Abstract

Biosurfactants are natural compounds with surface activity and emulsifying properties produced by several types of microorganisms and have been considered an interesting alternative to synthetic surfactants. Glycolipids are promising biosurfactants, due to low toxicity, biodegradability, and chemical stability in different conditions and also because they have many biological activities, allowing wide applications in different fields. In this review, we addressed general information about families of glycolipids, rhamnolipids, sophorolipids, mannosylerythritol lipids, and trehalose lipids, describing their chemical and surface characteristics, recent studies using alternative substrates, and new strategies to improve of production, beyond their specificities. We focus in providing recent developments and trends in biotechnological process and medical and industrial applications.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Synthetic surfactants are an important group of chemical compounds widely used in different fields, although many of these compounds have been associated with environmental and toxicological problems and still considered expensive (Gudiña et al. 2015; Liu et al. 2013; Lechuga et al. 2016). Therefore, in recent years, it has increased the interest in compounds with tensoactive properties, biodegradability, and low toxicity characteristics, such as natural surfactants. These compounds are surface-active agents that can be produced by plants (saponins), animals (pulmonary surfactant), and microorganisms (biosurfactants) (Lang et al. 1989; Luna et al. 2011).

The biosurfactants are a diverse group of amphiphilic compounds produced by bacteria, fungi, and yeast strains that have the ability to reduce surface and interfacial tension in liquids or biphasic systems (e.g., liquid/gas, liquid/liquid, and solid/liquid) and may display emulsifying activity and interesting biological properties (Cameotra and Makkar 2010; Banat et al. 2014a). In addition, biosurfactants have clear advantages when compared to synthetic surfactants such as lower critical micelle concentration (CMC), lower toxicity, higher biodegradability, thermostability, and tolerance in several pH and ionic strength conditions (Varvaresou and Iakovou 2015; Soberón-Chávez and Maier 2011). Other advantage of the biological surfactant production is the possibility of using low-cost substrates. Most of reported process have been using agro-industrial wastes in the culture medium, in order to reduce costs and make the process more attractive in large scale (Nitschke and Pastore 2006; Barros et al. 2008; Andrade et al. 2016).

Biosurfactants can be classified according to their molecular weight in two groups: low and high molecular weight biosurfactants (Gudiña et al. 2013). The low molecular weight biosurfactants are the most studied group and comprises two important subgroups: glycolipids and lipopeptides. These can be subdivided into several biosurfactant families such as rhamnolipids, sophorolipids, trehalolipids, mannosylerythritol lipids (glycolipids), surfactins, fengycins, and iturins (lipopeptides), among others. In addition, each family is composed of different types of structurally related compounds. For example, the family of mannosylerythritol lipids (MELs) is divided into four types of major structures (called MEL-A to MEL-D). Also, the surfactin family comprises different compounds including bamylocin A, esperin, lichenysin, pumilacidin, and surfactin isoforms (Jacques 2011).

Considering the need to develop sustainable surfactant, glycolipid biosurfactants are promising due to possibility of their production from natural renewable resources by biotechnological means (Varvaresou and Iakovou 2015; Kuyukina et al. 2015). Nowadays, a main question in the biosurfactant field is how the knowledge constructed in these last years in terms of production process and applications has contributed to the insertion of these compounds in market, particularly in the production in industrial scale and product development. Thus, it is important that new studies in this field focus beyond the cost reduction of the biotechnological process and also perform the evaluation of the biosurfactant applicability in bioremediation or as a surfactant in products and also which biological properties these compounds exhibit.

In this present review, we provide the recent advances in the biotechnological production of the four main glycolipids, the most advantageous biosurfactants known considering its characteristics and production yields, describing the essential information about its structures, as well the latest studies on its biological properties. Moreover, in the scope of this work, we will focus in the major applications of biosurfactants, showing process conditions, optimization strategies, and use of alternative substrates to reduce production costs that has been performed in the recent years.

Glycolipid Biosurfactants

Glycolipid biosurfactants are most common subgroup of low molecular weight biosurfactants. Structurally, they are composed of a hydrophobic moiety that consists in a long-chain fatty acid (which can be aliphatic, hydroxylated, or unsaturated) in combination with a hydrophilic carbohydrate-based component (glucose, trehalose, mannose, galactose, sophorose, and rhamnose) (Muller and Hausamann 2011; Mukherjee and Das 2010). The most studied families of glycolipid biosurfactants are rhamnolipids, sophorolipids, trehalose lipids, and mannosylerythritol lipids. Table 1 comprises studies performed with these glycolipids, most of them using microorganisms isolated from oil-contaminated samples, demonstrating their potential in terms of surface activity, yield, use of renewable sources as substrate, and proposed applications.

Rhamnolipids

Rhamnolipids are glycolipids that consist in a hydrophilic group, one or two rhamnose molecules in L-form, linked to a hydrophobic group represented by saturated or unsaturated β-hydroxy fatty acids (Desai and Banat 1997; Řezanka et al. 2011; Gudiña et al. 2015). These compounds are generally produced by pathogenic Pseudomonas species, but some studies have shown the production of rhamnolipids by other microorganisms such as Burkholderia sp., Myxococcus sp., Enterobacter sp., Pseudoxanthomonas sp., Acinetobacter sp., and recently Streptomyces strains (Andrä et al. 2006; Ohlendorf et al. 2009; Rooney et al. 2009; Nayak et al. 2009; Čejková et al. 2014; Chen et al. 2012; Yan et al. 2014). The production of rhamnolipids by nonpathogenic strains has become an attractive possibility, and more studies have described biotechnological processes using Pseudomonas putida, Acinetobacter calcoaceticus, Enterobacter asburiae, and Burkholderia thailandensis (Wittgens et al. 2011; Hošková et al. 2013; Díaz De Rienzo et al. 2016a; Funston et al. 2016).

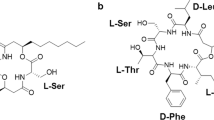

In fermentative processes, a variety of rhamnolipid analogues can be obtained, predominantly rhamnosyl-β-hydroxydecanoate (Rha-C10), rhamnosyl-β-hydroxydecanoyl-β-hydroxydecanoate (Rha-C10-C10), mono-rhamnolipids and rhamnosyl-rhamnosyl-β-hydroxydecanoate (Rha-Rha-C10), and rhamnosyl-rhamnosyl-β-hydroxydecanoyl-β-hydroxydecanoate (Rha-Rha-C10-C-10)-di-rhamnolipids (Fig. 1) (Chayabutra et al. 2001; Soberón-Chavez et al. 2005; Pinzon et al. 2009; Abdel-Mawgoud et al. 2010; Hošková et al. 2013). The proportion of these analogues and global yield of production depend on several parameters such as medium composition, microorganism producer, and fermentation conditions, and the ratio of the isoforms determines variation in physicochemical properties of the biosurfactant mixture (Mata-Sandoval et al. 2001; Clarke et al. 2010; Onwosi and Odibo 2012; Kumar et al. 2012; Rikalovic et al. 2013). In addition, it is suggested to keep the production process in controlled conditions in order to maintain the well-defined and consistent properties of rhamnolipids (Bai and McClements 2016). Therefore, studies that perform the scale-up and use fermenters to carry the rhamnolipid production are more interesting since it allows greater repeatability in the type of analogues that are obtained when compared with experiments in laboratory scale.

Rhamnolipids are considered one of the most potent biosurfactants, mainly due the reduction of water surface tension from 72 to 31 or <30 mN/m and that the critical micellar concentration (CMC) values can vary between 20 and 225 mg/L in water (Syldatk et al. 1985; Nitschke et al. 2005; Dubeau et al. 2009). The surface properties of rhamnolipids described in literature can vary because of the production process type conducted, generally in laboratorial scale, or the utilization of purification steps. Nitschke et al. (2005) reported low critical micelle tension for different rhamnolipids: the di-rhamnolipid Rha-Rha-C10-C10 showed 5 mg/L of CMC, while the mono-rhamnolipid Rha-C10-C10 reached 40 mg/L. Another example, rhamnolipids obtained by Gudiña et al. (2015), showed low CMC values (10–200 mg/L) and great ability to reduce surface tension (28–30 mN/m) and also exhibited high values of emulsification index in the order of 60–70 %. In addition, Ma et al. (2016) found that a mixture of six rhamnolipid homologs, obtained from Pseudomonas aeruginosa DN1, was able to reduce the surface tension of water to 25.88 mN/m with CMC of 50 mg/L and showed excellent emulsification activity in the order of 100 % to several hydrocarbons. Most studies do not describe the properties for each rhamnolipid analogues obtained in fermentation process due to difficulty in purification processes. However, the purification and individual evaluation would be extremely important when it comes of therapeutic applications because each compound alone could act differently.

