Abstract

The present work shows the comprehensive investigations of phase state, magnetic properties, magnetoresistive, and magnetocaloric effects of AlCrFeCoNiCu thin-film high-entropy alloy (HEA). Mosaic target with six segments has been used for tailoring the film composition. The results show that the magnetic and magnetoresistive properties of HEA thin films are significantly affected by the presence of the face-centered-cubic (FCC) phase, which is formed during the annealing process. High-defective structure of thin films in as-deposited state results in the presence of the paramagnetic phase causing the absence of spontaneous magnetization and magnetoresistance. The formation of the FCC phase during heat treatment leads to the anisotropic magnetoresistance appearance. Besides, the low values of coercivity and magnetization at 300 K of annealed thin films point out that these samples could be potentially useful for the magnetocaloric application due to the compositional tunability.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

The conventional alloys are typically composed of one or two principal elements. Their properties are limited by the properties of their basic elements, although they can be expanded by the addition of the third constituent elements [1, 2]. High-entropy alloys (HEAs) are another class of alloys that are typically composed of five or more basic elements. These elements are often found in equimolar/equiatomic or near equimolar ratios/near equiatomic compositions. The concentration of each basic element can be changed within the range from 5 to 35%, with or without the addition of minor alloying elements at a concentration of less than 5%. Up to now, more than 400 HEAs have been developed, forming a new range of metallic materials [3,4,5,6].

The unique design concept and physical properties (electrical, thermal, mechanical, and anticorrosive) [7,8,9] give them potential applications in thin-film-resistors, electronic products, and functional coatings [10, 11]. It is worth noting that HEAs, which consist of one or more ferromagnetic elements (Co, Fe, and Ni), along with good mechanical and structural stability at high-temperature, exhibit good soft magnetic properties [12,13,14]. In addition, HEAs are promising candidates for the realization of a large magnetocaloric effect (MCE).

The MCE is manifested as a change of the temperature of a magnetic material upon the alternation of the applied magnetic field [4]. Magnetocaloric materials have good potential for magnetic refrigeration near room temperature [4, 15]. The use of solid-state cooling technology allows improving the efficiency of traditional gas compression refrigeration and avoiding the use of environment-harming refrigerants. One of the recent problems, however, is the search for new alloys with a high peak entropy change and a wide temperature range of transition [16,17,18].

Among various HEA compositions, the AlCrFeCoNiCu alloy is widely studied because of its interesting mechanical properties in the as-cast state (high hardness and good compressive strength) [19, 20]. It should be noted that, despite a very active investigation of AlCrFeCoNiCu-type thin-film HEA, many things are still unclear. It is well known that substituting or adding elements may change the phases present in the annealed sample. The resultant phases will determine the HEA’s magnetic properties [3]. For example, Ni content yields an increase in the face-centered-cubic (FCC) phase fraction, resulting in a drop-off in magnetization [16]. Thus, the magnetic properties of such types of HEAs have been studied in the past. At the same time, the influence of heat treatment on their magnetoresistive properties has not been given enough attention.

In this paper, the experiments focus on the comprehensive research of magnetic properties, magnetoresistive, and magnetocaloric effect of AlCrFeCoNiCu-type thin-film HEA. Besides, the effect of phase formation on those properties in investigated thin films will be discussed. A co-evaporation technique using a mosaic target with six segments for tailoring the film composition was adopted.

2 Experimental techniques

Magnetron sputtering was used for the deposition of HEA thin films. The peculiarity of our technology is using mosaic targets as opposed to the traditional use of alloyed target formed by melting or casting as in Refs. [21, 22]. The main advantage of this deposition method is a variation of the stoichiometry by changing the surface area of the target segment. Wafers of naturally oxidized single-crystalline Si(111) are used as substrates. The temperature of the substrate was 300 K and stayed unchanged during the condensation process. Thin-film samples were subsequently annealed at 700 K for 60 min in Ar/H2 atmosphere, then cooled, and investigated after annealing. The annealing of the samples was performed with the purpose to improve their homogenization, crystal structure, and healing of the structural defects.

