Abstract

Time-dependent reliability-based design optimization (RBDO) can provide the optimal design parameter solutions for the time-dependent structure, and thus plays a significant role in engineering application. Directly solving the time-dependent RBDO needs a nested double-loop optimization procedure, which undoubtedly leads to large computational costs. A novel decoupling method called two-step method (TSM) is proposed to efficiently solve the time-dependent RBDO. In the two-step method, the first step makes the minimum instantaneous reliability index satisfy the reliability target index by solving a transformed time-independent RBDO, and the second step performs time-dependent reliability analysis and deterministic optimization to obtain the optimal design parameters which meet the reliability target. Only a few time-dependent reliability analyses and several deterministic optimizations are involved in the proposed procedure; thus, the time-dependent RBDO can be efficiently solved. Several examples containing one numerical example and two engineering examples are introduced to show the effectiveness of the proposed TSM.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Due to the fact that lots of uncertainties including geometrical size, material property, and applied load widely exist in engineering application, traditional deterministic optimization takes these uncertainties into account by adding the safety factors to design constraints, but it is somewhat subjective to assign the values of the safety factors. Compared with the traditional deterministic optimization, reliability-based design optimization (RBDO) need not assign the values to the safety factors and has gained more and more attention at present. RBDO considers the reliability requirements as constraints in the optimization process and then it will lead to the optimal optimization solution satisfying the reliability requirements (Tu et al. 1999). Up to now, RBDO plays a significant role in design optimization of engineering application. Directly solving the RBDO requires a nested optimization, in which the outer loop searches for the optimal design parameters and the inner loop estimates the reliability. The nested optimization process often needs massive computational costs, especially for the structure with multiple reliability constraints and high-dimensional input parameters. Fortunately, several methods have been proposed to efficiently solve the RBDO problems. Generally, the existing RBDO methods can be classified into three categories (Chen et al. 2013a). The first category is the double-loop method, which mainly involves the reliability index approach (RIA) formulated RBDO method (Zou and Mahadevan 2006) and performance measure approach (PMA) formulated RBDO method (Keshtegar and Lee 2016; Huang et al. 2017a). Furthermore, Meng and Li (Meng and Li 2016) proposed a method to estimate the probabilistic constraints by combining the RIA and PMA for improving the computational efficiency. The second one is the single-loop method, which avoids the reliability analysis in the inner loop by introducing the Karush-Kuhn-Tucker (KKT) optimality condition. Kharmanda et al. (Kharmanda et al. 2002) presented a hybrid formulation in which the objective function is replaced by the product of the objective function and structural reliability to solve the RBDO. Jiang et al. (Liang et al. 2004) proposed a single-loop method (SLM) which collapses the nested optimization process into an equivalent single-loop optimization process, and thus converts the probabilistic optimization problem into an equivalent deterministic optimization problem. Agarwal et al. (Agarwal et al. 2007) combined the KKT optimality condition with the most probable point (MPP) identification to avoid the reliability analysis in the inner loop. Li at al. (Li et al. 2013) presented a single-loop deterministic method based on first-order reliability method to convert the probabilistic constraints into approximate deterministic constraints; thus, the RBDO can be solved by deterministic optimization problem. The third category is the decoupling method, which fully uses the information from the reliability analysis stage to the optimization stage in order to improve the computational efficiency. Tu et al. (Tu et al. 2001) constructed the linear approximation of the probabilistic constraints to formulate the RBDO as a linear programming problem, in which the special treatments of active and inactive constraints are imposed to improve the efficiency. Cheng et al. (Cheng et al. 2006) proposed a decoupling method by solving a sequence of sub-programming problems including an approximate objective function subjected to several approximated constraints. Du and Chen (Du and Chen 2004) developed the sequential optimization and reliability assessment (SORA) approach to transform the RBDO into a series of deterministic optimization and reliability analysis problem, and a shifting vector is constructed in each iterative step according to the reliability solutions from previous iteration to shift the boundaries of the violated constraints to the feasible direction. Huang et al. (Huang et al. 2012) presented an enhanced SORA method to further improve the computational efficiency of SORA in solving RBDO by considering both cases of constraint and variances of random design parameter. Huang et al. (Huang et al. 2016) proposed an incremental shifting vector approach to efficiently solve RBDO by performing the shifting vector estimation and a deterministic optimization in each cycle. For the structure with multiple uncertainties, Huang et al. (Huang et al. 2017b) established an efficient decoupling strategy to solve the RBDO with both probabilistic and interval uncertainties. Li et al. (Li et al. 2019) proposed a sequential sampling strategy by extending the SORA for RBDO with probabilistic and convex set uncertainties, and this method can successively choose samples to update the surrogate model so to provide accurate solutions with low computational costs. Other researches about the RBDO can be found in Refs. (Li et al. 2015; Kang and Luo 2010; Huang et al. 2019; Chen et al. 2013b; Du et al. 2008).

Above RBDO methods are mostly proposed for the time-independent structures, but the RBDO for the time-dependent structures is more concerned by the engineers. The time-dependent RBDO treats the time-dependent reliability requirements as constraints to lead to the optimal design parameter solutions for the time-dependent structure. The time-dependent RBDO is more complicated than the time-independent one, and methods for time-independent RBDO cannot be directly employed to solve time-dependent RBDO. Wang et al. (Wang and Wang 2012a) proposed a nested extreme response surface method to convert the time-dependent RBDO problem to time-independent one. Huang et al. (Huang et al. 2017c) developed a single-loop approach to convert time-dependent RBDO into a sequentially iterative process involving time-dependent reliability analysis, constraint discretization, and deterministic optimization. Li et al. (Li et al. 2018) presented a sequential kriging modeling approach to solve time-dependent RBDO, in which the time-dependent performance function is transformed into time-independent one by dealing the stochastic processes and time parameter as the random variables. Fang et al. (Fang et al. 2018) proposed the definition of the equivalent MPP, and employed the equivalent MPP to transform the time-dependent RBDO into an equivalent time-independent RBDO formulated by PMA. Hawchar et al. (Hawchar et al. 2018) constructed the surrogate models of constraints in an augmented sample space, and then solved the time-dependent RBDO based on the constructed surrogate models. Hu and Du (Du Z Hu 2015) extended the SORA to time-dependent RBDO with input random variable and stationary stochastic process, and the solutions are satisfied. But the time-dependent SORA cannot be directly used to solve the time-dependent RBDO with input random variable, stationary stochastic process, and time parameter. By constructing an equivalent time-independent RBDO problem, Jiang et al. (Jiang et al. 2017) proposed a time-invariant equivalent method (TIEM) which decouples time-dependent RBDO into a series of time-independent RBDO and time-dependent reliability analysis, and the solutions illustrate that this method is an accurate and efficient one in solving time-dependent RBDO. More studies about time-dependent RBDO can be found in Refs. (Wang et al. 2018; Wang and Wang 2012b; Singh et al. 2010). Although several methods have been be used to save the computational cost of time-dependent RBDO, it is still a major challenge to solve time-dependent RBDO with high efficiency. Therefore, it is necessary to develop efficient method for dealing time-dependent RBDO.

The aim of this work is to propose a novel decoupling method for time-dependent RBDO. There are two steps in the proposed method, the first step performs the design parameter solutions that make the minimum instantaneous reliability index satisfy the reliability index target, and the second step executes the final optimal design parameter solutions to meet reliability target of the time-dependent reliability. In the first step of the proposed method, the time-dependent RBDO is converted to the calculation of an incremental shifting vector and a deterministic design optimization in each cycle, and converges to the design parameter solutions where the minimum instantaneous reliability indices satisfy the required one. The second step of the proposed method preserves the information from the last step and only a few time-dependent reliability analyses are needed to obtain the optimal design parameter solutions. Thus, we call the proposed method as the two-step method (TSM). The proposed TSM exhibits high computational efficiency and wide application range in the time-dependent RBDO of structure and product. Up to the author’s knowledge, this approach has not been previously presented.

