Abstract

A new, rapid, and inexpensive method using two-step ultrasonic assisted liquid–liquid micro-extraction (UALLME) coupled with capillary electrophoresis-ultraviolet (CE-UV) was developed for 5-hydroxymethylfurfural (HMF) analysis in high ion strength samples (like vinegar and soy sauce). The factors affecting the extraction efficiency were optimized such as the extraction volume, the ultrasonic time, and the power density of ultrasonic. Under the optimum conditions, the limit of detection (LOD) and the limit of quantification (LOQ) for HMF were 0.03 and 0.10 mg/L, respectively. The relative standard deviations (RSD %) for HMF were ranging from 0.53 to 3.17%, and the recoveries of HMF were ranging from 91.24 to 109.39%. The results turned out that two-step UALLME-CE-UV was applicable to analyze HMF in vinegar and soy sauce. Eleven brands of vinegar and soy sauce were tested by two-step UALLME-CE-UV, and the results showed that the method had a potential application in analysis of foodstuffs. The two step UALLME method was effective to improve the selectivity and sensitivity of CE-UV method for HMF analysis in vinegar and soy sauce.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Vinegar and soy sauce were important food additives which effectively improved the flavor and color quality of food products (Kim et al. 2004; Tesfaye et al. 2002). A great number of vinegar and soy sauce were consumed in daily life of Asian countries such as China and Japanese. Usually, the colorants like caramel color were added into the vinegar and soy sauce to improve the color quality (Theobald et al. 1998; Stute et al. 2002). However, the addition of caramel color in vinegar and soy sauce induced the presence of 5-hydroxymethylfurfural (HMF), which was a potential carcinogenic substance (Abraham et al. 2011) and may have a negative influence on gene. In addition, HMF may be produced during the process of vinegar and soy sauce microbiological fermentation or chemical synthesis and storage (Theobald et al. 1998). However, there were little report about HMF in soy sauce and vinegar. Therefore, it is necessary to analyze the content of HMF in vinegar and soy sauce.

Up to now, lots of methods were used to analyze HMF in honey, fruit juices, coffee, wine, and so on (Andrade et al. 2016). The analytical methodology involved high-performance liquid chromatography (HPLC) coupled with a diode array detector (DAD) (Abu-Bakar et al. 2014; Rovira et al. 1993) or mass spectrum (MS) detector (Takino et al. 2003) and gas chromatography (GC) (Gaspar and Lopes et al. 2009). Although the use of chromatography methods (like GC or HPLC) for HMF analysis was accurate and stable, the operation cost of chromatography methods was the main concern including the consumption of analytical column, solvent, and sample clean-up supply. A few years ago, the relatively economic method was developed for HMF analysis in honey sample on the basis of micellar electro kinetic capillary chromatography technique (MEKC) (Teixidó et al. 2011). The previous studies indicated that CE involved low solvent consumption and offered high separation efficiency (Acunha et al. 2016), being an alternative to HPLC in the analysis of residues in different fields (Tejada-Casado et al. 2016). Nevertheless, the separation of HMF on CE system was readily interfered by the complex matrix with high ion strength like acid and salt in food samples (such as vinegar and soy sauce). Thus, the sample pretreatment process is necessary prior to the CE analysis for high ion strength food samples, especially for vinegar and soy sauce samples.

Generally, solid phase extraction (SPE) and liquid–liquid extraction (LLE) were applied to eliminate the ionic compounds from samples. However, both of the cleanup methods were time-consuming or solvent-consuming. Especially, SPE was relatively expensive, and the low enrichment factors were obtained without solvent evaporation. In recent years, the miniaturization extraction technique has been developed as rapid sample pretreatment methods like solid phase micro-extraction (SPME) and liquid–liquid micro-extraction (LLME). Because of the limited amount of solid absorbent in expensive SPME, LLME as a promising pretreatment method was inexpensive and environmentally friendly. In addition, the diversified operation modes were developed for LLME application such as single-drop micro-extraction (SDME) that could be achieved on-line injection (ALOthman et al. 2012), dispersive liquid–liquid micro-extraction(DLLME) (Chandrasekaran et al. 2011), and hollow fiber–liquid phase micro-extraction (HF-LPME) (María Ramos Payán et al. 2009). Furthermore, kinds of assisted energy fields like vortex (Yiantzi et al. 2010), ultrasonic (Sereshti et al. 2011), and microwave (Ahmadi-Jouibari and Fattahi 2015) were attempted to be introduced into LLME for improving the extraction efficiency. Unfortunately, the organic phase from LLME was not compatible with direct CE analysis. Though a solvent evaporation after LLME was suitable to avoid the organic solvent interference in CE analysis, the operation duration including vacuum evaporation and aqueous redissolution was time-consuming and tedious. Using the aqueous phase to back extract, the organic phase after LLME could be an applicable and handy technique for CE determination HMF.

