Abstract

The 2,3-dihydro-3,5-dihydroxy-6-methyl-4(H)-pyran-4-one (DDMP), 5-hydroxymethylfurfural (HMF), furfural, and 5-methylfurfural (MF) are the components of caramel colors with intense bitterness. In this study, a practical and simple method for the simultaneous analysis of these four bitter compounds in caramel colors and beverages was proposed using high-performance liquid chromatography–diode array detector–atmospheric pressure chemical ionization–mass spectrometry (HPLC-DAD-APCI-MS). For the sample preparation, the extract efficiencies from different extract solvents and quick, easy, cheap, effective, rugged, and safe (QuEChERS) salt pockets were compared. The correlation coefficients (R2) of all analytical curves were ≥ 0.9914. The satisfactory recoveries ranged between 70.1% and 101.5%, with relative standard deviations ranged from 1.7% to 9.1%. The matrix effect was evaluated, and HMF, furfural, and MF showed signal enrichment. This method was successfully applied to the analysis of bitter compounds content in several caramel colors and beverages from a local market in China. Four compounds were found in eight samples, with concentration ranging from 0.5 to 1058.1 mg kg−1.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Taste is one of the most important factors influencing the food people choose to eat. For many years, humans mainly perceive five different taste modalities: sweet, salt, umami, sour, and bitter (Rodgers et al. 2006). Recently, 2,3-dihydro-3,5-dihydroxy-6-methyl-4(H)-pyran-4-one (DDMP) and 5-hydroxymethylfurfural (HMF) were identified as key bitter compounds in bread (Jiang and Peterson 2013; Bin and Peterson 2016). Furfural and 5-methylfurfural (MF), as bitter compounds, were also isolated and identified from caramel colors by our group. Bitter compounds are rejected, because they are considered to be associated with toxicity and against being eaten. The European Commission has set a threshold concentration for HMF at 40 mg kg−1 for general type honey, 80 mg kg−1 for honeys of tropical origin or after blending, and 15 mg kg−1 for honey with low enzymatic levels (European Commission 2001). The maximum levels of furfural consumed as a flavor ingredient in ready-to-eat products is 50.0, 44.3, 63.2, 52.6, 32.8, 28.4, 7.0, 4.2, 21.0, and 56.4 mg kg−1 in baked food, frozen dairy, meat products, soft candy, gelatin puddings, non-alcoholic beverages, alcoholic beverages, gravies, hard candy, and chewing gum, respectively (Adams et al. 1997). Therefore, it is necessary to establish a method to assess the amounts of bitter compounds and thus to improve the food quality. These compounds were commonly found from sugary food products, such as sugar (Polovkova and Simko 2017), honey (Verissimo et al. 2017), caramel colors (Guan et al. 2011), alcoholic beverages (Monakhova and Lachenmeier 2012), soy sauce (Wu et al. 2018), and heated pear (Hwang et al. 2013). They also formed in various Maillard reactions (Yu et al. 2013; Kim and Baltes 1996) via different reaction pathways. Up to now, gas chromatography–mass spectrometry (GC-MS) was frequently used for the determination of DDMP (Zhou et al. 2014) and furfural (Moreira et al. 2019), while high-performance liquid chromatography–diode array detector (HPLC-DAD) and capillary electrophoresis-ultraviolet were commonly used to analyze HMF (Wu et al. 2018; Akpinar et al. 2011; Murkovic and Pichler 2006).

Due to the complexity of the matrix, efficient sample preparation and trace-level detection and identification are important to obtain reliable results. Sample pretreatment methods to detect these compounds commonly employed include headspace–solid-phase micro-extraction (HS-SPME) (Verissimo et al. 2017), solid-phase extraction (SPE) (Murkovic and Pichler 2006), and liquid-liquid extraction (Akpinar et al. 2011; Durmaz and Goekmen 2010). In order to detect HMF in high ionic strength samples like vinegar and soy sauce, a two-step ultrasonic-assisted liquid-liquid micro-extraction was reported by Wu et al. (2018). Since 2003, the quick, easy, cheap, effective, rugged, and safe (QuEChERS) method was firstly developed by Anastassiades et al. (2003) to detect multi-class pesticide residues. There are many follow-up reports using QuEChERS to determine pesticides (Moreno-González et al. 2018; Li et al. 2018; Tette et al. 2016) in many food products. These food matrixes include honey, chicken, pork, beef, egg, milk, grapes, tomatoes, wheat, melons, and fruits. QuEChERS coupled with HPLC-MS was used to detect HMF and pesticides (Tomasini et al. 2012). Kasiotis and Machera (2017) employed QuEChERS coupled with HPLC-DAD to determine HMF and related furfurals in honey.

