Abstract

Application of new techniques to convert brown algal biomass to glucose suitable for microbiology is implemented by complete enzymatic hydrolysis of cellulose and laminarin. We proposed a scheme for obtaining cellulose-rich fraction (CRF) from the Arctic species Laminaria digitata, Saccharina latissima, Ascophyllum nodosum, Fucus vesiculosus and subsequent saccharification using glycoside hydrolases produced by Penicillium verruculosum and 1,3-β-glucanases from Myceliophtora thermophila. The dependence between the composition, degree of polymerization, and crystallinity of the substrates and its impact on the glucose yield during enzymatic hydrolysis was demonstrated. The enzyme preparations utilized in this study exhibited a conversion degree of up to 72% for L. digitata CRF. Alkaline pretreatment provides an increase in conversion of about 20%. Laminariaceae species (L. digitata and S. latissima) CRF demonstrated a higher potential for the production of fermentable sugars due to the accessible and well-developed structure of the cellulose fibrils and the higher laminarin content.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Brown algae are a type of marine plants that are widespread in the Arctic seas. They are commonly used in industry to produce carbohydrates such as alginates, fucoidan, and mannitol. The biomass of brown algae contains up to 13% dry matter of cellulose, which is one of the most important structure-forming components and imparts elasticity to the algal thallus [1]. When examining the properties of algal cellulose as a component of the cell wall, it is worth noting that there are variations between the cellulose found in algae and that of higher plants, as described by Strømme et al. [2] and Mihranyan [3]. Algal cellulose has a greater surface area and smaller particle size, which leads to the creation of thinner and smaller fibers. This, in turn, enables the development of a multifaceted capillary-porous and crystalline-amorphous structure. Thus, it can be observed that the type of cellulose synthase complex present in algae determines the predominant content of the metastable Iα phase, whereas land plant wood contains the more stable Iβ type of cellulose [4].

Macroalgae are the subject of enzymatic hydrolysis investigations due to their capacity to produce sustainable feedstock, along with their high content of carbohydrates and low lignin [5,6,7]. Despite extensive study, there are still a few limitations and gaps. Among the various algal species, brown algae have been studied to a greater extent than green species. However, they are not considered a promising source of cellulose, in contrast to green algae [8]. This is due to the relatively low cellulose content in brown algae and the complex structure of their cell walls, which impede the availability of cellulose [9]. Consequently, there is a paucity of studies investigating the saccharification of cellulose from brown algae. Typically, these are converted to fucose and uronic acids’ derivatives [8]. Researchers commonly propose a conversion of the whole biomass with a complex mixture of enzymes [10]. However, this approach is hindered by the presence of inhibitors. Non-pretreated biomass contains multiple compounds that can interfere with enzyme activity or produce inhibitors, thereby reducing the efficacy of targeted reactions. Consequently, to achieve high yields, algal biomass should be subjected to pretreatment at an early stage of the biotechnological processing [11].

In this context, industrial residues have the potential to be utilized as substrates for saccharification. The traditional processing of brown algae frequently results in the production of a cellulose-rich fraction (CRF), which remains after the extraction of soluble compounds that could potentially impede enzymatic hydrolysis. The CRF is based on insoluble cellulose and contains bound protein and residual amounts of polysaccharides. From a biotechnological perspective, the CRF presents a relatively pure cellulosic material that can be easily converted to glucose. Furthermore, this approach significantly contributes to the waste’s management and comprehensive biorefinery.

The interest in eco-biotechnological approaches to synthesizing substances that are currently produced from petroleum and its by-products has driven the potential for using cellulose-rich fractions. The proposed approach involves carefully selecting a suitable substrate for saccharification, which results in a hydrolyzate that is saturated with mono- and oligosaccharides. This hydrolyzate can then be used as a carbon source for microbiological cultures that produce specific compounds, such as lactic, succinic, fumaric, maleic acids, glycerin, sorbitol, and amino acids [12,13,14]. The physicochemical features of algal substrates (CRF) are highly complex, necessitating the development of unique approaches to effectively convert free and bound carbohydrates to fermentable sugars. The search for new specific enzymes and their mixtures is of the utmost importance in order to achieve this goal.

The high metabolic activity and protein expression make filamentous fungi an efficient platform for production plant glycoside hydrolases. Cultivation of fungi on different substrates, combined with strain modification using genetic and protein engineering methods, allows the production of enzyme complexes with a wide range of activities that can selectively act on different carbohydrate components. The glycoside hydrolases produced by the ascomycete fungus Penicillium verruculosum have been shown to efficiently hydrolyze polysaccharides from both herbaceous and woody substrates. These broad-spectrum hydrolases were initially obtained at the Chemical Department of Lomonosov Moscow State University and Federal Research Centre “Fundamentals of Biotechnology” RAS, Russia. Currently, there is ongoing research in the field of developing new and improving existing enzyme preparations to obtain new beneficial properties. A complex of 1,3-β-glucanases was designed from the ascomycete fungus Myceliophtora thermophila [15] for the effective conversion of grain β-glucans. This enzyme complex has the potential to convert algal laminarin, which has glucopyranose residues connected by 1,3-glycosidic linkages. The cultivation of filamentous fungi strains on growth media containing polysaccharide components of various origins can lead to the production of enzyme complexes with a broad range of activities. This ensures the versatility and high specificity of fungal hydrolases.

The enzyme complexes of P. verruculosum and M. thermophila are primarily adapted for the saccharification of terrestrial plant substrates and have never been implemented in the hydrolysis of algal substrates. Given the presence of laminarin in seaweeds, it can be reasonably assumed that these enzyme preparations will demonstrate high effectiveness in glucose production when applied to marine plants. The primary objective of the current study was to evaluate the reactivity of brown algae cellulose-rich fractions for enzymatic hydrolysis of glucans. It is postulated that the physicochemical characteristics of substrates, including chemical composition, crystallinity, and surface morphology, which are dependent on taxonomic classification, will determine the efficacy of glucans’ conversion. Furthermore, the efficiency of the enzymatic hydrolysis could be optimized through the integration of pre-treatment techniques, which would enhance the accessibility of reactive sites for interaction with enzymes. In this study, four species of Arctic brown algae (Fucaceae and Laminariaceae families) were employed as the initial material to obtain cellulose-rich fractions for subsequent optimization of enzymatic saccharification. Consequently, the current research could facilitate the investigation of these renewable plant materials for the effective production of glucans, which could then be utilized in further biotechnological fermentation processes.