The rest of this work is constructed as follows. The definition of the time-dependent RBDO is given in Section 2. The proposed new decoupling TSM for time-dependent RBDO is showed in Section 3. The estimation procedure of the proposed TSM is summarized in Section 4. Discussions about the proposed TSM are provided in Section 5. Several examples are introduced in Section 6. Conclusions are summarized in Section 7.

2 Definition of time-dependent RBDO

The performance function of the time-dependent structure can be expressed as g(Z, Y(t), t), where Z means the nZ-dimensional random variable vector, Y(t) represents the nY-dimensional stochastic process vector, and t ∈ [t0, te] is the time parameter. The failure probability Pf of the time-dependent structure can be estimated by:

in which P{·} represents probability operator.

The equivalent time-dependent reliability index β(t) is expressed as follows (Jiang et al. 2017):

where Φ−1(·) means the inverse cumulative distribution function (CDF) of standard normal variable. Generally, at a time instant tl ∈ [t0, te], the performance function g(Z, Y(tl), tl) is time-independent and the instantaneous reliability index βl can be easily obtained by the existing MPP searching techniques. It is well known that the relationship between time-dependent reliability index β(t) and instantaneous reliability βl can be expressed by:

The time-dependent RBDO treats the time-dependent reliability requirements as probability constraints in the optimization process and it can be expressed in the following form.

in which f(d, μX) represents the objective function, and gi(d, Z, Y(t), t)(i = 1, 2, …, ng) is the performance function of the i-th probability constraint. d means the nd-dimensional deterministic design parameter vector with the lower bound vector dL and upper one dU respectively. X represents the nX-dimensional random design vector with mean vector μX, where the lower and upper bounds of μX are \( {\boldsymbol{\upmu}}_X^L \) and \( {\boldsymbol{\upmu}}_X^U \) respectively. P is the nP-dimensional random parameter vector and \( {\beta}_i^{\mathrm{tar}} \) denotes the reliability index target of the i-th probability constraint.

3 The proposed TSM for time-dependent RBDO

The proposed method estimates the optimal design parameter solutions of the time-dependent RBDO by two steps, in which the first step performs the design parameter solutions that make the minimum instantaneous reliability index satisfy reliability index target and the second step obtains the optimal design parameter solutions satisfying the time-dependent reliability target. The first step converts the nested time-dependent RBDO into the calculation of an incremental shifting vector and deterministic design optimization in each iteration, and sequential approximation is used to ensure stable convergence in the iteration process. It should be noted that the second step of the proposed method can be regarded as an amendment of the first one, and thus make the design parameter solutions satisfy the time-dependent reliability index target. There are only a few time-dependent reliability analyses in the whole optimization process of the proposed TSM. Details of the TSM are showed as follows.

3.1 First step of the TSM

As discussed in Section 2, the performance function gi(d, Z, Y(tl), tl)(i = 1, 2, ..., ng) can be viewed as the time-independency at a time instant tl ∈ [t0, te], and the corresponding instantaneous reliability index βil can be easily obtained by the existing MPP searching techniques. When the time instant tl screens the interval [t0, te], the minimum instantaneous reliability index βimin for the i-th performance function can be expressed as follows:

The time instant timin corresponding to the minimum instantaneous reliability index βimin can be obtained by:

Therefore, we first convert the original time-dependent RBDO showed in Eq. (4) into the following time-independent one.

It is easy to know that the optimal design parameter solutions of Eq. (7) can make \( {\beta}_{i\min}\ge {\beta}_i^{tar}\left(i=1,2,...,{n}_g\right) \) but not \( {\beta}_i(t)\ge {\beta}_i^{tar}\left(i=1,2,...,{n}_g\right) \) in the original time-dependent RBDO problem. Anyhow, the aim of the first step of the proposed TSM is to solve Eq. (7) to obtain the design parameter solutions that make \( {\beta}_{i\min}\ge {\beta}_i^{tar}\left(i=1,2,...,{n}_g\right) \), and the second step will employ the information of the first step to gain the optimal design parameter solutions that make \( {\beta}_i(t)\ge {\beta}_i^{tar}\left(i=1,2,...,{n}_g\right) \). Although Eq. (7) is a time-independent RBDO problem, it is difficult to directly use the existing time-independent RBDO approaches to solve this design optimization because timin varies with different design parameters and estimating timin in each iteration will lead to lots of computational costs. This work presents an incremental shifting vector strategy to efficiently solve Eq. (7). Although the incremental vector strategy (Huang et al. 2016) has been employed in the time-independent RBDO, it has not be used in the time-dependent RBDO procedure.

Based on the well-known SORA strategy (Du and Chen 2004) in time-independent RBDO, Eq. (7) is equivalent to the following deterministic optimization.

where μP and \( {\boldsymbol{\upmu}}_{Y\left({t}_{i\min}\right)} \) are the mean vectors of the random parameter vector P and the stochastic process vector Y(timin) at time instant timin respectively. \( {\mathbf{M}}_i^{(k)} \) is the shifting vector in the k-th iteration, and \( {\mathbf{M}}_i^{(k)} \) determines the difference between the probabilistic constraint boundary and equivalent deterministic constraint boundary. The shifting vector \( {M}_i^{(k)} \) in the k-th iteration is generally estimated based on the original boundary gi(d, μS, timin) = 0, and it makes the deterministic constraint \( {g}_i\left(\mathbf{d},{\boldsymbol{\upmu}}_S-{\mathbf{M}}_i^{(k)},{t}_{i\min}\right)\ge 0 \) equivalent to the original probabilistic constraint \( P\left\{{g}_i\left(\mathbf{d},\mathbf{Z},\mathbf{Y}\left({t}_{i\min}\right),{t}_{i\min}\right)\le 0\right\}\le \varPhi \left(-{\beta}_i^{tar}\right) \). By referring to the work in Ref (Huang et al. 2016) for time-independent RBDO, an incremental shifting vector \( \varDelta {\mathbf{M}}_i^{(k)} \) combining with the shifting vector \( {\mathbf{M}}_i^{\left(k-1\right)} \) in the previous step is employed to construct the current shifting vector \( {\mathbf{M}}_i^{(k)} \) in the following form.

It can be seen from Eq. (9) that the shifting vector in each iteration is only an adjustment to the shifting vector in the previous iteration, and only the shifting vector increment \( \varDelta {\mathbf{M}}_i^{(k)} \) needs to be estimated in the k-th iteration.

For determining the shifting vector increment \( \varDelta {\mathbf{M}}_i^{(k)} \) in the k-th iteration, we first transform the original probabilistic space into the standard normal space, which can be realized by the following equivalent probability transformation.

where S = [X, P, Y(timin)], Sj is the variable in S and j = 1, 2, ..., nX + nP + nY. \( {\mathrm{F}}_{S_j}\left({S}_j\right) \) is the CDF of Sj. It is supposed that the i-th performance function gi and the shifting vector increment \( \varDelta {\mathbf{M}}_i^{(k)} \) are denoted by Gi and \( \varDelta {\mathbf{M}}_{Ui}^{(k)} \) respectively in the standard normal space. Figure 1 shows the geometric representation of the shifting vector increment \( \varDelta {\mathbf{M}}_{Ui}^{(k)} \) in the standard normal space. The curves \( {G}_i\left(\mathbf{d},\mathbf{U}-{\mathbf{M}}_{Ui}^{\left(k-1\right)},{t}_{i\min}\right)=0 \) and \( {G}_i\left(\mathbf{d},\mathbf{U}-{\mathbf{M}}_{Ui}^{(k)},{t}_{i\min}\right)=0 \) represent the equivalent constraint boundaries of the (k − 1)-th iteration and k-th iteration respectively, where U is the input variable vector in the standard normal space. From the limit state function Gi(d, U, timin) = 0 in Fig. 1, one can see that the actual minimum instantaneous reliability index \( {\beta}_{i\min}^{(k)} \) is less than the target reliability index \( {\beta}_i^{tar} \), and the difference can be expressed as \( \varDelta {\beta}_i^{(k)}={\beta}_i^{tar}-{\beta}_{i\min}^{(k)} \). In order to improve the design reliability, the constraint boundary should be adjusted toward the feasible domain in the k-th iteration. That is to say, the equivalent constraint boundary should be shifted from the previous iterative step by \( \varDelta {\beta}_i^{(k)} \) in the MPP gradient direction. It is just the shifting vector increment \( \varDelta {\mathbf{M}}_{Ui}^{(k)} \) that should be considered and we can obtain the equivalent constraint boundary \( {G}_i\left(\mathbf{d},\mathbf{U}-{\mathbf{M}}_{Ui}^{(k)},{t}_{i\min}\right)=0 \). Considering the design parameters vector d and timin are mutative in the iterative process, and the k-th constraint boundary \( {G}_i\left(\mathbf{d},\mathbf{U}-{\mathbf{M}}_{Ui}^{(k)},{t}_{i\min}\right)=0 \) is influenced by the (k − 1)-th design parameters vector d(k − 1), the shifting vector increment \( \varDelta {\mathbf{M}}_{Ui}^{(k)} \) can be estimated by:

