Abstract

The expense of cellulase enzymes is the main barrier to the enzymatic saccharification of biomass. Numerous tactics, such as the utilizing inexpensive lignocellulosic substrates as well as economically feasible fermentation techniques for the production of the enzyme may reduce the cost of cellulases. The present investigation was aimed to improve cellulase production employing potential cellulolytic soil fungi, Aspergillus stellatus NFCCI 5299 using wheat bran as substrate. Employing response surface methodology (RSM) with central composite design (CCD), the most efficient process parameters were determined. The ideal conditions for the synthesis of carboxy methyl cellulase (CMCase) and filter paper cellulase activity (FPase) were 6 days of incubation, inoculum size of 4 mycelial disc, 125 rpm of agitation, and 3.5% of wheat bran. The significant mycelial development and enzymatic digestion of wheat bran were discovered by scanning electron microscopy (SEM) and fourier transform infrared (FTIR) analysis. The findings suggested that it can be practicable to use wheat bran as substrate under submerged fermentation utilizing Aspergillusstellatus NFCCI 5299 for efficient cellulase production.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

An apprehension over pollution caused by agro-industrial waste products has sparked interest in recycling waste materials to produce goods with a high commercial value. Crop leftovers (remaining stalks, rice straw, leaves, corn husks, wheat bran, etc.) are readily available and effortlessly renewable. The food business generates a considerable volume of waste, which can be recycled and converted into the variety of valuable products (Sirohi et al.2019). Agricultural wastes are huge source of lignocellulosic biomass and can easily be digested by microorganisms primarily by fungi, making it appropriate for enzyme production. It consists of three major polymers viz., cellulose, hemi-cellulose, and lignin. Huge amount of cellulose is produced every year making this polysaccharide an immense natural carbon repository on the planet (Goukanapalle et al. 2020). Wheat bran is a major contributor of agricultural waste, a key crop grown worldwide, mostly for human consumption and cattle feed. There are three main portions in a wheat kernel, namely endosperm, germ, and bran. Wheat bran consists of a lot of nutrients viz., fibre, minerals, vitamins, as well as phenolic compounds which are all significant components of a healthy diet. Due to its immense nutrition value, it can be utilized as cost effective substrate for production of industrially important enzymes like cellulases (Saini et al. 2017). Cellulases are responsible for digesting the cellulose’s β-1, 4-glucosidic linkages to produce glucose, cellobiose, and cello-oligosaccharides as their main by-products. These multi-component enzymes are made up of endoglucanases (EG), cellobiohydrolases (CBH) and β-glucosidases (BGL). Endo-glucanases work on the cellulose polymer to cleave it, exposing the reducing and non-reducing ends. Cellobiohydrolases then act on these ends to release cello-oligosaccharides and cellobiose units. Later, cellobiose was broken down by glucosidases into glucose, concluding the hydrolysis. Therefore, this enzyme make complex with components of CBH, EG, and BGL and works to convert crystalline cellulose to glucose. Due to its numerous industrial applications, these enzymes have been ranked as the third-largest industrial enzymes in the World (Castro Ochoa et al. 2023). Submerged fermentation (SmF) has conventionally been used to produce industrially significant enzymes and is mostly favoured due to sufficient agitation and aeration, among other factors. To make the process economically viable, there should be also better control over environmental variables like temperature, pH and they are easy to handle (Matker et al. 2013; Meena et al. 2018). It is necessary to develop an appropriate approach for process optimization that affects the final output of enzyme. The traditional method of optimizing various physicochemical parameters involves adjusting one-factor-at-a-time (OFAT) and it works as long as only a small number of variables have an impact on the production process. This method does not, however, depict the cumulative influence of all the contributing factors. It demands patience and the conduct of numerous tests (Hajji et al. 2008; Braga et al. 2011; Abdullah et al. 2021). As a result, it was discovered that the conventional one-factor-at-a-time (OFAT) technique for the optimization process takes more time. However, it also performs the function of providing a rough estimate of the ideal levels. Response Surface Methodology (RSM), which combines statistical and mathematical methodologies, can be used to circumvent this issue. Researchers can analyze the interactions between all the variables and responses during the experiments by using RSM to construct the experiments (Verma et al. 2020; Shaktimay et al. 2010; Vishwanatha et al. 2010; Nisar et al. 2020). By selecting a fungal strain that is complementary to the substrate, cellulase production can be increased. Different types of agro-industrial waste has been documented in the literature viz., rice straw, rice bran, wheat bran, coir waste, pea hulls, sugarcane bagasse etc., utilizing Aspergillus spp. However, the potential of Aspergillus stellatus for producing cellulases has not been fully investigated so far. Therefore, the goal of this study is to determine the efficiency of Aspergillus stellatus under shake flask submerged fermentation affecting the yield of cellulases utilizing wheat bran.

Material and methods

Chemicals

Carboxy methyl cellulose sodium salt, analytical-grade chemicals were utilized throughout the entire experimental process. Ammonium sulphate, dinitrosalicyclic acid, magnesium sulphate, malt extract, potassium dihydrogen phosphate, potato dextrose agar, tri-sodium citrate, yeast extract were procured from Sigma-Aldrich and Himedia Laboratories Pvt. Ltd. Mumbai, India.

