Abstract

The time-dependent failure probability function (TDFPF) is defined as a function of the time-dependent failure probability (TDFP) varying with the design parameters and the service time, and it is useful in the reliability-based design optimization for the time-dependent problem. For the lack of method estimating TDFPF, the direct Monte Carlo simulation (DMCS) and an adaptive Kriging-MCS based on Bayes formula (shorten as AK-MCS-Bay) are developed to estimate TDFPF. The DMCS is time-consuming, but its convergent solution can be used as reference to validate other methods. In the AK-MCS-Bay, the TDFPF is primarily transformed into the estimation of the augmented TDFP and the conditional probability density function (PDF) of design parameters on the time-dependent failure event. Then, a single AK model is constructed to efficiently identify the failure samples in the MCS sample pool at different service times. By using these identified failure samples, the TDFPs under different service times can be estimated by the double-loop MCS without any extra model evaluations, and the conditional PDF of design parameters can be also acquired by the kernel density estimation method. The numerical and engineering examples indicate the efficiency and accuracy of the proposed method.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

In many engineering fields, uncertainties widely exist in the manufacturing process, assembling process, and service environment, which will lead to the failure of structure or system to be random (Hu and Du 2012; Feng et al. 2019a; Fan et al. 2019). In order to quantitatively measure the safety degree of the structure or system involving random uncertainties, the failure probability was proposed and then studied by many scholars (Li 1995; Shi et al. 2017; Yun et al. 2019a). Afterwards, the reliability-based optimization design (RBDO) was introduced to replace the traditional deterministic one (Enevoldsen and Sorensen 1994; Papadrakakis and Lagaros 2002; Zou and Mahadevan 2006). When solving a RBDO problem, plenty of failure probabilities of the structure or system under various design settings are needed to be estimated (Ching and Hsieh 2007; Meng et al. 2018; Yuan 2013; Feng et al. 2019b). The failure probability function (FPF) Pf(θ), defined as the failure probability with respect to the design parameter vector θ = (θ1, θ1, ⋯, θm) where m is the number of design parameters, is usually estimated in advance to simplify the process of the RBDO. As pointed out in Ref. (Yuan 2013), the RBDO problem can be decoupled into an ordinary optimization problem if the whole FPF Pf(θ) can be obtained in advance. In addition, by using Pf(θ), the reliability-based sensitivity indices, such as reliability-based Sobol’ index (Zhou et al. 2019) and reliability-based moment-independent sensitivity index (Yun et al. 2019b; Xu et al. 2019), can be directly estimated without any extra model evaluations. These sensitivity indices can be used for model simplification, model validation, and optimization.

At present, many computational methods have been developed to estimate the FPF, and they can be mainly classified into two groups, i.e., the interpolation method and the Bayes formula method. In the interpolation method, numerous failure probabilities at some predefined interpolation design parameter points ought to be estimated at first; then, the FPF can be approximately obtained by different interpolation techniques. For instance, Jensen (Jensen 2005) employed a linear function to locally approximate the function log[Pf(θ)], and at least m reliability analyses are needed to determine the corresponding coefficients of the linear function. Gasser (Gasser and Schueller 1997) adopted a quadratic function to replace the linear function used in Jensen’s method to get a better approximation of the function log[Pf(θ)], but the minimum required number of reliability analyses soars to m + m(m + 1)/2. Although the interpolation method is suitable for many mathematical and engineering problems, the total computational cost involved may be unaffordable for the practitioners in solving some complicated engineering problems. Thereof, Au (Au 2005) proposed the Bayes formula method so as to reduce the total computational burden of estimating the FPF. The key of this method is to regard the design parameters θ as a random vector, and then the FPF Pf(θ) can be expressed as a combination of the probability density function (PDF) of θ, the conditional PDF of θ based on the failure event F and the failure probability considering uncertainties of both input variables and design parameters. By using a single reliability analysis, all the three components of the FPF can be simultaneously estimated, and subsequently the whole FPF can be acquired. In order to further improve the efficiency and accuracy of the Bayes formula method, some enhancements to the original method were developed. For example, Ching (Ching and Hsieh 2007) employed the maximum entropy principle to estimate the conditional PDF of θ. Yuan (Yuan 2013) proposed some weighted approaches to rewrite the failure probability and then estimated the FPF efficiently.

It should be pointed out that, in the existing researches, the FPF is mostly independent with the time t, which therefore can be called time-independent FPF (TIFPF) in these researches. However, for a large number of engineering problems, the time t plays an important role in affecting the performance of the structure or the system, thereof the failure probability of a structure or system is also a function with respect to its service time te (Hu and Du 2013). Hence, the authors of this contribution expect to propose the concept of the time-dependent failure probability function (TDFPF) Pf(θ, te) in this paper, which can be defined as a function of the time-dependent failure probability (TDFP) with respect to the design parameters θ and service time te. When the service time te is fixed at certain value \( {t}_e^{\ast } \), the TDFPF \( {P}_f\left(\boldsymbol{\theta}, {t}_e^{\ast}\right) \) can be regarded as a TIFPF. When the design parameters are fixed at certain values θ∗, the TDFPF Pf(θ∗, te) can be considered as a one-dimensional FPF with respect to its service time. If the entire TDFPF can be obtained, the RBDO for the time-dependent problem defined in Refs. (Wang and Wang 2012; Hu and Du 2015a) can be decoupled into an ordinary optimization problem and solved by many existing mature methods.

In order to estimate the TDFPF, the direct Monte Carlo simulation (DMCS) is primarily proposed. In this method, for each given design parameter point, the TDFP is estimated by the double-loop MCS (Okuda et al. 1997), then the TDFPF can be acquired based on the above obtained TDFPs corresponding to all given design parameter points. To drastically reduce the computational cost, an efficient computational method by combining an adaptive Kriging-MCS (AK-MCS) and Bayes formula (shorten as AK-MCS-Bay) is developed. In this method, the Bayes formula is employed to transform the TDFPF Pf(θ, te) into the form of the pre-defined PDF of θ, the conditional PDF of θ based on the time-dependent failure event, and the augmented TDFP considering uncertainties of both input variables and design parameters. Next, a single AK model is constructed to estimate the augmented TDFP at any specific service time. By using the failure samples recognized by AK model trained in the MCS sample pool, the conditional PDF of θ can be evaluated by the kernel density estimation (KDE) method.

