Abstract

Lignocellulosic substrates are the largest source of fermentable sugars for bioconversion to fuel ethanol and other valuable compounds. To improve the economics of biomass conversion, it is essential that all sugars in potential hydrolysates be converted efficiently into the desired product(s). While hexoses are fermented into ethanol and some high-value chemicals, the bioconversion of pentoses in hydrolysates remains inefficient. This remains one of the key challenges in lignocellulosic biomass conversion. Native pentose-fermenting yeasts can ferment both glucose and xylose in lignocellulosic biomass to ethanol. However, they perform poorly in the presence of hydrolysate inhibitors, exhibit low ethanol tolerance and glucose repression, and ferment pentoses less efficiently than the main hexoses glucose and mannose. This paper reviews classical and molecular strain improvement strategies applied to native pentose-fermenting yeasts for improved ethanol production from xylose and lignocellulosic substrates. We focus on Pachysolen tannophilus, Scheffersomyces (Candida) shehatae, Scheffersomyces (Pichia) stipitis, and Spathaspora passalidarum which are good ethanol producers among the native xylose-fermenting yeasts. Strains obtained thus far are not robust enough for efficient ethanol production from lignocellulosic hydrolysates and can benefit from further improvements.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

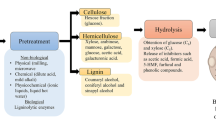

Efficient utilization of pentose sugars in conjunction with the overall utilization of lignocellulose is important in the bioconversion of plant biomass for the production of chemicals and liquid fuels [17, 43, 71]. Potential substrates envisioned for the application of pentose-fermenting technologies include hydrolysates of plant biomass or waste liquors of pulp and paper processing industries. However, xylose is not as readily utilized as glucose by yeasts. Native strains of the well-known fermentative yeast, Saccharomyces cerevisiae, are unable to utilize xylose as a sole carbon source for aerobic growth [44] despite the existence of activities for xylose transport, xylose reductase (XR), xylulokinase, and subsequent enzymes needed for a full xylose metabolic pathway [7]. Prior to 1981, xylose was thought to be unfermentable by yeasts and schemes to ferment xylose typically involved two stages: (1) xylose was transformed to xylulose in vitro using glucose isomerase; and (2) fermentation of xylulose to ethanol [87]. This picture changed with the discovery of pentose-fermenting yeasts in 1981–1982 [19, 28, 74, 77]. This discovery was considered a significant milestone due to the recognized need for complete utilization and conversion of all sugars in potential lignocellulosic substrates to improve process economics.

Since 1981, numerous yeasts able to produce some ethanol from xylose have been identified. Among these, Pachysolen tannophilus, Scheffersomyces (Candida) shehatae, and Scheffersomyces (Pichia) stipitis were notable for their ability to produce relatively high ethanol yields from xylose. Considerable research was undertaken on the physiology and biochemistry of these yeasts [33]. The results showed that the rate and yield of ethanol produced from xylose by these yeasts were lower than those for glucose fermentation [30]. This low ethanol yield was partially attributed to concurrent utilization of ethanol in the presence of appreciable concentrations of xylose [58] and to formation of by-products such as xylitol, ribitol, arabitol, and acetic acid [73].

Yeasts that convert xylose efficiently in defined media often perform poorly in pretreated biomass hydrolysates or waste liquors of lignocellulosic materials. A central problem is the presence of hexoses (mainly glucose and mannose) that compete with or inhibit xylose utilization [9, 63]. Pentose-fermenting yeasts can convert glucose or xylose individually to ethanol. The fermentation of xylose present in a mixture with glucose, however, does not proceed efficiently. This is because the fermentation of glucose precedes that of xylose and pentose-fermenting yeasts are generally not sufficiently tolerant of ethanol to complete the second process. Another problem is the occurrence of cofactor imbalance in the first two enzymes of xylose metabolism, XR that has a higher affinity for NADPH and xylitol dehydrogenase (XDH) that is only active with NAD [11]. During xylose metabolism, the different coenzymes preferred by XR and XDH result in an accumulation of NADP and NADH from the first and second reactions, respectively. This cofactor imbalance inhibits further metabolism along this pathway and regeneration of the cofactors by oxygen is necessary for xylose metabolism to continue. This led Bruinenberg et al. [12] to propose that having an NADH-preferring XR would obviate the need for cofactor regeneration and this may enable xylose to be fermented anaerobically. The requirement of oxygen for xylose utilization by P. tannophilus was observed by Neirinck et al. [61], and this was recognized as one of the reasons for inefficient xylose fermentation. Moreover, the presence of oxygen during xylose fermentation contributes to the concurrent production and utilization of ethanol while considerable amount of xylose remains in the medium [56]. Another problem is the presence of various pretreatment-derived inhibitors that adversely affect yeast growth and fermentation. Both physical and chemical pretreatments yield a complex mixture of inhibitors that adversely affect yeast growth, viability and fermentation [40, 53, 70, 85]. Different upstream processing conditions are needed for different substrates and these factors may result in the production of varying concentrations of different inhibitors.

The above challenges have led to efforts to address these problems to improve the performance of native pentose-fermenting yeasts in lignocellulosic hydrolysates. This review examines research to genetically improve xylose-fermenting yeasts, with a focus on the improvement of P. tannophilus, S. shehatae, S. stipitis and S. passalidarum for ethanol production from xylose and lignocellulosic hydrolysates.

Genetic improvement of native pentose-fermenting yeasts

Improved tolerance to pretreatment-derived inhibitors

Adaptation

The complex and variable nature of the mixture of toxic compounds in lignocellulosic hydrolysates and difficulties in identifying them limit our understanding of how each may contribute to overall cellular toxicity. Furthermore, various inhibitory compounds may act synergistically to exert toxicity; thus even compounds present at low concentrations may contribute to the overall toxicity. Due to this lack of knowledge on the mechanisms involved in inhibitor toxicity and tolerance, adaptation has been hypothesized as the best approach to address their combined toxic effect. A number of studies have used adaptation to improve the performance of pentose-fermenting yeasts, mostly S. stipitis (Table 1). Adaptation involves repeated sub-culturing or recycling of yeast cells to increasing concentrations of the inhibitor(s) in lignocellulosic hydrolysates. One advantage of adaptation is that strains adapted to tolerate one hydrolysate may exhibit cross-tolerance to other hydrolysates. This is not surprising considering that different lignocellulosic hydrolysates contain similar kinds of inhibitors but with different compositions and concentrations. However, very few studies assessed this possible cross-tolerance in the adapted strains. Initial screens for adaptation are typically growth-based, but another key improvement sought is fermentation, which cannot be selected for on the basis of growth alone. Thus, adapted strains selected for improved growth have to be assessed also for the ability to ferment the sugars in the presence of inhibitors in lignocellulosic hydrolysates. The availability of yeast strains with the ability to tolerate inhibitory compounds in lignocellulose hydrolysates would reduce the need for detoxification procedures, and this can decrease the overall production cost.

Adaptation has been done to individual inhibitor(s) as well as to a mixture of inhibitors, with the latter approach being the most common. A limitation to adaptation to individual inhibitors is that the adapted strain(s) may not exhibit improved growth and fermentative ability in the complex mixture of inhibitors found in lignocellulosic hydrolysates. In one study of this kind, Liu et al. [52] adapted S. stipitis NRRL Y-7124 cells to increasing concentrations of hydroxymethyl furfural (HMF). After 100 cycles, the adapted strain, designated 307-10H60, showed an enhanced ability to transform HMF to 2,5-bis-hydroxymethylfuran compared to the wild-type (WT) strain. In defined medium containing 60 mM HMF, strain 307-10H60 converted 60 % of HMF and utilized glucose in 20 h to produce 10 g/L ethanol. In comparison, the WT did not ferment glucose at this HMF concentration [52]. Unfortunately, the adapted strain was not tested for xylose fermentation or in a mixture of inhibitors typically found in lignocellulosic hydrolysates. Thus, it is not known if tolerance to HMF would improve the performance of this xylose-fermenting strain in industrially relevant hydrolysates.

More commonly, adaptation was performed by sequential transfers or recycling of cultures to increasing concentrations of lignocellulosic hydrolysates. Several groups have independently obtained S. stipitis strains adapted to different hydrolysates (Table 1). These studies demonstrate the potential for using adaptation to obtain yeast strains more tolerant to pretreatment-derived inhibitors, thereby producing higher fermentation rates and yields compared to the WT strains. Possibly, adaptation resulted in selection of mutant strains, although this has not been explicitly stated and the nature of possible mutations was not examined. A drawback of these studies was that adaptation and subsequent testing were done in the presence of yeast extract and peptone. These adapted strains would not perform as well in hydrolysates without these added nutrients; thus the utility of these adapted strains under industrial conditions remains uncertain. Furthermore, the long-term stability of the adapted strains was not assessed in these studies.