Composition and elemental analysis of thin films was performed using a scanning electron microscope (SEM) equipment (Tescan VEGA3) with an energy-dispersive X-Ray (EDX) detector (Oxford Instruments) to determine elemental composition. Glassy carbon plates with a size 5 × 5 mm were used as a substrate for these investigations. Such a choice was justified by the fact that Кα X-ray radiation from Si coincides with Al, and if silicon or glass was used as a substrate, it would be impossible to determine the concentration of Al in the alloy precisely, considering the film thickness (70 nm).

The crystal structure of HEA thin films was analyzed by X-ray Diffractions (XRD) in a conventional Bragg–Brentano θ–2θ geometry with the Cu Kα radiation (DRON-4). The atomic force microscopy (Bruker, Dimension Icon AFM) was used for the examination of the surface morphology and roughness.

Magnetic measurements of the temperature dependence of the magnetization M(T) in the zero-field-cooled (ZFC) and field-cooled (FC) mode were performed using a commercial SQUID magnetometer (Quantum Design MPMS3) in the temperature range 2–400 K with an applied magnetic field of 10 mT. The sample was first measured in the ZFC mode, i.e., the sample was cooled to the lowest measured temperature in zero magnetic field, and then, the field was switched on and the measurement was performed while warming up the sample to temperature 400 K. Then the magnetic field was kept on, the sample was cooled (FC mode) and the measurement was made again while warming up. To evaluate magnetocaloric behavior, the measurement of the isothermal magnetization curves was conducted up to 5 T in the temperature range from 100 to 350 K.

The isothermal magnetic entropy change ∆SM has been calculated using the Maxwell relation [18]:

where Bi and Bf represent the initial and final magnetic fields, respectively.

To calculate the mass of the samples, the density is determined as the sum of the products of each component concentrations obtained from EDX analysis by its density. A large number of components makes it difficult the control the thickness during the deposition process by the quartz resonator method. Therefore, the thickness of the samples was additionally controlled by the AFM method. For this purpose, the depressions were made on the surfaces of the thin film in several places. The scanning of these areas in the tapping mode allows us to determine the depth of the resulting depression relative to the surrounding thin-film (i.e., the thickness of the thin-film) with high precision. Thus, the accuracy of the mass determination was ± 5%.

The magnetoresistive properties were measured using a software–hardware complex with current-in-plane geometries in an external magnetic field from 0 to 500 mT at room temperature. The measuring current was I = 1 mA. The values of longitudinal (LMR) and transverse (TMR) magnetoresistance have been calculated by equation MR = (R(B) – R(B0))/R(B0), where R(B) is the current value of resistance in the magnetic field B; R(B0) is the resistance of the sample in the field B0.

3 Experimental results and discussion

The crystallographic phases were examined for as-deposited samples and after the heat treatment process in Ar/H2 atmosphere at 700 K. Figure 1 shows XRD patterns of as-deposited and annealed AlCrFeCoNiCu-type HEA thin film. Analysis of the phase composition of the as-deposited HEA thin-film has shown that the obtained samples exhibit a BCC phase with a lattice parameter a = 0.296 nm. This result is in agreement with the data presented in Ref. [20], which evidence that as-cast alloy has a BCC structure. The mean crystallite size L that was determined by the Scherrer equation is 13 nm.

After heat treatment, the intensity of the peak at θ = 43.05° is increased, with a decrease in full width half maximum, and new peaks have arisen. By comparing peak intensities with the as-prepared sample, the annealed AlCrFeCoNiCu HEA exhibits a BCC phase with the unchanged lattice constant a = 0.296 nm and FCC phase with a = 0.360 nm. The mean crystallite size that belongs to the BCC phase increases to the value of LBCC = 22 nm. The value of L = 23 nm for crystallites that belong to the FCC phase is close to LBCC.

The unidentified peak in X-ray diffraction patterns after annealing probably corresponds to oxide phases CrO or Al2O3 that are most likely formed during the sample handling due to the higher chemical activity of the thin film.

