Abstract

The world is now experiencing the first real global energy crisis, the effects of which will be felt for many years to come. Fossil fuels have accounted for more than 80% of the world’s energy requirements for decades. The cost of coal has reached record highs, while the price of oil reached at it’s peak in the middle of 2022 at well over 100 US dollars per barrel before declining. Rising energy costs of fossil fuels are driving a significant wealth shift from consumers to producers. The primary causes of the growing level of carbon dioxide in the atmosphere are fossil fuels. Stated Policy Scenario predicts a 1% annual growth in primary energy demand through 2030, which will be mostly satisfied by greater usage of renewable energy sources. Biodiesel is gaining popularity as a means of supplying energy since it is a renewable fuel, non-toxic, biodegradable, and locally available using recycled or agricultural materials with a lesser environmental effect. Biodiesel refers to a non-petroleum-based diesel fuel consisting of short-chain esters, made by using numerous resources, which can be used (alone or blended with conventional diesel) in an unmodified diesel engine. The greenhouse gas emission for biodiesel is 74% lesser as compared to diesel fuel. With the widespread implementation of blending rules, the usage of biofuels rises to 5.5 million barrels of oil equivalent per day (mboe/day) in 2030 from 2.2 mboe/day in 2022. This study explores the numerous rare biodiesel feedstock, production, fatty acid content, physical properties and their effect on diesel engine output behaviour. These resources contain a large amount of free fatty acids and triglycerides which are usually used in the preparation of biodiesel. Since biodiesel has a higher oxygen content and a lower energy content than diesel fuel, it often offers better brake thermal efficiency, brake specific fuel consumption, NOx emission, and decreased HC, CO and smoke emissions at some blending ratio. The exhaust gas recirculation assembly in the engine reduces the NOx emission. The incorporation of non-additive in biodiesel blend acts as a catalyst during the combustion process and improves engine combustion by increasing the surface area of combustion. Biodiesel is clean energy and can be a promising future energy source for diesel engines.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

As the population grows, so does the need for energy. Energy has revolutionised human lifestyles over the past several centuries, and new sources of energy are being discovered to meet the demand. Basic sources of energy in the ancient times have included human muscles, plants, timber and crops, as well as decaying animal corpses. As the industrial revolution progressed, a plethora of energy resources became available for the generation of various forms of energy. In the current scenario, some energy sources include fossil fuels energy, hydro-energy, nuclear energy and renewable energy. During the industrialisation period, energy is mostly obtained from fossil fuels. The combustion of fossil fuels has a variety of adverse consequences, including abrupt climate change, global warming and the release of greenhouse gases. Every year, millions of species die as a result of air pollution, which is mostly caused by the burning of fossil fuels. As per the International Energy Agency, the world is now experiencing the first really global energy crisis, the effects of which will be felt for many years to come. The unprovoked Russian invasion of Ukraine in February had a profound effect on the global energy system, upsetting supply and demand trends and shattering long-standing trade alliances. The cost of coal has reached record highs, while the price of oil peaked in the middle of 2022 at well over 100 US dollars per barrel before declining. For decades, the proportion of fossil fuels in the world’s energy mix has remained persistently high, at over 80%. In the Stated Policy Scenario, this percentage decreases to less than 75% by 2030 and to little around 60% by 2050. In the Stated Policy Scenario, the globe struggles with the energy price shocks of today, with some areas returning to earlier patterns and others seeing a quicker move to renewable energy and end-use electrification due to stronger decarbonisation policies. The Stated Policy Scenario predicts a 1% annual growth in primary energy demand through 2030, which will be mostly satisfied by greater usage of renewable energy sources. Under the Stated Policy Scenario, renewable energy sources continue to grow more quickly than any other source of energy. Wind and solar PV continue to dominate the expansion of renewable electricity, which is primarily supplemented by hydropower, biofuels and geothermal energy. In addition, because of the widespread implementation of blending rules, the usage of biofuels rises to 5.5 million barrels of oil equivalent per day (mboe/day) in 2030 from 2.2 mboe/day in 2022. The use of renewable energy sources helps reduce the amount of carbon. In the Stated Policy Scenario, worldwide energy-related CO2 emissions peak in 2025 at 37 billion tonnes (Gt) year and then decline to 32 Gt by 2050. According to the Net Zero Emissions (NZE) by 2050 Scenario, CO2 emissions will be nil in 2050 and will drop to 23 Gt in 2030, which is compatible with keeping global warming to less than 1.5 °C in 2100. As a potential replacement for diesel and a means of reducing the energy problem, biodiesel has a lot of potential in the upcoming decades. Biodiesel is a fuel with the designation B100 that complies with ASTM D6751 specifications and is made up of mono-alkyl esters of long-chain fatty acids obtained from vegetable oils or animal fats (International Energy Agency 2022). Biodiesel is created using a variety of plant oils (such as soybean, cottonseed, canola and corn oils), recycled cooking greases or oils (such as yellow grease), animal fats (such as beef tallow and swine lard), or recycled cooking greases and oils. Used cooking oils are mostly made of plants, although they may also include animal fats. Cooking oil waste may be recycled and is renewable. New feedstocks are being created, and they could soon be made available on the market, as biodiesel production and consumption rise. Numerous resources can be used to produce biodiesel, which has many benefits. Biodiesel has the following benefits: it is renewable that does not have any sulphur or polycyclic aromatic compounds in it; it can replace fossil diesel fuel; biodiesel can be used directly in existing diesel equipment with slight to no modification; it can lower greenhouse gas emissions; it is compatible with new technology diesel engines; it can reduce engine exhaust emissions, including air toxics; biodiesel is nontoxic and biodegradable; it is appropriate for sensitive environments; biodiesel can be made locally using recycled or agricultural materials. Greenhouse gas emissions are drastically reduced when biodiesel is used instead of petroleum. In comparison to fossil fuel diesel, B100 has been determined to produce 74% less greenhouse gas emissions across its whole life cycle (O’Connery 2010). Biodiesel helps to reduce the dependency on foreign energy sources (Mishra and Goswami 2018). Nowadays, biodiesel become an alternative and economical source of renewable energy. Sodium hydroxide (NaOH), potassium hydroxide (KOH), and other homogeneous and heterogeneous catalysts in presence of alcohol are used throughout the transesterification process to produce biodiesel (Atabani et al. 2013).

As far as biodiesel is concerned, more than 350 sources of fats and oils have the potential to be used to make biodiesel, although more than 95% of biodiesel is made from edible vegetable oils (Sierra-Cantor & Guerrero-Fajardo 2017). Brazil, USA, Malaysia, Argentina, Spain, Belgium and Germany are some of the biggest biodiesel producers and meet the 80% demand of biodiesel (Rezania et al. 2019). A significant replacement for diesel made from petroleum is microdiesel, which is produced by microorganisms utilising renewable resources as carbon sources (Bhatia et al. 2017). The biodiesel burns similarly to fossil fuels up to a certain biodiesel–diesel blending ratio and does not need any modifications to current engines (A. Saravanan et al. 2020). There have been reports of the production of biodiesel using a variety of food oils, including sunflower, maize, mustard palm, soybean, canola and coconut oils. Ahmad et al. (2022) have critically examined the catalytic transesterification reaction’s use in the generation of biodiesel from coconut oil. Öztürk and Can (2022) have evaluated the performance and emission behaviour of direct-injection diesel engines running on canola oil biodiesel–diesel blends under various operating conditions. Rezania et al. (2022) have produced biodiesel from wild mustard seed oil using a heterogenous nanoparticle catalyst and found more than 90% biodiesel yield. Rama Krishna Reddy et al. (2022) have analysed the diesel engine’s performance, combustion and emission characteristics while using corn-based biodiesel blends. Foroutan et al. (2022) have studied the biodiesel production from sunflower oil using the composite catalyst. Jayakumar et al. (2022) investigated the direct-injection diesel engine emission and performance behaviour fuelled with soybean biodiesel.

