotenoid of Chlorella with λ max at 478 nm. The seventh peak was attributed to astaxanthin due to the great resemblance. Finally, pheophytin a is the degradation pigment of chlorophyll a and shows two maximum absorptions at 409 and 666 nm. The compound in the sixth peak showed the same absorbance and the same UV-Vis spectra with pheophytin a, as reported in similar studies (Milenković et al. 2012).

In contrast to total carotenoids and chlorophyll a, the recovery of proteins in extracts is enhanced with water. This behavior can be explained by the high hydrophilic content of Chlorella and by the fact that proteins are water soluble molecules. Furthermore, an increase of protein content in the aqueous extracts derived from dried biomass was observed. The water diffusion in the dried biomass cell is enhanced, increasing the extractability of water soluble compounds, such as proteins (Kwang et al. 2010).

The determination of the antioxidant activity of the extracts showed that water extracts presented higher antiradical capacity than ethanolic extracts. Generally, the antioxidant activity is linked to bioactive compounds, such as carotenoids, phenolic acids and chlorophylls (Jaime et al. 2005). Also, phenolic acids are known as hydrophilic antioxidants and carotenoids as lipophilic. Thus, phenolic acids are more soluble in polar solvents such as water and less ethanol. Since the DPPH method detects better the antioxidant activity of phenolics rather than that of carotenoids (Müller et al. 2011) and water recovers more phenolic acids than ethanol, the antioxidant activity of the water extracts is higher. That means that the presence of phenolic compounds in the extracts has a positive impact on their total antioxidant activity (Plaza et al. 2012). Furthermore, the heat energy during hot-air drying ruptures the molecular structure of the covalent complex and releases many antioxidant compounds. The high antioxidant activity of the thermally processed samples is a result of the increased concentration of the abovementioned or other phytochemical components released during drying. Also, during thermal processing, the cells are being stressed and produce more metabolites to resist change. These metabolites are polar, and the combination of polar solvent (water) with intense drying conditions allows recovery of substances with antioxidant activity (Orikasa et al. 2014).

In conclusion, the most suitable drying method among FD and HAD is the former, which greatly limits moisture and maintains the nutrient and bioactive content. If the aim is to recover pigments, then drying is not needed and the optimum solvent for the extraction is ethanol. However, if in terms of logistics and effective handling dried biomass is considered, despite that the content of bioactive compounds is considerably degraded, the optimal solvent for the recovery of compounds of interest is water. In the case that the goal is to have high protein recover, FD is suggested in combination with water. Finally, if the preparation of extracts with high antioxidant capacity is required, HAD is considered the optimum treatment, especially when the biomass is extracted with water. The selection of food grade solvents allows the application of C. vulgaris extracts and extraction residues, which have a remarkable bioactive content, in food systems.

References

Abreu AP, Fernandes B, Vicente AA, Teixeira J, Dragone G (2012) Mixotrophic cultivation of Chlorella vulgaris using industrial dairy waste as organic carbon source. Bioresour Technol 118:61–66

Ahn HM, Kim S-H, Hyun S-H, Lim SR, Kim H-Y, Oh J, Lee K-M, Hong S-J, Cho B-K, Lee H, Lee C-G, Choi H-K (2016) Effects of the timing of a culture temperature reduction on the comprehensive metabolite profiles of Chlorella vulgaris. J Appl Phycol 28:2641–2650

Aitzetmüller K, Strain HH, Svec WA, Grandolfo M, Ktz JJ (1969) Loroxanthin, a unique xanthophyll from Scenedesmus obliquus and Chlorella oulgaris. Phytochemistry 8:1761–1770

Aremu AO, Masondo NA, Molnár Z, Stirk WA, Ördög V, Van Staden J (2016) Changes in phytochemical content and pharmacological activities of three Chlorella strains grown in different nitrogen conditions. J Appl Phycol 28:149–159

Bampouli A, Kyriakopoulou K, Papaefstathiou G, Louli V, Aligiannis N, Magoulas K, Krokida M (2015) Evaluation of total antioxidant potential of Pistacia lentiscus var. chia leaves extracts using UHPLC-HRMS. J Food Eng 167:25–31

Bradford MM (1976) A rapid and sensitive method for the quantitation of microgram quantities of protein utilizing the principle of protein-dye binding. Anal Biochem 72:248–254

