Abstract

Biological reduction is an effective method for removal of perchlorate (ClO4−), where perchlorate is transformed into chloride by perchlorate-reducing bacteria (PRB). An external electron donor is required for autotrophic and heterotrophic reduction of perchlorate. Therefore, plenty of suitable electron donors including organic (e.g., acetate, ethanol, carbohydrate, glycerol, methane) and inorganic (e.g., hydrogen, zero-valent iron, element sulfur, anthrahydroquinone) as well as the cathode have been used in biological reduction of perchlorate. This paper reviews the application of various electron donors in biological perchlorate reduction and their influences on treatment efficiency of perchlorate and biological activity of PRB. We discussed the criteria for selection of appropriate electron donor to provide a flexible strategy of electron donor choice for the bioremediation of perchlorate-contaminated water.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Perchlorate (ClO4−) is widespread in the production of pulp and paper, textiles, explosives, and rocket propellants (Crump and Gibbs 2005; Dasgupta et al. 2005; Xu et al. 2015a). As an emerging persistent pollutant, it has received great attention over the past few decades because it interferes with thyroid hormone secretion and causes damage to humans (Logan 2001; Luo et al. 2015; Ma et al. 2016). Perchlorate has low adsorption to natural solids, sluggish reactivity, and high solubility, so its amount is increasing year by year in environment (Choe et al. 2013; Song et al. 2017). Generally, the concentration of perchlorate is under 100 μg L−1 in groundwater, but it was reported that the value reached 630–3700 mg L−1 in the groundwater in Las Vegas and Nevada in the USA (Bardiya and Bae 2011).

Common methods for the remediation of perchlorate-contaminated water include physical separation, chemical/electrochemical reduction, and biological reduction (Logan 2001; Coates and Achenbach 2004; Zhao et al. 2011). Ion exchange (IX) is the most common in physical separation of perchlorate from wastewater. However, its application is limited because the concentrated residual waste brines are difficult to disposal. Meanwhile, the spent resins also need the regeneration (Hatzinger 2005; Chitrakar et al. 2012; Ye et al. 2012; Lin et al. 2014). The chemical reduction of perchlorate is difficult due to its special tetrahedral structure, where the central chlorine atom is surrounded by four oxygen atoms. The unique structure makes the chemical reduction of perchlorate need high activation energy (Srinivasan and Sorial 2009). The electrochemical reduction exhibited perfect efficiency and selectivity for perchlorate removal, but the high cost is a significant problem (Yang et al. 2016; Yao et al. 2017). Among the approached for the perchlorate-contaminated water treatment, biological reduction is more suitable because of its low cost, high efficiency, and free secondary pollution (Son et al. 2011; Wang et al. 2013; Lai et al. 2018). During this process, perchlorate is utilized by functional microorganisms as respiratory chain electron acceptor and reduced to chloride and oxygen when a suitable electron donor is present in anaerobic environment (Wen et al. 2016; Wen et al. 2017). So the suitable electron donor is necessary to provide the electrons to perchlorate molecules for their reduction. These functional microorganisms are defined as perchlorate-reducing bacteria (PRB), which can be classified into autotrophic PRB, using inorganic electron donors (Shrout et al. 2005a; Yu et al. 2006; Yu et al. 2007; Son et al. 2011) and heterotrophic PRB, using organic electron donors (Okeke and Frankenberger 2005; Wang et al. 2008; Xu et al. 2015b).

PRB are ubiquitous in natural environment and can grow with the processes of perchlorate bioreduction. Figure 1 shows the mechanism of the biological perchlorate reduction by PRB. These biological processes have been proved to be an enzymatic reaction (Steinberg et al. 2005; Van Trump and Coates 2009; Hutchison et al. 2013). With the assistance of (per)chlorate reductase (pcr), perchlorate is reduced by PRB to chlorate (ClO3−) and chlorite (ClO2−) successively and ends with the dismutation of ClO2− into chloride (Cl−) and molecular oxygen (O2) catalyzed by chlorite dismutase (Cld). Furthermore, most of PRB are facultative anaerobes (Coates and Achenbach 2004; Nerenberg et al. 2008; Ma et al. 2016), molecular oxygen produced from biological reduction of perchlorate should be rapidly consumed by the reducing equivalents provided by electron donor to avoid its accumulation in the system (Choi and Silverstein 2008; Zhao et al. 2013b; Xu et al. 2015b). Thus, maintenance of the suitable electron donor at useful levels is the key factor for efficient biological reduction of perchlorate.

The mechanism for the biological reduction of perchlorate by PRB. Adapted with permission from Song et al. (2017), Copyright 2017, Elsevier

There are plenty of published reviews on perchlorate, but their topic mainly focus on the fate, toxicity, and remediation of perchlorate (Srinivasan and Viraraghavan 2009; Srinivasan and Sorial 2009; Van der Zee and Cervantes 2009; Zhu et al. 2010). To the best of our knowledge, the systematical review on the role of electron donors for biological perchlorate reduction is rare. This article comprehensively summarized the type of electron donors used in bioreduction of perchlorate, the mechanistic reactions involved, and the major functional microorganisms. Then, the criteria of selection for the appropriate electron donor were discussed to provide a flexible strategy for selection of an electron donor for the bioremediation of perchlorate-contaminated water. Finally, the future research directions were prospected.

Electron donors for biological perchlorate reduction

The type of electron donors used in the biological perchlorate reduction is very abundant. Table 1 summarizes the performance of biological perchlorate reduction with various electron donors. For heterotrophic process, organic compounds such as acetate, methane, ethanol, glycerol, acetic acid, and glucose are the common carbon source and organic electron donor (Ahn et al. 2009; Xu et al. 2015b). However, these organic compounds can be utilized by other heterotrophic microorganisms as the carbon source, even superior to PRB, resulting in the deficiency of electron donors and the flourish of heterotrophic microorganisms. Therefore, the electron donor should be excessive in order to ensure that the perchlorate is completely removed. Whereas, excessive organic matter can lead to organic residues, which may bring excessive residual chemical oxygen demand (COD) in the effluent, resulting in the requirement for further treatment of water (Ju et al. 2008; Mieseler et al. 2013). Thus, the appropriate molar ratio of an electron donor to perchlorate is important. Among organic electron donors, acetate is the most suitable because of higher perchlorate removal rate and lower biomass production in the effluent, which not only reduces the secondary contamination but also reduces the maintenance cost. Obviously, the inorganic electron donors such as hydrogen (H2), zero-valent iron (Fe0), elemental sulfur (S0), and thiosulfate (S2O32−) are the good alternative, especially in drinking water treatment (Zhang et al. 2002; Nerenberg and Rittmann 2004; Shrout and Parkin 2006). Compared to acetate (2064 mg L−1 day−1), the perchlorate removal rate using H2 as the electron donor reached to 7638.53 mg L−1 day−1, but S0 only achieved 672 mg L−1 day−1. However, the utilization of inorganic substance not only avoids the secondary organic contamination but also has decreased sludge production, which all can decrease the operation cost (Park and Yoo 2009; Mieseler et al. 2013). From Table 1, it can be clearly found that S0 as the electron donor induces the lower biomass yield (2.47–11.4 mg-VSS mg-perchlorate−1).