Most native xylose-fermenting yeasts are subject to glucose repression [9, 13, 39] and glucose inactivation [47]. In repression, glucose inhibits the synthesis of xylose-metabolizing enzymes at the transcriptional level. On glucose depletion, xylose-metabolizing enzymes are synthesized to enable xylose utilization, i.e., de novo protein synthesis is required. In inactivation, glucose inhibits the activities of xylose transport and/or other xylose-metabolizing enzymes. Xylose consumption may resume before glucose is completely consumed, and this resumption does not require de novo protein synthesis. As a result, in a glucose-xylose mixture, glucose is fermented before xylose and the yeast is often not sufficiently tolerant of ethanol [5] to complete the xylose fermentation. One exception to the above scenario is S. passalidarum which utilizes xylose and glucose simultaneously and ferments glucose, xylose and cellobiose simultaneously under oxygen-limiting conditions [54]. To improve the ability of S. passalidarum NRRL Y-27907 to ferment the sugars in hydrolysates, this strain was adapted to YPX-Cb medium (containing 10 g/L yeast extract, 10 g/L peptone, 45 g/L xylose and 25 g/L cellobiose) followed by cultivation in corn stover hydrolysate for 2 months (54 doublings) under oxygen-limiting conditions [54]. Fermentation of the adapted strain E7 on maple hemicellulose hydrolysate (MHH) was compared to that on a sugar mixture (SM) designed to mimic the hydrolysate (65 g/L xylose and 35 g/L glucose). Glucose and xylose were co-utilized in the MHH, while xylose utilization was delayed by 12 h in the SM. E7 produced a peak ethanol concentration (40 g/L) more rapidly in SM (38 h) than in MHH (38 g/L and 59 h, respectively). However, the fermentation performance was not compared to the WT strain under the same conditions; thus, the extent of the improvement for the adapted strain is not known. The inherent ability of S. passalidarum to ferment xylose faster than glucose and to simultaneously ferment glucose, xylose and cellobiose are desirable characteristics for use in lignocellulosic biomass conversion.

Random mutagenesis

The adaptation approach, while useful, can be slow and time-consuming. Industrial strain improvement typically involves randomly generated mutants from which a few of the top performers are selected for further mutagenesis and screening. An effective and sensitive screen is necessary to select mutants of interest.

Despite the attractiveness of random mutagenesis, only a few studies have used this approach to obtain mutants of xylose-fermenting yeasts with improved tolerance to inhibitors in lignocellulosic hydrolysates. In one study, successive rounds of UV mutagenesis followed by screening on a gradient plate of hardwood spent sulfite liquor (HW SSL) was used to successfully obtain mutants of S. stipitis NRRL Y-7124 with improved tolerance to HW SSL [5]. Growth assessment indicated the WT grew in 65 % (v/v) HW SSL while mutants (PS301 and PS302) selected after three rounds of UV mutagenesis and screening grew in 75 % (v/v) HW SSL and survived in 80 % (v/v) HW SSL. In addition, these mutants were more tolerant of HMF than the WT and grew faster with a shorter lag phase in 5 g/L HMF. The WT did not produce ethanol in 60 % (v/v) HW SSL whereas mutants produced peak ethanol ranging from 3.3 to 6.4 g/L. These mutants also showed slightly improved tolerance to acetic acid (2.8–3.0 g/L) compared to the WT (2.5 g/L).

Using a similar approach, Harner et al. [21] obtained mutants of P. tannophilus NRRL Y-2460 with enhanced tolerance to HW SSL and acetic acid in two separate selection lines. The WT strain grew in 50 % (v/v) HW SSL while third round HW SSL mutants (UHW301, UHW302 and UHW303) grew in 60 % (v/v) HW SSL with two of these isolates (UHW302 and UHW303) being viable and growing, respectively, in 70 % (v/v) HW SSL. In defined liquid media containing acetic acid, the WT strain grew in 7 g/L acetic acid, while third round acetic acid mutants (UAA301, UAA302 and UAA303) grew in 8 g/L acetic acid with one isolate (UAA302) growing in 9 g/L acetic acid. Cross-tolerance of HW SSL-tolerant mutants to acetic acid and vice versa was observed. The fermentative ability of UAA302 in defined media was similar to that of the WT, while UHW303 fermented slightly less well than the WT [21].

Genome shuffling

Genome shuffling combines classical mutagenesis with the possibility of recombination to allow for further strain improvement. This method uses recursive recombination to enhance the genetic diversity of mutant populations with improved phenotypes, allowing for the creation of new mutant combinations and strains with superior characteristics [10, 66]. Whole genome recombination accelerates the accumulation of multiple beneficial mutations in strains while having the potential to remove deleterious mutations, thereby allowing for the engineering of complex phenotypic traits with less time and effort [64, 100]. As with random mutagenesis, the key criterion for successful genome shuffling is an effective and sensitive screen to select the improved mutants.

In genome shuffling, recombination can be carried out using recursive protoplast fusion or cross-mating. Most reports on genome shuffling to improve inhibitor tolerance or ethanol productivity of yeasts are based on protoplast fusion [22, 94]. Genome shuffling carried out by protoplast fusion, however, may yield unstable hybrids [18].

A strategy using yeast cross-mating instead of protoplast fusion was performed to improve the tolerance of S. stipitis to HW SSL [4]. Six UV-induced mutants of S. stipitis NRRL Y-7124 were subjected to four rounds of genome shuffling. Two mutants from the third round (GS301 and GS302) grew in 85 % (v/v) HW SSL, with GS301 being viable in 90 % (v/v) HW SSL. The WT S. stipitis was unable to grow in HW SSL unless it was diluted to 65 % (v/v) or lower [4]. In fermentation tests, the WT did not utilize any sugars in undiluted HW SSL (pH 5.5), while GS301 and GS302 utilized glucose faster than PS302, the best UV-induced mutant [5]. The WT and two genome shuffled S. stipitis strains (GS301 and GS302) were tested for growth and fermentation performance in three wood hydrolysates: steam-pretreated enzymatically hydrolyzed poplar hydrolysate, steam-pretreated poplar hydrolysate and mixed hardwood pre-hydrolysate [3]. All strains grew in the steam-pretreated enzymatically hydrolyzed poplar hydrolysate, GS301 and GS302 grew in the mixed hardwood pre-hydrolysate, but none of the strains grew in the steam pretreated poplar hydrolysate. In fermentation tests, GS301 and GS302 completely utilized glucose and xylose in each hydrolysate and produced between 3.9 and 14 g/L ethanol while the WT did not utilize, or poorly utilized, the sugars, producing low concentrations of ethanol. These results demonstrated cross-tolerance of the mutants to inhibitors in different wood hydrolysates [3].

One advantage of using a cross-mating-based genome shuffling approach for industrial yeast strain improvement is that the genetically stable haploid cells obtained are amenable to further improvement by mutagenesis and mating. In contrast, after several rounds of protoplast fusion, the resulting population may have uncertain ploidy levels or may be aneuploid, some of which may be unstable or not amenable for further improvement. Bajwa et al. [2] have provided a detailed protocol for genome shuffling based on recursive cross-mating in S. stipitis.

Improved ethanol tolerance and production

Random mutagenesis

Native pentose-fermenting yeasts are known to be less tolerant of ethanol than the fermentative yeast S. cerevisiae. The basis for this is not known and there has always been a desire to improve the ethanol tolerance of pentose-fermenting yeasts. Ethanol tolerance is thought to be a multi-genic trait and different approaches have been used to identify potential genetic elements contributing to this phenotype [16, 55, 81, 84]. The complex nature makes genetic studies and improvement of ethanol tolerance difficult. Ethanol tolerant strains have been obtained primarily using random mutation approaches.

Watanabe et al. [90] used UV mutagenesis followed by screening on a solid medium containing 50 g/L ethanol (supplemented with 50 g/L xylose, 1.7 g/L YNB without amino acids, 2.0 g/L ammonium sulfate and 5.0 g/L peptone) to select mutants of S. stipitis NBRC1687 with improved tolerance to ethanol. Three mutants (PXF4, PXF36 and PXF58) producing larger colonies compared to the WT on plates were selected. During xylose fermentation in the same medium above, the WT produced less ethanol (16.4 g/L) compared to PXF4 (17.4 g/L), PXF36 (17.3 g/L) and PXF58 (19.4 g/L). In a medium containing xylose (110 g/L), glucose (120 g/L) or fructose (120 g/L) supplemented with peptone, the WT produced about 30 g/L ethanol while PXF58 produced about 40 g/L ethanol. To further improve its ethanol tolerance, PXF58 was subjected to 20 cycles of adaptation in increasing ethanol concentrations (50–70 g/L). This resulted in the isolation of a mutant (PET41) which produced 44 g/L ethanol compared to 40 g/L by PXF58 and 38 g/L by the WT strain after fermentation (96 h) in peptone-supplemented media containing 45 g/L xylose with glucose added to final concentrations of 40 and 60 g/L after 36 and 60 h, respectively [90]. The performance of the mutants, however, was not tested in a defined medium without peptone supplementation; thus, it is uncertain how these strains might perform in the absence of rich nutrient components.

Protoplast fusion

Some researchers have used cross-species protoplast fusion to combine the desirable traits of S. cerevisiae, such as greater tolerance to ethanol and inhibitors with xylose-utilizing ability of pentose-fermenting yeasts, to generate hybrids with improved properties. In an earlier study, Yoon et al. [97] combined S. cerevisiae STV 89 and S. stipitis CBS 5776 by protoplast fusion. Based on its fermentation performance in xylose and sucrose media, one fusant (designated F5) was selected for further study. During fermentation of 100 g/L xylose (medium also contained 5 g/L yeast extract, 5 g/L peptone and mineral salts), F5 produced more ethanol with a higher yield (44 g/L and 0.44 g ethanol/g xylose consumed, respectively) compared to the S. stipitis parental strain (38.8 g/L and 0.39 g/g, respectively). However, the fusants were unstable. After six rounds of sub-culturing all fusants, including F5, dissociated into segregants which resembled S. stipitis based on fermentation performance.