The utilisation of edible oil for biodiesel creates the problem of food security and hike in edible oil prices. The largest producers of biodiesel are the USA, Brazil, Indonesia, etc. Biodiesel produced from edible oil requires a large area of agriculture land that causes a dispute between food and fuels (Lustig 2009). Some important edible oil resources used for the production of biodiesel are soybean, sunflower and palm which leads to problems like starvation in developing countries (Anwar et al. 2010). Although neat edible oil poses a threat to food security, it is the most easily convertible feedstock for biodiesel production. In addition, for so many, the edible oil crop plantation is already well established, with certain crops generating good quality oil that delivers the greatest conversion to biodiesel via the transesterification process. A sustainable plantation can resolve the problem associated with edible oil biodiesel (Janaun and Ellis 2010). Many non-edible oils like Jatropha, castor, karanja, neem, tobacco and mahua have also been studied widely for biodiesel production. Singh et al. (2022) have produced biodiesel from Jatropha oil employing heterogeneous catalyst and optimise the engine performance and emission output fuelled with Jatropha biodiesel blend. Attia et al. (2022) have examined the diesel performance and particulate emission behaviour at different blending ratios of castor biodiesel in neat diesel. Kishore Khatri et al. (2023) have developed the predictive modelling for diesel engine performance behaviour fuelled with karanja biodiesel, using artificial neural network tool. Ansari et al. (2022) investigated the diesel engine performance and emission characteristics using mahua biodiesel–diesel blend. Vinodkumar and Karthikeyan (2022) have examined the diesel engine behaviour using neem biodiesel with an injection of n-decanol in the manifold. Arivarasu et al. (2023) have done work on production of biodiesel from tobacco seed oil by employing a tungstophosphoric acid catalyst. Due to the presence of some toxic substances, non-edible oils are not suitable for human foods. Non-edible resources of biodiesel require land that are not productive for crops (A. L. Ahmad et al. 2011). Some research shows that non-edible oil resources used for the production of biodiesel have the advantage over edible oil resources like resolving the problems of fuel versus food, environmental as well as economic issues related to edible oils resources (Gui et al. 2008). Generally, non-edible oils like waste oil, grease and animal fats are called ‘lipids’ (Rajak and Verma 2018). As compared to edible and non-edible oils, waste oils provide more efficiency. Waste oil consists of tallow, waste cooking oil, chicken fat, by-product of fish oil, etc. Waste oils possess more amount of ‘triglycerides’ contained in their composition which is very useful in the production of biodiesels by the process of transesterification in the presence of some alcoholic catalysts. Biodiesels produced from waste oils are more economical and eco-friendly as compared to biodiesel produced from edible and non-edible oils (Al-Kahtani 1991). Waste oils can be collected from various sources like restaurants, households and fast-food factories and then further recycled to come in use as a biofuel resource (Canakci 2007). Waste oil production has grown as a consequence of rising food consumption. In Spain, Canada and the EU, respectively, around 4000, 135,000 and 7000–10,000 tonnes of WCO are generated annually (Chhetri et al. 2008). García-Martín et al. (2018) have done an investigation on production of biodiesel from waste cooking oil and used this biodiesel as a fuel to analyse the performance behaviour of turbocharged diesel engine. Sivakumar et al. (2014) investigated the utilisation of cashew nut shell oil in diesel engine. The study reveals that the oil properties are nearly similar to the diesel fuel and it can be used in diesel engine as biofuel. Deepalakshmi et al. (2014) converted discarded avocado seed directly into biodiesel. The procedure used is in situ solvent-aided alkali-catalysed transesterification and found 94.4 wt.% biodiesel yield. Pandian Sivakumar et al. (2013) have explored the production of biodiesel from Ceiba pentandra oil. Two-step acid–base transesterification served as the catalyst for the process. The conversion of biodiesel was measured to be 99.5% under optimal conditions of 1.0 wt.% KOH, 6:1 methanol oil molar ratio and at 65 °C for 45 min. See et al. (2022) used fuzzy optimisation tool for biodiesel production from karanja oil. The optimised conditions of the process were obtained as 5:1 methanol/oil ratio, catalyst loading of 0.85 wt.%, 79% duty cycle and time 89.35 min. From the last few years, microalgae possesses some excellent features like their high growth rate, availability and oil content (triglycerides) and do not require any high quality of agricultural land for their growth (Scott et al. 2010). The processes involved in the production of biodiesel are very challenging. The challenges are in releasing the lipids from their intracellular location in the most energy-efficient and economical way possible, avoiding the use of large amounts of solvents, such as hexane, and utilising as much of the carbon in the biomass as liquid biofuel as possible, potentially with the recovery of minor high-value products (Krohn et al. 2011). There are many challenges which are associated with biodiesel production and use. The challenges are feedstock availability at large scale, cost-effective production of fuel, the policy of a country, lack of customer awareness about biodiesel and availability of infrastructure (Kant Bhatia et al. 2021).

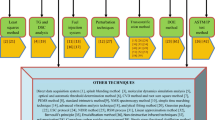

In the past, only a few researchers undertook a detailed investigation of the numerous uncommon accessible feedstocks for biodiesel synthesis and their application as fuel for diesel engine behaviour studies. The current endeavour aims to investigate some uncommon feedstock for biodiesel production. In this study, a novel comprehensive review is done on the availability of uncommon biodiesel feedstock, biodiesel production, fatty acid composition, the properties of resources and their biodiesel, as well as the effect of different blending proportions of biodiesel on diesel output behaviour. The feedstock that have been discussed in this work are Prosopis juliflora oil, sea mango oil, Parinari polyandra oil, Ailanthus altissima oil, Michelia champaca oil, Abrus precatorius oil, Crambe abyssinica oil, Aegle marmelos, Eichhornia crassipes oil, Cuphea oil, lemon grass oil, cedar wood oil, Shorea robusta oil, Melia azedarach oil, jojoba oil, Garcinia indica oil, taramira oil, Raphanus sativus L. oil, many strains of microalgae, Chukrasia tabularis, industrial waste and other feedstock.

Fatty Acid Composition of Biodiesel Feedstock

Fatty acid composition is an essential parameter for any biodiesel feedstock since it impacts the efficiency of the biodiesel production process. The quantity and type of fatty acid composition are mostly determined by plant species and growing circumstances. The various fatty acids that are generally found in the biodiesel feedstock are caprylic acid, capric acid, lauric acid, myristic acid, palmitic acid, palmitoleic acid, stearic acid, oleic acid, linoleic acid, linolenic acid, ricinoleic acid, arachidice acid, eicosenoic acid, eicosadienoic acid, behenic acid, tricosanoic acid, lignoceric acid, nervonic acid and keto acid. The fatty acid content of different biodiesel feedstock proven appropriate for biodiesel production is shown in Table 1.

Characteristics of Feedstock and Biodiesel

The physical properties of biodiesel feedstock and biodiesel have been presented in Tables 2 and 3, respectively. The physical characteristics of biodiesel feedstock determine whether a particular oil is appropriate for producing biodiesel or not. Similarly, the physical characteristics of biodiesel have also been discussed. The physical characteristics of biodiesel fall under the ASTM, IS, EN or other standards for use in the engine.

Transesterification summary biodiesel feedstock

The transesterification method for biodiesel production is one of the most effective and widely used ways. The high biodiesel yield is one of the advantages of this method. The transesterification method to produce biodiesel from some rare feedstock is presented in Table 4.

Feedstocks and Engine Behaviour

The various rare feedstock-related details for biodiesel production and the effect of biodiesel on engine performance and emission characteristics are discussed below.

Prosopis juliflora

It belongs to the family of the Fabaceae and grows primarily in dry tropical climatic conditions. Prosopis juliflora is a shrub that is found in Mexico, Venezuela, Peru and the Caribbean, and it is used to treat poison and in making medicine or biodiesels (Asokan et al. 2019). It is also found in the southern part of India (Masimalai and Kuppusamy 2015). The fruit of Prosopis julifera is flattened and straight, measuring 6–30 cm in length, 5–16 mm in width and 4–9 mm in thickness. The mature pods will enlarge, become pulpy and appear yellowish brown in colour. Up to 6.5 mm in length, seeds weigh between 0.25 and 0.3 g (25,000–30,000 seeds/kg). Depending on the circumstances and ecology, pod output may range from 5 to 40 kg per tree (Rajeshwaran et al. 2018). Biodiesel produced with the help of Prosopis juliflora seed oil has flash point, specific gravity and kinematic viscosity which are more than diesel, and the calorific value of diesel is more than biodiesel due to the presence of oxygen in biodiesel (Asokan et al. 2019). The production of biodiesel with the Prosopis juliflora seed oil was done by the process of transesterification (Islam et al. 2015). Soon, Prosopis juliflora might serve as an appealing alternative biodiesel feedstock and the average oil production is 5000 l/ha (Ramalingam et al. 2020). As these plants thrive in salty soil, they have little competition for farmland. Oleic acid is dominant in the concentration of Prosopis juliflora seed oil. Figure 1 shows the Prosopis juliflora tree and the Juliflora seed is depicted in Fig. 2. The engine performance and emission characteristics of the engine with Prosopis juliflora biodiesel are shown in Table 5.

Prosopis juliflora tree (Asokan et al. 2019)

Prosopis juliflora seed (Ramalingam et al. 2020)

Cymbopogon citratus (Lemon Grass)

Lemon grass is a plant that produces lemon grass oil. It is obtained from lemon which is found in Australia and Asia. Approximately 90% of lemon grass oil is created and 250 tonnes of oil is refined in an area of 4000 ha in the waste lands of India (Kotaiah et al. 2020). The engine behaviour with lemon grass biodiesel is discussed in Table 6.

Tamarindus indica L. (Tamarind)

Tamarind seed oil is produced from the seed of the tamarind tree. It has a long life span to grow up to a medium height of 12–30 m. Tamarind tree is found in Africa, Pacific islands, Sri Lanka, Malaysia and India; Thailand has the largest plantation of tamarind tree. In India, tamarind tree is mainly found in Maharashtra, Karnataka and Tamil Nadu. The saponification value of tamarind seed oil is 186 mg/g. Oil content of tamarind seed oil is found between 7 and 8%/kg of seeds. Tamarind seed oil contains fatty acids like lauric acid (0.3%), oleic acid (19.6–27%), palmitic acid (8.7–14.8%), linoleic acid (7.5–55.4%) and arachidic acid (3.7–12.2%) (Kumbhar et al. 2022). The tamarind seed and fruit are shown in Figs. 3 and 4, respectively. Table 7 presents the engine behaviour with tamarind biodiesel blend.

Tamarind seed for oil extraction (Idris et al. 2022)

Tamarind fruit (Dhana Raju et al. 2018)

Cerbera odollum (Sea Mango)

Cerbera odollum is also called sea mango. The Cerbera odollum tree is very toxic since it is a member of the Apocynaceae family (Gaillard et al. 2004). Cerbera odollam survives in the salt marshes and coastal streams of southern India, as well as in the middle and southern regions of Vietnam, Cambodia, Sri Lanka, Myanmar, Madagascar and Malaysia (Kumar and Sharma 2011). The sea mango tree is around 12 m in height and is evergreen. Fruits of this tree are 5–10 cm in length and have an egg form, while the leaves are glossy dark green and grouped in a spiral (Rohith Renish et al. 2021). This tree is often found along the coasts of South India, Malaysia, Vietnam, Sri Lanka, Madagascar and Myanmar (Renish et al. 2022a). The seed of sea mango contains 54% oil (Kumar and Sharma 2011). Among the Cerbera odollam oil’s fatty acids, oleic acid makes up 48.1%, palmitic 30.3%, linoleic 17.8% and stearic 3.8% (Kansedo et al. 2009). A viable substitute feedstock for the production of biodiesel is Cebrera odollam oil (Kansedo et al. 2009). Sea mango fruit is depicted in Fig. 5. The performance and emission behaviors of a diesel engine fueled with sea mango biodiesel are presented in Table 8.