Organic electron donors

Acetate

Acetate is the most commonly used in bioreduction of perchlorate by PRB (Giblin et al. 2000; Gingras and Batista 2002; Ahn et al. 2009). Acetate can serve as both carbon source and electron donor during the perchlorate reduction (Zhu et al. 2016b). Patel et al. (2008) achieved the complete reduction of perchlorate from synthetic ion-exchanged brines in granular activated carbon (GAC)-based fluidized bed reactors (FBR) fed with acetate. Some studies indicated that acetate had better performance in perchlorate reduction (London et al. 2011; Lian et al. 2017). Lian et al. (2017) compared the acetate, succinate saccharose, and glucose on perchlorate bioreduction and bioelectricity generation in microbial fuel cell (MFC). Due to the simpler molecular structure, acetate could be easily utilized by microorganisms, which made it a more suitable electron donor (Xu et al. 2015b). Azospira sp. KJ., a heterotrophic PRB, achieved the maximum perchlorate reduction rate of 13.2 mg-perchlorate L−1 h−1 with acetate as the electron donor (Xu et al. 2015b). The process of using acetate to reduce perchlorate is shown in Fig. 2, and the equation can be described as following (Ucar et al. 2016a):

The process of perchlorate (per)chlorate/nitrate reduction. Adapted with permission from Xu et al. (2015b), Copyright 2015, Elsevier

Perchlorate reduction followed first-order degradation kinetics when acetate served as the electron donor (Patel et al. 2008). The ratio of acetate to perchlorate is the key factor affecting the rate and efficiency of perchlorate reduction. Zhu et al. (2016a) reported that only a small amount of perchlorate was reduced without acetate, and as increased of the amount of acetate, the reduction extent and rate were improved. Shrout and Parkin (2006) investigated the bacterial perchlorate degradation in a mixed culture bioreactor and 100% perchlorate removal was achieved between 10 and 30 h at 1.2 mg-acetate mg-perchlorate−1. The value was obviously lower than the results (2 and 1.94 mg-acetate mg-perchlorate−1) reported by Zhu et al. (2016a) and Kim and Logan (2001). In order to achieve complete reduction of perchlorate, an excess of acetate was usually provided because it could alleviate the inhibition of perchlorate reduction led by the co-contaminant nitrate in water (Choi and Silverstein 2008; Zhu et al. 2016b). Contrary to the previous researches, Guan et al. (2015) thought that acetate could inhibit the growth of PRB. Simultaneously, they reported that nitrate could attenuate the inhibition and promoted the growth of PRB, further accelerating the degradation rate of perchlorate (Guan et al. 2015). In addition, excessive supply of acetate during biological perchlorate reduction may lead to the incomplete oxidation of acetate. The residual acetate and fermentation metabolites in the effluent contributed significantly to secondary organic pollution, which is actually a major shortcoming in practical application (Liamleam and Annachhatre 2007; Mieseler et al. 2013).

Ethanol

Ethanol has been utilized for dentrification, biological sulfate reduction, and biological perchlorate reduction as an effective organic electron donor (Liamleam and Annachhatre 2007). Ravnjak et al. (2013) found that the degradation efficiency of nitrate was higher than 99% using ethanol as electron donor in a two-stage anoxic/oxic biofilm membrane bioreactor. Ethanol also could be used to remove anionic contaminant in ion exchange membrane bioreactor (IEMB) (Matos et al. 2006). PRB Dechloromonas and denitrifiers, e.g., Thauera, Azoarcus, and Paracoccus, could proliferate in IEMB with the simultaneously removal of nitrate and perchlorate using ethanol (Ricardo et al. 2012). With the participation of microorganisms, the ethanol degradation process is as follows:

Acetogenesis:

Methanogenesis:

So the theoretical stoichiometry of the perchlorate reduction is as follows:

The concentration of ethanol in the biological treatment system must be controlled. Low concentration of ethanol could limit perchlorate and nitrate reduction (Matos et al. 2006). Under limiting ethanol supply, reduction of perchlorate declined from 33.8 ± 3.0 to 8.3 ± 0.8 mg L−1 and the reduction rate of nitrate was almost unaffected (from 29.3 ± 0.7 to 27.6 ± 1.5 mg L−1 day−1) (Ricardo et al. 2012). Although part of ethanol also can be consumed by heterotrophic organisms, excessive ethanol may cause residual COD in the effluent (Velizarov et al. 2000). IEMB technology solves the problem of organic residual because of the low diffusion coefficient of ethanol (1.8 × 10−8 cm2 s−1) in the membrane (Fonseca et al. 2000). The biofilm on the membrane surface can decrease the ethanol concentration on the membrane surface, which ensures the sufficient utilization of ethanol by organisms. Ricardo et al. (2012) found that the biomass growth yield (Yp) was 3.64 mg-VSS mg-perchlorate−1 using ethanol as electron donor, which deviated strongly from the stoichiometric ratio of perchlorate/ethanol. The estimation value was 1.53 g g−1 while the obtained experimental value was 0.042 g g−1. They attributed the overestimated Yp to the ethanol consumed by other organisms, e.g., fermentative bacteria to produce acetic acid.

Carbohydrate-based electron donor

Carbohydrate-based electron donors (CBEDs) such as molasses, glucose, high fructose corn syrup, and cellobiose are effective electron donors that are susceptibly degradable under anaerobic conditions. The CBED has been approved by the National Sanitation Foundation (NSF) International for drinking water treatment (Upadhyaya et al. 2015). CBED has been used as a substitute for acetic acid to reduce perchlorate from drinking water in fixed bed reactors (FXBRs) and fluidized bed reactors (FLBRs) (Upadhyaya et al. 2015). As Upadhyaya et al. (2015) reported, it needed longer empty bed contact time (EBCT) and higher influent CBED COD to attain water quality comparable to that of acetic acid. In addition, the biomass yield using CBED was higher, which required more frequent maintenance.