In another study, S. cerevisiae 2.0251 was fused with P. tannophilus ATCC 2.1662 [95]. Fermentation in media containing 10 g/L glucose, 10 g/L peptone and 5 g/L yeast extract (YEPD) supplemented with xylose (5.52 g/L) was carried out with 20 putative fusants. Based on fermentation performance, the best isolate (Fusant 1) utilized more xylose (72 %) and produced more ethanol (3.4 g/L) than the P. tannophilus parental strain (32 % and 1.2 g/L). During fermentation of mixed sugars (30 g/L glucose and 20 g/L xylose), Fusant 1 produced more ethanol (11.76 g/L) compared to either the S. cerevisiae (11.2 g/L) or P. tannophilus (8.8 g/L) parental strains. Maximum ethanol concentrations and complete glucose utilization occurred after 24 h for all strains. Fusant 1 was capable of simultaneous sugar utilization and consumed 20 % of the initial xylose within the first 24 h. In contrast, the P. tannophilus parental strain began to utilize xylose after 24 h, which may explain the unusually low peak ethanol concentration produced by this strain. Fusant 1 was tolerant to an ethanol concentration (63.1 g/L) which was intermediate between that of S. cerevisiae (78.9 g/L) and P. tannophilus (39.45 g/L) and exhibited better growth in softwood acid hydrolysate (pH 5.5) compared to the parental strains. The average DNA content of Fusant 1 (0.80 × 107 μg/mL) suggested that most of its DNA came from the P. tannophilus parental strain (DNA content = 0.78 × 107 μg/mL) and only a small amount from the S. cerevisiae parental strain (DNA content = 1.74 × 107 μg/mL). Fusant 1 appeared to be stable based on mixed sugar fermentation performance assessed periodically over 15 generations. Its long-term stability or ploidy level is not known.

Kumari and Pramanik [45] fused S. cerevisiae NCIM-3090 individually with different pentose-fermenting yeasts including S. shehatae NCIM-3500, P. tannophilus NCIM-3502 and S. stipitis NCIM-3507 to yield hybrids capable of converting hexose and pentose sugars. The fermentation performance of the fusants was first evaluated in a glucose (150 g/L) and xylose (50 g/L) mixture (containing 2 g/L yeast extract and minerals). Three fusant strains produced more ethanol with a greater yield and higher volumetric productivity than the S. cerevisiae parental strain (69.1 g/L, 0.436 g ethanol/g sugar consumed and 0.96 g/L/h, respectively). A S. cerevisiae and P. tannophilus fusant (RPR39) was found to be the most efficient strain giving high-peak ethanol concentration (76.8 g/L), volumetric productivity (1.06 g/L/h) and ethanol yield (0.458 g/g). Comparable fermentation efficiencies were also observed with another S. cerevisiae and P. tannophilus fusant (RPR51) and a S. cerevisiae and S. stipitis fusant (RPR16) producing ethanol yields of 0.454 and 0.437 g/g, respectively. The percentage of the DNA originating from each parental strain was not determined. The DNA content in fusants was analyzed using flow cytometry, and fusant DNA content was found to be doubled that of individual parental strains. Fusants were considered stable if they retained their characteristic mixed sugar utilization and ethanol production profiles for 9 months. The long-term stability of RPR39 was not investigated. The fusant RPR51 was found to be unstable while RPR39 and RPR16 were stable after 9 months.

To further improve the fermentation properties of RPR39, Kumari and Pramanik [46] subjected it to combinations of mutagens (ethyl methane sulphonate, N-methyl-N′-nitro-N-nitrosoguanidine, near UV or far UV radiation) followed by screening under various stress conditions to obtain putative mutants more tolerant to multiple fermentation stressors. Among the eight mutants, RPRT90 was the best in terms of genetic stability and tolerance to ethanol, temperature and inhibitory compounds. The combined effect of these stress factors was studied by subjecting PRPT90 to various conditions simultaneously during fermentation of a glucose (187.5 g/L) and xylose (62.5 g/L) mixture (containing 2 g/L yeast extract and minerals). When subjected to the combined effect of temperature (39 °C), ethanol (55.2 g/L) and inhibitors (0.25 g/L vanillin, 0.5 g/L furfural and 4 g/L acetic acid), RPRT90 converted 64.8 % of the sugars, producing an additional 47.9 g/L ethanol with a yield of 0.295 g/g and volumetric productivity of 0.57 g/L/h. Under the same conditions, fusant RPR39 converted 40.3 % of the sugars, producing an additional 25 g/L ethanol, with an ethanol yield of 0.21 g/g and volumetric productivity of 0.42 g/L/h. At the end of the 96-h fermentation, more glucose was utilized (about 45 and 55 g/L remaining) compared to xylose (about 45 g/L remaining) by both RPRT90 and RPR39 strains [46].

In a slightly different approach, a combination of UV mutagenesis and protoplast fusion was used to improve the inhibitor tolerance and fermentative ability of S. passalidarum MYA-4345 in wheat straw hydrolysate [24]. Furfural-tolerant mutants were isolated by plating UV mutagenized cells on a rich medium containing 10 g/L yeast extract, 20 g/L peptone, 30 g/L xylose and 2.5 g/L furfural (YPXF). Two selected mutants (M5 and M7) showed improved xylose consumption, ethanol yield, final ethanol concentration achieved and higher furfural reduction rates during fermentation in YPXF compared to the WT. Cross-species protoplast fusion was carried out between M7 and S. cerevisiae ATCC 96581. Putative fusants were plated on agar prepared with 75 % wheat straw hydrolysate (containing 1.72 g/L glucose, 2.29 g/L xylose, 0.54 g/L furfural, 0.29 g/L HMF and 3.39 g/L acetic acid) supplemented with 30 g/L xylose to select for hybrids. Repeated transfers between 75 % wheat straw hydrolysate and medium containing 10 g/L yeast extract, 20 g/L peptone and 30 g/L xylose (YPX) were done to maintain the hybrids’ tolerance character. This selection regime was based on the knowledge that unfused parents could not grow on the plate, as S. cerevisiae could not utilize xylose as the sole carbon source and M7 could not tolerate the high inhibitor concentration. Among the 24 hybrids selected, FS22 was the best isolate during anaerobic fermentation in 75 % wheat straw hydrolysate supplemented with 30 g/L xylose. Hybrid FS22 showed good xylose consumption (39.4 %) and ethanol yield (0.40 g ethanol/g xylose consumed) compared to M7 which was unable to survive or ferment at this concentration of hydrolysate. Based on the restriction patterns of the PCR fragments, it was determined that S. passalidarum M7 was the dominant contributor of DNA to the hybrid.

Interestingly, none of these inter-genera hybridization studies provided the percentage of the DNA in hybrids from each parental strain. Based on DNA content comparisons, phenotypic characterization or partial molecular characterization it is difficult to determine whether these are true hybrids. Whole genome sequencing would be an effective strategy to better characterize these hybrid strains and perhaps identify the genetic factors from each parental strain conferring the improved phenotypes in the hybrids as well as to confirm hybridization of parental strains.

Genome shuffling

Zhang and Geng [99] used recursive recombination of the whole genomes of S. stipitis CBS 6054 and S. cerevisiae ATCC 24860 to construct strains with enhanced ethanol production, tolerance to ethanol and faster rates of xylose utilization. Genomic DNA of S. stipitis was extracted and transferred into the S. cerevisiae strain by electroporation to allow genetic recombination. Selection of first round strains was carried out on plates containing 6.7 g/L YNB and 50 g/L xylose followed by fermentation of 150 g/L xylose in a rich medium (containing 7 g/L yeast extract and 2 g/L peptone). The best ethanol producing strain (F1-8) was used for the next round of genome shuffling in which the whole genome of S. cerevisiae was extracted and transferred into F1-8 by electroporation. Second round strains were screened on plates containing 6.7 g/L YNB, 50 g/L xylose and 50 g/L ethanol. One obtained strain (ScF2) produced 47 g/L of ethanol in 6 days from 250 g/L xylose in a medium supplemented with 7 g/L yeast extract, 2 g/L peptone and minerals. In comparison, the S. stipitis parental strain produced 20 g/L ethanol on day 7 under the same conditions. During mixed sugar (50 g/L glucose and 50 g/L xylose) fermentation, S. cerevisiae only utilized glucose and produced a peak ethanol concentration of 22 g/L in about 24 h. In contrast, S. stipitis and ScF2 utilized both sugars, producing peak ethanol concentrations of 31 g/L at 96 h and 40 g/L at 144 h, respectively. Randomly amplified polymorphic DNA (RAPD) analysis showed different banding patterns between ScF2 and its parental strains, suggesting that ScF2 is genetically different from the parental strains. This genome shuffling approach successfully combined features of parents, S. cerevisiae (ethanol and sugar tolerance) and S. stipitis (xylose utilization), in ScF2. Its performance in defined media and industrially relevant hydrolysates remains to be assessed.

Glucose derepression

Random mutagenesis

As mentioned before, native xylose-fermenting yeasts typically suffer from glucose repression [9] and glucose inactivation [47]. As a result, in a glucose-xylose mixture, glucose is fermented before xylose and these yeasts are often not sufficiently tolerant of ethanol [6] to complete the xylose fermentation.

Some researchers have selected for glucose derepressed cells using the glucose analog 2-deoxyglucose (2-DG) which cannot be metabolized by yeasts beyond the initial phosphorylation step [79]. In an earlier study, glucose derepressed mutants of P. tannophilus NRRL Y-2460 were obtained by isolating UV mutants resistant to 2-DG followed by replica-plating on solid media containing hexose sugars to select for strains showing reduced growth [92]. During growth on mixed sugars, mutant P509-1B exhibited reduced glucose repression and was able to co-utilize glucose and xylose compared to the WT. Enzyme studies showed this strain to be deficient in hexose-phosphorylating activity (possessing only 6 % of the WT activity) [92]. Wedlock and Thornton [93] further examined the role of the two hexokinases in glucose repression in P. tannophilus. Three mutants were constructed and grown under mixed or individual sugars followed by measurement of XR and XDH activities as an indicator of glucose repression. Mutant P510-5A had a defect in glucokinase (encoded by glk), P509-3C had a defect in hexokinase (encoded by hxk-a) and P509-1B had defects in both glk and hxk-a [92]. When grown in a mixture of glucose (20 g/L) and xylose (20 g/L), reduced XR and XDH activities were seen in P510-5A, but not P509-3C and P509-1B. The results indicate the involvement of hxk-a, but not glk, in glucose repression in P. tannophilus [93]. Unfortunately, the fermentation performance of P510-5A in mixed sugars was not tested to confirm the glucose derepressed phenotype.