In order to detect HMF in high ionic strength samples like vinegar and soy sauce, the two-step ultrasonic assisted liquid–liquid micro-extraction was applied to reduce the ionic effecting on the analysis of HMF by capillary electrophoresis-ultraviolet (CE-UV). In this study, the optimization of experimental parameters for the second step UALLME was carried out, and the method performances were evaluated carefully.

Materials and Methods

Chemicals and Solutions

HMF was purchased from Sigma-Aldrich (St. Louis, MO, U.S.A). Trichloromethane (CHCl3), sodium hydroxide, acetic acid, and hydrochloric acid of analytical grade were provided by Sigma-Aldrich (St. Louis, MO, USA). All vinegar and soy sauce were bought from a local supermarket in Da-Lian city of Liaoning province, PR China. Deionized water was used in the whole experiment.

HCl of 1 M and 0.1 M NaOH were prepared for CE, and 1% of acetic acid solution was used else. All solutions were filtered by inorganic membrane (0.22 μm). Stock solution of HMF (2000 mg/L) was prepared in acetic acid solution, stored at 4 °C until analysis.

UALLME Procedure

The process of two-step UALLME was carried out as follows. First, the vinegar or soy sauce was diluted in deionized water (1:4, v/v), then added 500 μL CHCl3 (accepted phase) to extract the analyte under the ultrasonic condition. In the first step of UALLME, the optimal condition was carried out as follows: the ultrasonic extractor (SCIENTZ-II D, Shenyang, China) was applied, and the ultrasonic power density was 168 W/cm2 at 12 °C (the temperature was maintained by a circulating water bath) for 4 min. In the second step of UALLME, 150-μL accepted phases containing HMF were added into acetic acid solution (aqueous phase) and extracted by the UALLME method. The aqueous phase (30 μL) could be directly analyzed using CE-UV.

CE-UV Analysis of HMF

The CESI 8000 Plus provided by BECKMAN COULTER (USA) coupled with UV was used for the separation and determination of HMF. The capillary was coated with silica-tubing (50 cm effective length, 75 μm i.d., 375 μm o.d.). The new capillary was conditioned by rinsing with 1 M HCl (5 min), followed by deionized water (2 min) and 0.1 M NaOH (10 min), then by deionized water (2 min) and 10% acetic acid (5 min). The whole process of condition was operated under 20 psi at 25 °C (forward). The sample injection time, injection press, and separation voltage were 10 s, 5 psi, and 25 kV, respectively. The detection wavelength was set at 280 nm. The capillary was rinsed by 0.1 M NaOH (5 min), water (2 min), and 10% acetic acid (5 min) under 20 psi at 25 °C. Sample was injected to the instrument with a 10-μL loop.

Statistical Analysis

Mean and standard deviation of the data were calculated for each treatment. Analysis of variance was carried out to determine any significant differences (p < 0.05) among the applied treatments by the SPSS software package (SPSS 10.0 for Windows).

Results and Discussion

Optimization of UALLLME Conditions

In this study, the two-step UALLME method was applied in eliminating the ionic compounds from vinegar and soy sauce for compatibility CE analysis. The high density organic solvent including CHCl3, CCl4, and CS2 was selected as the extractant screened through the property of solvent like density, vapor pressure, boiling point, and solubility in aqueous solution. Unlike the dispersive liquid–liquid micro-extraction method, the disperse solvent was absent under UALLME operation due to a micro-drop formation during ultrasonic cavitation (Tadeo et al. 2010). In our previous study, the excellent extraction efficiency for HMF in the first step of UALLME could be obtained by using CHCl3 as extractant (Ting-Ting et al. 2017). Meanwhile, the optimum conditions (the power density of ultrasound: 168 W/cm2, volume ratio of sample to extraction solvent: 25:1, ultrasound time: 4 min) at room temperature were applicable for extracting HMF into organic solvent.