To the best of our knowledge, each of these works just reports the determination of only one or two compounds by one method. HPLC-MS detection has been reported for the analysis of HMF and MF, but has not been applied to DDMP and furfural. No report was involved to simultaneously detect these four bitter compounds using QuEChERS coupled with HPLC-MS. Herein, this paper aimed to develop an acceptable method for the determination of four bitter compounds in caramel colors and beverages. In this study, the optimization of experimental parameters for the modified QuEChERS was carried out, and the method performances were evaluated carefully.

Materials and Methods

Chemicals and Reagents

Furfural, 5-methylfurfural (MF), and 5-hydroxymethylfurfural (HMF) were all bought from Aladdin Industrial Corporation (Shanghai, China). The 2,3-dihydro-3,5-dihydroxy-6-methyl-4(H)-pyran-4-one (DDMP) was isolated and purified using semi-preparing liquid chromatography by our group. The identification of DDMP was in agreement with published reports (Kim and Baltes 1996; Li et al. 2019). Methanol (≥ 99.9%) and acetonitrile (≥ 99.9%) were all HPLC grade and obtained from Merck (Damstadt, Germany). Dichloromethane, ethyl acetate, acetone, and di-hydrate tri-sodium citrate (all analytical reagents) were all supplied by Sinopharm Chemical Reagent Co., Ltd. (Shanghai, China). Anhydrous magnesium sulfate and sodium chloride were all purchased from Tianjin DAMAO Chemical Reagent Factory (Tianjin, China). Sodium acetate anhydrous and disodium citrate were bought from Tianjin FUCHEN Chemical Reagent Factory (Tianjin, China) and Damas-beta International Co., Ltd. (Shanghai, China), respectively. The water was purified on an ultrapure water system (Millipore, Bedford, MA, USA) and used throughout.

Caramel colors including class I, III, and IV were supplied by Sethness-Roquette Food Ingredients Co., Ltd. (Lianyungang, China). Various beverages with or without caramel colors addition were bought from local market randomly (Guangzhou, China). All samples were stored at – 4 °C in a freezer (BCD-610W, Qingdao Haier Co., Ltd., Qingdao, China) for no more than 7 days before analysis.

Standard Solutions Preparation

Ten milligrams of each compound was dissolved in 10 mL of methanol, respectively, to get stock solution of single compound of 1000 mg L−1, which was stored in brown glass-stopper bottles at – 18 °C in a freezer. Due to the different response values of each compound in the liquid chromatography–mass spectrometer (LC-MS), the mixed stock solution of four compounds in different concentrations was prepared: 200 mg L−1 for DDMP, 100 mg L−1 for HMF, 500 mg L−1 for furfural, and 50 mg L−1 for MF. Mixed working standard solutions were prepared by appropriately diluting the stock solution using methanol/water solution (v/v, 2080). Successive dilutions of this working solution were prepared to obtain a concentration gradient daily.

Sample Preparation by Modified QuEChERS

The following procedure was used to treat the caramel colors: 1.0 g caramel color was mixed with 50 mL of water in a 100-mL polypropylene tube. The mixture was vortexed with a Vortex mixer (XW-80A, Shanghai Precision and Scientific industrial Co., Ltd., Shanghai, China) for 1 min. Then, 2.0 mL of the caramel color solution or beverage was mixed with 10 mL acetonitrile in a 50-mL polypropylene tube and the sample was homogenized for 1 min. The sample was placed at − 18 °C for 10 min and then 4.0 g anhydrous magnesium sulfate and 1.0 g sodium acetate anhydrous was added. Afterwards, the mixture was vortexed again for 1 min and then ultrasonically extracted with ice water in the ultrasonic system (KQ3200DA, Kunshan Ultrasonic Instruments Co., Ltd., Kunshan, China). The mixtures were centrifuged for 10 min at 8000 rpm at 4 °C using a high-speed refrigerated centrifuge (CR22G Hitachi Limited Co., Ltd., Tokyo, Japan), and the acetonitrile extract was collected by a 15-mL glass tube. The extract was concentrated to dryness by gentle stream of nitrogen (99.0%) and the residue was dissolved by 2.0 mL methanol/water solution (v/v, 20:80).

