Abstract

Owing to their exceptional properties, high-entropy alloys (HEAs) and high-entropy materials have emerged as promising research areas and shown diverse applications. Here, the recent advances in the field are comprehensively reviewed, organized into five sections. The first section introduces the background of HEAs, covering their definition, significance, application prospects, basic properties, design principles, and microstructure. The subsequent section focuses on cutting-edge high-entropy structural materials, highlighting developments such as nanostructured alloys, grain boundary engineering, eutectic systems, cryogenic alloys, thin films, micro-nano-lattice structures, additive manufacturing, high entropy metallic glasses, nano-precipitate strengthened alloys, composition modulation, alloy fibers, and refractory systems. In the following section, the emphasis shifts to functional materials, exploring HEAs as catalysts, magneto-caloric materials, corrosion-resistant alloys, radiation-resistant alloys, hydrogen storage systems, and materials for biomedicine. Additionally, the review encompasses functional high-entropy materials outside the realm of alloys, including thermoelectric, quantum dots, nanooxide catalysts, energy storage materials, negative thermal expansion ceramics, and high-entropy wave absorption materials. The paper concludes with an outlook, discussing future directions and potential growth areas in the field. Through this comprehensive review, researchers, engineers, and scientists may gain valuable insights into the recent progress and opportunities for further exploration in the exciting domains of high-entropy alloys and functional materials.

Graphic abstract

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Background

1.1 Definition and background of high-entropy alloys

In the early stages of high-entropy alloys (HEA) research, it was initially defined as an alloy composed of five or more elements, typically in equimolar or nearly equimolar compositions, with the range of each principal component falling within 5@%–35 at% [1]. This definition was primarily composition based. As research progressed, an alternative approach emerged, where high-entropy alloys were defined by the utilization of mixing configurational entropy. Evidently, entropy describes the intrinsic degree of disorder within a closed system, with a higher entropy indicating a greater system disorder. In the field of materials science, higher entropy is manifested as a higher degree of disorder in the distribution of elements or other words, increased randomness.

Following Boltzmann’s hypothesis, the mixing configurational entropy of an n-element equimolar alloy changing from an elemental to a random solution state (ideal state or regular state) can be calculated from [2]:

where k is the Boltzmann constant, ω denotes the number of microstates in the distribution, which can also be construed as thermodynamic probability, and R is the gas constant. Binary equimolar alloys exhibit a mixing configurational entropy of 0.693R, while ternary, quaternary, and quinary equimolar alloys manifest mixing entropies of 1.10R, 1.386R, and 1.61R, respectively. Consequently, the relationship between the number of principal elements and the mixing configurational entropy established by this equation enables the definition of high-entropy alloys based on the magnitude of the system's mixing entropy [1]: when \(\Delta S_{{{\text{mix}}}} < 0.693R\), it comes to low-entropy alloys, when \(0.693{{R}} < \Delta S_{{{\text{mix}}}} < 1.61R\), it comes to medium-entropy alloys, and when \(\Delta S_{{{\text{mix}}}} > 1.61R\), it comes to high-entropy alloys. Even for non-equimolar compositions, as long as the system's mixing entropy falls within the aforementioned range, it can be classified as such.

This method of categorizing high-entropy alloys based on the mixing entropy further expands the already vast family of high-entropy alloys, which imparts substantial compositional flexibility, facilitating the tailoring of properties for specific applications. Furthermore, another advantage of utilizing mixing entropy to define high-entropy alloys lies in its emphasis on the mixing configurational entropy, which typically supersedes the enthalpy of compound formation, thereby stabilizing solid solutions during solidification rather than intermetallic compounds. Consequently, high-entropy alloys usually possess a simple phase constitution, with various constituent atoms randomly distributed within the crystallographic lattice sites, erasing distinctions between solutes and solvents. The high mixing entropy of these systems broadens the solubility between multiple elements, giving rise to numerous novel mechanisms that bestow high-entropy alloys with diverse and distinctive mechanical and physical properties.

1.2 Significance and application prospects of high-entropy alloys

High-entropy alloys exhibit exceptional room-temperature mechanical properties, showcasing outstanding strength-ductility synergy. The elevated mixing configurational entropy imparts high-entropy alloys with several distinctive attributes, such as severe lattice distortion [3], sluggish diffusion [4], cocktail effect [5] and the high entropy effect [6]. Consequently, high-entropy alloys can manifest unique characteristics that set them apart from conventional alloys, particularly due to their large chemical complexity (e.g., differing atomic sizes, electronic structures, mixing enthalpy) and the resulting local structural inhomogeneities [7]. These atomic-scale inhomogeneities, operating at the atomic scale, enhance lattice friction within the alloy and significantly affects its deformation behaviors [8, 9], ultimately contributing to its high intrinsic strength of high-entropy alloys. Furthermore, reasonable alloy design and control of heat treatment processes, such as the utilization of metastable engineering to induce transformation-induced plasticity (TRIP) [10, 11], the introduction of ordered oxygen complexes (OOCs) through the addition of interstitial atoms [12, 13], and the induction of multi-stage coherent precipitates [14, 15], all contribute to enhancing the strength and ductility of high-entropy alloys. The outstanding balance of strength and ductility in high-entropy alloys makes them suitable for high-strength structural materials required in various fields. Figure 1 shows the development of high-entropy alloys [16‒23].

HEAs can overcome low-temperature embrittlement, showcasing exceptional low-temperature performance. Among the most extensively researched high-entropy alloys to date, the Cantor alloy with single-phase face-centered cubic (FCC) crystal demonstrates fracture toughness superior to that of the majority of metallic materials [20]. Furthermore, its adaptability to low-temperature environments is particularly noteworthy. When the temperature decreases from room temperature to as low as − 200 °C, it no longer exhibits the low-temperature embrittlement effects commonly observed in conventional alloys. Instead, it experiences concurrent increases in strength and ductility, with its low-temperature fracture toughness reaching as high as 200 MPa·m1/2. This opens new possibilities for FCC high-entropy alloys as high-performance materials for low-temperature applications in polar regions, aerospace, and space materials.

HEAs demonstrate outstanding high-temperature strength and stability. Refractory high-entropy alloys primarily composed of refractory elements, such as Nb, Ta, Mo, W, benefit from the high melting points of these elements and the unique structural characteristics induced by the high-entropy effect. These alloys can maintain a stable single-phase body center cubic (BCC) structure even at temperatures as high as 1400 °C [21]. Furthermore, they exhibit exceptional strength at ultra-high temperatures of up to 1600 °C, displaying a high resistance to high-temperature softening. Refractory high-entropy alloys hold the promise of playing a crucial role in various fields, including aerospace, high-temperature molds, and ultra-high-temperature coatings.

HEAs exhibit exceptional resistance to radiation. From an energetic perspective, the multitude of principal elements in high-entropy alloys, coupled with their intrinsic chemical disorder, serves to reduce both the average energy propagation mean free path and alters the energy propagation mechanisms, thereby diminishing the accumulation of radiation damage. From a structural perspective, severe lattice distortion within HEAs impacts the generation and recombination of radiation-induced defects, primarily vacancies and interstitial atoms, consequently lowering dislocation mobility and enhancing the radiation resistance of HEAs [22]. Currently, HEAs in various systems have demonstrated promising resistance to neutron irradiation, making them potential candidates for advanced nuclear energy materials [23]. They hold potential applications as structural materials in nuclear reactors.

Furthermore, HEAs also exhibit exceptional physical properties, such as superconductivity [24], interesting magnetic properties [25], and significant corrosion resistance [26]. These outstanding properties make high-entropy alloys promising candidates for various applications, including aerospace, energy, electronics, and automotive industries.

1.3 Basic properties of high-entropy alloys

1.3.1 Density and crystalline structure

The mechanical and physical properties of high entropy alloys (HEAs) strongly depend on their crystalline structures [27, 28]. According to the entropy hypothesis, the HEAs containing multiple principal elements in equal or near-equal molar ratios would help to stabilize single-phase solid solution structures due to the high configurational entropy [29, 30]. In the early studies of HEAs, many types of single-phase HEAs were successfully developed with different crystalline structures such as FCC, BCC or HCP structures [10, 31, 32]. The FCC and BCC HEAs are usually composed of transition elements i.e., Cr, Mn, Fe, Co, Ni, Cu, etc., and refractory elements, i.e., Mo, Nb, Ta, W, Zr etc., respectively, while HCP HEAs typically consist of rare earth elements [10, 31, 32]. However, it is worth noting that apart from single-phase solid solutions, many HEAs exhibit multiphase structures or intermetallic phases such as L12 [33], B2 [34], Laves phase. As a consequence, the chemical complexity makes it hard to study the phase selection and prediction of HEAs. Notwithstanding, many empirical parameters were proposed to guide the design of HEAs such as atomic size difference δ, mixing enthalpy ΔHmix, VEC, and electron concentration e/a [29, 35]. In addition, machine learning and high throughput approaches have also been adopted recently to predict the crystalline structure of HEAs which improve the efficiency of alloy design [36,37,38]. It is worth noting that compared to conventional alloys, these transition/refractory/rare earth HEAs typically have higher densities due to their complex composition [39]. Besides these aforementioned HEA systems, light weight HEAs also attracted great research interests due to the great application potentials [40, 41].

