Abstract

In present work, the effect of Ge substitution for Mn on crystal structure and martensitic transformation was carefully investigated in magnetic shape memory Ni50Mn36−xGexSn14 (x = 0, 1) alloys. From X-ray diffraction (XRD) patterns, it can be found that each sample possesses cubic austenitic structure (L21) at room temperature and the main peak (220) shifts to higher degree with Ge doping, indicating that the cell volume of austenitic phase shrinks. With Ge content increasing, martensitic transformation (MT), temperature shifts to higher temperature region and the difference of magnetization between martensitic and austenitic phases (ΔM) also increases. In addition, the magnetocaloric effect (MCE) and phase transition strain (ΔL/L) were investigated in Ni50Mn35GeSn14 alloy. The maximal magnetic entropy change (ΔS m) associated with martensitic transition is 3.9 J·kg−1·K−1 with applied magnetic field change of 5 T and the maximal ΔL/L reaches 0.18% in this alloy.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Ni–Mn-based ferromagnetic shape memory alloys (FMSAs) with some critical concentration can undergo martensitic transformation (MT), which is a first-order magnetostructural transition from high temperature phase (austenite) to low temperature phase (martensite) accompanying by an abrupt change of magnetization (ΔM) on cooling [1–3]. Such a change of magnetization in the process of MT leads to the difference of Zeeman energy (ΔM·H, where H is magnetic field) between austenitic and martensitic phases under external magnetic field, giving rise to a field-induced martensitic transition (FIMT). Owing to this unusual property, inverse magnetocaloric effect (IMCE) [4–6] and magnetic superelasticity effect [7–9] were observed in those alloys.

Among Ni–Mn–X alloys, the one with X = Sn is relatively cheap compared to In, Sb. Thus, a lot of attention was focused on optimizing multifunctional properties of off-stoichiometric Ni–Mn–Sn alloys. Up to now, to tune the martensitic transformation temperature (T M) or enhance ΔM, much effort has been made by varying the stoichiometric ratio of chemical composition (Ni/Mn, Mn/Sn or Ni/Sn) [10–14] or by other elements substitution like Fe [15, 16], Co [17–20], Cu [21, 22], Ge [23], Al [24], Si [25], Cr [26], C [27], Pd [28], Gd [29], Pr [30], Ti [31]. However, those researches were mainly concentrated on the substitution of Ni/Mn by transition element or rare earth element and Sn by main group element, and there are few reports on tuning T M by substituting main group element for Mn. As is well known, the magnetic properties in Ni–Mn-based Heusler alloys can be mainly attributed to the localized Mn magnetic moments and the magnetism is determined by the distance of Mn atom [32]. In the off-stoichiometric form, the regular Mn atoms are ferromagnetically coupled with each other [33], while antiferromagnetically coupled with Mn atom in Sn site due to the shorter distance compared to the critical distance [33, 34]. When main group element with smaller atomic radius substitutes for Mn, it is likely to reduce Mn–Mn distance which is expected to strengthen the ferromagnetic coupling and enhance ΔM across MT. Moreover, T M is known to increase with pressure [35].

Therefore, main group element doping is expected to a feasible way to optimize the functional properties. As Ge atom is smaller than Mn atom, the replacement of Mn by Ge is expected to enlarge ΔM and shift MT toward to higher temperature. Based on this motivation, polycrystalline bulk samples Ni50Mn36−xGexSn14 (x = 0, 1) were prepared. The variation of T M, the MCE and the phase transition strain in those alloys were investigated.