Parinari polyandra L. (Sand Apple)

Parinari polyandra is also known as the sand apple. The Parinari polyandra seed is often found in West Africa. It comes from the Rosaceae family, which mostly grows in tropical savanna regions. These places include Nigeria, Ghana, Senegal, Ivory Coast, Mali, Cameroon and Sudan. Evergreen Parinari polyandra trees may grow to heights of 10–12 m. Its profile is low and bushy, and its bark is smooth. The blossoms are fleshy and are around 1.3–2 cm in length. The freshly harvested seed kernel has an oil content ranging from 31 to 60%, based on the variety and the time of year it was harvested (Ogunkunle and Ahmed 2019b). It has been discovered that the Parinari polyandra seed oil has a high oil yield content, which may be used for the manufacturing of biodiesel and alkyd resin (Motojesi et al. 2011). For fruits harvested in April, the main components of Parinari polyandra benth seed oil are n-hexadecanoic acid (46.3%), 9,12-octadecadienoic acid (18.10%) and phytol (26.0%), whereas for fruits harvested in November, the main components are n-hexadecanoic acid (4.69%), 9,12-octadecadieonic acid (8.31%), arachidonic acid (43.38%) and stigmasterol (13.41%) (Ogunkunle and Ahmed 2019b). The research revealed that the oil extracted from seeds collected in April of the year would be suitable for the production of biodiesel (Motojesi et al. 2011). The fruit and nut of Parinari polyandra feedstock are shown in Fig. 6.

Parinari polyandra fruit and nut (Ogunkunle and Ahmed 2019a)

The performance of CI engine sand apple ethyl ester used with its blends B5, B10, B15, B20 and B25 has been evaluated. It is observed that BSFC is decreased from 4.50 to 3.59 g/kWh when the loading condition increased. BSFC for B5, B10, B15, B20 and B25 ranges from 5.16 to 4.73, 6.12–5.38, 6.97–6.34, 8.68–6.98 and 11.46–9.47 g/kWh, respectively. BTE decreases when the load on the specimen increases. BTE for B5, B10, B15, B20 and B25 ranges from 76.98 to 83.97, 64.54–73.62, 56.86–62.46, 45.64–56.73 and 34.84–42.13%, respectively (Saleh et al. 2021). The diesel engine testing has been done with automotive gas oil and biodiesel blends B5, B10, B15 and B20. It is observed that BSFC is increased when the loading condition increases. BSFC for B5, B10, B15 and B20 ranges from 4.73 to 5.6, 5.38–6.12, 6.34–6.97 and 6.98–8.68 g/kWh, respectively. Brake thermal efficiency increases for the B5 blend when the load on the specimen increases. BTE for B5, B10, B15 and B20 ranges from 71.26 to 16.26, 15.29–14.02, 13.07–12.43 and 11.95–10.64%, respectively (Ahmed 2018). Engine emissions and engine performance analysis is done for diesel engines fuelled with Parinari polyandra biodiesel and its blends B10, B20 and B30. In the performance testing of biodiesel blends in marine diesel engines, the BSFC is increased when the content of biodiesel increased in the blended fuel. BTE increased when the biodiesel content increased in blended fuel. For B10, B20 and B30, total CO2 emission is reduced by 53.8%, 33.5% and 21.7% as compared to diesel. For B10, B20 and B30, total CO emission is reduced by 53.4%, 67.8% and 81.7% as compared to diesel. For B10, B20 and B30, total hydrocarbon emissions is reduced by 7.8%, 11.0% and 13.8% as compared to diesel (Ogunkunle and Ahmed 2020).

Ailanthus altissima (Tree of Heaven)

Ailanthus altissima is also called the fruit of the tree of heaven. Ailanthus altissima belongs to the Simaroubacae family. The growth rate of Ailanthus altissima tree roots and leaves is very high compared to other oil resources of biodiesel resources. The plant of Ailanthus altissima is environment-friendly. The tree of Ailanthus altissima grows up to 12–18 m; within 25 years after cultivation, they start to produce seeds which amount to around 80,000 seeds per tree and increase up to 3 lakhs, and weight of Ailanthus altissima seeds varies from 7 to 22 kg (Hoseini et al. 2020). The Ailanthus tree, shrub and seed are shown in Figs. 7, 8 and 9, respectively. The emission and performance of diesel engine running on Ailanthus altissima biodiesel is presented in Table 9.

Ailanthus tree (Hoseini et al. 2018a)

Ailanthus tree shrub (Hoseini et al. 2020)

Ailanthus seed (Hoseini et al. 2018a)

Michelia champaca L.

Michelia champaca is an evergreen tree. Michelia champaca belongs to the Magnoliaceae family, which has 9 genera and 70 species. It is a tall, attractive evergreen tree with a straight stem and smooth, dark-brown bark. The tree blooms in hot, wet weather and bears fruit in late August(Hosamani et al. 2009). The size of Michelia champaca is small or sometimes medium. Michelia champaca tree cultivates in Nepal, India, Sri Lanka, Bangladesh, China, Indo-China, Myanmar, Thailand, Malaysia, Indonesia, etc. Michelia champaca requires moist condition, well-drained sandy loam soil (Hotti and Hebbal 2015). Michelia champaca seed contains 45% oil. It is generally used in pharmaceuticals industries and perfumery industries (Khan et al. 2014). The saponification value (SV), iodine value (IV) and cetane number (CN) of Michelia champaca methyl esters indicate their viability for biodiesel synthesis (Hosamani et al. 2009). The important fuel property of Michelia champaca biodiesel, ethanol and diesel blend has been analysed for utilisation of blend as fuel in engine (Chandra et al. 2020). The flower fruit and seed of Michelia champaka is shown in Fig. 10.

Azolla

An example of a bio-oil derived from algae is Azolla oil. There are seven different species of azolla, all of which have the same genus and common names: Azolla caroliniana, Azolla filiculoides, Azolla microphylla, Azolla mexicana, Azolla africanna, Azolla nilotica and Azolla pinnata. Azolla oil yields around 25 to 30 ml per kilogramme of Azolla biomass. It forms a symbiotic relationship with the blue-green alga Anabaena azolla, which grows in the cavities of azolla leaves. Azolla is able to utilise atmospheric nitrogen (Narayanasamy and Jeyakumar 2019). The azolla algal biomass is shown in Fig. 11. The performance of diesel engines fuelled with azolla algal biodiesel is discussed in Table 10.

Azolla algal biomass (Kannan and Christraj 2018)

Abrus precatorius

Abrus precatorius is a non-edible oil and belongs to the family of Fabaceae. It grows 10–20 ft tall when supported by other plants (Kuete 2014). The seed oil yield is 2.52% (w/w). Abrus precatorius seed is found in India, Thailand, Sri Lanka, South Chinaa and Nigeria. Abrus precatorius seed contains moisture (5.06%), crude protein (39.20%), oil content (2.5%) and carbohydrates (42.4%) (Attal et al. 2010). The Abrus precatorius seed is shown in Fig. 12.

Abrus precatorius seed (Bhutia and Maiti 2011)

Crambe abyssinica Oil

A more sustainable fuel may be produced using non-edible oils from Crambe abyssinica oil (Costa et al. 2018). The species Crambe abyssinica, often referred to as ‘Crambe’, which is a member of the Cruciferous family, is one of the non-food oil crops having a significant potential for the generation of biodiesel. It is native to Ethiopia and Tanzania and comes from the Mediterranean area, but because of its resistance to pests and illnesses, it can also adapt to the widest range of climatic circumstances (cold and dry places) (Falasca et al. 2010). The short yearly cycle (90–100 days) of Crambe, which allows for its use as a second crop, especially in crop rotation, makes it feasible to produce a lot of biodiesel (Rosa et al. 2014). The seed has a high oil content of around 38% weight, and mechanical pressing may readily extract that oil (de Aquino et al. 2018). Crambe can withstand heavy metals and salt, making it suitable for cultivation in marginal areas or polluted soils; nevertheless, further research is needed to improve crop yields (Ionov et al. 2013). In an attempt to evaluate the full viability of Crambe through seeding, harvesting, oil extraction and biodiesel production, the entire cycle of seeding, harvesting, oil extraction and biodiesel production was carried out; probably the first study of this species to be conducted in Portugal (Costa et al. 2019). The diesel engine fuelled with Crambe abyssinica biodiesel is discussed in Table 11. The Crambe abyssinica crop is presented in Fig. 13.

Crambe crop after 15 days (left) and Crambe crop after 55 days (right) (Costa et al. 2019)

Aegle marmelos Oil

Aegle marmelos species falls under the Rutaceae plant family (Krishnamoorthi snd Malayalamurthi 2018). It is a little tree with powerful, straight, cutting spines. The fragrant, foliate leaves are a greenish white colour (Katagi et al. 2011). The bael (Aegle marmelos) tree produces non-edible seeds that might be used to make biodiesel. In Southeast Asia, including Thailand, China and Malaysia, as well as the arid Indian subcontinent, these seeds are commonly accessible. The oil content in bael seeds ranges from 42 to 55 weight percent on average, and the potential for its production makes it more competitive than any other non-edible seed(Kolli et al. 2020a, b). Due to the salient feature like huge availability, medicinal benefits, bio-fertiliser usages, high oil content species nature, minimum requirements of irrigation and superiorly non-edible feedstock advantages, Aegle marmelos is selected as a biomass material. The Aegle marmelos plant with fruit and seed cake after oil extraction are shown in Figs. 14 and 15, respectively. Table 12 presents the diesel engine performance and emission behaviour fuelled with Aegle marmelos biodiesel.

