Abstract

The influences of various factors on the formation of 2,3-dihydro-3,5-dihydroxy-6-methyl-4(H)-pyran-4-one (DDMP) were investigated in a solid-state Maillard reaction system. Thermogravimetric analysis (TG) and differential scanning calorimetry analysis (DSC) showed that the solid-state Maillard reaction mainly occurred at around 150 °C. The DDMP formation from reducing sugars (glucose or fructose) and several selected amino acids (l-proline, l-alanine, l-asparagine, l-threonine, l-tyrosine and l-lysine) was compared. Proline was found to have special activity in DDMP formation when reacted with glucose because of its special catalytic action. The influences of reactant ratios, oxygen, reaction temperature and reaction time on DDMP formation from the reaction of proline with glucose were studied. Reactant molar ratios of glucose to proline played important impact on DDMP formation, and the formation of DDMP was improved when the ratio was higher than 1:1 and achieved the highest level at 2:1. Oxygen had no obvious effects on DDMP formation. The effects of reaction time and temperature were investigated together and revealed the information on the highest yield and minimum temperature for DDMP formation. Furthermore, the kinetics of DDMP formation was studied, and DDMP formation in the initial stage was shown to follow an apparent first-order reaction with an activation energy of 68.8 kJ/mol.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Maillard reaction (MR) is a nonenzymatic browning reaction between carbonyl groups of reducing sugars and amino groups from amino acids, peptides or proteins. It occurs in three major stages (early, intermediate and final stage) producing a large number of products including aroma compounds [1–3] and melanoidins [4, 5]. MR has played an important role in improving the appearance and taste of food, and the MR products have shown antioxidant capacities [6, 7], metal chelation activity [7] and biological activities [8]. On the other hand, it can also reduce the nutritive value of food and produce mutagenic compounds [5, 9].

Among the numerous MR products, 2,3-dihydro-3,5-dihydroxy-6-methyl-4(H)-pyran-4-one (DDMP) is one of the most abundant [10, 11] and is a well-known indicator of 2,3-enolization pathway in MR [12, 13]. It was found to be the major product of Maillard reaction between reducing sugars with various amino acids and proteins [11, 12, 14–16]. It can also be formed during heating of hexose [17, 18]. Therefore, it universally exists in heated foods, and some researchers proposed DDMP as a chemical marker for prediction of process lethality [19, 20]. It is also easily produced in low-water foods such as prunes [21], cookies [14, 15], popcorns [22], sweet potatoes [23] and malts [24] during the process of drying, baking and roasting. In addition, it has also been reported to be present in strawberry jam [25], cotton honey [26] and cigarette smoke [27]. In recent years, the biological activities of DDMP have garnered attention. Hiramoto et al. [28] found that DDMP could generate active oxygen species and cause DNA strand breaking and mutagenesis. On the other hand, DDMP also showed antioxidant activity [21, 29–31] and mushroom tyrosinase inhibitory activity [32]. In addition, DDMP was found to have the anti-proliferation and pro-apoptotic activity [33] and to affect sympathetic nerve activity and metabolism of rats [34].

Simple model systems using amino acid–sugar mixtures or Amadori rearrangement products are usually used to investigate the formation of browning or flavor instead of actual food samples [10, 11, 35]. Generally, these reactions can be conducted in liquid phase or solid phase. The liquid-phase models can mimic the MR occurred during cooking or autoclaving, whereas the solid-phase reactions represent the procedure conducted during drying, baking, roasting or cigarette smoking. The formation mechanism of various important MR products under both phases is the same although reaction phase influences MR on reaction time and number of generated products under comparable conditions [36]. This facilitates the analysis of formation mechanism of specific MR products. Some model systems concerning DDMP were performed. Nishibori et al. [10, 15, 16] investigated the DDMP formation from fructose with various proteins or amino acids as well as the formation mechanism of DDMP from β-alanine and fructose under conditions used for baking. The role of DDMP in MR and its degradation pathways were investigated in aqueous solution using isotopic labeling experiments [37]. Considering the universal existence and various biological activities of DDMP, it is crucial to illuminate the effects of reaction conditions on the formation of DDMP and the formation mechanism. Although some researchers have mentioned that DDMP formation was affected by some factors, a systematical investigation on the effects of various factors on DDMP generation is still required to perform. In this paper, we investigated the influences of various factors on DDMP formation from reducing monosaccharides (glucose and fructose) with amino acids (especially proline) in a solid-phase reaction system as a model of baking and cigarette smoking. The DDMP formation mechanisms as well as the effects of these factors on DDMP generation pathways were also proposed.