In another study, Sreenath and Jeffries [79] used chemical mutagenesis (ethyl methane sulphonate) followed by selection on 2-DG to obtain mutants of S. stipitis FPL-061 with improved xylose utilization in the presence of glucose. Of the 2-DG resistant strains selected, FPL-DX26 was the best in fermentation. When grown in a mixture of 40 g/L glucose and 40 g/L xylose, this strain consumed the sugars simultaneously after 20 h and all the sugars were consumed by 45 h. In comparison, the WT utilized xylose only after glucose was consumed and complete utilization of these sugars required 120 h [79].

Miscellaneous attempts to improve xylose utilization and fermentation

Random mutagenesis

Approaches, ranging from random to semi-rational, have been used to improve xylose utilization in native xylose-fermenting yeasts. Some of the successful attempts are described below. Mutants able to utilize xylose faster typically exhibit better xylose fermentation rate.

In an effort to isolate strains with improved mixed sugar fermentation, Sreenath and Jeffries [78] selected for rapidly growing mutants of S. stipitis CBS 6054 on l-xylose in the presence of respiratory inhibitors antimycin A and salicyl hydroxamic acid (SHAM). The ability to grow on l-xylose was used to select for mutants whose aldose reductase may be derepressed. To ensure that selected strains retained fermentative ability, mutants exhibiting lower respiratory activity were selected via resistance to respiratory inhibitors. S. stipitis possesses both antimycin-sensitive and SHAM-sensitive respiratory pathways and inhibitors for both pathways were used to inhibit growth, as blockage of either pathway alone is insufficient to inhibit growth [78]. One mutant isolated (FPL-061) produced higher ethanol concentration (29.4 g/L) and yield (0.42 g ethanol/g sugar consumed) compared to the WT (25.7 g/L and 0.35 g/g, respectively) in a 1:1 mixture of glucose and xylose (having final sugar concentrations of 60–80 g/L) supplemented with salts and some peptone [78].

In another study, Jeffries [29] used UV mutagenesis followed by selection for rapid growth in nitrate-xylitol broth to obtain mutants of P. tannophilus NRRL Y-2460 with enhanced rates of xylose fermentation. Nitrate utilization requires an active pentose phosphate pathway, which provides NADPH for nitrate reduction. The rationale was that strains capable of rapid growth on nitrate should possess higher levels of pentose phosphate pathway enzymes, consequently having faster xylose fermentation rates. One mutant (NO3–NO3-4) fermented xylose more rapidly, produced ethanol twice as fast and had a 32 % higher ethanol yield compared to the WT (0.25 g ethanol/g xylose consumed compared to 0.19 g/g) [29].

Some pentose-fermenting yeasts are known to produce and consume ethanol concurrently during xylose fermentation, and this has been suggested as one of the reasons for low ethanol yield from xylose [58]. In an effort to minimize such loss, UV-induced mutants of P. tannophilus NRRL Y-2460 with diminished ability to grow on ethanol while retaining the ability to utilize xylose were isolated [49]. Several ethanol-defective mutants that produced more ethanol than the WT were obtained. One mutant, designated eth 2-1, showed considerably improved ethanol production from xylose than the WT. During fermentation in 40 g/L xylose, the maximum ethanol concentration (10 g/L) and ethanol yield (0.29 g ethanol/g xylose consumed) produced by eth 2-1 exceeded those (6.5 g/L and 0.16 g/g, respectively) produced by the WT [49]. In addition, eth 2-1 produced less xylitol than the WT. Biochemical studies showed the eth 2-1 mutant to be deficient in malate dehydrogenase, an enzyme in the tricarboxylic acid cycle [49].

To further improve their xylose-fermenting ability, mutant eth 2-1 [49] was cross-mated with mutant NO3–NO3-4 [29] described above. This led to the isolation of P. tannophilus recombinants that possessed the desired characteristics of both strains [14]. Four hybrid strains (P587-4A, P587-7B, P587-10D and P587-11B) produced as much ethanol as strain NO3–NO3-4. The incorporation of the eth 2-1 mutation was confirmed by decreased ethanol consumption under aerobic conditions by the hybrids [14].

In other research to minimize aerobic ethanol loss, Hughes et al. [26] selected for UV-generated mutants of S. stipitis NRRL Y-7124 able to grow anaerobically on xylose plates for 5 months. Five strains (WT-1-11, WT-2-1, 14-2-6, 22-1-1 and 22-1-12) were isolated and tested for fermentation of mixed sugars (20 g/L xylose, 20 g/L glucose; supplemented with 10 g/L yeast extract and 20 g/L peptone) under microaerophilic conditions. Sugar utilization and ethanol yields obtained for the mutants (ranging from 0.23 to 0.24 g ethanol/g sugar consumed) were slightly lower than those for the WT (0.27 g/g). Mixed sugar fermentation under strictly anaerobic conditions was also tested using three of the mutants (WT-1-11, 14-2-6 and 22-1-12) and S. cerevisiae NRRL Y-2034. S. cerevisiae achieved a maximum ethanol concentration (9.5 g/L) and yield (0.24 g/g) within 12 h, but no further increase in ethanol concentration occurred after depletion of glucose. The mutants produced a similar concentration of ethanol as that by S. cerevisiae in 80–180 h after which ethanol continued to be produced from xylose. Mutant 22-1-12 produced the highest peak ethanol (13 g/L) and yield (0.33 g/g) in 490 h. Ethanol production by the S. stipitis WT was not evaluated because the strain could not grow under strictly anaerobic conditions [26]. The researchers succeeded in obtaining mutants of S. stipitis able to ferment glucose and xylose under anaerobic conditions, though at exceedingly low rate(s).

Recently, Li et al. [51] isolated a high ethanol yielding UV mutant of S. shehatae ATCC 22984 that also produces less xylitol. Two rounds of mutagenesis and screening on rich xylose-containing medium (3 g/L yeast extract, 3 g/L peptone, 3 g/L malt extract and 10–20 g/L xylose; YPM-X) supplemented with 0.05 g/L antimycin and 0.05 g/L of 2-3-5-triphenyltetrazolium chloride (TTC) were conducted. Antimycin A is a respiratory inhibitor and TTC is reduced under anaerobic conditions by dehydrogenases to the red compound formazan. The selected mutant Cs3512 showed better fermentation of xylose (initial concentration 121.3 g/L) and of sugar mixtures containing xylose (21.2 g/L) and glucose (52.9 g/L) in rich media, while producing more ethanol (44.4 and 31.0 g/L, respectively) compared to the WT (39 and 28.7 g/L, respectively) and less xylitol (10.2 and 1.81 g/L, respectively) compared to the WT (16.3 and 2.86 g/L, respectively). Fermentation was also assessed in rice straw hydrolysate (pH 6.5). After 72 h of fermentation CS3512 produced 21.3 g/L of ethanol, which is about 77 % of the theoretical yield. The fermentation performance of the WT was not assessed; thus the extent of improvement in the fermentation performance of CS3512 in rice straw hydrolysate is not known.

Protoplast fusion

Protoplast fusion has been used to generate polyploidy fusants, some of which exhibit improved xylose fermentation, as summarized in Table 2. Maleszka et al. [57] tested the fermentation performance of several polyploidy strains of P. tannophilus NRRL Y-2460. They observed a correlation between increasing the chromosome number above the haploid level to increases in ethanol yield from xylose. A tetraploid strain (P45-#14) gave the highest ethanol yield from 20 g/L xylose (83.3 % of theoretical). A triploid strain (P56-#8) also produced high ethanol yield from 40 g/L xylose (70 % of theoretical). These values were 14.2 and 11 % higher than those of the haploid WT strain on 20 and 40 g/L xylose, respectively. Interestingly, an aneuploid strain P45-#9 gave a high rate of ethanol production from xylose (1.87 times that of the haploid WT), followed by the tetraploid strain P45-#14 (1.83 times the WT rate). Thus, using polyploids could be a useful approach to obtain strains that produce ethanol more efficiently. It is not known, however, how stable the polyploids are, considering these are strains of P. tannophilus which prefer the haploid state. A similar trend was seen using diploid, triploid and tetraploid strains of S. shehatae CBS2779 [35] in that an increase in ploidy levels led to enhanced rate, but not the final yield of ethanol produced from xylose. The increase in fermentative ability was attributed to the increased gene pool. However, many of the presumptive diploid, triploid and tetraploid strains isolated were unstable and readily segregated into cells of lower ploidy level [35].

In contrast to the reported enhanced rates and yields of ethanol production from xylose with increasing chromosome number in P. tannophilus, polyploid strains of S. stipitis CSIR Y633 produced by protoplast fusion did not show improved ethanol productivity with increasing ploidy levels [20]. Of the four fusant strains showing an approximate two-fold increase in cellular DNA content, only strains P2-2 and P2-3 produced slightly higher yields (0.47 g ethanol/g xylose consumed) compared to the WT (0.45 g/g) in a slightly shorter fermentation period (44, 45 and 47 h, respectively). The reason for the variable fermentation performance of polyploids from different species of pentose-fermenting yeasts is not known.

Metabolic engineering

Classical strain improvement approaches may result in random changes throughout the genome, some of which may be undesirable. In contrast, metabolic engineering approaches allow precise modifications of specific pathways [31, 32]. The difficulty with the latter methods is that there is limited knowledge of what changes are required to produce a desired phenotypic effect.