The paper is outlined as follows. Section 2 introduces the concepts of TDFP and TDFPF. Section 3 proposes the DMCS to estimate the TDFPF. Section 4 develops the AK-MCS-Bay for efficiently estimating the TDFPF. Section 5 employs one mathematical example and three engineering examples to demonstrate the accuracy and efficiency of the two proposed computational methods. Section 6 summarizes the conclusions.

2 Problem definition

Consider a general time-dependent limit state function Y = G(α, β(t), t), where \( \alpha =\left[{\alpha}_1,{\alpha}_2,\cdots, {\alpha}_{n_1}\right] \) represents the n1-dimensional random variable vector, \( \beta (t)=\left[{\beta}_1(t),{\beta}_2(t),\cdots, {\beta}_{n_2}(t)\right] \) denotes the n2-dimensional stochastic process vector, and t expresses the time. It is quite difficult to deal directly with the stochastic process in time-dependent reliability analysis. Thanks to the spectral representation methods, such as expansion optimal linear estimation (EOLE) (Li and Der Kiureghian 1993), orthogonal series expansion (OSE) (Zhang and Ellingwood 1994), and Karhunen-Loeve expansion (KLE) (Ghanem and Spanos 2003), the stochastic process vector β(t) can be transformed into a function with respect to the random variable vector \( \xi =\left[{\xi}_1,{\xi}_2,\cdots, {\xi}_{n_3}\right] \) and time t, i.e., \( \beta (t)\approx \overset{\sim }{\beta}\left(\xi, t\right) \). Therefore, the time-dependent limit state function Y = G(α, β(t), t) can be transformed into the form onlycontaining random variables and time, i.e., \( Y=G\left(\alpha, \beta (t),t\right)\approx G\left(\alpha, \overset{\sim }{\beta}\left(\xi, t\right),t\right)=g\left(X,t\right) \), where X = [X1, X2, ⋯, Xn] = [α, ξ] and n = n1 + n3. According to the transformed time-dependent limit state function g(X, t), the TDFP Pf(te) within the time interval [0, te] can be described as

where P(⋅) denotes the probability operator, and F(te) = {X| g(X, t) ≤ 0, ∃t ∈ [0, te]} represents the time-dependent failure event. Equation (1) indicates that the TDFP and time-dependent failure event are both functions with respect to the service time te.

In practical engineering, the distribution types of the input variables are usually known, and their distribution parameters, e.g., the mean or standard deviation, should be further designed. Let θ = (θ1, θ1, ⋯, θm) be the m-dimensional design parameter vector, and the TDFP for a given θ is formulated as

In the RBDO for the time-dependent problem, numerous TDFPs for some values of θ within the admissible region are usually required to estimate. Meanwhile, in practice, the design service time te may be continually adjusted in different design stages; thus, a number of TDFPs under different service times are needed to evaluate. The quantity Pf(θ, te) as a function of θ and te is defined as the TDFPF, which is the main objective in this paper.

3 Direct Monte Carlo simulation for TDFPF

The basic idea of the DMCS for estimating the TDFPF Pf(θ, te) is to discretize the design parameters θ and service time te in their regions [θL, θU] and [tL, tU] at first, and then the double-loop MCS is employed to estimate the TDFP for each discrete point. The detailed procedure of the DMCS can be summarized as follows:

-

Step 1.

Discretize the region [θL, θU] into Nθ points, i.e., θi(i = 1, 2, ⋯, Nθ), and the region [tL, tU] into Nt points, i.e., tj(j = 1, 2, ⋯, Nt).

-

Step 2.

For each discrete point {θi, tj}(i = 1, 2, ⋯, Nθ, j = 1, 2, ⋯, Nt), the TDFP Pf(θi, tj) can be estimated as follows.

-

Step 2.1. Generate N1 samples of the input variables X = [X1, X2, ⋯, Xn] according to the joint PDF fX(x| θi) and uniformly generate N2 samples of the time variable t in the interval [0, tj], which are denoted as sample matrices A and B respectively, i.e.,

Let k = 1.

-

Step 2.2. Define the matrix C(k), i.e.,

Compute the model outputs \( g\left({C}_l^{(k)}\right) \) at N2 samples \( {C}_l^{(k)}\left(l=1,2,\cdots, {N}_2\right) \) in matrix C(k), then judge each sample matrix whether fail or not according to the following indictor function:

If IF(C(k)) = 0, the sample matrix C(k) is regarded to be safe; otherwise, it is considered to be failed. Then, k = k + 1.

-

Step 2.3. If k < N1, go to step 2.2; otherwise, compute the TDFP Pf(θi, tj) according to (7).

After estimating the Nθ × Nt TDFPs, the TDFPF can be approximately obtained by the interpolation technique.

According to the above three steps, it can be observed that the total number of model evaluations in the DMCS is NM = NθNtN1N2. For the complicated engineering problem with small TDFP, the values of N1 and N2 need to be large enough so as to obtain accurate results. Thus, for such problems, the computational burden in evaluating the entire TDFPF by the DMCS might be too large to be accepted by the engineers. Recently, numerous meta-model approach, such as double-loop Kriging model (Wang and Wang 2015), single-loop Kriging model (Hu and Mahadevan 2016), importance sampling based Kriging model (Meng et al. 2019), and response surface model (Zhang et al. 2017), have been proposed to estimate the TDFP. Although these meta-models are pretty efficient in estimating the TDFP compared with the double-loop MCS, they were mainly proposed to evaluate the TDFP at certain design parameters θ and service time te. If the designers want to obtain the whole TDFPF by using these existing methods, the basic meta-models should be primarily constructed to estimate the TDFP at fixed design parameter and service time, and then TDFP at other design parameters and service times can be subsequently estimated by adaptively updating the basic meta-model. Therefore, the computational cost and time for estimating the TDFPF by employing existing meta-models are higher and longer than those in estimating a single TDFP. In order to dramatically reduce the total number of model evaluations in estimating TDFPF, an efficient AK-MCS-Bay is developed in the next section.