Fungal strain and morphological characterization

The potent cellulolytic fungal strain Aspergillus stellatus NFCCI 5299 was isolated from soil sample which was obtained from the vicinity of Pt. Ravishankar Shukla University, India. On the basis of their cultural and morphological traits, the potent cellulolytic fungi was characterized after seven days of incubation on Czapek Dox yeast extract agar (CYA), malt extract agar (MEA), and potato dextrose agar(PDA). The colony’s diameter, texture, presence of pigmentation, and exudates were determined. To better recognize conidial traits, the fungal species were identified using both a slide culture technique and an adhesive tape method. The fungal identification was done in accordance with the literature (Klich et al. 2002), Leica DM750 microscope with Leica ICC50 digital camera was used to conduct the identification. Software Leica LAS V. 3.8.0 was used to examine the photos.

Inoculum preparation

The fungus was preserved at 4 ℃ on potato dextrose agar slants. Inoculum was made by allowing the cultures to grow on malt extract agar at 28 ℃ for 7 days, until the sufficient fungal growth was observed. For inoculation, a 10 mm diameter mycelial disc was employed.

Preparation of substrate

Wheat bran, one of the most prevalent agro-industrial waste was procured from the nearby farm of Raipur, Chhattisgarh, India. The substrate was washed, allowed to dry in sun and grounded to a fine powder.

Alkaline pre-treatment of wheat bran

Wheat bran along with NaOH (0.2 g NaOH/g dry wheat bran) and de-ionized water (15 g H2O/g dry wheat bran) were added in a beaker and heated to 100 ℃ with continuous stirring for 1 h on a hot plate. After this alkaline treatment, pH of the solution was maintained using 0.1N HCl to the final pH of 5. The soluble product of this solution was removed by washing with distilled water and leftover solid biomass was then dried at 50 ℃ for 12 h in an incubator. This dried biomass was used as a substrate for fermentation (Lodha et al. 2020).

Submerged fermentation

Vogel’s media was used for the enzyme production. The media consisted of tri-sodium citrate (0.5%), potassium dihydrogen phosphate (0.5%), ammonium sulphate (0.4%), magnesium sulphate (0.02%), yeast extract (0.1%) dissolved in 100 ml distilled water in a conical flask. In this study, submerged fermentation was used for the synthesis of cellulases. Dried wheat bran was incorporated in the flask containing 50 ml of Vogel’s media, mixed gently and autoclaved at standard temperature and pressure. Mycelial disc (10 mm) was inoculated in each flask. However, the concentration of wheat bran and amount inoculum were varied as per experimental design. After the inoculation, flasks were shifted to shaking incubator for different time of incubation, and agitation speed. The culture broth was filtered to obtain crude enzyme which was used further for enzyme assay.

Enzyme assay

CMCase and FPase activity were determined according to the method of Wood and Bhat (1988) and dinitrosalicyclic acid (DNSA) method (Miller 1959) was used for the estimation of reducing sugar.

CMCase assay

1 ml of citrate buffer (pH 4.5), 0.5 ml of 1% CMC (w/v) as a substrate, 0.5 ml of enzyme extract and the mixture were incubated at 50 ℃ for 30 min and further reaction was ceased by the addition of 3 ml DNSA reagent to the mixture. The mixture was boiled for 15 min until color change was observed in the reaction mixture. 1 ml of Rochelle salt and distilled water up to 7 ml were added before the cooling of the reaction mixture for stabilizing the color change formation. 1 ml citrate buffer and 0.5 ml undiluted enzyme extract were used as control and absorbance at 540 nm was noted. One unit of CMCase was defined as the amount of enzyme that release one micromole of glucose performed under standard reaction condition.

FPase assay

Filter paper activity of the culture filtrate was measured. The concoction was prepared by taking 1 ml of citrate buffer (pH 4.5), Whatman no. 1 filter paper (1 × 6), 0.5 ml of crude enzyme, and the mixture was incubated at 50 ℃ for 60 min. The reaction was ceased by the addition of 3 ml DNSA reagent to the mixture and boiled for 15 min until color change was observed in the reaction mixture. 1 ml of Rochelle salt and distilled water up to 7 ml was added before the cooling of the reaction mixture for stabilizing the color change formation and absorbance at 540 nm was noted.

Response surface methodology

RSM modelling was used in the current work to optimize the crucial physicochemical parameters. Using the central composite design (CCD) with four independent variables, the statistical model was created. The parameters viz., the incubation period (2–10 days), inoculum size (2–6 mycelial disc, 10 mm), agitation rate (75–175 rpm) and wheat bran (0.5–6.5%) were selected as important factors as per the literature review. Their effect on CMCase and FPase activity was analyzed employing a 24 full factorial central composite design with 30 runs. Under 150 ml of Erlenmeyer flask with 50 ml of production medium in submerged fermentation, the experiments were carried out in triplicates.

The experimental results were fitted using second-order polynomial equation:

where Y is the predicted response, β0 is the intercept term, βi is the linear coefficient, βij is the quadratic coefficient and βii is the interaction coefficient.

The analysis of cellulase activities (FPase, CMCase) was done usingANOVA together with the F-test. The model’s lack of fit, adequacy in terms of precision, and effectiveness in predicting the response were evaluated. The coefficient of determination (R2) and adjusted R2 were used to statistically assess the quality of the polynomial model equation. The design expert software (version 10.0.7.0- × 64) was used to create all three-dimensional response surface plots.

Experimental validation

Experiments have been carried out independently with optimal levels of medium components in shake flasks to validate the statistical model and its predictions. The observed ideal levels of parameters were maintained. Following incubation, culture filtrate was removed and tested for CMCase and FPase activity as mentioned earlier.