The EDX method (Fig. 1) allowed us to verify the concentration of all components of the HEA (Table 1). From the EDX composition maps of the alloy (Fig. 2), it can be observed that Al, Cr, Fe, Co, Ni, and Cu are equally distributed in the volume of the film. The deviation of the concentration over the volume of the films is not more 1 at. %. This result confirms the efficiency of using of co-evaporation method for thin-film HEA preparation.

AFM study of HEA thin-film surface has confirmed that the size of crystallites changes insignificantly after annealing (Fig. 3). Based on AFM results, the values of Rq (root-mean-squared) and Ra (arithmetical mean deviation of the assessed profile) that characterize the surface-profile roughness of investigated samples were calculated too. The increase of the calculated data on the Rq from 1.31 to 2.66 nm and Ra from 0.98 to 2.04 nm for annealed sample denotes that the crystallites grow during annealing. This result corresponds to the data obtained from the XRD method.

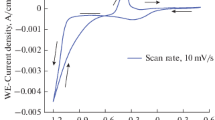

To examine magnetoresistive properties of AlCrFeCoNiCu-type thin-film high-entropy alloy, field dependences of the longitudinal (L) and transverse (T) magnetoresistance were measured. For as-deposited samples, the magnetoresistive effect was not observed. The value of MR is close to zero. The high-defective structure of thin films in an as-deposited state results in the presence of the paramagnetic phase causing the absence of the spontaneous magnetization, and, as a result, magnetoresistance. The annealing process improves magnetoresistive properties significantly. The MR field dependences after annealing of the HEA thin films are presented in Fig. 4. It can be seen that MR(B) curves partly overlap in both geometries and hysteretic behavior of magnetoresistance is observed. Thus, the heat treatment process leads to the appearance of anisotropic MR (AMR). These features indicate the presence of magnetic clusters. Such improvement of magnetoresistance is likely to be caused by the formation of FCC phase due to the annealing at 700 K. As reported in the literature [23, 24], as-deposited and annealed (700 K) thin films of Fe, Co, and Ni that promote the formation of FCC phase in HEAs [25] are characterized by AMR. The value of MR is 0.01–2.00% and depends on the metal type, thin-film thickness, annealing temperature, and temperature at which the measurement is conducted.

The magnetic properties of the investigated samples are stabilized after the annealing process only. The field dependence of magnetization measured for AlCrFeCoNiCu HEA thin films at 2 K and 300 K is shown in Fig. 5. The coercivity (Bc), remnant magnetization (Mr), and saturation magnetization (Ms) for parallel and perpendicular magnetic field orientations are listed in Table 2. All parameters are primarily determined by the temperature at which the magnetic measurements were performed. As the measurement temperature decreases from room temperature to 2 K, the change of magnetic loops shape is observed together with an increase of all magnetic parameters. The magnitude of coercivity does not exceed 6 mT at 300 K and grows significantly at cooling to 2 K, especially for parallel geometry.

The low value of the coercivity at 300 K leads to the conclusion that the investigated HEA belongs to the class of soft magnetic materials. This result correlated with data presented in Refs. [21, 26] that devoted to the study of magnetic properties of AlCrFeCoNiCu HEA thin films. In contrast, the saturation magnetization is slightly affected by the measurement temperature.

Figure 6 shows the temperature dependence of the magnetization performed in two geometries (parallel and perpendicular) for the AlCrFeCoNiCu HEA thin films. The ZFC–FC curves obtained for AlCrFeCoNiCu HEA thin film do not indicate direct evidence of the magnetic transition from the ferromagnetic to the paramagnetic state. Only a broad maximum similar to the one found in superparamagnetic systems was observed, with the blocking temperature TB ≈ 325 K, which has been determined from the position of maximum in the temperature dependence of ZFC magnetization.