Aegle marmelos plant with fruit (Palatty et al. 2013)

Seed cake after oil extraction (Paramasivam et al. 2019)

Cuphea

An oil extracted from the seeds of the subtropical flowering plant Cuphea (Lythraceae), which grows in the eastern United States, Mexico and Brazil, is a novel feedstock that is being researched as a biodiesel fuel. About 260 different species of cuphea have been identified. Similar to coconut oil, cuphea oil has a high concentration of medium-chain fatty acids (Lovestead et al. 2010). Based on the species, one fatty acid dominates the content of seed oil, comprising nearly between 50 and 85% of all fatty acid contents. The oil is found in the plant’s embryo, which typically has a weight-to-oil ratio of 30–33% (Graham et al. 2016). Cuphea oil serves as a feedstock because it is substantially concentrated in decanoic acid, which enhances the qualities of the biodiesel fuel produced from it. However, agronomic challenges must be resolved before Cuphea production can be scaled up for commercial use (Knothe 2014). Fisher et al. (2010) investigated the diesel engine behaviour fuelled with Cuphea biodiesel at different injection timing. The results show that the timing of the injection had a greater impact on biodiesel liquid lengths. The early direct-injection and late-cycle injection may be advantageous for Cuphea biodiesel. Knothe et al. (2009) suggested the Cuphea oil looks to be a promising prospective resource for biodiesel and may serve as a paradigm for other possible feedstocks with high decanoic acid concentration even if it faces substantial technical challenges with respect to its commercial availability.

Eichhornia crassipes

The water hyacinth, or Eichhornia crassipes Martius, is a monocotyledonous freshwater aquatic plant that is endemic to the regions of Brazil and Equador. It is a member of the family Pontederiaceae, which is closely related to the lily family, the Liliaceae. In addition to its beauty, it is widely recognised as a decorative aquatic plant found in water gardens and aquariums. It has lovely blue to lilac-coloured blooms, round to oblong curved leaves and waxy coated petioles. The water hyacinth is a kind of plant that can both survive and multiply in fresh water, where it floats freely on the top (Vidya Sagar and Kumari 2013). The fatty acid composition of Eichhornia crassipes oil is tetradecanoic acid (0.4%), eicosanoic acid (3.4%), hexadecanoic acid (2.7%), cis-9-hexadecenoic acid (0.9%), octadeconoic acid (2.6%), cis-9-octadecenoic acid (65.2%), cis, cis-9 acid, cis-12 octadecenoic acid (24.2%) and tetracosanoic acid (0.6) (Venu et al. 2019). Venu et al. (2019) investigated the viability of running a compression engine on biodiesel derived from Eichhornia crassipes as a viable alternative energy source. The feedstock used to make the biodiesel comes from the Tamil Nadu region of India’s Pondicherry district. Investigators examined samples of 10%, 20%, 30%, 40% and 100% quantities of blended biodiesel as well as pure diesel. It has been concluded that although HC and CO emissions were decreased, the engine’s thermal efficiency had increased. The amounts of CO2 and NOx emissions did, however, modestly increase when blending was introduced. The Eichhornia crassipes plant and stem are depicted in Figs. 16 and 17, respectively. The diesel engine behaviour fuelled with Eichhornia crassipes biodiesel is discussed in Table 13.

Eichhornia crassipes plant (Abdul Wahhab and Al-Kayiem 2021)

Eichhornia crassipes stem (Venu et al. 2019)

Melia azedarach

The M. azedarach (syringa tree) is a member of the Meliaceae family. Melia azedarach is a deciduous tree that reaches heights of 7 to 12 m. It is found in southern China, India and Australia. The toxic (non-edible) dried syringa berries have an oil concentration of around 10% (Stavarache et al. 2008). This is a non-edible oil which has capability to produce biodiesel through transesterification reaction with 89.37% methy ester yield (Ogunkunle et al. 2021). Syringa oil has a high content of unsaturated fatty acids, particularly oleic (21.8 wt.%) and linoleic (64.1 wt.%) acids. Other components that make up more than 1 wt.% include saturated fatty acids like palmitic (10.1 wt.%) and stearic (3.5 wt.%) acids (Kumar and Sharma 2011). The Melia azedarach tree, fruit and dry seed are presented in Figs. 18, 19 and 20, respectively.

Cedar wood oil

Cedar wood (Cedrus deodara) is a member of the Pinaceae family and is a reasonably big tree that may grow up to 85 m tall. It has scattering branches with 2–5 cm needle-like leaves that are rough black in colour (Mehra 2018). This tree has a 600-year lifespan. In October and September, flowers bloom. This tree is found in portions of Tibet, western Nepal, north Pakistan and north central India. This tree can only be found in the dry parts of the Himalayas since it cannot survive in moist environments (AHMED et al. 2011). Oil has been employed in the pharmaceutical industry in the past. Now in current times this non-edible cedar wood oil can be utilised for the biofuel production. Cedar wood (Cedrus deodara) trees would be planted more often in forested regions if the oil extracted from them could be used to make biodiesel (Majid et al. 2015). The source of cedar wood oil is wood (EdwinGeo et al. 2021). Sridhar Raja and Ganesan (2022) investigated the diesel engine performance and emission behaviour with cedar wood biodiesel blend incorporated with magnesium oxide nano-additive. The result shows that B30 blending performs better than other biodiesel blending. EdwinGeo et al. (2021) have analysed the diesel engine performance and emission characteristics of diesel engine fuel with cedar wood biodiesel blend (B20). The experimental results show that the BTE and NOx emission is higher for biodiesel blend as compared to neat diesel. CO2 emissions were lower with biodiesel blends because of fewer carbon contents in the fuel. The biodiesel blends reduced smoke emissions because there was more oxygen and the combustion process was better. This helps to cut down on HC and CO emissions as well. The cedar wood tree is shown in Fig. 21.

Cedar wood tree (Mehra 2018)

Shorea robusta (Sal)

Sal oil comes from the seeds of trees, and about 0.18 million tonnes of sal seed oil are made each year. It is a non-edible oil source (Rai and Sahoo 2021b). Sal trees cover roughly 5% of India’s forested land and sal oil has the capability to produce biodiesel (Vedaraman et al. 2012). The oil extraction from the sal seed kernel produced a yield of 20.16% (Hasan et al. 2020a). The sal seed is processed into sal butter than transesterification method for biodiesel production (Kumar Rai and Rekha Sahoo 2020). The Shorea robusta tree, leaf, seed and butter are shown in Fig. 22. Table 14 presents the engine performance and emission of diesel fuelled with Shorea robusta biodiesel blend.

Simmondsia chinensis (Jojoba)

The jojoba tree is a member of the Simmondsiaceae family. This is a perennial shrub that is native to the Sonoran and Mojave deserts of Mexico, Arizona and California. The lipid content of the seeds, which ranges from 45 to 55% of yields, is in the form of long-chain esters of fatty acids and alcohols (wax esters) (Atabani et al. 2013). This oil has potential to produce biodiesel. The dry jojoba seed and seed with tree are depicted in Figs. 23 and 24. The engine behavior of diesel engine fuelled with Jojoba biodiesel blend is given in Table 15.

Dry jojoba seed (Agarwal et al. 2020)

Jojoba seed with tree (Kumar and Sharma 2011)

Garcinia indica (Kokum)

Garcinia indica is a member of the Guttiferae plant family, which has more than 630 species spread across 40 genera. It is a slender evergreen tree with branches. It grows naturally in the tropical forests of the Western Ghats, Konkana, North Kanara, South Kanara, Bombay, Goa and Coorg (Hosamani et al. 2009). The oil content of Garcinia indica seeds is 45.5% (Atabani et al. 2013). The characteristics of Garcinia indica methyl esters have promoted its usage as a possible source for the production of biodiesel (Khan et al. 2014). The Garcinia indica tree, fruit, etc. are shown in Figs. 25, 26, 27 and 28. The engine performance and emission of engine with Garcinia indica biodiesel is presented in Table 16.

Kokum fruit with tree (Pandey et al. 2009)

Garcinia indica fruit (Swami et al. 2012)

Garcinia indica seed with pulp (Swami et al. 2012)

Dried kokum (Pandey et al. 2009)

Eruca sativa L. (Taramira)

Eruca sativa, a member of the Cruciferae family of plants, is used to make various traditional medicines and treatments. It grows in South Asia, India and Pakistan and is called taramira (Flanders & Abdulkarim 1985). It can be figured as a non-edible feedstock for biodiesel. Eruca sativa L. has a production of 1106 kg oil per hectare, and the oil yield is 30%(Chakrabarti et al. 2011). Mumtaz et al. have performed the optimisation for biodiesel production from Eruca sativa oil (Mumtaz et al. 2012).

Raphanus sativus L. (Radish Seed)

The radish (Raphanus sativus L.), which is commonly planted in some regions of Brazil and Asia, has physical and chemical properties favourable to the manufacture of biofuels. It is a member of the family of oilseeds known as Brassicaceae (Faria et al. 2018). It is a herbaceous plant that climbs vertically to a height of more than 1.8 m. Since it can withstand frigid temperatures, it might potentially be planted there (e.g. winter frosts). Moreover, it helps the soils recover micronutrients, particularly nitrogen and phosphorus. It has a quick growth rate that lasts between 150 and 200 days. Also, its agriculture has less agronomic requirements and cheaper per-hectare production costs (Fadhil et al. 2020). The oil content of radish seeds is rather high, at around 35% on average; however, this oil is not considered edible since it includes erucic acid (C22:1), a poisonous substance (Stevanato and da Silva 2019). Cold pressing of radish seed results in an average yield of 284 L/ha of oil since the productivity is 1500 kg/ha (Stevanato and da Silva 2019). Chokkalingam et al. (2022) have investigated and optimised the engine output behaviour fuelled with Raphanus sativus biodiesel blend incorporated with alumina nanoparticles. At biodiesel blend ratio B20, 60 ppm nano-Al2O3, injection timing 27° before top dead centre and 220 bar pressure, BTE is increased and BSFC and EGT are lowered on favoured full load condition, whereas at 23° before top dead centre injection time and 180 bar pressure, the CO, CO2, NOx and HC emissions are found lower. Senthilkumar et al. (2019) have taken non-edible wild radish oil for biodiesel production. The oil from seeds has been mechanically extracted, and the oil yield was discovered to be 46.2 wt.%. Taguchi and RSM tool is used for the catalytic transesterification process optimisation, and under optimised conditions, 94.58% biodiesel production is attained.