Molasses, a sugar production by-product, is one of the most cost-effective CBED because of its low price and easy availability. The major components in molasses are the polysaccharides with long carbon chains. Therefore, similar to other CBEDs, molasses must be better fermented to lactate by microorganisms such as Lactobacilli in order to increase its bioavailability before it is used as the electron donor (Maree et al. 1991). In addition, there are plenty of non-biodegradable caramelized products in molasses, which can accumulate in the sludge (Annachhatre and Suktrakoolvait 2001). The accumulation of non-biodegradable caramelized product reduced the activity of biomass and impacted the COD removal, leading to excessive residual COD in outflow (Liamleam and Annachhatre 2007). Another major defect of using molasses is that there are the high volatile fatty acid (VFA) contents in the reactor due to the fermentation of molasses. The acidification induced by VFAs accumulation negatively affects the growth of both methanogens and PRB. But the problem can be solved well by the addition of NaOH or NaHCO3.

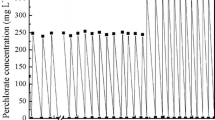

Glycerol

Glycerol is a non-expensive by-product of the growing biodiesel production industry, so it is cheap and easily available (Yazdani and Gonzalez 2007). When it was used as an electron donor in IEMB, bioreduction efficiency of perchlorate exceeded 99% with inlet perchlorate concentration as high as 250 mg L−1 (Fox et al. 2016). The benefit of glycerol as the electron donor is its much lower diffusion rate (6.9 × 10−9 (± 4.7 × 10−10) cm2 s−1) to penetrate the membrane, which is 60% lower than the ethanol (Velizarov et al. 2000). So the organic carbon concentration in effluent was kept lower level, averaging 1.82 (± 0.70) mg-C L−1 and always less than 3 mg-C L−1 (Fox et al. 2016). In order to further avoid the cross-contamination led by organic carbon, the supply of carbon source (e.g., glycerol, ethanol) can be controlled according to the stoichiometric demand for complete perchlorate degradation.

Glycerol is a complex organic that is difficult to be utilized directly by PRB. So biological reduction of perchlorate with glycerol as the electron donor is a two-stage process, in which glycerol is firstly fermented in the suspension of IEMB, and then PRB in the biofilm attached on the membrane use these fermentation products to achieve the bioreduction of perchlorate (Fox et al. 2016). The population analysis showed that a glycerol fermenter, Klebsiella oxytoca, was the dominant bacteria in the suspension phase, while the typical PRB, Azospirillum sp. were the foremost strain in the biofilm (Fox et al. 2016).

The reduction reaction of perchlorate utilized glycerol is as follows:

Methane

Recently, simple gaseous organics methane (CH4) has received extensive attention as a carbon source and electron donor for biological perchlorate reduction (Beal et al. 2009; Ettwig et al. 2010; Ettwig et al. 2016). Firstly, the price of CH4 is relatively low and it can be obtained from anaerobic digesters (Zhang et al. 2016; Wang et al. 2017a, b). Meanwhile, different with that of high water solubility for common organic carbon sources such as acetate and ethanol, CH4 is poorly soluble in water, which avoids the secondary organic contamination, especially when treating perchlorate-containing groundwater (Lv et al. 2018). So CH4 is an ideal organic carbon source. Although its availability to PRB is limited by the low solubility, membrane biofilm reactor (MBfR) can solve the issue by achieving high gas transmission rate, which has been successfully applied to biological wastewater treatment with gaseous H2 and CH4 as the electron donors (Nerenberg and Rittmann 2004; Martin and Nerenberg 2012). CH4 can be directly used by denitrifiers, PRB, methylotrophs, and methanotrophs (Chen et al. 2016; Xie et al. 2018). When perchlorate serves as the electron acceptor, the reaction is thermodynamically feasible (Luo et al. 2015; Xie et al. 2018):

As was mentioned above, the pathway of biological perchlorate reduction involves a step to produce O2, which is necessary for the CH4 oxidation (Bender et al. 2005; Luo et al. 2015; Chen et al. 2016). But Miller et al. (2014) demonstrated that aerobic methanotrophs could not utilize the O2 produced through perchlorate bioreduction. Actually, there was no report that CH4 could reduce perchlorate until Luo et al. (2015) demonstrated that the bioreduction of perchlorate using CH4 is feasible.

It is well-known that there are two categories of CH4 oxidation: anaerobic and aerobic CH4 oxidation (Xie et al. 2018), which are usually coupled to denitrification. Anaerobic CH4 oxidation coupled to denitrification (ANMO-D) usually involves two distinct bacterial groups: archaea and denitrifying bacteria (Ettwig et al. 2008; Ettwig et al. 2009; Hu et al. 2009). Archaea can generate H2 by reverse methanogenesis to reduce nitrate to nitrite (NO2−) themselves. Denitrifiers such as NC10 further reduce the nitrite using CH4 via an “intra-aerobic” pathway (Ettwig et al. 2009). Aerobic methane oxidation coupled to denitrification (AMO-D) is carried out by the effects of methane oxidizers (methanotrophs) and denitrifiers in combination (Eisentraeger et al. 2001; Knowles 2005; Knittel and Boetius 2009). Methanotrophs oxidize CH4 in the presence of O2 and produce acetate and other soluble organic matters. Then the denitrifiers use these organics as electron donors to reduce nitrate (Eisentraeger et al. 2001; Knowles 2005; Knittel and Boetius 2009).