A C18 cartridge (500 mg/3 mL, Beijing Ruifeng Tongchuang Analytical Instrument Co., Ltd., Beijing, China) was employed for cleanup procedure. Initially, the cartridge was equilibrated with 3 mL methanol and 3 mL ultrapure water. The above extracts were passed through the cartridge at a rate of about 1 drop s−1 until air came through the column. Then, 0.5 mL of water and 0.5 mL methanol were orderly passed through the cartridge in order to eliminate any interference. The sample was eluted by passing 6 mL of methanol and collecting all of the eluate in a glass tube. The resulting extract was evaporated to dryness under a stream of nitrogen followed by reconstitution in 1.0 mL methanol/water solution (v/v, 20:80). Each extract was filtered through 0.45-μm nylon membrane filter (Ameritech Technology Tianjin Co., Ltd., Tianjin, China) prior to the analysis by LC-MS. Each sample measurement was performed in triplicate.

LC-DAD-MS Conditions

High-performance liquid chromatography (HPLC) analysis was performed with a Waters 600 pump, a Waters 2707 auto-sampler, and a Waters 2998 diode array detector (Waters, Milford, USA), connected to an LCQ-Fleet ion-trap mass spectrometer (Thermo Fisher Scientific, San Jose, CA, USA). The HPLC was equipped with a 5-μm Waters Atlantis T3 RP C18 250 × 4.6 mm column (Waters, Milford, USA). An aliquot of 20 μL of the sample was injected into LC-DAD-MS system for analysis with UV detection at 284 nm. The column oven was set at 30 °C. Mobile phases A and B were water and methanol, respectively. The gradient program was as follows: 10–40% B, 0–15 min; 40–100% B, 15–20 min; 100–10% B, 20–21 min; and 10% B, 21–25 min. The flow rate was 1.0 mL min−1. MS was performed with an atmospheric pressure chemical ionization (APCI) interface in the positive ionization mode and using the following conditions: sheath gas flow rate, 35 arbitrary units (arb); aux gas flow rate, 10 arb; discharge current, 3.00 μA; vaporizer temperature, 350 °C; capillary temperature, 350 °C; capillary voltage, 17.5 V; and tube lens, 64 V. Quantification of compounds was achieved by external standard using HPLC-DAD (monitored at 284 nm). Confirmation was performed by comparing the retention time with those of the analytical standards and APCI/MS, functioning in the selected ion monitoring mode (SIM), monitoring the [M + H]+ ions of each analyte. The selected ions of DDMP, HMF, furfural, and MF were 145, 127, 97, and 111 m/z, respectively.

Validation of Method

Limit of Detection and Quantification

A signal-to-noise ratio (S/N) of three in the pure solution is used to estimate the instrumental limit of detection (LODI) and often is used to estimate the instrumental limit of quantification (LOQI), while a signal-to-noise ratio (S/N) of three in the matrix (caramel colors class III) is used to evaluate the methodological limit of detection (LODM) and often is used to evaluate the methodological limit of quantification (LOQM).

Linearity and Matrix Effect

The external standard and calibration curve method were used for the quantitative analysis. Standard curves were obtained by using seven concentrations (0.1, 0.2, 0.5, 1.0, 2.0, 5.0, and 10.0 mg L−1 for DDMP, 0.05, 0.1, 0.2, 0.5, 1.0, and 5.0 mg L−1 for HMF; 0.25, 0.5, 1.0, 5.0, 10.0, and 25.0 mg L−1 for furfural; and 0.025, 0.05, 0.1, 0.5, 1.0, and 2.5 mg L−1 for MF). However, due to the lack of corresponding internal standards of several analytes, it was necessary to evaluate the matrix effect of target compounds. Matrix effect is the presence of co-extractives that can affect the ionization of the target compounds by reducing or enhancing the detector response compared with that produced by the analytes in solvent (Kebarle and Tang 1993). There is no systematical investigation and analysis about the mechanism of the matrix effect, but the majority of analytical experts believed that it probably originates from the competition between targeted compounds and the co-eluting un-targeted components (Tomasini et al. 2012). The interfering species can be components of the sample, compounds released during the pre-treatment/extraction process, or reagents added to the mobile phase to improve chromatographic resolution (Gosetti et al. 2010). It is generally recognized as a suppression or enhancement of the analytical signal by comparing the slopes in calibration solutions prepared in solvent and in matrix. A concentration gradient of analytes in pure solvent and spiking into the samples was injected in to HPLC system to obtain three calibration curves. Matrix effects were evaluated by the following equation (Eq. 1) according to a published report (Economou et al. 2009):

\( \mathrm{ME}=\left(1-\frac{s_m}{s_s}\right)\times 100 \) (1)

where ME is the matrix effect (%), Sm is the slope of matrix-matched calibration curve, and Ss is the slope of calibration curve in solvent. It is considered low when the ME values were found between − 20% and + 20%; it is considered medium when these values were found + 20% ~ + 50% or − 50% ~ − 20%; and it is considered high when these values were found below − 50% or above +5 0%.