Previous studies have shown that some respiratory deficient yeast strains can accumulate higher ethanol concentrations, although the mechanisms involved are not well understood [27, 75, 76]. It is known that in addition to the cytochrome-based respiratory system, S. stipitis possesses a secondary SHAM-sensitive respiratory system. To examine the contribution of the SHAM-sensitive system towards xylose fermentation without influence of the cytochrome system, Shi et al. [76] created a strain with a nonfunctional cytochrome pathway by disrupting the heme protein cytochrome c. Interestingly, this mutant produced more ethanol (36.8 g/L) than the WT (27.2 g/L) from xylose (80 g/L) in a rich peptone-containing medium. The authors postulated that the limited energy produced by the secondary SHAM respiratory system was sufficient for cell growth and ethanol production by the mutant [76].

Efforts to address cofactor imbalance during xylose metabolism

Yeasts metabolize xylose through an inducible pathway where it is first reduced by an NAD(P)H-dependent XR to xylitol. Xylitol is then oxidized by an NAD-dependent XDH to xylulose which can enter the pentose phosphate, Embden-Meyerhof or phosphoketolase pathways [91]. Some yeast XRs are strictly NADPH-dependent [36], while most function with either NADH or NADPH, with a preference for NADPH [48]. Two exceptions are the XRs from Candida parapsilosis [50] and S. passalidarum [23, 54] that prefer NADH to NADPH. During xylose metabolism, the different coenzymes required by XR and XDH cause a cofactor imbalance resulting in an accumulation of NADP and NADH from the first and second reactions, respectively. In the absence of a transhydrogenase, oxygen is required for the regeneration of NAD. It is postulated that the ability of some yeasts to ferment xylose anaerobically is due to the NADH-dependent XR activity [12]. Consistent with this postulate, a P. tannophilus mutant deficient in NADPH-dependent XR activity, but expressing normal levels of NADH-dependent XR activity, exhibited a xylose utilization rate similar to the WT under anoxic conditions [72]. More recently, the yeast S. passalidarum, which possesses NADH-preferring XR, was shown to ferment xylose efficiently under oxygen-limited conditions [23, 54].

One approach to address the cofactor imbalance in pentose-fermenting yeasts is to change the cofactor preferences of XR or XDH. Many studies have attempted to alter the cofactor preferences of these two enzymes in an effort to improve xylose flux and fermentation (Table 3). Addressing the cofactor imbalance in these enzymes can theoretically enable anaerobic xylose fermentation. Two approaches have been used to alter the cofactor dependence of XRs or XDHs. The first is to construct NADH-preferring XR (to be coupled with NAD-dependent XDH) and the second is to construct NADP-preferring XDH (to be coupled with NADPH-dependent XR). Successes have been reported with both approaches and selected examples are described below. The physiological effects of some of the XR and XDH variants have been tested mostly in S. cerevisiae, and some in Candida utilis and Hansenula polymorpha (Table 4).

Modifying XRs for increased NADH preference and reduced NADPH preference

Yeast XRs, members of the aldo–keto reductase (AKR) superfamily, typically contain a conserved IPKS (Ile–Pro–Lys–Ser) motif. The Lys residue within this motif interacts with the 2’-phosphate group of NADPH [48]. Removing this stabilizing interaction should reduce the affinity for NADPH without affecting the affinity for NADH, which lacks the 2’-phosphate group. This was observed in a K270 M variant of the S. stipitis XR which showed a 16.7-fold decrease in affinity towards NADPH, while the affinity towards NADH was unaffected [42]. Unexpectedly, the K270 M variant showed a 14-fold reduced affinity for xylose compared to the WT (K m = 43.5 mM) [42]. When two copies of the SsXR/K270M gene were expressed in S. cerevisiae TMB3001 (the parental strain) along with the genes encoding the S. stipitis XDH and S. cerevisiae XK, the resultant TMB3271 strain exhibited considerably higher XR activities (XRNADH activity = 4.7 U/mg and XRNADPH activity = 11.0 U/mg) compared to TMB3001 (XRNADH activity = 0.1 U/mg and XRNADPH activity = 0.3 U/mg) in cell extracts. The ethanol yield from 50 g/L xylose after 70 h in a defined medium was 0.31 g ethanol/g of xylose [34].

In a subsequent study, Bengtsson et al. [8] prepared a K270R variant of the SsXR and tested the physiological effect of this mutation on xylose fermentation in S. cerevisiae. Two S. cerevisiae strains, with the native XR gene deleted, were constructed: TMB 3321 (carrying the native SsXR) and TMB 3323 (carrying the SsXRm/K270R). In anaerobic batch fermentation of glucose (20 g/L) and xylose (50 g/L) in defined media, TMB 3323 had a slightly higher xylose consumption rate (0.39 g/L/h) but a lower xylitol yield (0.09 g xylitol/g sugar consumed) compared to TMB 3321 (0.26 g/L/h and 0.26 g/g, respectively). As a result, the peak ethanol produced for TMB 3323 was higher (25.3 g/L) compared to TMB 3321 (16.7 g/L) [8].

In addition to the IPKS motif, other amino acid residues are also involved in interaction with the cofactor in yeast XRs. Based on sequence information of the AKR family enzymes and the structure of the Candida tenuis XR (CtXR), several residues thought to interact with different functional groups of the cofactors were mutated in combination. Two double mutants [RH (K274R/R280H) and RD (K274R/N276D)] of the C. tenuis XR were constructed in an effort to increase affinity towards NADH [67, 68]. Of these, the RH variant (K m, NADH = 12 µM, K m, NADPH = 2 µM) can bind to both cofactors slightly better than the WT (K m, NADH = 38 µM, K m, NADPH = 3 µM), while the RD variant had similar NADH binding affinity (K m, NADH = 41 µM), but poorer NADPH binding (K m, NADPH = 128 µM) compared to the WT [67, 68].

In a follow-up study, Petschacher and Nidetzky [69] expressed the RD variant of the C. tenuis XR along with XDH from Galactocandida mastotermitis (GmXDH) and an extra copy of the endogenous ScXK gene in S. cerevisiae. The recombinant strain (BP10001) was tested for anaerobic fermentation of 20 g/L xylose in defined medium and compared to the parent strain (BP000) that expressed the WT CtXR, GmXDH and endogenous ScXK. BP10001 showed elevated NADH-dependent XR activity (0.26 U/mg) compared to BP000 (0.15 U/mg). The NADPH-dependent XR activity for BP10001 was 0.33 U/mg compared to 0.18 U/mg for BP000. BP10001 had a 42 % increase in ethanol yield (0.34 g ethanol/g xylose consumed), a 52 % decrease in xylitol yield (0.19 g/g) and a 57 % decrease in glycerol yield (0.02 g/g) during anaerobic fermentation compared to BP000 [69].

Based on results from Petschacher et al. [67] and Petschacher and Nidetzky [68], Dmytruk et al. [15] introduced two point mutations K341R and N343D in the H. polymorpha XR. The XR variant displayed reduced affinity towards NADPH (K m = 152 µM) compared to the WT enzyme (K m = 7 µM), while the affinity towards NADH was unaffected. The physiological effect of this XR variant was assessed in fermentation tests using the xylose-utilizing, but non-fermenting H. polymorpha. The results showed insignificant ethanol productivity [15].

Candida utilis is another xylose-utilizing, but non-fermenting, yeast which can be imparted with the ability to ferment xylose to ethanol by heterologous expression of XR, XDH and XK from other xylose-fermenting yeasts [80]. In this study, a NADH-preferring K275R/N277D XR variant and WT XDH from S. shehatae along with the WT XK from S. stipitis were expressed in C. utilis to yield the recombinant strain TMS174. The amino acid modifications in the XR were selected based on greater preference towards NADH seen in the SsXR bearing the same corresponding mutations from a previous study [8]. The recombinant strain TMS174 had elevated NADH-dependent XR activity (0.75 U/mg) compared to a parental strain TMS170 expressing native SsheXR, SsheXDH and SsXK (0.41 U/mg) and lower NADPH-dependent XR activity (0.25 U/mg) compared to TMS170 (0.73 U/mg). In a peptone-based fermentation containing 50 g/L xylose, TMS174 produced 17.4 g/L ethanol in 20 h. This ethanol yield was much higher than the parental strain which produced 2.1 g/L ethanol in 30 h [82]. To further improve ethanol yield, the same group constructed a strain by transforming different ratios of the XR variant and WT XDH from S. shehatae, along with the WT XK from S. stipitis into C. utilis. Following screening, a recombinant strain (CI35) with an integrated copy number ratio of 4.9:7.2:7.4 in SsheXR(K275R/N277D):SsheXDH:SsXK was found to give the best ethanol yield. During fermentation of 80 g/L xylose in a peptone-containing medium, strain CI35 produced peak ethanol of 29.2 g/L with a yield of 0.402 g/g sugar within 70 h. This was a considerable improvement over the performance of TMS174 (peak ethanol of 21.3 g/L; ethanol yield of 0.283 g/g sugar; 142 h) [83]. This research suggested that adjusting the ratios of enzymes involved in xylose metabolism might further improve xylose fermentation.

Wang et al. [86] suggested that in the S. stipitis XR, Lys21 forms H-bond with NADPH. A K21A variant of the S. stipitis XR was constructed to disrupt this H-bond. The XR variant had no detectable NADPH-dependent activity, but exhibited similar NADH-dependent activity (K m, NADH = 32 µM) compared to the WT (K m, NADH = 21 µM) [98]. This study suggests that a single amino acid substitution may be able to completely eliminate NADPH-dependent activity in the S. stipitis XR. The reason for the complete loss of NADPH-dependent activity is not entirely clear, as many residues are involved collectively in cofactor interactions. It would be useful to verify and test such a substitution in other yeast XRs.