Degradation study of wheat bran

FTIR spectra was employed to examine the structural alterations in fermented wheat bran samples using Brucker alpha, FTIR spectrophotometer, in the range of 400–4000 cm−1, with resolution of 4 cm−1. Bran specimens were prepared by combining some potassium bromide in moderate amounts. Sixteen scans were recorded at room temperature to acquire the absorbance. The analysis of degradation in fermented wheat bran was carried out using a Karl and Zeiss (Germany SEM 50) Scanning electron microscope (SEM). Samples were gold coated before observation.

Results

Colonial and morphological characterization of Aspergillus stellatus NFCCI 5299

Colonies in CYA had a velvety appearance, were initially slow-growing, sulcate in pattern, and reversed dull brown with pigments present. On PDA, however, colonies showed a darker shade of green, were slightly floccose and velutinus, and had exudates on their surface. On MEA, colonies that were initially yellowish green turned dark green with time. No exudates were discovered, but the colony’s reverse was seen to have a dark brown hue due to the presence of pigments. Green colored, radiating conidial heads were observed and were found to be columnar in shape and free forming. The philaides (8.2–9 × 2.6–2.9 µm) were colorless and biseriate along with the presence of metulae (4.2–6.5 × 1.7–2.0 µm). The shape of the philaides was found to be ampuliform. The vesicles observed were hemispherical in shape ranging in diameter from 10–11.5 µm. Green, rough-walled conidia was observed, entirely globose in shape and had a diameter of 2.4 to 3.0 mm. Spherical cliestothecia with many hulle cells (320–400 m in diameter) were seen along with smooth and straight conidiophores. The hyphae of the fungi were found to be septate (Fig. 1).

Effect of fermentation parameters on CMCase and FPase production using central composite design

Response surface approach incorporates interaction effects between the discrete variables assisting in the simultaneous optimization of several process parameters throughout the course of the fewest possible experimental runs (Table 1). In the current study, Aspergillus stellatus NFCCI 5299 was employed to optimize the independent fermentation parameters, including incubation period, inoculum size (10 mm mycelial disc), agitation rate (RPM) and concentration of wheat bran (g/100 ml) using four factor central composite design (CCD). With all of the conceivable combinations of these four independent variables, a series of 30 tests were carried out with four coded levels (− 2, − 1 and + 2, + 1). All of the selected factors were discovered to have a favorable impact on the synthesis of cellulases for both CMCase and FPase activities. According to RSM simulation, the quadratic model was the best strategy for elucidating the relationship between responses and parameters. A second-order polynomial equation demonstrated the experimental relationship between the distinct variables and responses (CMCase and FPase), which are provided in Eq. (1) and Eq. (2).

where Y is the CMCase/FPase activity (IU/ml), A is incubation period (days), B is inoculum size (10 mm mycelial disc), C is the agitation rate (rpm), D is wheat bran (g/100 ml). AB, AC, AD, BC, BD and CD represent interaction effect among variables, whereas quadratic effect is shown as A2, B2, C2 and D2.

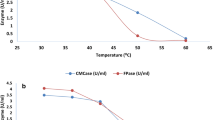

Using design expert software 10.0.7.0, the F-test (Fischer’s test) for ANOVA was employed to statistically evaluate the quadratic model for CMCase and FPase activity as shown in Tables 2 and 3. The findings revealed that the values of “Prob > F” less than 0.0500 indicate highly significant regression model. The resulting F-value of 45.81 and 11.55 inferred that the quadratic model is significant and the large F-value is caused by noise only which happens with a 0.01% chance. A, C, AB, AC, BC, CD, A2, C2 were found to be significant model terms for CMCase activity. However, AC, BC, A2 were significant model terms for FPase. Values greater than 0.1000 indicate that the model terms are not significant. The “Lack of Fit F-value” of 0.85 and 0.65 for CMCase and FPase indicates that the lack of fit is not significant relative to the pure error.This demonstrated the model’s precision and assisted in fitting the present model. The analysis of coefficient R2, predicted R2, and an adequate precision helped to identify the model’s accuracy and dependability. The signal-to-noise ratio is measured using an indicator termed adequate precision. The ratio greater than 4 is recommended. The calculated ratio of 29.59 and 15.09 for CMCase and FPase activity, suggests a strong signal. Consequently, it is possible to navigate the design space using this approach. In case of CMCase activity, the Pred R-Squared” value of 0.9051 for CMCase activity was in acceptable agreement with the "Adj R-Squared" of 0.9558, whereas the “Pred R-Squared” of 0.6702 was in acceptable agreement with the “Adj R-Squared” of 0.8358 for FPase activity i.e., the difference was less than 0.2 which essentially states that the existing model fits the experimental data pretty well. The model’s ability to predict the outcome increases as R2 approaches 1. It has also been confirmed that the expected CMCase and FPase activity closely matched with the activity that was actually observed. Figure 2 shows the experimental and predicted values of the model, and the fact that the data points are clustered along the diagonal line indicates that the model is reliable. To comprehend the impact of variable interactions and to determine the ideal values of each parameter for achieving the highest FPase and CMCase yields, response surface curves were plotted. By using 3D response surface plots against any two independent factors and their respective enzyme production while keeping other variables at their center (0) level, the interactive effects of variables on the production of these enzymes were examined. The 3D plots revealed that the highest CMCase and FPase activities occurred at moderate levels of the incubation period, inoculum size, and agitation rate and wheat bran concentration. The predictions of the quadratic model indicated highest CMCase and FPase activity of 0.508 IU/ml and 0.623 IU/ml, which is possible with the ideal values of bioprocess parameters viz., incubation period (6 days), inoculum size (4 disc of 10 mm diameter), agitation rate (125 rpm) and 3.5% wheat bran. With the projected optimum values of various parameters, shaking flask experiments were used to validate the final optimized media. The value obtained of 0.508 IU/ml for experimental CMCase activity as optimized media is in remarkable agreement with the predicted value of 0.500 IU/ml. FPase activity was experimentally determined to be 0.623 IU/ml, which is in line with the predicted value of 0.630 IU/ml (Table 4). It shows that created model was effective and reliable for predicting the biosynthesis of both CMCase and FPase by Aspergillus stellatus NFCCI 5299.