2 Materials and methods

2.1 Enzymes

For the hydrolysis of algal CRF, 1,3-β-glucanases produced by the filamentous fungus M. thermophila, and complexes of glycoside hydrolases with endoglucanase, cellobiohydrolase, and β-glucosidase activities produced by the ascomycete P. verruculosum were used. The enzyme dosage was determined as mg of protein per 1 g of dry weight of substrate (d.w.). The enzyme dosages and combinations were selected based on previous studies of the level of substrate conversion of the glycoside hydrolases utilized [15]. In instances where the selected dosages resulted in insufficient glucose formation, the dosage was doubled to ensure sufficient substrate conversion. Protein concentration was determined according to the Lowry protein assay [16] using BSA as a standard. The loading of cellulase complex was 80 mg of protein/g d.w.; the loading of the 1,3-β-glucanase ranged from of 30 to 220 mg of protein/g d.w. Additionally, β-glucosidase preparation was also added to the reaction mixture in the dosage of 1–5 mg protein/g d.w. The specific activities of the enzyme preparations towards sodium carboxymethyl cellulose (CMC, endoglucanase activity), birch xylan (xylanase activity), microcrystalline cellulose (MCC, cellobiohydrolase activity), p-NF-β-D-glucopyranoside (p-NFG) (β-glucosidase activity), and laminarin (β-1,3-glucanase activity) were determined at pH 5.0, 50 °C [17, 18]. Table 1 presents the specific activities per 1 g d.w. for both single enzyme preparations and their combinations.

2.2 Preparation of cellulose-rich fraction (CRF)

The CRF was obtained from the biomass of brown algae species Ascophyllum nodosum (AN), Fucus vesiculosus (FV), Laminaria digitata (LD), and Saccharina latissima (SL) (Fig. 1). The seaweeds were collected at mid-August 2021 from the White Sea (Solovetsky Archipelago, 65°00′55″N 35°59′39″E).

In the first stage, the lipid-pigment complex was removed through chloroform extraction in a Soxhlet apparatus. Subsequently, the defatted mass underwent a series of extractions to remove acid- and water-soluble components and alginic acids from the biomass. This included extraction with 0.1 M hydrochloric acid at 60 °C, 1:20, three times for 1 h; 1.5% sodium carbonate at 50 °C, 1:20 twice for 1 h; and water at 60 °C, hydromodulus 1:30 six times for 30 min. The resulting material was dried under natural conditions. To increase the accessibility of CRF in enzymatic hydrolysis, acid or alkaline pretreatment was carried out according to the scheme in Fig. 1.

2.3 Analysis of cellulose-rich fraction

The mannitol content was determined spectrophotometrically by the optical density of solutions of the mannitol complex with copper ions [19]. The protein content was determined using the total nitrogen conversion method (EuroEA 3000, EuroVector, Italy). The amount of alginic acids in the biomass was determined titrimetrically following the Alcian blue binding method [20]. The Kürschner-Hoffer method was used for the gravimetric determination of cellulose, which involves boiling of CRF with a mixture of ethanol and concentrated nitric acid [21]. To quantify easily hydrolyzable polysaccharides, CRF were preliminary hydrolyzed with 6 M hydrochloric acid at 110 °C. The amount of reducing substances in the resulting hydrolyzate was then determined titrimetrically using Fehling’s reagent [21]. The ash content was determined through gravimetric analysis after the complete combustion of the organic portion of the sample in a muffle furnace at 550 °C.

2.4 Physicochemical properties of CRF

The composition and ratio of crystalline phases in CRF samples were evaluated using the Rietveld method. The crystallinity index (CI) was calculated using the Ruland method [22,23,24] using the following formula:

where \({\int }_{{2\theta }_{1}}^{{2\theta }_{2}}I\left(2{\theta }_{i}\right)d\left(2\theta \right)\) is the total integral scattering intensity of the crystalline and amorphous phases, \({\int }_{{2\theta }_{1}}^{{2\theta }_{2}}{I}_{am}\left(2{\theta }_{i}\right)d\left(2\theta \right)\) is the integral scattering intensity of amorphous phase, and θ is Bragg’s angle.

The degree of polymerization (DP) was determined by viscometry of CRF solutions in cadoxene [25]. Intrinsic viscosity was determined by the formulas:

where ηγ is the specific viscosity characterizing the increase in the viscosity of the solution relative to the viscosity of the solvent; t1 is the solution outflow time, s; t0 is the solvent outflow time, s; and C is the concentration of the solution, g/mL.

The degree of polymerization was calculated by the following formula:

where Km and α are constants equal to 0.7 and 0.9, respectively (for cadoxene solutions) and [η] is intrinsic viscosity, mL/g.

Infrared spectra were recorded on an IR Prestige 21 (Shimadzu, Japan) at a resolution of 4 cm−1 and 128 scans. Surface images were obtained using scanning electron microscopy (SEM) on a Zeiss SIGMA VP scanning microscope (Carl Zeiss, Germany).

2.5 Enzymatic saccharification of CRF

The CRF before and after pretreatment was enzymatically hydrolyzed at a substrate loading of 1% (d.w.) in a Biosan es-20/60 incubator shaker (Biosan, Latvia) with constant stirring at 150 rpm and a temperature of 50 °C. The pH level of the reaction mixture was maintained at 5.0 using 0.05 M sodium acetate buffer. The hydrolysis lasted for 24–48 h. For analysis, 1 mL of the suspension was taken, centrifuged at 13,400 rpm in a MiniSpin Plus centrifuge (Eppendorf, Germany). The supernatant (hydrolyzate) was collected for further glucose analysis, and the solid residue was freeze-dried on a FreeZone 2.5 (Labconco, USA, Canada).