4 Efficient AK-MCS-Bay for TDFPF

4.1 The equivalent transformation of TDFPF based on Bayes formula

According to Au’s idea (Au 2005), the design parameters θ can be treated as uncertain variables. Given a prior joint PDF fθ(θ) for the design parameters, the TDFPF defined in (2) can be transformed into (8) based on the Bayes formula:

where P{F(X, θ, te)} denotes the augmented TDFP by considering both input variables X and design parameters θ as random variables, and it can be defined as follows:

fθ{θ| F(X, θ, te)} is the joint PDF of θ conditioned on the time-dependent failure event F(X, θ, te) defined in (10),

Based on (8), it can be concluded that the TDFPF Pf(θ, te) can be divided into three parts, i.e., fθ(θ), P{F(X, θ, te)} and fθ{θ| F(X, θ, te)}. In practical application, the joint PDF fθ(θ) is usually assigned beforehand. The TDFP P{F(X, θ, te)} is a function with respect to the service time te. If te is fixed at a certain value \( {t}_e^{\ast } \), the TDFP \( P\left\{F\left(X,\boldsymbol{\theta}, {t}_e^{\ast}\right)\right\} \) will be a constant which can be estimated by many existing computational algorithms, such as double-loop MCS (Okuda et al. 1997), first-passage based approach (Sacks et al. 1989; Hu et al. 2013), extreme performance-based approach (Au and Beck 2001; Du and Sudjianto 2004), and meta-model approach (Zhao and Ono 2001; Yun et al. 2017). Then, after estimating the TDFP \( P\left\{F\left(X,\boldsymbol{\theta}, {t}_e^{\ast}\right)\right\} \), the samples of θ on the failure domain can be also obtained, so the conditional joint PDF \( {f}_{\boldsymbol{\theta}}\left\{\boldsymbol{\theta} |F\left(X,\boldsymbol{\theta}, {t}_e^{\ast}\right)\right\} \) can be evaluated according to the obtained failure samples of θ by several methods, such as the parametric density estimation (Izenman 2008), the histogram estimation (Scott 1992), and the kernel density estimation (KDE) (Park and Marron 1990) etc. At present, the most popular density estimation approach is KDE, which is a proven important tool in the statistical analysis of data (Botev et al. 2010). Thus, in this paper, the KDE is employed to estimate the joint PDF \( {f}_{\boldsymbol{\theta}}\left\{\boldsymbol{\theta} |F\left(X,\boldsymbol{\theta}, {t}_e^{\ast}\right)\right\} \), and one can refer ref. (Saltelli et al. 2008) for details.

From the above analysis, the most direct computational method based on (8) for estimating the TDFPF Pf(θ, te) is to primarily discretize the service time te at its region [tL, tU] into Nt points, i.e., tj(j = 1, 2, ⋯, Nt). Then, for each tj(j = 1, 2, ⋯, Nt), the TDFP P{F(X, θ, tj)} can be estimated by the time-dependent reliability analysis method, and subsequently, the joint PDF fθ{θ| F(X, θ, tj)} can be estimated by the KDE technique. Thereof, this MCS based on Bayes formula (shorten as MCS-Bay) needs Nt time-dependent reliability analyses to obtain the whole TDFPF Pf(θ, te), while the DMCS proposed in the last section needs NθNt time-dependent reliability analyses. Compared with the DMCS, the MCS-Bay can reduce the total computational cost in estimating the TDFPF Pf(θ, te) to some extent, but Nt time-dependent reliability analyses still need a great deal of model evaluations for some complicated problems. Hence, in order to extremely reduce the number of model evaluations, an AK-MCS-Bay is introduced for estimating the TDFPF Pf(θ, te) in the next subsection.

4.2 An AK-MCS-Bay for estimating TDFPF

The basic idea of the AK-MCS-Bay is to constitute a MCS sample pool of X ∣ θ and t at first, then the AK model is constructed to distinguish the signs of the time-dependent limit state function at all the samples in the MCS sample pool. Therefore, the key issues of the AK-MCS-Bay are how to constitute the MCS sample pool and how to construct and update the Kriging model.

In order to generate the samples of X ∣ θ, \( {N}_1^{(MCS)} \) samples of θ should be generated according to its assigned joint PDF fθ(θ) at first, i.e., \( {\boldsymbol{\theta}}_{j_1}\left({j}_1=1,2,\cdots, {N}_1^{(MCS)}\right) \). Next, based on the joint PDF \( {f}_X\left(X|{\boldsymbol{\theta}}_{j_1}\right) \) at the corresponding distribution parameters \( {\boldsymbol{\theta}}_{j_1}\left({j}_1=1,2,\cdots, {N}_1^{(MCS)}\right) \), \( {N}_1^{(MCS)} \) samples of X ∣ θ can be generated as \( {x}_{j_1}\mid {\boldsymbol{\theta}}_{j_1}\left({j}_1=1,2,\cdots, {N}_1^{(MCS)}\right) \). It is noticed that the purpose of the proposed AK-MCS-Bay is to estimate all the TDFPs under different service times te ∈ [tL, tU] by using a single Kriging model. Thus, the interval boundary of the time t should be introduced as t ∈ [0, tU]. By uniformly generating \( {N}_2^{(MCS)} \) samples in the interval [0, tU], the samples of time t can be labeled as \( {t}_{j_2}\left({j}_2=1,2,\cdots, {N}_2^{(MCS)}\right) \). Finally, the MCS sample pool including \( {N}_1^{(MCS)}{N}_2^{(MCS)} \) samples can be constituted by the combination of \( {N}_1^{(MCS)} \) samples of model inputs and \( {N}_2^{(MCS)} \) samples of the time variable, i.e.,

\( \left({x}_{N_1^{(MCS)}}|{\boldsymbol{\theta}}_{N_1^{(MCS)}},{t}_1\right),\left({x}_{N_1^{(MCS)}}|{\boldsymbol{\theta}}_{N_1^{(MCS)}},{t}_2\right),\cdots, \left({x}_{N_1^{(MCS)}}|{\boldsymbol{\theta}}_{N_1^{(MCS)}},{t}_{N_2^{(MCS)}}\right)\Big] \). If the states of all the samples in the MCS sample pool, i.e., safety state or failure state, can be clearly recognized, all the TDFPs under different service times te ∈ [tL, tU] can be estimated by the double-loop MCS. For this purpose, the AK model is constructed as follows.