Graphical interpretation of 3D response surface plots

The three-dimensional response surface graphs were plotted to comprehend the impacts of variable interactions and to determine the ideal values of each parameter for achieving the highest CMCase and FPase yields. The computed responses from the response surface plots by interactions between the factors are represented in Fig. 3 and 4. Inoculum sizes and incubation time have an impact on CMCase activity as shown in Fig. 3a, and their interactions are shown to be significant. However, in case of FPase activity (Fig. 4a), they were found to be insignificant. The 3D graph shows that CMCase activity rises with longer incubation times and then falls off. Varying the inoculum size does not have any significant effects, however varying incubation period, inoculum size enhanced FPase production at moderate levels and later on declined. Similar outcomes can be seen when incubation time and agitation speed were combined (Figs. 3b, 4b). Both interactions were confirmed to be statistically significant for both CMCase and FPase yield. Although varied levels of agitation rate had no significant impact, further moderate levels of incubation time led to maximal CMCase activity and FPaseactivity. A 3D plot between CMCase and FPase activity for incubation time vs wheat bran was shown in Figs. 3c and 4c. However, modest levels of incubation period led to elevated CMCase and FPase activity, which dropped after extended incubation period. Both interactions were discovered to be insignificant. Wheat bran also had no noticeable effect on the production of enzymes. Figures 3d and 4d demonstrated the response surface plot as a function of inoculum size vs. agitation speed. CMCase and FPase yield increased marginally at moderate agitation rates, but inoculum size had no discernible effect. A response surface plot as a function of inoculum size and wheat bran was shown in Figs. 3e and 4e. No enzyme output was seen and the interactions were not statistically significant. A plot was shown in Figs. 3f and 4f as a function of agitation speed and wheat bran.

For optimal CMCase production: Response surface graphs illustrating the interactions between factors in the cellulose conversion to reducing sugars: interaction between (A) inoculum size & incubation period (B) agitation speed & incubation period (C) wheat bran (%) & incubation period (D) agitation speed & inoculum size (E) wheat bran (%) & inoculum size (F) wheat bran (%) & agitation speed

For optimal FPase production: Response surface graphs illustrating the interactions between factors in the cellulose conversion to reducing sugars. Interaction between (A) inoculum size & incubation period (B) agitation speed & incubation period (C) wheat bran (%) & incubation period (D) agitation speed & inoculum size (E) wheat bran (%) & inoculum size (F) wheat bran (%) & agitation speed

Structural assessment of wheat bran before and after fermentation

FTIR analysis

The findings showed that crude enzyme produced from Aspergillus stellatus NFCCI 5299 was good at hydrolyzing wheat bran. According to the FTIR spectra of the unfermented and fermented wheat bran, the modifications to the functional groups of wheat bran after fermentation were examined (Fig. 5). FTIR of pre-treated wheat bran showed medium and sharp peaks at 3562.20, 3552.34, 3518.69, 3364.36, and 3345.61 \({{\text{cm}}}^{-1}\) indicating O–H stretching. Whereas the new peak of fermented wheat bran was generated due to the degradation of wheat bran at a range at 3209.84 \({{\text{cm}}}^{-1}\) and 3104.44 \({{\text{cm}}}^{-1}\) which is an attribute of the stretching vibration of the O–H bond in polysaccharides. This peak includes intermolecular hydrogen bond vibration in cellulose. The medium and sharp absorption bands at 3091.02, 3065.99, 3039.59, 3023.22, 2937.11 and 2908.68 \({{\text{cm}}}^{-1}\) were also observed in fermented wheat bran which is attributed to C-H stretching vibration of all hydrocarbon constituents in polysaccharides. More peaks at 1638.51, 1423.23, 1081.15, 407.65, and 433.11 \({{\text{cm}}}^{-1}\) were observed in unfermented wheat bran. However, after saccharification the fermented wheat bran showed new strong and broad peaks at 1637.15 \({{\text{cm}}}^{-1}\) and 1661.78 \({{\text{cm}}}^{-1}\) indicating the C = C stretching which was considered as the double bond region. Further, sharp band at 1401.33 \({{\text{cm}}}^{-1}\) in fermented wheat bran indicated O–H bending and medium to broad absorbance peak at the range of 1092 \({{\text{cm}}}^{-1}\) indicated C–O–C stretching, this region indicated the fingerprint region. The signal at 634.59 \({{\text{cm}}}^{-1}\), 618.09 \({{\text{cm}}}^{-1}\) indicated the C–OH out-of-plane bending mode. The absorption band at 531.31, 487.97, 460.76, 442.41 \({{\text{cm}}}^{-1}\) is the characteristic of β-glycosidic linkage between glucose units.

SEM analysis

The structure and surface morphology of alkaline pre-treated/unfermented and fermented wheat bran were studied using SEM analysis. Extensive mycelial proliferation on fermented wheat bran and mycelial invasion in bran pores was evident in the SEM image. However, the control image of chemically pre-treated/unfermented wheat bran revealed the thick textures and intact surfaces. The breakdown and alteration of the fibre structure as well as an increase in pores and cavities were caused by the fungal proliferation on fermented wheat bran (Fig. 6). In addition, the exposed surfaces of the fermented wheat bran were greater than those of the pre-treated/unfermented wheat bran Table 4.