2.6 Evaluation of the efficiency of enzymatic hydrolysis of CRF

The degree of conversion (DC), % of CRF polysaccharides was calculated according to Formula (5)

where \({m}_{CRF}\) is the weight of CRF (d.w.) (g), \({m}_{res}\) is the weight of solid residue (d.w.) after hydrolysis (g), and \({\%}_{soluble}\) is the share of soluble compounds in CRF.

The concentration of glucose in hydrolyzates was measured using the glucose oxidase–peroxidase method. The DC of β-glucans, especially cellulose and laminarin, was estimated based on the amount of glucose produced during hydrolysis. The glucose yield (GY) was calculated according to Formula (6)

where \({C}_{GL}\) is the concentration of glucose in hydrolyzate (g/L), \({C}_{S}\) and \({C}_{E}\) are background glucose concentrations from substrate and enzyme preparation, respectively (g/L), \({C}_{CRF}\) is the loading of CRF (d.w.) (g/L), and 0.9 is the coefficient of water addition of polysaccharides.

3 Results and discussion

3.1 Structure and physicochemical properties of CRF

Among algae, brown species are known for their developed structure, which often resembles that of higher plants. Upon examining the surface of the CRF, a fibrous structure was observed in samples LD and SL (Fig. 2c and d), while samples AN and FV (Fig. 2a and b) have a more uniform surface. The SEM images indicate that the non-glucan compounds in the CRF are evenly distributed, effectively covering the cellulose matrix of the algae, particularly in AN and FV. The SL and LD samples, which belong to the Laminariaceae family, exhibit a more complex physiological structure compared to other algae. This is attributed to the presence of sieve tubes in their tissues, which facilitate the transportation of assimilated substances [26]. Consequently, the morphology of the SL and LD samples is fibrous and forms a network structure with a greater surface area and activity. Consequently, the developed structure serves to alleviate interactions between enzymes and target macromolecular segments. Consequently, scanning electron microscopy (SEM) images permit the assumption that the Laminariaceae species (LD and SL) exhibit a higher degree of reactivity.

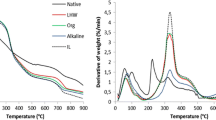

Figure 3 presents FTIR data of the algal cellulosic-rich fraction samples in comparison with a pure microcrystalline cellulose as a reference. The most notable dissimilarities are observed in the 1500–1700 cm−1 region, which is specific for the vibrations of amide bonds. This finding is consistent with the hypothesis that protein molecules are tightly bound to the cellulose matrix, and that non-glucan compounds, which comprise up to one-third of CRF biomass (Table 2), are mainly presented by proteins. The presence of uronic acids, particularly in the AN and FV samples, is notable in the 800 cm−1 area. Additionally, the C = O vibrations of the carboxylic groups are evident as a peak at 1732 cm−1. The FTIR data indicates that the studied samples possess multifunctional characteristics, necessitating a tailored approach to further saccharification.

Table 2 presents the aspects of chemical composition and physicochemical characteristics of CRF that influence enzymatic hydrolysis. The degree of polymerization was determined (Table 2), and it was observed that samples AN and FV contain cellulose with a lower molecular weight. X-ray diffraction studies revealed that cellulose Iβ is the predominant form in the LD and SL samples. The AN and FV samples display notable differences in crystallinity when observed in reflection and transmission. This disparity could be a sign of unformed cellulose and implies a considerable level of material anisotropy.

3.2 Enzymatic hydrolysis of brown algae polysaccharides

The enzymatic conversion of polysaccharides into sugars is based on the cleaving 1,4- and 1,3-glycosidic linkages. Cellulose, which is a polymer of D-glucopyranose linked by β-1,4-glycosidic bonds, can be hydrolyzed to glucose through the simultaneous action of endo- and exocellulases. Endoglucanases depolymerize amorphous structures, which can increase the number of reducing and non-reducing ends available for cellobiose cleavage by cellobiohydrolases. β-glucosidases cleave terminal non-reducing-D-glucose residues from cellobiose and oligosaccharides, producing glucose. The mutual action of endo- and exohydrolases has a positive synergistic effect owing to the removal of oligo- and disaccharides, which are known inhibitors of enzymatic hydrolysis. These inhibitors can cause a limitation of the adsorption of the enzyme by the surface area of the substrate. Endoxylanases, xylosidases, endofucoidanases, fucosidases, and 1,3-β-glucanases act by similar mechanisms, catalyzing the hydrolysis of xylans and fucoidans, respectively [8, 27, 28].

To assess the potential bioconversion of seaweed glucan-based polysaccharides, four CRF samples were subjected to hydrolysis with enzyme combination №1 (Table 1). The results indicate that the highest degree of conversion for non-pretreated samples after 24 h (Fig. 4a) was observed in L. digitata (LD). These significant findings for LD and SL samples are associated to their higher cellulose and laminarin content compared to AN and FV (Table 2). The overall low yields of fermentable sugars from AN and FV seaweeds can be explained by the reduced surface of cellulose, hemicelluloses, and laminarin accessible to enzyme molecules, hindered by phenolic compounds, fucoidans with sulfate ester groups, and other components. The similarities between AN and FV, LD, and SL are due to these species belonging to the Fucaceae and Laminariaceae families, respectively. Therefore, the potential for glucose production varies among seaweed due to interspecific differences in the content and accessibility of the convertible polysaccharides (Table 2).