Recoveries and Repeatability

The recovery and repeatability of the method were verified by spiking standard solution in the sample (caramel colors III) with three levels (1 × LOQM, 2 × LOQM and 5 × LOQM, Table 1) of four standards in six replicate experiments. The recoveries were obtained by the following equation (Eq. 2):

where R is the recovery (%), mspiked+sample is the total amount of compounds in spiked sample (μg), msample is the amount of compounds in the sample itself (μg); and mspiked is the spiked amounts of compounds (μg). Intraday and interday RSD were performed by spiking samples at three concentration levels with six replicates in 1 day and by repeating the spiked level of 5× LOQM for five consecutive days, respectively

Statistical Analysis

Data given in Table 3 and Fig. S1, and 2 were means and standard deviations of triplicate experiments. Statistical analyses were carried out using statistical product and service solutions (SPSS) 13.0 (IBM spss Inc., NY, USA) analytical software. For all data, different letters in the same system with different treatments indicate statistically significant differences (p < 0.05).

Results and Discussion

Stability of Studied Compounds

It has been observed that instability of the calibration standard solution may lead to significant deviation of the results. Three standard solutions (1.0 mg L−1 for all compounds) were kept at − 18, 4, and 25 °C, respectively, and injected into HPLC-MS analysis for 15 consecutive days. All the four compounds were stable at − 18 °C and the stability study is shown in Fig. S1 (Supplementary material). The DDMP was stable for just about 4 and 7 days at 25 °C and 4 °C, respectively (data not shown). That may be caused by the self-degradation thermolabile DDMP (Huyghues-Despointes et al. 1994). Therefore, the mixed stock solution of four compounds was stored at − 18 °C before analysis.

Modified QuEChERS

Originally, QuEChERS method involves an extraction of 10.0-g sample with acetonitrile, followed by liquid-liquid extraction, freezing, and then partitioning formed by adding a specific salt packet, and a clean-up step by dispersive solid-phase extraction with primary-secondary amine (PSA) (Anastassiades et al. 2003). Based on the stability and formation pathway of studied compounds, the heat may decompose them or promote their formation. An exothermic process could occur in QuEChERS method by adding the salts pocket into aqueous; therefore, the freezing is necessary before addition of salts pocket. In this study, some parameters such as extraction solvent and salt pockets were studied and optimized due to different chemical properties of the studied compounds.

Selection of Extraction Solvent

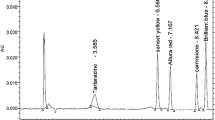

Four solvents including acetone, ethyl acetate, acetonitrile, and dichloromethane were compared to assess their extraction efficiency. The experiments were carried out on III-like caramel colors by spiking standard (10.0 mg L−1 for HMF and 1.0 mg L−1 for other compounds) and then the recoveries were obtained to select the extraction solvent. Fig. 1 shows the effects of selected solvent on the recoveries of tested compounds. The recoveries of compounds from III-like caramel colors with solvents were analyzed by variance analysis and results indicated that the recoveries extracted from ethyl acetate and acetonitrile were apparently higher than that from acetone and dichloromethane (p < 0.05 in all cases). Published reports of a variety of foods have used acetonitrile as the extraction solvent for its lesser co-extracts of matrices components and satisfactory recovery (Tian et al. 2016; Rong et al. 2018). In addition, the recovery of furfural from ethyl acetate was less than 70% in comparison of acetonitrile, thus the acetonitrile was selected as the extraction solvent.