Discussions

Utilizing cellulolytic microbes in place of chemical and mechanical processing of cellulose has been recognized as being more eco-sustainable approach. Numerous cellulolytic microbes have been discovered in a variety of habitats, including soil, organic waste, guts, animal waste, marine sediments, and seaweed. However, the available enzymatic repertoire is currently insufficient to fulfil industrial demands, thus efforts to obtain potent isolates from uncharted habitats are continuously being made. In this investigation, a potent cellulolytic fungal strain was isolated from soil sample. The colonial and morphological characteristics were found to be comparable with Aspergillus sp. Further, the organism was deposited at national fungal culture collection, India and identified as Aspergillus stellatus NFCCI 5299. The synthesis of extracellular cellulase is significantly impacted by fluctuations in the physical factors as well as substrate concentration. Therefore, one strategy to lower the cost of producing cellulase by microorganisms is to optimize each factor of the medium. RSM is a widely used statistical technique that uses cost efficient experimental designs and provides statistical assessments and predictions. To boost the CMCase and FPase production by Aspergillus stellatus NFCCI 5299, RSM was used in conjunction with CCD to optimize physical parameters including wheat bran concentration. The RSM simplified the optimization techniques in 30 trials. The model developed was found to be very effective in optimizing the chosen medium constituents which is evident from R2 value 0.9051 for CMCaseand 0.6078 for FPase. The model’s ability to predict the outcome increases as R2 approaches 1. When compared to earlier studies, the observed R2 value was similar. The use of 3D plots, which enables the direct display of the individual and interactive interaction of variables, makes it possible to effectively optimize the synthesis of microbial enzymes. According to the 3D plots, the maximum CMCase and FPase activities took place during the moderate incubation period (6 days), inoculum size (4 disc of 10 mm diameter), agitation rate (125 rpm) and 3.5% wheat bran. Sravanan et al. (2012) reported similar results using Box-Behnken design for enzyme optimization with Trichoderma reesei and observed six days of incubation period for maximal cellulase activity. Similar studies were also reported with Aspergillus niger under solid-state fermentation. Six days was optimum incubation period after statistical optimization of cellulases (Verma et al. 2019). Researchers also investigated cellulase production with endophytic fungus Pestalotiopsismicrospora using RSM. The outcome demonstrated that the incubation time of 5–6 days was ideal for increasing the activity of the cellulase enzyme (Goukanapalle et al. 2020). The results were also in agreement with Gad et al. (2022), who reported six days as optimal incubation time for CMCase production. The decrease in activity following the ideal incubation period may be caused by a number of factors. This includes modifications to the fungus’s machinery for secreting enzymes under stress brought on by the depletion of vital nutrients (Mrudula and Murugammal 2011), an inhibitory effect of cellobiose (Azzaz et al. 2012) or glucose accumulated in the medium, the production of proteases (Nathan et al. 2014), or other physiological conditions. Production of cellulase is significantly influenced by the quantity of fungal inoculum. A number of four mycelial discs of 10 mm diameter were inoculated into the fermentation medium in the current study. However, no significant impact of inoculum size on enhancing cellulase production was observed. According to Saravanan et al. (2012) and El-Hadi et al. (2014), an imbalance between growing biomass and nutrient accessibility may lead to decrease in enzyme activity. Cell clumping can also interfere with oxygen intake and enzyme release. On the contrary, insufficient inoculum levels result in less biomass production, which leaves many nutrients unused and reduces the synthesis of enzymes (El-Hadi et al. 2014). Similar findings were made by Agrawal (2016), who found that a 2.5% (v/w) inoculum size was the ideal one for increasing CMCase production from Aspergillus sp. According to Saini et al. 2017, two mycelial discs of Trichoderma reesei (NCIM 992) per gram of substrate resulted in the best CMCase production. Authors (Ezeilo et al. 2022), studied the solid-state fermentation using palm oil leaves Trichoderma asperellum and Rhizopus oryzae for efficient production of cellulose degrading enzymes. They observed 2.0 × 107 spores g−1 as optimal inoculum size for both CMCase and FPase production. Agitation speed of 125 rpm was found to be optimal for maximal CMCase and FPase production. Increased dissolved oxygen in the medium and consistent distribution of nutrients and catabolites are both influenced by the rate of agitation. However, increase in agitation rate can also lead to damages in cell structure, leading to morphological changes brought on by shear stresses. Comparable results were reported by (Deka et al. 2013), viz., 121 rpm as optimal agitation speed for CMCase production using Bacillus subtilis. Researchers (Tabassum et al. 2018), also reported 120 rpm as optimal agitation rate for enhanced CMCase activity. One study (Chavan et al. 2022) reported 157 rpm as optimal agitation rate for maximal cellulase production from Penicillium funiculosum NCIM 1228 using response surface methodology. According to the investigations mentioned above, cellulase is best produced at an agitation rate