Abstract

The increasing production of plastics has raised concerns over the depletion of fossil fuels. In addition, the environmental issues associated with the improper management of plastic waste are increasingly alarming. Therefore, there is a sharp rise of researches conducted on one of the most promising biopolymers for the production of biodegradable plastics, which is known as polylactic acid (PLA). Subsequently, this has led to an increased interest in the production of its monomer, lactic acid (LA). However, the high production cost of LA has been limiting its large-scale manufacturing. The utilization of expensive raw materials and complicated downstream processes have led to the high overall production cost of LA. This review explores the potential of 3G feedstock, specifically macroalgae biomass, as a substrate for LA production. Then, the recent technological advancements for LA production and the challenges currently faced in the LA industry are addressed. Lastly, the sustainability aspect of macroalgae biomass is evaluated economically and environmentally by utilizing engineering tools such as life cycle assessment and exergy analysis, which represent the highlights of this review paper.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

Over the years, the production and consumption of plastic have increased exponentially due to its favorable properties, such as light-weighted, waterproof, economical, and versatile [1]. Currently, the reported annual production capacity of plastics worldwide has approached 350 million tons [2]. According to Garside [3], the worldwide production of plastics would triple to 1100 million tons per year by 2050 [3]. The consumption of plastics follows a “take-make-dispose” pattern, where the single-used plastics were manufactured, used, and discarded. The accumulation of plastic waste worldwide creates a huge burden toward the environment. Meanwhile, the depletion of non-renewable resources driven by the consumption of petroleum-based plastics is also increasingly alarming [1].

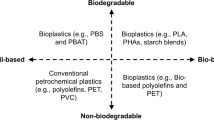

The urgent situation poses a threat for humanity, drawing attention to alternative materials such as biodegradable plastics from bio-based polymers to replace petroleum-based plastics. Serle [4] had mentioned that the decomposition of biodegradable plastics could be achieved within three to six months under specific conditions [4]. Minimal carbon is emitted during the decomposition process since plant-based materials are used during the manufacturing of biodegradable plastics where the carbon is absorbed from the atmosphere during the photosynthesis [5]. Hence, biodegradable plastics offer a reduced carbon footprint when compared to traditional plastics made from fossil fuels, mitigating the risk of climate change (CC). Biodegradable plastic from polylactic acid (PLA) is one of the most widely used substitutes as it has low processing temperature, high flexibility, and high mechanical properties [6]. Other than that, PLA is also biocompatible and friendly toward the environment [6]. Due to the increasing demand of PLA, the market demand of l-lactic acid has also expanded as it is an essential building block for the biopolymer. However, PLA is more costly compared to synthetic plastics due to several challenges faced in the LA industry [7, 8].

At present, large-scale production of LA through the fermentation route is not economically feasible due to the expensive carbon sources [9]. Therefore, this challenge requires immediate action from researchers to explore a cheaper alternative renewable carbon source. Initially, researchers had focused their studies on edible food resources which are rich in readily fermentable sugars [10]. However, edible feedstock received opposition due to food security issues. Consequently, residual waste from various sources such as forestry and agriculture has been implemented to overcome the food conflict and has been proven to be feasible by producing a high yield of LA [11,12,13,14]. Even though the food security issue was resolved, the commercialization of LA using lignocellulosic biomass is still hindered due to its high lignin content. Delignification is relatively energy-consuming as a sequence of complex pre-treatment methods are involved, leading to high production cost [15, 16]. Thus, the macroalgae biomass is explored as another viable alternative carbon source. Apart from the limitation in the fermentation phase, technological breakthrough in the downstream processes of LA is essential as the final market price and optical purity of LA are highly dependent on the efficient separation and purification methods.

This review paper highlights the latest information on the emergence of macroalgae biomass as a promising feedstock in LA biorefinery, and the current challenges faced by the industrial production of LA. In order to analyze the sustainability of macroalgae biomass as a feedstock for LA production, effective engineering tools such as life cycle assessment and exergy analysis were further discussed in this context.

1.1 Introduction of lactic acid

Lactic acid (LA) is an organic acid denoted as 2-hydroxy propanoic acid. Typically, the chiral molecule is available as two optical isomers, l-lactic acid and d-lactic acid [6]. An optically inactive form known as a racemic mixture with an equimolar (50:50) mixture of l-lactic acid and d-lactic acid can be obtained through chemical synthesis [17]. It is suggested that the physical properties of products differ in accordance with the proportion of each optical isomer [8]. An inappropriate proportion of l-lactic acid and d-lactic acid would lead to unpredictable properties of final products, whereas a racemic mixture of LA produces an inactive polymer, which is less desired for the PLA production [6]. Hence, pure enantiomers of LA have a higher market value when compared to the optically inactive form [8]. l-lactic acid tends to have the highest demand in the PLA production and food-related industries. This is due to its rapid metabolic conversion, indicating the ease of assimilation inside the human body [17]. On the other hand, d-lactic acid is less desirable because it often causes disruptions on the metabolic system in the human body, impacting human health with adverse conditions such as acidosis and decalcification [8].

The versatility of LA provides a broad range of applications in the food, cosmetic, pharmaceutical, and chemical industries. It acts as an essential platform chemical for producing value-added products. Generally, l-lactic acid, the isomer with higher compatibility with the human body, is preferable for the food, pharmaceutical, cosmetic-related industries [17]. However, the pure isomers or a racemic mixture can sometimes still be needed by the chemical industry, depending on the application. The potential applications of LA are illustrated in Fig. 1.

In the food industry, LA is utilized extensively in various forms as food additives due to its classification as GRAS (generally recognized as safe). It works effectively as a pH regulator, acidulant, emulsifier, preservative, and mineral fortification. The addition of these food additives in processed meat industries allows an increased shelf life and a regulated microflora activity. Meat products are prone toward Salmonella infection, and LA is usually used to reduce the contamination risks with its antimicrobial properties [18]. LA is also functional as an acidulant and preservative to add acidic taste and stabilize the microbial activity in salad dressings, pickled vegetables, and beverages. LA can also be found in confectionery as an acidulant to achieve a sourness effect on sugar candies. Other than that, it allows the production of clear high boiled sweets, which avoiding the occurrence of sugar inversion [18]. As a pH regulator, it adjusts the pH level of beer and wine during the mashing process while enhancing their flavor [18]. At the same time, LA has the potential as a mineral fortification in food and beverages, where it enriches the food products with micronutrients [18].

According to Vijayakumar et al. [18], LA is well known as the mildest form of alpha hydroxy acid (AHA), which is a promising alternative to glycolic acid [18]. It is a potent skincare ingredient for over-the-counter skincare products. LA works as a chemical exfoliant which helps to remove dead cells from the surface of the skin and stimulating skin rejuvenation [20]. This also renders it as a favorable active ingredient in treating acne by reducing the growth of bacteria [20]. Next, LA is also regularly used as a natural pH adjuster in formulations [20]. It maintains the pH of products on the skin at a low pH value to inhibit microbial and fungal infections. Furthermore, LA at low concentration is a natural humectant where it helps to attract moisture from the inner levels of skin to the outer skin surface for hydration. It also helps to restore the natural moisture factor of the skin and keeps the skin moisturized throughout the day [20]. However, it increases the sensitivity of skin toward the sunlight upon application and renders new cells to be more vulnerable to UV damage.

LA, as a normal constituent of blood, is also commonly used in the pharmaceutical industry as intravenous (IV) fluids because it has a lower implication of side effects on human health. IV fluids allow the replenishment of the body fluids for patients with kidney failure during the dialysis session. Several examples of IV fluids are dialysis solutions for conventional kidney machines, Ringer’s Lactate for resuscitation, and continuous ambulant peritoneal dialysis (CAPD). Currently, LA polymer has been given considerable attention in biomedical applications as surgical sutures and orthopedic implants due to its biodegradability and compatibility with the metabolic system of the human body [8]. The antimicrobial property of LA has been applied as a sanitizer and anti-acne topical cream [8].

As a chemical product, LA can be made as a descaling and cleaning agent for decalcification of coffee machines and cleaning of washrooms and washing machines [18]. It also works well as a neutralizer in the production of detergents and personal care products [18]. Furthermore, it has the potential as a metal sequestering agent to bind with heavy metal ions and prevent the metals from oxidizing onto the surfaces of hard water [18]. LA is also used as an acidulant in the deliming process of leather to remove alkali traces and adjust the pH prior to the tanning process [18].