Modified Methods Using Various Salt Pockets

The matrixes surroundings, especially for pH values, may play an important role on the extraction of some pesticides (Corta et al. 1999; Korta et al. 2001). Therefore, the influence of pH on recoveries was often investigated in many reports. The surroundings were commonly performed on the acidic, alkaline, and the sample without pH adjustment. The glacial acetic acid was often used to adjust the acidic medium, while ammonium hydroxide and other alkali were used for adjusting the alkaline medium (Korta et al. 2001). Tomasini et al. (2012) used the ammonium hydroxide to adjust the pH values in honey samples. However, because the addition of salt pocket into aqueous is an exothermic reaction, the NH4+ inserted into these samples may form extra DDMP and HMF from Maillard reaction and thus affect the analysis results. The Maillard reaction may occur easily due to the addition of NH4+ into these samples consist of reduced sugar and dicarbonyl compounds (Papetti et al. 2014). Hence, ammonium hydroxide might not be a good option used to adjust sample pH values. In this study, four modified methods using various salt pockets selection were employed to compare the extraction efficiency and the results were seen in Fig. 2. The salt pockets buffered method may affect the surrounding mildly and they were chosen on basis of the commercial QuEChERS extraction products from Thermo Fisher scientific Co., Ltd., (San Jose, CA, USA), the Association of Official Analytical Chemists (AOAC), and European Norm (EN). Method 1 consists of 4 g anhydrous MgSO4 and 1 g anhydrous NaCl is the initial QuEChERS method; method 2 consists of 4 g anhydrous MgSO4 and 1 g anhydrous sodium acetate is the method from AOAC 2007.01; method 3 consists of 4 g anhydrous MgSO4, 1 g anhydrous NaCl, 1 g di-hydrate tri-sodium citrate and 0.5 g disodium citrate is the method from EN 15662; method 4 consists of 4 g anhydrous MgSO4, 1 g anhydrous NaCl, and 0.5 g disodium citrate is modified according to method 3. As seen in Fig. 2, the modified methods using different salts pocket have significant effect on the extraction of four bitter compounds. Recoveries of HMF obtained from four methods were all satisfactory; however, the weak recoveries of DDMP and furfural obtained from method 1, of furfural and MF obtained from method 4, and of furfural obtained from method 3 were observed, which indicated that the method 2 had balanced superiority to extract the studied compounds. Therefore. the method 2 was selected to extract the studied compounds in this study. Results also inferred that pH values of samples may have significant effect on the recoveries of studied compounds.

Validation of Optimized Method

Limit of Detection and Quantification

Figure S2 (supplementary material) shows the chromatogram and mass spectrum of standard solution of 1.0 mg L−1 of four compounds. The developed method was validated by studying the LOD, LOQ, and linearity indifferent matrixes seen in Table 1. The method showed good linearity with correlation coefficients (R2) for four compounds between 0.9914 and 0.9996 for the analytical obtained from spiked samples after extraction and analysis. These curves were also used for calculation of the recoveries and precision.

The lower amounts of standards were spiked into blank samples and submitted to the sample extraction procedure detailed in “Sample Preparation by Modified QuEChERS” and then injected into HPLC-MS system until an signal to noise (S/N) of 3 was observed to obtain actual LODs. Compared with the LODs reported in other papers (Kasiotis and Machera 2017; Tomasini et al. 2012; Teixido et al. 2008), the LODs of this method is lower, which is in favor of the determination of these compounds.

Recovery and Precision

Recovery studies were carried out using caramel color samples and cola with quantifiable compounds residues. Each level of spiked concentration was performed six times to obtain precision. The results were shown in Table 2. The recoveries of four compounds ranged from 70.1% to 101.5% and intraday relative standard deviation (RSDs) from 1.7% to 9.1%. In this study, the slightly poor recovery (70.1%) of DDMP in caramel colors was observed, suggesting the concern of proposed method to monitor DDMP. This can be explained by the use of APCI as ionization source on the mass spectrometry detector. The APCI are commonly used for the analysis of non-polar molecules of high volatility, but DDMP has relatively high polarity causing slightly poor recovery. Furthermore, the European Commission (2002) criteria set that the recovery ranged from − 50% to + 20% is acceptable when the spiking concentration < 1.0 μg. Therefore, this method provides acceptable recoveries and good repeatability. The inter-day precision was evaluated in 5 × LOQM levels and the RSD was lower than 12.2% (data are not shown)..

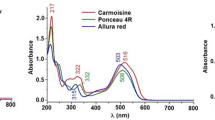

Matrix Effect

Matrix interference was an inevitable factor in analytical science field, especially in the complex food products. Fig. 3 shows the distribution of matrix effects for studied compounds in caramel colors and cola with and without a cleanup step. Results indicated that cleanup step can significantly reduce the matrix effect of DDMP, HMF, and MF, but slightly reduce that of furfural (still presented high signal enrichment effect in two matrixes). After a cleanup step, Both HMF and MF showed low signal enrichment but only DDMP presented medium signal suppression. Except for furfural, low effects were observed for other three compounds in cola. Both HPLC-electro-spray ionization (ESI)-MS and HPCI-APCI-MS used in food analysis revealed different matrix effects. Gosetti et al. (2010) systematically reviewed the signal suppression or enhancement in HPLC-MS and they concluded that the effect is lower in APCI than ESI and a signal enhancement is mainly observed. The high signal enrichment for HMF detection was reported using HPLC-APCI-MS/MS in honey samples (Tomasini et al. 2012). HMF and furfural were also determined in honey (Kasiotis and Machera 2017) and orange juices, breakfast cereals, plum jams, biscuits, and oranges samples (Teixido et al. 2008) using HPLC-MS, but they did not discuss the matrix effects in detail. The calibration curves prepared in different matrix (Table 1) were used to compensate for the occurrence of ME.