The basic idea of Kriging model is that time-dependent limit state function g(X| θ, t) can be regarded as a realization of a stochastic field gK(X| θ, t) which is given as

where f(X| θ, t) = [f1(X| θ, t), f2(X| θ, t), ⋯, fp(X| θ, t)] represents the p-dimensional basis function vector, ξ = [ξ1, ξ2, ⋯, ξp]T denotes the vector of regression coefficients, and Z(X| θ, t) is a stationary Gaussian process with zero mean. The first item f(X| θ, t)ξ is the deterministic part which approximately gives a mean value of the model response. The second item is the nonparametric stochastic process whose covariance between two points \( \left({x}_{j_1}|{\boldsymbol{\theta}}_{j_1},{t}_{j_1}\right) \) and \( \left({x}_{j_2}|{\boldsymbol{\theta}}_{j_2},{t}_{j_2}\right) \) is defined in (12),

where \( {\sigma}_Z^2 \) is the process variance and RZ is the correlation function. Generally, Gaussian correlative model is employed to define the stochastic process and one can refer ref. (Echard et al. 2011) for details.

In general, the initial Kriging model is constructed by using a few number of samples according to (11). The initial samples can be generated by employing the Hammersley sampling approach (Hammersley et al. 1996) or Latin Hypercube Sampling approach (Stein 1987). The number of initial samples varies from tens to hundreds according to the nonlinear degree of the time-dependent limit state function. In general, the higher the nonlinearity of the time-dependent limit state function is, the bigger the number of initial samples should be selected (Yun et al. 2019c). Then, the samples in the MCS sample pool are used to update the model. At present, several available sampling criterions for the selection of new sample to update the Kriging model have been proposed, such as the CA-learning function proposed in ref. (Wang and Wang 2015) and the U-learning function developed in ref. (Echard et al. 2011). The application of CA-learning function is to estimate the failure probability with certain confidence level, which is accurate and efficient in estimating the failure probability, but may misjudge the signs of the limit state functions corresponding to the samples which have fewer impacts on the failure probability. The basic idea of the U-learning function is to accurately recognize the signs of the limit state functions corresponding to all the samples in the sample pool. Then, the failure probability can be estimated as the ratio between the number of the failure samples recognized by the U-learning function and the number of all the samples in the sample pool. Thus, compared with the CA-learning function, the U-learning function is more accurate but less efficient in estimating failure probability. It should be pointed out that the purpose for constructing an adaptive Kriging model in this subsection not only includes accurately estimating the augmented TDFP, but also contains accurately recognizing the signs of the limit state functions corresponding to all the samples in the sample pool. Therefore, the U-learning function is adopted in this paper.

For the sample point \( \left({x}_{j_1}|{\boldsymbol{\theta}}_{j_1},{t}_{j_2}\right) \), the U-learning function is defined as

The bigger the value of the U-learning function is, the bigger the probability of accurately recognizing the signs of the time-dependent limit state function at the sample point is. Hence, the confidence level of the Kriging model for recognizing the signs of all the samples in the MCS sample pool is introduced as

According to (13) and (14), it can be observed that CLk is the minimum value of the U-learning functions with respect to all the samples in MCS sample pool, and CLk can reflect the worst case that the current Kriging model misjudges the sign of \( g\left({x}_{j_1}|{\boldsymbol{\theta}}_{j_1},{t}_{j_2}\right),\kern1.1em {j}_1=1,2,\cdots, {N}_1^{(MCS)},{j}_2=1,2,\cdots, {N}_2^{(MCS)} \). In general, the bigger the value of the CLk is, the greater power the current Kriging model can accurately recognize the sign of g(x| θ, t) .

If the value CLk fails to meet the requirement, a new sample from the MCS sample pool would be added to update the Kriging model. The criterion for selecting the new sample \( {\left({x}_{j_1}|{\boldsymbol{\theta}}_{j_1},{t}_{j_2}\right)}^{\ast } \) is given as

By adding the most contributive sample selected by (15) in sequence, the Kriging model can be constantly updated until the confidence level \( C{L}_k^{\ast } \) satisfies the requirement. As suggested in ref. (Echard et al. 2011), the required confidence level \( C{L}_k^{\ast } \) is set to 2 in this paper, which indicates that the probability of misjudging the sign of g(x) is no more than Φ(−2) = 0.0228.

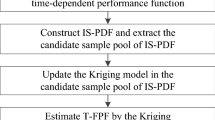

4.3 The implementation of AK-MCS-Bay

Based on the Kriging model gK(X| θ, t), the TDFP P{F(X, θ, te)} for any service time te ∈ [tL, tU] can be estimated by using the samples in the MCS sample pool. At the same time, the conditional joint PDF fθ{θ| F(X, θ, te)} can also be estimated according to the samples of θ on the failure domain. Thus, without any extra model evaluations and samples, the whole TDFPF Pf(θ, te) can be obtained based on the existing MCS sample pool. The flowchart of the efficient AK-MCS-Bay is given in Fig. 1. It consists of 10 steps:

-

Step 1.

Input the time interval [tL, tU] of the service time te. Assume a prior PDF \( {f}_{{\boldsymbol{\theta}}_p}\left({\boldsymbol{\theta}}_p\right)\left(p=1,2,\cdots, m\right) \) for each design parameter, and their joint PDF can be represented as \( {f}_{\boldsymbol{\theta}}\left(\boldsymbol{\theta} \right)=\prod \limits_{p=1}^m{f}_{{\boldsymbol{\theta}}_p}\left({\boldsymbol{\theta}}_p\right) \) when the parameters are independent. Ref. (Au 2005) indicated that the choice of fθ(θ) does not affect the accuracy of the failure probability estimates, and the uniform distribution is chosen in this paper for simplicity.

-

Step 2.