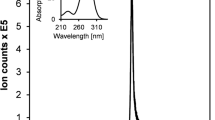

The optimization of the back extraction of HMF into aqueous solution by UALLME method based on CHCl3 solvent was studied at 24-mg/L HMF standard solutions. The extracted organic solution (150 μL) was further extracted by the 10% acetic acid solution. As shown in Fig. 1, the extraction parameters including the aqueous phase volume (extraction volume), the power density of ultrasonic, and extraction time significantly affected the extraction efficiency. For example, the increase of back extraction solvent (10% acetic acid solution) volume was performed from 20 to 50 μL; the back-extracted HMF level was increased at 30 μL back extraction solvent but lowered at 50 μL back extraction solvent. In addition, the power density of ultrasonic was very important to obtain an excellent back-extraction of HMF. In this study, the power density of ultrasonic including 0.14, 0.17, and 0.21 W/cm2 was applied to improve the back-extraction efficiency. Obviously, the 0.17 W/cm2 of ultrasonic power density was suitable for HMF back extraction, while a higher ultrasonic power density like 0.21 W/cm2 decreased the level of HMF back extraction. The result indicated that the increase of HMF back-extraction could be induced by the increase of the miscibility between water and organic solvent by ultrasonic cavitation, while the too high intensity of ultrasound could increase the miscibility between water and organic solvent and induce the decrease of HMF back-extraction.

Optimum condition of the second extraction step: extraction volume (the experiment parameters of extraction volume were 20, 30, and 50 μL, the organic accepted phase volume was 150 μL, the power density of ultrasonic was 0.17 W/cm2, the ultrasound time was 2 min), the power density of ultrasonic (the parameters of ultrasonic power density were 0.14, 0.17, and 0.21 W/cm2, the organic accepted phase volume was 150 μL, the extraction volume was 30 μL, the ultrasound time was 2 min), the ultrasound time (the parameters of ultrasound time were 1, 2, 3, 4, and 5 min, the organic accepted phase volume was 150 μL, the power density of ultrasonic was 0.17 W/cm2, the extraction volume was 30 μL), each experiment was replicated three times

In addition, the extraction time was an important factor on HMF extraction into aqueous solution. For example, the increase of extraction time from 1 to 4 min induced a significant improvement of HMF back extraction. However, a prolonged ultrasonic treatment induced the decrease of HMF extraction. The phenomenon could be explained that the long time ultrasonic treatment could induce the strong emulsification between water and organic solvent, which had a bad effect on the phase separation and induced the extraction efficiency decrease.

CE-UV Analysis of HMF

CE involves the high separation efficiency, being an optional substitute for liquid chromatography (LC) in separation of analytes with small sample volume. Therefore, this study established the two-step UALLME coupled with CE-UV method (simple, convenient) to detect the HMF in vinegar and soy sauce.

The HMF separation was performed on capillary tube and detected by the characteristic UV absorption at 280 nm; the quantification and identification were realized by the CE-UV. The results are shown in Fig. 2; HMF was eluted out at 13.5 min. All peaks were confirmed by comparing the retention times to the standard solution. In addition, the UALLME method significantly improved the method selectivity. As shown in Fig. 2, the samples including vinegar and soy sauce without two-step UALLME pretreatment were directly injected into CE system. Obviously, the 5-HMF peak was totally interfered by the impurities in soy sauce (Fig. 2a) and vinegar (Fig. 2b). Thus, the HMF in the unclean-up sample was not suitable to be analyzed by the CE-UV. Moreover, no HMF peak appeared in the extracts containing organic solvent, which was also not applicable for direct analysis of HMF in CE-UV (Fig. 2c). As a result, the organic solvent should be removed before CE-UV analysis. In this study, the second step UALLME was applied to back extract the HMF into aqueous solution in order to remove the organic solvent. Besides, compared with the previous method (Bignardi et al. 2014), the mass spectrometer was coupled to CE system for improving the selectivity of HMF analysis. However, the two-step UALLME method in this study was very effective to improve the method selectivity in the vinegar and soy sauce. The results are shown in Fig. 3. Clearly, the HMF peaks in vinegar (D) or soy sauce (B) were symmetrical and totally separated from the impurities. To confirm the matrix effect in vinegar and soy sauce on the separation of HMF, the spiked HMF standards were added into vinegar (Fig. 3c), soy sauce (Fig. 3a) during the process of two-step UALLME treatment. As shown in Fig. 3, nearly no shoulder peaks appeared, and the increased peak areas are listed as recoveries in Table 2. Therefore, the two-step UALLME method was important to improve the method selectivity.