Many rhamnolipid derivatives have been described, and different analytical techniques are necessary to characterize and quantify these glycolipids in culture medium after fermentation and purification steps. The use of ultra-performance liquid chromatography tandem mass spectrometry (HPLC-MS) is considered a powerful and appropriate tool for analysis of several rhamnolipid analogues (Zgoła-Grześkowiak and Kaczorek 2011; Ma et al. 2016). Another point is that the development of new methods such as the use of high-performance liquid chromatography coupled to charged aerosol detection for quantification analysis also allows achieving good results (linearity, limits of quantification, and detection and accuracy) and together with rapid validated methods of individual rhamnolipid congeners has been recommended to several processes using different carbon sources (Zgoła-Grześkowiak and Kaczorek 2011; Rudden et al. 2015; Behrens et al. 2016).

Beyond the powerful surface activity and interesting emulsification capacity, the rhamnolipids also present low toxicity and biodegradability, relevant properties that can make them applicable in diverse industrial process, such as bioremediation, cosmetic and detergent formulations, enhancement of oil recovery, agriculture, food control, and drug delivery. For these reasons, several reviews show future perspectives for its use and strategies for production (Nitschke and Costa 2007; Lourith and Kanlayavattanakul 2009; Nguyen et al. 2010; Bafghi and Fazaelipoor 2012; Sachdev and Cameotra 2013; Amani et al. 2013; Magalhães and Nitschke 2013; Irfan-Maqsood and Seddiq-Shams 2014; Gudiña et al. 2016; Lovaglio et al. 2015; Kiran et al. 2016).

The effect of the rhamnolipid incorporation in washing powder was performed by Bafghi and Fazaelipoor (2012), where the formulation with this biosurfactant was comparable to commercial detergents in terms of the stain removal and conferred a sustainable characteristic to the final product due the biodegradability of the compound added. In addition, the oil removal capacity of commercial detergent supplemented with 10 % of rhamnolipid was enhanced (Bafghi and Fazaelipoor 2012). In this context, detergent formulations have been developed by companies in order to increase cleaning performance of their products. In the detergent formulations for textile industry, patented by Evonik Ind., mixtures of rhamnolipids, predominantly di-rhamnolipids, were used, while the detergent composition from Unilever Co. comprises mono-rhamnolipids in combination with lipase enzyme (Kuppert et al. 2014; Parry et al. 2012).

Significant attention has been given to the application of rhamnolipids in bioremediation of polluted environments and the enhancement of oil recovery (in this case, the process is called microbial enhanced oil recovery—MEOR) (Nikolopoulou et al. 2013; Yan et al. 2012; Kryachko et al. 2013; Long et al. 2013). Toxic compounds such as metals, polycyclic aromatic hydrocarbons (PAHs), petroleum hydrocarbons, and pesticides can be removed from the contaminated environment by using diverse techniques that employ rhamnolipids (Salmani Abyaneh and Fazaelipoor 2016; Sponza and Gök 2010). Bioremediation studies carried out with herbicide atrazine in mineral salt medium and soil spiked with atrazine demonstrated that rhamnolipids at 2.5 CMC value are most efficient than the synthetic surfactant Triton X-100 at 2.5 CMC in enhancing microbial degradation by Acinetobacter sp. A6 strain (Singh and Cameotra 2014). In this case, the biosurfactants cause an increase in the bioavailability of toxic compounds, resulting in a larger fraction that can be assimilated and degraded by microorganisms. Moreover, interactions of the toxic compounds with micellar structures formed by biosurfactants may occur and recent study showed that the solubility of hydrophobic PAH compounds (naphthalene, phenanthrene, and pyrene) was enhanced with the increase of rhamnolipid concentration above CMC value in aqueous phase (Li et al. 2015). In these concentrations, rhamnolipids form micelles and the solubilization of PAHs can be due to the diffusion of these hydrophobic compounds into the center of the micelles that are dispersed in the solution. Furthermore, solubilization of hydrophobic compounds depends of the majority rhamnolipid type in solution, being that di-rhamnolipids are most efficient in this process (Guo and Hu 2014).

MEOR comprises methods that apply microorganisms or microbial products to enhance petroleum recovery. MEOR process can be done in two different ways: the ex situ MEOR is the mainly applied method and consists in the laboratorial production of biosurfactants and injection into oil reservoirs, while in the in situ MEOR, the production of biosurfactant occurs directly in oil reservoirs (Kosaric 1992; Zhao et al. 2015). In situ MEOR can be considered the most advantageous since it would not be necessary to use culture media, fermenters, or other processes for the biosurfactant production and also would not need purification steps which make the global process expensive. However, this technique depends on anaerobic biosurfactant-producing microorganism and, generally, rhamnolipids are produced with better yields by aerobic microorganisms, which may limit the application of in situ MEOR (Amani et al. 2013). Considering this application, in a study performed by Yan et al. (2012), a rhamnolipid-producing Pseudomonas aeruginosa (F-2) was used to recover oil from refinery oil sludge in experiments carried out in laboratory and pilot scale (similar to in situ MEOR) demonstrating the importance of the screening and prospection of new rhamnolipid producers.

In agriculture, surfactant compounds can be used to enhance the pesticide and agrochemical solubility, acting as emulsifiers, spreaders, and dispersing agents, and also may be in direct contact with the plant surface and be found in food produced. Hence, biosafety characteristics of these compounds such as biodegradability and low toxicity have become a trend as they are associated with environmental and health concerns. In this context, studies showed that rhamnolipids are potentially applied in agriculture field to enhance soil quality through bioremediation, increasing the nutrient bioavailability, and elimination of plant pathogen (Sha et al. 2011; Kim et al. 2011; Nalini and Parthasarathi 2014). Moreover, the use of rhamnolipids to control plant pathogens is an important perspective as an alternative to the use of harmful agrochemicals and it was described in their antifungal potential against Fusarium oxysporum wilt disease in tomato plants with the application of 200 μg/L of purified rhamnolipid (Deepika et al. 2015). More recently, it was proved that a di-rhamnolipid and mono-rhamnolipid mixture enhances the foliar penetration of soluble molecules in isolated cuticular membrane and greenhouse plants and also showed better wettability and surface properties when compared to an alkyl polyglucoside chemical surfactant (Liu et al. 2016).

Regarding the employment of rhamnolipids in food industry, the use of these compounds as antimicrobial and emulsifying agents and to disrupt or prevent biofilm formation of some foodborne pathogens was proposed (Do Valle Gomes and Nitschke 2012; Haba et al. 2014; Magalhães and Nitschke 2013; Banat et al. 2014b; Phillips 2016). The possible anti-adhesive effect demonstrated by rhamnolipids preventing the formation of bacterial biofilms consists in the modification of surface hydrophobicity and interference into adhesive properties of microorganisms (Dusane et al. 2010; De Araujo et al. 2011). On the other hand, in cases in which the biofilm has been formed, the biofilm removal effect of rhamnolipids could be due to interactions into microcolonies and alteration of biofilm environment and also in the removal of extracellular polymeric substances (EPS) causing the biofilm disruption (Davey et al. 2003; Díaz De Rienzo and Martin 2016). This feature makes these biosurfactants extremely attractive not only for use in the sanitization in the food industry but also in medical field due to their potential in biofilm control of opportunistic pathogens that cause medical device-related infections.

In addition, the combination of rhamnolipids with different compounds as organic acids and comparative studies with other biosurfactants to enhance biofilm removal activity are an interesting approach and good results were obtained against Gram-positive and Gram-negative strains (Díaz De Rienzo et al. 2016b). Among the most recent results from this perspective, it was demonstrated that there is susceptibility of P. aeruginosa ATCC 15442 and Staphylococcus aureus ATCC 9144 biofilms when 0.04 % of rhamnolipids and 0.01 % of caprylic acid was applied (Díaz De Rienzo et al. 2016c). Furthermore, different effects on Bacillus subtilis BBK006 biofilm were observed for mono-rhamnolipids produced by P. aeruginosa ATCC 9027 and di-rhamnolipids by B. thailandensis at same concentration (0.4 g/L), and this result is related to the structure type of biosurfactant produced, being that the most efficient was a di-rhamnolipid (Díaz De Rienzo and Martin 2016).

Some studies with rhamnolipid biosurfactants have demonstrated important biological properties such as antitumor and antiproliferative. Lotfabad et al. (2010) related the inhibitory effect of rhamnolipids from P. aeruginosa MR01 and gamma ray-induced mutant strain (MR01-C) against human cancer Hela cells. In addition, this study demonstrates the enhancement of the di-rhamnolipid production using gamma irradiation and that the predominant components in rhamnolipid mixture with anticancer activity were Rha-Rha-C10-C10, Rha-Rha-C10-C12:1, and Rha-Rha-C10-C12. Christova et al. (2013) showed the inhibitory activity of rhamnolipids Rha-C10-C10 and Rha-Rha-C10-C10 produced by Pseudomonas BN10 on the growth of the human cancer cell lines HI-60 (acute myeloid leukemia), BV-173 (chronic myeloid leukemia in blast crisis), SKW-3 (T cell lymphocytic leukemia), and JMSU-1 (urinary bladder carcinoma). These researchers demonstrated for the first time that a mono-rhamnolipid had better and significant inhibitory activity against growth of the human cancer cell lines compared to the di-rhamnolipid. The inhibitory effect in vitro of mono-rhamnolipids into cancer cells is correlated with their cytotoxicity, possibly caused by surface tension reduction of the culture medium used in test, as a demonstrated in a recent study that cytotoxicity against cancer cells such as HepG2, Caco-2, Hela, and MCF-7 was directly dependent on the decrease of surface tension of culture medium in that cells were cultivated (Jiang et al. 2014). However, it is suggested that further studies, preferably in vivo, should be conducted to establish the extent of the effects on complex models so that anticancer activity can be established respecting the biosafety concerns.