To enhance the conversion of cellulose-rich complexes in brown seaweed, we screened glycoside hydrolases to optimize the composition and dosage of enzymes on the LD sample as the most promising of the presented CRFs (Fig. 4b). It was determined that enzyme combination №4 is the optimal choice for the hydrolysis of CRF due to its significant 1,3-β-glucanase and increased β-glucosidase activities. In comparison to the results obtained, it was observed that enzyme combination №3, despite having a similar and twice higher 1,3-β-glucanase activity, exhibited a reduced efficiency of saccharification. Even with a fourfold increase in combination №3 loading, it was not possible to fully compensate for the insufficient exocellulase and hemicellulase activities. The mixture №2 mainly consists of cellulases but lacks enzymes that catalyze the hydrolysis of the 1,3-glycosidic linkages. According to the data presented in Table 1, it appears that a higher level of endoglucanase activity in cellulase and 1,3-β-glucanase preparations results in a more intensive accumulation of cellooligosaccharides. These cellooligosaccharides are subsequently hydrolyzed by exo-enzymes into cello- and laminaribiose, which may cause an inhibitory effect on enzymatic reactions. The lower yield of sugars observed may be attributed to an insufficient level of β-glucosidase activity. Enzyme combination №4 has been found to have significant endo-1,3(4)-β-glucanase activity and contains a sufficient level of β-glucosidases activity to accelerate the saccharification of seaweed biomass [28]. The synergistic interaction of 1,3- and 1,4-glycoside hydrolases allows for a reduction in enzyme dosage of up to 4 times without a decrease of hydrolysis efficiency, which is an important economic factor for further scaling up enzymatic saccharification processes.

Several pretreatment methods have been found to enhance the saccharification processes of seaweed polysaccharides [29, 30]. Chemical and thermochemical pretreatment methods, such as ozonolysis [31, 32], treatment with alkalis [33,34,35] and alkali metal salts [29], and dilute acids [36,37,38], have been shown to promote partial depolymerization of holocellulose. In addition, various physical (physicothermal) methods, which typically involve mechanical grinding and steam explosion, have been found to be highly effective [32, 39]. The use of concentrated acids or alkalis for pretreatment is less common, as it may cause extensive degradation of sugars. This can result in the formation of inhibitors such as 5-hydroxymethylfurfural, furfural, furan, formic, acetic, levulinic, and aliphatic acids, which can hinder the enzymatic hydrolysis and fermentation process [30]. In this perspective, the utilization of diluted acid represents the most optimal solution. Accordingly, to facilitate the accessibility of enzymes to the CRFs, we propose a chemical pretreatment (Fig. 1) of the most promising CRFs of two families of seaweed (LD and AN) with 1.5% H2SO4 [40]. Subsequently, enzyme combination №1 was used for further enzymatic hydrolysis of the acid-pretreated CRF. The acid pretreatment resulted in a 5% increase in the degree of conversion of LD, leading to an overall DC of 77%. Notably, no significant increase in glucose concentration was observed for AN (Fig. 5). The low efficacy of acid pretreatment may be attributed to the presence of condensed phenolic structures (analogous to lignin), which are not effectively removed by diluted acids.

Given the moderate effectiveness of acid pretreatment, we proposed alkalization of CRF as an alternative means of enhancing hydrolysis yield. In the case of hemicellulosic biomass, the most commonly applied approach to pretreatment is the use of alkaline solutions. This medium facilitates the solubilization of non-glucans by destroying ester linkages and promotes swelling of cellulose fibers [40]. For this experiment, we employed 1 M NaOH, which gave result in 96% yield of CRF. The kinetics of glucose accumulation during the enzymatic hydrolysis of the alkaline-pretreated CRF is shown in Fig. 6.

The results suggest that enzymatic hydrolysis efficiency reaches plateaus after the first 24 h, indicating that longer treatment may not be necessary. Additionally, alkalization was found to have a positive effect, reducing enzyme dosage and enabling the use of combination №5. Alkaline pretreatment results in ~ 20% increase of the DC compared to the non-pretreated and acid-pretreated CRF. It also provides a significant increase in glucose concentration in SL hydrolyzates. Alkali solution dissolves the hemicelluloses in CRF, thereby increasing the surface area of cellulose fibers available for interaction with cellulases. AN and FV show a lower degree of conversion, despite being alkalized in the same manner as SL and LD samples. 40% was the limiting DC of AN sample, achieved after hydrolysis of CRF pretreated with dilute sulfuric acid. AN and FV seaweed contain fucoidan, which cannot be converted to sugars by the enzymes used in this research owing to the specific and complex sulfated structure [27]. To increase the conversion of these types of seaweeds (Fucaceae family), it is necessary to search for an enzyme with fucoidanase [41,42,43] and other activities.

A direct comparison of the results obtained with the literature data is complicated by the use of algal residues instead of the whole biomass and interspecific differences. Nevertheless, the results obtained in the current research are comparable and, in some cases, even greater than those reported by other researchers [7, 44, 45]. Manns and colleagues employed L. digitata brown algae for saccharification. The highest glucose yield achieved was 40.8%, which is approximately twofold lower than that observed in our study [46]. Romero-Vargas et al. [10] demonstrated that intense ultrasound pretreatment of the whole brown algae D. dichotoma resulted in a 10–13% glucose yield. Enzymatic hydrolysis of acid-pretreated Sargassum brown algae yielded up to 4.5% glucose, even under more extreme conditions (3.4–4.6% H₂SO₄, 1.5 h, 115 °C) [47]. Therefore, the algal residue (cellulose-rich fraction) employed in the present study yielded comparable and even greater values of glucose than the crude algal biomass utilized in other studies, which contains other carbohydrates with the potential to produce reducing sugars. This finding underscores the significant potential of this type of residue to markedly enhance marine biomass valorization through the enzymatic conversion of industrial waste.

3.3 Effect of CRF composition and structure on the bioconversion rate

The degree of polymerization, crystallinity index, specific surface area, and chemical composition (non-glucan compounds) are the main characteristics of the cellulosic substrate which affect the rate of the enzymatic hydrolysis and its efficiency. According to the results, the highest yield of glucose and other reducing sugars specifically is the characteristic of LD and SL samples. These CRF have higher values of the DP, as well as the CI (Table 2). This result contradicts the generally accepted concept that the shorter the macromolecular chain and the higher content of the amorphous phase, the more effective enzymatic hydrolysis is. However, this issue is ambiguous and there are plenty of research that contain results similar to presented in the current study. Thus, Thielemans et al. [48] showed that the decrease in the DP does not compensate the removal of the amorphous phase of macromolecules, which leads to a decrease in glucose yield. Other studies revealed that there is no significant relationship between the rate, efficiency of enzymatic hydrolysis, and the degree of polymerization of cellulose [49,50,51]. Surface area does not show a correlation with the degree of conversion. It is noteworthy that even highly polymerized celluloses could give a high glucose yield through thorough optimization of hydrolysis and pretreatment conditions [52].