where \( \nabla {G}_i\left({\mathbf{d}}^{\left(k-1\right)},{\mathbf{U}}_{MPP\min}^{(k)},{t}_{\mathrm{min}}^{(k)}\right) \) represents the derivative vector of performance function with respect to the input variables at \( {\mathbf{U}}_{MPP\min}^{(k)} \) in the standard normal space, and \( \left\Vert \nabla {G}_i\left({\mathbf{d}}^{\left(k-1\right)},{\mathbf{U}}_{MPP\min}^{(k)},{t}_{\mathrm{min}}^{(k)}\right)\right\Vert \) means the 2-norm of \( \nabla {G}_i\left({\mathbf{d}}^{\left(k-1\right)},{\mathbf{U}}_{MPP\min}^{(k)},{t}_{\mathrm{min}}^{(k)}\right) \). \( {\mathbf{U}}_{MPP\min}^{(k)} \) is the MPP corresponding to the minimum instantaneous reliability index \( {\beta}_{i\min}^{(k)} \). Directly estimating Eq. (11) needs to obtain the information of MPP corresponding to the minimum instantaneous reliability index \( {\beta}_{i\min}^{(k)} \), which is a nested double-loop multi-variant optimization problem. It may cause huge error to solve this optimization problem when the number of inputs is large, and undoubtedly, this will lead to huge computational costs in engineering application.

For saving the computational cost, the gradient at the origin U0 = 0 can be employed to approximate the gradient at the MPP \( {\mathbf{U}}_{MPP\min}^{(k)} \). This approximation strategy has been used in time-independent RBDO (Huang et al. 2016) and it leads to a satisfied solution. Then, the approximate minimum instantaneous reliability index \( {\hat{\beta}}_{i\min}^{(k)} \) and time instant \( {\hat{t}}_{i\min}^{(k)} \) can be obtained as follows:

Equation (12) transforms the original nested double-loop multi-variant optimization problem into the single-loop double-variant optimization process, and thus saves the computational cost. After that, the k-th iterative shifting vector increment \( \varDelta {\mathbf{M}}_{Ui}^{(k)} \) in the standard normal space can be obtained by:

Using Eq. (10) to map \( \varDelta {\mathbf{M}}_{Ui}^{(k)} \) to the original probabilistic space, the shifting vector increment \( \varDelta {\mathbf{M}}_i^{(k)} \) can be efficiently obtained.

Therefore, the time-independent RBDO showed in Eq. (7) is estimated by alternately shifting vector increment \( \varDelta {\mathbf{M}}_{Ui}^{(k)} \) in Eq. (13) and deterministic optimization in Eq. (8). Generally, there may be many probabilistic constraints in Eq. (7) or deterministic constraints in Eq. (8), and some of these constraints may always satisfy the reliability target in the iterative process. It is no need to shift the vector for the constraints satisfying the reliability requirements, and the corresponding shifting vector increment \( \varDelta {\mathbf{M}}_i^{(k)} \) can be set to be zero, i.e., \( \varDelta {\mathbf{M}}_i^{(k)}=0 \). The value of performance function at the MPP in the previous iteration is used to assess this condition.

where \( {t}_{i\min}^{\ast \left(k-1\right)} \) corresponds to the inverse MPP \( {\mathbf{U}}_{MPP\min}^{\ast \left(k-1\right)} \) with the performance function Gi(d(k − 1), U, t), and the inverse MPP \( {\mathbf{U}}_{MPP\min}^{\ast \left(k-1\right)} \) is estimated as \( \Big\{{\displaystyle \begin{array}{l}\min\;{G}_i\left({\mathbf{d}}^{\left(k-1\right)},{\mathbf{U}}_{MPP\min}^{\ast \left(k-1\right)},{t}_{i\min}^{\ast \left(k-1\right)}\right)\\ {}s.t.\left\Vert {\mathbf{U}}_{MPP\min}^{\ast \left(k-1\right)}\right\Vert ={\beta}_i^{tar},{t}_{i\min}^{\ast \left(k-1\right)}\in \left[{t}_0,{t}_e\right]\end{array}} \). Combining the above analysis that the gradient at the origin U0 = 0 can be employed to approximate the gradient at the MPP, Eq. (14) can be approximated as follows:

Equation (15) is a simple single-variant optimization problem and can be efficiently estimated. \( {t}_{i\min}^{\ast \left(k-1\right)} \) can be approximated by:

Then, before each iterative process, \( {G}_i\left({\mathbf{d}}^{\left(k-1\right)},{\mathbf{U}}_{MPP\min}^{\ast \left(k-1\right)},{t}_{i\min}^{\ast \left(k-1\right)}\right) \) showed in Eq. (15) will be estimated firstly. If \( {G}_i\left({\mathbf{d}}^{\left(k-1\right)},{\mathbf{U}}_{MPP\min}^{\ast \left(k-1\right)},{t}_{i\min}^{\ast \left(k-1\right)}\right)\ge 0 \), then the i-th constraint satisfies the reliability index target and we set \( \varDelta {\mathbf{M}}_i^{(k)}=0 \); else, \( \varDelta {\mathbf{M}}_i^{(k)} \) will be estimated by the proposed procedure.

The first step of the proposed method performs the design parameter solutions satisfying \( {\beta}_{i\min}\ge {\beta}_i^{tar}\left(i=1,2,...,{n}_g\right) \). In the next subsection, the second step of the proposed method will be established based on the information of the first step in order to make time-dependent reliability index βi(t) satisfy reliability target \( {\beta}_i^{\mathrm{tar}} \), i.e., \( {\beta}_i(t)\ge {\beta}_i^{\mathrm{tar}}\left(i=1,2,...,{n}_g\right) \).

3.2 Second step of the TSM

The second step of the proposed method can be regarded as an amendment of the first step. Denote the obtained design parameter solutions by the convergent first step as \( \left[{\mathbf{d}}^{\mathrm{first}},{\boldsymbol{\upmu}}_X^{\mathrm{first}}\right] \), and the corresponding minimum instantaneous reliability index and MPP as \( {\beta}_{i\min}^{\mathrm{first}} \) and \( {\mathbf{U}}_{MPP\min}^{\mathrm{first}} \) respectively. Here, we firstly perform time-dependent reliability analysis of i-th performance function gi(d, Z, Y(t), t) based on the design parameter solutions \( \left[{\mathbf{d}}^{\mathrm{first}},{\boldsymbol{\upmu}}_X^{\mathrm{first}}\right] \), and the corresponding time-dependent reliability index is denoted as \( {\beta}_i^{\mathrm{first}}(t) \) by Eq. (2). Combining with Eq. (3), it is easy to know that \( {\beta}_i^{\mathrm{first}}(t)\le {\beta}_{i\min}^{\mathrm{first}} \) which is showed in Fig. 2. From Fig. 2, one can see that \( {\beta}_i^{\mathrm{first}}(t)<{\beta}_i^{\mathrm{tar}} \) which illustrates the design parameter solutions \( \left[{\mathbf{d}}^{\mathrm{first}},{\boldsymbol{\upmu}}_X^{\mathrm{first}}\right] \) from the first step are not the optimal solutions and they should be updated to \( \left[{\mathbf{d}}^{\mathrm{second}},{\boldsymbol{\upmu}}_X^{\mathrm{second}}\right] \) in order to satisfy \( {\beta}_i^{\mathrm{second}}(t)\ge {\beta}_i^{\mathrm{tar}} \), where \( {\beta}_i^{\mathrm{second}}(t) \) is the time-dependent reliability index corresponding to the design parameter solutions \( \left[{\mathbf{d}}^{\mathrm{second}},{\boldsymbol{\upmu}}_X^{\mathrm{second}}\right] \). Fortunately, this can be realized by shifting the equivalent constraint boundary Gi(dfirst, U, timin) = 0 with a shifting vector increment by \( \left({\beta}_i^{\mathrm{tar}}-{\beta}_i^{\mathrm{first}}(t)\right) \) along the MPP gradient direction. Combining the discussion in the first step of the proposed method, the following shifting vector increment \( \varDelta {\mathbf{M}}_{Ui}^{\mathrm{second}} \) can be constructed.

where \( {\hat{t}}_{i\min}^{\mathrm{second}} \) can be estimated by the following simply optimization process.