The use of low-cost substrates such as glycerol, sugar- and glycerol-containing wastes, oils, fats and fatty acids, molasses, and other agro-industrial wastes for production of rhamnolipids is an advantageous approach in environmental terms and has attracted the attention of researchers in recent years (Benicasa et al. 2010; Henkel et al. 2012; Ebadipour et al. 2016). Deepika et al. (2015) showed that the production of rhamnolipid was 5.26 g/L using mineral salt medium supplemented with 2 % molasses by P. aeruginosa strain KVD-HM52. In this study, the biosurfactant produced consists in a mixture of mono- and di-rhamnolipids (Rha-C10-C10 and Rha-Rha-C10-C10) and were able to reduce the surface tension of water from 74 to 33 mN/m at a CMC value of 120 mg/mL. Recently, Gudiña et al. (2016) evaluated the potential application of low-cost medium based in corn steep liquor (10 %) with sugarcane molasses (10 %) (CSLM) and CSLM supplemented with 25 % of oil mill wastewater (OMW), a residue from olive oil extraction, to rhamnolipid production by P. aeruginosa no. 112 in flasks and reactor experiments. The best results in terms of rhamnolipid production and CMC values were obtained using CSLM/25 % OMW:4.5 g/L and 14 mg/L in flask experiments; 5.1 g/L and 14 mg/L in reactor experiments in 168 h of the process, when compared with CSLM:3.2 g/L and 50 mg/L in flask experiments in 144 h of the process; and 2.2 g/L and 30 mg/L in reactor experiments in 96 h of the process. It is necessary that the works using low-cost medium provide more information on the pretreatment of these substrates or economic analysis compared with conventional culture media should be performed to attract the interest of large companies from various sectors for large-scale rhamnolipid production.

New strategies to enhance the production of rhamnolipids in fermentative process have been studied using statistical methods, engineered microorganisms, co-culturing/mixed culture of microorganisms, or associating these approaches with use of low-cost substrates (Jamal et al. 2014; Tavares et al. 2013; Hošková et al. 2015). Pereira et al. (2013) performed the optimization study of rhamnolipid production by P. aeruginosa PA1 using crude glycerol as sole carbon source. Through response surface methodology (RSM), highest product concentrations in simple batch (2.75 g/L) and fed batch (3.88 g/L) were achieved after 120 h of process. Using this same approach, a previous study performed by De Sousa et al. (2011) achieved a rhamnolipid concentration of 1.2 g/L, with hydrolyzed glycerin as carbon source. Using a 24 full factorial design to evaluate the effects of several variables in rhamnolipid production by P. aeruginosa MSIC02, it was possible to select the most significant parameters in the process, using cashew apple juice as substrate (Rocha et al. 2014). In an optimization study applying RSM, P. aeruginosa isolate P6 was able to produce 7.54 g/L of rhamnolipids using 2 % (v/v) of glycerol as a carbon source in mineral medium at 30 °C, 250 rpm, an inoculum size of 5 % v/v, and pH of 7.5 (El-Housseiny et al. 2016). Recently, Hassan et al. (2016) showed that it is advantageous to use a sequential Placktt-Burman design to investigate the effects of several variables (carbon and nitrogen source, metal concentration in media, pH, temperature, and others) in order to optimize rhamnolipid production by Pseudomonas spp. strains. The screening of significant variables using the same approach and RSM performed with a Box–Behnken design was described in a bioprocess for rhamnolipid production by P. aeruginosa strain KVD-HR42, which resulted in a biosurfactant concentration of 5.9 g/L using karanja oil as a carbon source and sodium nitrate as a nitrogen source at 37 °C after 48 h of process (Deepika et al. 2016). Therefore, the development of studies with the use of statistical methods aiming at the optimization of process conditions and evaluation of their effects in fermentation process, associated with use of low-cost substrates, constitutes a powerful tool to improve the biosurfactant production (Zhao et al. 2016; Ebadipour et al. 2016).

In addition to parameter optimization, studies have shown the potential application of engineered microorganisms and the importance of the metabolic engineering for rhamnolipid production (Wittgens et al. 2011; Kryachko et al. 2013; Tavares et al. 2013; Dobler et al. 2016). Metabolic engineering tools can provide information about genes and metabolic pathways involved in rhamnolipid production, enabling the adoption of strategies for modifying microorganisms or development of nonpathogenic producers with better amounts and physicochemical of rhamnolipids produced (Toribio et al. 2010; Lovaglio et al. 2015). Considering this approach, Zhao et al. (2015) developed an anaerobic rhamnolipid production by engineering a Pseudomonas stutzeri strain, with rhlABRI genes for rhamnolipid biosynthesis and the biosurfactant produced reduced water surface tension from 73.3 to 30.3 mN/m, oil–water interfacial tension from 26.1 to 0.169 mN/m, and also the cell-free broth showed emulsifying index (E 24) of 74 %. Previously, Colak and Kahraman (2013) performed a study to evaluate the feasibility of the use of whey and olive oil mill wastewater as a substrate to rhamnolipid production by P. aeruginosa and its recombinant strain (PaJC) expressing Vitreoscilla hemoglobin gene (vgb). High yields of rhamnolipids were obtained from whey in the biotechnological process and also were demonstrated that the recombinant strain exhibited better production capacity (13.3 g/L) when compared with wild-type strain (9.6 g/L).

Sophorolipids

Sophorolipids are biosurfactants that can be produced by several yeasts species, such as Candida bombicola, Candida albicans, Candida floricola, Cryptococcus sp., Wickerhamiella domercqiae, Pichia anomala, Rhodotorula bogoriensis, and others. Structurally, they consist of a dimeric carbohydrate sophorose, a diglucose with β-1,2 bond also called 2-O-β-d-glucopyranosyl-d-glucopyranose, attached with a long chain of hydroxyl fatty acid, linked by a β-glycosidic bond (Hirata et al. 2009; Yang et al. 2012; Hu and Ju 2001; Ma et al. 2012; Konishi et al. 2015; Imura et al. 2010; Basak et al. 2014). These compounds are capable to reduce the surface tension of water to 40–24 mN/m and showed CMC values of 0.68–100 mg/L (Van Bogaert et al. 2011a; Dengle-Pulate et al. 2013).

In contrast to rhamnolipids, sophorolipids are generally produced by nonpathogenic strains and this feature can assist in the development of large-scale production considering safety aspects. These biosurfactants are synthesized as a mixture of different molecules and can be divided into two major forms, acidic or lactonic sophorolipids, and may have acetyl groups in their sophorose moiety, with variation in physicochemical and biological properties (Asmer et al. 1988; Despande and Daniels 1995; Van Bogaert et al. 2011a). Furthermore, the fatty acid chain structure (carbon number, unsaturation, and hydroxylation) present in sophorolipids may vary according to the substrate used as a hydrophobic carbon source in the fermentation process (Shin et al. 2010; Díaz De Rienzo et al. 2015). Figure 2 presents the structures of sophorolipid types produced by Candida species.

In a comparison between the two types of sophorolipids, the acidic forms have shown better foaming capacity and solubility, while the lactonic forms have a superior surface and antimicrobial activities and better properties in many applications, for example, in cosmetic preparations for skin (Van Bogaert et al. 2011a; Yang et al. 2012; Maingault 1999; Concaix 2003). Structurally, lactonic sophorolipids showed low capacity of rotation between its atoms due to lactonization and this characteristic results in the formation of crystals during fermentation process, making their isolation easier (Van Bogaert et al. 2011a). Typically, C. bombicola is able to produce mostly a di-O-acetyl lactone form of sophorolipid while other species such as Candida stellata and Candida riodocensis produce a di-O-acetyl free acid form and some amounts of mono-O-acetyl and non-acetyl forms (Price et al. 2012). Kurtzman et al. (2010) demonstrated this variety and that major heterogeneity of sophorolipid forms is obtained by Candida apicola, which produce di-O-acetyl, mono-O-acetyl, and non-acetyl sophorolipids in the free acid and lactone forms in fermentative medium. Thus, the structural diversity that can be obtained using different substrates or Candida species has expanded the number of sophorolipid analogues described in recent years. Seventeen polymeric sophorolipids were described in a process conduced with newly identified yeast Candida sp. NRRL Y-27208 and consist in dimeric and trimeric structures that can be mono-acyl- and di-acyl-disophorose and di-acyl- and tri-acyl-trisophorose analogues with different degrees of acetylation (Price et al. 2012). In addition, it was observed that two mono-acyl-disophorose analogues (named of mono-O-acetyl dimer B and tri-O-acetyl dimer D) are predominantly produced by Candida sp. NRRL Y-27208.