Samples directly analyzed by capillary electrophoresis-ultraviolet (CE-UV). a Soy sauce filtered by organic membrane (0.22 μm). b Vinegar filtered by organic membrane (0.22 μm). c Vinegar extracted into organic accepted phase by the first step ultrasonic assisted liquid–liquid micro-extraction. d 5-Hydroxymethylfurfural (HMF) standard (8 mg/L)

Method Validation

The validation parameters involving linearity, correlation coefficient (R 2), limit of detection (LOD), limit of quantitation (LOQ), and recovery were tested under the optimum condition of the two-step UALLME method.

As shown in Table 1, the correlation coefficient of standard curves in vinegar and soy sauce matrix was 0.9918 and 0.9942, respectively. The calibration standards were prepared at concentrations of 0.50, 1.00, 2.00, 4.00, 8.00, 16.00, 24.00, and 32.00 mg/L to generate the calibration curves. In addition, the LOD and LOQ were calculated as the signal to noise ratio of 3 and 10, to evaluate the performance of CE-UV instruments. The values of LOD and LOQ in both vinegar and soy sauce sample were 0.03 and 0.10 mg/L, respectively. Significantly, the LOD and LOQ in this study were comparable with the previous method such as CE-MS (LOD = 0.03 mg/L and LOQ = 0.10 mg/L) (Bignardi et al. 2014). In addition, the method in this study was more sensitive for HMF determination with respect to the micellar electrokinetic capillary chromatography (MEKC) methodology (LOD = 0.09 mg/L and LOQ = 0.30 mg/L) (Rizelio et al. 2012). Actually, the two-step UALLME method for HMF pre-concentration could be obtained in this study.

In addition, the addition of 8.00, 16.00, and 24.00 mg/L HMF standards into the vinegar and soy sauce sample was carried out to evaluate the accuracy calculated by recovery, while the relative standard deviation (%RSD, n = 3) was tested to evaluate the stability of method. As shown in Table 2, the observed RSD % was ranging from 0.53 to 3.74, which indicated that the method stability was satisfactory for HMF analysis in vinegar and soy sauce sample. The recovery values of HMF, calculated as the ratio of the tested level to spiked level, were ranging from 91.24 to 109.39%. The results indicated that the tested HMF contents in samples by CE-UV after UALLME pretreatment were reliable and available.

Analysis of HMF in Vinegar and Soy Sauce

Although HMF was presented in vinegar and soy sauce, there was little literature available up to now. Moreover, the complex matrix in vinegar and soy sauce such as colored components and salts could interfere with the analyte separation and detection (Fig. 2). By the two-step UALLME method, the influence factors could be mostly eliminated to improve the accuracy and flexibility, and the analysis could be practiced in a stabilized condition. In this study, the content of HMF was measured under the optimum conditions. As shown in Table 3, the levels of HMF in vinegar and soy sauce depended on the different brands. HMF could not be detected in some brands of vinegar such as vinegar 1 and vinegar 6. The levels of HMF in vinegars without caramel color (vinegars 3 and 4, 22.92 and 17.54 mg/L, respectively.) were higher than those in vinegars with addition of caramel color (vinegars 2 and 5, 7.66 and 9.01 mg/L). The results suggested that HMF in vinegar could be formed during the process of fermentation (Kowalski et al. 2013) and the addition of caramel colorants induced the increase of HMF in vinegar (Hewala et al. 1993). In addition, the contents of HMF in soy sauce 2 (produced by solid-state fermentation) were 17.68 mg/L, which was lower than that of HMF in soy sauces containing caramel color(soy sauces 1 and 3, 4.29 and 5.56 mg/L, respectively). In sum, the addition of caramel color could be an important factor for the increase of HMF in vinegar or soy sauce (Eixidó et al. 2011). Thus, the two-step UALLME pretreatment was applicable for the HMF determination in CE-UV in food samples with high ion strength.