In our results, the bioconversion rate is more significant for substrates that have a higher CI (53% and 59% for LD and SL, respectively) compared to AN and FV (10% and 15%). However, it is necessary to consider the influence of amorphous non-glucan polysaccharides on the results of XRD analysis. Koo et al. [53] stated that degree of crystallinity and crystallinity index values do not correlate. The effect of “hornification” should be taken into consideration when evaluating the bioconversion potential. A never-dried samples have a hydrolysis efficiency of 96%, while cellulose after drying demonstrates a reduced bioconversion efficiency. 13C NMR analysis data showed that drying and subsequent humidification do not affect crystallinity. Thus, the authors concluded that there is no correlation between an increased crystallinity and a decrease in the level of enzymatic conversion.

Kashcheyeva et al. [54] revealed an atypical relationship between the yield of hydrolysis and the degree of polymerization and crystallinity index of cellulose of various origins. Thus, bacterial cellulose with the highest DP and CI values showed the same glucose yield as the miscanthus cellulose with the lowest DP and CI. The authors highlighted that degree of polymerization and crystallinity index are not the sole factors determining the bioconversion efficiency. Thus, bacterial cellulose has a developed “network” structure available to the multiple interactions with enzymes. Regarding seaweed cellulose, species L. digitata and S. latissima have a more intricate structural organization of the cell walls. They contain conducting channels similar to the sieve tubes of higher plants. Probably, this developed structure of LD and SL samples, which is visible in the SEM images (Fig. 2), makes them more accessible to interaction with the enzymes. An equally important factor is the accumulation of inhibitors during the hydrolysis [40].

Desorption of the enzyme from the substrate’s surface is an essential factor on a par with sorption. Enzyme molecule being a catalyst have to move to the next site to maintain the hydrolytic reactions [55]. Various nonproductive interactions between the enzyme and substrate components could hamper desorption. Regarding the wood pulp, lignin bonds cellulases via hydrophobic, electrostatic, and hydrogen interactions preventing their interaction with cellulose [56]. Seaweeds and CRF specifically lack lignin per se, while still containing a lot of accompanying non-glucan compounds. Instead of lignin, brown seaweeds produce phlorotannins—polymers of 1,3,5-trihydroxybenzene [57], which have a high affinity for proteins and cellulose [58]. As stated by Ximenes et al. [59], polymers rich in phenolic -OH groups, such as tannic acid, have a more pronounced effect of deactivating glycoside hydrolases (from 60 to 100% inhibition) than monomeric phenols. Consequently, phlorotannins, which are specific for seaweeds of the Fucaceae family (AN and FV), may contribute to the reduced bioconversion of these substrates, as corroborates with the results of Obata et al. [60, 61]. Even though numerous extractions were performed to obtain CRF and remove most of non-glucan components of seaweed, its structure and composition still remain heterogeneous, primarily because of the presence of strong bonds with protein, phenols, and alginates. Therefore, a mono enzyme combination will not work as efficiently as with pure cellulose [62]. Introducing additional enzymes for the breakdown of fucoidans and alginates will probably achieve a more complete conversion of the CRF of the Fucaceae family (AN and FV) into glucose. The synergistic effect should increase the yield of glucose as a target product [46, 63]. As been said, many factors affect the bioconversion potential of cellulose-based materials, sometimes in the opposite directions [55]. Therefore, when describing the influence of certain structural features of the substrate on the efficiency of enzymatic hydrolysis, it is necessary to consider their mutual influence.

This perspective suggests that a comprehensive examination of the substrate before and after hydrolysis could assist in comprehensively understanding the limitations of the approach and the potential for modifying experimental conditions to achieve even more pronounced results. In light of the apparent lack of promise exhibited by the Fucaceae species in the context of the current experiment, it is plausible that their performance could be enhanced through a more rigorous selection process and the application of enzymes with fucoidanase activity. Nevertheless, the quantitative results obtained permit the conclusion that the cellulose-rich fraction of the Arctic seaweeds is a promising third-generation feedstock for the production of economically valuable substances via chemical or fermentation processes [8, 13, 29, 64,65,66].

4 Conclusions

This article presents an evaluation of the bioconversion potential of four Arctic seaweed cellulose-rich fractions using glycoside hydrolases with broad hydrolytic performance produced by fungal strains Penicillium verruculosum and Myceliophtora thermophila. Laminaria digitata (LD), a member of the Laminariaceae family, exhibits the highest glucose yield of 50%, likely due to its notable content of highly accessible cellulose and laminarin, as well as its developed web-like structure of cellulose fibrils, which collectively contribute to its high glucose-producing capacity. Prior to enzymatic conversion, a chemical treatment is required to remove cellulase-binding proteins, phenols, and polysaccharides that impede further biocatalytic reactions. Pretreatment with a 1.5% H₂SO₄ solution allows for an increase in the degree of conversion to 77%, while alkalization with 1 M NaOH results in a reduction of the enzymes’ dosage without a loss of sugars’ yield. The results obtained indicate that caution should be exercised when attempting to draw conclusions regarding the correlation between the degree of crystallinity/polymerization and glucose yield, as there are numerous factors affecting hydrolysis efficiency. It is therefore of the utmost importance to consider the mutual action of these factors. The substrates utilized in this study (cellulose-rich fraction) are analogous to industrial waste products derived from seaweed processing. Consequently, the bioconversion of this substrate will contribute to the comprehensive processing, rational resource management, circular economy, and the expansion of the range of practically useful materials of algal origin.

Data availability

The raw data required to reproduce these findings can be obtained from the authors via email.