Analysis of Real Samples

Once the method was established and validated, it was applied to the analysis of four bitter compounds used for some caramel colors and beverages. Fig. 4 displayed the typical mass spectrum of sample caramel colors IV. The concentrations of four compounds in real samples shown in Table 3 suggested that four compounds were found in eight samples. Unexpectedly, there is too much HMF in sample of caramel color IV (1058.1 mg kg−1), dozens of times more than other compounds, causing the limitation of this method in application of the sample with extremely different contents. Hence, the suitable diluted ratio was performed to balance all studied compounds. DDMP was found in two caramel colors. The sources of these two caramel colors may be related to the caramelization or Maillard reaction between sugar and ammonia. During the preparation of caramel colors class I, the sugar would be thermal degradation into HMF (Table 3); while for caramel colors class III and IV, carbonyl compounds could be formed from the degradation of reducing sugars and reacted with ammonia to form HMF or DDMP. HMF found in two beverages may be explained by the addition of caramel colors. In addition, furfural and MF was detected in caramel colors and they might be the degradation products of HMF.

Conclusion

An efficient HPLC-DAD-APCI-MS method coupled with QuEChERS extraction for the analysis of four bitter compounds was developed and validated in terms of recoveries (77.9%–107.3%) and RSDs (2.5%–9.6%). Sample preparation with an efficient extraction, followed by a rapid chromatographic determination to complete the entire analysis in 25 min. This procedure is simple and shows good repeatability, linearity, and sensitivity. The proposed HPLC-MS method was successfully applied for determining the presence of four bitter compounds in caramel colors and beverages.

References

Adams TB, Doull J, Goodman JI, Munro IC, Newberne P, Portoghese PS, Smith RL, Wagner BM, Weil CS, Woods LA, Ford RA (1997) The FEMA GRAS assessment of furfural used as a flavour ingredient. Food Chem Toxicol 35(8):739–751. https://doi.org/10.1016/S0278-6915(97)00056-2

Akpinar K, Karakas B, Akca H, Certel M (2011) Determination of HMF in roasted flour/oil mixtures and effect of solvent used in the extraction procedure. Food Chem 128(3):790–794. https://doi.org/10.1016/j.foodchem.2011.03.060

Anastassiades M, Lehotay SJ, Stajnbaher D, Schenck FJ (2003) Fast and easy multiresidue method employing acetonitrile extraction/partitioning and “dispersive solid-phase extraction” for the determination of pesticide residues in produce. J AOAC Int 86(2):412–431

Bin Q, Peterson DG (2016) Identification of bitter compounds in whole wheat bread crumb. Food Chem 203:8–15. https://doi.org/10.1016/j.foodchem.2017.06.001

Corta E, Bakkali A, Berrueta LA, Gallo B, Vicente F (1999) Kinetics and mechanism of amitraz hydrolysis in aqueous media by HPLC and GC-MS. Talanta 48(1):189–199. https://doi.org/10.1016/S0039-9140(98)00237-9

Durmaz G, Goekmen V (2010) Determination of 5-hydroxymethyl-2-furfural and 2-furfural in oils as indicators of heat pre-treatment. Food Chem 123(3):912–916. https://doi.org/10.1016/j.foodchem.2010.05.001

Economou A, Botitsi H, Antoniou S, Tsipi D (2009) Determination of multi-class pesticides in wines by solid-phase extraction and liquid chromatography-tandem mass spectrometry. J Chromatogr A 1216(31):5856–5867. https://doi.org/10.1016/j.chroma.2009.06.031

European Commission. (2001). “Council Directive 2001/110/EC of 20 December 2001 relating to honey.” http://eurlex.europa.eu/LexUriServ/LexUriServ.do?uri=OJ:L:2002:010:0047:0052:EN:PDF. Accessed 11 Dec 2015

European Commission (2002). Commission decision of 12 August 2002 implementing Council Directive 96/23/EC concerning the performance of analytical methods and the interpretation of results. In Communities OJOT (Ed.) 15. Reprinted.