Despite the great variety of sophorolipid analogues, few studies have focused on the development and validation of analytical methods for their characterization and quantification. Most of the methodologies found in sophorolipid studies use carbohydrate and lipid analysis by chromatographic methods, mass spectrometry, and NMR spectroscopy to structural elucidation (Price et al. 2012; Ribeiro et al. 2012). However, there is no standardization of these methods and the data are not clear, in terms of composition and contents of different analogous, being limited to only classification of the types produced in the biotechnological process, as lactonic or acid.

The applications of different hydrophobic and hydrophilic low-cost substrates as a carbon source to sophorolipid production have been performed to enhance yields and types of the analogues obtained. Hence, many studies showed the use of diversified low-cost substrates (preferably hydrophobic), variation of medium composition, modification of process, and development of assisted methods (e.g., ultrasound) for sophorolipid production (Daverey and Pakshirajan 2009; Van Bogaert et al. 2011a; Morya et al. 2013; Maddikeri et al. 2015). Previous studies using alternative raw materials, such as animal fat, restaurant waste oil, soy molasses, and deproteinized whey, achieved good yields and demonstrated the possibility of overall process cost reduction (Despande and Daniels 1995; Shah et al. 2007; Solaiman et al. 2007; Daniel et al. 1999). Using animal fat as a hydrophobic carbon source in a production medium containing (g/L): glucose, 100; fat, 100; urea, 1.5; K2HPO4, 1.0; corn steep liquor (CSL), 4; NaCl, 0.1, it was achieved 97–120 g/L of sophorolipids in 60–68 hours of process (Despande and Daniels 1995).

Regarding the importance of the carbon source effects, some studies have evaluated the influence of different fatty acid types. In a work conducted by Shin et al. (2010), various fatty acids (oleic acid, 18; erucic acid, 22:1; 22 carbon-enriched rapeseed oil 54 % of docosanoic acid, 22:0; or docosadienoic acid, 22:2) with and without methyl esterification were used as hydrophobic carbon sources in the sophorolipid production by Candida bomicola ATCC 2214. This study concluded that methyl esterification of 22 carbon fatty acid chain does not affect its production, since methyl ester C22-enriched rapeseed oil and unmodified C22-enriched rapeseed oil showed the same concentration, about 105 g/L. Furthermore, the concentration obtained with the use of methyl erucic acid (22:1) was in order of 47 g/L, while the concentration using methyl ester oleic acid was 71 g/L. Therefore, these results obtained by Shin et al. (2010) agree with a previous study that also demonstrated the influence of substrates in production and characteristics of sophorolipids (Shin et al. 2008).

Other studies have reported the use of hydroxylated fatty acids, arachidonic acid, linoleic acid, and linolenic acid for sophorolipid production and the evaluation of their properties (Prabhune et al. 2002; Shah and Prabhune 2007; Van Bogaert et al. 2009; Kasture et al. 2008; Van Bogaert et al. 2011b; Gupta and Prabhune 2012). Delbeke et al. (2016a) describe the innovative use of petroselinic acid, a positional isomer of oleic acid, obtained from the vegetable oil of Coriandrum sativum fruits. The microbial production of petroselinic acid-based sophorolipids was performed using C. bombicola ATCC 22214 and a C. bombicola lactone esterase overexpression for the selective synthesis in high concentration of diacetylated sophorolipid lactone (Roelants et al. 2016). The petroselinic acid-derived sophorolipid lactone (PA-SLL) was modified by alkaline hydrolysis to production of based sophorolipid acid (PA-SLA), and the surface properties of these novel analogues were compared with their correspondent oleic acid sophorolipid lactone and acid analogues (OA-SLL and OA-SLA). In terms of efficiency, the PA-SLL and PA-SLA showed low CMC values (4.2 and 154 mg/L) when compared with respective OA-SLL and OA-SLA analogues (45.1 and 245 mg/L) in reduce of surface tension to around 34 mN/m and 42 mN/m approximately (Delbeke et al. 2016a; Roelants et al. 2016).

Previously, Wadekar et al. (2012) describes the use of the Jatropha oil, karanja oil, and neem oil, three nonedible oils traditionally produced in India, as a low-cost carbon sources to sophorolipids production by C. bombicola ATCC 22214 at 30 °C, 210 rpm after 200 h in shake flask experiments. The effect of these oils in sophorolipid concentration and biomass production were evaluated in comparison with sunflower oil, obtaining 12 g/L in sunflower oil, 7.66 g/L in karanja oil, 6 g/L with Jatropha oil and 2.63 g/L in neem oil. The reduction in the biomass formation and concentration of sophorolipids observed when using the nonedible oils is probably because of the fatty acid composition and presence of inhibitory compounds found in these nonconventional oils. Thus, for the development of novel processes is important to consider the influence of fatty acid type in the substrate, making possible to customize the properties of sophorolipids for specific industrial applications using specific hydrophobic carbon sources (Wadekar et al. 2012; Delbeke et al. 2016a; Ahn et al. 2016).

Using different fractions of mango kernel fat as lipid source, Parekh et al. (2012) showed that different yields can be obtained when submerged fermentation (SmF) and solid-state fermentation (SSF) are used to production of sophorolipids by C. bombicola NRRL Y-17069. The SmF process was carried in a medium composed of 40 g/L of glucose, 5 g/L of yeast extract, and 20 g/L of various lipid sources (mango kernel fat, mango kernel olein, mango stearin, oleic acid, and stearic acid) at pH 3, 30 °C, and 180 rpm in shake flask experiments, while the SSF process was performed using a sterilized medium with 4 g of substrate containing 2 g of glucose and 2 g of lipid substrate blended with 6 g of wheat bran powder, used as a solid support, in a 250-ml Erlenmeyer flask at pH 4 and 30 °C. In both cases, it used 2 ml of inoculum and the process was monitored for 240 h. The highest yields (g/100 g of substrate) were obtained using SSF with mango kernel fat (7.48), mango kernel olein (17.48), mango stearin (8.1), and stearic acid (8.5), while using SmF, the best result was with oleic acid (30.0).

In biotechnological process using C. bombicola ATCC 22214 and a fermentation medium based in 15 % coconut oil and 10 % glucose as hydrophobic and hydrophilic carbon sources, Morya et al. (2013) achieved 54 g/L of low molecular weight sophorolipids (C12–C14). The same perspective was used by using lauryl alcohol (C12–14) as a hydrophobic source, leading to the production of an efficient sophorolipid with antimicrobial activity against Gram-negative and Gram-positive bacteria strains (Dengle-Pulate et al. 2014). The sophorolipids obtained using lauryl alcohol (SLLA) showed also better performance (surface tension reduction (STR) of 24 mN/m and CMC value of 0.68 mg/L) when compared with commercial surfactants such as sodium dodecyl sulfate (SDS; anionic surfactant; STR = 35 mN/m; CMC = 6.73 mg/L), dodecyl tetraethylene glycol ether (laureth 4; nonionic surfactant; STR = 32; CMC = 3.03 mg/L), and sophorolipid obtained using oleic acid (SLOA; natural surfactant; STR = 34 mN/m; CMC = 0.12 mg/L) (Dengle-Pulate et al. 2013).

In a two-stage fed-batch process, Daniel et al. (1998) obtained a high concentration of sophorolipids (422 g/L). In the first step, a strain of Cryptococcus curvatus ATCC 20509 was cultivated in deproteinized whey concentrate containing 100 g/L lactose, in order to obtain a crude cell extract (single cell oil—SCO) since this microorganism is able to accumulate intracellular lipids. The SCO was used in the second step with rapeseed oil as hydrophobic carbon source using C. bombicola ATCC 22214 as biocatalyst. Similarly, a recent study was performed using delignined corncob residue (DCCR), hydrolysate (DCCRH), and detoxified DCCRH (DCCRH mixed with activated carbon) to SCO and single cell protein (SCP or cell homogenate containing both SCO and cell debris) production by C. curvatus ATCC 96219 and to sophorolipid production by W. domercqiae var. sophorolipid CGMCC 1576 (Ma et al. 2014). First, the feasibility of DCCR and DCCRH in the process of production of SCO and SCP was tested, and then, these products were mixed with DCCRH and used for growth and sophorolipid production by the yeast W. domercqiae. Total sophorolipid production obtained was 39.0 g/L using DCCRH + SCO, 42.0 g/L with detoxified DCCRH + SCO, 37.2 g/L with DCCRH + oleic acid + cell homogenate of C. curvatus, and 49 g/L using detoxified DCCRH + oleic acid + cell homogenate of C. curvatus. In addition, the pretreatment of corncob residues (heat treatment and acid saccharification) to obtain a corncob hydrolysate to be used as a hydrophilic carbon source has been showed as an efficient alternative to develop an eco-friendly substrate for sophorolipid production (Konishi et al. 2015).