Materials and methods

Materials and reagents

d-glucose hydrate (C6H12O6·1H2O), d-glucose, d-fructose, l-proline (Pro), l-alanine (Ala), l-asparagine (Asn), l-threonine (Thr) and l-tyrosine (Tyr) were biological reagents. Phenylethyl acetate (internal standard), 2-furaldehyde, 2-furanmethanol, 2-acetylfuran, anhydrous sodium sulfate and the 14 hydrocarbons of C7–C20 were analytical pure. All the reagents mentioned above were purchased from J&K Scientific Ltd (Beijing, China). The solvent used in the experiment was dichloromethane (in GC grade purity) and was supplied by Tedia Company (Fairfield, USA). The proline Amadori product 1-[(2′-carboxy)pyrrolidinyl]-1-deoxy-d-fructose (Fru–Pro) was synthesized according to published procedures [38, 39].

Model reactions and sample preparations

Reducing sugar (d-glucose or d-fructose, 1 mmol) and amino acid (1 mmol) were mixed and sufficiently grinded in a mortar. The mixture or Fru–Pro (1 mmol) was placed in a test tube full of 10 % oxygen in nitrogen, and after enclosed with stopper, the compounds were heated in a heater block at 150 °C for 10 min. On cooling, 20 microgram internal standard and 20 mL dichloromethane were added to the test tube, and the sample was extracted for 15 min under ultrasonic. After dehydrated with anhydrous sodium sulfate and clarified by filtration, the extract was concentrated to 1 mL under a vacuum of 0.06 MPa. Each sample was prepared and detected at least in duplicate.

Gas chromatography–mass spectrometry (GC–MS) analysis

An HP-6890 gas chromatography coupled with HP-5975C mass spectrometer (Agilent Technologies, Wilmington, DE, USA) was used for analyses and acquisition of the electron impact mass spectra. One microliter of sample solution was injected in split mode with a ratio of 5:1. Separations were performed on a J&W HP-5MS column (60 m × 0.25 mm I.D., 0.25 μm film thickness). Ultrahigh-purity helium was used as carrier gas at a constant flow of 1.0 mL/min. Injector temperature was 240 °C. The oven temperature program was from 50 °C (5 min) to 250 °C (10 min) at 8 °C/min. The mass detector was operated in the electron impact mode with ionization energy of 70 eV and a scanning range of 35–500 a.m.u. The transfer line was maintained at 250 °C and the ion source temperature was 230 °C.

Identification and quantitation of the compounds

The volatile compounds were identified based on the comparison of mass spectra with those of NIST 08 library and authentic compounds (when available). Their linear retention indices (LRI) were calculated according to van den Dool and Kratz equation [40] using the retention times of the n-alkanes from n-heptane to n-tridecane and compared with the values from the literature or authentic compounds (when available). The identified compounds were quantified with respect to the internal standard using the total ion chromatography, assuming that the relative response factor was 1 and the recovery ratio was 100 %.

Thermogravimetric analysis (TG) and differential scanning calorimetry analysis (DSC)

The TG and DSC of the samples were performed using a thermogravimetric analyzer (Netzsch STA 449C, Netzsch Machinery and Instruments Co. Ltd., Germany) in the atmosphere of 10 % oxygen in nitrogen with a flow rate of 100 mL/min. Approximate 20 mg sample powder was put in a standard alumina crucible and heated at a heating rate of 10 °C/min, with temperature rising from 30 to 600 °C.

Statistical analysis

The results were reported as mean ± standard deviation (SD). One-way analysis of variance (ANOVA) was performed to determine the significance of differences among treatment means using IBM SPSS Statistics version 19.0 with a significance level of 0.05.

Results and discussion

Thermogravimetric analysis (TG) and differential scanning calorimetry analysis (DSC)

To gain insight into the temperature required to occur solid-state reaction, the samples (proline Amadori compound Fru–Pro and equimolar mixtures of proline–glucose, proline–glucose hydrate and proline–fructose) were investigated by TG and DSC with a heating rate of 10 °C/min. An atmosphere of 10 % oxygen in nitrogen was used to mimic the mean oxygen level throughout the pyrolysis/distillation zone inside the burning cigarette [41]. Figure 1a shows the TG, differential thermogravimetric (DTG) and DSC curves of proline–glucose mixture. In the entire temperature range, there were three mass loss regions observed in the TG curve. The first mass change region was from 110 to 220 °C with a mass loss of 37.3 %, corresponding to the peak at 155 °C in DTG plot and an endothermic peak in the DSC curve. This indicated that solid-state reactions had occurred because proline and glucose would not sublime in this temperature region [39]. The second region with constant mass loss occurred between 220 and 440 °C (14.4 %). The last region was from 440 to 600 °C (25.5 %) with a peak at 536 °C in DTG curve. Carbonization and combustion might have occurred in this region because a strong exothermic peak was observed in the DSC plot [42]. A different TG curve of 1:1 (by weight) mixture of proline and glucose under argon at heating rate of 10 °C/min was obtained by Britt and Buchanan et al. [39]. This might imply that the atmosphere plays an important impact on the mass loss of the sample. The proline–glucose hydrate (Fig. 1b) and proline–fructose (Fig. 1c) mixtures and Fru–Pro (Fig. 1d) produced similar TG, DTG and DSC curves with that of proline–glucose mixture. However, a new small mass loss region was observed in low temperature (55–90 °C) for the mixture of glucose hydrate and proline (Fig. 1b). This might mainly ascribe to the loss of crystal water in glucose hydrate. Similar mass loss region (65–100 °C) was found for Fru–Pro (Fig. 1d). This region was also observed for Fru-Pro under argon and attributed to water loss [39]. Furthermore, another mass loss region between 380 and 460 °C was detected for the mixture of fructose and proline, and an unobvious endothermic peak was observed from DSC plot in this region (Fig. 1c). Component sublimation or decomposition seemed to have taken place in this region. The TG and DSC results indicated that the proline-reducing sugar mixtures and Fru–Pro all underwent solid-state reactions at about 150 °C. Therefore, the model reactions were conducted at this temperature.