Cha KH, Kang SW, Kim CY, Um BH, Na YR, Pan CH (2010) Effect of pressurized liquids on extraction of antioxidants from Chlorella vulgaris. J Agric Food Chem 58:4756–4761

Champenois J, Marfaing H, Pierre R (2015) Review of the taxonomic revision of Chlorella and consequences for its food uses in Europe. J Appl Phycol 27:1845–1851

Chen C-L, Chang J-S, Lee D-J (2015) Dewatering and drying methods for microalgae. Dry Technol 33:443–454

Crupi P, Milella RA, Antonacci D (2010) Simultaneous HPLC-DAD-MS (ESI+) determination of structural and geometrical isomers of carotenoids in mature grapes. J Mass Spectrom 45:971–980

Cunniff PA (1998) Official methods of analysis of AOAC international. Assoc Off Anal Chem Int CD-ROM. doi:10.3109/15563657608988149

Dey S, Rathod VK (2013) Ultrasound assisted extraction of β-carotene from Spirulina platensis. Ultrason Sonochem 20:271–276

Doucha J, Lívansky K (2012) Production of high-density Chlorella culture grown in fermenters. J Appl Phycol 24:35–43

Giri SK, Prasad S (2007) Drying kinetics and rehydration characteristics of microwave-vacuum and convective hot-air dried mushrooms. J Food Eng 78:512–521

Görs M, Schumann R, Hepperle D, Karsten U (2010) Quality analysis of commercial Chlorella products used as dietary supplement in human nutrition. J Appl Phycol 22:265–276

Gouveia L, Veloso V, Reis A et al (1996) Evolution of pigment composition in Chlorella vulgaris. Bioresour Technol 57:157–163

Jaime L, Mendiola JA, Herrero M, Soler-Rivas C, Santoyo S, Señorans FJ, Cifuentes A, Ibáñez E (2005) Separation and characterization of antioxidants from Spirulina platensis microalga combining pressurized liquid extraction, TLC, and HPLC-DAD. J Sep Sci 28:2111–2119

Jeffrey SW, Mantoura RFC, Wright SW (1997) Phytoplankton pigments in oceanography, International Council of Scientific Unions. Scientific Committee on Oceanic Research. UNESCO Publishing, Paris

King VA, Liu CF, Liu YJ (2001) Chlorophyll stability in spinach dehydrated by freeze-drying and controlled low-temperature vacuum dehydration. Food Res Int 34:167–175

Krokida MK, Karathanos VT, Maroulis ZB, Marinos-Kouris D (2003) Drying kinetics of some vegetables. J Food Eng 59:391–403

Kwang HC, Song YIK, Lee DU (2008) Antiproliferative effects of carotenoids extracted from Chlorella ellipsoidea and Chlorella vulgaris on human colon cancer cells. J Agric Food Chem 56:10521–10526

Kwang HC, Lee HJ, Koo SY, Song DG, Lee DU, Pan CH (2010) Optimization of pressurized liquid extraction of carotenoids and chlorophylls from Chlorella vulgaris. J Agric Food Chem 58:793–797

Kyriakopoulou K, Pappa A, Magdalini K, Detsi A, Kefalas P (2013) Effects of drying and extraction methods on the quality and antioxidant activity of sea buckthorn (Hippophae rhamnoides) berries and leaves. Dry Technol 31:1063–1076

Lewicki PP (2006) Design of hot air drying for better foods. Trends Food Sci Technol 17:153–163

Maskan M (2001) Drying, shrinkage and rehydration characteristics of kiwifruits during hot air and microwave drying. J Food Eng 48:177–182

Milenković SM, Zvezdanović JB, Andelković TD, Marković DZ (2012) The identification of chlorophyll and its derivatives in the pigment mixtures: HPLC-chromatography, visible and mass spectroscopy studies. Adv Technol 1:16–24

Molina Grima E, Acién Fernández FG, Robles-Medina A (2013) Downstream processing of cell-mass and products. In: Richmond A, Hu Q (eds) Handbook of microalgal culture. Biotechnology and applied phycology. Blackwell, Oxford, pp 267–309

Müller L, Fröhlich K, Böhm V (2011) Comparative antioxidant activities of carotenoids measured by ferric reducing antioxidant power (FRAP), ABTS bleaching assay (αTEAC), DPPH assay and peroxyl radical scavenging assay. Food Chem 129:139–148

Nelson JA (2015) Postharvest degradation of microalgae: effect of temperature and water activity. MSc Thesis, Utah State University