Considering the similar structure to nitrate, it is logical that the key PRB can reduce the perchlorate using a chlorite dismutase in a manner similar to nitric oxide (NO) disproportionation in denitrification (Ettwig et al. 2010). Therefore, Luo et al. (2015) pointed out that there were two possible mechanisms for the degradation of perchlorate with CH4: (1) anaerobic methane oxidation coupled to perchlorate reduction (ANMO-PR) and (2) micro-aerobic methane oxidation coupled to perchlorate reduction (mAMO-PR) and illustrated the mechanisms in Fig. 3. According to the influence of dissolved oxygen (DO) and CH4/NO3− mole ratio on perchlorate reduction, Chen et al. (2016) found that ANMO-PR played important role for the biological perchlorate reduction in the MBfR fed with CH4. Bacteria domination in the perchlorate-reducing biofilm, and the increasing proportion of the particulate methane mono-oxygenase (pMMO) in respiratory gene copies all supported that the CH4-oxidizing biofilm likely respired perchlorate combined with the mono-oxygenation of CH4 using the O2 intracellularly generating from ClO2− dismutation, whose manner is similar to nitrate disproportionation in denitrification (Bender et al. 2005; Luo et al. 2015; Chen et al. 2016). Rikken et al. (1996) discovered that O2 was released extracellularly during complete perchlorate degradation. Luo et al. (2015) speculated that the reduction of perchlorate coupling oxidation of CH4 may be realized by a mixture of PRB and methanotrophs using pMMO and perchlorate reductase (pcrA) separately. Miller et al. (2014) confirmed that the methanotrophs used extracellular O2 come from ClO2− disproportion by PRB Dechloromonas agitate CKB to oxidize CH4 aerobically. However, O2 is also a competitive electron acceptor of perchlorate and is superior to perchlorate by PRB acceptance. Therefore, the actual DO concentrations in the MBfR system should be far below theoretical demand. Luo et al. (2015) named this hypothesized mechanism as mAMO-PR, and the mechanism is demonstrated in Fig. 3b.

a, b Mechanisms of the degradation of perchlorate with the CH4 as the electron donor. Adapted with permission from Luo et al. (2015), Copyright 2015, American Chemical Society

Inorganic electron donors

Hydrogen

Hydrogen (H2) has been used for perchlorate biological treatment in many researches (Zhao et al. 2011; Wang et al. 2014; Chen et al. 2017). According to Ontiveros-Valencia et al. (2013), the removal of perchlorate could reach 98% with inlet perchlorate concentration at 10 mg L−1 in a H2-based MBfR. MBfR is one of the most widely used reactors when the electron donor is gaseous, because it can achieve near 100% gas utilization efficiency for high gas transmission rate, further ensuring high nitrate and perchlorate removal rates (Tang et al. 2012; Tang et al. 2013; Zhao et al. 2013a). H2 as the electron donor in heterotrophic perchlorate reduction has a number of advantages, including (1) H2 has low solubility, so it is easy to be stripped from water; (2) H2 is non-poisonous; (3) hydrogenotrophic bacteria utilizing inorganic carbon sources (CO2, HCO3−) grow slowly, thus producing less metabolic sludge, and the metabolites are mainly H2O (Zhao et al. 2013b); and (4) H2 as the electron donor does not require additional organic substances, avoiding excessive COD residue in the effluent (Nerenberg et al. 2002; Sahu et al. 2009). However, the price of H2 is expensive to limits its extensive use. Meanwhile, the explosive risk of H2 in transportation, storage, and utilization also is the issue.

In the bio-reduced perchlorate membrane reactor, almost no microorganisms can grow, except for a few anaerobic bacteria, under the conditions where only H2 was used as energy (Liamleam and Annachhatre 2007). Wan et al. (2016) found that the Thauera genus dominated in the mixed culture, which could simultaneously remove nitrate and perchlorate utilizing H2. And Dechloromonas was in the ascendant during perchlorate reduction in a H2-based MBfR (Zhao et al. 2011). Thrash et al. (2007) found a novel PRB, strain VDY, which could use H2 readily as an electron donor to respire perchlorate. However, the typical PRB Dechloromonas and Azospira species could not utilize H2 in the BER; they used the electrons directly on the surface of electrode or indirectly via an electron shuttle (AQDS) for the perchlorate reduction (Achenbach et al. 2001; Coates et al. 2001a). The theoretical stoichiometry is as follows (Thrash et al. 2007):

Nitrate and perchlorate can be reduced simultaneously by the combined action of PRB and denitrifying bacteria in a H2-based MBfR. Similar to PRB, sulfate-reducing bacteria (SRB) can also use H2 to reduce sulfate in water. To some extent, there is a competition not only to the common electron donor (H2) but also to the space in the biofilm among these three groups (Zhao et al. 2014; Zhao et al. 2013b). Therefore, the unnecessary reduction of sulfate should be restricted. The degradation of varies electron acceptors in H2-based reactors is illustrated in Fig. 4. Hydrogenotrophic perchlorate reduction by PRB is listed as follows (Zhao et al. 2013b):

Degradation of electron acceptors in H2-based reactors. Adapted with permission from Chen et al. (2017), Copyright 2017, Elsevier

The perchlorate removal using H2 as electron donor fitted zero-order kinetics model (Van Ginkel et al. 2008; Wang et al. 2014; Wan et al. 2016). And the availability of H2 controlled the reduction kinetics when the system was not salt-inhibited (Butler et al. 2010). When H2 was limiting, facultative denitrifying bacteria were superior to strict autotrophs, since organic products can be used as electron donors (Zhao et al. 2011). And the perchlorate reduction was suppressed by high nitrate loading (Zhao et al. 2013b). When the surface loading of nitrate was higher than 0.65 ± 0.04 g-N m−2 day−1, perchlorate removal was only 30 ± 8% in H2-based MBfR. With the surface loading decreasing to 0.34 ± 0.04–0.53 ± 0.04 g-N m−2 day−1, perchlorate in effluent was nondetectable. Meanwhile, reduction of nitrate to N2 gas can produce the base and cause the increases of pH, which will exacerbate the precipitation of magnesium and calcium carbonates on the MBfR fibers. The precipitates influenced the H2 flux to the biofilm and lead to a decline of denitrification and perchlorate reduction performance, but mild citric-acid washing can alleviate the states (Van Ginkel et al. 2011). Salinity is also an important factor because of the lower solubility of H2 in high salinity solution (Sahu et al. 2009). The mass transfer coefficient of H2 in brine is relatively low. Meanwhile, most of microorganisms are difficult to survive in high salinity environments. MBfRs solved this problem well and gave 30% nitrate and 42% perchlorate removal from synthetic IX brine (Sahu et al. 2009). Contaminated water and H2 are introduced into different parts of the reactor: the shell side of the reactor and the cylindrical cavity of microporous hollow fiber membranes, respectively.