According to the joint PDF fθ(θ), generate \( {N}_1^{(MCS)} \) samples of the design parameters θ, i.e., \( {\boldsymbol{\theta}}_{j_1}\left({j}_1=1,2,\cdots, {N}_1^{(MCS)}\right) \), then \( {N}_1^{(MCS)} \) samples \( {x}_{j_1}\mid {\boldsymbol{\theta}}_{j_1}\left({j}_1=1,2,\cdots, {N}_1^{(MCS)}\right) \) of input variables X ∣ θ can be generated based on \( {f}_X\left(x|{\boldsymbol{\theta}}_{j_1}\right)\left({j}_1=1,2,\cdots, {N}_1^{(MCS)}\right) \).

-

Step 3.

Uniformly generate \( {N}_2^{(MCS)} \) samples of the time variable t in the interval [0, tU], i.e., \( {t}_{j_2}\left({j}_2=1,2,\cdots, {N}_2^{(MCS)}\right) \).

-

Step 4.

On the basis of the samples generated in Steps 2 and 3, the MCS sample pool is constituted as \( \Big[\left({x}_1|{\boldsymbol{\theta}}_1,{t}_1\right),\left({x}_1|{\boldsymbol{\theta}}_1,{t}_2\right),\cdots, \left({x}_1|{\boldsymbol{\theta}}_1,{t}_{N_2^{(MCS)}}\right),\kern0.5em \left({x}_2|{\boldsymbol{\theta}}_2,{t}_1\right),\left({x}_2|{\boldsymbol{\theta}}_2,{t}_2\right),\cdots, \left({x}_2|{\boldsymbol{\theta}}_2,{t}_{N_2^{(MCS)}}\right),\kern0.3em \cdots \kern0.4em , \)

-

Step 5.

Randomly select N0 training samples from the MCS sample pool and compute the corresponding responses. Then, the initial Kriging model gK(X| θ, t) can be constructed based on these N0 training samples.

-

Step 6.

Compute the confidence level CLk of the current Kriging model in the MCS sample pool. If CLk is smaller than \( C{L}_k^{\ast } \), go to step 7; otherwise, go to step 8.

-

Step 7.

According to (15), select new training sample \( {\left({x}_{j_1}|{\boldsymbol{\theta}}_{j_1},{t}_{j_2}\right)}^{\ast } \) from the MCS sample pool. Compute \( g\left[{\left({x}_{j_1}|{\boldsymbol{\theta}}_{j_1},{t}_{j_2}\right)}^{\ast}\right] \) and update the Kriging model gK(X| θ, t) by adding the selected new training sample in the training set. Then, go to Step 6.

-

Step 8.

Discretize the region [θL, θU] into Nθ points, i.e., θi(i = 1, 2, ⋯, Nθ), and the region [tL, tU] into Nt points, i.e., tj(j = 1, 2, ⋯, Nt).

-

Step 9.

For each discrete point {θi, tj}(i = 1, 2, ⋯, Nθ, j = 1, 2, ⋯, Nt), the TDFP Pf(θi, tj) can be estimated according to the samples in the MCS sample pool as follows.

-

Step 9.1. Search the samples which satisfy the inequality \( 0<{t}_{j_2}<{t}_j \) in the MCS sample pool, and judge whether each sample \( {x}_{j_1}\mid {\boldsymbol{\theta}}_{j_1}\kern0.5em \left({j}_1=1,2,\cdots, {N}_1^{(MCS)}\right) \) of input variable fails or not according to the indictor function shown in (16)

-

Step 9.2. The TDFP P{F(X, θ, tj)} can be estimated by (17).

-

Step 9.3. According to the failure samples of θ which satisfy the equation \( {I}_F\left({x}_{j_1}|{\boldsymbol{\theta}}_{j_1}\right)=1 \), the joint PDF fθ{θ| F(X, θ, tj)} can be estimated by the KDE technique.

-

Step 9.4. The TDFP Pf(θi, tj) can be estimated by (18).

-

Step 10.

After estimating the Nθ × Nt TDFPs, the TDFPF can be approximately obtained by the interpolation technique.

5 Test example

In this section, four examples, i.e., a mathematical example, a four-bar generator mechanism, an automobile front axle, and a corroded bending beam involving stochastic load, are employed to demonstrate the feasibility, accuracy, and effectiveness of the two proposed computational methods in estimating the TDFPF. In these examples, four methods, i.e., the DMCS, double-loop Kriging model (DLKM), single-loop Kriging model (SLKM), and AK-MCS-Bay, are used for comparison. In order to compare the accuracy of these four methods in estimating TDFPF, the mean relative error (MRE) is defined as follows:

where Nθ is the number of discrete points of θ, \( {P}_f^{(j)} \) represents the failure probability estimated by the DMCS and \( {\hat{P}}_f^{(j)} \) denotes the failure probability estimated by other new computational methods.

5.1 Example 1: A mathematical example

Consider a time-dependent limit state function Y = g(X, t) which is expressed by (Yun et al. 2017),

where t is the time variable, X1 and X2 are two independent input variables with normal distribution, i.e., \( {X}_1\sim N\left({\mu}_{X_1},{0.3}^2\right) \) and X2~N(3.5, 0.32). The mean value of X1 is taken as the design parameter, i.e., \( \boldsymbol{\theta} ={\mu}_{X_1} \) and θ ∈ [3, 4]. The interval of the service time te is chosen as te ∈ [0, 3].

At first, the DMCS is employed to estimate the TDFPF Pf(θ, te), where Nθ and Nt are both set to 10. Thereof, 10 × 10 = 100 time-dependent reliability analyses are needed in estimating TDFPF. In each time-dependent reliability analysis, the number of samples of the input variables is N1 = 104, and the number of samples of the time variable is N2 = 102. Thereof, the total number of model evaluations for the DMCS in estimating the TDFPF Pf(θ, te) is NM = NθNtN1N2 = 108. The results of the TDFPF Pf(θ, te) estimated by the DMCS are plotted in Fig. 2(a). Then, the AK-MCS-Bay is employed to estimate the TDFPF Pf(θ, te). The total number of model evaluations for constructing the AK model is 28, i.e., 10 initial samples and 18 updating samples. The estimates of the TDFPF Pf(θ, te) obtained by the AK-MCS-Bay are established in Fig. 2(b). From Fig. 2, it can be seen that the results of the DMCS and the AK-MCS-Bay are consistent with each other. To further compare the results obtained by the DMCS and the AK-MCS-Bay, respectively, Fig. 3 plots the TDFPs varying with service time te where θ is fixed at 3, and Fig. 4 plots the TDFPs varying with the design parameter θ where te is fixed at 3. The results in Figs. 3 and 4 also demonstrate that the AK-MCS-Bay is accurate enough in estimating the TDFPF compared with the DMCS.