Due to the compositional tunability of the Curie temperature in other HEA materials, they were suggested for the magnetocaloric application as shown in Refs. [16, 27, 28]. Motivated by these reports, we have estimated the magnetocaloric response of the prepared AlCrFeCoNiCu thin-film high-entropy alloy. While small in value, the broad magnetic entropy change centered near room temperature may lead to large refrigerant capacity, which is a measure of the energy that can be transferred between high and low temperatures [16]. The temperature dependences of the magnetic entropy change under isothermal magnetization from 0 T to different values of the final field varying from 1 to 5 T are shown in Fig. 7. The results of the studies showed that the change in the entropy of the systems is very sensitive to measurement geometry. For parallel orientation, the maximum in the temperature dependence of the isothermal entropy change has a diffuse form, which is associated with the process of non-uniform blocking. The maximum value of the isothermal entropy change − ∆SM = 0.38 JK−1 kg−1 for parallel orientation and − ∆SM = 0.53 JK−1 kg−1 for perpendicular orientation was observed at 295 K for the final field of 5 T. The position of the maximum in the -∆SM(T) dependence becomes more noticeable for perpendicular geometry, as compared to the parallel one, and the magnitude of the effect becomes more pronounced with increasing magnetic field. The maxima in the − ∆SM(T) dependence correspond to the direct MCE. Besides, as anticipated, the magnetocaloric response is focused on the critical region, and the position of its maximum is very little affected by the magnitude of the final magnetic field.

It should be noted that a similar amplitude value of isothermal entropy change has been characteristic of HEAs, which do not contain lanthanides in their composition. For example, in equiatomic alloys CoCuFeMnNi, the value of − ∆SM = 0.115 JK−1 kg−1 (an applied field of ∼ 1.5 T) at 395 К [27]; for FeCoNiCrAl, the value of − ∆SM = 0.674 JK−1 kg−1 (an applied field of ∼ 7 T) at 290 K [16]; and for FeCoNiCuPt, the value of − ∆SM = 0.2 JK−1 kg−1 (an applied field of ∼ 0.55 T) at ~ 950 K was observed [28]. Unfortunately, in the case of the prepared films, the increased isothermal entropy change spans over a wide temperature region and the magnetic cooling would be ineffective similar to some results as in [16, 28].

4 Conclusion

In this work, the efficiency of a co-evaporation technique using a mosaic target with six segments for AlCrFeCoNiCu HEA thin-film preparation has been shown. The samples exhibit the coexistence of BCC and FCC phase after annealing to 700 K only. In the as-deposited state, the BCC phase is stabilized only. In the high-defective structure of thin films in an as-deposited state, the presence of the paramagnetic phase causes the absence of magnetization, and, as a result, magnetoresistance. The presence of Fe, Co, and Ni atoms in the alloy that promotes the formation of the FCC phase in HEA during heat treatment leads to the appearance of anisotropic magnetoresistance. For annealed thin films, the low value of the coercivity at 300 K and a low magnetization at room temperature point out that these samples could be potentially useful for the magnetocaloric application. The maximum amplitude of the MCE − ∆SM = 0.53 JK−1 kg−1 at 295 K was observed for annealed thin films similar to other HEA materials.

References

C. Luo, L. Sun, Y. Zhang, H.B. Huang, M. Yang, Y. Zhai, J. Du, H.R. Zhai, Investigations of magnetic properties of Tb-doped Ni78Fe22 thin films. Phys. Status Solidi C 9, 81–84 (2012). https://doi.org/10.1002/pssc.201084182

I.M. Pazukha, D.O. Shuliarenko, O.V. Pylypenko, L.V. Odnodvorets, Concentration and heat treatment effects on magnetoresistive properties of Ag-added Ni80Fe20 film systems. J. Magn. Magn. Mater. 485, 89–94 (2019). https://doi.org/10.1016/j.jmmm.2019.04.079

D.B. Miracle, O.N. Senkov, A critical review of high entropy alloys and related concepts. Acta Mater. 122, 448–551 (2017). https://doi.org/10.1016/j.actamat.2016.08.081

V. Franco, J.S. Blázquez, J.J. Ipus, J.Y. Law, L.M. Moreno-Ramírez, A. Conde, Magnetocaloric effect: from materials research to refrigeration devices. Prog. Mater. Sci. 93, 112–232 (2018). https://doi.org/10.1016/j.pmatsci.2017.10.005

E.P. George, D. Raabe, R.O. Ritchie, High-entropy alloys. Nat. Rev. Mater. 4, 515–534 (2019). https://doi.org/10.1038/s41578-019-0121-4

O.N. Senkov, D.B. Miracle, K.J. Chaput, J.-P. Couzinie, Development and exploration of refractory high entropy alloys—a review. J. Mater. Res. 33, 3092–3128 (2018) https://doi.org/10.1557/jmr.2018.153.