The shifting vector increment \( \varDelta {\mathbf{M}}_{Ui}^{\mathrm{second}} \) in the standard normal space is then transformed into the original input space \( \varDelta {\mathbf{M}}_i^{\mathrm{second}} \) by Eq. (10), and the new shifting vector can be expressed as \( {\mathbf{M}}_i^{\mathrm{second}}={\mathbf{M}}_i^{\mathrm{first}}+\varDelta {\mathbf{M}}_i^{\mathrm{second}} \), where \( {\mathbf{M}}_i^{\mathrm{first}} \) is the shifting vector at the end of the first step. We further perform the deterministic optimization by Eq. (8) to obtain the final design parameter solutions \( \left[{\mathbf{d}}^{\mathrm{second}},{\boldsymbol{\upmu}}_X^{\mathrm{second}}\right] \).

It should be noted that \( \left[{\mathbf{d}}^{\mathrm{second}},{\boldsymbol{\upmu}}_X^{\mathrm{second}}\right] \) is general little different from \( \left[{\mathbf{d}}^{\mathrm{first}},{\boldsymbol{\upmu}}_X^{\mathrm{first}}\right] \) because that the difference between \( {\beta}_i^{\mathrm{first}}(t) \) and \( {\beta}_{i\min}^{\mathrm{first}} \) is usually small. Now that the first step of the proposed method provides the convergent design parameter solutions \( \left[{\mathbf{d}}^{\mathrm{first}},{\boldsymbol{\upmu}}_X^{\mathrm{first}}\right] \), ideally we just need to perform once time-dependent reliability analysis to obtain \( {\beta}_i^{\mathrm{first}}(t) \) and once deterministic optimization by Eq. (8) to obtain the design parameter solutions \( \left[{\mathbf{d}}^{\mathrm{second}},{\boldsymbol{\upmu}}_X^{\mathrm{second}}\right] \) satisfying \( {\beta}_i^{\mathrm{second}}(t)\ge {\beta}_i^{\mathrm{tar}}\left(i=1,2,...,{n}_g\right) \). Furthermore, if \( {\beta}_i^{\mathrm{first}}(t)\ge {\beta}_i^{\mathrm{tar}} \), which means that the i-th constraint under the design parameter solutions \( \left[{\mathbf{d}}^{\mathrm{first}},{\boldsymbol{\upmu}}_X^{\mathrm{first}}\right] \) satisfies the reliability target and we do not need to shift this constraint boundary; thus, we set \( \varDelta {\mathbf{M}}_i^{\mathrm{second}}=0 \) and the estimating of \( \varDelta {\mathbf{M}}_{Ui}^{\mathrm{second}} \) in Eq. (17) can be eliminated. In order to guarantee the final design parameter solutions \( \left[{\mathbf{d}}^{\mathrm{second}},{\boldsymbol{\upmu}}_X^{\mathrm{second}}\right] \) strictly satisfy \( {\beta}_i^{\mathrm{second}}(t)\ge {\beta}_i^{\mathrm{tar}}\left(i=1,2,...,{n}_g\right) \), we also perform the similar iteration process as the first step of the proposed TSM to estimate the final design parameter solutions.

4 Estimation procedure of the proposed TSM

We briefly summarize the estimation procedure of the proposed TSM as follows.

Step 1: Set the initial design parameter solutions \( \left[{\mathbf{d}}^{\mathrm{first}(0)},{\boldsymbol{\upmu}}_X^{\mathrm{first}(0)}\right] \) and the convergence threshold \( {\varepsilon}_f^{\mathrm{first}} \) of objective function for the first step, and let k = 0 and \( \varDelta {\mathbf{M}}_i^{first(0)}=\mathbf{0} \).

Step 2: Let k = k + 1 and estimate \( {G}_i\left({\mathbf{d}}^{\mathrm{first}\left(k-1\right)},{\mathbf{U}}_{MPP\min}^{\ast \mathrm{first}\left(k-1\right)},{t}_{i\min}^{\ast \mathrm{first}\left(k-1\right)}\right) \) and corresponding \( {t}_{i\min}^{\ast \mathrm{first}\left(k-1\right)} \) by Eq. (15) and Eq. (16) respectively for i = 1, 2, ..., ng.

Step 3: If \( {G}_i\left({\mathbf{d}}^{\mathrm{first}\left(k-1\right)},{\mathbf{U}}_{MPP\min}^{\ast \mathrm{first}\left(k-1\right)},{t}_{i\min}^{\ast \mathrm{first}\left(k-1\right)}\right)\ge 0 \), then let \( \varDelta {\mathbf{M}}_i^{\mathrm{first}(k)}=0 \) and \( {\hat{t}}_{i\min}^{\mathrm{first}(k)}={t}_{i\min}^{\ast \mathrm{first}\left(k-1\right)} \); else, use Eq. (13) and Eq. (12) to estimate \( \varDelta {\mathbf{M}}_{Ui}^{\mathrm{first}(k)} \) and \( {\hat{t}}_{i\min}^{\mathrm{first}(k)} \) respectively, and transform \( \varDelta {\mathbf{M}}_{Ui}^{\mathrm{first}(k)} \) to \( \varDelta {\mathbf{M}}_i^{\mathrm{first}(k)} \) by the equivalent probability transformation showed in Eq. (10).

Step 4: Estimate the shifting vector \( {\mathbf{M}}_i^{\mathrm{first}(k)}={\mathbf{M}}_i^{\mathrm{first}\left(k-1\right)}+\varDelta {\mathbf{M}}_i^{\mathrm{first}(k)} \) and employ the following deterministic optimization to obtain the updated design parameter solutions \( \left[{\mathbf{d}}^{\mathrm{first}(k)},{\boldsymbol{\upmu}}_X^{\mathrm{first}(k)}\right] \).

-

Step 5: If the convergence condition is satisfied, i.e., \( \mid \frac{f\left({\mathbf{d}}^{\mathrm{first}(k)},{\boldsymbol{\upmu}}_X^{\mathrm{first}(k)}\right)-f\left({\mathbf{d}}^{\mathrm{first}\left(k-1\right)},{\boldsymbol{\upmu}}_X^{\mathrm{first}\left(k-1\right)}\right)}{f\left({d}^{\mathrm{first}(k)},{\mu}_X^{\mathrm{first}(k)}\right)}\mid \le {\varepsilon}_f^{\mathrm{first}} \), then let \( \left[{\mathbf{d}}^{\mathrm{first}},{\boldsymbol{\upmu}}_X^{\mathrm{first}}\right]=\left[{\mathbf{d}}^{\mathrm{first}(k)},{\boldsymbol{\upmu}}_X^{\mathrm{first}(k)}\right] \), \( {\mathbf{M}}_i^{\mathrm{first}}={\mathbf{M}}_i^{\mathrm{first}(k)} \), \( {\hat{t}}_{i\min}^{\mathrm{first}}={\hat{t}}_{i\min}^{\mathrm{first}(k)} \), k = 0 and go to step 6; else, go to step 2.