LA also emerges as a good potential monomer for chemical conversion [7]. It possesses the flexibility of undergoing a variety of chemical conversions because of the presence of a hydroxyl group and a carboxylic group. Numerous chemicals such as acetaldehyde, acrylic acid, ethyl lactate, propanoic acid, and polylactic acid (PLA) can be produced through polymerization, dehydration, hydrogenation, and dehydrogenation of LA. Apart from that, PLA is a promising biopolymer for biodegradable plastics with its latest application in additive manufacturing (AM) technology, namely 3D printing [8, 21]. PLA is regarded as one of the best choices for 3D printing owing to its feasibility to recycle and reuse, causing no environmental pollution [21]. It is commonly used to manufacture biomedical components, particularly implants. As reported, metal implants that are coated with PLA tend to have better resistance toward corrosion [21].

In summary, the development of PLA is highlighted due to the alarming environmental issue particularly related to the accumulation of non-biodegradable plastic waste. It has the potential to serve as biodegradable commodity plastics. The developed biopolymer has favorable properties such as durability, heat-resistance, and elasticity. It provides a wide range of applications in food packaging, trash bags, textiles, plates, and trays. Despite the recognition of the society for the advantages of biodegradable plastics, the high production cost of LA is still hampering its commercial viability. The high expenses are resulted from the fermentation and the downstream processes of l-lactic production. This had prevented the wide-spread adaption of bio-based plastics to replace synthetic plastics made from petroleum due to the latter cheaper cost [7, 8].

1.2 Production of l-lactic acid

Recently, l-lactic acid has received tremendous attention as a monomer to produce polylactic acid (PLA), an environmental-friendly biopolymer for biodegradable plastics. The demand for PLA had subsequently driven the worldwide demand for l-lactic acid. Currently, the annual production capacity of LA is around 270,000 tons [13]. Further increment in the production capacity of LA was expected as Parker [14] stated that the annual growth of the LA market was 11.5% until 2026 [14].

LA can be manufactured industrially by using both routes, chemical process and microbial fermentation, as summarized in Fig. 2 [7]. For the chemical synthesis of LA, the process is based on the hydrolysis of lactronitrile, a product formed when hydrogen cyanide (HCN) reacts with acetaldehyde (CH3CHO) in the presence of a base agent. Meanwhile, ammonium chloride is produced from the process as a by-product. Despite the fact that the production of LA takes a shorter time through the synthesis route, this method only produces a racemic mixture of LA. Furthermore, this method is not ideal for the industrial production of LA because it involves the utilization of petrochemical resources. Increasing reliance on non-renewable resources is not friendly toward the environment and the resources will also suffer from depletion [23]. The experts had mentioned that the production of PLA relied on pure LA enantiomers rather than the racemic mixture of LA due to their potential to produce high crystalline PLA through polymerization, which is great for commercial usage. The high optical purity of l-lactic acid and d-lactic acid enantiomers can be achieved through microbial fermentation with the appropriate microbial strains. Therefore, the microbial production of LA has received a significant amount of attention recently. Industrially, the production of LA derived from microbial fermentation of starch and other polysaccharides accounts for over 90% of the total worldwide production [8]. The advantages of fermentation over chemical synthesis are significantly improved environmental sustainability and a relatively cheaper raw material is needed [24, 25]. It provides opportunities to utilize raw materials such as organic waste and renewable sources, as shown in Table 1. Additionally, microbial fermentation is more favorable because it consumes less energy [25, 42].

Overview of two commercial lactic acid production methods [22]

Currently, the industrial-scale LA is manufactured through fermentation on pure sugars, which are easily available from food crops such as potato, sugar cane, sugar beet, corn, and cassava [16]. The utilization of pure sugar as substrates is not economically feasible as it contributes to a significant proportion of LA production costs. In addition to the financial challenge, the usage of food crops for biochemicals production is sparking debates due to the food security issue. Thus, the discovery of alternative renewable substrates for LA production is urgently prioritized by researchers. Thereafter, it was discovered that non-food crops or cellulosic materials can also be promising raw materials for LA production. These non-food crops and cellulosic biomass have attracted attention because they are easily accessible, renewable, and cheap that does not fall into the food versus fuel debate. However, the effective utilization of cellulosic biomass was still faced with many bottlenecks. For instance, some of the substrates cannot be utilized directly without pre-treatment process due to the presence of lignin or the absence of hydrolytic enzymes in microbial LA producers. The additional pre-treatment is an energy-intensive process which may contribute to the overall processing cost of LA. The expensive downstream processing for recovery and purification of LA is an additional challenge to microbial fermentation.

2 Lactic acid producers

In nature, several microbes have been used for feedstock consumption in microbial fermentation of LA. They can be classified into bacteria, fungi, and metabolically engineered strains [43]. Each microbe has one or more merits over the others, such as low nutritional requirements, enhanced yield, and productivity, or increased optical purity of LA. The properties of microbes used for LA production are described in Table 2.

2.1 Fungi

Among the fungal species, Rhizopus spp. is widely studied in LA production. It involves the utilization of Rhizopus spp. in various renewable resources, including xylo-oligosaccharides [26], rice straw [44], cassava starch [45], and Sophora flavescens residues [37]. This species, Rhizopus spp. consists only l-ldh gene encoding L-LDH. Therefore, it has the ability to produce only optically pure l-Lactic acid via fungal fermentation [22, 46]. According to Thongchul [46], the LA production by Rhizopus spp. allows direct fermentation of various starch-rich raw materials without prior saccharification due to its secretion of hydrolytic enzymes [22, 46, 47]. The next advantage associated with fungal fermentation is its low nutritional requirements [22]. However, the fermentation generally resulted in a low productivity rate, which was below 3 g/L h, possibly because of the requirement of oxygen during fermentation and low reaction rate due to the limitation in mass transfer [19, 22]. The fermentation also produces undesirable by-products such as fumaric acid and ethanol [19, 22, 46].

2.2 Yeast

Yeast has also received attention for fungal fermentation due to its cost-effective nutrient requirements and high tolerance to low pH levels [22, 47]. As such, the regeneration of precipitated lactate can be avoided under low pH levels and reduce the demand for neutralizing agents. However, most wild-type yeast naturally produces low concentrations of LA. Therefore, genetically engineered yeasts were developed to enhance LA production. For instance, Ilmén et al. [48] found out that the application of Candida sonorensis strain could produce 92 g/L of l-lactic acid at a yield of 0.94 g/g glucose. Kong et al. [42] utilized K. marxianus strain YKX071 for fermentation on corncob residue in fed-batch simultaneous saccharification and co-fermentation (SSCF) process to produce 103 g/L of high optical purity of l-lactic acid (99.5%) [42].

2.3 Bacteria

The production of LA by many genera of bacteria includes the four main microorganisms: lactic acid bacteria (LAB), Bacillus strains, Escherichia coli, and Corynebacterium glutamicum. Bacterial fermentation has been extensively used for the commercial production of LA as a primary product of the fermentation process [49].

2.3.1 Bacillus strains

Bacillus spp., especially Bacillus coagulans, has been widely studied in microbial production of LA due to their abilities in producing high optical purity and high yield at thermophilic temperatures [22, 47]. Ma et al. [50] employed Bacillus coagulans to produce l-lactic acid with high optical purity (> 99.5%), with a concentration of 92 g/L, yield of 0.91 g/g, and productivity of 13.8 g/L h from corn stover hydrolysate [50]. Bacillus spp. are Gram-positive bacteria, and the optimal temperature for growth is 50 °C [51]. In contrast to the conventional LAB, Bacillus spp. have several merits, such as the reduction of fermentation cost by growing and producing LA in a simple mineral salt medium with minimal nitrogen sources [51]. The microbe can be fermented at 50 °C, which reduces the risk of contamination since the sterilization of fermentation medium using coolant water is not necessary [47, 51]. Thus, this reduces the cost associated with medium sterilization. Other than that, the usage of Bacillus spp. enables the simultaneous saccharification and fermentation (SSF) on both pentose and hexose sugars for lignocellulosic biomass at optimum temperature [22, 47, 51]. However, the oxygen requirement by Bacillus spp. is a disadvantage for economical LA fermentation as it prefers aerobic growth and anaerobic fermentation [22].