Identification of the compounds in the reaction of glucose or fructose with proline

Equimolar mixtures (1 mmol) of fructose or glucose with proline were heated at 150 °C for 10 min. The volatile compounds from the reaction mixtures were extracted with dichloromethane and analyzed with GC/MS. Seven volatile components including 5 furans and 2 pyrans were identified (Online Resource 1). They have been reported as MR products [36, 43, 44]. DDMP was the major component among them. 4-Hydroxy-2,5-dimethyl-3(2H)-furanone (HDMF) was reported as an important odorant generated from the MR model of glucose and proline [38, 45]. Nishibori and Bernhard [10] also found that HDMF was produced in the reactions of fructose and glucose with β-alanine under dry-heated conditions, which was similar with the system used in our study. Furthermore, no free carbohydrate degradation products were detected from the glucose/fructose–proline mixtures, and this indicated the high efficiency of Maillard reaction under present conditions.

Influences of amino acids on the formation of DDMP

2,3-Dihydro-3,5-dihydroxy-6-methyl-4(H)-pyran-4-one (DDMP) can be generated from the reaction of reducing sugar with various amino acids [15]. Proline (Pro), asparagine (Asn), alanine (Ala), tyrosine (Tyr) and threonine (Thr) were chosen in this work because they are the most abundant in flue-cured tobacco leaves [46–48]. Lysine (Lys) was also taken into account in that it is an essential amino acid and sensitive to food processing. The amounts of DDMP generated from these amino acids and two reducing sugars (glucose and fructose) were measured, and the results are shown in Fig. 2. DDMP was hardly produced from the mixtures of tyrosine with glucose and fructose. Similar results were also observed in the model of baking cookies [15] and in liquid-phase models [49, 50]. More Tyr-specific products, such as phenols and aromatic compounds, were generated in the Tyr-glucose/fructose system. Furthermore, Tyr was also reported browning more intensively than other amino acids studied here when reacted with glucose and fructose [35, 51]. Major DDMP was generated from the reaction of alanine and proline with glucose and fructose. The generation amount of DDMP from fructose was higher than that from glucose when they reacted with asparagine, alanine, lysine and threonine, respectively. Some researchers found that fructose was more effective than glucose in the formation of DDMP under conditions used for baking [15, 16]. Fructose was reported more reactive with amino acids than glucose in MR [8]. It reacted faster than glucose in Maillard browning reactions and in the initial stage of MR [52]. These differences may mainly result from their different carbonyl groups: the presence of an aldehydic group in glucose in comparison with fructose containing a keto group. Furthermore, fructose exists to a greater extent in open-chain form than glucose does, which facilitates the reaction between carbonyl groups of reducing sugars and amino groups from amino acids or proteins [52]. However, we found that the formation amount of DDMP from glucose–proline was higher than that from fructose–proline, and this implied that glucose showed higher reactivity with proline than fructose. To confirm the high reactivity of glucose with proline, DDMP formation from the equimolar mixtures of glucose–proline and fructose–proline heated at 150 °C for 2–10 min was compared (data were not shown). The highest DDMP yield was achieved faster/earlier from the glucose–proline mixture (8 min) compared with the fructose–proline mixture (10 min). The special reactivity of proline with glucose is due to its special structure. Some amino acids can catalyze aldol reaction [53], and the reactivity for aldol catalysis is similar to that of MR [54]. As a cyclic secondary amino acid with 5-membered ring, proline is a more effective catalyst compared to primary amino acids and noncyclic secondary amino acids, and the five-membered pyrrolidine ring is the most reactive for the secondary cyclic amine moiety [53–55]. The reactivity of proline for aldol reaction as well as MR with glucose was enhanced by its molecular structure. A detailed explanation on the high reactivity of proline with glucose in MR can be found in the literature [54].