ranging from 120 to 160 rpm. Wheat bran of 3.5% was found optimal for improving enzyme production. Similar outcomes were reported by Gomathi et al. 2012, i.e., 4% wheat bran as optimal substrate concentration for improved cellulase synthesis. Another study (Kumar et al.2018) also reported 1% wheat bran for maximal enzyme production with Schizophyllum commune NAIMCC-F-03379. Yousef et al. 2022 investigated in one study about how Virgibacillussalarius produces thermo and halostable cellulase. They claimed that 30 g/L of wheat bran was the ideal concentration for producing enzymes and for achieving the highest possible saccharification output. It is generally accepted that the form and content of the carbohydrates in wheat bran make them ideal for stimulating the production of cellulases by filamentous fungus throughout both submerged and solid-state fermentation (Deswal et al. 2011). The significance of previous work on cellulase production from Aspergillus species using agro-residual waste lies in its potential to alleviate environmental and industrial challenges while contributing to sustainable resource. Researchers have investigated various factors influencing cellulase production, such as substrate selection, microbial strains, fermentation parameters and inducer molecules. These findings guide the optimization of cellulase production processes for higher yields and cost-effectiveness, as well as the investigation of other cellulase-producing strains, including various species of Aspergillus, Trichoderma, and other fungi. Sasi et al. (2012) observed the optimization, production, and purification of cellulase enzyme from marine Aspergillus flavus. The experimental results showed that the cellulase production was higher at pH 8 and 30 ℃ on seven days of incubation period. The effect of different carbon sources like rice bran, wheat bran, bagasse were used for cellulase enzyme production. Reddy et al. (2015) investigated the cellulase production by Aspergillus niger on different natural lignocellulosic substrates (rice bran & wheat bran). Maximum titers of FPase, CMCase and β-glucosidase obtained on this combination were 2.632, 2.478 and 2.984 U/mL in SmF and 29.81, 25.2 and 32.18 U/g DS in SSF, respectively. This work helps in identifying the most promising strains with high enzyme yields and specific cellulase activities. The current investigation suggests that A. Stellatus is an uncommon isolate reported up to this point for optimizing cellulase production using solid substrate, despite the fact that there are only a few reports of it having cellulolytic capability. Enzyme characterization studies have revealed the diversity of endoglucanases, exoglucanases, and β-glucosidases and their synergistic actions in cellulose degradation. Analyzing various cellulase-producing strains and evaluating the cost-effectiveness of cellulase production process by particular strain, substrate cost, enzyme yield and downstream processing expenses are crucial for determining utility in large scale industrial production and application. Comparative studies of different agro-residue waste substrate (rice straw, wheat straw,corn stover) with various fermentation conditions (temperature, pH, aeration and agitation), enzyme profiling across different strain can provide insights into variation in the types and proportion of cellulase enzyme. Cellulases have enormous potential in industries and are used in food, beverages, textile, laundry, paper, waste management, medical/pharmaceutical industry, protoplast production, genetic engineering, pollution treatment and in other area and pulp industries etc. (Gomathi et al. 2012). The field of bioprocess engineering has been benefited from earlier research by developing strategies for scaling up cellulase production from laboratory to industrial level (Khan et al. 2016). In summary, earlier work in cellulase production serves as a knowledge base for understanding the process, optimizing conditions, synergetic effects of different cellulase enzyme and identifying promising microbial strains. Based on the FTIR spectra of the unfermented and fermented wheat bran, the modifications to the functional groups of wheat bran after fermentation produced absorption bands at 3209.84 \({{\text{cm}}}^{-1}\) and 3104.44 \({{\text{cm}}}^{-1}\) indicating stretching vibration of the O–H that confirms the presence of cellulose. The findings concurred with the literature (Vinche et al. 2021), who also investigated the enzyme optimization using wheat bran as substrate. Absorption bands at 3091.02–2908.68 \({{\text{cm}}}^{-1}\) ascribed to C-H stretching vibration, 1637.15 \({{\text{cm}}}^{-1}\) and 1661.78 \({{\text{cm}}}^{-1}\) indicated the C = C stretching, 1401.33 \({{\text{cm}}}^{-1}\) revealed O–H bending and 1092 \({{\text{cm}}}^{-1}\) indicated C–O–C stretching. The results were in agreement with other work Silva et al. (2021), absorption bands in the region 500–1000 \({{\text{cm}}}^{-1}\) was related to the carbohydrate skeletal vibrations (Wiercigroch et al. 2017; Hong et al. 2021). SEM analysis was used to examine the structure and surface morphology of pre-treated and fermented wheat bran. The chemically pre-treated/unfermented wheat bran revealed the dense and solid surfaces. The breakdown and modification of the fibre structure were caused by the mycelial growth on fermented wheat bran. Similar observations were reported by some researchers (Vinche et al. 2021; Kumari et al. 2022; Abdullah et al. 2021), on agricultural waste. The findings showed that crude enzyme produced from Aspergillus stellatus NFCCI 5299 was good at hydrolyzing wheat bran.