2.3.2 Lactic acid bacteria

Although the LA production through fungal fermentation and Bacillus spp. has been attempted persistently, lactic acid bacteria (LAB) is still the most predominantly used LA producer. Bacteria, in the form of LAB, is Gram-positive, anaerobic, acid-tolerant, and aero-tolerant. The morphology can vary from short cocci or long rod-shaped to excrete LA as the major anaerobic product from the fermentation of reducing sugars, with high yield and high productivity [43, 47]. They are highly adaptable in various optimal growth environments, where some of the producers can grow in the pH range between 3.2 and 10.0 and temperature within 5 to 45 °C [8, 47, 51]. A few strains of LAB can even survive in a harsh environment and produce LA under higher temperature (> 45 °C) [29, 52]. A novel thermophilic LAB strain known as Enterococcus faecium QU 50 facilitated the fermentation of LA at optimal conditions (pH 6.5 and 50 °C), achieving optically pure l-lactic acid (≥ 99.2%) [52]. Similarly, at the same temperature of 50 °C, a thermo-alkaliphilic strain known as Enterococcus durans BP130 was able to produce a high LA titer of 28.8 g/L when demonstrated under the alkaline environment with the pH-controlled at 9.0 [31].

Several of the major naturally found genera are Lactococcus, Lactobacillus, Streptococcus, Leuconostoc, Pediococcus, Aerococcus, Carnobacterium, Enterococcus, Oenococcus, Tetragenococcus, Vagococcus, and Weisella [22, 43, 46]. Among them, Lactobacilli is available abundantly and comprises of approximately 80 species [43]. This species has a good reputation in commercial-scale LA production without affecting the health of both the consumers and the production workers [47]. The Lactobacillus strain, which is a commercially viable LAB strain, has been particularly effective due to their tolerance toward high acidity conditions and their potential to be engineered genetically for the selective production of d- or l-lactic acid.

The conversion of fermentable sugars into LA by LAB via different fermentation patterns can be divided into two groups: homofermentative or heterofermentative. Homofermentative LAB contains an aldolase enzyme where it generates LA as the major product. This group of LAB ferments more yield of LA because one mol of glucose can be converted into 2 mol of LA, without generation of any by-products through Embden-Meyerhof-Parnas (EMP) glycolytic pathway, as illustrated in Fig. 3a [17]. Thus, homofermentative LAB is favored industrially due to its high yield of LA formation and carbon-neutral properties [8]. Several of the genera categorized under homofermentative LAB are Lactococcus, Streptococcus, Pediococcus, Enterococcus, and some species of Lactobacillus [47]. In contrast to homofermentative LAB, the maximum LA yield produced by heterofermentative LAB only reached 0.5 g/g and 0.6 g/g with the utilization of hexoses and pentoses, respectively [46, 47]. The production of LA is accompanied with by-products such as ethanol, acetic acid, and carbon dioxide (CO2), through the phosphoketolase pathway as illustrated in Fig. 3b. Several reported genera of heterofermentative LAB are Leuconostoc, Oenococcus, and species of Lactobacillus [47].

Metabolic pathways of a homofermentative and b heterofermentative LAB in glucose [53]

In general, bacterial fermentation faces a limitation in biosynthetic capabilities where they cannot produce sufficient B-vitamins and amino acids [43, 51, 54]. Therefore, they only show rapid growth when adequate vitamin B, peptides, yeast extract, and fatty acids are supplied to the growth medium [43, 51, 54]. Furthermore, LAB tends to perform efficiently only at lower temperatures. Thus, the sterilization of culture media should be carried out before starting the fermentation. These two factors had contributed to a substantial rise in the downstream production cost of LA. Meanwhile, the requirement of low temperature for cell growth hampers the performance of LAB in the simultaneous saccharification and fermentation (SSF) process since hydrolytic enzymes tend to develop at higher optimal temperatures for saccharification when compared to LAB [47].

According to Abdel-Rahman et al. [55], most of the LAB strains favored the neutral or slightly acidic pH ranged from 5.5 to 6.5 which increased the contamination risks [55]. They further emphasized that the usage of the alkaline solution for fermentation when paired with alkaliphilic LAB strains was a promising solution to overcome this limitation. Most contaminant strains do not favor this alkali growth condition, whereas the usage of alkaliphilic LAB strains can tolerate pH levels at 9.0 and above which resolves the contamination problems during fermentation. Calabia et al. [56] found out that the isolation of alkaliphilic Halolactibacillus halophilus could produce 65.8 g/L of l-lactic acid in batch fermentation at pH 9.0 with a yield of 0.76 g/g [56]. Abdel-Rahman et al. [55] had isolated alkaliphilic Psychrobacter maritimus BoMAir 5 in a batch fermentation [55]. It showed high pH adaptation at 9.0 and produced a high LA production titer of 140.8 g/L with a yield of 0.93–0.99 g/g glucose consumed [55]. The isolated thermo-alkaliphilic Enterococcus faecium FW26 is capable of producing LA yield of 0.84 g/g consumed sugars by direct utilization of mixed lignocellulosic and food waste at pH 9.0 and 50 °C [29]. Aside from this, Hassan et al. [31] also effectively obtained LA concentration of 28.8 g/L from untreated mixed waste through direct utilization, facilitated by Enterococcus durans BP130 at pH 9.0 [31].

2.3.3 Escherichia coli

Escherichia coli has shown good potential in the rapid production of LA from the metabolism of both pentose and hexose sugars [47, 51]. Overall, this lactic acid producer requires a simpler nutritional requirement for growth when compared to the conventional LAB. Other than that, it is easy for gene replacement into engineered E. coli strains to achieve a higher yield of LA production [47, 51]. The major drawback of this LA producer is the generation of undesirable organic acids (d-lactic acid, acetic acid, succinic acid, formic acid), and ethanol due to its carbon flux distribution [47, 51]. There are a few reported studies on the application of engineered Escherichia coli strains for LA production. Parra-Ramírez, Martinez, and Cardona [57] had evaluated the performance of a metabolically engineered Escherichia coli strain JU15 for fermentation using Aspen Plus software to produce d-lactic acid from xylose and glucose. It was reported that the strain achieved a maximum concentration of 40 g/L with a yield of 0.6 g/g sugars consumed [57]. Wang et al. [58] reengineered a d-lactic acid-producing strain, Escherichia coli HBUT-D, to be fitted for l-Lactic acid fermentation through gene replacement. The consumption of this strain on combined wastes of molasses and corn steep liquor achieved 97 g/L of l-lactic acid with high optical purity of 99%, productivity of 3.17 g/L h, and a conversion rate of 90% [57]. Both experiments demonstrated that engineered E. coli strains can be a great approach in waste conversion into the high concentration of LA.

2.3.4 Corynebacterium glutamicum

Corynebacterium glutamicum is a Gram-positive soil bacterium that is extensively used for the industrial production of amino acid [51]. It has several advantages, such as simple fermentation medium, high growth rate, and predominantly producing l-lactic acid as the main product under oxygen-deprived conditions [22, 47, 51]. It produces combined organic acids such as l-lactic acid, succinic acid, and acetic acid with the consumption of various sugars [59]. However, the by-products formed during LA fermentation are disadvantageous since this led to low LA yield [22].

Tsuge et al. [59] reported the use of metabolically engineered Corynebacterium glutamicum strains to consume a mixture of glucose and xylose for LA fermentation [59]. The study conducted the fermentation anaerobically and managed to achieve a high titer of d-lactic acid up to 119.3 g/L with a yield of 0.79 g/g of mixed sugar consumed after 80 h. At the same time, they learned that the gene encoded Corynebacterium glutamicum strains decreased the yield of by-products, DHA, and glycerol by 74% and 24%, respectively. Tsuge et al. [60] conducted another experiment on two different metabolically engineered Corynebacterium glutamicum, namely LPglc429 and LPglc402, respectively for glucose fermentation into l- and d-lactic acid [60]. They found out that each strain had the ability to produce high productivity of LA without the requirement of the nutrient-rich medium for growth. Corynebacterium glutamicum, LPglc429 produced 212 g/L l-lactic acid, and Corynebacterium glutamicum, LPglc402 produced 264 g/L d-lactic acid, where each of the yields was above 95%. They successfully produced high optical purity of l- and d-lactic acid with the usage of inexpensive mineral salts medium. Further study of metabolically engineered Corynebacterium glutamicum strains in minimizing or eliminating the production of by-products is highly encouraged since it has a high potential for industrial LA production.