References

Bogolitsyn K, Parshina A, Ivanchenko N, Polomarchuk D (2023) Seasonal variations in the chemical composition of Arctic brown macroalgae. Algal Res 72:103112. https://doi.org/10.1016/j.algal.2023.103112

Strømme M, Mihranyan A, Ek R (2002) What to do with all these algae? Mater Lett 57:569–572. https://doi.org/10.1016/S0167-577X(02)00831-5

Mihranyan A (2011) Cellulose from Cladophorales green algae: from environmental problem to high-tech composite materials. J Appl Polym Sci 119:2499–2460. https://doi.org/10.1002/app.32959

Heinze T (2016) Cellulose: structure and properties. Adv Polym Sci 271:1–52. https://doi.org/10.1007/12_2015_319

Vasic K, Knez Z, Leitgeb M (2021) Bioethanol production by enzymatic hydrolysis from different lignocellulosic sources. Molecules 26:1–23. https://doi.org/10.3390/molecules26030753

Hong IK, Jeon H, Lee SB (2014) Comparison of red, brown and green seaweeds on enzymatic saccharification process. J Ind Eng Chem 20:2687–2691. https://doi.org/10.1016/j.jiec.2013.10.056

Chung MRWY, Tan IS, Foo HCY, Lam MK, Lim S (2023) Potential of macroalgae-based biorefinery for lactic acid production from exergy aspect. Biomass Convers Biorefinery 13:2623–2653. https://doi.org/10.1007/s13399-021-01375-3

Han J, Jo Y, Sun H, Lee ES, Chae UJ, Han SO, Kim JH, Hyeon JE (2023) The enzymatic process of macroalgae for conversion into high-tech bioproducts. Biotechnol Bioprocess Eng 28:356–370. https://doi.org/10.1007/s12257-022-0265-8

Al Abdallah Q, Nixon BT, Fortwendel JR (2016) The enzymatic conversion of major algal and cyanobacterial carbohydrates to bioethanol. Front Energy Res 4:1–15. https://doi.org/10.3389/fenrg.2016.00036

Romero-Vargas A, Muñoz I, Marzo C, Díaz AB, Romero-García LI, Blandino A (2023) Ultrasound pretreatment to enhance the enzymatic hydrolysis of Dictyota dichotoma for sugars production. Algal Res 71:103083. https://doi.org/10.1016/j.algal.2023.103083

Johnston KG, Abomohra A, French CE, Zaky AS (2023) Recent advances in seaweed biorefineries and assessment of their potential for carbon capture and storage. Sustainability 15:13193. https://doi.org/10.3390/su151713193

Werpy T, Petersen G (2004) Top value added chemicals from biomass. Volume I — results of screening for potential candidates from sugars and synthesis gas. National Renewable Energy Laboratory, Golden, CO, USA. https://doi.org/10.2172/15008859

Alvarado-Morales M, Gunnarsson IB, Fotidis IA, Vasilakou E, Lyberatous G, Angelidaki I (2015) Laminaria digitata as a potential carbon source for succinic acid and bioenergy production in a biorefinery perspective. Algal Res 9:126–132. https://doi.org/10.1016/j.algal.2015.03.008

Nagarajan D, Chen CY, Ariyadasa TU, Lee DJ, Chang JS (2022) Macroalgal biomass as a potential resource for lactic acid fermentation. Chemosphere 309:136694. https://doi.org/10.1016/J.CHEMOSPHERE.2022.136694

Merzlov DA, Zorov IN, Dotsenko GS, Denisenko YA, Rozhkova AM, Satrutdinov AD, Rubtsova EA, Kondratieva EG, Sinitsyn AP (2015) Properties of enzyme preparations and homogeneous enzymes — endoglucanases EG2 Penicillium verruculosum and LAM Myceliophthora thermophila. Biochem 80:473–482. https://doi.org/10.1134/S0006297915040112

Lowry OH, Randall RJ (1951) Protein measurement by the Folin reagent. J Biol Chem 193:265–275. https://doi.org/10.1016/0304-3894(92)87011-4

Ghose TK (1987) Measurement of cellulase activities. Pure Appl Chem 59:257–268. https://doi.org/10.1351/pac198759020257

Nelson N (1944) A photometric adaptation of the Somogyi method for the determination of glucos. J Biol Chem 153:375–380. https://doi.org/10.1016/S0021-9258(18)71980-7

Obluchinskaya ED (2008) Comparative chemical composition of the Barents Sea brown algae. Appl Biochem Microbiol 44:305–309. https://doi.org/10.1134/S0003683808030149

Schiener P, Black KD, Stanley MS, Green DH (2015) The seasonal variation in the chemical composition of the kelp species Laminaria digitata, Laminaria hyperborea, Saccharina latissima and Alaria esculenta. J Appl Phycol 27:363–373. https://doi.org/10.1007/s10811-014-0327-1

Obolenskaya AV, El’nitskaya ZP, Leonovich AA (1991) Laboratory workshop on the chemistry of wood and cellulose. Ekologia, Moscow, p 320 (in Russian)

Ioelovich M, Leykin A, Figovsky O (2010) Study of cellulose paracrystallinity. BioResources 5:1393–1407. https://doi.org/10.15376/biores.5.3.1393-1407

Terinte N, Ibbett R, Schuster KC (2011) Overview on native cellulose and microcrystalline cellulose I structure studied by X-ray diffraction (Waxd): comparison between measurement techniques. Lenzinger Berichte 89:118–131. https://doi.org/10.1163/156856198X00740

Ahvenainen P, Kontro I, Svedström K (2016) Comparison of sample crystallinity determination methods by X-ray diffraction for challenging cellulose I materials. Cellulose 23:1073–1086. https://doi.org/10.1007/s10570-016-0881-6

State standard 25438–82 (1982) Dissolving pulp. Intrinsic viscosity determination, p 22 (in Russian)

Knoblauch J, Peters WS, Knoblauch M (2016) The gelatinous extracellular matrix facilitates transport studies in kelp: visualization of pressure-induced flow reversal across sieve plates. Ann Bot 117:599–606. https://doi.org/10.1093/aob/mcw007

Deniaud-Bouët E, Kervarec N, Michel G, Tonon T, Kloareg B, Hervé C (2014) Chemical and enzymatic fractionation of cell walls from Fucales: insights into the structure of the extracellular matrix of brown algae. Ann Bot 114(6):1203–1216. https://doi.org/10.1093/aob/mcu096