In addition, the computational cost and MRE of the DMCS, DLKM, SLKM, and AK-MCS-Bay are listed in Table 1, where NOME denotes the number of model evaluations. From Table 1, it can be concluded that AK-MCS-Bay is more efficient than the two existing meta-models in estimating TDFPF, while they have similar precision.

5.2 Example 2: A four-bar generator mechanism

A four-bar generator mechanism (Du n.d.) shown in Fig. 5 consists of three rotatable bars and a fixed bar. The length of these bars is considered as input variables, i.e., X = (R1, R2, R3, R4), and the distribution types and parameters of these input variables are listed in Table 2. The mean value of R1 is viewed as the design parameter, i.e., \( \boldsymbol{\theta} ={\mu}_{R_1} \) and θ ∈ [50, 55]. The motion output can be easily derived by the following two equations:

where α denotes the motion input, and φ and δ represent the two motion outputs. By solving the equations defined in (21), φ and δ can be expressed as

where D, E, and F are given by the following equations:

The concerned motion output is φ, and the desired motion output function is assumed as

Thereof, by regarding the motion input α as the time variable t, the time-dependent limit state function of the four-bar generator mechanism can be indicated as

where C is the allowable threshold and it is set to 0.6 in this case. The lower limit of t is 95.5°, and the service time te is chosen as te ∈ [99.5, 125.5].

Firstly, the DMCS is used to estimate the TDFPF Pf(θ, te), where Nθ, Nt, N1, and N2 are chosen as 16, 14, 104, and 102, respectively. Thus, the total number of model evaluations for the DMCS in estimating the TDFPF Pf(θ, te) is NM = NθNtN1N2 = 2.24 × 108. The estimates of the TDFPF Pf(θ, te) obtained by the DMCS are plotted in Fig. 6(a). Next, the AK-MCS-Bay is used to estimate the TDFPF Pf(θ, te) of the four bar function generator mechanism. The total number of model evaluations for constructing the AK model is 101, i.e., 30 initial samples and 81 updating samples. The results of the TDFPF Pf(θ, te) estimated by the AK-MCS-Bay are plotted in Fig. 6(b). According to Fig. 6, it can be observed that the results of the DMCS and the AK-MCS-Bay are approximately consistent with each other. In order to further compare the estimates obtained by the two different computational methods, Fig. 7 plots the TDFPs varying with service time te where θ is fixed at 55 mm, and Fig. 8 plots the TDFPs varying with the design parameter θ where te is fixed at 125.5°. Figures 7 and 8 show that despite small differences between the estimates of these two computational methods which may be caused by the error of the KDE, they lead to the same changing trends. Besides, the results of the DMCS, DLKM, SLKM, and AK-MCS-Bay are shown in Table 3. According to Table 1, it can be seen that compared with other three methods, AK-MCS-Bay can dramatically reduce the computational cost in estimating TDFPF with accept precision.

5.3 Example 3: An automobile front axle

Consider the automobile front axle (Shi et al. 2017) shown in Fig. 9. The maximum normal stress and shear stress are σ = M/Wx and τ = T/Wρ, where M and T represent the bending moment and torque which are time-varying, i.e., \( M={M}_0\left(\frac{1}{10}\cos \frac{t}{4}+\frac{9}{10}\right) \) and \( T={T}_0\sin \frac{t}{3} \), in which M0 and T0 are initial bending moment and torque. Wx and Wρ denote the section factor and the polar section factor which are given as

In order to check the strength of the front axle, the limit state function is defined as

where σS is the ultimate stress of yielding, and it is set to σS = 460 Mpa. The distribution types and parameters of the six input variables, i.e., a, b, l, h, M0, and T0, are established in Table 4. The mean values of M0 and T0 are viewed as the design parameters, i.e., θ = [θ1, θ2] and \( {\boldsymbol{\theta}}_1={\mu}_{M_0}\in \left[3.4\times {10}^6,3.6\times {10}^6\right]N\cdot mm \), \( {\boldsymbol{\theta}}_2={\mu}_{T_0}=\left[3.0\times {10}^6,3.2\times {10}^6\right]N\cdot mm \). The service time te is chosen as te ∈ [3, 10].

In the DMCS, the sample number Nθ, Nt, N1, and N2 are chosen as 100, 15, 104, and 102, respectively. Thus, the total number of model evaluations for the DMCS in estimating the TDFPF Pf(θ, te) is NM = NθNtN1N2 = 1.5 × 109. In the AK-MCS-Bay, the total number of model evaluations for constructing the AK model is 154, i.e., 50 initial samples and 101 updating samples. In order to compare the results of the TDFPF Pf(θ, te) estimated by the two computational methods, the TDFPs varying with the two-dimensional design parameters where the service time is fixed at 4, 7, and 10, respectively, are plotted in Figs. 10, 11, and 12. Meanwhile, Fig. 13 plots the TDFPs varying with service time te where θ1 is fixed at 3.6 × 106N ⋅ mm and θ2 is fixed at 3.2 × 106N ⋅ mm. From Figs. 10, 11, 12, and 13, it can be observed that the results obtained by the AK-MCS-Bay are approximately consistent with those obtained by the DMCS. Furthermore, the MRE and NOME of the DMCS, DLKM, SLKM, and AK-MCS-Bay are established in Table 5. Table 5 indicates that AK-MCS-Bay is more efficient than DLKM and SLKM in estimating TDFPF of this example, while the precision of AK-MCS-Bay is not lower than that of SLKM.