Oliveira EG, Duarte JH, Moraes K, Crexi VT, Pinto LAA (2010) Optimisation of Spirulina platensis convective drying: evaluation of phycocyanin loss and lipid oxidation. Int J Food Sci Technol 45:1572–1578

Orikasa T, Koide S, Okamoto S, Imaizumi T, Muramatsu Y, Takeda J-I, Shiina T, Tagawa A (2014) Impacts of hot air and vacuum drying on the quality attributes of kiwifruit slices. J Food Eng 125:51–58

Papadaki S, Krokida M, Economides D, Koukios E (2014) Effect of drying methods on dyeing capacity of dyestuff plant materials. Dry Technol 32:1500–1511

Plaza M, Santoyo S, Jaime L, Avalo B, Cifuentes A, Reglero G, Reina GG-B, Senorans FJ, Ibanez E (2012) Comprehensive characterization of the functional activities of pressurized liquid and ultrasound-assisted extracts from Chlorella vulgaris. LWT—Food Sci Technol 46:245–253

Pu YY, Sun DW (2017) Combined hot-air and microwave-vacuum drying for improving drying uniformity of mango slices based on hyperspectral imaging visualisation of moisture content distribution. Biosyst Eng 156:108–119

Ratti C (2001) Hot air and freeze-drying of high-value foods: a review. J Food Eng 49:311–319

Ryckebosch E, Muylaert K, Eeckhout M, Ruyssen T, Foubert I (2011) Influence of drying and storage on lipid and carotenoid stability of the microalga Phaeodactylum tricornutum. J Agric Food Chem 59:11063–11069

Sáez-Plaza P, Navas MJ, Wybraniec S, Michalowski T, Asuero AG (2013) An overview of the Kjeldahl method of nitrogen determination. Part II. Sample preparation, working scale, instrumental finish, and quality control. Crit Rev Anal Chem 43:224–272

Safi C, Zebib B, Merah O, Pontalier P-Y, Vaca-Garcia C (2014) Morphology, composition, production, processing and applications of Chlorella vulgaris: a review. Renew Sust Energy Rev 35:265–278 7

Senger H, Wagner C, Hermsmeier D, Hohl N, Urbig T, Bishop NI (1993) The influence of light intensity and wavelength on the contents of α- and β-carotene and their xanthophylls in green algae. J Photochem Photobiol B 18:273–279

Sofiyanti N, Fitmawati DI, Roza AA (2015) Stenochlaena riauensis (Blechnaceae), a new fern species from Riau, Indonesia. Bangladesh J Plant Taxon 22:137–141

Sogi DS, Siddiq M, Dolan KD (2015) Total phenolics, carotenoids and antioxidant properties of Tommy Atkin mango cubes as affected by drying techniques. LWT—Food Sci Technol 62:564–568

Stoscheck CM (1990) Quantitation of protein. Meth Enzymol 182:50–68

Sugawara T, Ganesan P, Li Z, Manabe Y, Hirata T (2014) Siphonaxanthin, a green algal carotenoid, as a novel functional compound. Mar Drugs 12:3660–3668

Vigani M, Parisi C, Rodríguez-Cerezo E, Barbosa MJ, Sijtsma L, Ploeg M, Enzing C (2015) Food and feed products from micro-algae: market opportunities and challenges for the EU. Trends Food Sci Technol 42:81–92

Viswanathan T, Mani S, Das KC, Chinnasamy S, Bhatnagar A, Singh RK, Singh M (2012) Effect of cell rupturing methods on the drying characteristics and lipid compositions of microalgae. Bioresour Technol 126:131–136

Wu LC, Ho JAA, Shieh MC, Lu IW (2005) Antioxidant and antiproliferative activities of Spirulina and Chlorella water extracts. J Agric Food Chem 53:4207–4212

Young A (2004) Carotenoids: handbook. Synthesis 2004:1901

Acknowledgments

The authors would like to thank MEDBIO S.A. for the Chlorella vulgaris biomass. Also, special thanks are addressed to Dr. Ioannis Tzovenis for his collaboration.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Stramarkou, M., Papadaki, S., Kyriakopoulou, K. et al. Effect of drying and extraction conditions on the recovery of bioactive compounds from Chlorella vulgaris . J Appl Phycol 29, 2947–2960 (2017). https://doi.org/10.1007/s10811-017-1181-8

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10811-017-1181-8