1.3.2 Mechanical properties

The superior mechanical properties of HEAs are typically attributed to their unique local chemical ordering and microstructure, which can be further tailored by via adjusting the alloy composition and processing conditions. For these single-phase solid solution HEAs, there are two widely studied alloy families i.e., 3d transition metal HEAs and refractory metal HEAs. The 3d transition metal HEAs such as CoCrNi, CoCrFeNi, and CoCrFeNiMn typically exhibit excellent ductility but relatively low strength. Therefore, they usually serve as the model materials for the systematic study of effective approaches to overcome the strength-ductility trade-off [10, 42]. Here, it is worth noting that only at cryogenic temperature, do these FCC HEA alloys usually exhibit incredibly high fracture toughness and strength due to their low stacking fault energy [20, 43, 44].

When compared with the single-phase FCC ones, the refractory HEAs with BCC structure, however, possess much higher strength [31, 39] but poor plasticity, except for several TiZrHfNb, TiZrHfNbTa alloys with tensile ductility [28, 31, 39]. Consequently, extensive efforts have been devoted to achieving the balance between strength and ductility for refractory BCC HEAs. Lei et al. [12] found that adding the interstitial atom O into TiZrHfNb can simultaneously enhance its strength and ductility. Furthermore, they have reported that coherent nanoprecipitates can be introduced into the tungsten-containing refractory HEAs, which thus significantly increases their strength without sacrificing ductility [45]. Another unprecedented mechanical property of these refractory HEAs is their high-temperature strength and thermal stability [46, 47]. Apart from single-phase HEAs, dual-phase eutectic HEAs have also been developed as advanced structural materials with high-strength, high ductility, and good castability [48]. Note that their mechanical properties can be improved by tuning microstructure configurations through thermomechanical processing [49] or introducing second phase or heterostructure structures [50,51,52].

1.3.3 Thermal properties

The thermal conductivity of HEAs was pioneered studied by Chou et al. [53] for an AlxCoCrFeNi alloy system. It is observed that the thermal conductivity of these alloys increases with increasing temperature. Compared to the pure element metals, these HEAs have a much lower value of thermal conductivity due to the lattice distortion effect [53]. They also found that the thermal conductivities of FCC-structured alloys (x<0.375) are only half of these in BCC-structured alloys (x>1.25). In the single-phase regions, the thermal conductivity decreases with increasing Al contents. Recently, Sun et al. [54] studied the thermal physical properties of Al0.3CoCrFeNi HEAs at elevated temperatures, showing that the HEA with prominent semi-metallic characteristics have values of thermal conductivity varying from 3.14 to 5.99 W·m·K–1. Laplanche et al. [55] reported the thermal expansion coefficients (TECs) of a series FCC HEAs CoNi, MnCoNi, MnFeNi, FeCoNi, CoCrNi, CrFeNi CoCrFeNi at temperature range 100–673 K. It is found that the thermal expansion behavior of these alloys is similar to that of austenitic steel [56] and pure metals. Furthermore, Rao et al. [57] developed a set of CoCrFeNiCu invar alloys with extremely low TECs around 2x10−6−5x10−6 K–1 at 300 K. More recently, He et al. [34] developed an Elinvar alloy Co25Ni25(TiZrHf)50, which exhibits a constant elastic modulus over a wide temperature range between room temperature to 900K. The above findings indicate that the HEAs have great potential for designing invar and Elinvar alloys for engineering applications.

1.3.4 Electrical properties

While HEAs have gained considerable attention for their remarkable mechanical properties, their electrical properties are equally intriguing and have sparked significant research interest. The electrical conductivity of HEAs can vary widely depending on their constituent elements and microstructure. The electrical conductivity of HEA composite with copper (50 wt% TiZrNbTa /Cu) increased up to 340% induced by the second phase strengthening effect [58]. Compared with Ti3SiC2/Cu joint composited with Sn6Ag7Ni4Co2Ti filler, it is lower at all test temperatures, which is reduced by up to 15.99% at 300 °C [59]. HEA’s resistivity is tunable by adjusting their composition of constituent elements. In AlCuxNiTiZr0.75 HEA films, the increase in Cu content changed the electronic structure and hence the resistivity that decreased sharply to 66 μΩ·cm at x = 1.4 [60]. The nanocrystalline NbMoTaW HEAs thin films show a good combination of hardness, resistivity, thermal stability and strong size-independent electrical resistance (~170 µΩ·cm). This type of HEA film is promising for diffusion barriers in nano-devices [61]. While not common, superconducting behavior has been observed in HEAs at ultra-low temperatures. A polycrystalline sample of the high-entropy-alloy-type telluride AgInSnPbBiTe5 superconductivity with a transition temperature of 2.6 K was observed. Since AgInSnPbBiTe5 has a cation site (Ag, In, Sn, Pb, and Bi) and an anion site (Te), this is the first example of a high-entropy alloy (HEA) pseudo-binary superconductor [62].

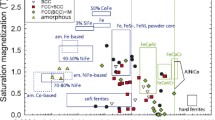

1.3.5 Magnetic properties

HEAs have a variety of interesting magnetic properties including ferromagnetic, paramagnetic, and antiferromagnetic properties. Magnets are the essential components of instruments and devices used in our daily lives, like motors, generators, transformers, and actuators. It was found that about 9% of the generated electricity was lost due to the core loss of the transformer. For a better soft magnetic material (core material), it is expected that these materials must have high saturation magnetization (Ms), low coercivity (Hc), high electrical resistivity, and the right balance of magnetic and mechanical properties [63]. FeCoNiTaAl HEA with ferromagnetic matrix and paramagnetic alloy has a tensile strength of 1,336 MPa at 54% tensile elongation, extremely low coercivity of 78 A·m−1 (less than 1 Oe), moderate saturation magnetization of 100 A·m2·kg−1 and high electrical resistivity of 103 μΩ·cm [25]. The FeCoNiCuAl HEA has good magnetic and mechanical properties and corrosion resistance, which can be finely tuned by the fraction, composition, and distribution of the BCC and FCC phases [64]. FCC, BCC, and B2 phases, the most common phases in (HEA), are widely investigated to tailor their mechanical and magnetic performances. The detailed investigation of FCC to BCC/B2 phase transformation of AlCoCrFeNi HEA reveals its evolution and structure-properties relations in terms of both temperature and holding duration [65]. The inclusion of Cr in HEA is responsible for high temperature corrosion resistance and thermal stability of soft-magnetic high entropy alloy [66].

1.3.6 Chemical stability

HEAs have excellent chemical stability with applications in chemical processing equipment, heat exchangers, marine applications, aerospace applications, biomedical devices, and nuclear energy applications. HEAs have impressive resistance to oxidation at high temperatures. The formation of protective oxide layers, often consisting of complex oxide phases, contributes to their oxidation resistance [67]. HEAs containing corrosion-resistant elements like chromium (Cr) and nickel (Ni) tend to exhibit excellent resistance to various forms of corrosion [68]. The high configurational entropy of HEAs makes them less susceptible to forming intermetallic compounds, which are often weak and susceptible to corrosion [69]. The presence of multiple elements in HEAs can lead to forming a protective surface layer, which can help prevent corrosion. The CoCrFeMnNi is corrosion-resistant in diverse environmental conditions, including exposure to aggressive chemicals and high radiation environments and in acidic media [51, 52]. HEAs have the best cryogenic stability. Al/Ta co-doped NiCoCr twinned medium entropy alloy with some B2 phase has ultrahigh strength and stability at cryogenic temperature [70, 71]. Irradiation-resistant behavior of HEAs makes it a possible candidate in the fusion reactor for sustainable energy production [72].

1.4 Design principles of high-entropy alloys

The concept of HEAs offers an unprecedented level of design flexibility for advanced alloys with promising performance. Given the incorporation of diverse elements, characterized by variable atomic sizes, induces a departure of atoms from their ideal lattice positions within HEAs, culminating in marked local lattice distortions [28, 73]. Such distortions can hinder dislocation motion, thereby leading to a significant strengthening effect [74]. In pursuing greater strength, initiatives have been undertaken to engender coherent intermetallic precipitates, concomitantly preserving a medium- to high-entropy matrix in HEA design [75]. Furthermore, the minimal lattice misfit observed in HEAs is suggested to reduce the nucleation barrier for precipitation, facilitating the stabilization of precipitates with elevated number density [76]. The potential of HEAs as an innovative methodology for the development of lightweight and cost-effective materials reinforced by precipitation is highlighted, especially for applications at high temperatures [40, 77]. In the development of developing such materials, implementing the critical, purpose-driven design strategies is deemed an indispensable antecedent. These strategies include utilizing cost-effective raw materials, achieving low density, a high melting temperature (Tm), exceptional oxidation resistance, superior creep resistance, and high strength with tolerable ductility. Consequently, the careful selection of chemical compositions is underscored as playing an essential role in fulfilling these critical criteria [78].