Modifying XDHs for increased NADP preference and reduced NAD preference

In addition to modifying the XR in pentose-fermenting yeasts, the cofactor preference of XDH can also be modified to address the cofactor imbalance. XDH shares a similar coenzyme-binding motif with the medium-chain dehydrogenase/reductase (MDR) superfamily of enzymes. For most NAD-dependent enzymes, amino acids from this conserved coenzyme-binding region are responsible for interacting with the 2’- and 3’-OH groups of NAD. Generally, changing the charged amino acid residues to uncharged residues can alter cofactor preference by reducing interactions with –OH groups of NAD [32, 41, 65].

Several groups have altered XDH to reduce its affinity towards NAD. Metzger and Hollenberg [60] constructed single (D207G) and double (D207G/D210G) mutants of the S. stipitis XDH. The mutations were designed to eliminate H-bonding interaction with the 2’-OH group of NAD and introduce bonding with 2’-phosphate group of NADP. These mutants exhibited no change in affinity towards NADP, but an 11-fold decrease in NAD affinity (K m, NAD = 2.5 mM) compared to the WT enzyme (K m, NAD = 0.227 mM).

In an experiment to increase the affinity of SsXDH towards NADP, Watanabe et al. [89] replaced Asp207 with a small and uncharged residue and changed an adjacent residue to Arg to form a binding site for NADP. Other combinations of mutations were made also to active site residues based on information from the strictly NADP-dependent Bemisia argentifolii sorbitol dehydrogenase. Of the ten mutants constructed, the triple mutant ARS (D207A/I208R/F209S) and quadruple mutant ARSdR (D207A/I208R/F209S/N211R) were the best in terms of improved NADP-dependent activity and affinity. The NAD-dependent specific activities for the ARS and ARSdR variants were 320 and 259 µmol cofactor min−1 compared to 1,110 µmol cofactor min−1 for the WT enzyme; their NADP-dependent specific activities were 2,350 and 2,570 µmol cofactor min−1 compared to 1.2 µmol cofactor min−1 for the WT enzyme. The K m values for NAD were 1.3 and 17.3 mM for the ARS and ARSdR variants, respectively, and those for NADP were 0.90 and 1.38 mM, respectively. In comparison, the K m values of the WT enzyme were 0.381 and 170 mM for NAD and NADP, respectively. Thus, both mutants showed increased activities and affinity towards NADP, accompanied by decreased activities and affinity towards NAD. To assess the physiological performance of the NADP-preferring XDH variants, a recombinant S. cerevisiae strain [SsXR/Ss(ARSdR)XDH/ScXK] was constructed [88]. Enzymatic activities were measured in cell extract after growth of the transformant in rich peptone media and compared against a S. cerevisiae strain (Y-WT) harboring SsXR, SsXDH and ScXK. The recombinant strain D-XR/ARSdR/XK produced NAD-dependent XDH activity of 0.048 U/mg (two-fold higher than the WT) and NADP-dependent XDH activity of 0.426 U/mg (13-fold higher than the WT). During oxygen-limited fermentation at 30 °C in YNB medium containing glucose (5 g/L) and xylose (15 g/L) supplemented with essential amino acids, strain D-XR/ARSdR/XK consumed all the glucose within 15 h and 68 % of the xylose in 72 h. Under the same conditions, the WT also consumed glucose in the first 15 h, but only 58 % of xylose was consumed in 72 h. Strain D-XR/ARSdR/XK produced a peak ethanol concentration of 7.02 g/L and a yield of 0.46 g ethanol/g sugar consumed, both values being 1.4-fold higher than those of Y-WT [88].

Modifying both XR and XDH

Some researchers have attempted to address the cofactor imbalance during xylose fermentation by reducing the NADH preference of XRs to make them more NADPH-dependent and coupling this with a NADP-preferring XDH. Khattab et al. [38] constructed two double mutants [E223D/S271A (DA) and E223A/S271A (AA)] of the S. stipitis XR (SsXR) with increased affinity towards NADPH. Both variants exhibited slightly increased activity with NADPH, but much reduced or no activity towards NADH. The DA variant showed similar affinity for NADPH (K m = 20.4 µM) compared to the WT XR (K m = 16.2 µM), but a 7.3-fold decrease in affinity for NADH (K m = 391 µM) compared to the WT (K m = 30.6 µM). The affinity of the AA variant towards NADPH (K m = 17.5 µM) was also similar to the WT XR, but it had non-detectable activity towards NADH [38]. In a follow-up study, Khattab et al. [37] tested the physiological performance of the NADP-preferring XR [38] and XDH variants described earlier [89] in S. cerevisiae. The control S. cerevisiae strain, SK-N1, carried the SsXR(WT)-SsXDH(ARSdR)-ScXK construct while the test strain SK-N2 carried the construct SsXR(AA)-SsXDH(ARSdR)-ScXK. During mixed sugar (55 g/L xylose and 20 g/L glucose) semi-aerobic fermentation in peptone-rich media, strain SK-N2 produced a peak ethanol concentration of 30.1 g/L which was 20 % higher than that of the control strain SK-N1 (25.1 g/L peak ethanol) [37]. It remains to be seen how strain SK-N2 performs under anaerobic conditions in a chemically defined medium.

Testing with native NADH-preferring XRs

While most yeast XRs are either strictly NADPH-dependent or prefer NADPH over NADH, there are two known exceptions. They are the XR from C. parapsilosis (K m, NADH = 3.3 µM; K m, NADPH = 36.5 µM) [50] and the mixed XRs from S. passalidarum (K m, NADH = 17.3 ± 1.8 µM; K m, NADPH = 31.7 ± 2.6 µM) [23, 54] that exhibit a higher affinity towards NADH than NADPH. Since S. passalidarum contains two genes for XR, it was not known which gene product contributed more to the cofactor affinities measured in crude homogenates [54]. These unique NADH-preferring XRs have been used to alleviate cofactor imbalance during xylose metabolism when expressed heterologously. Lee et al. [50] expressed the xyl1 gene encoding the C. parapsilosis XR in C. tropicalis to yield strain BN-1 which was subjected to micro-aerobic fed-batch fermentation (glucose 45 g/L first and subsequently 300 g/L xylose supplied at rates of 5–40 mL/h). For the WT, ethanol production declined after complete consumption of glucose, and the peak ethanol produced was 15 g/L. Strain BN-1 produced the same amount of ethanol from glucose, but after depletion of glucose, ethanol continued to be produced up to 21 g/L when all the xylose was consumed. The C. tropicalis strain used is a natural xylitol producer. Expression of CpXR in strain BN-1 had no apparent effect on xylitol productivity, and this strain produced a similar amount of xylitol (250 g/L) compared to WT. Given that a NADH-preferring XR should enable anaerobic xylose utilization, it would be interesting to test how a recombinant ethanol-producing strain with NADH-preferring XR might perform under anaerobic conditions. Equally interesting would be to examine the effect of expressing the NADH-preferring C. parapsilosis XRs in a xylose-fermenting yeast such as S. stipitis which does not produce much xylitol.

The gene encoding the NADH-preferring XR from S. passalidarum was cloned and expressed in S. cerevisiae [59]. However, xylose fermentation in this case was not tested.

The studies described in this section showed that the cofactor preference of either XR or XDH can be altered successfully. While some of the XR or XDH variants have been tested in vivo, more testing needs to be done preferably in pentose-fermenting yeasts to better assess the potential for improved xylose fermentation under anaerobic conditions. While changing the cofactor preference for XR and XDH is a prerequisite for addressing the cofactor imbalance, the work of Tamakawa et al. [83] suggests that the activity ratios of these two enzymes should be balanced also to further improve the overall xylose flux.

Concluding remarks

Lignocellulosic plant biomass represents one of the most attractive feedstocks for the production of fuel ethanol and chemicals. To improve the economic prospect of such a process, it is essential that potential biocatalysts be able to efficiently convert both the hexoses and pentoses found in industrially relevant lignocellulosic hydrolysates into the desired end product(s). Native xylose-fermenting yeasts possess the ability to ferment the major sugars in lignocellulose hydrolysates into ethanol, and they have been the subject of intense interest ever since their discovery in the early 1980s. However, these yeasts ferment xylose less efficiently and with considerably lower yield than glucose fermentation. Moreover, they suffer from glucose repression, low ethanol tolerance and are susceptible to various pretreatment-derived inhibitors in industrially relevant hydrolysates. These problems have limited their biotechnological potential and have prompted efforts to improve their properties over the past 30 years using a blend of classical and molecular methods. Although improved strains have been developed, ethanol yield and productivity from xylose have not yet matched the performance of the traditional fermentative yeast S. cerevisiae on glucose. Furthermore, the performance of these yeasts in pretreated industrially relevant hydrolysates remains poor.

Genetic improvement of microorganisms, including native pentose-fermenting yeasts, will continue to be essential for the development of competent strain(s) for lignocellulosic biomass conversion. With the advent of high-throughput screening and various “omics” approaches, strain development is poised for significant advancement. In particular, the new approaches, applied to pentose-fermenting yeasts, can potentially uncover new vistas on some of the biological factors and metabolic constraints that limit efficient fermentation of pentose sugars in lignocellulosic hydrolysates. These new insights hold considerable promise towards the development of robust strains that can ferment all the sugars in lignocellulosic hydrolysates to ethanol.