2 Experimental

Polycrystalline samples of Ni50Mn36−xGexSn14 (x = 0, 1) with nominal composition were prepared by conventional arc melting process in argon atmosphere. The purities of Ni, Mn, Sn and Ge are 99.980%, 99.900%, 99.999%, 99.999%, respectively. Since Mn vaporizes easily, excess Mn (approximately 2 wt%) was added to compensate for the weight loss during melting. For homogenization, the sample ingots were flipped and re-melted four times. Then, the obtained ingots were annealed in evacuated quartz capsules at 1173 K for 24 h and then quenched in ice water. The real compositions of Ni50Mn36−xGexSn14 (x = 0, 1) were determined by energy-dispersive spectrometer (EDS, ProX, Phenom), corresponding to Ni49.8Mn35.7Sn14.5 and Ni49.9Mn34.9Ge0.9Sn14.3 for x = 0 and x = 1, respectively, which are close to the nominal compositions. The crystal structures were determined by X-ray diffractometer (XRD, Rigaku 18 kWD/Max-RB) with Cu Kα radiation at room temperature. The magnetization data were acquired using physical property measurement system (PPMS-9, Quantum Design Inc.). Examination of thermal strain was performed by standard strain gauge technology using rectangular specimen with dimension of 2 mm × 10 mm × 10 mm. First, the strain gauge was stuck on the specimen, and then both of the strain gauge and specimen and anther strain gauge (as referential objective to eliminate the strain induced by thermal deformation of the strain gauge) were fixed on the puck (metrical appurtenance of Verslab). Finally, they were put into sample chamber of Verslab. Thus, either the temperature or magnetic field can be controlled by Verslab. The strain of specimen was confirmed by strain gauge and data logger (TDS102, Tokyo Sokki Kenkyujo Co., Ltd.).

3 Results and discussion

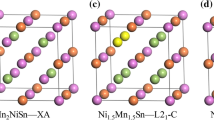

Figure 1 shows XRD patterns of Ni50Mn36−xGexSn14 (x = 0, 1) alloys at room temperature. It is clearly seen that XRD patterns of Ni50Mn36−xGexSn14 alloys show bcc fundamental lattice reflections of (220), (400) and (422) at room temperature, and the superlattice reflection such as (111) is also observed. These features indicate that these two alloys have a highly ordered cubic L21 phase. Such a L21 phase corresponds to austenite (parent phase), indicating that T M is below room temperature. The lattice parameters are calculated to be with a = 0.59835 and 0.59622 nm for the samples with x = 0 and 1, respectively. One can find that the lattice parameter decreases with Ge concentration increasing, which could be attributed to the substitution of the larger atomic radius Mn (0.179 nm) by the smaller atomic radius Ge (0.152 nm).

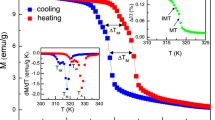

In order to study the transforming characters of Ni50Mn36−xGexSn14 alloys, a series of thermomagnetic curves were measured in a field cooled cooling (FCC) and a field cooled warming (FCW) modes, respectively. Figure 2 shows magnetization–temperature (M-T) curves of Ni50Mn36−xGexSn14 alloys under an applied magnetic field of 0.05 T in the temperature range of 150–280 K. The direct martensitic transition (DMT) starting and finishing temperatures (M s and M f) and the reverse martensitic transition (RMT) starting and finishing temperatures (A s and A f) are denoted as the crosspoints of the linear extrapolation lines of M-T curves from both the higher and the lower temperature ranges, as shown in Fig. 2. For x = 0, as shown in Fig. 2a, in the cooling process, a sharp drop of magnetization is observed between M s and M f, corresponding to DMT. With temperature further decreasing, the magnetization increases slightly and the martensite still exhibits a weak magnetic behavior. Nevertheless, in the heating process, RMT occurs between A s and A f. In addition, it can be noted that a thermal hysteresis of 15 K is also observed between cooling and heating processes, indicating the first-order nature of MT. For x = 1, similar behavior with a thermal hysteresis of 18 K is also observed between DMT and RMT, as shown in Fig. 2b. All the characteristic temperatures are collected in Table 1. Furthermore, it can be found that ΔM increases slightly with Mn replacing by Ge. In Ni–Mn-based Heusler alloys, the magnetism is dependent on Mn–Mn bond length. For the studied alloys, the substitution of Mn by Ge can shorten the distance between Mn atoms in regular site, leading to the enhancement of Mn–Mn interaction. Moreover, Ge doping could break the antiferromagnetic interaction between regular site Mn atom and X site Mn atom. These factors can explain the increase in ΔM with Ge doping.