An obvious difference in DDMP formation amount was observed between glucose and glucose hydrate when reacted with proline. Yeo and Shibamoto reported that moisture content had a significant impact on the amount of volatiles (including DDMP) in l-cysteine/d-glucose model system [56]. We found that DDMP generation amount was also affected by the crystal water in glucose for glucose–proline mixtures. Water may have multiple impacts on MR. The reactants are more concentrated in a lower water activity, and this results in an increase in reaction rate. However, the system diffusion also becomes increasingly difficult with lower water activity, the reactants meet each other harder, and the reaction rate decreases. Apart from that, water participates also in the reaction itself, for instance when the glycosylamine is rearranged to the Amadori product (Fig. 4). Furthermore, water may affect the existing state of the reactants, intermediates and products which may further influence the reaction rate and pathway. Amino acids and amines are more effective for catalyzing aldol reactions under nonaqueous conditions where the amine functionality can be maintained in its reactive unprotonated state [55]. The influence of water on DDMP formation actually reflected the comprehensive result of several specific effects.

Further investigation based on the proline–glucose system was performed because proline was one of the most important and abundant amino acids in flue-cured tobacco leaves and effective in DDMP formation.

Effects of reactant ratios and oxygen concentration on DDMP formation from Fru–Pro and proline–glucose mixtures

Equal amount (by weight or by mole) of reducing sugars and amino acids is usually used in the model system concerning DDMP formation [10, 16, 57]. However, the reactant ratios between reducing sugars and amino acids in real samples (such as tobacco leaves and foods) vary dramatically. In order to study the effect of reactant ratio on DDMP generation, the mixtures with different mole ratios of glucose to proline were prepared and heated at 150 °C for 10 min. The results are shown in Fig. 3. The DDMP formation efficiency was higher when glucose was excess and achieved the highest level at the ratio of 2:1. Glucose was reported to be consumed faster than amino acids in MR [58]. Van Boekel and Martins ascribed this to the isomerization of glucose to fructose and the regeneration of amino acid from the initial condensed intermediates (such as Amadori product) [59]. Glucose and fructose were found to isomerize into one another via the Lobry de Bruyn-Alberda van Ekenstein transformation with 1,2-enediol anion as the key intermediate [60, 61], and this reaction was more apparent in higher temperature [58]. It seems that this transformation easily takes place taking into account of the high temperature used in the present study. Figure 4 shows the possible formation pathway of the early Maillard intermediates and some volatile compounds [16, 38, 62]. The N-glucosylproline is formed by condensation of glucose and proline, and it then loses water to form the Schiff base. The Schiff base can tautomerize to form the enamine which then leads to the formation of the Amadori compound 1-[(2′-carboxy)pyrrolidinyl]-1-deoxy-d-fructose (Fru–Pro). The subsequent degradation of Fru–Pro basically follows two main decomposition pathways. One is 1,2-enolization producing 3-deoxyhexosulose with HMF as a characteristic degradation product; the other one is 2,3-enolization leading to 1-deoxy-2,3-hexodiulose with DDMP and HDMF as typical reaction products. Meanwhile, proline was released during the degradation of Fru–Pro through enolization. Proline acts to a certain extent as a catalyst in the reaction from proline–sugar mixtures to the formation of deoxyosones [59]. Furthermore, the main product formed from the pyrolysis of proline alone was a cyclic diamide (proline dimer) [11], and this compound was found and identified by comparison with the mass spectrum from the literature [63]. Figure 5 shows the chromatograms of proline–glucose mixtures with different reactant ratios heated at 150 °C for 10 min. No free glucose pyrolysis products were detected. The peak of proline dimer was the most intense for the 1:1 mixture of proline and glucose. The formation of proline dimer was inhibited with excess glucose, and DDMP formation was enhanced; meanwhile, opposite results were obtained when the ratio of glucose to proline was lower than 1:1. This indicated that the efficiency of Maillard reaction was improved, and secondary reaction such as proline pyrolysis reaction was suppressed with excessive glucose under present conditions.

In order to investigate the effect of oxygen on DDMP formation, the glucose–proline mixture with a ratio of 1:1 and Fru–Pro were heated at 150 °C for 10 min under 0, 5, 10 and 20 % oxygen in nitrogen, respectively. The 20 % oxygen in nitrogen was used to represent the air. The results are shown in Fig. 6. The DDMP generation amounts were not significantly affected by oxygen concentration. Oxygen is a potent catalyst of MR between glucose and proline under physiological conditions [64] and may be involved in Maillard browning reactions [65, 66]. However, the formation of DDMP was not significantly affected by oxygen in our study, this might imply that the reactants were not susceptible to oxidative decomposition, and oxygen was not involved in the formation of DDMP under present conditions.