Industrial Feedstock

The industry-based feedstock can also be utilised to produce biodiesel. Saravanan et al. (2022) have taken tannery sludge to produce biodiesel with nanoparticles as catalyst through transesterification reaction. In process of reaction at a 20:1 molar ratio of methanol to oil, 9 wt.% catalyst loading, reaction temperature of 65 °C, 300 min reaction duration and at 450 rpm stirring rate, the optimum biodiesel yield of 98.6 wt.% has been obtained. Booramurthy et al. (2022ab) transesterified the fat recovered from tannery sludge with a short-chain alcohol and a nanocatalyst (Fe3O4/BaO) and produced biodiesel. In the work, influence of different process factors was studied to achieve an optimal biodiesel yield of 97.6%. Booramurthy et al. (2022ab) had taken nanocatalysts (ferric-manganese doped sulphated zirconia) to make biodiesel from tannery waste. At the optimum conditions of 12:1 methanol to fat, 6 wt.% catalytic loading at 65 °C and 450 rpm stirring for 300 min, the highest biodiesel production of 96.6 wt.% has been obtained. Booramurthy et al. (2020) have used waste sheep fat to produce biodiesel using nano-sulphated zirconium catalyst and at optimised conditions, 98.7% biodiesel yield is obtained. Saravanan Arumugamurthy et al. (2019) explored the production of biodiesel from industrial waste using heterogeneous acid catalyst made up of brewer’s spent yeast. The reaction has been carried at constant 25 Hz ultrasonic frequency. At certain optimum reaction input parameters, 87.8% of biodiesel yield is obtained. Balasubramanian et al. (2018) had looked at using activated sludge from milk processing plants as a cheap feedstock to make biodiesel. The conventional transesterification reaction is used to make biodiesel from sludge. Sivakumar et al. (2011) have studied the biodiesel production from dairy waste scum oil. While using 1.2 wt.% of potassium oxide, 75 °C for the reaction, 30 min and a 6:1 methanol/oil ratio at 350 rpm, the production of biodiesel achieved 96.7%. The various industrial wastes have great potential to produce biodiesel and they can be a promising feedstock for biodiesel production.

Algae

Algae-derived biodiesel is seen as a viable third-generation feedstock. Moreover, algae may be produced in fresh, marine or sewer water, requiring no arable land and competing with food production (Ashokkumar et al. 2017). Microalgae are chosen over other species of algae because of their high lipid content (5–70 wt.% on a dry basis) and rapid development rate (20–30 times faster than agricultural plants) (Almutairi 2020). In some conditions, some algae species can have a maximum lipid content of up to 90 wt.%. Moreover, it may be often harvested and use ambient CO2 as a main supply of carbon (Arunachalam Sivagurulingam et al. 2019). Since marine microalgae have a high tolerance for various environmental variables including salinity, temperature and contaminations that occur during open pond production, it has the greatest potentials to satisfy the feedstock needs and are economically practical (Chew et al. 2018). Arunachalam Sivagurulingam et al. (2022) have done a microalgal biodiesel production. In this work, marine microalgae from the Bay of Bengal were separated, and their capacity to produce biodiesel is examined. Five distinct microalgae strains were found, and each strain was used to produce biodiesel. The maximum biodiesel production yield of 97% has been found for Nannochloropsis salina microalgal strain. Arunachalam Sivagurulingam et al. (2019) have used calcium methoxide as a catalyst in optimisation and kinetic studies for biodiesel generation from the microalga (Euglena sanguinea). The biodiesel output is 94.83% at its optimum condition. Ashokkumar et al. (2017) investigated the brown marine macroalgae Padina tetrastromatica for biodiesel production and found 7.8% biodiesel yield through tranestrification.

Chukrasia tabularis L.

Chukrasia tabularis is also known as Indian mahogany. It is an indigenous tree to India, Bangladesh, Cambodia, China, Sri Lanka, Vietnam and Malaysia, and is a medium to big deciduous or evergreen tree that produces non-edible oil. The fruits, leaves and stem of this tree contain anti-inflammatory, anti-malarial and antiviral effects (Mursiti et al. 2019). Eswaramoorthi et al. (2022) have revealed a novel source of Chukrasia tabularis L. seed for biodiesel production. The maximum oil yield from seed is obtained as 32 wt.%. This oil must undergo a single-step esterification cum transesterification process due to its high free fatty acid (FFA) concentration. Maximum biodiesel conversion was achieved by analysing the conditions influencing the biodiesel process, which resulted in a 98.5% yield.

Other Feedstocks

Some more biodiesel feedstock that has the potential to produce biodiesel is presented in Table 17.

Future Scope

Biodiesel has recently gained popularity due to its economic and environmental advantages. Biodiesel has a promising future since it is a clean renewable energy source. This fuel will contribute to the global goal of net zero emissions by 2050. Cost-effective large-scale production is needed for commercialising biodiesel in the market; however, the biodiesel market is not yet mature enough. The various local feedstock needs to be promoted as per the geography of the location. The government must build infrastructure and implement blending policies to allow biodiesel to be used in diesel engines. In the future, hybrid biodiesel can be a wise strategy for cost-effective biodiesel production and commercialisation. In recent years, Kukana and Jakhar (2022b) have investigated the overall engine using composite biodiesel from waste cooking oil–Hibiscus cannabinus oil. Kukana and Jakhar (2022a) examined the effect of ternary blends diesel/n-propanol/composite biodiesel on diesel engine operating parameters. Harisha et al. (2021) have done research on hybrid biodiesel production and optimisation.

Conclusion

Biodiesel is gaining popularity as a cleaner alternative to conventional diesel. It is produced using plant oils, animal fats, recycled cooking greases or oils, and different combinations of these feedstocks. In the current scenario, biodiesel is gaining attention because it has several benefits, i.e. it is renewable with no sulphur or polycyclic aromatic compounds in it, it can replace fossil diesel fuel and can be used directly in existing diesel equipment with slight to no modification, lowers greenhouse gas emissions, reduces engine exhaust emissions, it is non-toxic and biodegradable, it is appropriate for sensitive environments, it can be made locally using recycled or agricultural materials and contains extra oxygen for better combustion. Greenhouse gas emissions are drastically reduced when biodiesel is used instead of petroleum. In comparison to fossil fuel diesel, B100 has been determined to produce 74% less greenhouse gas emissions across its whole life cycle. As biodiesel use and production rise, additional rare feedstocks are being investigated. Some examples include Prosopis juliflora oil, sea mango oil, Parinari polyandra oil, Ailanthus altissima oil, Michelia champaca oil, Abrus precatorius oil, Crambe abyssinica oil, Aegle marmelos, Eichhornia crassipes oil, Cuphea oil, lemon grass oil, cedar wood oil, Shorea robusta oil, Melia azedarach oil, jojoba oil, Garcinia indica oil, taramira oil, Raphanus sativus L. oil, many strains of microalgae, Chukrasia tabularis, industrial waste and other feedstock. These resources include a high concentration of free fatty acids and triglycerides, which are used in the production of biodiesel. Even though there is not much biodiesel made from these feedstocks now on the market, they have a lot of potentials to increase the supply. There are many challenges which are associated with biodiesel production and use. Transesterification is the most common and efficient method for producing biodiesel with a high yield. Since biodiesel has a higher cetane number than diesel, it may be blended with diesel at ratios to enhance engine performance and reduce emissions. There are many challenges which are associated with biodiesel production and use. The addition of nanoparticles in biodiesel boosts engine performance characteristics and reduces emissions. The challenges are feedstock availability at a large scale, cost-effective production of fuel, the adaption policy of a country, lack of customer awareness about biodiesel and availability of infrastructure. The biodiesel can be utilised as a substitute of diesel fuel for the operation of diesel engines.

Data Availability

The data used to support the findings of this study are included in the article.