As a rule of thumb, the valence electron concentration (e/a) is a critical factor that influences the characteristic temperatures of MT in Ni–Mn-based Heusler alloys. A general rule based on these alloys shows that T M sharply shifts to lower temperature with e/a decreasing [2, 3]. The variation slope of T M with e/a is dependent on the specific Z elements in Ni–Mn–Z Heusler alloys [36]. According to the real compositions of Ni50Mn36−xGexSn14 alloys, it is easy to calculate e/a by noting the valence electron number: Ni, 3d84 s2-10; Mn, 3d54 s2-7, Sn, 5s25p2-4; Ge, 4s24p2-4. The obtained e/a are 8.059 and 8.041 for x = 0 and 1, respectively. From Table 1, one can notice that T M slightly increases with e/a decreasing, which is oppositional to the general rule. Therefore, it is considered that e/a cannot be responsible for the increase in T M in the studied alloys. Some literatures reported that the effect of other factor on T M needs to take into account, i.e., doping with smaller elements would decrease the cell volume and lead to increase the density of states (DOS) near Fermi level, inducing the material to undergo martensitic transition [22, 37]. Therefore, this factor could account for the increase in T M in Ni50Mn36−xGexSn14 alloys, which is consistent with the results of the similar FSMAs systems from earlier reports [38, 39].

To understand effect of magnetic field on MT, the isofield M-T curves were carried out upon heating around MT under different magnetic fields varying from 1 to 5 T, as shown in Fig. 3. From Fig. 3, it can notice that all the magnetic isofield M-T curves are similar in nature, but MT shifts to lower temperature with magnetic field increasing. This behavior is attributed to the additional Zeeman energy stabilizing the austenitic state. The decrease in phase equilibrium temperature (T 0) in RMT under applied magnetic fields can be estimated directly from the position of the maximum dM/dT, as shown in the insets in Fig. 3. The change rate of T 0 with respect to magnetic field (dT 0 /dH) is 1 K·T−1 for x = 0 and 1. Based on ΔM and dT 0 /dH, the transformation entropy (ΔS tr) can be calculated with C–C equation and the calculated values for these two alloys are 8.9 and 11.3 J·kg−1·K−1 for x = 0 and 1, respectively. This indicates that ΔS tr increases with the substitution of Mn by Ge.

Figure 4 shows temperature dependence of magnetic entropy change (ΔS m) in the alloy with x = 1. To avoid the mixed phases disturbing the final results [40], the magnetization was measured as a function of temperature in the vicinity of RMT at different constant fields to calculate the ΔS m, as shown in the inset in Fig. 4. ΔS m was calculated using Maxwell relation given below:

As shown in Fig. 4, a positive peak is observed around RMT, which is contributed to the positive temperature derivative of magnetization. Both ΔS m and temperature window develop gradually with magnetic field increasing. The maximal ΔS m reaches 0.8, 2.4 and 3.9 J·kg−1·K−1 corresponding to magnetic field changes of 1, 3 and 5 T, respectively. Obviously, these values are significantly lower than those obtained in other Mn-rich Ni–Mn-based alloys [4–6]. It can be ascribed to that the dT 0 /dH is so small that only limited martensite can transform to austenite trigged by a moderate magnetic field for present alloy.

In addition, we also investigated the phase transition strain in Ni50Mn35GeSn14 alloy. Figure 5 shows the temperature dependence of relative length change (ΔL/L) of Ni50Mn35GeSn14 around MT under different magnetic fields. In the absence of magnetic field, ΔL/L rapidly decreases to about 0.18% in cooling process, indicating the volume shrinks in this sample. For the heating process, however, the decreased ΔL/L quickly increases and recovers to the initial state, exhibiting a good spontaneous phase transition strain induced by temperature. The maximal spontaneous phase transition strain of this sample is smaller than that observed in Ge free sample (about 0.21%, not shown here), indicating that Ge doping decreases the difference of volume between martensitic and austenitic phases. With applying the external field, the strain almost keeps constant but the loop shifts to lower temperature, resulted from that the magnetic field makes martensitic transformation shift to lower temperature.