5.4 Example 4: A corroded bending beam involving stochastic load

In this subsection, a corroded bending beam (Fig. 14) involving stochastic load is employed from refs. (Zhang et al. 2017; Hu and Du 2015b; Feng et al. 2019c) as the fourth example. The time-dependent limit state function of this corroded bending beam is defined as

where a0 and b0 denote the width and height of the beam, respectively, σu represents the ultimate strength, ρst = 7.84 × 104N, k = 5 × 10−5m/year, and L = 5m are the density, corrosion coefficient, and the length of the beam, and F(t) is a stochastic process modeled by (Shi et al. 2017)

in which ξi(i = 1, 2, ⋯, 7) are seven independent random variables, aij, bij, cij(∀i, j = 1, 2, ⋯, 7) are coefficients of the sine wave basis functions, i.e.,

By transforming the input stochastic process F(t) into (29), this time-dependent problem Y = G(α, β(t), t) is transformed into Y = g(X, t) where X is a 10-dimensional input random variable vector, and its distribution type and parameters are listed in Table 6. The mean values of a0 and b0 are viewed as the design parameters, i.e., θ = [θ1, θ2] and \( {\boldsymbol{\theta}}_1={\mu}_{a_0}\in \left[0.15,0.2\right]m \), \( {\boldsymbol{\theta}}_2={\mu}_{b_0}=\left[0.03,0.04\right]m \). The service time te is chosen as te ∈ [0, 35]year.

At first, the DMCS is adopted to estimate the TDFPF Pf(θ, te), where Nθ, Nt, N1, and N2 are chosen as 100, 7, 104, and 102, respectively, which causes the total number of model evaluations to NM = NθNtN1N2 = 7 × 108. In the AK-MCS-Bay, the total number of model evaluations for constructing the AK model is 379, including 50 initial samples and 329 updating samples. In order to compare the results of the TDFPF Pf(θ, te) estimated by DMCS and AK-MCS-Bay, the TDFPs varying with the design parameters where the service time is fixed at 10, 35, respectively, are plotted in Figs. 15 and 16. Furthermore, Fig. 17 plots the TDFPs varying with service time te in which θ is fixed at [0.2, 0.04]. Based on Figs. 15, 16, and 17, it can be seen that the results acquired by the AK-MCS-Bay are approximately consistent with those obtained by the DMCS. In addition, the results of the DMCS, DLKM, SLKM, and AK-MCS-Bay are shown in Table 7. From Table 7, it can be observed that compared with DMCS, DLKM, and SLKM, AK-MCS-Bay can greatly reduce the computational cost in estimating TDFPF with accept precision, and the relatively large error of AK-MCS-Bay may be mainly caused by the error of the KDE.

6 Conclusion

In this paper, the concept of the TDFPF is proposed for facilitating the reliability-based design optimization for the time-dependent problem. The TDFPF is a function of the TDFP with respect to the design parameters θ and the service time te. In order to estimate the whole TDFPF, two computational methods, i.e., the DMCS and the AK-MCS-Bay, are developed. In the DMCS, the regions of the design parameters θ and service time te are discretized to some points at first. Then, the double-loop MCS is employed to estimate the TDFP for each discrete point. Despite that the DMCS is accurate and easy to implement in estimating the TDFPF, it needs a great deal of model evaluations for the complicated engineering problem with small TDFP. Thereof, to efficiently estimate the TDFPF, the AK-MCS-Bay is introduced. In the AK-MCS-Bay, the Bayes formula is employed to transform the TDFPF Pf(θ, te) into three components, i.e., the pre-defined probability density function (PDF) of θ, the conditional PDF of θ based on the time-dependent failure event, and the augmented TDFP by regarding both the input variables and design parameters as random variables. Next, a single Kriging model is constructed so as to efficiently estimate all the TDFPs under different service times te. At the same time, the conditional PDF of θ based on the time-dependent failure event can be also acquired on the basis of the samples in the failure domain by the KDE method. Finally, the TDFP at any combination of the design parameters and service time can be evaluated. Four numerical examples are used to demonstrate the feasibility, accuracy, and effectiveness of the two proposed computational methods. The results illustrate that compared with DMCS, the proposed AK-MCS-Bay computational method can greatly reduce the total number of model evaluations with acceptable precision. The error of AK-MCS-Bay mainly comes from two sources, the first one is the error of the adaptive Kriging model which can be reduced by increasing the sample pool size or improving the required confidence level; the second one is the error of KDE which is the mainly error source because the existing density estimation method may lose accuracy in dealing with high-dimensional problems. In the future, a widely used density estimation technique will be possibly explored to further improve the accuracy of the proposed method.

References

Au SK (2005) Reliability-based design sensitivity by efficient simulation. Comput Struct 83(14):1048–1061

Au SK, Beck JL (2001) Estimation of small failure probabilities in high dimensions by subset simulation. Probab Eng Mech 16(4):263–277

Botev ZI, Grotowski JF, Kroese DP (2010) Kernel density estimation via diffusion. Ann Stat 38:2916–2957

Ching JY, Hsieh YH (2007) Local estimation of failure probability function and its confidence interval with maximum entropy principle. Probab Eng Mech 22:39–49

Du XP Time-dependent mechanism reliability analysis with envelope functions and first-order approximation. J Mech Des 136(8):081010

Du XP, Sudjianto A (2004) The first order saddle point approximation for reliability analysis. AIAA J 42(6):1199–1207

Echard B, Gayton N, Lemaire M (2011) AK-MCS: an active learning reliability method combining Kriging and Monte Carlo simulation. Struct Saf 33:145–154

Enevoldsen I, Sorensen JD (1994) Reliability-based optimization in structural engineering. Struct Saf 15:169–196

Fan CQ, Lu ZZ, Shi Y (2019) Time-dependent failure possibility analysis under consideration of fuzzy uncertainty. Fuzzy Sets Syst article in press

Feng KX, Lu ZZ, Yun WY (2019a, article in press) Aircraft icing severity analysis considering three uncertainty types. AIAA J. https://doi.org/10.2514/1.J057529

Feng KX, Lu ZZ, Ling CY, Yun WY (2019b) An innovative estimation of failure probability function based on conditional probability of parameter interval and augmented failure probability. Mech Syst Signal Process 123:606–625

Feng KX, Lu ZZ, Pang C, Yun WY (2019c) Time-dependent failure credibility analysis and its optimization based computational methods. Eng Struct 181:605–616

Gasser M, Schueller GI (1997) Reliability-based optimization of structural systems. Math Meth Oper Res 46(3):287–307

Ghanem RG, Spanos PD (2003) Stochastic finite elements: a spectral approach. Springer, New York

