Abstract

Magnetic and magnetocaloric properties of HoFe1−xCoxAl (x = 0, 0.3) were investigated. Both HoFeAl and HoFe0.7Co0.3Al undergo a second-order ferromagnetic (FIM) to paramagnetic (PM) transition at Curie temperatures (T C) of 87 and 82 K, respectively. The magnetocaloric effect is improved by the introduction of Co in HoFeAl compound. For a field change from 0 to 5 T, the maximum values of magnetic entropy change (−ΔS M) are 7.0 J·kg−1·K−1 for HoFeAl and 8.6 J·kg−1·K−1 for HoFe0.7Co0.3Al. In addition, the refrigerant capacity (RC) is enhanced largely from 416.2 J·kg−1 for HoFeAl to 561.9 J·kg−1 for HoFe0.7Co0.3Al. This large RC is attributed to the large ΔS M and the wide temperature span of ΔS M peak in HoFe0.7Co0.3Al compound. The physical mechanism of improvement in magnetocaloric effect by Co substitution in HoFeAl was also discussed in detail.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Magnetic refrigeration, based on magnetocaloric effect (MCE), is considered to be one of the promising cooling technologies, due to its energy-saving and environmentally friendly properties in comparison with the conventional gas compression method. In the past decades, great effort has been devoted to researching magnetic refrigerant materials. Up to now, giant MCEs have been found in materials with a first-order magnetic transition (FOMT), such as Gd5Si2Ge2 [1], La(Fe, Si)13 [2], MnAs [3, 4], MnFeP1−xAsx [5] and Ni–Mn–X Heusler alloys [6–8]. However, FOMT is usually accompanied by considerable thermal and magnetic hysteresis, therefore reducing the effective refrigerant capacity (RC). At the same time, the materials with second-order magnetic transition (SOMT) attract much attention for the excellent magnetic reversibility and large RC, which signify that these materials are more reliable for the practical application of magnetic refrigeration.

Owing to the variation of crystalline structure of many RTX-type (R = rare earths, T = 3d transition metals and X = p-block elements) compounds, the magnetic and magnetocaloric properties were deeply explored [9]. RFeAl (R = heavy rare earths, except Yb) compounds crystallize in a hexagonal MgZn2-type structure [10] and undergo a ferrimagnetic (FIM) to paramagnetic (PM) transition at their respective Curie temperatures (T C) [11–13]. The results of Mican et al. [14] indicate that HoFe2−xAlx crystallizes in hexagonal MgZn2 structure and remains in ferrimagnetic ground state when Al content is tuned from 0.750 to 1.125. Dong et al. [15], Li et al. [16], Zhang et al. [17] and Kaštil et al. [18] successively reported the magnetocaloric properties of RFeAl compounds. Among all the RFeAl series, the magnetic entropy change (−ΔS M) of HoFeAl is the largest, i.e., 7.5 J·kg−1·K−1 at T C = 80 K with the field change of 0–5 T [17]. On the other hand, HoCoAl also exhibits the largest MCE in the series of RCoAl compounds, i.e., |ΔS M| = 21.5 J·kg−1·K−1 at T C = 10 K for a field change of 0–5 T [19]. Therefore, it is expected that MCE of HoFeAl could be improved by substituting Fe with Co. In order to confirm the speculation and further understand MCE of HoFe1−xCoxAl compounds, in this paper, the magnetic and magnetocaloric properties of HoFe1−xCoxAl (x = 0, 0.3) were investigated systematically.

2 Experimental

Polycrystalline compounds of HoFe1−xCoxAl (x = 0, 0.3) were prepared by arc melting appropriate quantity of high-purity elements in argon atmosphere. The ingots were turned over and remelted several times in order to ensure homogeneity. Then, the as-cast alloys were annealed in vacuum quartz tube at 1023 K for 10 days. The phase structure was examined by X-ray diffraction (XRD, Bruker Phaser) with Cu Kα radiation. The magnetic measurements were taken using vibrating sample magnetometer (VSM, Quantum Design SQUID).