Abbreviations

- KAC:

-

Potassium hydroxide (KOH)-activated Ailanthus cake

- CAC:

-

Calcined Ailanthus cake

- CdS:

-

Cadmium sulphide

- FMAE:

-

Fatty acid methyl ester

- BSEC:

-

Brake specific energy consumption

- BSFC:

-

Brake specific fuel consumption

- DMC:

-

Dimethyl carbonate

- RSM:

-

Response surface methodology

- CCD:

-

Central composite design

- VCR:

-

Variable compression ratio

- BTE:

-

Brake thermal efficiency

- EGT:

-

Exhaust gas temperature

- EGR:

-

Exhaust gas recirculation

- HRR:

-

Heat release rate

- CR:

-

Compression ratio

- UHC:

-

Unburned hydrocarbon

- US:

-

United States

- HC:

-

Hydrocarbon

- CO:

-

Carbon monoxide

- GO:

-

Graphene oxide

- DI:

-

Direct injection

- CI:

-

Compression ignition

- IEA:

-

International Energy Agency

- WCO:

-

Waste cooking oil

- IP:

-

Injection pressure

- IT:

-

Injection timing

- bTDC:

-

Before top dead centre

- B00:

-

100% Biodiesel

- B10:

-

10% Biodiesel + 90% diesel

- B15:

-

15% Biodiesel + 85% diesel

- B20:

-

20% Biodiesel + 80% diesel

- B30:

-

30% Biodiesel + 70% diesel

- B40:

-

40% Biodiesel + 60% diesel

- D100:

-

Neat diesel

- BP:

-

Brake power

- CuO:

-

Copper oxide

- Al2O3 :

-

Aluminium oxide

- ppm:

-

Parts per million

- PV:

-

Photovoltaic

- EU:

-

European Union

References

Abdul Wahhab HA, Al-Kayiem HH (2021) Environmental risk mitigation by biodiesel blending from Eichhornia crassipes: performance and emission assessment. Sustainability (switzerland) 13(15):1–16. https://doi.org/10.3390/su13158274

Agarwal S, Kumari S, Mudgal A, Khan S (2020) Green synthesized nanoadditives in jojoba biodiesel-diesel blends: an improvement of engine performance and emission. Renewable Energy 147:1836–1844. https://doi.org/10.1016/j.renene.2019.09.139

Ahmad AL, Yasin NHM, Derek CJC, Lim JK (2011) Microalgae as a sustainable energy source for biodiesel production: a review. Renew Sustain Energy Rev 15(1):584–593. https://doi.org/10.1016/j.rser.2010.09.018

Ahmad AF, Zulkurnain N, Rosid SJM, Azid A, Endut A, Toemen S, Ismail S, Abdullah WNW, Aziz SM, Yusoff NM, Rosid SM, Nasir NA (2022) Catalytic transesterification of coconut oil in biodiesel production: a review. Catal Surv Asia 26(3):129–143. https://doi.org/10.1007/s10563-022-09358-8

Ahmed NA (2018) Performance evaluation of a diesel engine using blends of optimized yields of sand apple (Parinari polyandra) oil biodiesel. Renewable Energy. https://doi.org/10.1016/j.renene.2018.09.040

Ahmed M, Shaukat SS, Siddiqui MF (2011) A multivariate analysis of the vegetation of Cedrus deodara forests in Hindu Kush and Himalayan ranges of Pakistan: evaluating the structure and dynamics. Turk J Bot. https://doi.org/10.3906/bot-1009-57

Al-Kahtani HA (1991) Survey of quality of used frying oils from restaurants. J Am Oil Chem Soc 68(11):857–862. https://doi.org/10.1007/BF02660602

Almutairi AW (2020) Effects of nitrogen and phosphorus limitations on fatty acid methyl esters and fuel properties of Dunaliella salina. Environ Sci Pollut Res 27(26):32296–32303. https://doi.org/10.1007/s11356-020-08531-8

Amos O, Ogunniyi DS, Odetoye TE (2016) Production of biodiesel from Parinari polyandra B. seed oil using bio-based catalysts. Nig J Technol Dev 13(1):26. https://doi.org/10.4314/njtd.v13i1.5

Ansari K, Goga G, Mohan R (2022) Performance and emission characteristics of Mahua blended biodiesel. Mater Today: Proc. https://doi.org/10.1016/j.matpr.2022.09.154

Anwar F, Rashid U, Ashraf M, Nadeem M (2010) Okra (Hibiscus esculentus) seed oil for biodiesel production. Appl Energy 87(3):779–785. https://doi.org/10.1016/j.apenergy.2009.09.020

Arivarasu A, Jini D, Vijay Samuel G, Meghna K, Ramkumar K (2023) Production of tobacco (Nicotiana tabacum L.) seed oil methyl esters using tungstophosphoric acid as catalyst (pp. 71–84). https://doi.org/10.1007/978-981-19-3931-0_5

Arunachalam Sivagurulingam AP, Sivanandi P, Pandian S, Arumugamurthi SS, Sircar A (2019) Optimization and kinetic studies on biodiesel production from microalgae (Euglena sanguinea) using calcium methoxide as catalyst. Energy Source, Part a: Recover, Util Environ Effects 41(12):1497–1507. https://doi.org/10.1080/15567036.2018.1549124

Arunachalam Sivagurulingam AP, Sivanandi P, Pandian S (2022) Isolation, mass cultivation, and biodiesel production potential of marine microalgae identified from Bay of Bengal. Environ Sci Pollut Res 29(5):6646–6655. https://doi.org/10.1007/s11356-021-16163-9

Ashokkumar V, Salim MR, Salam Z, Sivakumar P, Chong CT, Elumalai S, Suresh V, Ani FN (2017) Production of liquid biofuels (biodiesel and bioethanol) from brown marine macroalgae Padina tetrastromatica. Energy Convers Manage 135:351–361. https://doi.org/10.1016/j.enconman.2016.12.054

Asokan MA, Senthur Prabu S, Bade PKK, Nekkanti VM, Gutta SSG (2019) Performance, combustion and emission characteristics of juliflora biodiesel fuelled DI diesel engine. Energy 173:883–892. https://doi.org/10.1016/j.energy.2019.02.075

Atabani AE, Silitonga AS, Ong HC, Mahlia TMI, Masjuki HH, Badruddin IA, Fayaz H (2013) Non-edible vegetable oils: a critical evaluation of oil extraction, fatty acid compositions, biodiesel production, characteristics, engine performance and emissions production. Renew Sustain Energy Rev 18:211–245. https://doi.org/10.1016/j.rser.2012.10.013

Attal AR et al (2010) Abrus precatorius Linnaeus: a phytopharmacological review. J Pharm Res 3(11):2585–2587

Attal MM, Dave MC, Mahalle DAM (2014) Experimental investigation on performance of a diesel engine using Garcinia indica (kokam) and rice bran oil based biodiesels as fuels. IOSR J Mech Civil Eng 11(5):01–07. https://doi.org/10.9790/1684-11520107

Attia AMA, Kulchitskiy AR, Nour M, El-Seesy AI, Nada SA (2022) The influence of castor biodiesel blending ratio on engine performance including the determined diesel particulate matters composition. Energy 239:121951. https://doi.org/10.1016/j.energy.2021.121951

Awais M, Musmar SA, Kabir F, Batool I, Rasheed MA, Jamil F, Khan SU, Tlili I (2020) Biodiesel production from Melia azedarach and Ricinus communis oil by transesterification process. Catalysts 10(4). https://doi.org/10.3390/catal10040427

Azad AK, Rasul MG, Bhatt C (2019) Combustion and emission analysis of Jojoba biodiesel to assess its suitability as an alternative to diesel fuel. Energy Procedia 156:159–165. https://doi.org/10.1016/j.egypro.2018.11.121

Balasubramanian R, Sircar A, Sivakumar P, Anbarasu K (2018) Production of biodiesel from dairy wastewater sludge: a laboratory and pilot scale study. Egypt J Pet 27(4):939–943. https://doi.org/10.1016/j.ejpe.2018.02.002

Balasubramanian D, Papla Venugopal I, Viswanathan K (2019) Characteristics investigation on DI diesel engine with nano-particles as an additive in lemon grass oil. SAE Tech Papers, October. https://doi.org/10.4271/2019-28-0081

Baranitharan P (2020) Exergy analysis of a diesel engine fuelled with Aegle marmelos de-oiled seed cake pyrolysis oil opus. Environ Prog Sustain Energy 39(5). https://doi.org/10.1002/ep.13426

Baranitharan P, Ramesh K, Sakthivel R (2019) Measurement of performance and emission distinctiveness of Aegle marmelos seed cake pyrolysis oil/diesel/TBHQ opus powered in a DI diesel engine using ANN and RSM. Meas: J Int Meas Confederation 144:366–380. https://doi.org/10.1016/j.measurement.2019.05.037

Bhatia SK, Bhatia RK, Yang Y-H (2017) An overview of microdiesel — a sustainable future source of renewable energy. Renew Sustain Energy Rev 79:1078–1090. https://doi.org/10.1016/j.rser.2017.05.138

Bhutia SK, Maiti TK (2011) Crabs eye (Abrus precatorius) seed and its immunomodulatory and antitumor properties. In Nuts and Seeds in Health and Disease Prevention (pp. 409–415). Elsevier. https://doi.org/10.1016/B978-0-12-375688-6.10049-0

Booramurthy VK, Kasimani R, Pandian S, Ragunathan B (2020) Nano-sulfated zirconia catalyzed biodiesel production from tannery waste sheep fat. Environ Sci Pollut Res 27(17):20598–20605. https://doi.org/10.1007/s11356-020-07984-1

Booramurthy VK, Kasimani R, Pandian S (2022a) Biodiesel production from tannery waste using a nano catalyst (ferric-manganese doped sulphated zirconia). Energy Sources Part a: Recovery, Utilization Environ Effects 44(1):1092–1104. https://doi.org/10.1080/15567036.2019.1639849

Booramurthy VK, Kasimani R, Pandian S, Subramanian D (2022b) Magnetic nano-catalyzed synthesis of biodiesel from tannery sludge: characterization, optimization and kinetic studies. Arab J Sci Eng 47(5):6341–6353. https://doi.org/10.1007/s13369-021-06020-9

Bouaid A, Bajo L, Martinez M, Aracil J (2007) Optimization of biodiesel production from jojoba oil. Process Saf Environ Prot 85(5):378–382. https://doi.org/10.1205/psep07004

Canakci M (2007) The potential of restaurant waste lipids as biodiesel feedstocks. Biores Technol 98(1):183–190. https://doi.org/10.1016/j.biortech.2005.11.022

Chakrabarti MH, Ali M, Baroutian S, Saleem M (2011) Techno-economic comparison between B10 of Eruca sativa L. and other indigenous seed oils in Pakistan. Process Saf Environ Prot 89(3):165–171. https://doi.org/10.1016/j.psep.2010.11.006

Chandra H, Grag N, Kumar S, Ahmad W (2020) Materials today: proceedings influence of the catalytic activity of MgO catalyst on the comparative studies of Schlichera oleosa, Michelia champaca and Putranjiva based biodiesel and its blend with ethanol-diesel. Mater Today: Proceedings, xxxx. https://doi.org/10.1016/j.matpr.2020.05.432