Hammersley A, Svensson S, Hanfland M, Fitch A, Hausermann D (1996) Two-dimensional detector software: from real detector to idealised image or two-theta scan. Int J High Pressure Res 14(4–6):235–248

Hu Z, Du XP (2012) Reliability analysis for hydrokinetic turbine blades. Renew Energy 48(1):251–262

Hu Z, Du XP (2013) Time-dependent reliability analysis with joint upcrossing rates. Struct Multidiscip Optim 48:893–907

Hu Z, Du X (2015a) First order reliability method for time-variant problems using series expansions. Struct Multidiscip Optim 51(1):1–21

Hu Z, Du XP (2015b) Mixed efficient global optimization for time dependent reliability analysis. J Mech Des 137(5):051401

Hu Z, Mahadevan S (2016) A single-loop kriging surrogate modelling for time-dependent reliability analysis. J Mech Des 138(6):061406

Hu Z, Li HF, Du XP (2013) Simulation-based time-dependent reliability analysis for composite hydrokinetic turbine blades. Struct Multidiscip Optim 47:765–781

Izenman AJ (2008) Modern multivariate statistical techniques: regression, classification and manifold learning. Spring-Verlag, New York

Jensen HA (2005) Structural optimization of linear dynamical systems under stochastic excitation: a moving reliability database approach. Comput Methods Appl Mech Eng 194(12–16):1757–1778

Li CQ (1995) Computation of the failure probability of deteriorating structural systems. Comput Struct 56(6):1073–1079

Li CC, Der Kiureghian A (1993) Optimal discretization of random fields. J Mech Des 119(6):1136–1154

Meng Z, Zhang DQ, Liu ZT, Li G (2018) An adaptive directional boundary sampling method for efficient reliability-based design optimization. J Mech Des 140(12):121406

Meng Z, Zhang DQ, Li G, Yu B (2019) An importance learning method for non-probabilistic reliability analysis and optimization. Struct Multidiscip Optim 59(4):1255–1271

Okuda S, Yonezawa M, Shao S et al (1997) Time-dependent structural reliability analysis based on directional simulation. Trans Jpn Soc Mech Eng 63(612):1771–1777

Papadrakakis M, Lagaros ND (2002) Reliability-based structural optimization using neural networks and Monte Carlo simulation. Comput Methods Appl Mech Eng 191(32):3491–3507

Park BU, Marron JS (1990) Comparison of deta-driven bandwidth selectors. J Am Stat Assoc 85:66–72

Sacks J, Schiller SB, Welch WJ (1989) Design for computer experiment. Technimetrics 31(1):41–47

Saltelli A, Ratto M, Andres T, Campolongo F, Cariboni J, Gatelli D et al (2008) Global sensitivity analysis. The primer. John Wiley and Sons, Chichester

Scott DW (1992) Multivariate density estimation: theory, practice, and visualization. Wiley, New York

Shi Y, Lu ZZ, Cheng K, Zhou YC (2017) Temporal and spatial multi-parameter dynamic reliability and global reliability sensitivity analysis based on the extreme value moments. Struct Multidiscip Optim 56(1):117–129

Stein M (1987) Large sample properties of simulations using Latin hypercube sampling. Technimetrics 29(2):143–151

Wang ZQ, Wang PF (2012) A nested extreme response surface approach for time-dependent reliability-based design optimization. J Mech Des 134(12):121007

Wang ZQ, Wang PF (2015) A double-loop adaptive sampling approach for sensitivity-free dynamic reliability analysis. Reliab Eng Syst Saf 142:346–356

Xu LY, Lu ZZ, Xiao SN (2019) Generalized sensitivity indices based on vector projection with multivariate outputs. Appl Math Model 66:592–610

Yuan XK (2013) Local estimation of failure probability function by weighted approach. Probab Eng Mech 34:1–11

Yun WY, Lu ZZ, Jiang X, Zhao LF (2017) Maximum probable life time analysis under the required time-dependent failure probability constraint and its meta-model estimation. Struct Multidiscip Optim 55:1439–1451

Yun WY, Lu ZZ, Jiang X (2019a) A novel step-wise AK-MCS method for efficient estimation of fuzzy failure probability under probability inputs and fuzzy state assumption. Eng Struct 183:340–350

Yun WY, Lu ZZ, Jiang X (2019b) An efficient method for moment-independent global sensitivity analysis by dimensional reduction technique and principle of maximum entropy. Reliab Eng Syst Saf. article in press

Yun WY, Lu ZZ, Jiang X (2019c) AK-SYSi: an improved adaptive Kriging model for system reliability analysis with multiple failure modes by a refined U learning function. Struct Multidiscip Optim 59(1):263–278

Zhang J, Ellingwood B (1994) Orthogonal series expansions of random fields in reliability analysis. J Mech Des 120(12):2660–2677

Zhang DQ, Han X, Jiang C, Liu J (2017) Time-dependent reliability analysis through response surface method. J Mech Des 139:041404

Zhao YG, Ono T (2001) Moment method for structural reliability. Struct Saf 23(1):47–75

Zhou YC, Lu ZZ, Cheng K, Yun WY (2019) A Bayesian Monte Carlo-based method for efficient computation of global sensitivity indices. Mech Syst Signal Process 117(15):498–516

Zou T, Mahadevan S (2006) A direct decoupling approach for efficient reliability-based design optimization. Struct Multidiscip Optim 31(3):190–200

Funding

This work was supported by the National Natural Science Foundation of China (Grant No. NSFC 51775439) and the Innovation Foundation for Doctor Dissertation of Northwestern Polytechnical University (Grant No. CX201934).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Responsible Editor: Byeng D Youn

Replication of results

The original codes of the three numerical examples in the Sect. 5 are available in the Supplementary materials, i.e., Test 1.m, Test 2.m, Test 3.m, and Test 4.m.

Rights and permissions

About this article

Cite this article

Feng, K., Lu, Z., Ling, C. et al. Efficient computational method based on AK-MCS and Bayes formula for time-dependent failure probability function. Struct Multidisc Optim 60, 1373–1388 (2019). https://doi.org/10.1007/s00158-019-02265-z

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00158-019-02265-z