Gosetti F, Mazzucco E, Zampieri D, Gennaro MC (2010) Signal suppression/enhancement in high-performance liquid chromatography tandem mass spectrometry. J Chromatogr A 1217(25SI):3929–3937. https://doi.org/10.1016/j.chroma.2009.11.060

Guan Y, Shi W, Yu S, Xu X (2011) Ultrafiltration of caramel color solutions reduces 5-hydroxymethyl-2-furaldehyde. J Membr Sci 380(1-2):9–12. https://doi.org/10.1016/j.memsci.2011.05.056

Huyghues-Despointes A, Yaylayan VA, Keyhani A (1994) Pyrolysis/GC/MS analysis of 1-[(2′-carboxy)pyrrolidinyl]-1-deoxy-D-fructose (Proline Amadori Compound). J Agric Food Chem 42:2519–2524. https://doi.org/10.1021/jf950418u

Hwang IG, Kim HY, Woo KS, Lee SH, Lee J, Jeong HS (2013) Isolation and identification of the antioxidant DDMP from heated pear (Pyrus pyrifolia Nakai). Prev Nutr Food Sci 18(1):76–79. https://doi.org/10.3746/pnf.2013.18.1.076

Jiang DS, Peterson DG (2013) Identification of bitter compounds in whole wheat bread. Food Chem 141(2):1345–1353. https://doi.org/10.1016/j.foodchem.2013.03.021

Kasiotis KM, Machera K (2017) Improved liquid chromatographic photo diode array mass spectrometric determination of 5-hydroxymethylfurfural and related furfurals in honey. Toxicol Environ Chem 99(4):578–589. https://doi.org/10.1080/02772248.2016.1201674

Kebarle P, Tang L (1993) From ions in solution to ions in the gas phase—the mechanism of electrospray mass spectrometry. Anal Chem 65(22):972A–986A. https://doi.org/10.1021/ac00070a001?src=recsys

Kim MO, Baltes W (1996) On the role of 2,3-dihydro-3,5-dihydroxy-6-methyl-4(H)-pyran-4-one in the Maillard reaction. J Agric Food Chem 44(1):282–289. https://doi.org/10.1021/jf950208h

Korta E, Bakkali A, Berrueta LA, Gallo B, Vicente F, Kilchenmann V, Bogdanov S (2001) Study of acaricide stability in honey. Characterization of amitraz degradation products in honey and beeswax. J Agric Food Chem 49(12):5835–5842. https://doi.org/10.1021/jf010787s

Li H, Tang XY, Wu CJ, Yu SJ (2019) Formation of 2,3-dihydro-3,5-dihydroxy-6-methyl-4(H)-pyran-4-one (DDMP) in glucose-amino acids Maillard reaction by dry-heating in comparison to wet-heating. LWT-Food Sci Technol 105:156–163. https://doi.org/10.1016/j.lwt.2019.02.015

Li P, Duan Y, Ge H, Zhang Y, Wu X (2018) Multiresidue analysis of 113 pesticides in different maturity levels of mangoes using an optimized QuEChERS method with GC-MS/MS and UHPLC-MS/MS. Food Anal Methods 11(10):2742–2757. https://doi.org/10.1007/s12161-018-1263-5

Monakhova YB, Lachenmeier DW (2012) The margin of exposure of 5-hydroxymethylfurfural (HMF) in alcoholic beverages. Environmental Health and Toxicology 27:1–8

Moreira N, Araujo AM, Rogerson F, Vasconcelos I, De Freitas V, de Pinho PG (2019) Development and optimization of a HS-SPME-GC-MS methodology to quantify volatile carbonyl compounds in Port wines. Food Chem 270:518–526. https://doi.org/10.1016/j.foodchem.2018.07.093

Moreno-González D, Alcántara-Durán J, Addona SM, Beneito-Cambra M (2018) Multi-residue pesticide analysis in virgin olive oil by nanoflow liquid chromatography high resolution mass spectrometry. J Chromatogr A 1562:27–35. https://doi.org/10.1016/j.chroma.2018.05.053

Murkovic M, Pichler N (2006) Analysis of 5-hydroxymethylfurfual in coffee, dried fruits and urine. Mol Nutr Food Res 50(9):842–846. https://doi.org/10.1002/mnfr.200500262

Papetti A, Mascherpa D, Gazzani G (2014) Free α-dicarbonyl compounds in coffee, barley coffee and soy sauce and effects of in vitro digestion. Food Chem 164:259–265. https://doi.org/10.1016/j.foodchem.2014.05.022