References

Amartey S, Jeffries T (1996) An improvement in Pichia stipitis fermentation of acid-hydrolysed hemicellulose achieved by overliming (calcium hydroxide treatment) and strain adaptation. World J Microbiol Biotechnol 12:281–283

Bajwa PK, Harner NK, Richardson TL, Sidhu S, Habash MB, Trevors JT, Lee H (2013) Genome shuffling protocol for the pentose-fermenting yeast Scheffersomyces stipitis. In: Gupta VK, Tuohy MG, Ayyachamy M, Turner KM, O’Donovan A (eds) Laboratory protocols in fungal biology: current methods in fungal biology. Springer, New York, pp 447–454

Bajwa PK, Phaenark C, Grant N, Zhang X, Paice M, Martin VJJ, Trevors JT, Lee H (2011) Ethanol production from selected lignocellulosic hydrolysates by genome shuffled strains of Scheffersomyces stipitis. Bioresour Technol 102:9965–9969

Bajwa PK, Pinel D, Martin VJJ, Trevors JT, Lee H (2010) Strain improvement of the pentose-fermenting yeast Pichia stipitis by genome shuffling. J Microbiol Methods 81:179–186

Bajwa PK, Shireen T, D’Aoust F, Pinel D, Martin VJJ, Trevors JT, Lee H (2009) Mutants of the pentose-fermenting yeast Pichia stipitis with improved tolerance to inhibitors in hardwood spent sulfite liquor. Biotechnol Bioeng 104:892–900

Barbosa MDS, Lee H, Schneider H, Forsberg CW (1990) Temperature mediated changes of d-xylose metabolism in the yeast Pachysolen tannophilus. FEMS Microbiol Lett 72:35–40

Batt CA, Carvallo S, Easson DD, Akedo M, Sinskey AJ (1986) Direct evidence for a xylose metabolic pathway in Saccharomyces cerevisiae. Biotechnol Bioeng 28:549–553

Bengtsson O, Hahn-Hagerdal B, Gorwa-Grauslund MF (2009) Xylose reductase from Pichia stipitis with altered coenzyme preference improves ethanolic xylose fermentation by recombinant Saccharomyces cerevisiae. Biotechnol Biofuels 2:9–18

Bicho PA, Runnals PL, Cunningham JD, Lee H (1988) Induction of xylose reductase and xylitol dehydrogenase activities in Pachysolen tannophilus and Pichia stipitis on mixed sugars. Appl Environ Microbiol 54:50–54

Biot-Pelletier D, Martin VJJ (2014) Evolutionary engineering by genome shuffling. Appl Microbiol Biotechnol 98:3877–3887

Bruinenberg PM, Debot PHM, van Dijken JP, Scheffers WA (1983) The role of redox balances in the anaerobic fermentation of xylose by yeasts. Appl Microbiol Biotechnol 18:287–292

Bruinenberg PM, Debot PHM, van Dijken JP, Scheffers WA (1984) NADH-linked aldose reductase: the key to anaerobic alcoholic fermentation of xylose by yeasts. Appl Microbiol Biotechnol 19:256–260

Chen YL (2011) Development and application of co-culture for ethanol production by co-fermentation of glucose and xylose: a systematic review. J Ind Microbiol Biot 38:581–597

Clark T, Wedlock N, James AP, Deverell K, Thornton RJ (1986) Strain improvement of xylose-fermenting yeast Pachysolen tannophilus by hybridization of two mutant strains. Biotechnol Lett 8:801–806

Dmytruk OV, Dmytruk KV, Abbas CA, Voronovsky AY, Sibirny AA (2008) Engineering of xylose reductase and overexpression of xylitol dehydrogenase and xylulokinase improves xylose alcoholic fermentation in the thermotolerant yeast Hansenula polymorpha. Microb Cell Fact 7:21–28

Duitama J, Sanchez-Rodriguez A, Goovaerts A, Pulido-Tamayo S, Hubmann G, Foulquie-Moreno MR, Thevelein JM, Verstrepen KJ, Marchal K (2014) Improved linkage analysis of Quantitative Trait Loci using bulk segregants unveils a novel determinant of high ethanol tolerance in yeast. BMC Genomics 15:207–221

Girio FM, Fonseca C, Carvalheiro F, Duarte LC, Marques S, Bogel-Lukasik R (2010) Hemicelluloses for fuel ethanol: a review. Bioresour Technol 101:4775–4800

Giudici P, Solieri L, Pulvirenti AM, Cassanelli S (2005) Strategies and perspectives for genetic improvement of wine yeasts. Appl Microbiol Biotechnol 66:622–628

Gong CS, McCracken LD, Tsao GT (1981) Direct fermentation of d-xylose to ethanol by a xylose-fermenting yeast mutant, Candida sp XF-217. Biotechnol Lett 3:245–250

Gupthar AS (1987) Construction of a series of Pichia stipitis strains with increased DNA contents. Curr Genet 12:605–610

Harner NK, Bajwa PK, Habash MB, Trevors JT, Austin GD, Lee H (2014) Mutants of the pentose-fermenting yeast Pachysolen tannophilus tolerant to hardwood spent sulfite liquor and acetic acid. Antonie van Leeuwenhoek 105:29–43

Hou LH (2010) Improved production of ethanol by novel genome shuffling in Saccharomyces cerevisiae. Appl Biochem Biotechnol 160:1084–1093

Hou X (2012) Anaerobic xylose fermentation by Spathaspora passalidarum. Appl Microbiol Biotechnol 94:205–214

Hou XR, Yao S (2012) Improved inhibitor tolerance in xylose-fermenting yeast Spathaspora passalidarum by mutagenesis and protoplast fusion. Appl Microbiol Biotechnol 93:2591–2601

Huang CF, Lin TH, Guo GL, Hwang WS (2009) Enhanced ethanol production by fermentation of rice straw hydrolysate without detoxification using a newly adapted strain of Pichia stipitis. Bioresour Technol 100:3914–3920

Hughes SR, Gibbons WR, Bang SS, Pinkelman R, Bischoff KM, Slininger PJ, Qureshi N, Kurtzman CP, Liu SQ, Saha BC, Jackson JS, Cotta MA, Rich JO, Javers JE (2012) Random UV-C mutagenesis of Scheffersomyces (formerly Pichia) stipitis NRRL Y-7124 to improve anaerobic growth on lignocellulosic sugars. J Ind Microbiol Biotechnol 39:163–173

Hutter A, Oliver SG (1998) Ethanol production using nuclear petite yeast mutants. Appl Microbiol Biotechnol 49:511–516

Jeffries TW (1981) Conversion of xylose to ethanol under aerobic conditions by Candida tropicalis. Biotechnol Lett 3:213–218

Jeffries TW (1984) Mutants of Pachysolen tannophilus showing enhanced rates of growth and ethanol formation from d-xylose. Enzym Microb Technol 6:254–258

Jeffries TW (1985) Emerging technology for fermenting d-xylose. Trends Biotechnol 3:208–212

Jeffries TW (2006) Engineering yeasts for xylose metabolism. Curr Opin Biotechnol 17:320–326

Jeffries TW, Jin YS (2004) Metabolic engineering for improved fermentation of pentoses by yeasts. Appl Microbiol Biotechnol 63:495–509

Jeffries TW, Kurtzman CP (2004) Strain selection, taxonomy, and genetics of xylose-fermenting yeasts. Enzym Microb Tech 16:922–932

Jeppsson M, Bengtsson O, Franke K, Lee H, Hahn-Hagerdal R, Gorwa-Grauslund MF (2006) The expression of a Pichia stipitis xylose reductase mutant with higher KM for NADPH increases ethanol production from xylose in recombinant Saccharomyces cerevisiae. Biotechnol Bioeng 93:665–673

Johannsen E, Eagle L, Bredenhann G (1985) Protoplast fusion used for the construction of presumptive polyploids of the d-xylose fermenting yeast Candida shehatae. Curr Genet 9:313–319

Kavanagh KL, Klimacek M, Nidetzky B, Wilson DK (2003) Structure of xylose reductase bound to NAD(+) and the basis for single and dual co-substrate specificity in family 2 aldo-keto reductases. Biochem J 373:319–326

Khattab SMR, Saimura M, Kodaki T (2013) Boost in bioethanol production using recombinant Saccharomyces cerevisiae with mutated strictly NADPH-dependent xylose reductase and NADP(+)-dependent xylitol dehydrogenase. J Biotechnol 165:153–156

Khattab SMR, Watanabe S, Saimura M, Kodaki T (2011) A novel strictly NADPH-dependent Pichia stipitis xylose reductase constructed by site-directed mutagenesis. Biochem Biophys Res Commun 404:634–637

Kim JH, Block DE, Mills DA (2010) Simultaneous consumption of pentose and hexose sugars: an optimal microbial phenotype for efficient fermentation of lignocellulosic biomass. Appl Microbiol Biotechnol 88:1077–1085

Klinke HB, Thomsen AB, Ahring BK (2004) Inhibition of ethanol-producing yeast and bacteria by degradation products produced during pre-treatment of biomass. Appl Microbiol Biotechnol 66:10–26

Knoll M, Pleiss J (2008) The medium chain dehydrogenase/reductase engineering database: a systematic analysis of a diverse protein family to understand sequence structure function relationship. Protein Sci 17:1689–1697

Kostrzynska M, Sopher CR, Lee H (1998) Mutational analysis of the role of the conserved lysine-270 in the Pichia stipitis xylose reductase. FEMS Microbiol Lett 159:107–112

Kuhad RC, Gupta R, Khasa YP, Singh A, Zhang YHP (2011) Bioethanol production from pentose sugars: current status and future prospects. Renew Sustain Energy Rev 15:4950–4962

Kuhn A, van Zyl C, van Tonder A, Prior BA (1995) Purification and partial characterization of an aldo-keto reductase from Saccharomyces cerevisiae. Appl Environ Microbiol 61:1580–1585

Kumari R, Pramanik K (2012) Improved bioethanol production using fusants of Saccharomyces cerevisiae and xylose-fermenting yeasts. Appl Biochem Biotechnol 167:873–884

Kumari R, Pramanik K (2012) Improvement of multiple stress tolerance in yeast strain by sequential mutagenesis for enhanced bioethanol production. J Biosci Bioeng 114:622–629

Lee H (1992) Reversible inactivation of d-xylose utilization by d-glucose in pentose-fermenting yeast Pachysolen tannophilus. FEMS Microbiol Lett 92:1–4

Lee H (1998) The structure and function of yeast xylose (aldose) reductases. Yeast 14:977–984