3 Results and discussion

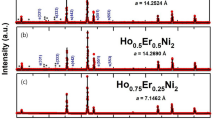

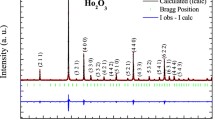

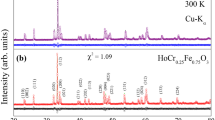

Figure 1 shows room-temperature XRD patterns of HoFe1−xCoxAl (x = 0, 0.3) compounds. It reveals that all the peaks can be indexed according to the previous work [10], and the samples are determined to crystallize in a clean-phase hexagonal MgZn2-type structure (space group: P63/mmc, No. 194) as reported before [9, 10]. In addition, the Bragg peak position deviation between the two patterns suggests that the lattice constant decreases when partial Fe atoms were replaced by smaller Co.

Thermomagnetic measurements were taken in order to investigate the phase transition of HoFe1−xCoxAl (x = 0, 0.3) compounds. Figure 2a, b displays the temperature dependencies of zero-field-cooling (ZFC) and field-cooling (FC) magnetizations (M) under a field of 0.01 T for HoFeAl and HoFe0.7Co0.3Al, respectively. A phase transition from FIM to PM state takes place at TC, which is defined as the local minimum of dM/dT curve (insets in Fig. 2). The TC of HoFeAl is 87 K, which is roughly close to the value reported earlier [11]. The obtained T C of HoFe0.7Co0.3Al is 82 K, which is slightly lower than that of HoFeAl. Isostructure HoTAl (T = Fe and Co) compounds have different TC because of their different magnetic coupling strengths due to atom distances. It is estimated that the T C of HoFe0.7Co0.3Al should be 67.4 K if the T C decreases linearly from HoFeAl (T C = 92 K from Ref. [9]) to HoCoAl (T C = 10 K from Ref. [9]). However, the measured value is not in accordance with this speculation, implying the nonlinear function between the transition temperature and x in HoFe1−xCoxAl compounds. A small quantity of Co in RTX compounds does not show magnetic moment [9, 20], but Fe still has small moment [15]. Thus, it is speculated that the dilution and substitution of Fe by Co in HoFe1−xCoxAl may weaken the antiferromagnetic coupling between Ho and Fe sublattices and then increase the total magnetization shown in thermomagnetic curves (Fig. 2). It is observed that the ZFC and FC curves are nearly reversible in the vicinity of T C, which is a typical characteristic of SOMT. However, thermomagnetic irreversibility between the two branches is observed at lower temperatures, which is usually explained as the ZFC frozen narrow domain-wall-pinning effect, competing magnetic interactions and the strong magnetic anisotropy [9, 21].

The isothermal magnetization relation (M–H curves) of HoFeAl and HoFe0.7Co0.3Al was measured to evaluate their magnetocaloric properties under different fields up to 5 T. The temperature step is 4 K in the vicinity of T C, while larger temperature step is chosen in the regions far away from T C. Figure 3a, b shows M–H curves of HoFeAl and HoFe0.7Co0.3Al, respectively. Below their T C, the magnetization increases rapidly at low fields and tends to saturate with the increase of field. However, the saturation magnetization (M S at 5 T) of HoFe0.7Co0.3Al at 47 K (150.6 A·m2·kg−1) is 6.5% larger than that of HoFeAl at 48 K (141.4 A·m2·g−1), and furthermore, the magnetic field required to reach saturation magnetization of HoFe0.7Co0.3Al is lower than that of HoFeAl. The increase of saturation magnetization and lowered saturation field might be related to the weakened antiferromagnetic coupling between Ho and Fe, or the change of domain wall structure. Figure 3c, d displays Arrott–Belov plots of HoFeAl and HoFe0.7Co0.3Al, respectively. It is found that these plots do not show either inflection point or negative slope, proving the characteristic of second-order FIM-PM transition [22]. This is consistent with the fact of absence of thermal hysteresis in Fig. 2.