C.-C. Juan, M.-H. Tsai, C.-W. Tsai, C.-M. Lin, W.-R. Wang, C.-C. Yang, S.-K. Chen, S.-J. Lin, J.-W. Yeh, Enhanced mechanical properties of HfMoTaTiZr and HfMoNbTaTiZr refractory high-entropy alloys. Intermetallics 62, 76–83 (2015) https://doi.org/10.1016/j.intermet.2015.03.013.

C. Yang, J. Lin, J. Zeng, S. Qu, X. Li, W. Zhang, D. Zhang, High-strength AlCrFeCoNi high entropy alloys fabricated by using metallic glass powder as precursor. Adv. Eng. Mater. 18, 348–353 (2016). https://doi.org/10.1002/adem.201500339

T. Borkar, B. Gwalani, D. Choudhuri, C.V. Mikler, C.J. Yannetta, X. Chen, R.V. Ramanujan, M.J. Styles, M.A. Gibson, R. Banerjee, A combinatorial assessment of AlxCrCuFeNi2 (0<x<1.5) complex concentrated alloys: Microstructure, microhardness, and magnetic properties, Acta Mater. 116, 63–76 (2016). https://doi.org/10.1016/j.actamat.2016.06.025

M.M.C. Gao, J.W. Yeh, P.K. Liaw, Y. Zhang, High-Entropy Alloys: Fundamentals and Applications, first ed., (Springer International Publishing: Cham, Switzerland, 2016), 516p.

X.Z. Lim, Metal mixology stronger, tougher, stretchier: with a simple new recipe, metallurgists are creating a generation of alloys with remarkable properties. Nature 533, 306–307 (2016). https://doi.org/10.1038/533306a

J.Y. He, W.H. Liu, H. Wang, Y. Wu, X.J. Liu, T.G. Nieh, Z.P. Ly, Effects of Al addition on structural evolution and tensile properties of the FeCoNiCrMn high-entropy alloy system. Acta. Mater. 62, 105–113 (2014). https://doi.org/10.1016/j.actamat.2013.09.037

P. Li, A. Wang, C.T. Liu, A ductile high entropy alloy with attractive magnetic properties. J. Alloys Compd. 694, 55–60 (2017). https://doi.org/10.1016/j.jallcom.2016.09.186

P.F. Yu, L.J. Zhang, H. Chen, H. Zhang, M.Z. Ma, Y.C. Li, G. Li, P.K. Liaw, The high-entropy alloys with high hardness and soft magnetic property prepared by mechanical alloying and high-pressure sintering. Intermetallics 70, 82–87 (2016). https://doi.org/10.1016/j.intermet.2015.11.005

M. Balli, S. Jandl, P. Fournier, A. Kedous-Lebouc, Advanced materials for magnetic cooling: fundamentals and practical aspects, Appl. Phys. Rev. 4, 021305–1−021305–27 (2017). https://doi.org/10.1063/1.4983612

S.-M. Na, P.K. Lambert, H. Kim, J. Paglione, N.J. Jones, Thermomagnetic properties and magnetocaloric effect of FeCoNiCrAl-type high-entropy alloys. AIP Adv. 9, 035010 (2019). https://doi.org/10.1063/1.5079394

V. Dolique, A.-L. Thomann, P. Brault, Y. Tessier, P. Gillon, Complex structure/composition relationship in thin films of AlCoCrCuFeNi high entropy alloy. Mater. Chem. Phys. 117, 142–147 (2009). https://doi.org/10.1016/j.matchemphys.2009.05.025