Lee H, James AP, Zahab DM, Mahmourides G, Maleszka R, Schneider H (1986) Mutants of Pachysolen tannophilus with improved production of ethanol d-xylose. Appl Environ Microbiol 51:1252–1258

Lee JK, Koo BS, Kim SY (2003) Cloning and characterization of the xyl1 gene, encoding an NADH-preferring xylose reductase from Candida parapsilosis, and its functional expression in Candida tropicalis. Appl Environ Microbiol 69:6179–6188

Li Y, Park JY, Shiroma R, Ike M, Tokuyasu K (2012) Improved ethanol and reduced xylitol production from glucose and xylose mixtures by the mutant strain of Candida shehatae ATCC 22984. Appl Biochm Biotechnol 166:1781–1790

Liu ZL, Slininger PJ, Gorsich SW (2005) Enhanced biotransformation of furfural and hydroxymethylfurfural by newly developed ethanologenic yeast strains. Appl Biochem Biotechnol 121:451–460

Lohmeier-Vogel EM, Sopher CR, Lee H (1998) Intracellular acidification as a mechanism for the inhibition by acid hydrolysis-derived inhibitors of xylose fermentation by yeasts. J Ind Microbiol Biotechnol 20:75–81

Long TM, Su YK, Headman J, Higbee A, Willis LB, Jeffries TW (2012) Cofermentation of glucose, xylose, and cellobiose by the beetle-associated yeast Spathaspora passalidarum. Appl Environ Microbiol 78:5492–5500

Ma MG, Liu LZ (2010) Quantitative transcription dynamic analysis reveals candidate genes and key regulators for ethanol tolerance in Saccharomyces cerevisiae. BMC Micrbiol 10:169–188

Mahmourides G, Lee H, Maki N, Schneider H (1985) Ethanol accumulation in cultures of Pachysolen tannophilus on d-xylose is associated with a transition to a state of low oxygen consumption. Biotechnology 3:59–62

Maleszka R, James AP, Schneider H (1983) Ethanol production from various sugars by strains of Pachysolen tannophilus bearing different numbers of chromosomes. J Gen Microbiol 129:2495–2500

Maleszka R, Schneider H (1982) Concurrent production and consumption of ethanol by cultures of Pachysolen tannophilus growing on d-xylose. Appl Environ Microbiol 44:909–912

Mamoori YI, Yahya AI, AL-Jelawi MH (2013) Expression of xylose reductase enzyme from Spathaspora passalidarum in Saccharomyces cerevisiae. Iraqi J Sci 54:316–323

Metzger MH, Hollenberg CP (1995) Amino acid substitutions in the yeast Pichia stipitis xylitol dehydrogenase coenzyme binding domain affect the coenzyme specificity. Eur J Biochem 228:50–54

Neirinck LG, Maleszka R, Schneider H (1984) The requirement of oxygen for incorporation of carbon from d-xylose and d-glucose by Pachysolen tannophilus. Arch Biochem Biophys 228:13–21

Nigam JN (2001) Development of xylose-fermenting yeast Pichia stipitis for ethanol production through adaptation on hardwood hemicellulose acid prehydrolysate. J Appl Microbiol 90:208–215

Panchal CJ, Bast L, Russell I, Stewart GG (1988) Repression of xylose utilization by glucose in xylose-fermenting yeasts. Can J Microbiol 34:1316–1320

Patnaik R, Louie S, Gavrilovic V, Perry K, Stemmer WPC, Ryan CM, del Cardayre S (2002) Genome shuffling of Lactobacillus for improved acid tolerance. Nat Biotechnol 20:707–712

Persson B, Hallborn J, Walfridsson M, Hahn-Hagerdal B, Keranen S, Penttila M, Jornvall H (1993) Dual relationships of xylitol and alcohol dehydrogenases in families of 2 protein types. FEBS Lett 324:9–14

Petri R, Schmidt-Dannert C (2004) Dealing with complexity: evolutionary engineering and genome shuffling. Curr Opin Biotechnol 15:298–304

Petschacher B, Leitgeb S, Kavanagh KL, Wilson DK, Nidetzky B (2005) The coenzyme specificity of Candida tenuis xylose reductase (AKR2B5) explored by site-directed mutagenesis and X-ray crystallography. Biochem J 385:75–83

Petschacher B, Nidetzky B (2005) Engineering Candida tenuis xylose reductase for improved utilization of NADH: antagonistic effects of multiple side chain replacements and performance of site-directed mutants under simulated in vivo conditions. Appl Environ Microbiol 71:6390–6393

Petschacher B, Nidetzky B (2008) Altering the coenzyme preference of xylose reductase to favor utilization of NADH enhances ethanol yield from xylose in a metabolically engineered strain of Saccharomyces cerevisiae. Microb Cell Fact 7:9–20

Richardson TL, Harner NK, Bajwa PK, Trevors JT, Lee H (2011) Approaches to deal with toxic inhibitors during fermentation of lignocellulosic substrates. In: Zhu JJY, Zhang X, Pan XJ (eds) Sustainable production of fuels, chemicals, and fibers from forest biomass. ACS Symposium Series; American Chemical Society, Washington, D.C., pp 171–202

Saha BC (2003) Hemicellulose bioconversion. J Ind Microbiol Biotechnol 30:279–291

Schneider H, Lee H, Barbosa MDS, Kubicek CP, James AP (1989) Physiological properties of a mutant of Pachysolen tannophilus deficient in NADPH-dependent d-xylose reductase. Appl Environ Microbiol 55:2877–2881

Schneider H, Mahmourides G, Labelle JL, Lee H, Maki N, McNeill HJ (1985) Correlation between limitation of growth of Pachysolen tannophilus on d-xylose with the formation of ethanol and other products. Biotechnol Lett 7:361–364

Schneider H, Wang PY, Chan YK, Maleszka R (1981) Conversion of d-xylose into ethanol by the yeast Pachysolen tannophilus. Biotechnol Lett 3:89–92

Shi NQ, Cruz J, Sherman F, Jeffries TW (2002) SHAM sensitive alternative respiration in the xylose metabolizing yeast Pichia stipitis. Yeast 19:1203–1220

Shi NQ, Davis B, Sherman F, Cruz J, Jeffries TW (1999) Disruption of the cytochrome c gene in xylose-utilizing yeast Pichia stipitis leads to higher ethanol production. Yeast 15:1021–1030

Slininger PJ, Bothast RJ, Van Cauwenberge JE, Kurtzman CP (1982) Conversion of d-xylose to ethanol by the yeast Pachysolen tannophilus. Biotechnol Bioeng 24:371–384

Sreenath HK, Jeffries TW (1997) Diminished respirative growth and enhanced assimilative sugar uptake result in higher specific fermentation rates by the mutant Pichia stipitis FPL-061. Appl Biochem Biotechnol 63–65:109–116

Sreenath HK, Jeffries TW (1999) 2-deoxyglucose as a selective agent for derepressed mutants of Pichia stipitis. Appl Biochem Biotechnol 77:211–222

Stoutenburg RM, Perrotta JA, Nakas JP (2011) Overcoming inhibitors in a hemicellulosic hydrolysate: improving fermentability by feedstock detoxification and adaptation of Pichia stipitis. J Ind Microbiol Biotechnol 38:1939–1945

Swinnen S, Schaerlaekens K, Pais T, Claesen J, Hubmann G, Yang YD, Demeke M, Foulquie-Moreno MR, Goovaerts A, Souvereyns K, Clement L, Dumortier F, Thevelein JM (2012) Identification of novel causative genes determining the complex trait of high ethanol tolerance in yeast using pooled-segregant whole-genome sequence analysis. Genome Res 22:975–984

Tamakawa H, Ikushima S, Yoshida S (2011) Ethanol Production from xylose by a recombinant Candida utilis strain expressing protein-engineered xylose reductase and xylitol dehydrogenase. Biosci Biotechnol Biochem 75:1994–2000

Tamakawa H, Ikushima S, Yoshida S (2013) Construction of a Candida utilis strain with ratio-optimized expression of xylose-metabolizing enzyme genes by cocktail multicopy integration method. J Biosci Bioeng 115:532–539

Teixeira MC, Raposo LR, Mira NP, Lourenco AB, Sa-Correia I (2009) Genome-wide identification of Saccharomyces cerevisiae genes required for maximal tolerance to ethanol. Appl Environ Microb 75:5761–5772

Tran AV, Chambers RP (1985) Red oak wood derived inhibitors in the ethanol fermentation of xylose by Pichia stipitis CBS-5776. Biotechnol Lett 7:841–845

Wang JF, Wei DQ, Lin Y, Wang YH, Du HL, Li YX, Chou KC (2007) Insights from modeling the 3D structure of NAD(P)H-dependent d-xylose reductase of Pichia stipitis and its binding interactions with NAD and NADP. Biochem Biophys Res Commun 359:323–329

Wang PY, Johnson BF, Schneider H (1980) Fermentation of d-xylose by yeasts using glucose isomerase in the medium to convert d-xylose to d-xylulose. Biotechnol Lett 2:273–278

Watanabe S, Abu Saleh A, Pack SP, Annaluru N, Kodaki T, Makino K (2007) Ethanol production from xylose by recombinant Saccharomyces cerevisiae expressing protein engineered NADP(+)-dependent xylitol dehydrogenase. J Biotechnol 130:316–319

Watanabe S, Kodaki T, Makino K (2005) Complete reversal of coenzyme specificity of xylitol dehydrogenase and increase of thermostability by the introduction of structural zinc. J Biol Chem 280:10340–10349

Watanabe T, Watanabe I, Yamamoto M, Ando A, Nakamura T (2011) A UV-induced mutant of Pichia stipitis with increased ethanol production from xylose and selection of a spontaneous mutant with increased ethanol tolerance. Bioresour Technol 102:1844–1848