The ΔS M in the vicinity of T C is calculated by using the following integration [1]:

where H is magnetic field. The temperature dependences of ΔS M under different magnetic field for HoFeAl and HoFe0.7Co0.3Al are presented in Fig. 4a, b, respectively. For a field change of 0–5 T, the maximum values of −ΔS M reach 7.0 J·kg−1·K−1 at 85 K for HoFeAl and 8.6 J·kg−1·K−1 at 77 K for HoFe0.7Co0.3Al. The entropy changes of these two compounds can be comparable to or even larger than those of some FOMT materials in the same temperature range, such as Er(Co0.9Mn0.1)2, Mn2.95Co0.05GaC and Ce2Fe17 [23]. In addition, the value of RC is calculated by:

where T 1 and T 2 are the temperatures at half-maximum of the |ΔS M| peak [1], and they are 46 and 122 K for HoFeAl, and 32 and 114 K for HoFe0.7Co0.3Al, respectively. For μ 0ΔH = 5 T(µ 0 is the permeability in vacuum, and ΔH is the field change), the RC values are obtained to be 416 J·kg−1 for HoFeAl and 562 J·kg−1 for HoFe0.7Co0.3Al. It is clearly noted that the RC value increases remarkably by 35% after the substitution of Fe by Co, which is attributed to the larger ΔS M of HoFe0.7Co0.3Al in a wider temperature span. This large value of RC for HoFe0.7Co0.3Al is comparable to that of DyGa (382 J·kg−1) [24] and HoGa (455 J·kg−1) [25] in the same temperature range, making HoFe0.7Co0.3Al alloy a good candidate for magnetic refrigerants operating on an Ericsson cycle over a wide temperature range.

4 Conclusion

In summary, HoFe1−xCoxAl (x = 0, 0.3) alloys crystallize in MgZn2-type structure. A second-order FIM-PM transition is observed at their respective T C of 87 and 82 K. For a field change of 0–5 T, the maximum values of −ΔS M are 7.0 J·kg−1·K−1 for HoFeAl and 8.6 J·kg−1·K−1 for HoFe0.7Co0.3Al. The corresponding values of RC are 416.2 and 561.9 J·kg−1. The substitution of Fe by Co in HoFe1−xCoxAl (x = 0, 0.3) weakens the antiferromagnetic coupling and leads to the enhancement of magnetization and MCE. The result may give some clues for improving the performance of magnetic refrigeration materials.

References

Gschneidner KA Jr, Pecharsky VK, Tsokol AO. Recent developments in magnetocaloric materials. Rep Prog Phys. 2005;68(6):1479.

Shen BG, Sun JR, Hu FX, Zhang HW, Chen ZH. Recent progress in exploring magnetocaloric materials. Adv Mater. 2009;21(45):4545.

Wada H, Tanabe Y. Giant magnetocaloric effect of MnAs1−xSbx. Appl Phys Lett. 2001;79(20):3302.

Gama S, Coelho AA, de Campos A, Carvalho AMG, Gandra FCG. Pressure-induced colossal magnetocaloric effect in MnAs. Phys Rev Lett. 2004;93(23):237202.

Tegus O, Brück E, Buschow KHJ, de Boer FR. Transition-metal-based magnetic refrigerants for room-temperature applications. Nature. 2002;415:150.

Hu FX, Shen BG, Sun JR. Magnetic entropy change in Ni51.5Mn22.7Ga25.8 alloy. Appl Phys Lett. 2000;76(23):3460.

Krenke T, Duman E, Acet M, Wassermann EF, Moya X, Mañosa L, Planes A. Inverse magnetocaloric effect in ferromagnetic Ni–Mn–Sn alloys. Nat Mater. 2005;4(6):450.