Conclusion

Cellulase output can be enhanced by Aspergillus stellatus NFCCI 5299 using wheat bran as substrate in submerged fermentation. To improve growth and the potential for the synthesis of enzymes, it is important to consider the physicochemical characteristics and composition of the wastes. Due to its favorable lignocellulosic characteristics for cellulose production, the wheat bran provided great support for the enzyme’s synthesis. Using RSM with central composite design, the best process parameters for maximizing the production of CMCase and FPase were identified. The optimal conditions for the production of CMCase and FPase were achieved at the incubation period of 6 days, inoculum size of 4, agitation rate of 125 rpm and wheat bran concentration of 3.5%. Utilizing SEM and FTIR analysis, the morphological structure and surface of alkaline-pre-treated and fermented wheat bran were examined. The high cellulolytic activity of the enzyme can be utilized in a wide range of biotechnological and manufacturing industries. Other agro-industrial waste can further be tested to get closer to the proper valorization parameters supporting production of enzymes.

References

Abdullah MM, Aldughpassi ADH, Sidhu JS et al (2021) Effect of psyllium husk addition on the instrumental texture and consumer acceptability of high-fiber wheat pan bread and buns. Ann Agric Sci 66:75–80. https://doi.org/10.1016/j.aoas.2021.05.002

Agrawal S (2016) Central composite design for parameter optimization and cellulase production using Aspergillus sp. Octa J Biosci 4(1):1–5

Azzaz HH, Murad HA, Kholif AM, Hanfy MA, Gawad MA (2012) Optimization of culture conditions affecting fungal cellulase production. Res J Microbiol 7:23

Braga FR, Araújo JV, Soares FEF, Araujo JM, GeniêrHL A et al (2011) Optimizing protease production from an isolate of the nematophagous fungus Duddingtoniaflagrans using response surface methodology and its larvicidal activity on horse cyathostomins. J Helminthol 85(2):164–170. https://doi.org/10.1017/S0022149X10000416

Castro-Ochoa LD, Hernández-Leyva SR, Medina-Godoy S, Gómez-Rodríguez J et al (2023) Integration of agricultural residues as biomass source to saccharification bioprocess and for the production of cellulases from filamentous fungi. 3 Biotech 13(2):43. https://doi.org/10.1007/s13205-022-03444-4

Chavan SB, Shete AM, Dharne M (2022) Optimization for improved cellulase production of Penicillium funiculosum NCIM 1228 in submerged fermentation. Res Sq. https://doi.org/10.21203/rs.3.rs-1721851/v1

Deka D, Das SP, Sahoo N et al (2013) Enhanced cellulase production from Bacillus subtilis by optimizing physical parameters for bioethanol production. ISRN Biotechnol 2013:965310. https://doi.org/10.5402/2013/965310

Deswal D, Khasa YP, Kuhad RC (2011) Optimization of cellulase production by a brown rot fungus Fomitopsis sp. RCK2010 under solid state fermentation. Bioresour Technol 102:6065–6072. https://doi.org/10.1016/j.biortech.2011.03.032

El-Hadi AA, El-Nour SA, Hammad A, Kamel Z, Anwar M (2014) Optimization of cultural and nutritional conditions for carboxymethylcellulase production by Aspergillus hortai. J Appl Sci Res 7(1):23–28. https://doi.org/10.1016/j.jrras.2013.11.003

Ezeilo UR, Wahab RA, Huyop F, David EE, Tin LC (2022) Solid‐state valorization of raw oil palm leaves by novel fung Tirichoderma asperellum UC1 and Rhizopus oryzae UC2 for sustainable production of cellulase and xylanase. J Chem Technol Biotechnol 97:520–533

Gad AM, Suleiman WB, El-Sheikh HH et al (2022) Characterization of cellulase from Geotrichumcandidum strain Gad1 approaching bioethanol production. Arab J Sci Eng 47:6837–6850. https://doi.org/10.1007/s13369-021-06391-z

Gomathi D, Muthulakshmi C, Kumar DG et al (2012) Submerged fermentation of wheat bran by Aspergillus flavus for production and characterization of carboxy methyl cellulase. Asian Pac J Trop Biomed 2:S67–S73. https://doi.org/10.1016/S2221-1691(12)60132-4

Goukanapalle PKR, Kanderi DK, Rajoji G et al (2020) Optimization of cellulase production by a novel endophytic fungus Pestalotiopsismicrospora TKBRR isolated from Thalakona forest. Cellulose 27:6299–6316. https://doi.org/10.1007/s10570-020-03220-8

Hajji M, Rebai A, Gharsallah N, Nasri M (2008) Optimization of alkaline protease production by Aspergillus clavatus ES1 in Mirabilis jalapa tuber powder using statistical experimental design. Appl Microbiol Biotechnol 79:915–923. https://doi.org/10.1007/s00253-008-1508-0

Heidary Vinche M, Khanahmadi M, Ataei SA, Danafar F (2021) Optimization of process variables for production of beta-glucanase by Aspergillus niger CCUG33991 in solid-state fermentation using wheat bran. Waste Biomass Valorization 12:3233–3243. https://doi.org/10.1007/s12649-020-01177-0

Hong T, Yin JY, Nie SP, Xie MY (2021) Applications of infrared spectroscopy in polysaccharide structural analysis: progress, challenge and perspective. Food Chem X 12:100168. https://doi.org/10.1016/j.fochx.2021.100168

Khan MN, Luna IZ, Islam MM, Sharmeen S, Salem KS, Rashid TU, Zaman A, Haque P, Rahman MM (2016) Cellulase in waste management applications new and future developments in microbial biotechnology and bioengineering. Elsevier, Amsterdam, pp 237–256

Klich MA (2002) identification of common Aspergillus species. ASM press, Washington, DC, p 116

Kumar B, Bhardwaj N, Alam A et al (2018) Production, purification and characterization of an acid/alkali and thermo tolerant cellulase from Schizophyllum commune NAIMCC-F-03379 and its application in hydrolysis of lignocellulosic wastes. AMB Express 8:173. https://doi.org/10.1186/s13568-018-0696-y

Kumari S, Kumar A et al (2022) A cold-active cellulase produced from Exiguobacteriumsibiricum K1 for the valorization of agro-residual resources. Biomass Convers Biorefin. https://doi.org/10.1007/s13399-022-03031-w

Lodha A, Pawar S, Rathod V (2020) Optimised cellulase production from fungal co-culture of Trichoderma reesei NCIM 1186 and Penicillium citrinum NCIM 768 under solid state fermentation. J Environ Chem Eng 8:103958. https://doi.org/10.1016/j.jece.2020.103958

Matkar K, Chapla D, Divecha J, Nighojkar A, Madamwar D (2013) Production of cellulase by a newly isolated strain of Aspergillus sydowii and its optimization under submerged fermentation. Int Biodeterior Biodegradation 78:24–33. https://doi.org/10.1016/j.ibiod.2012.12.002