2.4 Evolution of lactic acid biorefineries

As of today, various feedstocks have been published in the literature for the production of LA [11, 14, 41, 61, 62]. These feedstocks can be categorized into three primary groups based on their sources of biomass, advantages, limitations, and technological progress, as presented in Table 3.

Biorefineries can be represented as either first-generation (1G), second-generation (2G), or third-generation (3G), depending on the sources of the substrate. Currently, commercialized LA in the market is mostly derived from food crops, which are known as 1G feedstock [16]. The sources of 1G feedstock mainly consist of food crops rich in sugar, starch, vegetable oils, and animal fats. The carbon sources are readily extractable for the fermentation of LA without further pre-treatment process accompanied with maturity in conversion technology at commercial scale. However, the use of 1G feedstock as LA feedstock suffers from the food versus energy debate since food prices will increase along with the expansion of the LA industry. The biomass supply for LA production has also increased the demand for more agricultural land for food supply [65]. This also comes with a higher overall production cost for LA as pure carbon sources are economically unfeasible. Several studies of LA production from sugarcane [66], wheat bran [67], rice [68], sweet sorghum juice [62], and cassava [45] had been published in the literature.

The drawbacks in 1G feedstock have subsequently led to the development of 2G feedstock. In contrast to easily extractable carbon sources, 2G focuses on lignocellulosic biomass such as forest and agricultural waste. Lignocellulose is primarily composed of cellulose (35–45%), hemicellulose (20–25%), and lignin (15–20%) [69]. It is rich in hexose and pentose sugars, which are fermentable [70]. The usage of 2G feedstock is effective in overcoming the food security issue encountered in the 1G feedstock. However, it is challenging to release fermentable sugars from lignocellulosic biomass due to its high lignin content. Owing to the complex structure, complicated and cost-intensive pre-treatment methods are required to remove the lignin from the lignocellulosic biomass [15, 16]. The market of LA from lignocellulosic biomass is not as established as 1G feedstock due to the high cost of processing technologies. Even though LA from 2G feedstock is available at a commercial scale, there is still a potential for further cost reduction following the advancement of technologies. A few studies on LA production using lignocellulose biomass had been reported, such as bagasse of cassava [71], orange peel waste [14, 72], corn cob residue [11], waste cooking oil glycerol [73], bagasse from sugar cane [74], municipal solid waste [75], coffee mucilage [12], and coffee pulp [13].

As a result of criticism received from 1G feedstock and technological challenges associated with 2G feedstock, researchers have focused their attention to the macroalgae biomass known as 3G feedstock.

3 Macroalgae: sustainable feedstock for LA

3.1 Diversity of algae species

In this context, algae biomass has recently received much attention as a 3G feedstock because of supply abundance and sustainability. According to Abdul Latif et al. [76], a quarter of 400,000 algae species have been discovered worldwide [76]. Algae biomass can be categorized into macroalgae and microalgae in accordance with its morphological features, size, carbohydrates, and lipids content [77, 78]. In general, microalgae produce a relatively higher lipid content, which serves as raw material mainly for biodiesel production [79, 80]. On the other hand, macroalgae possess a high content of carbohydrates, which are useful for the production of alcohol-based biofuels and biochemicals [77, 78, 81, 82]. The biochemical composition of macroalgae and microalgae is illustrated in Table 4. It shows that most macroalgae generally have a low content of protein (5–13% dry wt.) and lipids (7–12% dry wt.), whereas most microalgae are observed to have a relatively high protein content (30–60% dry wt.) and high composition of lipid (10–20% dry wt.).

Macroalgae can be broadly grouped into three categories: green algae (Chlorophyceae), brown algae (Phaeophyceae), and red algae (Rhodophyceae). The general carbohydrate contents of macroalgae is highly dependent on the species of macroalgae strain such as green, red, and brown algae, which ranges between 30–60%, 30–50%, and 20–30% dry weight, respectively [77]. Since macroalgae have a variety of species, biochemical characterization is performed using proximate analysis after the harvesting of macroalgae [78]. There are four main components which are necessary to be studied on macroalgae strains, including carbohydrate, protein, lipid, and ash content [78]. This information is required so that the macroalgae species can be effectively utilized as carbon sources for bioenergy and bioproducts. The carbohydrate composition of several of the macroalgae species is presented in Table 5.

Based on a review paper published by Gomez-Zavaglia et al. and Renganathan and Takriff [96, 97], the following macroalgae species made up most of the current total cultivated macroalgae: the brown algae (Laminaria japonica, Saccharina japonica, and Undaria pinnatifida), the red algae (Porphyra sp., Eucheuma striatum, Kappaphycus alvarezii, and Gracilaria sp.), and green algae (Monostroma and Enteromorpha). The population of the two species for brown macroalgae (Laminaria japonica and Undaria pinnatifida) and three species of red algae (Eucheuma, Kappaphycus, and Gracilaria spp.) are highly cultivated and they occupied approximately 40% of the total production capacity [97, 98]. When compared to the other two species, the production number of green algae is considered negligible [97, 98].

3.2 Comparisons between macroalgae and lignocellulosic plants

The structural polysaccharides of macroalgae are significantly different from those of terrestrial plants, which are composed of cellulose, hemicellulose, and lignin. The type of principle carbohydrates presents in each species of macroalgae, microalgae, and lignocellulosic biomass is tabulated in Table 6. The unique compositions in macroalgae such as ulvan, carrageenan, agar, mannitol, fucoidan, and alginate are generally differed according to the three macroalgae groups and cannot be found in other microalgae and lignocellulosic biomass [99]. The existence of alginate, fucoidan, and mannitol can be found in brown macroalgae (Phaeophyta); while carrageenan and algae can be found in red macroalgae (Rhodophyta) [100, 101]. The green macroalgae (Chlorophyta) are known to contain cellulose, starch, and mannose [101]. In contrast to the terrestrial plants, the other two categories of macroalgae have a lower starch content and lipid, except for green macroalgae (Chlorophyta) [15].

In terrestrial plants, lignin is an essential constituent for structural support to provide rigidity of the plant cell wall. Macroalgae are cultivated in marine environments and are held up by the buoyant force of water. Hence, they do not require the rigidity provided by lignin [15, 102]. The characteristic of macroalgae having negligible lignin is an added advantage over 2G feedstock as the complexity of the pre-treatment process can be reduced and lower the production cost [51, 77, 78, 103, 104]. Additionally, macroalgae does not compete with food crops for agricultural land since macroalgae are resistant to extreme growth conditions and can be cultivated in a variety of water environments such as wastewater and saline water [64, 105]. In the case where the cultivation of macroalgae is conducted in wastewater, the wastewater can be treated effectively along with the growth of macroalgae biomass [104].

Meanwhile, an added merit of macroalgae biomass would be a shorter harvesting cycle compared to terrestrial plants because of a higher photosynthetic efficiency [104]. A large quantity of macroalgae biomass per unit area can be produced in one harvesting cycle, ensuring an abundance of supply [103, 104, 106]. On average, green algae has a productivity of 7100 g/m2 year compared to brown algae and red algae, which recorded a maximum of 11,300 g/m2 year [77]. The cultivation of macroalgae biomass can also be easily sustained through photosynthesis with light, CO2, and nutrients in the water environments [77]. At the same time, macroalgae can fix CO2 from the atmosphere while releasing oxygen in the process.

3.3 Opportunities for macroalgae-based biorefinery

As mentioned previously, the production of LA in the current market is mostly derived from expensive carbohydrates categorized under 1G feedstock [16]. To resolve this concern, researchers had taken the initiative to explore the sustainability of macroalgae for the production of LA as it showed high potential in biochemical conversion without compromising the food versus fuel debate and agricultural issues. According to Jung et al. [98], the most viable macroalgae species at the moment for biorefinery feedstock were Laminaria japonica, Eucheuma spp., Kappaphycus alvarezii, Undaria pinnatifida, and Gracilaria verrucose [98]. The development in macroalgae-based refinery technology should be based on the exploitation of brown and red algae rather than green algae after considering the rising market demand of PLA and the current technology for macroalgae cultivation.