DDMP was produced more efficiently from proline–glucose mixture than from Fru–Pro (Fig. 6). Huyghues-Despointes et al. [11] ascribed this to the ability of glucose alone to produce DDMP. However, Nishibori and Kawakishi [15] stated that no DDMP was observed in the pyrolysis products of glucose. More secondary reactions may have occurred for Fru–Pro relative to the mixture. Some pyrrolidine derivatives and maltoxazine were produced more efficiently from Fru–Pro than from the mixture under pyrolysis conditions [11]. The Amadori products were also found browning more intensively than their precursor mixtures [65]. The reaction products of Fru–Pro and the mixtures were basically the same, but their amounts and relative ratios varied obviously; similar results were also observed in somewhere else [11].

Effects of temperature and time on DDMP formation from proline–glucose mixture and kinetic study of DDMP generation

DDMP was reported to produce the most efficiently at 150 °C heated for 10 min [16], and this was consistent with the TG results in our study and indicated that the mass loss of the stage around 150 °C mainly arose from the formation of volatile compounds such as DDMP and HDMF. However, the effects of temperature and time should be investigated together because the reaction goes faster at higher temperature, so that the time needed to reach the highest DDMP formation level is shorter. Figure 7 shows the DDMP formation from glucose–proline mixture with a reactant ratio of 2:1 at 100, 120, 150 and 200 °C. The formation amount of DDMP increased with time at first and then decreased slowly after the peak was achieved. This indicated that DDMP might lose during reaction due to degradation or oxidation because it was thermal instable under pyrolysis conditions [11, 12]. The main degradation products of DDMP after roasting were 5-hydroxymaltol, 2,4-dihydroxy-2,5-dimethyl-3(2H)-furanone (acetylformoin) and maltol [37]. A good correlation between DDMP and 5-hydroxymaltol or acetylformoin was observed in our study, and this supported the parent daughter relationship between the compounds. DDMP was found to accumulate with time in aqueous-phase model [20]. The reason might be that the investigated time was not long enough to reach the peak because Maillard reaction in liquid phase is much slower than its solid-phase counterpart [36]. The time at which DDMP began to be detected was defined here as induction period, and the time when the highest DDMP amount was achieved was referred to as peak time. They were found to be temperature dependent: the higher the temperature, the shorter the induction period and the peak time. Furthermore, the peak value was found to increase with rising temperature and reached the highest level at 150 °C. No significant difference was observed between the peak value at 150 °C and that at 200 °C. This suggested that there might be a plateau in a certain temperature range for the plot of peak value versus temperature. There should also be a minimum temperature for the generation of DDMP according to the influence of temperature on the peak value. We found that it was about 80 °C because little DDMP was detected at this temperature heated as long as 24 h.

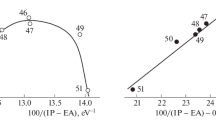

The kinetics study for DDMP formation was performed to better understand and predict DDMP formation, and the simple kinetic model was chosen. As shown in Fig. 7, an exponential relationship was observed from the plots of the formation amount of DDMP versus time, and this indicated that the formation of DDMP in the initial stage of the reaction followed obviously first-order kinetics:

where n 0 is the initial amount of DDMP, k is the reaction rate constant, and t is time. DDMP formation in aqueous solution was also reported to follow first-order kinetics [20]. The rate constants were determined through fitting of DDMP amount against time. They were calculated as 0.025, 0.095, 0.939 and 2.37 μmol/min for temperatures 100, 120, 150 and 200 °C, respectively. The temperature dependence of the rate constant is often expressed by the Arrhenius equation:

where k is the apparent first-order rate constant (μmol/min), A 0 is a pre-exponential constant, T is temperature (Kelvin), E a is activation energy (kJ/mol), and R is the universal gas constant (8.314 J/K mol). The activation energy and lnA 0 were determined by linear fit of lnk against 1/T:

This equation enables us to obtain the rate constant at any temperature between 100 and 200 °C for the solid-phase reaction of glucose–proline mixture. We can also calculate the amount of DDMP formation in the initial stage at temperatures 100, 120, 150 and 200 °C using Eqs. 1 and 3. The activation energy of DDMP formation was calculated as 68.8 kJ/mol. It was much lower than the activation energy of DDMP formation (122 kJ/mol) from the equimolar mixture of d-glucose, d-ribose and l-glutamic acid monosodium salt in aqueous model [20], which means that DDMP was easier to produce from the solid mixture of glucose and proline. The present kinetic analysis was performed under specific experiment conditions, some factors such as water activity and reactant ratios could affect the kinetics, and further research still needed to perform to elucidate the influence of these factors on the kinetics of DDMP formation.