In practical application, H2 can be externally supplied to the reactor or in situ generated. The external supply of H2 has a fatal disadvantage that there are potential safety hazards because of the inherent explosive nature of H2 (Thrash et al. 2007). Meanwhile, the expensive cost to produce the H2 also limits its supply in bulk quantities. Some reports indicated that newly produced H2 in situ had higher activity and could be more effectively utilized by bacteria than external supplied (Prosnansky et al. 2002). H2 can be produced in situ through the cathode electrolysis of water (Butler et al. 2010). The highly negative operating potential of − 375 mV versus Ag/AgCl and pH of 8.5 was sufficient to form H2 at the surface of electrode, providing a soluble electron donor for PRB to reduce perchlorate. It was found that the maximum specific perchlorate reduction rate (Vmax) reached to 17.46 mg g-VSS−1 h−1 (Wang et al. 2014), which is much than that fed with external H2 (2.518 mg g-VSS−1 h−1 in Wan et al. (2016)). In addition, H2 also is supplied through the corrosion of zero-valent iron (ZVI) (London et al. 2013). Yu et al. (2006) demonstrated that ZVI could play the role of electron donor providing H2 in situ for the PRB Dechloromonas sp. to reduce perchlorate without external supply of H2. The normalized maximum perchlorate utilization rate (rmax) reached to 9200 μg g-dry sludge−1 h−1. However, plenty of co-product hydroxide is formed accompanying with the H2 production, and there is a requirement to control pH in order to neutralize the hydroxide.

Zero-valent iron

As a strong reducing agent, ZVI has been used to treat pollutants via chemical reduction (Wu et al. 2013; Dong et al. 2017). Thermodynamically, perchlorate can be easily reduced by ZVI (ΔG° = − 2495.9 kJ mol−1). However, the activation energy barrier between perchlorate and ZVI is so high that chemical process is too slow to repair in situ (Moore et al. 2003; Son et al. 2006; Yu et al. 2006). Recently, several studies have shown that ZVI served as the ultimate electron donor to enhance the perchlorate reduction by in situ supplying H2 derived from the iron corrosion process (Son et al. 2006; Schaefer et al. 2007; Arthur et al. 2013). The batch addition of ZVI achieves the continuous supply of H2, which is obviously superior to the continuous supply of electron donors (organic matters, H2 gas, etc.). Besides, iron is low cost, is safe to operate, and has no organic residuals in effluent (Son et al. 2006).

Generally, the perchlorate reduction by combined ZVI-PRB divides into three steps: (1) ZVI reduces H+ to H2 at the surface; (2) the diffusion path of H2 is first to the bacteria attached to the iron surface, then to the bulk solution, and finally to bacteria suspended; and (3) PRB reduce perchlorate with H2 as electron donor (Yu et al. 2006). Perchlorate is mainly reduced by PRB attached to the ZVI because the microorganisms mass attached to the ZVI was much larger than in the liquid (Yu et al. 2007). In addition, when there are energetic compounds coexisting with perchlorate, ZVI pretreatment could degrade these energetic compounds to eliminate their toxic inhibition to PRB, simultaneously, and these smaller molecules degraded products also served as the electron donors for enhanced bioremediation of perchlorate (Schaefer et al. 2007; Ahn et al. 2014).

Improved perchlorate reduction rate with ZVI as the electron donor should be ascribed to (1) the increasing iron surface activity and formation of H2, (2) the strengthening mass transfer, and (3) the increasing cell density. However, the research of Yu et al. (2006) found that these factors all affected the biological reduction of perchlorate to some extent, but were not the key factor. Two factors that influence the success of this technology are cell density and pH. Bioreduction of perchlorate with ZVI as the electron donor is a complex process involving various functional microorganisms, including autotrophic and heterotrophic PRB, denitrifying bacteria, and homoacetogens. As the increase of initial cell density, the removal rate of perchlorate was enhanced, while amending the surface reactivity of ZVI by acid washing or sonication so as to accelerate the H2 production had no effect on the acceleration of perchlorate reduction rate (Yu et al. 2006). Meanwhile, the presence of bacteria could accelerate the rate of iron corrosion (Yu et al. 2006). Besides, chloride and O2, end-products of perchlorate bioreduction, would stimulate the corrosion of iron. Researches have shown that the optimum pH for PRB Dechloromonas sp. HZ is neutral 6.8, and little bioreduction of perchlorate happened at the initial pH 9 (Zhang et al. 2002; Yu et al. 2007). When the corrosion rate of iron is excessive, the pH will increase owing to the formation of OH−, which is intolerant to the PRB. Meanwhile, higher pH can result in the formation of iron precipitates such as iron hydroxide to encapsulate bacteria (Shrout et al. 2005b; Son et al. 2006). This may make the capability of PRB to reduce perchlorate became worse (Andrews and Novak 2001; Huang et al. 2003; Yu et al. 2006; Yu et al. 2007). The activity of PRB was primarily affected by the initial pH of the solution. As long as perchlorate bioreduction runs stably, microbial process was unaffected by pH (Yu et al. 2006). Therefore, pH control is crucial to maintain the stability of perchlorate bioreduction using ZVI as the electron donor. The most feasible inorganic phosphate-based buffer can effectively maintain the neutral pH, but it is inhibitive to the iron corrosion. Arthur et al. (2013) found Tris-EDTA (TE) was a cost-effective alternative.

Elemental sulfur

Inorganic sulfur compounds, sulfite (SO32−), tetrathionate (S4O62−), thiosulfate (S2O32−), elemental sulfur (S0), and sulfide (S2−), are wildly used as the inorganic electron donor in biological wastewater treatment. Among them, S0 is more favored because it is easy to handle and due to its low cost and the high sulfur content among the reduced sulfur compounds (Ju et al. 2007; Ju et al. 2008; Ucar et al. 2016a). Furthermore, insoluble S0 (solubility of 5 μg L−1 at 20°C) can discharge electrons slowly as needed, showing its price and maintenance advantages (Ju et al. 2008).

The reaction of perchlorate with S0 is a spontaneous exothermic reaction (Eq. (11)). As the perchlorate is reduced, the elemental sulfur is oxidized to sulfate (Ju et al. 2007; Ju et al. 2008):

In Ju et al. (2008), a faster perchlorate reduction rate of 1.12 mM day−1 was observed using S0 as electron donor. Sulfuricella, Sulfuritalea, Thiobacillus, and Sulfurimonas are proven to be the effective DB/PRB using S0 as electron donor (Wan et al. 2017). The maximum observed yield coefficient of microbial consortium with S0 was 0.19 mg-dry weight (DW) mg-perchlorate−1, which was less than that of heterotrophic perchlorate-reducing bacteria (0.34–0.36 mg-DW mg-perchlorate−1) (Gao et al. (2015). This indicated that less excess biomass was produced during autotrophic perchlorate reduction process due to the lower microbial growth rate, which is more beneficial in practical applications.