-

Step 6: Let \( {\mathbf{M}}_i^{\mathrm{second}(k)}={\mathbf{M}}_i^{\mathrm{first}} \), \( \left[{\mathbf{d}}^{\mathrm{second}(k)},{\boldsymbol{\upmu}}_X^{\mathrm{second}(k)}\right]=\left[{d}^{\mathrm{first}},{\mu}_X^{\mathrm{first}}\right] \) and \( {\hat{t}}_{i\min}^{\mathrm{second}(k)}={\hat{t}}_{i\min}^{\mathrm{first}} \).

-

Step 7: Compute the time-dependent reliability index \( {\beta}_i^{\mathrm{second}(k)}(t) \) of constraint function for i = 1, 2, ..., ng based on design parameter solutions \( \left[{\mathbf{d}}^{\mathrm{second}(k)},{\boldsymbol{\upmu}}_X^{\mathrm{second}(k)}\right] \).

-

Step 8: If \( {\beta}_i^{\mathrm{second}(k)}(t)\ge {\beta}_i^{\mathrm{tar}} \), then set \( \varDelta {\mathbf{M}}_i^{\mathrm{second}\left(k+1\right)}=0 \) and \( {\hat{t}}_{i\min}^{\mathrm{second}\left(k+1\right)}={\hat{t}}_{i\min}^{\mathrm{second}(k)} \); else, estimate \( \varDelta {\mathbf{M}}_{Ui}^{\mathrm{second}\left(k+1\right)} \) and \( {\hat{t}}_{i\min}^{\mathrm{second}\left(k+1\right)} \) by Eq. (17) and Eq. (18) respectively, and transform \( \varDelta {\mathbf{M}}_{Ui}^{\mathrm{second}\left(k+1\right)} \) to \( \varDelta {\mathbf{M}}_i^{\mathrm{second}\left(k+1\right)} \) by the equivalent probability transformation showed in Eq. (10).

-

Step 9: Estimate the shifting vector \( {\mathbf{M}}_i^{\mathrm{second}\left(k+1\right)}={\mathbf{M}}_i^{\mathrm{second}(k)}+\varDelta {\mathbf{M}}_i^{\mathrm{second}\left(k+1\right)} \). If \( {\mathbf{M}}_i^{\mathrm{second}\left(k+1\right)}={\mathbf{M}}_i^{\mathrm{second}(k)} \) for all i = 1, 2, ..., ng, go to step 10; else, employ the following deterministic optimization to obtain the design parameter solutions \( \left[{\mathbf{d}}^{\mathrm{second}\left(k+1\right)},{\boldsymbol{\upmu}}_X^{\mathrm{second}\left(k+1\right)}\right] \), and let k = k + 1 and go to step 7.

-

Step 10: Obtain the final optimal design parameter solutions \( \left[{\mathbf{d}}^{\mathrm{second}},{\boldsymbol{\upmu}}_X^{\mathrm{second}}\right]=\left[{\mathbf{d}}^{\mathrm{second}(k)},{\boldsymbol{\upmu}}_X^{\mathrm{second}(k)}\right] \).

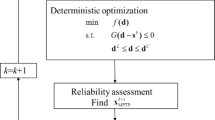

The flowchart of the proposed method is showed in Fig. 3. It is easy to conclude that the proposed TSM transforms the original nested optimization problem to the sequential deterministic optimization one for the time-dependent structure. In the first step of the proposed TSM, the deterministic optimization and calculation of shifting vector increment are alternately proceeded to obtain the updated design parameter solutions \( \left[{\mathbf{d}}^{\mathrm{first}},{\boldsymbol{\upmu}}_X^{\mathrm{first}}\right] \), and the second step of the proposed method inherits the information of first step so to lead to the optimal design parameter solutions \( \left[{\mathbf{d}}^{\mathrm{second}},{\boldsymbol{\upmu}}_X^{\mathrm{second}}\right] \). Furthermore, only a few time-dependent reliability analyses are needed in the whole procedure, which illustrates the high efficiency of the proposed method.

5 Discussions

This work mainly focuses on efficiently solving the time-dependent RBDO by an established decoupling method named TSM. In the proposed TSM, the time-dependent RBDO is solved by two steps. The first step constructs an equivalent time-independent RBDO satisfying \( {\beta}_{i\min}\ge {\beta}_i^{\mathrm{tar}}\left(i=1,2,...,{n}_g\right) \), and the second step makes an amendment based on the information from first step and further obtains the optimal design parameter solutions satisfying \( {\beta}_i(t)\ge {\beta}_i^{\mathrm{tar}}\left(i=1,2,...,{n}_g\right) \). Simultaneously, the incremental vector strategy (Huang et al. 2016) is embedded in the established two-step framework to solve the equivalent time-independent RBDO. It should be noted that the proposed TSM is different from the time-dependent SORA (Du Z Hu 2015). The first difference is that the time-dependent SORA (Du Z Hu 2015) is proposed for the time-dependent RBDO with only input random variable and stationary stochastic process, and it cannot be directly used to solve the time-dependent RBDO with input random variable, stationary stochastic process, and time parameter. While the proposed TSM has no limit for the form of the time-dependent RBDO, both forms can be solved by the TSM. The second difference is that the time-dependent SORA needs to solve a multi-dimensional optimization to obtain the shifting vector in each iteration, while the TSM estimates the incremental shifting vector by a double-variant optimization process and combines with the shifting vector in previous iteration to construct the shifting vector in current iteration. The third difference is that the TSM is a two-step estimation framework and the time-dependent SORA is a one-step estimation framework.

The advantages of the established TSM can be summarized as two points. First of all, a double-variant optimization process is constructed to estimate the incremental shifting vector in the TSM instead of a multi-dimensional optimization to calculate the shifting vector in the traditional methods. Generally, the double-variant optimization is easier to estimate than the multi-dimensional optimization. Secondly, there is no time-dependent reliability analysis in the first step and only a few time-dependent reliability analyses are needed in the second step; thus, the computational efficiency is improved. At the same time, the TSM employs the gradient in the origin to approximate that of the MPP in order to save computational cost. This strategy has been used in the time-independent RBDO (Huang et al. 2016), and the solutions show that this approximation generally makes little influence on the accurate estimation of the design parameters for the general non-linear problem.

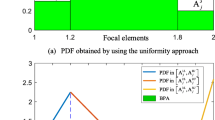

Generally, the time-dependent reliability in the second step of the TSM can be estimated by any time-dependent reliability analysis methods, such as the surrogate model methods (Hu and Mahadevan 2016; Wang and Chen 2016; Shi et al. 2019) and out-crossing methods (Andrieu-Renaud et al. 2004; Shi et al. 2017). This work employs the improved time-variant reliability analysis method based on stochastic process discretization (iTRPD) (Jiang et al. 2018) to estimate the time-dependent reliability. The iTRPD scatters the time-dependent performance function into a certain number of time-independent performance functions; thus, it converts the time-dependent reliability analysis into an equivalent time-independent series system reliability analysis. The final time-dependent reliability can be estimated by combining the components’ reliabilities and correlation coefficient matrix of all components’ performance functions. The numerical examples in Ref. (Jiang et al. 2018) illustrate that the computational stability, efficiency, and accuracy of the iTRPD are satisfied. Based on the analyses in Ref. (Jiang et al. 2018) and the computing validations by lots of examples, it can be concluded that iTRPD remains efficient at least in the 10−3 order of failure probability. For the problem with low failure probability, such as 10−5 order of failure probability, other accurate methods such as the surrogate model method (Shi et al. 2019) can be combined with the proposed TSM.

6 Examples

The double-loop nested optimization method (DNOM) and the TIEM (Jiang et al. 2017) are employed to be references, which can be used to illustrate the accuracy and efficiency of the proposed TSM. The DNOM is generally used to test the accuracy of the decoupling method. The DNOM employs a direct double-loop process to solve the time-dependent RBDO, in which the outer loop performs the optimization to estimate the design parameters and the inner loop analyzes the time-dependent reliability. These two loops are nested with each other; thus, huge computational costs are needed by using DNOM. For the fair comparison of these methods, the iTRPD (Jiang et al. 2018) is employed to estimate the time-dependent reliability for all these methods.