Chew KW, Chia SR, Show PL, Yap YJ, Ling TC, Chang J-S (2018) Effects of water culture medium, cultivation systems and growth modes for microalgae cultivation: a review. J Taiwan Inst Chem Eng 91:332–344. https://doi.org/10.1016/j.jtice.2018.05.039

Chhetri A, Watts K, Islam M (2008) Waste cooking oil as an alternate feedstock for biodiesel production. Energies 1(1):3–18. https://doi.org/10.3390/en1010003

Chokkalingam S, Chandrasekaran K, Pandian S, Asir O (2022) Optimization of performance and emission characteristics of biodiesel from non-edible Raphanus sativus oil with nano-additive. Theor Found Chem Eng 56(6):1158–1170. https://doi.org/10.1134/S0040579522060215

Costa E, Almeida MF, da C Alvim-Ferraz M, Dias JM (2018) Effect of Crambe abyssinica oil degumming in phosphorus concentration of refined oil and derived biodiesel. Renewable Energy 124:27–33. https://doi.org/10.1016/j.renene.2017.08.089

Costa E, Almeida MF, Alvim-Ferraz C, Dias JM (2019) The cycle of biodiesel production from Crambe abyssinica in Portugal. Ind Crops Prod 129:51–58. https://doi.org/10.1016/j.indcrop.2018.11.032

Costa E, Almeida MF, Alvim-Ferraz C, Dias JM (2021) Otimization of Crambe abyssinica enzymatic transesterification using response surface methodology. Renewable Energy 174:444–452. https://doi.org/10.1016/j.renene.2021.04.042

de Aquino GS, Ventura MU, Alexandrino RP, Michelon TA, de Araujo Pescador PG, Nicio TT, Watanabe VS, Diniz TG, de Oliveira ALM, Hata FT (2018) Plant-promoting rhizobacteria Methylobacterium komagatae increases crambe yields, root system and plant height. Ind Crops Prod 121:277–281. https://doi.org/10.1016/j.indcrop.2018.05.020

Deepalakshmi S, Sivalingam A, Thirumarimurugan M, Yasvanthrajan N, Sivakumar P (2014) In-situ transesterification and process optimization of biodiesel from waste avocado seed. J Chem Pharm Sci 2014-Decem(4):115–118

Dhana Raju V, Kishore PS, Yamini K (2018) Experimental studies on four stroke diesel engine fuelled with tamarind seed oil as potential alternate fuel for sustainable green environment. Eur J Sustain Dev Res 2(1). https://doi.org/10.20897/ejosdr/78489

Dhanamurugan A, Subramanian R (2015) Emission and performance characteristics of a diesel engine operating on diesel-bael (Aegle marmelos) biodiesel blends. Nat Environ Pollut Technol 14(2):331–336

Dhivagar R, Sundararaj S, Vignesh VR (2018) Biodiesel from lemon and lemon grass oil and its effect on engine performance and exhaust emission. IOP Conf Ser: Mater Sci Eng 330(1). https://doi.org/10.1088/1757-899X/330/1/012103

EdwinGeo V, Fol G, Aloui F, Thiyagarajan S, Jerome Stanley M, Sonthalia A, Brindhadevi K, Saravanan C (2021) Experimental analysis to reduce CO2 and other emissions of CRDI CI engine using low viscous biofuels. Fuel 283:118829. https://doi.org/10.1016/j.fuel.2020.118829

El-Seesy AI, Attia AMA, El-Batsh HM (2018) The effect of aluminum oxide nanoparticles addition with Jojoba methyl ester-diesel fuel blend on a diesel engine performance, combustion and emission characteristics. Fuel 224:147–166. https://doi.org/10.1016/j.fuel.2018.03.076

Eswaramoorthi Y, Pandian S, Sahadevan R (2022) Kinetic studies on the extraction of oil from a new feedstock (Chukrasia tabularis L. seed) for biodiesel production using a heterogeneous catalyst. Environ Sci Pollut Res 30(6):14565–14579. https://doi.org/10.1007/s11356-022-23163-w

Fadhil AB, Sedeeq SH, Al-Layla NMT (2019) Transesterification of non-edible seed oil for biodiesel production: characterization and analysis of biodiesel. Energy Sources, Part a: Recover Utilization Environ Effects 41(7):892–901. https://doi.org/10.1080/15567036.2018.1520367

Fadhil AB, Nayyef AW, Sedeeq SH (2020) Valorization of mixed radish seed oil and Prunus armeniaca L. oil as a promising feedstock for biodiesel production: evaluation and analysis of biodiesels. Asia-Pacific J Chem Eng 15(1). https://doi.org/10.1002/apj.2390

Falasca SL, Flores N, Lamas MC, Carballo SM, Anschau A (2010) Crambe abyssinica: an almost unknown crop with a promissory future to produce biodiesel in Argentina. Int J Hydrogen Energy 35(11):5808–5812. https://doi.org/10.1016/j.ijhydene.2010.02.095

Faria D, Santos F, Machado G, Lourega R, Eichler P, de Souza G, Lima J (2018) Extraction of radish seed oil (Raphanus sativus L.) and evaluation of its potential in biodiesel production. AIMS Energy 6(4):551–565. https://doi.org/10.3934/energy.2018.4.551

Fisher BT, Knothe G, Mueller CJ (2010) Liquid-phase penetration under unsteady in-cylinder conditions: soy- and cuphea-derived biodiesel fuels versus conventional diesel. Energy Fuels 24(9):5163–5180. https://doi.org/10.1021/ef100594p

Flanders A, Abdulkarim SM (1985) The composition of seed and seed oils of taramira (Eruca sativa). J Am Oil Chem Soc 62(7):1134–1135. https://doi.org/10.1007/BF02542308

Foroutan R, Peighambardoust SJ, Mohammadi R, Peighambardoust SH, Ramavandi B (2022) Application of waste chalk/CoFe2O4/K2CO3 composite as a reclaimable catalyst for biodiesel generation from sunflower oil. Chemosphere 289:133226. https://doi.org/10.1016/j.chemosphere.2021.133226

Gaillard Y, Krishnamoorthy A, Bevalot F (2004) Cerbera odollam: a ‘suicide tree’ and cause of death in the state of Kerala. India J Ethnopharmacol 95(2–3):123–126. https://doi.org/10.1016/j.jep.2004.08.004

Ganesan S, Mohanraj M, Khushal S, Lokesh S (2021) Effect of tertiary butyl hydroquinone on diesel engine performance fuelled with lemon grass oil. Mater Today: Proc xxxx 2–9. https://doi.org/10.1016/j.matpr.2021.03.669

García-Martín JF, Barrios CC, Alés-Álvarez F-J, Dominguez-Sáez A, Alvarez-Mateos P (2018) Biodiesel production from waste cooking oil in an oscillatory flow reactor. Performance as a fuel on a TDI diesel engine. Renewable Energy 125:546–556. https://doi.org/10.1016/j.renene.2018.03.002

Graham SA, Pinheirocoelhojosé G, Murad AM, Rech EL, Cavalcanti TB, Inglis PW (2016) Patterns of fatty acid composition in seed oils of Cuphea, with new records from Brazil and Mexico. Ind Crops Prod 87:379–391. https://doi.org/10.1016/j.indcrop.2016.04.008

Gui MM, Lee KT, Bhatia S (2008) Feasibility of edible oil vs. non-edible oil vs. waste edible oil as biodiesel feedstock. Energy 33(11):1646–1653. https://doi.org/10.1016/j.energy.2008.06.002

Hajra B, Sultana N, Pathak AK, Guria C (2015) Response surface method and genetic algorithm assisted optimal synthesis of biodiesel from high free fatty acid sal oil (Shorea robusta) using ion-exchange resin at high temperature. J Environ Chem Eng 3(4):2378–2392. https://doi.org/10.1016/j.jece.2015.08.015

Harisha P, Anil Kumar BN, Tilak SR, Ganesh C (2021) Production and optimization of biodiesel from composite Pongamia oil, animal fat oil and waste cooking oil using RSM. Mater: Today Proc 47(xxxx):4901–4905. https://doi.org/10.1016/j.matpr.2021.06.322

Harun Kumar M, Dhana Raju V, Kishore PS, Venu H (2020) Influence of injection timing on the performance, combustion and emission characteristics of diesel engine powered with tamarind seed biodiesel blend. Int J Ambient Energy 41(9):1007–1015. https://doi.org/10.1080/01430750.2018.1501741

Hasan MI, Mukta NA, Islam MM, Chowdhury AMS, Ismail M (2020a) Evaluation of fuel properties of sal (Shorea robusta) seed and its oil from their physico-chemical characteristics and thermal analysis. Energy Sources Part A: Recover Utilization Environ Effects 1–12. https://doi.org/10.1080/15567036.2020.1774684

Hasan MI, Mukta NA, Islam MM, Chowdhury AMS, Ismail M (2020b) Evaluation of fuel properties of sal (Shorea robusta) seed and its oil from their physico-chemical characteristics and thermal analysis. Energy Sources, Part A: Recover Utilization Environ Effects 1–12. https://doi.org/10.1080/15567036.2020.1774684

Hosamani KM, Hiremath VB, Keri RS (2009) Renewable energy sources from Michelia champaca and Garcinia indica seed oils: a rich source of oil. Biomass Bioenerg 33(2):267–270. https://doi.org/10.1016/j.biombioe.2008.05.010

Hoseini SS, Naja G, Ghobadian B, Mamat R, Ebadi MT, Yusaf T (2018a) Ailanthus altissima (tree of heaven) seed oil: characterisation and optimisation of ultrasonication-assisted biodiesel production. 220(January):621–630. https://doi.org/10.1016/j.fuel.2018.01.094