Packing insoluble S0 particles into the bioreactor provides a good way for long-term supply of electron donor. Ucar et al. (2016b) compared the performances of sulfur-based autotrophic and methanol-based heterotrophic perchlorate removal and the perchlorate reduction rates were 12 and 24 mg L−1 day−1, respectively. However, methanol in the effluent from heterotrophic reactor was up to around 20 mg L−1. Therefore, although methanol-based perchlorate reduction is fast and effective, S0 as an electron donor may be preferred due to elimination of effluent contamination by organic substrate. The removal of perchlorate in up-flow sulfur-packed reactors accorded with the half-order kinetic models (Wan et al. 2017), indicating that reduction rate was mainly limited by the diffusion in biofilm. Koenig and Liu (2001) thought that the supply and concentration of soluble S0 were not rate-limiting steps, because they were unable to control directly. If solid S0 is sufficiently supplied, the contaminate removal may be limited by its dissolution rate. Ju et al. (2007) found that the effect of increasing S0 concentrations on the kinetics of perchlorate reduction was related to particle size of S0. 4 mM powder S0 with particle size of 10–130 μm gave a rate of perchlorate reduction comparable to that of 200 mM granule S0 with the major and minor oblate spheroid axis of 1.75 and 1 mm.

The main weakness of sulfur-based autotrophic perchlorate reduction is the formation of sulfates and acids (Guo et al. 2017). Except for as the by-products of perchlorate reduction, the sulfate mainly originates from S0 disproportionation. S0 is subject to disproportionation to SO42− and S2, which is shown as Eq. (12) (Finster et al. 1998).

Although S2− had been used as an electron donor by certain isolates of PRB (Achenbach et al. 2001), e.g., Dechloromonas agitata sp. nov., 5 mM S2− appeared to cause toxicity for perchlorate bioreduction (Ju et al. 2007; Ju et al. 2008). Furthermore, the sulfate production from the S0 disproportionation exceeded the theoretical sulfate production during the biological perchlorate reduction with S0 as the electron donor, which is a potential drawback of this process (Boles et al. 2012; Gao et al. 2015; Wan et al. 2017). Previous research indicated that temperature, DO, and hydraulic retention time (HRT) had significant influence on S0 disproportionation tendencies (Wan et al. 2019). Considering the balance of S0 disproportionation and perchlorate reduction, higher temperature (27 ± 2 °C) and shorter HRT (0.75 h) was suitable to perchlorate removal by sulfur-packed bed reactor, in which over 99% perchlorate removal efficiency was achieved and sulfate in effluent was only 21.91 mg L−1.

Ucar et al. (2016a) found that methanol supplementation could stimulate the mixed nutrient denitrification process, offering the advantages of higher perchlorate removal and lower effluent sulfate concentration. But this method also had the defect that the organic concentration was excessive in the effluent. In the sulfur-based reactor, most of S0 disproportionation occurred close to the effluent where the oxyanion (such as nitrate, perchlorate) decreased to low concentration (Wan et al. 2017). Zhang et al. (2018) used the step-feeding method to solve the unreasonable pollutants distribution in sulfur-based reactor, leading to high perchlorate reduction rate and low sulfate yield.

Anthrahydroquinone

2,6-Anthrahydroquinone disulfonate (AH2DS), as an effective electron donor, could selectively stimulate the perchlorate bioremediation (Thrash et al. 2007; Van Trump and Coates 2009). Earlier studies showed that several organisms, including dissimilatory perchlorate-reducing bacteria (DPRB), could grow quickly with AH2DS and nitrate as the electron donor and acceptor respectively (Coates et al. 2001a; Coates et al. 2001b). Cultures of Azospira suillum, Geobacter, Dechloromonas agitate, and Dechloromonas aromatica could reduce perchlorate while oxidizing the AH2DS to 2,6-anthraquinone disulfonate (AQDS) (Thrash et al. 2007; Van Trump and Coates 2009).

Thrash et al. (2007) inoculated three representatives of environmentally dominant PRB Azospira suillum, D. aromatica, and Dechloromonas agitata in a bioelectrical reactor (BER) and found that the total concentration of anthraquinone remained constant during the experimental process, indicating an equal conversion between AH2DS and AQDS. Simultaneously, no perchlorate reduction was observed fed with AQDS only. In contrast, if AH2DS was provided, perchlorate was readily reduced by PRB Dechloromonas agitata. The same phenomena were observed in the study of Van Trump and Coates (2009). This demonstrated that AH2DS is oxidized to AQDS while reducing perchlorate. The theoretical stoichiometry of the reaction is as follows (Zhu et al. 2019):

Van Trump and Coates (2009) demonstrated that PRB did not preferentially use acetate over AH2DS as the electron donor. The oxidation rate of AH2DS was not significantly influenced when acetate was added, whereas the mixture of acetate and AH2DS provided additional electron-donating capacity and significantly enhanced the perchlorate reduction. 3.5 mM AH2DS could result in an additional 1.5 mM perchlorate reduction over acetate-only treatment (Van Trump and Coates 2009).

There are many advantages using AH2DS as electron donor. Firstly, the oxidation product of AQDS can be an electronic shuttle to accelerate electron transport efficiency and enhance perchlorate degradation in BER (Thrash et al. 2007). Secondly, AQDS, can be considered as a quinone-based redox mediators (QRM) because of its high redox buffering capacity, which could alleviate the inhibition of perchlorate reduction by long-term oxygen exposure and high concentration of nitrate (Zhu et al. 2019). In addition, the thermodynamic properties of hydroquinone make them only irritate a part of the underlying respiratory process. The midpoint reduction potential of AQDS/AH2DS is about − 0.184 V, which is suitable to inspire the perchlorate and nitrate reduction, but is too electropositive to the sulfate reduction or methanogenesis (< − 0.217 V) (Van Trump and Coates 2009). The unique property of AH2DS precludes undesirable respiratory activities and prevents gross overgrowth of microbial biomass. While successful to improve perchlorate reduction in BER, the existence of AQDS has a drawback because it increases the expense and the requirements for further processing of residual AQDS in effluent (Thrash et al. 2007).