Macroalgae can be cultivated easily and potentially reach a higher rate of production compared to other terrestrial plants due to their higher photosynthetic rate [104]. The macroalgae-based carbohydrates comprise mostly of cellulose and starch with negligible lignin, which acts as a readily accessible carbon source for microbial fermentation of LA in the biorefinery. Hence, due to the fast growth rate and immense carbohydrates content, macroalgae had received the focus as the feedstock for renewable fuels and chemicals production [92, 107]. From previous studies, the exploitation of macroalgae biomass was focused primarily on generating single products, while the residual solid or liquid waste remained unused and discarded [108]. In addition, most of the researches related to macroalgae was predominantly focused on biofuel production [82, 106, 109,110,111,112]. To the best of the author’s current knowledge, there is no available literature in the production of LA from macroalgae integrated biorefineries. However, it was reported that microalgae had been utilized in LA production at a laboratory scale and proven to be feasible. As of now, there were only three published articles proposing the conversion of LA from microalgae.

By using green microalga, Hydrodictyon reticulatum as substrate, Nguyen et al. [113] achieved 37.11 g/L of l-lactic acid at a yield of 0.46 g/g, and producing 1.03 g/L h with consumption of Lactobacillus paracasei LA104 in a simultaneous saccharification and co-fermentation (SSCF) process. The optical purity of l-lactic acid obtained was between 95.7 and 98%. Similarly, Nguyen et al. [114] also achieved 36.6 g/L of d-lactic acid in approximately 36 hours, from the same substrate, Hydrodictyon reticulatum consumed by Lactobacillus coryniformis subsp. torquens in a SSCF process at a yield of 0.46 g/g and maximum productivity of 1.02 g/L h [114]. Hydrodictyon reticulatum is a promising feedstock for high optical purity d-lactic acid production since this research shows encouraging results ranging from 95.8 to 99.6% [114]. In addition, another microalga, Nannochlorum sp. 26A4, with 40% dry weight of starch content, was successfully converted into d-Lactic acid with a conversion rate of 70%. This fermentation process occurred through an anaerobic reaction when isolated in a dark environment [115].

3.4 Pre-treatment of macroalgae biomass

In the bioprocessing of macroalgae, an effective pre-treatment is essential to achieve high carbohydrates hydrolysis and thereafter a high yield of LA. During pre-treatment, the outer cell wall of macroalgae will be broken down to release complex polysaccharides and further hydrolyzed into simple reducing sugars (majorly glucose and galactose) while avoiding the degradation of carbohydrates. Different from lignocellulosic biomass, macroalgae has negligible lignin, which simplifies the pre-treatment process to become more economical [15]. Currently, the most practiced pre-treatments of macroalgae are physical (e.g., milling and microwave-assisted extraction), chemical (e.g., dilute acid treatment), and biological process (e.g., enzymatic hydrolysis).

3.4.1 Physical pre-treatment

Physical pre-treatment is one of the most effective methods because it involves size reduction of macroalgae biomass [43, 116]. This process increases the surface area and liberates complex sugars for better accessibility to enzymes, thereby optimizing LA production. The physical methods can be categorized into mechanical pre-treatment and microwave-assisted extraction.

In general, mechanical pre-treatment comprises of three steps, which are washing, drying, and milling. Initially, the freshly collected macroalgae biomass undergoes a washing process using fresh water to remove salts, sand, and debris on the surface. Next, the removal of water content is carried out through drying to prolong the shelf life of macroalgae biomass for the subsequent procedure [78]. The biomass can be dried in a hot air oven or exposed to the sun. At the last step, milling is performed to reduce the size and subjected to sieving. Together with other pre-treatment methods, this approach can be utilized to reduce energy expenses and enhance the overall performance of the process for substrate extraction [117]. Although mechanical processes do not require temperature as a driving force or any usage of chemicals, energy consumption is perceived to be high [117, 118].

Microwave-assisted extraction has been used to extract multiple compounds of interest from lignocellulose, macroalgae, and microalgae biomass [119, 120]. This approach is based on the assistance of a short electromagnetic spectrum with high frequencies ranging from 0.3 to 300 GHz, where it raises the temperature to a boiling state rapidly and causes disruption in the cells [43, 120, 121]. This method induces the exposure of the intracellular contents available for fermentation. The main drawback of this method is that the generated heat might also damage the compounds which are sensitive toward heat and not commercially viable because it is energy-intensive [43, 120].

3.4.2 Acid and alkali hydrolysis

The chemical route is widely accepted for pre-treatment of macroalgae biomass because it is efficient in depolymerizing cellulose and solubilizing hemicellulose using dilute alkali or acid treatment. Sodium hydroxide (NaOH) is mostly used in alkali treatment, where it facilitates the simultaneous solvation and saponification on biomass [122]. This causes the fibres of macroalgae to swell and enlarge in pore sizes. Substantially, this enables the release of reducing sugars for efficient enzymatic hydrolysis or fermentation. The major drawback of alkali treatment is the requirement of large quantities of water for desalting, where it increases the overall production cost and wastewater generation [78].

For acidic pre-treatment, dilute sulfuric acid (H2SO4) is applicable to all the classes of macroalgae [78, 123]. In comparison to other pre-treatment methods, the energy consumption in acid pre-treatment is relatively low, and it delivers a higher sugar yield [77, 124]. However, the use of dilute acid pretreatment is restricted due to the generation of inhibitory compounds such as furfural, 5-hydroxymethylfurfural (HMF), levulinic acid, furfural, and caffeic acid [77, 98, 125]. The former two toxins can inhibit the activity of enzymes, thereby mitigating the glycolysis pathway. Levulinic acid, which is a type of weak acid, can hinder the growth of cells. These inhibitors can be mitigated with the addition of sodium hydroxide for neutralization to pH 7 prior to fermentation or using alternative methods such as enzymatic hydrolysis [77]. As discussed above, a host of factors such as acid strength, treatment duration, amount of biomass loading, temperature, and pH can affect the yield of acid hydrolysis [78, 117].

The above statement can be justified by the following studies conducted. Sudhakar et al. [126] investigated the effect of different concentrations of H2SO4 (0.1%, 0.5%, and 1%) for hydrolysis of spent seaweed [126]. They reported that a higher amount of total sugar can be obtained from the biomass by increasing to 1% diluted H2SO4. There was an increment of 30% from 62.62 mg/g of total sugar obtained when 1% of diluted H2SO4 was used compared to 0.1%. They also found that the biomass loading and volume of substrate loading ratio at 4:50 displayed the maximum amount of reducing sugar yield, which was 13.07 mg/g. The concentration greater than this value showed a declined trend in the reducing sugar yield. Hong et al. [127] pretreated red macroalgae, Gelidium amansii with 1% H2SO4 for 15 min at 111 °C. The concentration of reducing sugar in hydrolysate was found to improve by 80.95% when the treatment temperature was raised to 131 °C [127].

3.4.3 Enzymatic hydrolysis

As aforementioned, enzymatic hydrolysis is a more effective practice for fermentation processes. Although it has a longer incubation period for the release of sugar as compared to acid hydrolysis, this method is highly practiced due to the low production of toxic inhibitory compounds as compared to acid hydrolysis [15, 104, 128]. Meanwhile, it yields more reducing sugars from cellulosic biomass due to the high conversion rate. Jmel et al. and Trivedi et al. [84, 129] carried out an in-depth study concerning enzymatic hydrolysis on macroalgae biomass (Ulva fasciata Delile and Ulva lactuca) where cellulase preparations were used to yield a high concentration of reducing sugars, 97.5 mg/g and 206.82 mg/g, respectively [84, 129]. However, the enzymes utilized are highly specific in converting certain types of polysaccharides, while macroalgae are often composed of several types of polysaccharides [15, 117]. In addition, the application of expensive enzymes causes this method to be not economical for industrial-scale biomass pretreatment [117].