Conclusion

The effects of various factors on DDMP formation were investigated in dry-heated MR model system in our study. The Fru-Pro and mixtures of reducing sugar with proline produced similar TG and DSC curves, and all underwent solid-state reaction around 150 °C. Fructose was more effective in DDMP formation than glucose when reacted with amino acids except proline. Proline was a potent catalyst for aldol reaction, and for this reason, it enhanced the reactivity of glucose. Oxygen concentration had no obvious effects on DDMP formation. DDMP formation was favored when reducing sugar was excess, and its optimal proportion was the sugar–proline molar ratio at 2:1. DDMP yield in reaction increased with time at first and then decreased slowly after the peak was achieved. The peak value increased as rising temperature and then seemed to reach a plateau. Furthermore, the kinetics study provided us valuable information that can help us to better understand and predict the formation of DDMP. Although the present work was performed under model conditions, it could facilitate us to better understand the formation of DDMP under conditions such as drying, baking and cigarette smoking.

References

Weenen H (1998) Reactive intermediates and carbohydrate fragmentation in Maillard chemistry. Food Chem 62:393–401

van Boekel MAJS (2006) Formation of flavour compounds in the Maillard reaction. Biotechnol Adv 24:230–233

Fors S (1983) Sensory properties of volatile Maillard reaction products and related compounds. In: The Maillard reaction in foods and nutrition, ACS Symposium Series 215: 185–286

Lamberts L, Rombouts I, Delcour JA (2008) Study of nonenzymic browning in α-amino acid and γ-aminobutyric acid/sugar model systems. Food Chem 111:738–744

Martins SIFS, Jongen WMF, van Boekel MAJS (2001) A review of Maillard reaction in food and implications to kinetic modelling. Trends Food Sci Technol 11:364–373

Gu F, Kim JM, Hayat K, Xia S, Feng B, Zhang X (2009) Characteristics and antioxidant activity of ultrafiltrated Maillard reaction products from a casein–glucose model system. Food Chem 117:48–54

Maillard MN, Billaud C, Chow YN, Ordonaud C, Nicolas J (2007) Free radical scavenging, inhibition of polyphenoloxidase activity and copper chelating properties of model Maillard systems. LWT Food Sci Technol 40:1434–1444

Hwang IG, Kim HY, Woo KS, Lee J, Jeong HS (2011) Biological activities of Maillard reaction products (MRPs) in a sugar–amino acid model system. Food Chem 126:221–227

Brands CMJ, Alink GM, van Boekel MAJS, Jongen WMF (2000) Mutagenicity of heated sugar–casein systems: effect of the Maillard reaction. J Agric Food Chem 48:2271–2275

Nishibori S, Bernhard RA (1993) Model system for cookies: volatile components formed from the reaction of sugar and β-alanine. J Agric Food Chem 41:2374–2377

Huyghues-Despointes A, Yaylayan VA, Keyhani A (1994) Pyrolysis/GC/MS analysis of 1-[(2′-carboxyl)pyrrolidinyl]-1-deoxy-d-fructose (proline Amadori compound). J Agric Food Chem 42:2519–2524

Yaylayan VA, Mandeville S (1994) Mechanistic pathway for the formation of maltoxazine from intact 1-[(2′-carboxyl)pyrrolidinyl]-1-deoxy-d-fructose (Amadori–Proline). J Agric Food Chem 42:1841–1844

Davidek T, Clety N, Devaud S, Robert F, Blank I (2003) Simultaneous quantitative analysis of Maillard reaction precursors and products by high-performance anion exchange chromatography. J Agric Food Chem 51:7259–7265

Nishibori S, Kawakishi S (1992) Effect of various sugars on the quality of baked cookies. Cereal Chem 69:160–163

Nishibori S, Kawakishi S (1990) Effects of dough materials on flavor formation in baked cookies. J Food Sci 55:409–412

Nishibori S, Kawakishi S (1994) Formation of 2,3-dihydro-3,5-dihydroxy-6-methyl-4(H)-pyran-4-one from fructose and β-alanine under conditions used for baking. J Agric Food Chem 42:1080–1084

Shaw PE, Tatum JH, Berry RE (1971) 2,3-Dihydro-3,5-dihydroxy-6-methyl-4H-pyran-4-one, a degradation product of a hexose. Carbohydr Res 16:207–211

Ledl F, Schnell W, Severin T (1976) Nachweis von 2,3-dihydro-3,5-dihydroxy-6-methyl-4H-pyran-4-on in Lebensmitteln. Z Lebensm Unters Forch 160:367–370

Kim HJ, Choi YM, Yang APP, Yang TCS, Taub IA, Giles J, Ditusa C, Chall S, Zoltai P (1996) Microbiological and chemical investigation of ohmic heating of particulate foods using a 5 kW ohmic system. J Food Process Preserv 20:41–58

Wnorowski A, Yaylayan VA (2002) Prediction of process lethality through measurement of Maillard-generated chemical markers. J Food Sci 67:2149–2152

Čechovská L, Cejpek K, Konečný M, Velíšek J (2011) On the role of 2,3-dihydro-3,5-dihydroxy-6-methyl-(4H)-pyran-4-one in antioxidant capacity of prunes. Eur Food Res Technol 233:367–376