Cathode

A new technology involving electrochemically stimulating bacterial reduction in a bioelectrical reactor (BER) had been applied in perchlorate treatment (Thrash et al. 2007; Shea et al. 2008; Jiang et al. 2017). Former studies suggested that PRB may utilize the cathode as electron donor for growth (Thrash et al. 2007). However, the electrode potential in their microbial fuel cell (MFC) was maintained at − 450 mV, which was high enough to produce the H2 on the surface of electrode for PRB to reduce perchlorate. With the assistance of an electron shuttle, anthraquinone-2,6-disulfonate (AQDS), an overestimated perchlorate removal rate of 17 mg L−1 day−1 (batch configuration) and 60 mg L−1 day−1 (continuous configuration) was gained respectively.

In fact, the electrons can directly transfer from the surface of cathode electrode to bacterial cell membrane by a physical contact between them. As shown in Fig. 5a, the outer membrane redox macromolecules, such as cytochromes can directly accept the electrons from the electrode, resulting in the reduction of terminal electron acceptors, for example perchlorate (Huang et al. 2011; Xie et al. 2014). Perchlorate reduction in a biocathode of MFC in the absence of exogenous electron shuttles was firstly reported by Shea et al. (2008). In dual-chamber MFC, a denitrifying biocathode was adapted to perchlorate-reducing biocathode and PRB utilized the cathode as an electron donor with acetate oxidation in the anode compartment. However, the maximum perchlorate removal rate was only 12 mg-perchlorate L−1 day−1 since the soluble electron donor (acetate) in the medium was lacking. Butler et al. (2010) adopted a similar strategy to establish the perchlorate-reducing biocathode with a mixed culture. Curiously, Dechloromonas sp. PC1, a PRB, did not become an important member of the biocathode community after it was added. The observed maximum reduction rate of perchlorate reached to 24 mg L−1 day−1 without exogenous electron shuttles, but the perchlorate load increased slowly and reaching a 100% perchlorate feed needed 303 days. Mieseler et al. (2013) explored a new strategy to quickly set up stable biocathodic perchlorate reduction. They found that inoculation of cathodes with perchlorate-reducing preculture could shorten the startup time to only 21 days. The electrode properties can impact the microorganism attachment and the MFCs performance (Huang et al. 2011). Li et al. (2015) used a novel polyaniline (PANI)/graphite biocathode for perchlorate reduction in a non-membrane microbial electrolysis cell. PANI with good electrocatalytic and porous structure properties was beneficial to film-forming and electron transfer. The perchlorate reduction rate of the biocathode is increased by more than 12% compared to the cathode without biofilm.

Mechanisms of electron transfer using cathode as electron donor for perchlorate bioreduction. Adapted with permission from Huang et al. (2011), Copyright 2011, Elsevier

Except for direct electron transfer, some microbe could indirectly gain the electrons from electrode by the transportation of redox-active compounds (Fig. 5b). Acinetobacter calcoaceticus, a dominant bacteria in a mixed culture biocathode were found that they could utilize a self-excreted redox compound for extracellular electron transfer in microbially cathodic oxygen reduction (Freguia et al. 2008), which was similar to the function of pyrroloquinoline quinine, an electron shuttle between a soluble enzyme and an electrode (Laurinavicius et al. 2004). The reduction rate was mainly limited by the electron transfer between the bacteria and the anode in MFCs (Sun et al. 2013). Recently, artificial exogenous redox mediators, for example thionine (TH, C14H13N3O2S), potassium ferricyanide (FeCN, K3[Fe(CN)6]), methylene blue (MB, C16H18ClN3S), neutral red (NR, C15H17ClN4), anthraquinone-2,6-disulfonate (AQDS, C14H6O8S2), and resazurin (RZ, C12H7NO4), are used to speed up the electron transfer from electron donor to acceptor (Lian et al. 2016), which may increase the reaction rates by one to several orders of magnitude (Dos Santos et al. 2005). Compared with a mediator-free MFC, MFCs added 3–9 μM resazurin exhibited 50.8–101.6% increases in perchlorate reduction rate, respectively (Lian et al. 2016). The catalyzing mechanism should attribute to the accelerated electron transfer from NADH toperchlorate reductase and the anode via NADH reductase, NADH-ubiquinone reductase, and methylnaphthoquinone led by resazurin. However, these artificial exogenous redox mediators are highly toxic compounds and lack long-term stability, which are unlikely to be approved in real bioremediation.

Application of bioelectrochemical systems (BES) in biological perchlorate reduction (Table 2) can provide virtually inexhaustible electron donor due to the possible use of anode and cathode (Pous et al. 2018), avoiding (or drastically lowering) the continuous addition of chemical agents (e.g., H2, organic matter) as the electron donor or carbon source. Furthermore, the electrodes provide physical support for growth of microorganisms (Modin and Aulenta 2017).

1

Selection of electron donor

There are two basic principles can be considered when selecting an appropriate electron donor to reduce perchlorate biologically: (1) the capacity of electron donor to completely remove perchlorate while minimizing the existence of other contaminants in effluent and (2) the cost of electron donor per unit of perchlorate reduced to chloride.

The choice of electron donor is greatly influenced by thermodynamic and kinetic parameters because they influence the competition of PRB and other microbial, further affect the treatment efficiency and costs. H2 (with CO2) is a favored electron donor for various PRB. Meanwhile, suitable operating conditions should be controlled to minimize the competition between PRB and other microbial activities in order to make PRB be dominant. For example, sulfate reduction could be restricted through proper control over the H2-based MBfR (Chen et al. 2017). And SRB decreased significantly under high acceptor loading and high H2 pressure (Wan et al. 2016).

An excellent organic electron donor contributes to the growth and activity of the PRB. Compared with single organic substrate, multiple organic substrates had higher perchlorate degradation efficiency (Liamleam and Annachhatre 2007). For example, AH2DS did not significantly affect the oxidation of acetate, but the mixed medium of acetate/AH2DS brought additional electron-donating ability and markedly improved the reduction of perchlorate (Van Trump and Coates 2009). Better reduction efficiencies of perchlorate were observed in the methanol/S0-based mixotrophic reactor, simultaneously, and external carbon supplementation prevented the excessively high sulfate concentration in the effluent (Ucar et al. 2016a). Therefore, in order to obtain the optimal perchlorate reduction, it is necessary to use the mixture of multi-type electron donors.