6.1 Numerical example

Considering the following time-dependent RBDO problem (Wang and Wang 2012a):

where two random design parameters X1 and X2 are normal distribution variables, i.e., \( {X}_1\sim N\left({\mu}_{X_1},0.6\right) \) and \( {X}_2\sim N\left({\mu}_{X_2},0.6\right) \). The considered time parameter interval is [0, 5] and the target reliability is 0.9 for these three constraints.

The design parameter solutions estimated by the TIEM, the DNOM, and the TSM are listed in Table 1, in which the final time-dependent reliability index and the corresponding computational cost are also provided. It should be noted that the computational cost in the table involves all the necessary calls of the constraint functions. Failure probabilities of constraint functions at the optimal design parameters for all these methods are showed in Table 2. The computational statistics of these methods are showed in Table 3. The initial design parameters are set to be \( {\boldsymbol{\upmu}}_X^{\mathrm{first}(0)}=\left[5,5\right] \) for all these methods.

From Table 1, one can see that the design parameter solutions estimated by the proposed TSM can match well with that of the DNOM, which illustrates the accuracy of the proposed TSM for time-dependent RBDO. Simultaneously, the computational cost of the proposed TSM is extremely less than the DNOM and slightly less than TIEM, which demonstrates the high efficiency of the proposed TSM. The reason for the slight advantage of the proposed TSM over the TIEM in efficiency mainly resulted from the strict stopping criterion of the proposed TSM. TSM employs all the time-dependent reliability indexes of constraints satisfying reliability targets as the stopping criterion instead of the relative error between two adjacent objective functions less than given threshold in the TIEM. Thus, the solutions named as TSM1 estimated by the proposed TSM with the same stopping criterion in the TIEM are also provided. From the solutions of TSM1, one can see that the time-dependent reliability index of the second constraint is slightly less than the reliability target, which is similar to the solutions of the TIEM. But the computational cost of TSM1 is less than that of the TIEM, which demonstrates the high efficiency of the proposed method. For illustrating the estimation procedure of the proposed TSM, the iterative process in the standard normal space is showed in Fig. 4. Four iterations are needed to obtain the design parameter solutions \( {\boldsymbol{\upmu}}_X^{\mathrm{first}}=\left[3.7362,4.2770\right] \) in the first step of the proposed TSM, and three iterations are needed in the second step of the TSM. Based on the design parameter solutions \( {\mu}_X^{\mathrm{first}}=\left[3.7362,4.2770\right] \), the corresponding time-dependent reliability indexes of these three constraint functions can be obtained by \( {\beta}_1^{\mathrm{first}}(t)=1.1705 \), \( {\beta}_2^{\mathrm{first}}(t)=1.2679 \), and \( {\beta}_3^{\mathrm{first}}(t)=3.0423 \) respectively. The results show that the third constraint function satisfies the reliability target and the others do not satisfied the requirement one, which is showed in Fig. 5a. For obtaining the accurate design parameter solutions that make all the constraint functions satisfy the reliability target, the design parameter solutions \( {\boldsymbol{\upmu}}_X^{\mathrm{first}}=\left[3.7362,4.2770\right] \) need to be amended and updated, that are what the second step of the proposed method do. After the estimation of the second step of the proposed method, the final optimal design parameter solutions \( {\boldsymbol{\upmu}}_X^{\mathrm{second}}=\left[3.8339,4.3057\right] \) can be obtained. Based on the design parameter solutions \( {\boldsymbol{\upmu}}_X^{\mathrm{second}}=\left[3.8339,4.3057\right] \), all the constraint functions will satisfy the reliability requirement, which is showed in Fig. 5b. The failure probabilities of the constraints showed in Table 2 express that the solutions of all constraints by TSM and DNOM are satisfied, but the solutions of second constraint by TIEM and TSM1 are slightly unsatisfied. From Table 3, one can see that the TIEM needs 5 iterations with 15 time-dependent reliability analyses, and the total computational costs of the time-dependent reliability analyses are 10359 for the TIEM. In the TSM, 3 iterations are involved in the second step with 12 time-dependent reliability analyses, and the total computational costs of the time-dependent reliability analyses of the TSM are 8478, which is less than that of the TIEM. In the TSM1, 2 iterations are contained in the second step with 9 time-dependent reliability analyses, and the total computational costs of the time-dependent reliability analyses of TSM1 are 6369, which shows that TSM1 is the most efficient one among these methods. Simultaneously, it is easy to find that the DNOM has the worst efficiency in these methods, which needs 717 time-dependent reliability analyses and the computational costs of the time-dependent reliability analyses are 503621. It can be also seen from Table 3 that the proposed TSM is more efficient than the TIEM and the DNOM in considering the computational time.

The relationship between the output and design parameters in the iterative process. a Output at \( {\mu}_X^{\mathrm{first}(0)} \). b Output at \( {\mu}_X^{first(1)} \). c Output at \( {\mu}_X^{first(2)} \).d Output at \( {\mu}_X^{\mathrm{first}(3)} \). e Output at \( {\mu}_X^{\mathrm{first}} \). f Output at \( {\mu}_X^{\mathrm{second}(1)} \). g Output at \( {\mu}_X^{\mathrm{second}(2)} \). h Output at \( {\mu}_X^{\mathrm{second}} \)

6.2 A cantilever beam

A cantilever beam (Liang et al. 2004; Jiang et al. 2017; Gu and Yang 2003) showed in Fig. 6 is used to show the effectiveness of the proposed TSM for time-dependent RBDO. This cantilever beam is anchored at the left end and free at the right end. The length of the cantilever beam is L = 100 in. The free end of the beam is under a vertical time-dependent load of F1(t) and a horizontal time-dependent load of F2(t) that are mutually independent stationary Gaussian processes. The thickness h and width w of the cross-section are deterministic design parameters and the Young’s Modulus E and yield stress y are random parameters. The optimization objective is to minimize the weight of this beam. There are two probabilistic constraint functions which respectively represent that the maximum stress is not allowed to be greater than yield stress y and the replacement of the free end should be not less than the allowable displacement D0 = 2.5 in. The distribution parameters of the input random parameters and stochastic processes are showed in Table 4. The time-dependent RBDO of this cantilever beam can be expressed as follows:

where the considered time interval is [0, 10] year.

In this example, the deterministic design parameters, the random parameters, and the stochastic processes are involved in the constraint functions. The initial design parameters are set to be [wfirst(0), hfirst(0)] = [2, 4] for all these methods. The design parameter solutions estimated by the TIEM, the proposed TSM, and the DNOM are listed in Table 5. From Table 5, one can see that comparing with the TIEM and DNOM, the proposed TSM is the most efficient method which needs 326 costs of the constraint functions to obtain the final design parameters, while the TIEM needs 538 computational costs and the DNOM needs more than ten thousand costs of the constraint functions. The time-dependent reliability indexes in Table 5 and the failure probabilities in Table 6 show that the design parameter solutions estimated by the proposed TSM are slightly conservative, which is mainly resulted from the introduction of approximating the gradient of MPP by that of the origin for this highly non-linear problem. This can be avoided by directly using the real gradient of the MPP, but the computational cost will increase. Generally, this approximation makes little influence on the accurately estimation of the design parameters for the general non-linear problem, which is showed by the examples 6.1 and 6.3. However, it is difficulty to balance the estimation accuracy and efficiency in one method. This work just establishes a two-step framework to decouple the time-dependent RBDO, and future study will focus on further improving the computational accuracy and efficiency in time-dependent RBDO with highly non-linear problem based on this two-step framework. Furthermore, the design parameters estimated by the proposed TSM are acceptable by comparing with other solutions. From Table 7, one can see that the TIEM needs 4 iterations with 8 time-dependent reliability analyses, and the computational costs of the time-dependent reliability analyses are 145. The DNOM needs 136 time-dependent reliability analyses with total 2618 computational costs of time-dependent reliability analyses. Comparing with the TIEM and DNOM, the TSM just needs once iteration in the second step with 4 time-dependent reliability analyses, and the total computational costs of the time-dependent reliability analyses are 80, which are less than those of the TIEM and DNOM. The computational time showed in Table 7 also illustrates the high computational efficiency of the proposed TSM.