Hoseini SS, Najafi G, Ghobadian B, Mamat R, Ebadi MT, Yusaf T (2018b) Novel environmentally friendly fuel: the effects of nanographene oxide additives on the performance and emission characteristics of diesel engines fuelled with Ailanthus altissima biodiesel. Renewable Energy 125:283–294. https://doi.org/10.1016/j.renene.2018.02.104

Hoseini SS, Najafi G, Ghobadian B, Mamat R, Ebadi MT, Yusaf T (2018c) SC. Renewable Energy. https://doi.org/10.1016/j.renene.2018.02.104

Hoseini SS, Najafi G, Ghobadian B, Mamat R, Ebadi MT, Yusaf T (2018d) Ailanthus altissima (tree of heaven) seed oil: characterisation and optimisation of ultrasonication-assisted biodiesel production. Fuel 220:621–630. https://doi.org/10.1016/j.fuel.2018.01.094

Hoseini SS, Naja G, Ghobadian B, Ebadi MT, Mamat R, Yusaf T (2020) Biodiesels from three feedstock: the effect of graphene oxide (GO) nanoparticles diesel engine parameters fuelled with biodiesel. 145:190–201. https://doi.org/10.1016/j.renene.2019.06.020

Hotti SR, Hebbal OD (2015) Biodiesel production and fuel properties from non-edible champaca (Michelia champaca) seed oil for use in diesel engine. J Therm Eng 1(1):330–336

Idris SA, Rosli NR, Raja Aris RMA (2022) Supercritical carbon dioxide extraction of fatty acids compounds from tamarind seeds. Mater Today: Proceedings 63:S462–S466. https://doi.org/10.1016/j.matpr.2022.04.129

International Energy Agency. (2022). International Energy Agency (IEA) World Energy Outlook 2022. https://hww.iea.org/reports/world-energy-outlook-2022/Executive-Summary. 524

Ionov M, Yuldasheva N, Ulchenko N, Glushenkova AI, Heuer B (2013) Growth, development and yield of Crambe abyssinica under saline irrigation in the greenhouse. J Agron Crop Sci 199(5):331–339. https://doi.org/10.1111/jac.12027

Islam MN, Sabur A, Ahmmed R, Hoque ME (2015) Oil extraction from pine seed (Polyalthia longifolia) by solvent extraction method and its property analysis. Procedia Eng 105(Icte 2014):613–618. https://doi.org/10.1016/j.proeng.2015.05.039

Jabeen M, Munir M, Abbas MM, Ahmad M, Waseem A, Saeed M, Kalam MA, Zafar M, Sultana S, Mohamed A, Chaudhry B (2022) Sustainable production of biodiesel from novel and non-edible Ailanthus altissima (Mill.) seed oil from green and recyclable potassium hydroxide activated Ailanthus cake and cadmium sulfide catalyst. Sustainability 14(17):10962. https://doi.org/10.3390/su141710962

Janaun J, Ellis N (2010) Perspectives on biodiesel as a sustainable fuel. Renew Sustain Energy Rev 14(4):1312–1320. https://doi.org/10.1016/j.rser.2009.12.011

Jayakumar T, Arunprasad J, Thirugnanasambantham R, Rajesh R, Sugumar S, Elango T (2022) Performance and emissions characteristics of soyabean biodiesel in compression ignition engine, pp 13–22. https://doi.org/10.1007/978-981-19-0244-4_2

Joseph CO, Chidozie VA, Obioma UN, Christopher CO, Emeka GA (2014) Potentials of non-edible Abrus precatorius seed oil towards biodiesel production. Afr J Biotech 13(44):4226–4235. https://doi.org/10.5897/AJB2014.13979

Joshi HC, Grag N, Kumar S, Ahmad W (2021) Influence of the catalytic activity of MgO catalyst on the comparative studies of Schlichera oleosa, Michelia champaca and Putranjiva based biodiesel and its blend with ethanol-diesel. Mater Today: Proceedings 38:18–23. https://doi.org/10.1016/j.matpr.2020.05.432

Kannan D, Christraj W (2018) Emission analysis of Azolla methyl ester with BaO nano additives for IC engine. Energy Sources Part a: Recover Utilization Environ Effects 40(10):1234–1241. https://doi.org/10.1080/15567036.2018.1476617

Kansedo J, Lee KT, Bhatia S (2009) Cerbera odollam (sea mango) oil as a promising non-edible feedstock for biodiesel production. Fuel 88(6):1148–1150. https://doi.org/10.1016/j.fuel.2008.12.004

Kant Bhatia S, Kant Bhatia R, Jeon JM, Pugazhendhi A, Kumar Awasthi M, Kumar D, Kumar G, Yoon JJ, Yang YH (2021) An overview on advancements in biobased transesterification methods for biodiesel production: oil resources, extraction, biocatalysts, and process intensification technologies. Fuel 285. https://doi.org/10.1016/j.fuel.2020.119117

Katagi KS, Munnolli RS, Hosamani KM (2011) Unique occurrence of unusual fatty acid in the seed oil of Aegle marmelos Corre: screening the rich source of seed oil for bio-energy production. Appl Energy 88(5):1797–1802. https://doi.org/10.1016/j.apenergy.2010.12.010

Khan TMY, Atabani AE, Badruddin IA, Badarudin A, Khayoon MS, Triwahyono S (2014) Recent scenario and technologies to utilize non-edible oils for biodiesel production. Renew Sustain Energy Rev 37:840–851. https://doi.org/10.1016/j.rser.2014.05.064

Kishore Khatri K, Singh M, Khatri N (2023) An artificial neural network model for the prediction of performance and emission parameters of a CI engine-operated micro-tri-generation system fueled with diesel, Karanja oil, and Karanja biodiesel. Fuel 334:126549. https://doi.org/10.1016/j.fuel.2022.126549

Knothe G (2014) Cuphea oil as a potential biodiesel feedstock to improve fuel properties. J Energy Eng 140(3):1–4. https://doi.org/10.1061/(asce)ey.1943-7897.0000194

Knothe G, Cermak SC, Evangelista RL (2009) Cuphea oil as source of biodiesel with improved fuel properties caused by high content of methyl decanoate. Energy Fuels 23(3):1743–1747. https://doi.org/10.1021/ef800958t

Kolli V, Gadepalli S, Debbarma J, Mandal P, Barathula S (2020a) Experimental analysis on performance, combustion & emissions of a diesel engine fueled by Aegle marmelos seed oil biodiesel with additives: graphene nanosheets and oxygenated diethyl ether. Energy Sources Part A: Recover Utilization Environ Effects 00(00):1–20. https://doi.org/10.1080/15567036.2020.1783393

Kolli V, Gadepalli S, Debbarma J, Mandal P, Barathula S (2020b) Experimental analysis on performance, combustion & emissions of a diesel engine fueled by Aegle marmelos seed oil biodiesel with additives: graphene nanosheets and oxygenated diethyl ether. Energy Sources, Part A: Recover Utilization Environ Effects, 1–20. https://doi.org/10.1080/15567036.2020.1783393

Kotaiah K, Periyasamy P, Prabhahar M (2020) Performance and emission characteristics of small agricultural diesel engine using lemongrass oil and its diesel blends. Mater Today: Proc 33(xxxx):658–662. https://doi.org/10.1016/j.matpr.2020.05.773

Krishnamoorthi M, Malayalamurthi R (2017) Combined effect of compression ratio, injection pressure, and injection timing on performance and emission of a DI compression ignition engine fueled with diesel-Aegle marmelos oil-diethyl ether blends using response surface methodology. Energy Fuels 31(10):11362–11376. https://doi.org/10.1021/acs.energyfuels.7b01515

Krishnamoorthi M, Malayalamurthi R (2018) The influence of charge air temperature and exhaust gas recirculation on the availability analysis, performance and emission behavior of diesel - bael oil - diethyl ether blend operated diesel engine. J Mech Sci Technol 32(4):1835–1847. https://doi.org/10.1007/s12206-018-0340-4

Krishnamoorthi M, Malayalamurthi R, Mohamed Shameer P (2018) RSM based optimization of performance and emission characteristics of DI compression ignition engine fuelled with diesel/aegle marmelos oil/diethyl ether blends at varying compression ratio, injection pressure and injection timing. Fuel 221(May 2017):283–297. https://doi.org/10.1016/j.fuel.2018.02.070

Krohn BJ, McNeff CV, Yan B, Nowlan D (2011) Production of algae-based biodiesel using the continuous catalytic Mcgyan® process. Biores Technol 102(1):94–100. https://doi.org/10.1016/j.biortech.2010.05.035

Kuete V (2014) Physical, hematological, and histopathological signs of toxicity induced by African medicinal plants. In Toxicological Survey of African Medicinal Plants (pp. 635–657). Elsevier. https://doi.org/10.1016/B978-0-12-800018-2.00022-4

Kukana R, Jakhar OP (2022a) Performance, combustion and emission characteristics of a diesel engine using composite biodiesel from waste cooking oil - Hibiscus cannabinus oil. J Clean Prod 372:133503. https://doi.org/10.1016/j.jclepro.2022.133503

Kukana R, Jakhar OP (2022b) Effect of ternary blends diesel/n-propanol/composite biodiesel on diesel engine operating parameters. Energy 260:124970. https://doi.org/10.1016/j.energy.2022.124970

Kumar A, Sharma S (2011) Potential non-edible oil resources as biodiesel feedstock: an Indian perspective. Renew Sustain Energy Rev 15(4):1791–1800. https://doi.org/10.1016/j.rser.2010.11.020

Kumar Rai R, Rekha Sahoo R (2020) Taguchi-Grey method optimization of VCR engine performance and heat losses by using Shorea robusta biodiesel fuel. Fuel 281:118399. https://doi.org/10.1016/j.fuel.2020.118399