4 Conclusion

In this study, the influences of Ge substitution for Mn on martensitic transformation in Ni50Mn36−xGexSn14 (x = 0, 1) alloys, the MCE and the phase transition strain in Ni50Mn35GeSn14 were investigated. The structural measurement indicates that each sample possesses cubic L21 structure at room temperature, indicating MT below room temperature. With Mn slightly replacing by Ge, T M shifts to high temperature region and ΔM also increases. But Ge addition has little effect on dT 0/dH. Based on the calculation with C–C equation, it was found that Ge doping enhances ΔS tr, indicating that it is a feasible way to optimize MCE. And a maximum ΔS m of 3.9 J·kg−1·K−1 is obtained in external magnetic field change of 5 T for Ni50Mn35GeSn14 Heusler alloy. In this alloy, a phase transition strain of 0.18% is also observed without external magnetic field and the magnetic field has no effect on the maximal value of phase transition strain.

References

Sutou Y, Imano Y, Koeda N, Omori T, Kainuma R, Ishida K, Oikawa K. Magnetic and martensitic transformations of NiMnX (X = In, Sn, Sb) ferromagnetic shape memory alloys. Appl Phys Lett. 2004;85(19):4358.

Krenke T, Acet M, Wassermann EF. Martensitic transitions and the nature of ferromagnetism in the austenitic and martensitic states of Ni–Mn–Sn alloys. Phys Rev B. 2005;72(1):014412.

Krenke T, Acet M, Wassermann EF. Ferromagnetism in the austenitic and martensitic states of Ni–Mn–In alloys. Phys Rev B. 2006;73(17):174413.

Krenke T, Duman E, Acet M, Wassermann EF, Moya X, Mañosa L, Planes A. Inverse magnetocaloric effect in ferromagnetic Ni–Mn–Sn alloys. Nat Mater. 2005;4(6):450.

Emre B, Bruno NM, Emre SY, Karaman I. Effect of niobium addition on the martensitic transformation and magnetocaloric effect in low hysteresis NiCoMnSn magnetic shape memory alloys. Appl Phys Lett. 2014;105(23):231910.

Planes A, Mañosa L, Acet M. Magnetocaloric effect and its relation to shape-memory properties in ferromagnetic Heusler alloys. J Phys: Condens Matter. 2009;21(23):233201.

Kainuma R, Imano Y, Ito W, Sutou Y, Morito H, Okamota S, Kitakami O, Oikawa K, Fujita A, Kanomata T, Ishida K. Magnetic-field-induced shape recovery by reverse phase transformation. Nature. 2006;439(7079):959.

Krenke T, Duman E, Acet M, Wassermann EF. Magnetic superelasticity and inverse magnetocaloric effect in Ni–Mn–In. Phys Rev B. 2007;75(10):104414.

Li Z, Xu K, Zhang YL, Jing C. Reproducible magnetostrain behavior induced by structure transformation for Ni46Co4Mn39Sn11 Heusler alloy. J Appl Phys. 2015;117(2):023902.

Muthu SE, Rao NVR, Raja MM, Kumar DMR, Radheep DM, Arumugam S. Influence of Ni/Mn concentration on the structural, magnetic and magnetocaloric properties in Ni50−xMn37+xSn13 Heusler alloys. J Phys D Appl Phys. 2010;43(42):425002.

Xuan HC, Zheng YX, Ma SC, Cao QQ, Wang DH, Du YW. The martensitic transformation, magnetocaloric effect, and magnetoresistance in high-Mn content Mn47+xNi43−xSn10 ferromagnetic shape memory alloys. J Appl Phys. 2010;108(10):103920.

Liu FS, Wang QB, Li SP, Ao WQ, Li JQ. The martensitic transition and magnetocaloric properties of Ni51Mn49−xSnx. Phys B. 2013;412:47.