The foundational approach in developing HEAs is rendered by the design and research of new materials, guided by the principles of materials science. Such an approach is predicated upon a comprehensive understanding of elemental characteristics, including but not limited to melting points, atomic sizes, crystal structures, valence electrons, electronegativity, density, elastic constants, interactions between different elements, thermodynamics, kinetics, the relationships between microstructure and properties, as well as the four well-known effects of HEAs. By these principles, researchers in the HEA community are known to formulate novel HEAs endowed with targeted performance attributes. The compelling nature of this approach is set to be augmented with the progressive accumulation of HEA data, knowledge, and experience. For instance, in the study of the MoNbTaVW HEA system, which aims to combine high strength with reasonable toughness, multiple solid solution phases may emerge within the microstructure, marked by elevated hardness but compromised ductility. To analyze the compositions of these phases, scanning electron microscopy alongside energy-dispersive spectroscopy or electron probe microanalysis is utilized, and their microhardness is gaged using a microhardness tester. Subsequently, phase selection follows performance requisites, and a secondary alloy is synthesized. By excluding brittle phases, an overall structure with high strength and improved ductility can be achieved. The Gibbs phase rule intimates considerable latitude in the amalgamation of elemental concentrations, thus allowing for the enhancement of certain properties through the meticulous adjustment of individual elemental concentrations, all the while preserving a simplified phase structure for the alloy. It is evident that prospective HEAs frequently present non-equimolar molar compositions, with equimolar HEAs typically employed as a reference point for elucidating new alloy systems. Analogous to the evolution of traditional high-performance alloys, the refinement of composition and processing parameters is often necessary to realize stipulated performance objectives [6].

In the realm of material science, HEAs are acknowledged for their propensity to form simple phases such as FCC, BCC, and HCP structures, both ordered and disordered, each manifesting a spectrum of distinctive properties [20, 79,80,81,82]. Nonetheless, the benefits of single-phase HEAs are often limited. Specifically, alloys with an FCC structure tend to be relatively soft. Among common strengthening mechanisms, second-phase strengthening is widely acknowledged as one of the most effective approaches [83,84,85]. These secondary phases may either materialize directly during solidification or precipitate within the matrix following heat treatment. Characterized by sluggish diffusion kinetics [4], HEAs, upon exposure to protracted annealing at temperatures around 700 °C [86], or through homogenization followed by furnace cooling at 1100 °C, are prone to the formation of nanoscale secondary phases/precipitates in the as-cast state [87,88,89]. Therefore, HEAs are well-suited for the utilization of this strengthening mechanism. Reports indicate that incorporating secondary phases can considerably elevate the mechanical robustness of HEAs. For instance, the precipitation of the hard η-Ni3Ti phase greatly enhances the wear resistance of the Co27.3Cr18.2Fe18.2Ni27.3Ti9.1 alloy [90].Similarly, in the AlCoCrxFeMo0.5Ni alloy, the formation of σ phase results in improved resistance to high-temperature softening [91]. These observations underscore the efficacy of second-phase strengthening in enhancing HEA performance.

In recent endeavors, numerous research groups have embarked on the design of HEAs with designated crystal structures as secondary phases. A method has been adopted whereby diminutive amounts of titanium (Ti) and aluminum (Al) are integrated into an iron-cobalt-nickel-chromium-based alloy (FeCoNiCr) to precipitate nanoscale coherent strengthening phase L12-Ni3(Ti, Al) within the FCC FeCoNiCr matrix [92]. The resultant γ-γ′ structure, reminiscent of the structure found in nickel-based superalloys, is recognized for its pronounced precipitation-hardening effect. When subjected to thermomechanical processing, the (FeCoNiCr)94Ti2Al4 alloy was observed to attain a yield strength surpassing 1 GPa while preserving outstanding ductility of 17%. Conversely, Guo et al. [93] introduced carbon (C) alloying into the refractory HEA, which consists of Mo0.5NbHf0.5ZrTi, leading to the genesis of MC (where M signifies Hf, Nb, Zr and Ti) carbide particles. The compressive strength of the Mo0.5NbHf0.5ZrTiC0.1 alloy reaches 2139 MPa, coupled with a fracture strain of 38.4%, signifying a marked improvement in both compressive strength and plasticity compared to the foundational alloy. Moreover, the AlCoCrFeNi2.1 alloy, characterized by the co-presence of two distinct crystal structures, FCC and B2, is noted. Furthermore, these phases engender a layered structure in the as-cast state, associated with diminished hardness. Through thermomechanical processing, a dual-phase microstructure with ultrafine grains is achieved, yielding balanced mechanical properties—a yield strength of 1100 MPa and a ductility of 12% [94]

1.5 Microstructure of high-entropy alloys

Up to now, various HEAs with different microstructures and crystal structures, which have excellent extreme temperature resistance, radiation resistance, and corrosion resistance, have been developed and are expected to be applied in extreme environments. Therefore, achieving a comprehensive understanding of the microstructure of HEAs is a prerequisite for optimizing their mechanical and physical properties. In the past decades, researchers have realized that HEAs exhibit plentiful microstructures at trans-scale observations, i.e., at the atomic scale, they exhibit chemical and topological ordering, resulting in complex local structures [95,96,97]. At the nanoscale, phase separation and nanoscale precipitates can be observed [52], and then it also has feature structure including dendritic, eutectic or network structure at the mesoscopic scale [16, 98, 99], as shown in Fig. 2.

Owing to their metastable nature, HEAs exhibit microstructural heterogeneities from atomic to nanoscale [100,101,102]. Ma et al. proposed that in a high entropy solid solution, the enthalpy interaction between constituent atoms induces a complex local chemical environment or local chemical order [103]. Although atomic scale microstructures such as local chemical ordering or topological ordering have received great attention, there is still significant controversy due to the lack of relevant experimental evidence [104, 105]. Research on chemical ordering in high entropy alloys typically focuses on chemical short-range ordering. Some studies utilize a combination of Monte Carlo (MC) simulations and density functional theory (DFT) calculations or molecular dynamics (MD) simulations to reveal the existence of chemical short-range ordering [96, 106,107,108]. Others use techniques such as X-ray/neutron diffraction [109], atom probe tomography [109, 110], transmission electron microscopy (TEM) [111], to confirm the existence of chemical short-range ordering experimentally.

Further, to amplify the observation perspective, a fact about high entropy alloys is that single-phase FCC high entropy alloys typically exhibit low strength and high plasticity and manipulating solid solution phase separation and second phase particle precipitation can significantly improve phase stability and the strength of alloy [102]. Generally, phase separation and nano-phase formation occur during rapid curing or aging treatment, ultimately achieving component redistribution through the slow diffusion of multiple atoms [112]. Qi et al. [113] showed that the increase of Zr content can significantly affect the phase stability of the CoCrFeNi alloy, and promote the formation of intermetallic and obvious phase segregation (FCC→BCC phase). Similarly, Liu et al. found that in AlxCoCrCuFeNi alloy, the increase in Al content promotes the transformation of the crystal structure of the alloy system from FCC to BCC, accompanied by a large amount of nanoprecipitation in the dendritic region. Specifically, when the Al content is 0.5, due to the small change in the mixing enthalpy of the system, the coarsening of the Cu-rich nanoscale phase and the decomposition of the solid solution phase are inhibited [114]. Meanwhile, nanoscale decomposition has also been demonstrated in some HEAs, e.g., nanoscale modulated structure by spinodal decomposition, domains, and phases in AlCoCrCuFeNi [115]. Therefore, elucidating the phase separation phenomenon in high entropy alloys is crucial for predicting the thermal stability or controlling the microstructure and mechanical properties of alloys. Moreover, numerous researchers have realized that for high entropy alloys, its constituent elements between the solid solubility are the most important factor in deciding whether to form a single-phase solid solution [116]. This means that through appropriate heat treatment methods or careful control of the composition and content of alloy elements, controllable precipitation of specific nano phases can be achieved, thereby achieving the goal of adjusting the overall performance of the alloy. Significantly, even single-phase FCC and BCC high entropy alloys can easily generate nano precipitates in their matrix through heating treatment or adding alloying elements. For example, the pioneering Cantor alloy will also precipitate nanoscale Cr-rich σ phase, L10-NiMn, B2-FeCo and a Cr-rich BCC phase after heat treatment [117]. Wang et al. [118] prepared a single-phase CoCrFeNiMn0.75Cu0.25 high entropy alloy by casting method, which has a single-phase FCC crystal structure at room temperature. However, after cold rolling and heat treatment, some Cr-rich σ phases were generated in the matrix. On the other hand, tremendous research is devoted to strengthening HEAs through nanoparticles, which promotes the design and in situ precipitation of diverse nanoprecipitates in HEAs. Typical nanoparticles include coherent Ni3Al-typed L12 [119], Ni3Nb-typed D022 [120], semi-coherent NiAl-typed B2 phase strengthening HEAs and topologically closed-packed σ and μ phases [121,122,123]. Among them, the coherent L12 precipitation strengthening has been widely used in FCC matrix high entropy alloys by adding Al, Ti or V. As a kind of ductile precipitated phase, L12 phase can significantly improve the strength of the alloy and cause less loss of ductility. However, although hard precipitates such as B2, σ and μ phases can effectively hinder dislocation movement and achieve a more significant strengthening effect compared to L12 phase, it also leads to a decrease in the ductility of the alloy to some extent.