Few studies have explored the use of statistical methods to improve yields and evaluate the effects of variables in biotechnological process to sophorolipid production (Rispoli and Badia 2009; Rispoli et al. 2010). Rispoli et al. (2010) performed a study to optimize the sophorolipid production using a centroid screening mixture design to evaluate the most important variables in the process. The variables carbohydrates (glucose, glycerol, sucrose, lactose, and fructose), lipid (oleic acid and mineral oil), nitrogen sources (urea, soytone, peptone extract, malt extract, and yeast extract), phosphorus sources (K2HPO4 and KH2PO4), and metal salts (MgSO4 and CaCl2) were employed to construct a matrix with 33 different experiments associating diverse conditions and five of these variables (sucrose, oleic acid, CaCl2, and K2HPO4) proved to be crucial to achieve an optimized process. In an optimization stage, an augmented simplex centroid design for these five variables allowed to find better concentrations, reaching 177 g/L of sophorolipids.

Jiménez-Peñalver et al. (2016) performed the optimization of sophorolipid production by C. bombicola ATCC 22214 using solid-state fermentation (SSF). In this study, the applicability of winterization oil cake (WOC), a residual oil cake from the oil refining industry, and sugar beet molasses (MOL) in different ratios as hydrophilic and hydrophobic substrates, respectively, was evaluated. The SSF was carried using 45 g of substrates (WOC and MOL), 14 g of wheat straw, used as an inert support, and 10 mL of yeast inoculum at 30 °C. The sophorolipid production was optimized in terms of the ratio of substrates and the aeration rate using response surface methodology and the effects of these variables were assessed by a full experimental design consisting in a total of 12 experiments with three replicates in central point for statistical validation. The optimal condition in 10 days of process was 1:4 WOC/MOL ratio and an aeration rate of 0.30 L kg−1 min−1 enabling sophorolipid yield of 19.1 g/100 g of wet substrates, which increased to 25.1 g/100 g of wet substrates when intermittent mixing was applied (Jiménez-Peñalver et al. 2016). Besides the better conditions to enhance of sophorolipid production achieved through the application of surface response methodology, these authors point out the advantages of the use of SSF for sophorolipid production: use of inexpensive solid substrates, such as oil cakes from the food industry and avoids potential problems associated with foaming, a limiting parameter to enhance of yields of sophorolipids and others glycolipids in submerged fermentation.

Among diverse factors that affect the glycolipid production, it was proved that the cell density/biomass used is very important in the biotechnological process and that the use of high cell density fermentation is a good strategy in order to improve the productivity of sophorolipids (Gao et al. 2013). In this case, firstly the optimization of glucose concentration and other nutrients (vitamins, nitrogen source, and trace elements) to increase cell growth in absence of lipophilic substrate was necessary and only then the control of optimal parameters was started (pH, temperature, rate of glucose, and rapeseed oil) through computer monitoring in a 10-L fermenter which allowed to reach levels greater than 200 g/L in 54 h of process.

Nowadays, sophorolipids are the most applied biosurfactant in industry (cosmetic and cleaner industries) and with products available in market. Some companies (Soliance, Saraya, Ecover, and MG Intobio Co. Ltd) use sophorolipids in the commercial products such as ecological detergents and cleaning agents, dish washers, and cosmetics (Van Bogaert and Soetaert 2011). In addition, exploring its biodegradability and physicochemical characteristics, application in MEOR process was recently described, similarly to the method proposed for the rhamnolipids (Elshafie et al. 2015). In this context, a novel method to enhance the fluid recovery from subterranean environments was patented by Baker Hughes Company and consists in the injection of a sophorolipid mixture in well treatment operations in petroleum industry (Amstrong et al. 2015). In other patent, the same company used sophorolipids and mannosylerythritol lipids, isolated or in a combination, as component in a method to inhibit corrosion in alloy surface in well treatment operation (Gunawan et al. 2015). Considering these industrial applications combined with development of biotechnological processes with high yields, sophorolipids can be considered the most promising glycolipids and highly attractive in economic terms.

Moreover, the application of chemical methods to obtain sophorolipid analogues and evaluation of their applications are a new potential approach in recent years (Peng et al. 2014; Peng et al. 2015; Delbeke et al. 2015). Short-chain water-soluble sophorolipid analogues can be obtained using ring-opening cross-metathesis method that consists in chemical modification of lactonic forms breaking the double bond present in the lactone by reaction with variety olefin substrates (acrylate esters, trans-3-hexene, 1-hexene, and ethylene) and a Grubbs catalyst (first or second generation) to generate novel compounds with different physicochemical characteristics (Peng et al. 2015). Other study describes the synthesis of quaternary ammonium sophorolipids derivatives with better antimicrobial activities compared with gentamicin sulfate against Gram-positive strains (S. aureus LMG 8064, Enterococcus faecium LMG 11397, B. subtilis LMG 13579, and Streptococcus pneumoniae LMG 16738) using chemical modification of diacetylated sophorolipid lactone in six steps (Delbeke et al. 2015). Some of these derivatives were evaluated for their ability to form supramolecular aggregates in aqueous solution by using hydration of a lipid film and as possible vectors for gene delivery (Delbeke et al. 2016b). Only the quaternary ammonium sophorolipid methyl ester and peracetylated analogues showed high transfection efficacy with a low cell toxicity when assessed on A559, 16HBE, and SKMEL28 cell lines. In this perspective, Koh and Gross (2016a) proposed the application of the term “molecular editing” that refers to systematic chemical modification of natural products, in a study where novel sophorolipids (SL) derivatives (SL-ethyl ester, SL-hexyl ester, and SL-decyl ester) were prepared by esterification of the lipid chain and these modified sophorolipids exhibited interesting emulsifying properties and different effects in oil–water interfaces (Koh and Gross 2016b). These studies demonstrate the importance of use new strategies for chemical and structural modification of sophorolipids with improved biological activity profile enabling its application in various fields.

The correlation between different biological properties and chemical structure of sophorolipids has been proven, and previous studies showed that acetylated lactonic forms possess better biological and physicochemical properties such as antibacterial activity and lower CMC value when compared to non-acetylated lactonic, non-acetylated acid, and acid molecules (Lang et al. 1989; Lang et al. 2000). Another example was described by Shah et al. (2005), which demonstrated that sophorolipid diacetate ethyl ester derivative has better anti-HIV and spermicidal activities followed by monoacetylated and nonacetylated ethyl esters. The application of lactonic and acidic forms of sophorolipids for this purpose was previously claimed in a patent developed by researchers from the Polytechnic Institute of New York University and Synthezyme Company, showing the importance of the glycolipid chemical diversity investigation and their potential in medical field (Gross et al. 2004). Other patent from this collaboration was deposited claiming applications of sophorolipids and several analogues as biopesticides and antifungal and anti-inflammatory agents, in different compositions (Gross and Schofield 2011).

More recently, synergistic action of sophorolipids with traditional antibiotics was observed against pathogenic microorganisms (Joshi-Navare and Prabhune 2013). In this study, the sophorolipids were produced by C. bombicola ATCC 22214 and its characterization made by liquid chromatography analysis showed that the sophorolipid sample consists in 75 % of lactone form and the remaining 25 % of acidic form, while diacetylated lactonic sophorolipid of oleic acid (17-l-(oxy)-octadecanoic acid 1,4"-lactone 6',6"-diacetate) was detected by mass spectrometry analysis. This sophorolipid mixture was tested in association with cefaclor to study the conjugative effect against Escherichia coli ATCC 8739 and with tetracycline to conjugative effect against S. aureus ATCC 29737. Results suggested that the action of antibiotics was enhanced due to the ability of sophorolipids to form self-assembly systems to improve efficiency (Joshi-Navare and Prabhune 2013).

The antimicrobial activity of sophorolipids acetyl esters derivatives produced from glucose and lauryl alcohol as a substrates was tested against pathogenic Gram-negative (E. coli ATCC 8739 and P. aeruginosa ATCC 9027) and Gram-positive (S. aureus ATCC 6358 and B. subtilis ATCC 6633) bacteria strains and also pathogenic yeast C. albicans ATCC 2091 (Dengle-Pulate et al. 2014). Results revealed that the sophorolipids obtained using lauryl alcohol (called SLLA) showed complete inhibition against pathogenic strains in lower concentrations compared to reported values of sophorolipid derivatives from oleic acid and linolenic acid: E. coli 30 μg/mL; P. aeruginosa 1 μg/mL at a contact time of 2 and 4 h respectively; S. aureus 6 μg/mL; B. subtilis 1 μg/mL; and C. albicans 50 μg/mL after 4 h of contact time. In a study performed by Zhang et al. (2016), it was evaluated the antimicrobial potential of diacetylated lactone form of sophorolipid derived from glucose and oleic acid against E. coli O157:H7 in vitro and on spinach leaves during storage. After 2 h of treatment with sophorolipids at 1.0 %, E. coli population with an initial 7.1 log CFU/mL was reduced to a non-detectable level in bacterial suspension. However, in test with spinach leaves, sophorolipids at 1 % did not significantly affect E. coli when compared to a water wash after 7 days posttreatment and storage at 4 °C. The results suggested that sophorolipids could be used as sanitizers in wash water for control of foodborne pathogens, although more studies are needed to assess the real effectiveness in storage conditions of fresh fruits and vegetables.