Pramanick S, Chatterjee S, Giri S, Majumdar S. Excess Ni-doping induced enhanced room temperature magneto-functionality in Ni–Mn–Sn based shape memory alloy. Appl Phys Lett. 2014;105(11):112407.

Dan NH, Duc NH, Yen NH, Thanh PT, Bau LV, An NM, Anh DTK, Bang NA, Mai NT, Anh PK, Thanh TD, Phan TL, Yu SC. Magnetic properties and magnetocaloric effect in Ni–Mn–Sn alloys. J Magn Magn Mater. 2015;374:372.

Zhao XG, Tong M, Shih CW, Li B, Chang WC, Liu W, Zhang ZD. Microstructure, martensitic transitions, magnetocaloric, and exchange bias properties in Fe-doped Ni–Mn–Sn melt-spun ribbons. J Appl Phys. 2013;113(17):17A913.

Liao P, Jing C, Zheng D, Li Z, Kang BJ, Deng DM, Cao SX, Lu B, Zhang JC. Tuning martensitic transformation, large magnetoresistance and strain in Ni50−xFexMn36Sn14 Heusler alloys. Solid State Commun. 2015;217:28.

Huang L, Cong DY, Suo HL, Wang YD. Giant magnetic refrigeration capacity near room temperature in Ni40Co10Mn40Sn10 multifunctional alloy. Appl Phys Lett. 2014;104(13):132407.

Emre B, Bruno NM, Emre SY, Karaman I. Effect of niobium addition on the martensitic transformation and magnetocaloric effect in low hysteresis NiCoMnSn magnetic shape memory alloys. Appl Phys Lett. 2014;105(23):231910.

Ghosh A, Mandal K. Large inverse magnetocaloric effect in Ni48.5−xCoxMn37Sn14.5 (x = 0, 1 and 2) with negligible hysteresis. J Alloys Compd. 2013;579:295.

Yang LH, Zhang H, Hu FX, Sun JR, Pan LQ, Shen BG. Magnetocaloric effect and martensitic transition in Ni50Mn36−xCoxSn14. J Alloys Compd. 2014;588:46.

Wang DH, Zhang CL, Xuan HC, Han ZD, Zhang JR, Tang SL, Gu BX, Du YW. The study of low-field positive and negative magnetic entropy changes in Ni43Mn46−xCuxSn11 alloys. J Appl Phys. 2007;102(1):013909.

Das R, Sarma S, Perumal A, Srinivasan A. Effect of Co and Cu substitution on the magnetic entropy change in Ni46Mn43Sn11 alloy. J Appl Phys. 2011;109(7):07A901.

Raji GR, Uthaman B, Thomas S, Suresh KG, Varma MR. Magnetocaloric properties, exchange bias, and critical behavior of Ge substituted Ni50Mn36Sn14 Heusler alloys. J Appl Phys. 2015;117(10):103908.

Chen J, Han ZD, Qian B, Zhang P, Wang DH, Du YW. The influence of Al substitution on the phase transition and magnetocaloric effect in Ni43Mn46Sn11−xAlx alloys. J Magn Magn Mater. 2011;323(2):248.

Muthu SE, Kanagaraj M, Singh S, Sastry PU, Ravikumar G, Rao NVR, Raia MM, Arumugam S. Hydrostatic pressure effects on martensitic transition, magnetic and magnetocaloric effect in Si doped Ni–Mn–Sn Heusler alloys. J Alloys Compd. 2014;584:175.

Wang DH, Zhang CL, Han ZD, Xuan HC, Gu BX, Du YW. Large magnetic entropy changes and magnetoresistance in Ni45Mn42Cr2Sn11 alloy. J Appl Phys. 2008;103(3):033901.

Zhang Y, Liu J, Zheng Q, Zhang J, Xia WX, Du J, Yan A. Large magnetic entropy change and enhanced mechanical properties of Ni–Mn–Sn–C alloys. Scr Mater. 2014;75:26.