The diversity of fabrication methods and alloy composition makes HEAs rich in mesoscale structures, typical of which include dendrites, eutectic and network-like structures. Most single-phase high entropy alloys (FCC or BCC) obtained through casting display a dendritic morphology microstructure [16, 124, 125]. It is mainly due to the local enrichment of elements during the solidification process, leading to the formation of obvious matrix element-rich phases in the interdendritic region. In addition, as a subset of high entropy alloys, eutectic high entropy alloys (EHEAs) typically exhibit regular lamellar or rod-like eutectic structures, with near equilibrium microstructures that resist changes at higher temperatures, high fracture strength, and high-temperature creep resistance. The most commonly reported EHEA are generally composed of some soft and hard phases, such as FCC/BCC (or B2), which have superior fracture strength and acceptable tensile ductility (~15%) such as AlCoCrFeNi2.1 [98, 126], CrFeNi2.2Al0.8 [127]. Another type of EHEA composed of BCC/B2 or BCC/intermetallic phases, such as Al1.3CrFeNi [128], is usually brittle at room temperature but has outstanding high-temperature mechanical properties. Furthermore, some network-like structures are often observed in two-phase alloys with BCC and FCC. Shivam et al. [99] found a network-like structure in the interdendrite region while studying the formation of supersaturated phases during heat treatment of an equiatomic AlCrCuFeNi high entropy alloy.

2 High-entropy alloys as cutting-edge structural materials

2.1 Nanostructured high-entropy alloys

Recently, significant research has been carried out to tailor the properties of HEAs by tuning the microstructure. HEAs with nanocrystalline (nc) structure (Fig. 3) may enhance the physical and mechanical properties significantly compared to the conventional nc-metals and coarse-grained (cg) HEAs [129, 130]. nc-metals, often categorized by grain size less than 100 nm, exhibit unique and superior properties than the cg-alloys due to the grain refinement effects [131, 132]. However, the current limitation restricting the use of nc-metals is their poor thermal stability under stress or at elevated temperatures, as grains dramatically coarsen with time. Thus, developing nc-metals with good stability has been a topic of interest for many researchers. The practical approach to stabilize the nc-structure is through alloying and thereby stabilizing the grain boundaries (GBs) thermodynamically by solute segregation [133,134,135]. In this regard, HEAs with multi-principal elements in grain not only can improve microstructural stability by reducing the thermodynamic driving force for GB motion but also provide additional strength through combined GB and solid solution (SS) strengthening mechanisms. Thus, it would be advantageous to exploit the unique design of HEAs and unique properties of nc-structure to obtain significantly enhanced properties.

Reproduced with permission from Ref. [129]. Copyright 2020, Springer Nature

From single crystal metals to nanocrystalline metals to nanocrystalline high-entropy alloys.

2.1.1 Methods to prepare nc-HEAs

There are many methods of preparation nc-HEAs. The literature indicates that the nc-HEAs are fabricated mainly by mechanical alloying (MA) [136,137,138], high-pressure torsion (HPT) [139, 140], magnetron sputtering (MS) [141, 142], and inert gas condensation (IGC) [143,144,145]. Among these methods, HPT can produce bulk nc-HEAs in a single step. The MS technique produces nc-HEAs in the form of thin films, whereas the MA produces nc-HEAs in the form of powders, which requires an additional step of consolidation at high temperatures. The IGC method is to evaporate the alloys by laser ablation and condense the evaporated atoms or clusters into nano particles through collisions with the inert gas atoms, and finally, in situ compact them into bulk nc-HEAs. Among them, MA is the most popular synthesis method in the literature. The major benefit of MA is its incredible versatility. Any material that can be made in powder form could be refined using this method. The ease of use of the MA equipment is another advantage compared with more complex systems, such as MS and IGC. However, the most predominant issue in MA arises from the need to consolidate the refined nc-powders into a bulk material, which is usually done through spark plasma sintering (SPS). Consolidating powders at high temperatures often leads to grain growth, and the alloy becomes ufg- or fine-grained (fg) microstructure [146]. Another disadvantage of the MA method is the contamination that can occur during preparation, which can be largely avoided in the other three synthesis routes.

2.1.2 Mechanical properties of nc-HEAs

The 3d transition metal class has been the most popular NC HEA class. Figure 4a shows a wide range of hardness values that can be achieved in 3d transition metal-based nc-HEAs [147,148,149,150,151,152,153,154,155,156,157,158,159,160,161,162,163,164,165,166,167,168,169,170,171,172,173,174]. Generally, 3d transition metal-based nc-HEAs fall within HV 400–HV 800 hardness ranges. In comparison with conventional materials such as 304 stainless steel (660 MPa tensile strength, ~ HV 200) and Inconel 600 (660 tensile strength, ~ HV 200), the hardness of the 3d transition metal class exceeds ~ HV 400 at all grain sizes below 150 nm. However, insight into the toughness, ductility, and work-hardening characteristics of these nc-HEAs is currently lacking.

Figure 4b presents the hardness measured using instrumented indentation. As this testing technique continuously measures the depth and load throughout indentation, the reported results are more readily comparable to common testing procedures such as tensile and compression testing. For these HEAs, there is no distinct trend with varying grain sizes. Most HEAs fall in the range of 5–9 GPa.

For refractory nc-HEAs, Huang et al. [175] have prepared TiZrHfNb refractory bulk NC-HEAs by the IGC method. Feng et al. [141] and Kim et al. [176] have synthesized NbMoTaW nc-HEA thin films by MS method, which exhibits high hardness in the range of 12–16 GPa. Compared to 3d transition HEAs, the refractory class generally exhibits higher hardness.

2.1.3 Thermal stability of nc-HEAs

The thermal stability of mechanical properties is one of the most popular topics in the field of nc-HEAs, particularly for high-temperature applications. Figure 5 shows a collection of the thermal stability of hardness and grain size of nc-HEAs reported in recent literatures. In Fig. 5, the hardness stability between coarse- and nano-grained HEAs can be directly compared. Shahmir et al. [139, 165] have shown that in CoCrFeNiMnTi0.1, there is a considerable rise in the room temperature hardness (from ~ HV 125 to ~ HV 450) when the grain size is reduced from a few tens of micrometers down to sub-50 nm size. As temperature increases, excellent stability of these hardness values over an annealing time of one hour is observed, up to a temperature of about 600 °C. Likewise, with grain-size stability, significant grain growth only begins at about 600 °C. In general, most other alloys follow the same trend. However, some HEAs exhibit pronouncedly more significant thermal stability, such as the (CoCrFeNi)93.5Mn6.5 nc-HEA prepared by the IGC method, exceeding temperatures of 1000 °C while maintaining its original strength after 1 h of annealing [143].

As shown in Fig. 5b, it is also observed that refractory nc-HEAs, such as NbMoTaW, can operate and maintain smaller grain sizes at higher temperatures than purely 3d transition metal-based nc-HEAs. This is likely because those refractory elements, such as Nb, Mo and Ta, have higher melting points than the 3d transition metal constituents which may slow down the diffusion kinetics within the material.

2.1.4 Functional properties of nc-HEAs

Compared with the vast number of studies on the mechanical properties of nc-HEAs, their functional properties, such as corrosion resistance, electrical conductivity, and magnetic properties, have been much less reported.

In general, corrosion reactions will be significantly facilitated by a higher density of interfaces or GBs where the activation energy of corrosion is lower. For example, Shang et al. [182] reported that CoCrFeNi nc-HEAs exhibit a lower corrosion resistance than their coarse-grained counterparts. The negative trend for electrical conductivity also exists due to the enhanced scattering of electrons at the dramatically increased interfaces or GBs, however, their synergetic influence with high lattice distortion in nc-HEAs leads to promising thermoelectric properties [183].

So far, there have been few relevant studies on the magnetic properties of nc-HEAs. For example, Wang et al. presented systematic microstructure-oriented magnetic property investigations for CoCrFeNiMn [184] and Al/CoCrFeNi nc-HEA [185], respectively. It was found that the magnetic properties of nc-HEA can be effectively regulated through the control of the phase structures. Yao et al. [186] reported that the magnetic properties of a BiFeCoNiMn HEA system depend on its nanostructures.