Considering the importance of the development of new strategies and agents for microbial biofilms control, sophorolipids can be seen as the most advantageous biosurfactants in this perspective. Using a mixture of acidic and lactonic sophorolipids at different concentrations obtained from fed-batch cultivation of C. bombicola ATCC 22214 with glucose and rapeseed oil as substrate, Díaz De Rienzo et al. (2015) demonstrated antimicrobial properties and biofilm disruption capacity of these biosurfactants against Gram-positive and Gram-negative bacteria strains. Inhibitory and bactericidal effects against growth of Cupriavidus necator ATCC 17699 and B. subtilis BBK006 was observed when sophorolipids at 5 % were applied. Furthermore, using the same concentration of sophorolipids, the disruption biofilm capacity was observed by scanning electron microscopy for single and mixed cultures of B. subtilis BBK006 and S. aureus ATCC 9144 under static and flow conditions.

Other study showed that the combination between rhamnolipids (0.04 %) and sophorolipids (0.01 %) might be used as a specific strategy for the disruption or killing of preformed biofilms of P. aeruginosa ATCC 15442 and S. aureus ATCC 9144 or a mixed culture of both (Díaz De Rienzo et al. 2016c). The biofilms of the S. aureus and mixed culture with P. aeruginosa were efficiently removed by the glycolipid combination, while against the biofilm formed only by P. aeruginosa, it was observed that there is death of bacterial cells without removal of the preformed biofilm after treatment. However, the mechanism of bactericidal and biofilm removal effects presented by sophorolipids and rhamnolipids is unclear and requires further studies to elucidate the biochemical interactions involved in this process, making possible to use biosurfactants effectively to this application.

Recently, the antifungal effect of lactonic sophorolipids against pathogenic Candida species was investigated in a study performed by Haque et al. (2016) and the susceptibility of these strains, expressed by minimum inhibitory concentration (MIC), was 30 μg/mL to C. lusitaniae CL618, 60 μg/mL to C. albicans SC531418 and C. tropicalis MYA340450, and 120 μg/mL to C. glabrata CG46218. In addition, it was evaluated the sophorolipid capacity in inhibition of biofilm formation and in the eradication of the preformed biofilms, quantified by biofilm inhibiting concentration (BIC) and the biofilm-eradicating concentration (BEC), respectively. The similar results in terms of BIC were founded against C. albicans, C. tropicalis, and C. lusitaniae at 120 μg/mL of sophorolipids. The C. glabrata was the most resistant strain, requiring a concentration of around 480 μg/mL to inhibit its biofilm formation, and highly resistant to sophorolipids in a test to obtain the BEC value, followed by C. lusitaniae, where this parameter was not determined in both cases. For eradication, the preformed biofilms of C. albicans and C. tropicalis were found to have a BEC value of 480 μg/mL. Moreover, synergistic interaction of the sophorolipids when used along with amphotericin B and fluconazole was proved, showing an enhancement in the efficacy of these antifungals, against biofilm formation and preformed biofilms of C. albicans, suggesting a potent combination for the treatment of candidiasis (Haque et al. 2016). These results show the great potential of this glycolipid family as alternative antimicrobial and anti-adhesive agents for the treatment of infectious diseases caused by opportunistic pathogens.

Another sophorolipid biological activity of medical interest and related to the structural properties (lactonic or acid form and acetylation degree) is the anticancer activity (Van Bogaert et al. 2011a). In the researches performed by Chen et al. (2006) and Shao et al. (2012), it was observed that sophorolipid produced by W. domercqiae, a diacetylated lactonic compound with a C18 monounsaturated fatty acid, possessed the ability to induce apoptosis in H7402 human liver cancer cells with inhibition of cell proliferation by blocking cell cycle at G1 and partly S phase. Shao et al. (2012) also reported the anticancer effects of sophorolipid derivatives on human esophageal cancer cell lines and proved that different structural forms (lactonic or acid), unsaturation degree in fatty acid part, and acetylation degree of sophorose are associated with variation in cytotoxic effect.

Anticancer activity screening of sophorolipids from C. bombicola NRRL Y-17069 was studied with different human tumor cell lines including breast adenocarcinoma MCF-7; hepatocellular carcinoma HepG2, lung cancer A549, and colon cancer HCT116 and the results showed that some sophorolipids inhibit urokinase and histone deacetylase activities, being promising anticancer agents in HepG2 and A549 (Rashad et al. 2014). In a recent study, Ribeiro et al. (2015) describe the higher cytotoxic effects of the C18:0, C18:1, C18:2, and C18:3 diacetylated lactonic sophorolipid analogues toward MDA-MB-231 breast cancer cells and different effects could be observed depending of the concentration used, being that in lower concentrations there was reduction in the cancer cell migration while in high concentrations proved the death of MBA-MB-231 cells.

Trehalose lipids

Trehalose lipids (also known as trehalolipids) are a group of glycolipids produced by several bacteria, members of Actinomycetales order, such as Mycobacterium sp., Micrococcus sp., Nocardia sp., Gordonia sp., Dietzia sp., Tsukamurella sp., Skermania sp., Williamsia sp., Corynebacterium sp., Brevibacteria sp., Arthrobacter sp., Rhodococcus sp., and also by yeasts and fungus (Shao 2011; Lang and Philp 1998). The trehalolipids were described for the first time in 1933 in a study about chemical composition of the lipids of tubercle bacilli (Anderson and Newman 1933). Due to the structural diversity, these glycolipids have different surfactant properties: generally, they are capable to reduce the surface tension of water to 43–24.1 mN/m and show CMC values of 0.7–37 mg/L (Yakimov et al. 1999; Tuleva et al. 2009; Marqués et al. 2009).

Structurally, trehalolipids consist in a hydrophilic moiety (trehalose) formed by two glucose units linked through the α,α-1, 1-glycosidic linkage and a hydrophobic moiety represented by chains of fatty acids, such as succinic, octanoic, decanoic, and mycolic acids (Fig. 3) (Asselineau and Asselineau 1978; Petrikov et al. 2013; Franzetti et al. 2010). Trehalose is a nonreducing disaccharide with high thermostability, very resistant to acid hydrolysis, nonreactive to Maillard reaction, and, due to its properties, has been considered an attractive compound for industrial applications (Higashima 2002; Shao 2011). Moreover, this molecule is associated with biological properties like cryoprotection, growth regulation in plants, osmoregulation, suppression of “senior” body odor, and protection of the cornea against oxidative damage caused by UVB rays and acts in suppression of the proinflammatory cytokines (Duong et al. 2006; Rolland et al. 2002; Kempf and Bremer 1998; Higashima 2002; Cejková et al. 2011). Recently, it was described that trehalose exhibits preventive effects against hepatic steatosis, by inhibiting solute carrier 2A (also called as GLUT), member of a glucose transporter family (DeBosch et al. 2016). Thus, this sugar can contribute to the biological activities attributed to trehalose lipids. The hydrophobic portion can vary in length and type of chains, besides the position and number of glycosidic bonds at the sugar (Kügler et al. 2014).

The trehalose lipids have a wide variety of types and can be found in several forms: trehalose monomycolates, dimycolates, trimycolates, nonionic acylated trehalose derivatives, anionic trehalose tetraesters, and succinoyl trehalolipids (Kuyukina and Ivshina 2010; Kügler et al. 2014). Among all trehalose lipids, the most well-known is the 6,6′-trehalose lipid dimycolate, also called “cord factor,” composed by two mycolic acids of variable number of carbons esterified to the 6-hydroxyl group of each glucose, being found in various mycobacteria species (Ishikawa et al. 2009; Shao 2011). Mycolic acids are 2-alkyl-3-hydroxy fatty acids of high molecular mass, present exclusively in the cell envelope of bacteria of the mycolata taxa, include Rhodococcus species, and have been proposed that this mycobacterial glycolipid plays a key role in the immunopathogenesis of tuberculosis (Sutcliffe 1998; Ryll et al. 2001; Welsh et al. 2013).

Just like the other families of glycolipids, the microbial production of trehalose lipids can be affected by several factors such as carbon and nitrogen sources, salt composition, and use of yeast extract in culture broth (Franzetti et al. 2009; Pacheco et al. 2010; Kügler et al. 2014). Based on the published works, the yields of trehalose lipids production are very low when compared to sophorolipids, rhamnolipids, and mannosylerythritol lipids. Among all tested trehalose lipid producers, only a study describes high trehalose lipid yield, in this case using a Rhodococcus sp. SD-74 strain and achieving 40 g/L of the glycolipid using n-hexadecane under highly osmotic conditions (Uchida et al. 1989).