Meena SS, Vinay S, Sarika G (2018) In vitro optimisation of fungal cellulase production from fruit waste for handmade paper industries. Biotechnology 17(1):35–43. https://doi.org/10.3923/biotech.2018.35.43

Miller GL (1959) Use of dinitrosalicylic acid reagent for determination of reducing sugar. Anal Chem 31:426–428. https://doi.org/10.1021/ac60147a030

Mrudula S, Murugammal R (2011) Production of cellulase by Aspergillus niger under submerged and solid state fermentation using coir waste as a substrate. Braz J Microbiol 42:1119–1127. https://doi.org/10.1590/S1517-83822011000300033

Nathan VK, Esther Rani M, Rathinasamy G et al (2014) Process optimization and production kinetics for cellulase production by Trichoderma viride VKF3. Springerplus 3:92. https://doi.org/10.1186/2193-1801-3-92

Nisar K, Abdullah R, Kaleem A et al (2020) Application of Plackett Burman and Box Behnken design for the optimization of a-glucosidase production by thermophilic Thermomyces dupontii. Rev Chim 71:32–38. https://doi.org/10.37358/RC.20.9.8314

Reddy GPK, Narasimha G, Kumar KD, Ramanjaneyulu G, Ramya A, Kumari BS, Reddy BR (2015) Cellulase production by Aspergillus niger on different natural lignocellulosic substrates. Int J Curr Microbiol Appl Sci 4(4):835–845

Saini A, Aggarwal NK, Yadav A (2017) Cost-effective cellulase production using Parthenium hysterophorus biomass as an unconventional lignocellulosic substrate. 3 Biotech 7:1–11. https://doi.org/10.1007/s13205-017-0604-1

Saravanan P, Muthuvelayudham R, Rajesh Kannan R, Viruthagiri T (2012) Optimization of cellulase production using Trichoderma reesei by RSM and comparison with genetic algorithm. Front Chem Sci Eng 6:443–452. https://doi.org/10.1007/s11705-012-1225-1

Sasi A (2012) Optimization, production and purification of cellulase enzyme from marine Aspergillus flavus. Afr J Microbiol Res. https://doi.org/10.5897/ajmr11.074

Shaktimay K, Datta TK, Ray RC (2010) Optimization of thermostable α- amylase production by Streptomyces erumpens MTCC 7317 in solid-state fermentation using cassava fibrous residue. Braz Arch Biol Technol 53:301–309. https://doi.org/10.1590/S1516-89132010000200008

Silva TP, Ferreira AN, de Albuquerque FS et al (2021) Box-Behnken experimental design for the optimization of enzymatic saccharification of wheat bran. Biomass Convers Biorefin 12(2):1–8. https://doi.org/10.1007/s13399-021-01378-0

Sirohi R, Singh A, Tarafdar A et al (2019) Cellulase production from pre-treated pea hulls using Trichoderma reesei under submerged fermentation. Waste Biomass Valorization 10:2651–2659. https://doi.org/10.1007/s12649-018-0271-4

Tabssum F, Irfan M, Shakir HA, Qazi JI (2018) RSM based optimization of nutritional conditions for cellulase mediated saccharification by Bacillus cereus. J Biol Eng 12:7. https://doi.org/10.1186/s13036-018-0097-4

Verma N, Kumar V (2019) Application of Box-Behnken design for the optimization of cellulase production under solid-state fermentation. SN Appl Sci 1:1–10

Verma M, Ekka A, Mohapatra T, Ghosh P (2020) Optimization of kraft lignin decolorization and degradation by bacterial strain Bacillus velezensis using response surface methodology. J Environ Chem Eng 8:104270. https://doi.org/10.1016/j.jece.2020.104270

Vishwanatha KS, Rao AA, Singh SA (2010) Acid protease production by solid-state fermentation using Aspergillus oryzae MTCC 5341: optimization of process parameters. J Ind Microbiol Biotechnol 37(2):129–138. https://doi.org/10.1007/s10295-009-0654-4

Wiercigroch E, Szafraniec E, Czamara K et al (2017) Raman and infrared spectroscopy of carbohydrates: a review. Spectrochim Acta A Mol Biomol Spectrosc 185:317–335. https://doi.org/10.1016/j.saa.2017.05.045

Wood TM, Bhat KM (1988) Methods for measuring cellulase activities methods in enzymology. Elsevier, Amsterdam, pp 87–112. https://doi.org/10.1016/0076-6879(88)60109-1

Yousef NMH, Mawad AMM (2022) Characterization of thermo/halo stable cellulase produced from halophilic Virgibacillussalarius BM-02 using non-pretreated biomass. World J Microbiol Biotechnol 39:22. https://doi.org/10.1007/s11274-022-03446-7

Acknowledgements

Our appreciation extends to Head, Center for Basic Sciences, Pt. Ravishankar Shukla University, who provided the research facility. The researchers are thankful towards the Microbiology Research Laboratory, School of Studies in Life Science, Pt. Ravishankar Shukla University for providing chemicals.

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare that there is no conflict of interest regarding publication of this paper.

Ethical approval

The research does not require any ethical approval or consent because no humans or animals have been involved in the study.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Thakur, G., Sutaoney, P., Joshi, V. et al. Response surface optimization of cellulase production by Aspergillus stellatus NFCCI 5299 in shake flask submerged fermentation using wheat bran. 3 Biotech 14, 21 (2024). https://doi.org/10.1007/s13205-023-03860-0

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s13205-023-03860-0