2.2 Grain boundary engineered high-entropy alloys

(HEAs) have been specifically designed to optimize the properties and behavior of grain boundaries, which can significantly impact the material's strength, ductility, and corrosion resistance. Despite the considerable progress made by HEAs in overcoming the strength-ductility trade-off and obtaining a variety of excellent functional properties, for most of the current equiaxed polycrystalline HEAs, grain boundary-related brittleness issues are still constraining their industrial applications, such as intermediate-temperature embrittlement, grain-boundary instability, and hydrogen embrittlement [119, 187,188,189,190,191]. This section will review the recent advances in grain-boundary engineering of HEAs or compositionally complex alloys (CCAs).

Cao et al. [187] constructed a heterogenous columnar-grained (HCG) structure in a precipitation-strengthened HEA by a novel heat treatment process, which contains both uncrystallized deformed grains and fine recrystallized grains as a result of partial recrystallization, compared with the ordinary equiaxed-grained (EG) HEA. The inverse pole figure (IPF) and grain-boundary maps (the corresponding insets) of the EG-HEA and HCG-HEA are given in Fig. 6a, b, respectively, where partial recrystallization leads to changes in microstructural morphologies as well as alterations in the grain-boundary character distributions. Owing to this unique heterogeneous microstructure, the novel HCG-HEA has more low-angle grain boundaries (LAGB) and fewer high-angle random grain boundaries (HARGB) compared to the equiaxed-grained counterpart, as shown in Fig. 6c. The low-energy characteristics of LAGBs can not only reduce the probability of intergranular fracture but can also effectively destroy the connectivity of HARGBs, thus hindering the propagation of intergranular cracks during tensile deformation at 800 °C. As expected, the tensile curves demonstrated that the HCG-HEA can exhibit a high yield strength of ~652 MPa and excellent tensile ductility (~18.4%) at 800 °C, which is a substantial enhancement in tensile ductility compared to the EG-HEA and completely avoids the occurrence of intermediate-temperature embrittlement (Fig. 6d). Subsequently, Chou et al. [192] used a similar approach to obtain the heterostructured L12-strengthened HEA (Co40Cr20Ni30Al5Ti5, at%), which exhibited ultrahigh tensile strengths and excellent tensile ductility (>20%) in the intermediate-temperature region (500, 600 and 700 °C). These results suggest that the heterogeneous grain structure with optimized grain-boundary character distribution can effectively avoid the occurrence of intermediate-temperature embrittlement while ensuring high strength.

Reproduced with permission from Ref. [187]. Copyright 2021, Elsevier Ltd.

Avoiding intermediate-temperature intergranular embrittlement through architecting a heterogeneous grain structure in L12-strengthened HEAs. IPF image and corresponding grain-boundary maps (inset) of a equiaxed-grained (EG) HEA and b heterogeneous columnar-grained (HCG) HEA. c Grain boundary character distribution (GBCD) of EG and HCG HEAs, including low-angle grain boundaries (LAGB), coincidence-site lattice grain boundaries (CSLGB), and high-angle random grain boundaries (HARGB). d Engineering tensile curves of both HEAs tested at 800 °C in air.

Another group of materials that have also long been afflicted by intergranular brittleness are ordered intermetallic alloys. However, their strong chemical binding and associated low atomic mobility have led them to be considered promising candidates for high-temperature structural materials. Except for intrinsic brittleness caused by the lack of sufficient operating slip systems for the D019 or L10 structure, the ductility of the L12 or B2 structured alloys can be improved in a variety of ways to avoid the environmental brittleness at room temperature, such as doping with a small amount of boron (B) element [193, 194], compositional design with off-stoichiometry [194, 195], and the removal of water vapor in the ambient atmosphere [196, 197]. Nevertheless, traditional ordered alloys still have a relatively limited yield strength at ambient temperatures. Recently, Yang et al. [33] successfully fabricated a chemically complex intermetallic alloy (CCIMA) with L12 structure, i.e., the Ni43.9Co22.4Fe8.8Al10.7Ti11.7B2.5 (at%), by combining the multicomponent character of HEAs with the long-range ordered structure. It is found that an ultrathin-disordered nanolayer appeared near the grain boundaries, as shown in Fig. 7a. Compared to traditional ordered alloys, such as the Ni3Al-type alloy, the multicomponent features and the disordered nanolayers endow this new type of CCIMA with ultra-high strength (1.6 GPa) and excellent tensile ductility (25%), respectively, as presented in Fig. 7b. From the inset within Fig. 7b, it can be seen that a large number of dimples appear on the fracture surface of the CCIMA, indicating its intrinsically ductile fracture characteristics. The IPF (Fig. 7c) and corresponding kernel average misorientation (KAM) map (Fig. 7d) of the fractured specimens show evident grain misorientations and intense dislocation activities. It has also been demonstrated that these disordered interfacial nanolayers (DINL) near the grain boundaries can act as a ductile buffer zone between two neighboring ordered grains, which significantly improves the dislocation mobilities at the grain boundaries and helps avoid the intergranular fracture, resulting in an excellent tensile ductility at such an ultrahigh-strength level (Fig. 7e) [198].

Reproduced with permission from Ref. [33]. Copyright 2020, AAAS

a Scanning transmission electron microscopy high-angle annular dark-field (STEM-HAADF) image and corresponding site-specific fast Fourier transform (FFT) patterns revealing ultrathin disordered nanolayers near grain boundaries of a chemically complex intermetallic alloy. b Stress-strain curves of CCIMA and traditional Ni3Al-type alloy, indicating that CCIMA decorated by disordered nanolayers can overcome strength-ductility trade-off encountered by binary-ordered alloys. c Electron backscatter diffraction (EBSD) IPF image and d corresponding KAM map of fractured specimen, showing apparent grain misorientations and pronounced dislocation activities. e Schematic illustration showing remarkable ductilization response dominated by disordered interfacial nanolayer (DINL).

However, the common dilemma of intermediate-temperature embrittlement still rears its ugly head in CCIMAs containing equiaxed ordered grains encapsulated with disordered nanolayers, seriously limiting their further application as high-temperature structural materials. Fortunately, a recent study by Xiao et al. [199] has shown that the CCIMA with optimized grain-boundary architectures can substantially increase tensile strength while avoiding intermediate-temperature embrittlement. Figure 8a, b presents the microstructures of the equiaxed-grained (EG) and lamellar structured (LS) CCIMA (Co38.8Ni37.5Al13.8Ti3.1Ta2.8Nb3.5B0.5, at%) with the L12 structure, which were obtained by full recrystallization and partial recrystallization, respectively. In addition, the fraction of LAGBs in LS-CCIMA is statistically ~22%, which is much higher than that in the EG counterpart (~7%). This unique heterogeneous lamellar structure combined with a large fraction of LAGBs allows the newly designed CCIMA to effectively delay the onset of intergranular fracture and obtain an ultra-high yield strength of ~1.2 GPa and a considerable ductility of more than ~10% in the intermediate-temperature region of 600 to 800 °C (Fig. 8c). In comparison, the EG-CCIMA suffers from severe intermediate-temperature embrittlement, with less than 5% tensile ductility at the same temperature range. Furthermore, the cross section of the fracture surface of EG-CCIMA at 800 °C shows prominent intergranular fracture characteristics along the tensile direction. At the same time, the LS counterpart exhibits some small microvoids, as shown in Fig. 8d, e, respectively. It is once again demonstrated that the heterogeneous grain-boundary architectures can effectively eliminate the temperature-dependent grain-boundary brittleness in the long-range ordered CCIMAs.

Reproduced with permission from Ref. [199]. Copyright 2024, Elsevier

Combining heterogeneous grain structure and grain boundary disordered nanolayers to overcome intermediate-temperature intergranular embrittlement. IPF image of a EG-CCIMA and b LS-CCIMA. c Typical engineering stress-strain curves of EG- and LS-CCIMAs at intermediate-temperature regimes (600, 700 and 800 °C). d SEM images of fractured EG-CCIMA specimen show evident intergranular cracking. e SEM images of fractured LS-CCIMA specimen that exhibit some small micro-cavities in cross section of fractured surface, as highlighted by yellow circles.