Buttery RG, Ling LC, Stern DJ (1997) Studies on popcorn aroma and flavor volatiles. J Agric Food Chem 45:837–843

Sun J-B, Severson RF, Kays SJ (1993) Quantitative technique for measuring volatile components of baked sweet potatoes. Hort Sci 28:1110–1113

Čechovská L, Konečný M, Velíšek J, Cejpek K (2012) Effect of Maillard reaction on reducing power of malts and beers. Czech J Food Sci 30:548–556

Barron D, Etiévant PX (1990) The volatile constituents of strawberry jam. Z Lebensm Unters Forch 191:279–285

Alissandrakis E, Kibaris AC, Tarantilis PA, Harizanis PC, Polissiou M (2005) Flavour compounds of Greek cotton honey. J Sci Food Agric 85:1444–1452

Green CR (1977) Neutral oxygenated compounds in cigarette smoke and their possible precursors. Rec Adv Tob Sci 3:94–120. http://legacy.library.ucsf.edu/tid/ift68d00/pdf. Accessed 18 July 2013

Hiramoto K, Nasuhara A, Michikoshi K, Kato T, Kikugawa K (1997) DNA strand-breaking activity and mutagenicity of 2,3-dihydro-3,5-dihydroxy-6-methyl-4H-pyran-4-one (DDMP), a Maillard reaction product of glucose and glycine. Mutat Res 395:47–56

Yoshiki Y, Okubo K (1995) Active oxygen scavenging activity of DDMP (2,3-dihydro-2, 5-dihydroxy-6-methyl-4H-pyran-4-one) saponin in soybean seed. Biosci Biotechnol Biochem 59:1556–1557

Yu X, Zhao M, Liu F, Zeng S, Hu J (2013) Identification of 2,3-dihydro-3,5-dihydroxy-6-methyl-4H-pyran-4-one as a strong antioxidant in glucose-histidine Maillard reaction products. Food Res Int 51:397–403

Shibamoto YOT (2006) Antioxidative activity of volatile extracts from Maillard model systems. Food Chem 98:522–528

Takara K, Otsuka K, Wada K, Iwasaki H, Yamashita M (2007) 1,1-Diphenyl-2-picrylhydrazyl radical scavenging activity and tyrosinase inhibitory effects of constituents of sugarcane molasses. Biosci Biotechnol Biochem 71:183–191

Ban J, Hwang I, Kim T, Hwang B, Lee U, Jeong H-S, Yoon Y, Kim D, Hong J (2007) Anti-proliferate and pro-apoptotic effects of 2,3-dihydro-3,5-dihydroxy-6-methyl-4H-pyranone through inactivation of NF-κB in human colon cancer cells. Arch Pharm Res 30:1455–1463

Beppu Y, Komura H, Izumo T, Horii Y, Shen J, Tanida M, Nakashima T, Tsuruoka N, Nagai K (2012) Identification of 2,3-dihydro-3,5-dihydroxy-6-methyl-4H-pyran-4-one isolated from Lactobacillus pentosus strain S-PT84 culture supernatants as a compound that stimulates autonomic nerve activities in rats. J Agric Food Chem 60:11044–11049

Ashoor SH, Zent JB (1984) Maillard browning of common amino acids and sugars. J Food Sci 49:1206–1207

Wnorowski A, Yaylayan VA (2000) Influence of pyrolytic and aqueous-phase reactions on the mechanism of formation of Maillard products. J Agric Food Chem 48:3549–3554

Kim MO, Baltes W (1996) On the role of 2,3-dihydro-3,5-dihydroxy-6-methyl-4(H)-pyran-4-one in the Maillard reaction. J Agric Food Chem 44:282–289

Blank I, Devaud S, Matthey-Doret W, Robert F (2003) Formation of odorants in Maillard model systems based on l-proline as affected by pH. J Agric Food Chem 51:3643–3650

Britt PF, Buchanan AC, Owens CV Jr, Todd Skeen J (2004) Does glucose enhance the formation of nitrogen containing polycyclic aromatic compounds and polycyclic aromatic hydrocarbons in the pyrolysis of proline? Fuel 83:1417–1432

van Den Dool H, Dec Kratz P (1963) A generalization of the retention index system including linear temperature programmed gas–liquid partition chromatography. J Chromatogr A 11:463–471

Baker RR, Bishop LJ (2004) The pyrolysis of tobacco ingredients. J Anal Appl Pyrolysis 71:223–311

Wang W, Wang Y, Yang L, Liu B, Lan M, Sun W (2005) Studies on thermal behavior of reconstituted tobacco sheet. Thermochimi Acta 437:7–11

Mills FD, Hodge JE (1976) Amadori compounds: vacuum thermolysis of 1-deoxy-1-l-prolino-d-fructose. Carbohydr Res 51:9–21

Umano K, Hagi Y, Nakahara K, Shyoji A, Shibamoto T (1995) Volatile chemicals formed in the headspace of a heated d-glucose/l-cysteine Maillard model system. J Agric Food Chem 43:2212–2218