According to Kim et al. [130], the efficiency of saccharification tends to improve when accompanied with mechanical pretreatment prior to acid and enzymatic hydrolysis [130]. These methods are sometimes co-utilized on macroalgae biomass for enhanced yield in fermentable sugars. From several recent studies, macroalgae biomass was typically pretreated using dilute acid and then followed by enzymatic hydrolysis. Wu et al. [131] pre-treated the macroalgae biomass, 15% (w/w) of Ulva lactuca with 4% H2SO4 for 120 min at 80 °C before proceeding with LA production in ensilage at acidic condition (pH < 4) [131]. They observed a maximum reducing sugar yield of 155 mg/g as a result of acid hydrolysis. The high reducing sugar yield reflected the feasibility of ensilage and presented encouraging pretreatment effects of acid hydrolysis. The importance of enzymatic hydrolysis was further demonstrated where it resulted in a further spike in reducing sugar yield from 155 to 198 mg/g [131]. The reducing sugar was later consumed by Lactobacillus plantarum during fermentation for 24 h and achieved a LA yield of 0.58 g/g. Different combinations of pre-treatment methods and macroalgae-extracted reducing sugar yield are described in Table 7.

3.5 Lactic acid conversion technologies

Prior to the conversion of LA, macroalgae is subjected to mechanical processing, which involves drying and reduction in size before followed by pretreatment of biomass. Later, saccharification is incorporated to degrade the polysaccharides into reducing sugars, and finally, these substrates are subjected to the fermentation process of LA. The saccharification process can be combined with fermentation in the following sequence: (1) separate hydrolysis and fermentation (SHF), (2) simultaneous saccharification and fermentation (SSF), and (3) simultaneous saccharification and co-fermentation (SSCF).

SHF is a process where hydrolysis of polysaccharides from biomass and fermentation of reducing sugars are performed separately in two different units along with different reaction conditions [15]. This allows both hydrolysis and fermentation to be performed at optimal conditions to convert reducing sugars into LA and lowering the intake of enzymes [139]. However, this configuration could lead to increased contamination risk and unwanted inhibitory effects [139]. An increased inhibitory effect indirectly resulted in rate-limiting hydrolysis due to inhibition of cellulase activity [139]. Since this technique requires two vessels for operation, the operating cost may increase [43].

On the other hand, SSF aims to produce LA through polysaccharides’ hydrolysis and fermentation of hexoses in one-step [139]. This step is carried out in a single reactor, where the same reaction conditions are applied to both processes [43, 139]. SSF configuration effectively overcomes the drawbacks in SHF by reducing the risk of contamination, inhibitory effects and decreasing the operating cost by utilizing only one reactor [43, 139]. The main limitation of this configuration is the failure to maintain the performance of hydrolysis and fermentation under optimal conditions [43, 139]. It is relatively difficult to maintain the optimal pH below 5 and a temperature of about 50 °C for hydrolysis, and optimal pH between 5 and 7 at 37 to 43 °C for fermentation [43].

Even though both configurations were reported to deliver encouraging results in LA production, SSF was shown superior to SHF from previous studies. Zhang et al. [26] reported a l-lactic acid conversion yield of 0.34 g/g with SHF and a higher yield of 0.6 g/g with SSF from xylo-oligosaccharides [26]. In addition, Zaini et al. [40] studied the production of d-lactic acid from dried distiller’s grains and also discovered a higher d-lactic acid yield of 0.423 g/g with SSF when compared to SHF [40].

Contrarily to lignocellulosic biomass, macroalgae is composed of cellulose and galactan, which have the potential to be converted into reducing sugars after the hydrolysis process. The enzymatic hydrolysis can be performed simultaneously with the co-fermentation of hexoses and pentoses in a SSCF configuration [139]. This approach allows the LA producers to commence a continuous fermentation process without separating the sugars and the involvement of sterilization [140]. This configuration poses less contamination risk and shortens the time duration of the process while producing a higher yield of LA [43]. SSCF is currently a highly researched area that has yet to achieve commercialization status [140]. Similar to SSF, the hydrolysis and fermentation are conducted simultaneously in a single reactor, thus the difficulty in providing optimal conditions to satisfy both processes [43].

Currently, the studies of LA production from macroalgae biomass through SHF, SSF, and SSCF are still scarce when compared to lignocellulosic biomass. A study by Talukder et al. [141] had investigated the production of l-lactic acid from lipid depleted microalgae, Nannochloropsis salina using the SSF method [141]. The microalgae biomass was pretreated using 5% of H2SO4 at 120 °C for 1 h. The SSF configuration was studied in a batch fermentation with the addition of Lactobacillus pentosus to produce LA at optimal conditions. The maximum yield of l-lactic acid reached 0.93 g/g with a productivity of 0.45 g/L h. Talukder et al. [141] discussed that low productivity might be the result of inhibitor compounds such as furfural and HMF [141]. Nguyen et al. [113] investigated the feasibility of l-lactic acid production from microalgae, Hydrodictyon reticulum through the SSCF process [113]. Lactobacillus paracasei LA104 was isolated from traditional Korean dishes and utilized for fermentation because it is highly tolerant toward heat and low pH [113]. Other than that, it is also tolerant toward high concentrations of glucose and can eliminate unfavorable inhibitory effects. The final concentration of l-lactic acid attained at optimal conditions was 37.11 g/L, with a yield of 0.46 g/g, and a productivity of 1.03 g/L h [113].

3.6 Separation and purification of LA

Regardless of the conversion route, the separation and purification of LA from fermentation broth is crucial. The downstream processes play a significant part in the purity of LA since the expenses of downstream processes represent half of the overall production cost [61]. In order to achieve commercially feasible LA, an efficient upstream process must be matched with an economically and environmentally feasible downstream separation method to remove impurities such as cells, proteins, residual sugar, and cell metabolites present inside the fermentation broth. Many studies had been extensively reported on LA downstream processes, including precipitation, solvent extraction [142,143,144,145], various distillation systems [74], ion exchange [12], and membrane separation processes [146,147,148,149,150,151]. A summary of the main advantages and disadvantages of each method is tabulated in Table 8.

Industrially, the purification of LA is mainly based on precipitation [61]. During the purification, an excess base, either calcium carbonate or calcium hydroxide is added into the fermentation broth to neutralize the LA produced. This step maintains the pH of the growth media around 5 to 6 so that the LA producers can adapt and work efficiently at pH near neutrality. The precipitated calcium lactates can then be easily recovered by distillation and re-acidified using sulfuric acid for the release of LA accompanied by the generation of gypsum. The generated gypsum from this process will later be filtered and evaporated to obtain the technical grade (22–44%) LA [152]. However, the high optical purity of LA enantiomers is essential for the manufacturing of PLA to define the physical properties of the end products [8]. For high-purity products, the technical-grade LA will go through esterification with methanol or ethanol to form either methyl or ethyl lactate. The lactate salt can be recovered sequentially using distillation, hydrolysis, evaporation, and crystallization. This method is a mature technology but the requirement for large amounts of sulfuric acid leads to higher cost. Other than that, the purification of LA from this method is accompanied with gypsum as a solid waste, which poses a threat from an environmental standpoint. Thereby, to date, researchers had been studying the recovery of LA through methods such as solvent extraction [142,143,144,145], membrane separation [146,147,148,149,150,151], and emulsion liquid membrane [153].

Another popular method of LA purification is solvent extraction. The LA is removed from the aqueous phase by the addition of an organic solvent extractant. Afterward, the phase loaded with LA known as the organic phase is back-extracted. This method seems to be promising because the LA is removed directly from the fermentation broth without the need of chemicals to regulate the pH. The merit of solvent extraction is that the process of extracting LA with the extractant and diluent can be repeated through proper recycling. An innovative hybrid process accompanied with reactive extraction has justified the importance of repeated extraction. Lan et al. [145] studied the efficiency of a two-step extraction incorporating salting-out and reactive extraction for LA recovery from corn stover hemicellulose derived-liquor [145]. This two-step hybrid system achieved an extraction efficiency of 89.4% after five successive extraction cycles with back-extraction. This recorded a slight improvement as compared to 83% obtained from one-step extraction at optimized conditions [145]. At the same time, this process consumes less energy to produce a high yield of LA. Unlike purification, this method avoids the generation of gypsum waste since the process does not involve any calcium salts. However, solvent extraction requires expensive equipment to achieve an efficient separation at high mass transfer rate. The use of a large amount of toxic extractants increases the additional cost to the process and might be limiting the performance of the LA producers to produce LA.