Conclusion

The HMF level in vinegar and soy sauce after two-step UALLME pretreatment could be analyzed by CE-UV. Moreover, excellent linearity, recovery, and repeatability were obtained in the method. Therefore, two-step UALLME coupled with CE-UV was an alternative option for accurate, rapid, and effective detection of HMF in vinegar and soy sauce.

References

Abraham K, Gürtler R, Berg K, Heinemeyer G, Lampen A, Appel KE (2011) Toxicology and risk assessment of 5-Hydroxymethylfurfural in food. Molecular Nutrition & Food Research 55:667–678

Abu-Bakar NU, Makahleh A, Saad B (2014) Vortex-assisted liquid–liquid microextraction coupled with high performance liquid chromatography for the determination of furfurals and patulin in fruit juices. Talanta 120:47–54. doi:10.1016/j.talanta.2013.11.081

Acunha T, Ibáñez C, García-Cañas V, Simó C (2016) CifuentesA. Recent advances in the application of capillary electromigration methods for food analysis and foodomics Electrophoresis 37:111–141. doi:10.1002/elps.201500291

Ahmadi-Jouibari T, Fattahi N (2015) Speciation of inorganic arsenic species and total inorganic arsenic in rice using microwave-assisted dispersive liquid-liquid micro-extraction and electrothermal atomic absorption spectrometry. Food additives andContaminants Part A 32:1140–1147. doi:10.1080/19440049.2015.1049565

ALOthman ZA, Dawod M, Kim J, Soo Chung D (2012) Single-drop microextraction as a powerful pretreatment tool for capillary electrophoresis: A review. Analytica Chimica Acta 739:14–24. doi:10.1016/j.aca.2012.06.005

Andrade JKD, Komatsu E, Perreault H, Torres YR, Da Rosa MR, Felsner ML (2016) In house validation from direct determination of 5-hydroxymethyl-2-furfural (HMF) in Brazilian corn and cane syrups samples by HPLC–UV. Food Chemistry 190:481–486. doi:10.1016/j.foodchem.2015.05.131

Bignardi C, Cavazza A, Corradini C (2014) Selected product ion monitoring for quantification of 5-hydroxymethylfurfural in food products by capillary zone electrophoresis-tandem ion trap mass spectrometry. Food Control 46:41–48. doi:10.1016/j.foodcont.2014.04.049

Chandrasekaran K, Karunasagar D, Arunachalam J (2011) Dispersive liquid–liquid micro extraction of uranium(vi) from groundwater and seawater samples and determination by inductively coupled plasma–optical emission spectrometry and flow injection–inductively coupled plasma mass spectrometry. Analytical Methods 3:2140. doi:10.1039/c1ay05329a

Gaspar EMSM, Lopes JF (2009) Simple gas chromatographic method for furfural analysis. Journal of Chromatography A 1216:2762–2767. doi:10.1016/j.chroma.2008.10.049

Hewala II, Oweil M, Onsi SM (1993) Detection and determination of interfering 5–hydroxymethylfurfural in the analysis of caramel–coloured pharmaceutical syrups. Journal of Clinical Pharmacy and Therapeutics 18:49–53. doi:10.1111/j.1365-2710.1993.tb00566.x

Kim JH, Ahn HJ, Yook HS, Kim KS, Rhee MS, Ryu GH, Byun MW (2004) Color, flavor, and sensory characteristics of gamma-irradiated salted and fermented anchovy sauce. Radiation Physics and Chemistry 69:179–187. doi:10.1016/s0969-806x(03)00400-6

Kowalski S, Lukasiewicz M, Duda-Chodak A, Zięć G (2013) 5-Hydroxymethyl-2-furfural (HMF) – heat-induced formation, occurrence in food and biotransformation – a review. Polish Journal of Food and Nutrition Sciences 63:207–225. doi:10.2478/v10222-012-0082-4

Payán MR, Ángel Bello López M, Fernández-Torres R, Pérez Bernal JL, Callejón Mochón M (2009) HPLC determination of ibuprofen, diclofenac and salicylic acid using hollow fiber-based liquid phase microextraction (HF-LPME)Analytica. Chimica Acta 27:184–190. doi:10.1016/j.aca.2009.09.018

Rizelio VM, Gonzaga LV, Da Silva Campelo Borges G, Micke GA, Fett R, ACO C (2012) Development of a fast MECK method for determination of 5-HMF in honey samples. Food Chemistry 133:1640–1645. doi:10.1016/j.foodchem.2011.11.058