Hamouda HI, Fan Y-X, Abdalla M, Su H, Lu M, Li FL (2023) Distinct roles of carbohydrate-binding modules in multidomain β-1,3–1,4-glucanase on polysaccharide degradation. Appl Microbiol Biotechnol 107:1751–1764. https://doi.org/10.1007/s00253-023-12416-4

Dave N, Selvaraj R, Varadavenkatesan T, Vinayagam R (2019) A critical review on production of bioethanol from macroalgal biomass. Algal Res 42:101606. https://doi.org/10.1016/j.algal.2019.101606

Kavitha S, Gondi R, Kannah RY, Kumar G, Banu JR (2023) A review on current advances in the energy and cost effective pretreatments of algal biomass: enhancement in liquefaction and biofuel recovery. Bioresour Technol 369:128383. https://doi.org/10.1016/j.biortech.2022.128383

Sulfahri MS, Langford A, Tassakka ACMAR (2020) Ozonolysis as an effective pretreatment strategy for bioethanol production from marine algae. BioEnergy Res 13:1269–1279. https://doi.org/10.1007/s12155-020-10131-w

Schultz-Jensen N, Thygesen A, Leipold F, Thomsen ST, Roslander C, Lilholt H, Bjerre AB (2013) Pretreatment of the macroalgae Chaetomorpha linum for the production of bioethanol – comparison of five pretreatment technologies. Bioresour Technol 140:36–42. https://doi.org/10.1016/j.biortech.2013.04.060

Bhatia SK, Ahuja V, Chandel N, Gurav R, Bhatia RK, Govarthanan M, Tyagi Kumar V, Kumar V, Pugazendhi A, Banu JR, Yang YH (2022) Advances in algal biomass pretreatment and its valorisation into biochemical and bioenergy by the microbial processes. Bioresour Technol 358:127437. https://doi.org/10.1016/j.biortech.2022.127437

Masarin F, Cedeno FRP, Chavez EGS, De Oliveira LE, Gelli VC, Monti R (2016) Chemical analysis and biorefinery of red algae Kappaphycus alvarezii for efficient production of glucose from residue of carrageenan extraction process. Biotechnol Biofuels 9:122. https://doi.org/10.1186/s13068-016-0535-9

Kumar S, Gupta R, Kumar G, Sahoo D, Kuhad RC (2013) Bioethanol production from Gracilaria verrucosa, a red alga, in a biorefinery approach. Bioresour Technol 135:150–156. https://doi.org/10.1016/j.biortech.2012.10.120

Hebbale D, Ramachandra TV (2023) Optimal sugar release from macroalgal feedstock with dilute acid pretreatment and enzymatic hydrolysis. Biomass Convers Biorefinery 13:8287–8300. https://doi.org/10.1007/s13399-021-01845-8

Yuan Y, Macquarrie DJ (2015) Microwave assisted acid hydrolysis of brown seaweed Ascophyllum nodosum for bioethanol production and characterization of alga residue. ACS Sustain Chem Eng 3:1359–1365. https://doi.org/10.1021/acssuschemeng.5b00094

Park EY, Park JK (2021) Sequential hydrothermal HCl pretreatment and enzymatic hydrolysis of Saccharina japonica biomass. Energies 14:8053. https://doi.org/10.3390/en14238053

Kooren R, Sumithra TG, Sreenath KR, Anusree VN, Amala PV, Vishnu R, Jaseera KV, Kaladharan P (2023) Exploration of seaweed degradation potential of the prioritized microbes as a green saccharification technology. Biomass Convers Biorefinery. https://doi.org/10.1007/s13399-023-04673-0

Sun S, Sun S, Cao X, Sun R (2016) The role of pretreatment in improving the enzymatic hydrolysis of lignocellulosic materials. Bioresour Technol 199:49–58. https://doi.org/10.1016/j.biortech.2015.08.061

Barzkar N, Rungsardthong V, Tamadoni Jahromi S, Laraib Q, Das R, Babich O, Sukhikh S (2023) A recent update on fucoidonase: source, isolation methods and its enzymatic activity. Front Mar Sci 10:1129982. https://doi.org/10.3389/fmars.2023.1129982

Tran VHN, Nguyen TT, Meier S, Holck J, Cao HTT, Van TTT, Meyer AS, Mikkelsen MD (2022) The endo-α(1,3)-fucoidanase Mef2 releases uniquely branched oligosaccharides from Saccharina latissima fucoidans. Mar Drugs 20:305. https://doi.org/10.3390/md20050305

Ohmes J, Mikkelsen MD, Nguyen TT, Tran VHN, Meier S, Nielsen MS, Ging M, Seekamp A, Meyer AS, Fuchs S (2022) Depolymerization of fucoidan with endo-fucoidanase changes bioactivity in processes relevant for bone regeneration. Carbohydr Polym 286:119286. https://doi.org/10.1016/j.carbpol.2022.119286

Azizi N, Najafpour G, Younesi H (2017) Acid pretreatment and enzymatic saccharification of brown seaweed for polyhydroxybutyrate (PHB) production using Cupriavidus necator. Int J Biol Macromol 101:1029–1040. https://doi.org/10.1016/j.ijbiomac.2017.03.184

Jeyakumar N, Hoang AT, Nižetić S, Balasubramanian D, Kamaraj S, Pandian PL, Sirohi R, Nguyen PQP, Nguyen XP (2022) Experimental investigation on simultaneous production of bioethanol and biodiesel from macro-algae. Fuel 329:125362. https://doi.org/10.1016/j.fuel.2022.125362

Manns D, Nyffenegger C, Saake B, Meyer AS (2016) Impact of different alginate lyases on combined cellulase-lyase saccharification of brown seaweed. RSC Adv 6:45392–45401. https://doi.org/10.1039/c6ra06669k

Borines MG, de Leon RL, Cuello JL (2013) Bioethanol production from the macroalgae Sargassum spp. Bioresour Technol 138:22–29. https://doi.org/10.1016/j.biortech.2013.03.108