Membrane-based separation technologies such as electrodialysis, ultrafiltration, and nanofiltration have also been extensively studied [146,147,148,149,150,151]. López-Gómez et al. [28] reported the recovery of l-lactic acid from organic fraction municipal solid waste through a series of filtration followed by electrodialysis [28]. They managed to reduce the content of impurities to around 0.3 g/L, a value lower than the previously reported studies by Olszewska-Widdrat et al. and Neu et al. [12, 62]. Thus, a recovery percentage of 51.5% with a high purity of l-lactic acid at 98.7% was accomplished. Lee et al. [150] reported an integrated membrane separation process which is inclusive of ultrafiltration and nanofiltration for the recovery of LA from fermentation broth [150]. Both separation processes successfully separated most of the organic and inorganic components inside the fermentation broth. The recovery process was later combined with ion exchange and vacuum-assisted evaporation to remove residual salt ions further to achieve LA with high purity (> 99.5%). Pal and Dey [151] managed to obtain 95% pure l-lactic acid with a yield of 0.96 g/g and productivity of 12.4 g/L h using a three-stage membrane-integrated hybrid reactor system [151]. The hybrid system, which combined two processes, namely microfiltration, and nanofiltration, had permitted the selective production of l-lactic acid with repeated recycling of cells and unconverted reducing sugars. While separation through membrane provides high purity of LA, the advancement in this technology was limited due to the expensive membrane cost, membrane fouling, and polarization issues [150].

Recently, emulsion liquid membrane (ELM) technology was considered a new breakthrough for the recovery of LA. Emulsion liquid membrane is a technique used to separate solute molecules or ions using a liquid film between two miscible liquid phases [25, 153]. The transport mechanism of ELM is driven by kinetic instead of affinity in the solvent extraction process [153]. LA will first be extracted into the liquid membrane before being back-extracted from the membrane. This technology has been confirmed as a promising LA separation method due to its high extraction efficiency, the requirement of a small volume ratio between organic and aqueous phases, and large mass transfer area [25, 153]. Kumar et al. [154] managed to accomplish the extraction efficiency of LA at 96.59% at optimal conditions using ELM. The main concern of this method is due to the usage of non-renewable resources as organic solvent [25, 153]. In view of the importance of sustainable development, researchers are working progressively to search for a replacement for petroleum-based organic solvents in ELM. With respect to this constraint, the application of vegetable oils as the green solvent has been nominated as the most important development of ELM in recent years, proven to be feasible by several researchers [155,156,157].

4 Lactic acid sustainability assessment methods

Several useful methodologies have been extensively practiced to date to measure the efficiency and environmental sustainability of a system or process, namely life cycle assessment, techno-economic analysis, energy, and exergy analysis.

The approach of life cycle assessment can effectively evaluate the energy efficiency and the environmental hotspots in a system or process [158]. It provides data-driven insights on environmental impacts such as climate change, ecotoxicities in terms of marine, freshwater, or terrestrial and depletion of water or fossil resources. Thereby, future optimizations can be made to the whole system to reduce the environmental effects identified in a LA biorefinery.

When evaluating an energy system, energy analysis is the most commonly used engineering tool. It considers all the input and output energy in a boundary system to provide insights into the efficiency of the system. However, the reliance on energy analysis can be confusing since it cannot identify how the energy in a system is transferred or converted into one another. The sustainability of a system cannot be justified by energy analysis solely. On the other hand, an exergy analysis that quantifies both the quantity and quality of energy streams is a better approach than energy analysis. Exergy analysis can effectively discover the locations and the causes of thermodynamic irreversibility in a system by providing a quantitative analysis. After identification of the locations of thermodynamic irreversibility, potential enhancements can be made to the system to improve the overall system efficiency. As the exergy efficiencies are enhanced, the sustainability of the system can also be improved with the reduction in environmental impacts initiated by these existing thermodynamic losses. In general, exergy analysis provides more meaningful insights as a method which closely resembles ideal scenarios.

4.1 Exergy analysis

4.1.1 Energy versus exergy

The first law of thermodynamics states that energy is neither created nor destroyed but changed from one form into another. Based on the second law of thermodynamics, the exergy does not obey the conservation laws and tends to be destroyed when a process is irreversible. When exergy is destroyed, this phenomenon indicates that the quality or usefulness of the energy is lost and is identified as exergy destruction [74]. Exergy is conserved during real processes where they are reversible. Thus, energy differs from exergy such that energy is a measure of only the quantity, whereas exergy may be viewed as a measure of quality energy in a system. In other words, exergy is a property to measure the capacity of an energy form to do useful work. In fundamental theory, exergy is defined as the maximum amount of work that can be extracted from a system as it is brought to equilibrium relative to a reference environment [159,160,161]. The exergy will be equaled to zero when the system properties correspond to the reference environment that is called the dead state.

Energy analysis is mostly used to determine the thermodynamic efficiency in processes. It is important to note that, while the use of energy allows one to construct an energy balance around a given process, a focus on energy analysis alone can be misleading because it does not distinguish between heat and work. It does not provide any resourceful information with regards to how energy is transferred or whether the energy can be completely converted to another. Conversely, the exergy analysis can overcome these drawbacks from energy analysis in various energy processes. Table 9 presents the comparison between the key properties of energy and exergy.

4.1.2 Exergy reference environment

The evaluation of exergy concepts is with respect to a reference environment which acts as an infinite system. The specification of the concise characteristics for the reference environment is of utmost importance. This is commonly done by defining the temperature (To) and pressure (Po) at 25 °C and 101.325 kPa, respectively, and the chemical composition of the reference environment [160, 163]. The outcome of exergy analysis is usually relative to the specified reference environment mentioned, which is modeled after the actual local environment in most applications. When the system is in equilibrium with the reference environment, the exergy of a system is denoted as zero [161]. The exergy consumption is also zero in a reversible process [161].

4.1.3 Exergy efficiency and exergy destruction

The aforementioned energy analysis is incompetent at providing a measure of the performance of a system approaches ideal condition [164]. Furthermore, it is insufficient in pinpointing the factors and locations of energy losses, which causes the performance of the system to deviate from ideal conditions [164]. In contrast, exergy analysis tends to provide useful insights into improving the efficiency of a process under ideal conditions, practically overcoming the drawbacks associated with energy analysis.

Exergy analysis is an efficient methodology based primarily on the concept of irreversible production of entropy principle from the second law of thermodynamics and the conservation of energy principle from the first law of thermodynamics [160]. According to the exergy analysis, energy can neither be created nor destroyed, but the energy quality can be degraded during a process [160, 161]. The degraded energy eventually reaches the equilibrium state with the surroundings and cannot be used to perform tasks efficiently. Exergy analysis is a useful engineering tool which assists in improving and optimizing designs because it is a better indicator of nature, causes, and locations of thermodynamic losses in a system when compared to energy analysis [160, 164]. It can be applied in complex integrated systems such as biorefineries and provide a qualitative and quantitative estimation of energy requirements effectively and identify the thermodynamic inefficiencies taking place in the systems [74]. Once the thermodynamic inefficiencies, also known as exergy destructions, are quantified, and located, engineering measures can be taken to enhance the overall exergy efficiency. The exergy destruction can be minimized as the exergy efficiency increases.

4.1.4 Exergy and environmental sustainability

Exergy is closely related to sustainability. Novak [163] commented that a reduction in exergy destruction or depletion is crucial in improving the sustainability of a system [163]. In this context, exergy analysis is a practical approach related to the development of sustainability since it is instrumental in providing insights into exergy destruction. These exergy destructions can cause negative impacts to the environment. By minimizing or eliminating the source of exergy destruction, this can boost the efficiency of the overall process and contribute to reduced environmental damage. Rosen et al. [160] suggested that the utilization of non-renewable resources as a power source should be minimized to prevent harmful emissions to the environment [160].