Blank I, Devaud S, Matthey-Doret W, Pollien P, Robert F, Yeretzian C (2003) Formation of odour-active compounds in Maillard model systems based on proline. Flavour Research at the Dawn of the Twenty-First Century: 458–463

Leffingwell JC (1976) Nitrogen components of leaf and their relationship to smoking quality and aroma. Rec Adv Tob Sci 2:1–31

Yang SS, Smetena I (1993) Determination of free amino acids in tobacco by HPLC with fluorescence detection and precolumn derivatization. Chromatographia 37:593–598

Ali H, Pätzold R, Brückner H (2006) Determination of l- and d-amino acids in smokeless tobacco products and tobacco. Food Chem 99:803–812

Yu XY, Zhao MY, Hu J, Zeng ST, Bai XL (2012) Influence of pH on the formation and radical scavenging activity of volatile compounds produced by heating glucose with histidine/tyrosine. Eur Food Res Technol 234(2):333–343

Yu X, Zhao M, Hu J, Zeng S (2012) Formation and antioxidant activity of volatile compounds produced by heating glucose with tyrosine/histidine in water–ethanol and water–glycerol media. Food Chem 133(4):1394–1401

Yu X, Zhao M, Hu J, Zeng S, Bai X (2012) Correspondence analysis of antioxidant activity and UV–vis absorbance of Maillard reaction products as related to reactants. LWT—Food Sci Technol 46(1):1–9

Dills WL (1993) Protein fructosylation: fructose and the Maillard reaction. Am J of Clin Nutr 58:779S–787S

List B, Lerner RA, Barbas CF (2000) Proline-catalyzed direct asymmetric aldol reactions. J Am Chem Soc 122:2395–2396

Moens L, Evans RJ, Looker MJ, Nimlos MR (2004) A comparison of the Maillard reactivity of proline to other amino acids using pyrolysis-molecular beam mass spectrometry. Fuel 83:1433–1443

Sakthivel K, Notz W, Bui T, Barbas CF (2001) Amino acid catalyzed direct asymmetric aldol reactions: a bioorganic approach to catalytic asymmetric carbon–carbon bond-forming reactions. J Am Chem Soc 123:5260–5267

Yeo H, Shibamoto T (1991) Effects of moisture content on the Maillard browning model system upon microwave irradiation. J Agric Food Chem 39:1860–1862

Yaylayan VA, Mandeville S (1994) Stereochemical control of maltol formation in Maillard reaction. J Agric Food Chem 42:771–775

Martins SIFS, Van Boekel MAJS (2005) A kinetic model for the glucose/glycine Maillard reaction pathways. Food Chem 90:257–269

Van Boekel MAJS, Martins SIFS (2002) Fate of glycine in the glucose–glycine reaction: a kinetic analysis. Int Congr Ser 1245:289–293

Angyal SJ (2001) The Lobry de Bruyn-Alberda van Ekenstein Transformation and related reactions. In: Stütz A (ed) Glycoscience: topics in current chemistry, vol 215. Springer, Berlin, pp 1–14

Brands CMJ, van Boekel MAJS (2001) Reactions of monosaccharides during heating of sugar–casein systems: building of a reaction network model. J Agric Food Chem 49:4667–4675

Ledl F, Schleicher E (1990) New aspects of the Maillard reaction in foods and in the human body. Angew Chem Int Ed Engl 29:565–594

Chiavari G, Galletti GC (1992) Pyrolysis—gas chromatography/mass spectrometry of amino acids. J Anal Appl Pyrolysis 24:123–137

Litchfield JE, Thorpe SR, Baynes JW (1999) Oxygen is not required for the browning and crosslinking of protein by pentoses: relevance to Maillard reactions in vivo. Int J Biochem Cell Biol 31:1297–1305

Pilková L, Pokorný J, Davídek J (1990) Browning reactions of Heyns rearrangement products. Die Nahrung 34:759–764

Friedman M (1996) Food browning and its prevention: an overview. J Agric Food Chem 44:631–653

Acknowledgments

The authors are grateful for the financial support provided by the Scientific Foundation of China National Tobacco Corporation (No. 110200901002), China Tobacco Anhui Industrial Corporation and Shandong Rebirth Tobacco Company Limited.

Conflict of interest

None.

Compliance with Ethics Requirements

This article does not contain any studies with human or animal subjects.

Author information

Authors and Affiliations

Corresponding author

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Zhou, Z., Xu, Z., Shu, J. et al. Influence of various factors on formation of 2,3-dihydro-3,5-dihydroxy-6-methyl-4(H)-pyran-4-one (DDMP) in a solid-state model system of Maillard reaction. Eur Food Res Technol 239, 31–40 (2014). https://doi.org/10.1007/s00217-014-2191-2

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00217-014-2191-2