Polovkova M, Simko P (2017) Determination and occurrence of 5-hydroxymethyl-2-furaldehyde in white and brown sugar by high performance liquid chromatography. Food Control 78:183–186. https://doi.org/10.1016/j.foodcont.2017.02.059

Rodgers S, Glen RC, Bender A (2006) Characterizing bitterness: identification of key structural features and development of a classification model. J Chem Inf Model 46(2):569–576. https://doi.org/10.1021/ci0504418

Rong L, Wu X, Xu J, Dong F, Liu X, Zheng Y (2018) Determination of pydiflumetofen residues in some foods of plant and animal origin by QuEChERS extraction combined with ultra-performance liquid chromatography-tandem mass. Food Anal Methods 11(10):2682–2691. https://doi.org/10.1007/s12161-018-1178-1

Teixido E, Moyano E, Santos FJ, Galceran MT (2008) Liquid chromatography multi-stage mass spectrometry for the analysis of 5-hydroxymethylfurfural in foods. J Chromatogr A 1185(1):102–108. https://doi.org/10.1016/j.chroma.2008.01.057

Tette PAS, Da Silva Oliveira FA, Pereira ENC, Silva G, de Abreu Glória MB, Fernandes C (2016) Multiclass method for pesticides quantification in honey by means of modified QuEChERS and UHPLC–MS/MS. Food Chem 211:130–139. https://doi.org/10.1016/j.foodchem.2016.05.036

Tian CY, Xu J, Dong FS, Liu XG, Wu XH, Zhao HH, Ju C, Wei DM, Zheng YQ (2016) Determination of sulfoxaflor in animal origin foods using dispersive solid-phase extraction and multiplug filtration cleanup method based on multiwalled carbon nanotubes by ultraperformance liquid chromatography/tandem mass spectrometry. J Agric Food Chem 64(12):2641–2646. https://doi.org/10.1021/acs.jafc.6b00285

Tomasini D, Sampaio MRF, Caldas SS, Buffon JG, Duarte FA, Primel EG (2012) Simultaneous determination of pesticides and 5-hydroxymethylfurfural in honey by the modified QuEChERS method and liquid chromatography coupled to tandem mass spectrometry. Talanta 99:380–386. https://doi.org/10.1016/j.talanta.2012.05.068

Verissimo MIS, Gamelas JAF, Evtuguin DV, Gomes MTSR (2017) Determination of 5-hydroxymethylfurfural in honey, using headspace-solid-phase microextraction coupled with a polyoxometalate-coated piezoelectric quartz crystal. Food Chem 220:420–426. https://doi.org/10.1016/j.foodchem.2016.09.204

Wu J, Feng T, Liang X, Yu C, Dong L, Du M, Tan M, Xu X (2018) Determination of HMF in vinegar and soy sauce using two-step ultrasonic assisted liquid-liquid micro-extraction coupled with capillary electrophoresis-ultraviolet detection. Food Anal Methods 11(2):479–485. https://doi.org/10.1007/s12161-017-1018-8

Yu X, Zhao M, Liu F, Zeng S, Hu J (2013) Identification of 2,3-dihydro-3,5-dihydroxy-6-methyl-4H-pyran-4-one as a strong antioxidant in glucose-histidine Maillard reaction products. Food Res Int 51(1):397–403. https://doi.org/10.1016/j.foodres.2012.12.044

Zhou Z, Xu Z, Shu J, She S, Sun W, Yin C, Chen M, Li Y, Zhong F (2014) Influence of various factors on formation of 2,3-dihydro-3,5-dihydroxy-6-methyl-4(H)-pyran-4-one (DDMP) in a solid-state model system of Maillard reaction. Eur Food Res Technol 239(1):31–40. https://doi.org/10.1007/s00217-014-2191-2

Funding

All authors acknowledge the financial support from the National Science Foundation of China (Grant No. 31771931), the Science and Technology Planning Project of Guangdong Province of China (No. 2014B020205001 and No. 2013B051000015), and the 111 Project (B17018).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of Interest

The authors declare that they have no competing interests.

Ethical Approval

This article does not contain any studies with human participants or animals performed by any of the authors.

Informed Consent

Not applicable.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic supplementary material

ESM 1

(DOCX 60.4 kb)

Rights and permissions

About this article

Cite this article

Li, H., Wu, CJ., Tang, XY. et al. Determination of Four Bitter Compounds in Caramel Colors and Beverages Using Modified QuEChERS Coupled with Liquid Chromatography-Diode Array Detector-Mass Spectrometry. Food Anal. Methods 12, 1674–1683 (2019). https://doi.org/10.1007/s12161-019-01500-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12161-019-01500-z