For this reason, the large-scale production of trehalolipids is very challenging. Other problem that limits the effective use of biosurfactants is the high cost of production and complex downstream processing (Franzetti et al. 2010). In addition, when Rhodococcus strains are used for this purpose, the major problem is the fact that trehalose lipids are often associated with the cell walls leading to an increase in the costs of downstream processing and recovery (Espuny et al. 1996; White et al. 2013).

Some works show the feasibility in using different carbon sources (glycerol, diesel oil, and vegetable oil), being the best results achieved with the use of n-alkanes and these results also correlate the possibility of using trehalose lipid bioproducers as potential agents in bioremediation process (Bajaj et al. 2014). Kügler et al. (2014) performed a study using nonpathogenic actinomycetes Tsukamurella spumae and Tsukamurella pseudospumae using sunflower oil and glycerytrioleate as a carbon source in fermentation medium. It was found that there are unconventional trehalose lipids with C4–C6 and C16–C18 short acyl chains in hydrophobic moiety, with a low concentration of product (about 1.3 g/L). In comparison, Kuyukina et al. (2005) used n-dodecane and n-hexadecane as carbon source and obtained 6.5 and 9.4 g/L of trehalolipids, showing that the best method consists in the use of hydrocarbons in bioprocess. In this context, Rhodococcus wratislaviensis BN38 cultivated in n-hexadecane was able to produce 3.1 g/L of 2,3,4,2′-trehalose tetraesters containing succinic acid that showed high surface activity reducing the surface tension to 28.6 mN/m in mixture and 24.4 mN/m when purified at a CMC value of 5 mg/L (Tuleva et al. 2008). In other study carried out with Rhodococcus erythropolis 51T7 in a medium containing 2 % of tetradecane, the trehalose tetraester concentration varied 0.48–1.12 g/L and reduced the surface tension to 27.9 mN/m at a CMC value of 37 mg/L (Marqués et al. 2009).

In a study performed by Kundu et al. (2013), a trehalose lipid-producing Rhodococcus pyridinivorans NT2 strain was isolated from pesticides contaminated with effluent-sediment and evaluated for biodegradation of 4-nitrotoluene. The biosurfactant produced exhibited potent surface activity and reduced the surface tension of the media from 71 to 29 mN/m and with CMC value of the 30 mg/L. The results suggested that the cited strain can be able to produce trehalose-succinic acids and 2,3,4,2′-trehalose tetraester analogues as the most abundant trehalose lipid derivatives. In addition, higher emulsification index, 90–95 %, was obtained with long-chain hydrocarbons (diesel, liquid paraffin, motor oil, groundnut oil, and soybean oil) while shorter-chain alkanes resulted in less emulsification (50–80 %). Despite the low concentration in the production of trehalose lipids (45 mg/L), the microbial characteristics contributed to use this strain in new studies and suggest their potential for bioremediation field (Kundu et al. 2016a; Kundu et al. 2016b). The isolation of Rhodococcus strains of different environments can be considered an interesting way to obtain trehalose lipid producers. In this context, White et al. (2013) evaluated the trehalose lipid production by a novel marine bacterium Rhodococcus sp. PML026 using sunflower oil as a hydrophobic substrate. The purified glycolipid was able to reduce the surface tension of water to 29 mN/m with a CMC value of 250 mg/L.

In order to avoid the problem of low concentration of trehalose lipids in biotechnological process, the use of statistical methods is an alternative approach to increase yields and to reduce process costs. Through surface response methodology (SRM), Mutalik et al. (2008) achieve an increase of 3.2 to 10.9 g/L in the concentration of trehalose lipids, using n-hexadecane as a substrate and Rhodococcus spp. MTCC2574 as a biocatalyst (Mutalik et al. 2008). The feasibility of statistical tools has been proven to improve the yields of other glycolipids, mainly rhamnolipids, and their application in trehalose lipid production could be a new field for further research.

The biological activities of trehalose lipids include antiviral properties, inhibitory activity on calcium-dependent protein kinase C of human promyelocytic leukemia HL60 cells, inhibitory effects in growth and differentiation-induced against human leukemia cells, and immunomodulation activity (Lang and Philp 1998; Azuma et al. 1987; Hoq et al. 1997; Isoda et al. 1997a; b; Sudo et al. 2000; Kuyukina et al. 2007; Baeva et al. 2014). It is also known that free trehalose disaccharides act in the protection of biomolecules and cells against environmental stresses (heat, cold, oxidation, and others). Based on this, it was proved that trehalose lipids are determining factors in the protection of membranes, since its interaction with surrounding molecules can be considered essential to the development of resistance against desiccation by pathogenic Mycobacterium tuberculosis (Jain and Roy 2009; Harland et al. 2009).

Many studies showed the influence of trehalose lipid interaction with membranes, proteic models, and enzymes, demonstrating the role and hypothetical action site of these biosurfactants (Ortiz et al. 2011; Teruel et al. 2014; Zaragoza et al. 2012; 2013). These glycolipids are able to incorporate into dimyristoylphosphatidylglycerol (DMPG) membranes and affect their structural properties with increases in the fluidity of the acyl chains and dehydrates the interfacial region of this bilayer model but did not affect the macroscopic bilayer organization (Teruel et al. 2014; Ortiz et al. 2011).

As well as sophorolipids, for trehalose lipids, there is the possibility of further chemical modifications to obtain novel analogues with diverse properties, and also, it has been reported the production of trehalose surfactants that can be applied in medical field (Peng et al. 2015; Delbeke et al. 2015; Matsumoto et al. 2013a). The cited trehalose surfactants can be prepared by using sonication of a mixture containing -α-dimyristoylphosphatidylcoline (DMPC) and α-d-glycopyranosyl-α-d-glycopyranoside monomyristate for production of the 14 carbon derivative or α-d-glycopyranosyl-α-d-glycopyranoside monopalmitate for production of 16C derivative, in a 5 % glucose solution at 45 °C and 300 W, followed by filtration. This new approach has been used for the production of hybrid liposomes in association with DMPC for application in antiproliferative studies (Matsumoto et al. 2013b; Matsumoto et al. 2016). Inhibitory effects of trehalose liposomes (DMTre) on the growth of lymphoblastic leukemia (MOLT-4) cells in vitro and therapeutic effects in xenograft mice model of carcinoma in vivo were examined by Mastumoto et al. (2016). It was proved that DMTre is able to inhibit the growth of MOLT-4 cells in a dose-dependent manner and that a remarkable reduction of tumor weight was obtained in xenograft mice models treated with DMTre after inoculating MOLT-4 cells, demonstrating the great potential of trehalose lipids or their derivatives obtained by sonication.

Previously, it was showed that trehalose lipids, found in mono-acyl trehalose and di-acyl trehalose forms, produced by Rhodococcus ruber IEGM 23 cultivated in medium containing n-dodecane, prevented the adhesion of human monocytes to polystyrene surfaces and inhibited their cytokine production without any cytotoxic effects in vitro, assessed by measuring the inhibition of proliferative activity of cultured human peripheral blood lymphocytes (Gein et al. 2011). In addition, ultrasonic emulsions containing various concentrations of this glycolipid exhibited cytokine-stimulating activity and increasing the tumor necrosis factor-α (TNF-α), interleukin (IL)-1β, and IL-6 production when applied to the adherent human peripheral blood monocyte culture suggests the potential of trehalose lipids from R. ruber IEGM 23 as an immunomodulatory and antitumor agent.

The application of biosurfactants in environmental field, as in enhanced oil recovery and bioremediation, has been proposed mainly using rhamnolipids, but the use of trehalose lipids in this perspective also is a promising alternative (Christofi and Ivshina 2002; Franzetti et al. 2010). Polycyclic aromatic hydrocarbons consist in an important concern due to their toxic, mutagenic, tumorigenic, and ecological effects, and today, the use of eco-friendly methods for enhance their remotion from contaminated soils is a strong trend in biotechnology, especially in biosurfactant area (Haritash and Kaushik 2009; Cameotra and Bollag 2003). Considering that glycolipids are more suitable for soil remediation when compared to synthetic surfactants due to their low toxicity and biodegradability properties, the use of trehalose may be considered for this purpose. Thus, some studies have explored these concepts and developed new strategies using this glycolipid for simultaneous removal of PAHs and sulfur heterocycles (PASHs) (Ivshina et al. 2016).

Kuyukina et al. (2016) describe the production of trehalose lipid from Rhodococcus ruber IEGM 231 using 3 % (v/v) n-hexadecane at 160 rpm, 28 °C for 48 h, and the anti-adhesive and biofilm-preventing effects against Gram-positive and Gram-negative bacteria strains. Interesting results were obtained from anti-adhesive effects of this biosurfactant at 10 mg/L against actively growing B. subtilis ATCC 6613, Corynebacterium glutamicum IEGM 1861, E. coli K-12, Micrococcus luteus IEGM 401, and Pseudomonas fluorescence NCIMB 9046 cells with different percentages of inhibition (30–76 %). Moreover, these authors suggested that trehalose lipid anti-adhesive properties are not strongly dependent upon the concentration in this case and also is dependent of hydrophobicity/surface characteristics of the strains tested and their physiological stage.