In addition to intermediate-temperature brittleness, another major type of intergranular fracture associated with environmental embrittlement occurs in a hydrogen atmosphere, which is called hydrogen embrittlement [200]. High concentrations of hydrogen atoms can reduce the intrinsic cohesive strength of grain boundaries by promoting void initiation and coalescence, strain concentration, and stabilizing vacancies, leading to severe degradation of mechanical properties, usually manifested as intergranular brittle fracture [201]. The enormous compositional design freedom and tailored chemical-structural heterogeneities of HEAs provide great opportunities to avoid such an embrittlement problem. Recently, Li et al. found that architecting grain boundaries with interfacial segregation of some beneficial elements was an effective strategy to improve the hydrogen embrittlement resistance of HEAs [188]. They found that the Fe2.5Cr32.5Co32.5Ni32.5 (denoted as 2.5Fe) HEA is highly vulnerable to hydrogen embrittlement in the hydrogen-charged state, showing a drastically reduced tensile ductility compared to the hydrogen-free state (from 47.5% to 14.1%), as shown in Fig. 9a. In sharp contrast, the Fe25Cr25Co25Ni25 (denoted as 25Fe) HEA exhibits excellent hydrogen embrittlement resistance with only 6% ductility loss (δloss). The thermal desorption analysis (Fig. 9b) shows that these two HEAs have similar hydrogen atom concentrations, thus ruling out the effect of hydrogen concentration on the hydrogen embrittlement behavior. The STEM-HAADF images of the grain boundaries in hydrogen-free 25Fe and 2.5Fe HEA are presented in Fig 9c, e, respectively, and the corresponding line-scan analyses are shown in Fig. 9d, f. As can be seen from the line-scan results, the increase in Fe content promotes the nanoscale segregation of Cr near grain boundaries. In this way, such unusual interfacial segregation of Cr improves the intrinsic cohesive strength of grain boundaries. It hinders the enrichment of hydrogen atoms along them, resulting in the excellent hydrogen embrittlement resistance of 25Fe HEA. In short, reasonable adjustment of the grain-boundary morphologies, grain boundary characters, and elemental interfacial segregation can promote the stability of grain boundaries, thus avoiding environmentally relevant brittleness.

Reproduced with permission from Ref. [3]. Copyright 2008, AIP Publishing

Chemical segregation at grain boundary to eliminate hydrogen embrittlement in FeCrCoNi-type HEAs. a Engineering stress-strain curves of Fe2.5Cr32.5Co32.5Ni32.5 (2.5Fe) and Fe25Cr25Co25Ni25 (25Fe) alloys in hydrogen (H)-charged and -free states. b Thermal desorption analysis of H-charged 2.5Fe and 25Fe alloys. STEM-HAADF images of grain boundaries in c H-free 25Fe alloy and e H-free 2.5Fe alloy. d, f Corresponding element profiles across grain boundaries.

2.3 Eutectic high-entropy alloys

Recently, eutectic high-entropy alloys (EHEAs), which integrate the advantages of HEAs and traditional eutectic alloys, have become a research hotspot in metallic material due to their excellent castability and attractive properties [48, 98, 202]. Compared with single-phase or nano-precipitates HEAs, EHEAs not only exhibit outstanding formability, uniform microstructure, and rare casting defects by eutectic reaction [203, 204], but also possess excellent mechanical properties, wear resistance, and oxidation resistance through a combination of soft/hard eutectic phases [205,206,207]. The proposal of the concept of EHEAs has solved the problems of forming difficulties, compositional segregation, and severe casting defects in HEAs, promoting their potential application in large-scale and complex parts [48, 208]. Since the concept of EHEAs was proposed by Lu et al. [202] in 2014, several design strategies for EHEAs have been proposed and developed [75, 209,210,211,212,213,214,215]. Based on these design strategies, a large number of EHEA systems were prepared and investigated [48, 75, 208,209,210,211,212,213,214,215,216,217,218]. Among these EHEA systems, the most popular and widely studied is the FCC+B2 EHEA system due to its excellent mechanical properties during room-temperature tensile loading [219]. In addition, the mechanical properties of the FCC+B2 EHEA system can also be further optimized by advanced manufacturing technologies [220, 221] and tailored thermomechanical treatment processes [49, 126, 222]. In this section, we mainly discuss the design strategies, microstructural characteristics and mechanical properties of EHEAs.

2.3.1 Design strategies

Compared with traditional binary eutectic alloys, the design of multi-component EHEA is more difficult due to the complexity and diversity of the chemical compositions, which requires designers to consider the effect of multiple elements on the eutectic structure. However, with the accumulation of experimental parameters and the enrichment of phase diagram databases in HEAs [223,224,225], several design strategies for EHEAs have been proposed and developed, such as the mixing enthalpy strategy [211], simple mixture strategy [210], pseudo-binary strategy [75], CALPHAD strategy [209], machine learning strategy [213], A-(M+N) mode + computer-aided thermodynamic calculations strategy [215], infinite solid solution strategy [214], and calculating solidification paths strategy [212]. They provide adequate theoretical guidance for developing new EHEAs.

Although design methods vary, they also exhibit similar characteristics. The selected eutectic elements are basically divided into two groups based on mixing enthalpy, ΔHmix. One group is disordered solid solution phases forming elements with ΔHmix close to zero, while the other group is ordered intermetallic compounds (IMCs) comprising elements with extremely negative ΔHmix. Finally, a eutectic microstructure with disordered solid solution + ordered IMC was constructed. As shown in Table 1, the CoCrFeNi-M (M=Zr, Nb, Hf, Ta, and Al) EHEA systems were designed based on mixing enthalpy strategy [211], simple mixture strategy [210], pseudo-binary strategy [75], CALPHAD strategy [209], machine learning strategy [213]. It can be found that the Co, Cr, Fe, and Ni elements with ΔHmix close to zero are prone to form disordered FCC solid solution, while Ni/Zr, Ni/Nb, Ni/Hf, Ni/Ta, and Ni/Al atom pairs with extremely negative ΔHmix of / / / / /− 49, − 30, − 42, − 29 and − 22 kJ·mol–1 are prone to form ordered Laves/B2 IMCs. Thus, the eutectic microstructure with FCC + Laves/B2 IMCs eutectic microstructure was constructed. The CoCrFeNi-M+N (M=Ti, Mo, V, N= Si, C, B) EHEA systems were prepared by combining A-(M+N) mode and computer-aided thermodynamic calculations strategy [215]. Consistent with the above, the Co, Cr, Fe and Ni with ΔHmix close to zero are prone to form disordered FCC disordered solid solution. At the same time, Ti/Si, Mo/C and V/B atom pairs with extremely negative ΔHmix of − 66, − 67 and − 42 kJ·mol–1 are prone to form ordered silicide/carbide/boride IMCs. Thus, the eutectic microstructure with FCC + silicide/carbide/boride IMCs eutectic microstructure was constructed. The MoCrVFe-NiAl EHEA systems were fabricated by infinite solid solution strategy [214] and calculating solidification paths strategy [212]. The Mo, Cr, Fe, and V elements with ΔHmix close to zero are prone to form disordered BCC solid solution, while Ni/Al atom pairs with extremely negative ΔHmix of − 22 kJ·mol–1 is prone to form ordered B2 IMC. Thus, the eutectic microstructure with BCC + B2 IMC eutectic microstructure was constructed. In summary, whether thermodynamic phase diagram assisted calculation or formula derivation is used to design the compositions of EHEAs, the parameter of mixing enthalpy is crucial for the selection of eutectic elements, which provides inspiration for new EHEAs designs.

2.3.2 Microstructural characteristics

Like traditional eutectic alloys, the designed EHEAs also exhibit various eutectic morphologies. As shown in Fig. 10, the lamellar FCC+B2 EHEA [226], serrated strip FCC+M3B2 EHEA [227], needle-like BCC+HCP EHEA [228], seaweed FCC+Mn7Pd9 EHEA [229], chrysanthemum-like BCC+σ EHEA [230], sunflower-like BCC+B2 EHEA [231], granular FCC+BCC EHEA [232], network FCC+M16Ti6Si7 EHEA [233], and labyrinth-like FCC+B2 EHEA [75] are shown. The eutectic morphologies are one of the important factors affecting the thermal stability of EHEAs [234]. Usually, the eutectic morphologies, such as lamellar, granular, and network, labyrinth-like with less “large curvature” positions typically exhibit excellent thermal stability, while the eutectic morphologies, such as serrated strip, needle-like, seaweed-like, chrysanthemum-like, and sunflower-like eutectic with plentiful “large curvature” positions usually possess poor thermal stability [234, 235]. Zhang et al. [236] investigated the thermal stability of lamellar + network CoCrFeNi2(TiSi)0.7 EHEA. The results indicate that eutectic microstructure's lamellar and network morphologies exhibit good thermal stability and remain stable at 900 and 1000 °C, respectively, as shown in Fig. 11. Such good thermal stability enables such EHEA to exhibit excellent high-temperature mechanical properties with yield strength (YS) of ~703 MPa and plasticity > 50% at 800 °C, which exceeds most refractory HEAs. However, the serrated strip, needle-like, seaweed-like, chrysanthemum-like, and sunflower-like eutectic with plentiful “large curvature” positions are not conducive to thermal stability, but they can be fully utilized to improve mechanical properties through spheroidizing annealing [237, 238]. Zhang et al. [227] investigated the effect of annealing time on the microstructure and mechanical properties of four EHEAs containing B. When annealing at 1100 °C × 24 h, the M3B2 phase was completely transformed from serrated strip morphology to spherical morphology (Fig. 12), which increased the ductility by 3.4–6.1 times and maintained almost no change in tensile strength (Fig. 13).