Liu J, Gottschall T, Skokov KP, Moore JD, Gutfleisch O. Giant magnetocaloric effect driven by structural transitions. Nat Mater. 2012;11(5):620.

Gupta S, Suresh KG. Review on magnetic and related properties of RTX compounds. J Alloy Compd. 2015;618:562.

Oesterreicher H. Structural studies of rare-earth compounds RFeAl. J Less Common Met. 1971;25(3):341.

Oesterreicher H. Magnetic properties of scatter order compounds RFeAl (R = Gd, Tb, Dy, Ho, Er, Tm, Lu, and Y). Phys Status Solidi (a). 1977;40(2):K139.

Oesterreicher H. Magnetic studies on TbFeAl. Phys Status Solidi (a). 1971;7(1):K55.

Oesterreicher H. Structural, magnetic and neutron diffraction studies on TbFe2–TbAl2, TbCo2–TbAl2 and HoCo2–HoAl2. J Phys Chem Solids. 1973;34(7):1267.

Mican S, Benea D, Tetean R. Magnetism and large magnetocaloric effect in HoFe2−xAlx. J Alloy Compd. 2013;549:64.

Dong QY, Shen BG, Chen J, Shen J, Zhang HW, Sun JR. Magnetic entropy change and refrigerant capacity in GdFeAl compound. J Appl Phys. 2009;105(7):07A305.

Li LW, Huo DX, Qian ZH, Nishimura K. Study of the critical behavior and magnetocaloric effect in DyFeAl. Intermetallics. 2014;46:231.

Zhang YK, Wilde G, Li X, Ren ZM, Li LW. Magnetism and magnetocaloric effect in the ternary equiatomic REFeAl (RE = Er and Ho) compounds. Intermetallics. 2015;65:61.

Kaštil J, Javorský P, Kamarád J, Diop LVB, Isnard O, Arnold Z. Magnetic and magnetocaloric properties of partially disordered RFeAl (R = Gd, Tb) intermetallic. Intermetallics. 2014;54:15.

Zhang XX, Wang FW, Wen GH. Magnetic entropy change in RCoAl (R = Gd, Tb, Dy, and Ho) compounds. J Phys Condens Mater. 2001;13(31):L747.

Oesterreicher H, Roland P. Structural and magnetic studies on DyFe2–DyAl2 and DyCo2–DyAl2. J Appl Phys. 1972;43(12):5174.

Zhang H, Shen BG, Xu ZY, Shen J, Hu FX, Sun JR, Long Y. Large reversible magnetocaloric effects in ErFeSi compound under low magnetic field change around liquid hydrogen temperature. Appl Phys Lett. 2013;102(9):092401.

Banerjee SK. On a generalized approach to first and second order magnetic transitions. Phys Lett. 1964;12(1):16.

Franco V, Blázquez JS, Ingale B, Conde A. Magnetocaloric effect and magnetic refrigeration near room temperature. Annu Rev Mater Res. 2012;42:305.

Zheng XQ, Chen J, Shen J, Zhang H, Xu ZY, Gao WW, Wu JF, Hu FX, Sun JR, Shen BG. Large refrigerant capacity of RGa (R = Tb and Dy) compounds. J Appl Phys. 2012;111(7):07A917.

Chen J, Shen BG, Dong QY, Sun JR. Giant magnetocaloric effect in HoGa compound over a large temperature span. Solid States Commun. 2010;150(3–4):157.

Acknowledgements

This work was financially supported by the Fundamental Research Funds from National Institute of Metrology (Nos. 35-ALC1514-15 and 35-AHY1323-13) and the National Natural Science Foundation of China (No. 51402031).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Xu, ZY., Zhang, ZG., Gao, RL. et al. Large magnetic refrigerant capacity of HoFe1−xCoxAl (x = 0, 0.3) compounds. Rare Met. 40, 1–5 (2021). https://doi.org/10.1007/s12598-016-0829-x

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12598-016-0829-x