The use of genetic manipulation to improve production of biosurfactants has been highlighted recently. The first reported use of genetic engineering was the insertion and expression of the Vitreoscilla hemoglobin gene (vgb) in Gordonia amarae, resulting in enhancement of trehalose lipid production in a medium supplemented with 1 % hexadecane (Dogan et al. 2006). The elucidation of biosynthetic pathways through the identification of putative acyl coenzyme A (acyl-CoA) transferase (tlsA), fructose-biphosphate aldolase (fda), and alkane monooxygenase (alkB) genes and genetic manipulation allowed an increase in succinoyl trehalolipid production by Rhodococcus sp. strain SD-74 (Inaba et al. 2013). Despite the potential of the use of this tool, the works mentioned above did not show results considering reduction of surface tension, characterization of the product obtained, and data about production process.

Mannosylerythritol lipids

MELs are a family of nonionic glycolipid biosurfactants that contains 4-O-β-d-mannopyranosyl-meso-erythritol or 1-O-β-d-mannopyranosylerythritol as the hydrophilic moiety and a fatty acid and acetyl groups in the hydrophobic unit that are produced mainly by Pseudozyma spp., Ustilago spp., and related yeasts and also by filamentous fungi (Arutchelvi et al. 2008; Faria et al. 2014). These compounds usually have one or two acetyl groups at C-4′ and/or C-6′ of the mannose moiety and are classified as MEL-A (diacetylated), MEL-B (monoacetylated at C-6′), MEL-C (monoacetylated at C-4′), and MEL-D (deacetylated) (Kitamoto et al. 2001; Sajna et al. 2013) (Fig. 4).

The mannosylerythritol lipids are considered promising biosurfactants due to excellent surface-active properties, low toxicity, biodegradability, and versatile biochemical actions (Kitamoto et al. 2002; Lang 2002; Morita et al. 2015). Moreover, these biosurfactants are economically attractive due to the high quantity produced in biotechnological process, as well the sophorolipids, and can be applied in diverse fields such as bioremediation, pharmaceutical, and cosmetic industries (Arutchelvi and Doble 2011; Morita et al. 2013). The diversity in the MEL structures (e.g., number of acetyl groups) shows important influence in the physicochemical properties and consequent practical applications (Morita et al. 2015). Accordingly, different types of MEL are obtained depending on microorganism and substrate used in biotechnological process (Faria et al. 2014).

Other characteristic of these biosurfactants is their self-assembly properties that are defined as the auto-organization capacity of molecules into ordered structures. MELs can form different three-dimensional lyotropic liquid crystals such as cubic, sponge, lamella, and hexagonal phases and also self-assembled monolayer, liposomes, large unilamellar, and multilamellar vesicles (Imura et al. 2004; Imura et al. 2005; Imura et al. 2006; 2007; Konishi et al. 2008; Worakitkanchanakul et al. 2008; Kitamoto et al. 2009; Arutchelvi and Doble 2011).

Among all the types of MELs, MEL-A is the most found type, with lower water solubility and hydrophilicity, and it is able to reduce the surface tension of water from 72 mN/m to values below 30 mN/m (Imura et al. 2006; Morita et al. 2009b). Moreover, MEL-A exhibited good stability during exposure to temperature variation, high concentrations of salts, and wide range of pH values and the production of this type of molecule and MEL-A homologs is dependent of copper salts, manganese, and peptone when performed by Pseudozyma aphidis (Fan et al. 2014). In contrast, MEL-B and MEL-C exhibit better solubility in water, indicating that they could be more suitable for application in water-in-oil type emulsifiers and washing detergents (Morita et al. 2008a; 2009b).

The yields and types of mannosylerythritol lipids obtained from microbial production are affected by several factors such as hydrophilic and hydrophobic carbon sources, nitrogen source, temperature, and total time of the biotechnological process (Arutchelvi and Doble 2011; Morita et al. 2008b; Rau et al. 2005; Morita et al. 2009a). Konishi et al. (2011) describe the influence of yeast extract in the production of MELs by Pseudozyma hubeiensis SY62. In this study, the MEL production was carried using glucose, olive oil, and yeast extract at different concentrations. Using 1 g/L of yeast extract and 50 g/L of olive oil and glucose, it has achieved 8.5 g/L of MEL, while with 10 g/L of yeast extract and 100 g/L of olive oil and glucose resulted in a concentration of 49.2 g/L of glycolipids. However, when using the same concentration of yeast extract and 200 g/L of glucose and olive oil, it was observed that the concentration of biosurfactant produced was reduced, confirming the positive effect of yeast extract in the production of MELs. Considering the optimal concentration of these substrates, the fed-batch fermentation was performed, adding glucose and olive oil after 3 days of P. hubeiensis SY62 inoculation and 129 g/L of MEL was achieved in 7 days of process with volumetric productivity of 18.4 g/L day.

Fukuoka et al. (2008) related the production of three novel diastereomers of conventional mannosylerythritol lipids by Pseudozyma crassa. When glucose and oleic acid were used as carbon source, the total concentration of MELs reached approximately 4.6 g/L. The structures of these glycolipids were similar to well-known MEL-A, B, and C but with configuration of the erythritol moiety opposite to that of conventional MELs. Besides that, the MEL-A analogue was the major component of the diastereomers, with nearly the same surface-active properties as the conventional MEL-A, although it exhibited different aqueous phase behavior and biochemical properties.

In order to reduce process costs, many studies of MEL production have shown the feasibility of using alternative substrates. As for the other glycolipid families mentioned in this review, it should be considered that the use of alternative substrates requires more studies for its implementation on an industrial scale and all works reporting the use of this type of substrate as potential alternative give little information about the real benefit of these compounds. In this context, Bhangale et al. (2013b) used two types of honey as a carbon source for the production of MELs by Pseudozyma antarctica ATCC 32657. Authors showed that 14 % (w/v) of honey from red dwarf honeybees (RDH) (Apis florea) resulted in 5.61 g/L of MEL. In addition, MEL crude extract was capable to reduce surface tension of water from 72 to 29.5 mN/m, interfacial tension at water/n-heptane interface to 0.602 mN/m, and low CMC value of 0.066 g/L. The use of castor oil as a substrate for Pseudozyma tsukubaensis NBRC1940 achieved the production of diastereomer of MEL-B and new type of MEL-B with hydroxyl group in the fatty acid moiety with different interfacial properties (Yamamoto et al. 2013). The MEL-B water surface tension reduction was similar of the unconventional MEL-B, 28.5 and 28.2 mN/m, respectively, but the CMC value was fivefold higher than that of unconventional MEL-B, demonstrating the high influence of structure in the physiochemical properties.

Another interesting approach is the use of wild strains isolated from leaves, plant tissues, and soil samples. Pseudozyma churashimaensis strain isolated from leaves of sugarcane (Saccharum officinarum) was able to produce a mixture of mannosylerythritol lipids, including a novel tri-acetylated derivative (MEL-A2), from glucose with good surface properties like low CMC value of 0.0011 g/L and reduction of surface tension to 29.2 mN/m (Morita et al. 2011b). On the other hand, the selective production of MEL-B was observed by fungi Ustilago scitaminea from sugarcane juice with production of 25.1 g/L (Morita et al. 2011a). Moreover, the product concentration varied according to the carbon source used, the use of glucose enabled the production of 3.8 g/L, and while using soybean oil it reached 2.7 g/L. Previous studies with new strains of P. tsukubaensis isolated from leaves of Perilla frutescens showed that one these strains was able to produce MEL-B in concentration of 73.1 g/L (Morita et al. 2010b). Fai et al. (2015) demonstrated that P. tsukubaensis is able to produce, beyond of MEL biosurfactant, prebiotic galactooligosaccharides (GOS) in the same process using cassava wastewater. This shows the versatility of this microorganism to produce two compounds commercially attractive and the feasibility of the process using an alternative substrate in the biotechnological process. The results are consistent with studies that reported the use of cassava wastewater as substrate for lipopeptide biosurfactant production by Bacillus species (Quadros et al. 2011; Barros et al. 2008; Nitschke and Pastore 2003). However, using cassava wastewater for MEL production, the values of yields obtained were not given in consecutive production with GOS but only the surface tension values as a production parameter.

A screening study was conducted by Morita et al. (2012) using 43 fungal MEL producers isolated from sugarcane plants. Four strains were able to grown in culture containing 50 % sugarcane juice as alternative substrate with production varying from 0.8 to 3.7 g/L. Sari et al. (2013), using an endophytic yeast Pseudozyma Y10BS025 isolated from sirih leaf (Piper betle L.), observed mainly the production of MEL-C and showed excellent yield production reaching 115 g/L. After isolation and characterization, these MEL derivatives reduce the surface tension of water to 30.8 mN/m. The results of the studies above show the feasibility of obtaining high concentrations of MEL using new strains isolated from alternative sources, concluding that this is an attractive strategy.