6.3 A welded beam

A welded beam (Chen et al. 2013a) showed in Fig. 7 is used to illustrate the effectiveness of the proposed TSM for time-dependent RBDO. The welded beam problem was firstly proposed in Ref. (Ragsdell and Phillips 1976), and then it was employed to be an optimization example under uncertainty in Refs. (Deb and Gupta 2006; Braydi et al. 2019). The left end of this beam is welded and there is a time-dependent loading F(t) in the right end of this beam. The random design variables are relative to the welding point containing its depth X1, length X2, height X3, and thickness X4. Four time-dependent probabilistic constraint functions and one time-independent probabilistic constraint function are involved in this optimization, in which the four time-dependent probabilistic constraint functions related to the shear stress, bucking, bending stress, and the displacement of free end, and the time-independent probabilistic constraint function is about the restriction of welding size. The objective is to minimize the cost of welding. The random parameters are the Young’s Modulus E, the length of this beam L, the shear Modulus G, the allowable displacement of free end d0, and maximum shear stress τ and the maximum normal stress σ. The time-dependent loading F(t) is Gaussian process. The distribution parameters of all these inputs are provided in Table 8. In this work, two cases involving optimization under stationary stochastic process load and time-independent material properties, and optimization under non-stationary stochastic process load and time-dependent material properties are considered to construct the time-dependent RBDO.

6.3.1 Optimization under stationary stochastic process load and time-independent material properties

In this case, the time-dependent RBDO of this welding beam is showed below.

in which

In this case, random design variables, random parameter variables, and stationary stochastic process are involved in the constraint functions. The initial design parameters are set to be \( \left[{\mu}_{X_1}^{\mathrm{first}(0)},{\mu}_{X_2}^{\mathrm{first}(0)},{\mu}_{X_3}^{\mathrm{first}(0)},{\mu}_{X_4}^{\mathrm{first}(0)}\right]=\left[15,200,200,15\right] \) for all these methods. The DNOM cannot converge in this example. The design parameter solutions, reliability index solutions, failure probabilities, and computational statistics of the proposed TSM and the TIEM are showed in Tables 9, 10, 11, and 12 respectively.

From Tables 9, 10, and 11, one can see that the proposed TSM can give accurate estimation of the design parameters comparing with the TIEM. Simultaneously, it also can be seen from Table 9 that the proposed TSM just needs 2261 computational costs which illustrates the high efficiency of the TSM. But, the computational cost of the TIEM is almost double that of the proposed TSM. From Table 12, one can see that there are 2 iterations in the second step of the TSM with 15 reliability analyses (12 time-dependent reliability analyses and 3 time-independent reliability analyses), and the total computational costs of reliability analyses are 720. At the same time, the TIEM needs 4 iterations with 20 reliability analyses (16 time-dependent reliability analyses and 4 time-independent reliability analyses), and the total computational costs of reliability analyses are 1008, which are large than those of the proposed TSM. Thus, the proposed TSM is more efficient than the TIEM. From Table 12, one can also see that the proposed TSM is more efficient than the TIEM in considering the computational time.

6.3.2 Optimization under non-stationary stochastic process load and time-dependent material properties

In this case, the load is considered to be a non-stationary stochastic process FT(t), and FT(t) is expressed as FT(t) = F(t)e0.002t. The maximum shear stress τT and the maximum normal stress σT will decline as the time goes by, and they can be described by τT = τe−0.012t and σT = σe−0.01t respectively. Then, the time-dependent RBDO of this welding beam can be expressed as follows.

in which τ(Z, Y(t)), σ(Z, Y(t)), δ(Z, Y(t)), and Pc(Z) are showed in Eq. (24).

In this case, random design variables, random parameter variables, non-stationary stochastic process, and time parameter are involved in the constraint functions. The initial design parameters are set to be \( \left[{\mu}_{X_1}^{\mathrm{first}(0)},{\mu}_{X_2}^{\mathrm{first}(0)},{\mu}_{X_3}^{\mathrm{first}(0)},{\mu}_{X_4}^{\mathrm{first}(0)}\right]=\left[15,200,200,15\right] \) for all these methods. The DNOM cannot converge in this example. The design parameter solutions, reliability index solutions, failure probabilities, and computational statistics of the proposed TSM and the TIEM are showed in Tables 13, 14, 15, and 16 respectively.

In this case, except the third constraint, the other constraint functions are non-stationary stochastic processes. When using the iTRPD (Jiang et al. 2018) to estimate the reliabilities of these non-stationary stochastic processes, the time-independent reliabilities at each time instants are needed to be estimated, instead of only performing time-independent reliability analyses at one time instant in the first case. Therefore, the computational costs of time-dependent reliability analyses in this case are much larger than those in the first case. From Tables 13, 14, and 15, one can see that the proposed TSM and the TIEM give the similar design parameter solutions. But the proposed TSM is more efficient than the TIEM. It can be found from Table 16 that there are 3 iterations in the second step of the proposed TSM with 20 reliability analyses (16 time-dependent reliability analyses and 4 time-independent reliability analyses), and the total computational costs of reliability analyses are 43416. The TIEM needs 7 iterations with 35 reliability analyses (28 time-dependent reliability analyses and 7 time-independent reliability analyses), and the total computational costs of the reliability analyses are 91572, which are much larger than those of the proposed TSM. The computational time showed in Table 16 demonstrates the proposed TSM is more efficient than the TIEM.

7 Conclusions

A novel decoupling method called TSM is established to deal with the time-dependent RBDO. The first step of the TSM makes the minimum instantaneous reliability index satisfy reliability index target by solving a transformed time-independent RBDO, and the second step helps the time-dependent reliability meet the reliability target by performing time-dependent reliability analysis and deterministic optimization. The key point of the first step is to estimate the shifting vector increment in each iteration. This work employs the gradient in the origin to approximate that of the MPP for efficiently estimating the shifting vector increment. The solutions show that this approximation generally makes little influence on the accurately estimation of the design parameters for the general non-linear problem. After the first step converges, the final optimal design parameter solutions can be obtained by performing deterministic design optimization based on the information from the first step and the time-dependent reliability analysis. Therefore, the second step can be considered as the amendment of the first step. Only a few time-dependent reliability analyses are involved in the whole process of the proposed method.

Several examples involving a numerical example and two engineering examples are introduced to show the effectiveness of the proposed TSM. The solutions show that the TIEM provide good design parameter solutions for all these applications. By comparing with the TIEM and the DNOM, one can see that the proposed TSM can give an acceptable estimation of the design parameters by using the least computational costs.

It should be noted that for highly non-linear problem, the proposed TSM may cause large error. This can be avoided by directly using the real gradient in the MPP, but the computational cost will increase. This work just establishes a two-step framework to decouple the time-dependent RBDO, and future study will focus on further improving the computational accuracy and efficiency in dealing with time-dependent RBDO with highly non-linear problem based on this two-step framework by combining several surrogate model techniques (Hu and Mahadevan 2016). At the same time, the proposed TSM is a type of gradient-based optimization method, and it is better to solve the time-dependent RBDO with no more than five design parameters. When the time-dependent RBDO involves high-dimensional design parameters, gradient-based optimization methods may provide locally optimal design parameter solutions. For dealing with this issue, dimension reduction techniques (Sadoughi et al. 2018; Ping et al. 2019) can be combined with the proposed TSM, and this will be our future focus.

8 Replication of results

To further understand the proposed method for time-dependent RBDO and replicate the solutions presented in this paper, the MATLAB codes of the proposed TSM for the numerical example are provided as the supplementary material. Overall concepts and algorithms can be validated and extended through the numerical example.