Thielemans K, Bondt YD, Comer L, Raes J, Evaraert N, Sels BF, Courtin CM (2023) Decreasing the crystallinity and degree of polymerization of cellulose increases its susceptibility to enzymatic hydrolysis and fermentation by colon microbiota. Foods 12:1100. https://doi.org/10.3390/foods12051100

Sinitsyn AP, Gusakov AV, Vlasenko EY (1991) Effect of structural and physico-chemical features of cellulosic substrates on the efficiency of enzymatic hydrolysis. Appl Biochem Biotechnol 30:43–59. https://doi.org/10.1007/BF02922023

Ioelovich M, Morag E (2011) Effect of cellulose structure on enzymatic hydrolysis. BioResources 6:2818–2835. https://doi.org/10.15376/biores.6.3.2818_2835

Peciulyte A, Karlström K, Larsson PT, Olsson L (2015) Impact of the supramolecular structure of cellulose on the efficiency of enzymatic hydrolysis. Biotechnol Biofuels 8:1–13. https://doi.org/10.1186/s13068-015-0236-9

Betlej I, Antczak A, Szadkowski J, Dro M (2022) Evaluation of the hydrolysis efficiency of bacterial cellulose gel film after the liquid hot water and steam explosion pretreatments. Polymers (Basel) 14:2032. https://doi.org/10.3390/polym14102032

Koo B, Jo J, Cho SM (2020) Drying effect on enzymatic hydrolysis of cellulose associated with porosity and crystallinity. Appl Sci 10:1–12. https://doi.org/10.3390/app10165545

Kashcheyeva EI, Gismatulina YA, Mironova GF, Gladysheva EK, Budaeva VV, Skiba EA, Zolotuhin VN, Shavyrkin NA, Kortusov AN, Korchagina AA (2022) Properties and hydrolysis behavior of celluloses of different origin. Polymers (Basel) 14:3899. https://doi.org/10.3390/polym14183899

Karimi K, Taherzadeh MJ (2015) A critical review on analysis in pretreatment of lignocelluloses: degree of polymerization, adsorption/desorption, and accessibility. Bioresour Technol 203:348–356. https://doi.org/10.1016/j.biortech.2015.12.035

Liu H, Sun J, Leu SY, Chen S (2016) Toward a fundamental understanding of cellulase-lignin interactions in the whole slurry enzymatic saccharification process. Biofuels, Bioprod Biorefining 10:648–663. https://doi.org/10.1002/bbb.1670

Bogolitsyn K, Dobrodeeva L, Druzhinina A, Ovchinnikov D, Parshina A, Shulgina E (2019) Biological activity of a polyphenolic complex of Arctic brown algae. J Appl Phycol 31:3341–3348. https://doi.org/10.1007/s10811-019-01840-7

Jakobek L (2015) Interactions of polyphenols with carbohydrates, lipids and proteins. Food Chem 175:556–567. https://doi.org/10.1016/j.foodchem.2014.12.013

Ximenes E, Kim Y, Mosier N, Dien B, Ladisch M (2011) Deactivation of cellulases by phenols. Enzyme Microb Technol 48:54–60. https://doi.org/10.1016/j.enzmictec.2010.09.006

Obata O, Akunna J, Bockhorn H, Walker G (2016) Ethanol production from brown seaweed using non-conventional yeasts. Bioethanol 2:134–145. https://doi.org/10.1515/bioeth-2016-0010

Obata O, Akunna JC, Walker G (2015) Hydrolytic effects of acid and enzymatic pre-treatment on the anaerobic biodegradability of Ascophyllum nodosum and Laminaria digitata species of brown seaweed. Biomass Bioenerg 80:140–146. https://doi.org/10.1016/j.biombioe.2015.05.001

Hammed AM, Jaswir I, Amid A, Alam Z, Asiyanbi-H TT, Ramli N (2013) Enzymatic hydrolysis of plants and algae for extraction of bioactive compounds. Food Rev Int 29:352–370. https://doi.org/10.1080/87559129.2013.818012

Manns D, Andersen SK, Saake B, Meyer AS (2016) Brown seaweed processing: enzymatic saccharification of Laminaria digitata requires no pre-treatment. J Appl Phycol 28:1287–1294. https://doi.org/10.1007/s10811-015-0663-9

Panahi HKS, Dehhaghi M, Aghbashlo M, Karimi K, Tabatabaei M (2019) Shifting fuel feedstock from oil wells to sea: Iran outlook and potential for biofuel production from brown macroalgae (Ochrophyta; Phaeophyceae). Renew Sustain Energy Rev 112:626–642. https://doi.org/10.1016/j.rser.2019.06.023

Sukhikh S, Ivanova S, Babich O, Davydova A, Sirohi R, Michaud P, Dolganyuk V, Kriger O (2023) Study of parameters for bioethanol production from Baltic Sea macroalgae. Bioresour Technol Reports 24:101683. https://doi.org/10.1016/j.biteb.2023.101683

Scullin C, Stavila V, Skarstad A, Keasling JD, Simmons BA, Singh S (2015) Optimization of renewable pinene production from the conversion of macroalgae Saccharina latissima. Bioresour Technol 184:415–420. https://doi.org/10.1016/j.biortech.2014.09.105

Acknowledgements

In this work, we used instrumentation of the Core Facility Center “Arktika” of the Northern (Arctic) Federal University named after M.V. Lomonosov. We are grateful to Dmitry Chukhchin for performing the SEM images.

Funding

This study is financially supported by the Ministry of Science and Higher Education of the Russian Federation (Grant No. FSRU-2023–004).

Author information

Authors and Affiliations

Contributions

KB and AA were involved in planning and supervised the work and performed the analysis; AP, KM, and DP performed the measurements, processed the experimental data, and performed the analysis; KB, AP, KM, AA, and AS drafted the manuscript and designed the figures. OS and AS manufactured the enzyme preparations.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Bogolitsyn, K., Parshina, A., Mayorova, K. et al. Enzymatic hydrolysis of cellulose-rich fraction of Arctic seaweeds using Penicillium- and Myceliophtora-based glycoside hydrolases. Biomass Conv. Bioref. (2024). https://doi.org/10.1007/s13399-024-05934-2

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s13399-024-05934-2