K.A. Gschneidner Jr., V.K. Pecharsky, A.O. Tsokol, Recent developments in magnetocaloric materials. Rep. Prog. Phys. 68, 1479 (2005). https://doi.org/10.1088/0034-4885/68/6/R04

Y.P. Wang, B.S. Li, M.X. Ren, C. Yang, H.Z. Fu, Microstructure and compressive properties of AlCrFeCoNi high entropy alloy. Mater. Sci. Eng. A 491, 154–158 (2008). https://doi.org/10.1016/j.msea.2008.01.064

S. Singh, N. Wanderka, K. Kiefer, U. Glatzel, J. Banhart, Decomposition in multicomponent AlCoCrCuFeNi high entropy alloy. Acta Mater. 59, 182–190 (2011). https://doi.org/10.1016/j.actamat.2010.09.023

R. Kulkarni, B.S. Murty, V. Srinivas, Study of microstructure and magnetic properties of AlNiCo(CuFe) high entropy alloy. J. Alloys Compd. 746, 194–199 (2018). https://doi.org/10.1016/j.jallcom.2018.02.275

J. Huo, J.-Q. Wang, W.-H. Wang, Denary high entropy metallic glass with large magnetocaloric effect. J. Alloys Compd. 776, 202–206 (2018). https://doi.org/10.1016/j.jallcom.2018.10.328

S.I. Vorobiov, Ia.M. Lytvynenko, I.O. Shpetnyi, O.V. Shutyleva, A.M. Chornous, Magnetic and magnetoresistance properties of films of the ferromagnetic metals. Metallofiz. Nov. Tekhnol. 37, 1049–1062 (2015). https://doi.org/10.15407/mfint.37.08.1049

V. Ilkovič, Comparison of the effect of the exchange and single-ion anisotropy on the magnetic properties of thin ferromagnetic films. J. Magn. Magn. Mater. 402, 196–199 (2016). https://doi.org/10.1016/j.jmmm.2015.10.094

C.C. Tung, J.W. Yeh, T.T. Shun, S.K. Chen, Y.S. Huang, H.C. Chen, On the elemental effect of AlCoCrCuFeNi high entropy alloy system. Mater. Lett. 61, 1–5 (2007). https://doi.org/10.1016/j.matlet.2006.03.140

M.-H. Tsai, Physical properties of high entropy alloys. Entropy 15, 5338–5345 (2013). https://doi.org/10.3390/e15125338

A. Perrin, M. Sorescu, M. Burton, D. Laughlin, M. McHenry, The role of compositional tuning of the distributed exchange on magnetocaloric properties of high-entropy alloys. JOM 69, 2125–2129 (2017). https://doi.org/10.1007/s11837-017-2523-3

M. Kurniawan, A. Perrin, P. Xu, V. Keylin, M. McHenry, Curie temperature engineering in high entropy alloys (HEAs) for magnetocaloric applications. IEEE Magn. Lett. 7, 1–5 (2016). https://doi.org/10.1109/LMAG.2016.2592462

Acknowledgements

This work was funded by the State Program of the Ministry of Education and Science of Ukraine No. 0120U102005 (2020-2022). The work at Šafárik University was supported by grant VEGA No. 1/0204/18, and the grants of the Slovak Research and Development Agency under the contract No. APVV-17-0059, APVV-18-0358, and SK-BY-RD-19-0008. This publication is the result of the project implementation: New unconventional magnetic materials for applications, ITMS 313011T544, supported by the Operational Programme Integrated Infrastructure 2014–2020 (OPII) funded by the ERDF.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Vorobiov, S., Pylypenko, O., Bereznyak, Y. et al. Magnetic properties, magnetoresistive, and magnetocaloric effects of AlCrFeCoNiCu thin-film high-entropy alloys prepared by the co-evaporation technique. Appl. Phys. A 127, 179 (2021). https://doi.org/10.1007/s00339-020-04145-6

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s00339-020-04145-6