Saha R, Nigam AK. Room temperature inverse magnetocaloric effect in Pd substituted Ni50Mn37Sn13 Heusler alloys. Phys B. 2014;448:263.

Zhang P, Phan TL, Dan NH, Thanh TD, Yu SC. Magnetocaloric and critical behavior in the austenitic phase of Gd-doped Ni50Mn37Sn13 Heusler alloys. J Alloys Compd. 2014;615:S335.

Phan TL, Thanh PT, Dan NH, Zhang P, Thanh TD, Phan MH, Yu SC. Influence of Pr-doping on the magnetic properties and magnetocaloric effect of Ni50−xPrxMn37Sn13 alloys. J Alloys Compd. 2014;615:S261.

Chen F, Tong YX, Tian B, Li L, Zheng YF. Martensitic transformation and magnetic properties of Ti-doped NiCoMnSn shape memory alloy. Rare Met. 2014;33(5):511.

Webster PJ, Ziebeck KRA, Town SL, Peak MS. Magnetic order and phase transformation in Ni2MnGa. Philos Mag B. 1984;49(3):295.

Aksoy S, Acet M, Deen PP, Mañosa L, Planes A. Magnetic correlations in martensitic Ni–Mn-based Heusler shape-memory alloys: neutron polarization analysis. Phys Rev B. 2009;79(21):212401.

Buchelnikov VD, Entel P, Taskaev PSV, Sokolovskiy VV, Hucht A, Ogura M, Akai H, Gruner ME, Nayak SK. Monte Carlo study of the influence of antiferromagnetic exchange interactions on the phase transitions of ferromagnetic Ni–Mn–X alloys (X = In, Sn, Sb). Phys Rev B. 2008;78(18):184427.

Mañosa L, Moya X, Planes A, Gutfleisch O, Lyubina J. Effects of hydrostatic pressure on the magnetism and martensitic transition of Ni–Mn–In magnetic superelastic alloys. Appl Phys Lett. 2008;92(1):012515.

Krenke T, Moya X, Aksoy S, Acet M, Entel P, Mañosa L, Planes A, Elermanc Y, Yuceld A, Wassermann EF. Electronic aspects of the martensitic transition in Ni–Mn based Heusler alloys. J Magn Magn Mater. 2007;310(2):2788.

Sharma VK, Chattopadhyay MK, Nath SK, Sokhey KJS, Kumar R, Tiwari P, Roy SB. The effect of substitution of Mn by Fe and Cr on the martensitic transition in the Ni50Mn34In16 alloy. J Phys: Condens Matter. 2010;22(48):486007.

Wang RL, Yan JB, Xiao HB, Xu LS, Marchenkov VV, Xu LF, Yang CP. Effect of electron density on the martensitic transition in Ni–Mn–Sn alloys. J Alloys Compd. 2011;509(3):6834.

Xuan HC, Han PD, Wang DH, Du YW. The influence of Ge substitution on the magnetostructure transition and magnetocaloric effect of Mn–Ni–Sn–Ge alloys. J Alloys Compd. 2014;582:369.

Xu K, Li Z, Zhang YL, Jing C. An indirect approach based on Clausius–Clapeyron equation to determine entropy change for the first-order magnetocaloric materials. Phys Lett A. 2015;379(47–48):3149.

Acknowledgements

This study was financially supported by the National Natural Science Foundation of China (Nos. 51371111, 11364035 and 11404186), the Key Basic Research Program of Science and Technology Commission of Shanghai Municipality (No. 13JC1402400), the Project for Applied Basic Research Programs of Yunnan Province (No. 2013FZ110) and the Project for Innovation Research Team of Qujing Normal University (No. TD201301).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Zheng, D., Jing, C., Lu, B. et al. Martensitic transformation, magnetocaloric effect and phase transition strain in Ni 50 Mn 36− x Ge x Sn 14 Heusler alloys . Rare Met. 41, 4217–4222 (2022). https://doi.org/10.1007/s12598-016-0820-6

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12598-016-0820-6