References

Agarwal H, Mozumder C, Renaud J, Watson L (2007) An inverse-measure-based unilevel architecture for reliability-based optimization. Struct Multidiscip Optim 33(3):217–227

Andrieu-Renaud A, Sudret B, Lemaire M (2004) The PHI2 method: a way to compute time-variant reliability. Reliab Eng Syst Saf 84:75–86

Braydi O, Lafon P, Younes R (2019) On the formulation of optimization problems under uncertainty in mechanical design. Int J Interact Des Manuf 13(1):75–87

Chen Z, Qiu H, L Gao LS, Li P (2013a) An adaptive decoupling approach for reliability-based design optimization. Comput Struct 117(3):58–66

Chen Z, Qiu H, Gao L, Li P (2013b) An optimal shifting vector approach for efficient probabilistic design. Struct Multidiscip Optim 47:905–920

Cheng GD, Xu L, Jiang L (2006) A sequential approximate programming strategy for reliability-based structural optimization. Comput Struct 84:1353–1367

Deb K, Gupta H (2006) Introducing robustness in multi-objective optimization. Evol Comput 14(4):463–494

Du XP, Chen W (2004) Sequential optimization and reliability assessment method for efficient probabilistic design. ASME Journal of Mechanical Design 126:225–233

Du Z Hu XP (2015) Reliability-based design optimization under stationary stochastic process loads. Eng Optim 48(8):1296–1312

Du XP, Guo J, Beeram H (2008) Sequential optimization and reliability assessment for multidisciplinary systems design. Struct Multidiscip Optim 35(2):117–130

Fang T, Jiang C, Li Y, Huang ZL, Wei XP, Han X (2018) Time-variant reliability-based design optimization using equivalent most probable point. IEEE Trans Reliab 99:1–12

Gu L, Yang RJ (2003) Recent applications on reliability based optimization of automotive structures. Proceedings of SAE World Congress:2003–01-0152

Hawchar L, Soueidy CPE, Schoefs F (2018) Global kriging surrogate modeling for general time-variant reliability-based design optimization problems. Struct Multidiscip Optim 58(3):955–968

Hu Z, Mahadevan S (2016) A single-loop kriging surrogate modeling for time-dependent reliability analysis. ASME Journal of Mechanical Design 138:061406.1–061406.10

Huang HZ, Zhang XD, Liu Y, Meng DB, Wang ZL (2012) Enhanced sequential optimization and reliability assessment for reliability-based design optimization. J Mech Sci Technol 26(7):2039–2043

Huang ZL, Jiang C, Zhou YS, Luo Z, Zhang Z (2016) An incremental shifting vector approach for reliability-based design optimization. Struct Multidiscip Optim 53:523–543

Huang ZL, Jiang C, Zhang Z, Fang T, Han X (2017a) A decoupling approach for evidence-theory-based reliability design optimization. Struct Multidiscip Optim 56(3):647–661

Huang ZL, Jiang C, Zhou YS, Zheng J, Long XY (2017b) Reliability-based design optimization for problems with interval distribution parameters. Struct Multidiscip Optim 55:513–528

Huang ZL, Jiang C, Li XM, Wei XP, Fang T, Han X (2017c) A single-loop approach for time-variant reliability-based design optimization. IEEE Trans Reliab 66(3):651–661

Huang ZL, Jiang C, Zhang Z, Zhang W, Yang TG (2019) Evidence-theory-based reliability design optimization with parametric correlations. Struct Multidiscip Optim (1):16

Jiang C, Fang T, Wang ZX, Wei XP, Huang ZL (2017) A general solution framework for time-variant reliability based design optimization. Comput Methods Appl Mech Eng 323:330–352

Jiang C, Wei XP, Wu B, Huang ZL (2018) An improved TRPD method for time-variant reliability analysis. Struct Multidiscip Optim 58(5):1935–1946

Kang Z, Luo YJ (2010) Reliability-based structural optimization with probability and convex set hybrid models. Struct Multidiscip Optim 42(1):89–102

Keshtegar B, Lee I (2016) Relaxed performance measure approach for reliability-based design optimization. Struct Multidiscip Optim 54(6):1439–1454

Kharmanda G, Mohamed A, Lemaire M (2002) Efficient reliability-based design optimization using a hybrid space with application to finite element analysis. Struct Multidiscip Optim 24(3):233–245

Li F, Wu T, Badiru A, Hu MQ, Soni S (2013) A single-loop deterministic method for reliability-based design optimization. Eng Optim 45(4):435–458

Li G, Meng Z, Hu H (2015) An adaptive hybrid approach for reliability-based design optimization. Struct Multidiscip Optim 51(5):1051–1065

Li MY, Bai GX, Wang ZQ (2018) Time-variant reliability-based design optimization using sequential kriging modeling. Struct Multidiscip Optim:1–15

Li FY, Liu J, Wen GL, Rong JH (2019) Extending SORA method for reliability-based design optimization using probability and convex set mixed models. Struct Multidiscip Optim 59(4):1163–1179

Liang JH, Mourelatos ZP, Tu J (2004) A single-loop method for reliability-based design optimization. ASME Design Engineering Technical Conferences and Computers and Information in Engineering Conference:419–430

Meng Z, Li G (2016) Reliability-based design optimization combining the reliability index approach and performance measure approach. J Comput Theor Nanosci 13(5):3024–3035

Ping MH, Han X, Jiang C, Zhong JF (2019) A frequency domain reliability analysis method foe electromagnetic problems based on univariate dimension reduction method. SCIENCE CHINA Technol Sci 62(5):787–798

Ragsdell K, Phillips D (1976) Optimal design of a class of welded structures using geometric programming. ASME Journal of Engineering for Industry 98(3):1021–1025

Sadoughi MK, Li M, Hu C, Mackenzie CA, Lee S, Eshghi AT (2018) A high-dimensional reliability analysis method for simulation-based design under uncertainty. ASME Journal of Mechanical Design 140:071401.1–041401.12

Shi Y, Lu ZZ, Zhang KC (2017) Reliability analysis for structure with multiple temporal and spatial parameters based on the effective first-crossing point. ASME Journal of Mechanical Design 139(12):121403.1–121403.9

Shi Y, Lu ZZ, Xu LY, Chen SY (2019) An adaptive multiple-kriging-surrogate method for time-dependent reliability analysis. Appl Math Model 70:545–571

Singh A, Mourelatos ZP, Li J (2010) Design for lifecycle cost using time-dependent reliability. ASME Journal of Mechanical Design 132:091008

Tu J, Choi KK, Park YH (1999) A new study on reliability-based design optimization. AMSE Journal of Mechanical Design 121(4):557–564

Tu J, Choi KK, Park YH (2001) Design potential method for robust system parameter design. AIAA J 39(4):667–677

Wang ZQ, Chen W (2016) Time-variant reliability assessment through equivalent stochastic process transformation. Reliab Eng Syst Saf 152:166–175

Wang ZQ, Wang PF (2012a) A nested extreme response surface approach for time-dependent reliability-based design optimization. ASME Journal of Mechanical Design 134:121007.1–1210007.14

Wang Z, Wang P (2012b) Reliability-based product design with time-dependent performance deterioration. Prognostics and Health Management:1–12

Wang L, Wang XJ, Wu D, Xu MH, Qiu ZP (2018) Structural optimization oriented time-dependent reliability methodology under static and dynamic uncertainties. Struct Multidiscip Optim 57(4):1533–1551

Zou T, Mahadevan S (2006) A direct decoupling approach for efficient reliability-based design optimization. Struct Multidiscip Optim 31(3):190–200

Acknowledgments

This work was supported by the National Natural Science Foundation of China (Grant 51475370), the National Science and Technology Major Project (2017-IV-0009-0046) and the Innovation Foundation for Doctor Dissertation of Northwestern Polytechnical University (Grant CX201931). The authors would like to thank the reviewers’ for the constructive and helpful suggestions and comments on our paper.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Responsible Editor: Shapour Azarm

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published mapsand institutional affiliations.

Rights and permissions

About this article

Cite this article

Shi, Y., Lu, Z., Xu, L. et al. Novel decoupling method for time-dependent reliability-based design optimization. Struct Multidisc Optim 61, 507–524 (2020). https://doi.org/10.1007/s00158-019-02371-y

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00158-019-02371-y