Eutectic morphology of reported EHEAs. a Lamellar FCC+B2 EHEA. b Serrated strip FCC+M3B2 EHEA. c Needle-like BCC+HCP EHEA. d Seaweed FCC+Mn7Pd9 EHEA. e Chrysanthemum-like BCC+σ EHEA. f Sunflower-like BCC+B2 EHEA. g Granular FCC+BCC EHEA. h Network FCC+M16Ti6Si7 EHEA. i Labyrinth-like FCC+ B2 EHEA [75, 226,227,228,229,230,231,232,233]

Reproduced with permission from Ref. [251]. Copyright 2023, John Wiley and Sons

Microstructure and high-temperature mechanical properties of CoCrFeNi2(TiSi)0.7 with different annealing temperature. a–f Microstructure. g High-temperature mechanical properties. h Comparison of high-temperature YS and density with some reported EHEAs and refractory HEAs.

Reproduced with permission from Ref. [227]. Copyright 2022, Springer Nature

Microstructure of four EHEAs containing B element at annealing temperature of 1100 °C with different time. a–e CoCrNi2(V2B)0.43-EHEA. f–j CoCrFeNi2(V2B)0.5-EHEA. k–o CoCrNi2(V3B2Si)0.2-EHEA. p-u CoCrFeNi2(V6B3Si)0.149-EHEA.

Reproduced with permission from Ref. [227]. Copyright 2022, Springer Nature

Tensile engineering stress-strain curves of four EHEAs containing B element at annealing temperature of 1100 °C with different time. a CoCrNi2(V2B)0.43 EHEA. b CoCrFeNi2(V2B)0.5 EHEA. c CoCrNi2(V3B2Si)0.2 EHEA. d CoCrFeNi2(V6B3Si)0.149 EHEA.

2.3.3 Mechanical properties

Although a large number of EHEA systems with various morphologies have been designed and prepared, the most popular and widely investigated is still the lamellar FCC+B2 EHEA system due to the excellent combination of strength-ductility during tensile loading at room temperature [239,240,241,242,243]. The well-coordinated deformation capacity of soft FCC/hard B2 duplex provides a high ultimate tensile strength (UTS) of 1050 MPa and good ductility of 17%, which is superior to traditional Al alloys, Mg alloys, Ti alloys, Ni-based alloys, and cast iron in as-cast [244, 245]. In addition, higher strength and better ductility of FCC + B2 EHEA system were also achieved by advanced manufacturing technologies [220, 221]. Ren et al. [220] fabricated a nanolamellar FCC+B2 EHEA by additive manufacturing (AM). The ultrafine eutectic microstructure with interlamellar spacing of ~ 215 nm provides an extremely high YS of 1333 MPa and maintains good ductility of 14%. which surpasses those of state-of-the-art AM alloys. Shi et al. [221] prepared a herringbone FCC+B2 EHEA through directional solidification. This self-buffering herringbone EHEA possesses an excellent uniform tensile elongation of 50%, three times that of conventional EHEAs, without sacrificing tensile strength. Figure 14 shows the microstructure, mechanical properties and strength-conductivity of FCC+B2 EHEA under different fabrication processes [220, 221, 244, 245].

Microstructures, mechanical properties, and strength-ductility comparison charts of FCC+B2 EHEAs under different manufacturing processes. a Microstructure of arc-melted FCC+B2 EHEAs; g microstructure of directionally solidified FCC+B2 EHEAs. Reproduced with permission from Ref. [221]. Copyright 2021, AAAS. b Mechanical properties of arc-melted FCC+B2 EHEAs. Reproduced with permission from Ref. [244]. Copyright 2018, Elsevier. c Ultimate tensile strength versus elongation of arc-melted FCC+B2 EHEAs compared with traditional alloys. Reproduced with permission from Ref. [245]. Copyright 2019, Elsevier. d Microstructure of additive manufactured FCC+B2 EHEAs; e mechanical properties of additive manufactured FCC+B2 EHEAs; f yield strength versus uniform elongation of additive manufactured FCC+B2 EHEAs; g comparision with high-performance additive manufactured metal alloys; h mechanical properties of directionally solidified FCC+B2 EHEAs; i yield strength versus uniform strain of directionally solidified FCC+B2 EHEAs compared with those of previously reported as-cast eutectic and near-eutectic HEAs. Reproduced with permission from Ref. [220]. Copyright 2022, SpringerNature

In addition to advanced manufacturing processes, researchers have recently achieved synergistic improvement in the strength and ductility of EHEAs by customized thermomechanical treatment processes, as shown in Fig. 15 [49, 126, 222]. Wu et al. [49] constructed a phase-selectively recrystallized microstructure with a fully recrystallized FCC+ skeleton B2 by multistage cold-rolling and recrystallization annealing. The phase-selectively recrystallized EHEA achieves a high ductility of 35% with a true stress of 2 GPa. Shi et al. [126] designed a hierarchically-structural heterogenous FCC+B2 duplex microstructure by tailored cold-rolling and recrystallization process. The well-designed microstructure shows synergistic improvement in strength and ductility. Zhang et al. [222] achieved synergistic improvement in the strength and ductility of brittle CoCrNi2(V3B2Si)0.2 EHEA through spheroidized M3B2 and recrystallized FCC. This new spheroidization and recrystallization process exceeds the currently reported thermal-mechanical treatment processes in terms of strength and ductility increments.

Microstructures, mechanical properties, and strength-ductility comparison charts of EHEAs under different thermal mechanical treatment processes. a Microstructure of phase-selectively recrystallized (PSR)-FCC+B2 EHEAs; b mechanical properties of PSR-FCC+B2 EHEAs; c ultimate tensile strength versus uniform elongation of PSR-FCC+B2 EHEAs compared with those of previously reported as-cast (AC), ultra-fine grained (UFG), and fully recrystallized (FR) FCC+B2 EHEAs. Reproduced with permission from Ref. [49]. Copyright 2022, Springer Nature. d Microstructure of cold-rolled +recrystallized (CR)-FCC+B2 EHEAs; e mechanical properties of CR-FCC+B2 EHEAs; f yield strength versus elongation of CR-FCC+B2 EHEAs compared with traditional metallic materials and previously reported hardened HEAs. Reproduced with permission from Ref. [126]. Copyright 2019, Springer Nature. g Microstructure schematic diagram of spheroidized + cold-rolled + recrystallized (SCR)-FCC+M3B2 EHEAs; h mechanical properties of SCR-FCC+M3B2 EHEAs; i change in ultimate tensile strength and ductility observed for SCR-FCC+M3B2 EHEAs, relative to that of various further strengthened-FCC+B2 EHEAs. Reproduced with permission from Ref. [222]. Copyright 2023, Springer Nature

2.4 Cryogenic high-entropy alloys

With the rapid development of the aerospace field, the demand for materials used under extreme conditions is rising. For example, the surface temperature of Neptune can reach 70 K. Therefore, developing new materials with excellent mechanical properties under cryogenic temperatures is significant for space exploration. HEAs have attracted increasing attention due to their superb mechanical behaviors under cryogenic temperatures, especially for CrCoNi-based HEAs. In the following section, the mechanical behavior of HEAs at cryogenic temperatures will be briefly reviewed.

2.4.1 Single-phase FCC HEAs

2.4.1.1 Mechanical properties

CrMnFeCoNi and CrCoNi are the most extensively studied compositions in FCC HEAs. For example, the tensile property and fracture toughness of CrMnFeCoNi and CrCoNi alloys at room temperature and cryogenic temperatures were investigated [20, 42, 43, 246,247,248,249]. At room temperature, the yield strength (σy) and ultimate tensile strength (σu) of the CrMnFeCoNi alloy vary from 200 to 410 and 550 to 650 MPa, respectively, due to the variation in grain size. When the temperature decreases to 77 K, the σy, σu and ductility (εf) simultaneously increase to 759 MPa, 1280 MPa and 71%, respectively, as depicted in Fig. 16a [20, 247]. This phenomenon contradicts the ductile-to-brittle transition that occurs in traditional alloys under low temperatures. Furthermore, the fracture toughness of CrMnFeCoNi exceeds 200 MPa·m1/2 at 77 K (Fig. 16b). Electron backscatter diffraction (EBSD) analysis (Fig. 16c, d) revealed that the primary deformation mechanism at room temperature is dislocation slip. However, at 77K, deformation twinning emerges as an additional mechanism that contributes to continuous working hardening, consequently enhancing the mechanical properties. Deformation twinning occurred due to the lower stacking fault energy (SFE) at cryogenic temperatures as supported by DFT calculations [250].

Reproduced with permission from Ref. [20]. Copyright 2014, AAAS

Mechanical properties and microstructures of CrMnFeCoNi alloy deformed at 293, 200 and 77 K. a Engineering stress-strain curves and b fracture toughness. c EBSD image showing dislocation-induced grain misorientation at 293 K. d BSE and EBSD images illustrating presence of twinning at 77 K.