The relationship among sustainability, exergy efficiency, and environmental impact is represented in Fig. 4. When the exergy efficiency is approaching 100%, the environmental impact is kept at minimal and the sustainability of a system is approaching infinity as the system is experiencing the reversible process [160]. At this stage, the exergy is only converted from one form to another without suffering from exergy destruction. Conversely, when the exergy efficiency is approaching 0%, the system fails to achieve sustainability because energy resources are not utilized properly, resulting in an increasing amount of interfaced exergy destruction to the environment [160].

Relationships between exergy efficiency with sustainability and environmental impact [74]

4.1.5 Exergy analysis of biomass conversion in biorefinery

For the concept of biorefinery, reducing sugar is an essential component for the production of bioethanol and LA. In the conversion of biomass into reducing sugars, the drying and pretreatment process plays the role of minimizing the size of biomass and facilitating the conversion of cellulose to reducing sugar with better accessibility to enzymes, respectively [15]. It is reported that a significant amount of exergy is destroyed due to the heat and mass transfer phenomena during chemical reactions [74]. Thus, the selection of the suitable drying and pre-treatment methods is dependent on its thermodynamic performance instead of its potential yield of reducing sugar. For a fair comparison, exergy analysis would be a useful indicator of thermodynamic performance in a system [160, 164]. The following subsections outlined the research works where exergy-based analyses had been used for assessing the bioconversion of any of the three generations feedstock. Reported studies based on exergy aspects for developed biorefineries are summarized in Table 10.

Ofori-Boateng and Lee [165] carried out exergy analyses on the production of ethanol from oil palm fronds (OPFs) based on three different pretreatment methods, which are steam explosion, organosolv, and microbial pretreatment method [165]. The system which employed the microbial pretreatment method exhibited the highest overall exergy efficiency of 90.93%, followed by organosolv (90.30%), and steam explosion (66.65%), as illustrated in Fig. 5. The exergy destruction in the steam explosion was mainly originated from the high-pressure steam and dryer, which involved high energy consumption. Similarly, the drying unit was also the major contributor toward the exergy destruction in organosolv due to the heavy heat exchange. This is because OPFs have very high moisture content. Therefore, high energy was needed to decrease the moisture content to about 10%. It was recommended to employ sun drying for preliminary drying before the actual drying in dryers as this could reduce the demand for energy. Aside from the dryer being the hotspot for thermodynamic losses, the heavy usage of chemicals such as ethanol and water was also one of the underlying reasons behind the low exergy efficiency of orgonosolv. This limitation could be overcome with the recovery of ethanol to be reused in the process. The generation of wastes was the main cause of thermodynamic losses in the microbial pretreatment method. The conversion of these wastes into value-added products would be advantageous toward the overall performance and environmental sustainability of the system.

Overall exergy efficiency of system with different pre-treatment methods [165]

An exergy analysis was conducted by Silva Ortiz and de Oliveira [166] on four different pre-treatment technologies for the preparation of two types of lignocellulosic biomass with different chemical compositions for the production of bioethanol [166]. The pre-treatment methods were steam explosion (case study A), organosolv (case study B), liquid hot water (case study C), and a combination of steam explosion with hot water liquid (case study D). It was discovered that the lignin-rich part of sugarcane bagasse could lead to a declined exergy performance compared to parts with lower lignin content. Case study D showed the highest overall exergy efficiency as it utilized the exergy contents from outflow of steam explosion in hot water liquid method. The combined method was a breakthrough and should be entitled for an economic and environmental assessment for industrial-scale processing. When evaluated alone, both the hot water liquid method and steam explosion were reported to involve high pressure and temperature. Consequently, high energy was needed which affects its thermodynamic performance.

Modarresi et al. [167] applied exergy analysis for the quantification of thermodynamic efficiencies to evaluate the magnitude of irreversibility within bioethanol production processes from straw [167]. Pinch analysis was first conducted, and the minimum hot and cold utility demands of the plant were optimized by 40%. The exergy efficiency of the plant after optimization was concluded to be higher than the base case due to the effective reduction in demand for steam and cooling water. Following the exergy analysis, it was discovered that the bioethanol production process resulted in the highest exergy efficiency. This was attributed to the useful exergy outflow of stillage since it could be converted into biomethane and combusted in a steam boiler for power generation. On the other hand, the combined heat and power (CHP) process suffered from the high exergy destruction because the unit involved rapid heat losses to the surrounding during combustion and unknown materials which were not reacting correctly.

An exergy analysis was employed by Sanjuan-Acosta et al. [170] to assess the production of agar from macroalgae, Gracilaria sp. [170]. The macroalgae was washed, dried, and pretreated with sodium hydroxide (NaOH). This was followed by neutralization using acid solution and heating to obtain the diluted agar, which was later separated and purified through evaporation from other solid sludge. The cellulose-rich agar, when optimized with acid or alkali pretreatment, could produce reducing sugar, which would be a favorable carbon source for LA fermentation process [171]. The stage with the highest exergy irreversibility (16,552 MJ/h) was the evaporation unit due to the variations in temperature for the separation of agar from water. The second-largest contributor of exergy losses was the Filtration III stage, which resulted from the formation of undesired waste (6146.60 MJ/h) as illustrated in Fig. 6. In terms of exergy efficiency, filtration I associated with low consumption of utilities had the highest exergy efficiency of 98.9%, whereas the evaporation unit had the lowest exergy efficiency of 27.9%. Hence, efforts should be shifted to improve the performance of the evaporation unit and filtration III through better energy integration.

Overview of exergy analysis for production of agar from Gracilaria sp. [170]

Fudholi et al. [169] analyzed the thermodynamic performance of drying red seaweed using the solar system with the conventional energy and exergy analysis [169]. The solar dryer took 15 h to decrease the moisture content of 40 kg red seaweed from 90 to 10%. The energy analysis showed that the specific energy consumption of the system was 2.62 kWh/kg, whereas the maximum efficiency of moisture removal from the biomass was calculated to be 95% by maintaining the drying temperature between 35 and 60 °C. Throughout the day, the solar dryer displayed an exergy efficiency within the range of 1 to 93%, achieving an average of 30%. Thus, this study had proven that the utilization of solar dryer would be a great idea to decrease the exergy losses caused by drying unit for the biorefinery developed by Ofori-Boateng and Lee and Sanjuan-Acosta et al. [165, 170].

A lignocellulosic biorefinery for co-generation of LA and electricity production was exergetically analyzed by Aghbashlo et al. [74]. Aghbashlo et al. [74] discovered that the overall functional exergy efficiency of the system was 44.73% where the boiler contributed the highest exergy destruction rate (129.41 MW) followed by LA production sub-unit [74]. In other words, this study revealed that both sub-units have very poor exergy efficiencies due to the generation of entropy in large amounts. The quantitative results presented in Fig. 7 showed that the boiler had exergetic improvement potential as high as 68.90 MW, indicating the possibility of further optimization in the design to improve the overall efficiency of the process. However, they also learned that the refrigeration sub-unit had the least exergy efficiency rate, which was against the concept of exergy because this sub-unit had a low destruction rate. They further related this to the high consumption of power within the sub-unit. Notably, the results from this exergy analysis highlighted that future optimization can be focused on the steam generation and LA production sub-units.

Exergy destruction rates derived from subsystem of LA Biorefinery. (1) pre-treatment of feedstock; (2) production of cellulase enzyme; (3) saccharification; (4) boiler; (5) water treatment; (6) generation of power and distribution of steam; (7) production of LA; (8) refrigeration; and (9) cooling tower [74]

In another study, Soltanian et al. [172] conducted an exergoeconomic analysis on the lignocellulosic biorefinery system reported by Aghbashlo et al. [74]. Similarly, the steam generation unit accounted for 43.73% of the overall cost rate of the biorefinery, whereas the LA production sub-unit came in the second rank with 20.49%. The high-cost rate in each sub-unit is associated with the high exergy destruction, as mentioned previously. The pre-treatment and saccharification sub-units had the lowest relative cost difference of 0.07, whereas the refrigeration sub-unit which consumed higher energy had a higher relative difference of 20.47. This indicated that the refrigeration sub-unit can be further optimized for improvement whereas both the pre-treatment and saccharification sub-units were over-designed. They suggested that an absorption refrigerator can be a potential alternative for reduction in electrical energy consumption. In conclusion, the result from this exergoeconomic analysis was in line with the exergy analysis where it suggested major optimization actions should be carried out on both the steam generation and LA production sub-units.