Rovira R, Ribera F, Sanchis V, Canela R (1993) Improvements in the Quantitation of patulin in apple juice by high-performance liquid chromatography. Journal of Agricultural and Food Chemisity 41:214–216

Sereshti H, Izadmanesh Y, Samadi S (2011) Optimized ultrasonic assisted extraction-dispersive liquid-liquid microextraction coupled with gas chromatography for determination of essential oil of Oliveria decumbens. Vent Journal of Chromatography A 1218:4593–4598. doi:10.1016/j.chroma.2011.05.037

Stute R, Petridis K, Steinhart H, Biernoth G (2002) Biogenic amines in fish and soy sauces. European Food Research and Technology 215:101–107. doi:10.1007/s00217-002-0509-y

Tadeo JL, Sánchez-Brunete C, Albero B, García-Valcárcel AI (2010) Application of ultrasound-assisted extraction to the determination of contaminants in food and soil samples. J Chromatogr A 1217:2415–2440. doi:10.1016/j.chroma.2009.11.066

Takino M, Daishima S, Nakahara T (2003) Liquid chromatography/mass spectrometric determination of patulin in apple juice using atmospheric pressure photoionization. Rapid Communication Mass Spectrometry 17:1965–1972. doi:10.1002/rcm.1136

Teixidó E, Núñez O, Santos FJ, Galceran MT (2011) 5-Hydroxymethylfurfural content in foodstuffs determined by micellar electrokinetic chromatography. Food Chem 126:1902–1908. doi:10.1016/j.foodchem.2010.12.016

Tejada-Casado C, Hernandez-Mesa M, Del Olmo-Iruela M, Garcia-Campana AM (2016) Capillary electrochromatography coupled with dispersive liquid-liquid microextraction for the analysis of benzimidazole residues in water samples. Talanta 161:8–14. doi:10.1016/j.Talanta.2016.08.012

Tesfaye W, Garcia-Parrilla MC, Troncoso AM (2002) Sensory evaluation of Sherry wine vinegar. Journal of Sensory Studies 17:133–144. doi:10.1111/j.1745-459X.2002.tb00338.x

Theobald A, Müller A, Anklam E (1998) Determination of 5-Hydroxymethylfurfural in vinegar samples byHPLC. Journal of Agricultural and Food Chemisity 46:1850–1854

Ting-Ting F, Xu L, Jian-Hai W, Lei Q, Ming-Qian T, Bei-Wei Z, Xian-Bing X (2017) Isotope dilution quantification of 5-hydroxymethyl-2-furaldehyde in beverages using vortex-assisted liquid–liquid microextraction coupled with ESI-HPLC-MS/MS. Anal Methods 25:1–19. doi:10.1039/C7AY00927E

Yiantzi E, Psillakis E, Tyrovola K, Kalogerakis N (2010) Vortex-assisted liquid-liquid microextraction of octylphenol, nonylphenol and bisphenol-a. Talanta 80:2057–2062. doi:10.1016/j.talanta.2009.11.005

Acknowledgements

All the authors acknowledge the financial support from the 13th Five Years Key Programs for Science and Technology Development of China (Grant No. 2017YFD0400103), the National Science Foundation of China (Grant No. 31601467), and the 13th Five Years Key Programs for Science and Technology Development of China (Grant No. 2016YFD0400404).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of Interest

Jian-Hai Wu declares that he has no conflict of interest. Ting-Ting Feng declares that she has no conflict of interest. Xu Liang declares that she has no conflict of interest. Cui-Ping Yu declares that she has no conflict of interest. Liang Dong declares that he has no conflict of interest. Ming Du declares that he has no conflict of interest. Ming-Qian Tan declares that he has no conflict of interest. Xian-Bing Xu declares that he has no conflict of interest.

Ethical Approval

This article does not contain any studies with human participants or animals performed by any of the authors.

Informed Consent

Not applicable.

Rights and permissions

About this article

Cite this article

Wu, JH., Feng, TT., Liang, X. et al. Determination of HMF in Vinegar and Soy Sauce Using Two-Step Ultrasonic Assisted Liquid–Liquid Micro-Extraction Coupled with Capillary Electrophoresis-Ultraviolet Detection. Food Anal. Methods 11, 479–485 (2018). https://doi.org/10.1007/s12161-017-1018-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12161-017-1018-8