CrCoNi alloy exhibits superior mechanical properties to CrMnFeCoNi alloy [43, 44, 251]. Specifically, the σu, εf and fracture toughness at room temperature are approximately 1 GPa, 70% and 200 MPa·m1/2, respectively. At 77 K, the σu, εf and fracture toughness further increase to 1.3 GPa, 90% and 275 MPa·m1/2, respectively. These excellent mechanical properties stem from the low SFE of CrCoNi alloy ((22 ± 4) mJ·m−2), which is 25% smaller than that of CrMnFeCoNi alloy ((30 ± 5) mJ·m−2), as lower SFE activates additional deformation mechanisms, including stacking fault, nanotwinning, and even phase transformation [251, 252]. The interaction of multiple deformation mechanisms provides high and consistent work hardening, resulting in superior mechanical properties. Furthermore, at temperatures as low as liquid-helium temperature (around 20 K), the fracture toughness of CrCoNi alloy rises to 415 MPa·m1/2, significantly surpassing that of CrMnFeCoNi alloy (235 MPa·m1/2), which is also the highest reported value [44]. This exceptional fracture toughness can be attributed to the arrest and transmission of dislocations by stacking fault, twinning and phase transformation to the HCP phase [44, 253].

2.4.1.2 Deformation mechanisms

In order to thoroughly investigate the deformation mechanisms underlying the excellent properties of HEAs, in situ neutron diffraction measurements were conducted to study the deformation behavior of CrCoNi-based alloys at cryogenic temperatures [254,255,256,257,258,259]. In situ neutron diffraction is a powerful technique for investigating the deformation behavior of bulk samples under various environments. At temperatures approaching liquid helium temperature (around 15 K), CrMnFeCoNi, CrFeCoNi and CrCoNi alloys all demonstrate exceptional true strength (above 2.2 GPa) and elongation (~ 60%) [254,255,256]. Figure 17a shows the stress-strain curves of the CrMnFeCoNi alloy deformed at various temperatures. With temperature decreases, the strength and ductility both increase. Notably, serration occurred at 15 K which corresponded with a temperature change. The quantitative analysis of neutron diffraction data (Fig. 17c) revealed that, at 15K, the deformation of CrMnFeCoNi alloys starts with dislocation and immediately followed by stacking faults, twinning, and serration. The contribution of each deformation mechanism to the strengthening was estimated in CrFeCoNi alloy [255]. The results illustrate that while dislocation is the primary strengthening mechanism at cryogenic temperatures, the contribution from planar faults such as stacking faults, and twinning increases from 6% at room temperature to 28% at 25 K. Phase transformation is another effective method to increase ductility [254, 257], of which the strengthening mechanism was specified in CrFeCoNiMo0.2 alloy [258]. Specifically, the strain hardening behavior can correlate well with the phase transformation process that the increasing BCC phase accompanies the rise of strain hardening, while the strain hardening rate starts to decrease where phase transformation is saturated [258]. Overall, the cooperation of these deformation mechanisms contributes to significant work hardening, leading to higher strength and ductility at cryogenic temperatures than at room temperature.

In situ neutron diffraction results of CrMnFeCoNi deformed at 295, 140 and 15 K. a True stress-strain curves corresponded with temperature change of CrMnFeCoNi alloys at different temperatures. b Enlarged figure showing two serrations with temperature change. Reproduced with permission from Ref. [256]. Copyright 2020, The Authors. c Evolutions of stacking fault probability and integrated intensity of (111) upon true stress at room temperature and 15 K, where 1, 2, 3, and 4 dash lines represent start point of yielding, stacking fault, first serration and massive serration, respectively

Serration is a unique deformation behavior that occurs at near liquid helium temperature (< 40 K) in HEAs [253,254,255,256, 260,261,262]. The intensity drop of each serration increases with the deformation strain, reaching over 200 MPa at large strains [256, 262]. In addition, an intensity drop corresponds to a temperature rise. Generally, there are two theories regarding the origin of serration at cryogenic temperatures: (i) mechanical-driven, due to the instability of plastic deformation such as dislocation and twinning intersection; (ii) thermal-driven, because of the thermodynamic instability that thermal conductivity disappears [261, 263]. Wang’s work revealed that the serration is mechanically driven, as the load drop occurred first, followed by a rise in temperature, as illustrated in Fig. 17b [256]. The effect of serration on ductility is also controversial. Specifically, serration and phase transformation would deteriorate the ductility [260, 263]. In contrast, Wang et al. argued that serration can increase the ductility in HEAs due to its local disorder which prevents the propagation of serration, resulting in continuous strengthening [256].

In situ TEM test was also applied to CoCrNi-based HEAs with varying SFE at room and cryogenic temperatures (295 and 93 K) [264]. Particularly, this method enabled an insightful characterization of the deformation mechanisms. For example, various dislocation modes, such as the glide of partial and full dislocations, extensive cross-slip, multiple slips, as well as grain-boundary interaction and twinning, were observed at cryogenic temperature. In contrast, deformation at room temperature only involved partial dislocations and twins. The significant interaction of these extended defects enabled high strength and ductility at cryogenic temperatures.

Recognizing the potential of twinning and phase transformation for strengthening, i.e., twinning-induced plasticity (TWIP) and transformation-induced plasticity (TRIP) effects, researchers have employed these two mechanisms in HEAs through mechanical treatment and alloy design. For instance, Lee et al. introduce twins into V10Cr15Mn5Fe35Co10Ni25 alloy by cold rolling [265], which leads to a significant improvement in strength, with yield strength of around 1 GPa at 77 K. Metastable HEAs can be designed by decreasing the concentration of FCC stabilizer, Ni [266,267,268], or increase HCP-favored elements, Mn [10], etc.

2.4.2 Advanced preparation methods

Despite exhibiting high strain hardening and tensile ductility, homogeneous structured FCC HEAs generally have weak strength. To address this problem, Lu et al. introduced ultrafine-scaled gradient dislocation-cell structure (GDS) (Fig. 18e, f) into Al0.1CoCrFeNi HEA through cyclic torsion and investigated its mechanical properties at both room and cryogenic temperatures [50]. Interestingly, the GDS sample exhibits an extraordinary strain hardening rate at 77 K, superior to its CG counterpart, as shown in Fig. 18f, g. This alloy stands out among the previously reported cryogenic alloys (Fig. 18h). Detailed analysis revealed that this strain hardening arises from the abundant formation of tiny stacking faults within the cell structure, leading to dynamic structural refinement.

Reproduced with permission from Ref. [50]. Copyright 2023, AAAS

a Image of a dog-bone-shaped tensile specimen, with gauge section processed by cyclic torsion. b Schematic diagram showing level of GDS from surface to core. c 3D X-ray tomography of GDS tubular sample. d, e EBSD images showing cross-sectional morphology. f, g Engineering stress-strain curves and corresponding strain hardening rate of GDS, surface GDS and CG samples. h Comparison between GDS samples with other high-performance alloys at cryogenic temperatures.

Advanced preparation methods, like additive manufacturing, have also been employed to produce high-performance HEAs. The mechanical behaviors of 3D-printed alloys also show a temperature dependence that lowering the temperature would enhances the property [269,270,271,272]. The significant presence of initial dislocations, finer grain introduced by laser additive manufacturing, and the cellular structure produced by direct energy deposition [270] play crucial roles in enhancing the yield strength. Additionally, the interaction between dislocation and deformation twinning, activated at cryogenic temperature, promotes steady strain hardening, resists plastic instability, and thus improves strength and ductility at 77 K [269,270,271,272]. Furthermore, the wear resistance is also significantly improved due to the decreased oxygen concentration which prevents the formation of oxide particles in the liquid nitrogen [271].

2.4.3 Multi-phase HEA

Additional phases were introduced to further strengthen HEAs. Ritchie et al. developed a heterostructured FeCoNiAlTaB HEA with FCC matrix plus L12 and B2 precipitates and studied its mechanical properties over a wide temperature range [273]. FeCoNiAlTaB HEA possesses excellent strengths and good ductility, measuring 1.4 and 2.2 GPa at room temperature and 77 K, respectively. The enhanced strength at 77 K is a result of the martensitic transformation from FCC to BCC, combined with nanotwinning. Additionally, at 77 K, the sample demonstrates pseudoelasticity, which stems from the reversible phase transformation of thin-plate martensite as evidenced by TEM characterization (Fig. 19b−g). Tong et al. [274] and Yuan et al. [275] introduced Ti into the CoCrFeNi base alloy which also formed L12 coherent nanoparticles. Lowering the temperature increases both the strength and ductility, as assisted by stacking faults at cryogenic temperature.

Reproduced with permission from Ref. [273]. Copyright 2023, Elsevier

a Engineering stress-strain curve of FeNiCoAlTaB alloy deformed at different temperatures. b, c EBSD images showing microstructure of FeNiCoAlTaB alloy at strains of 7% and 12%, respectively. d, e TEM images showing existence of thin-plate martensite with nanotwins inside in coarse grain regions. f, g TEM images depicting thin-plate martensite with nanotwins inside fine grains.