The cost and availability of electron donor is the key factors in practical application and should also be considered. Table 3 shows the cost of some common electron donors in term of per ton of perchlorate removal. The performance of perchlorate bioreduction with acetate as the electron donor is better than molasses (Nerenberg et al. 2006; Lian et al. 2017), but the costs of acetate is higher than molasses. To start the treatment system, acetate may be necessary, and molasses can serve as the long-term electron donor (Perlmutter et al. 2001). It should be noted that complicated organic substrates such as hydrocarbons, glycerol, and molasses are difficult to be the completely utilized by microorganisms. Therefore, high-concentration COD in the effluent is inevitable, which requires subsequent process to residual organics. Meanwhile, complex organic substrates cannot be directly utilized by PRB and need extra pre-fermentation to convert into small molecules organic compounds. Therefore, complex organic electron donors should be avoided unless the above-mentioned issues can be solved well.

The inorganic electron donors (H2, S0, etc.) could completely reduce perchlorate and produce less metabolic sludge production. As a waste by-product of oil refining, the S0 is cost-effective. But the excessive sulfate production is a potential drawback (Boles et al. 2012; Gao et al. 2015; Wan et al. 2017). Generally speaking, H2 is a suitable electron donor, especially to treat high-concentration perchlorate. However, there are safety hazards in the storage and use of H2, even electrolysis of H2 with electrochemical and microbial coupling, or iron corrosion to produce H2 can be utilized. Recently, the simplest organic matter CH4 exhibits great potential to replace the H2 as the electron donor and carbon source in the perchlorate bioreduction (Bender et al. 2005; Luo et al. 2015; Chen et al. 2016). Compared with H2, CH4 is cheaper, is a more extensive source, and has lower explosion risk.

Conclusions and prospects

Biological reduction is considered to be a promising alternative due to its cost-effective way. In order to ensure complete removal of perchlorate, a sufficient amount of suitable electron donor is necessary. Acetate is a suitable electron donor because of its high perchlorate removal rate and low microbial residues. To some extent, organic electron donors are not an ideal choice unless further treatment is available to remove organic residues from the effluent. Multiple organic electron donors have better performance of perchlorate reducing compared with a single organic electron donor. Relatively speaking, H2 is a suitable inorganic electron donor, especially for the treatment of high-load perchlorate wastewater. When selecting the suitable electron donor, it needs to consider treatment costs, availability, reduction efficiency, and secondary pollution.

Despite its various advantages, biological treatment has its deficiency. When dealing with perchlorate-containing drinking water or groundwater, the unknown pathogens and the secondary contamination led by external electron donor should be concerned. To address the shortcoming of biodegradation, it needs to integrate one or more physicochemical and biological process. For example, integrating the ion exchange with a membrane bioreactor such as IEMB could address the problem of biomass accumulation and secondary contamination of effluent. In addition, appropriate reactors, such as FBR, should be designed to prevent the loss of organic matter, avoiding high COD residual in the effluent. And for gaseous electron donors such as H2 or CH4, hydrophobic microporous polyethylene fiber is suitable to increase gas utilization efficiency and improve the safe utilization of hazardous gas (Zhao et al. 2014; Luo et al. 2015). In situ electrochemical H2 production or combined with anaerobic digestion to produce the CH4 is also an ideal alternative, avoiding the storage of large amounts of H2 or CH4. Apart from these, a combination of organic and inorganic electron donors can be used to improve degradation efficiency.

Methanol is a common supplemental electron donor in wastewater treatment because of its availability and cost-effectiveness (Glombitza 2001; Weijma et al. 2003; Liamleam and Annachhatre 2007), but few studies have used it for perchlorate reduction. Therefore, methanol can also be considered as an electron donor for heterotrophic perchlorate reduction in future research. Furthermore, biological reduction has been proved to be an enzymatic reaction and the biocatalysts greatly affect the perchlorate reduction process. Some studies have shown that catalytic degradation of perchlorate is feasible (Chaturvedi and Dave 2013; Liu et al. 2013; Liu et al. 2015; Seraj et al. 2017). Ford et al. (2016) developed a bioinspired iron catalyst inspired by the active sites of (per)chlorate reductase enzymes and nitrate reductase. So it is an interesting idea that if it is possible to supplement enzymes instead of microorganisms to reduce perchlorate. Accordingly, the above recommendations must be further studied and applied in pilot-scale experiment.

References

Achenbach LA, Michaelidou U, Bruce RA, Fryman J, Coates JD (2001) Dechloromonas agitata gen. nov., sp nov and Dechlorosoma suillum gen. nov., sp nov., two novel environmentally dominant (per) chlorate-reducing bacteria and their phylogenetic position. Int J Syst Evol Micr 51:527–533

Ahn CH, Oh H, Ki D, Van Ginkel SW, Rittmann BE, Park J (2009) Bacterial biofilm-community selection during autohydrogenotrophic reduction of nitrate and perchlorate in ion-exchange brine. Appl Microbiol Biot 81:1169–1177

Ahn SC, Hubbard B, Cha DK, Kim BJ (2014) Simultaneous removal of perchlorate and energetic compounds in munitions wastewater by zero-valent iron and perchlorate-respiring bacteria. J Environ Sci Heal A 49:575–583

Andrews EJ, Novak PJ (2001) Influence of ferrous iron and pH on carbon tetrachloride degradation by Methanosarcina thermophila. Water Res 35:2307–2313

Annachhatre AP, Suktrakoolvait S (2001) Biological sulfate reduction using molasses as a carbon source. Water Environ Res 73:118–126

Arthur RD, Torlapati J, Shin K-H, Cha DK, Yoon Y, Son A (2013) Process control factors for continuous microbial perchlorate reduction in the presence of zero-valent iron. Front Env Sci Eng 8:386–393

Bardiya N, Bae JH (2011) Dissimilatory perchlorate reduction: a review. Microbiol Res 166:237–254

Beal EJ, House CH, Orphan VJ (2009) Manganese- and iron-dependent marine methane oxidation. Science 325:184–187

Bender KS, Shang C, Chakraborty R, Belchik SM, Coates JD, Achenbach LA (2005) Identification, characterization, and classification of genes encoding perchlorate reductase. J Bacteriol 187:5090–5096

Boles AR, Conneely T, McKeever R, Nixon P, Nusslein KR, Ergas SJ (2012) Performance of a pilot-scale packed bed reactor for perchlorate reduction using a sulfur oxidizing bacterial consortium. Biotechnol Bioeng 109:637–646

Butler CS, Clauwaert P, Green SJ, Verstraete W, Nerenberg R (2010) Bioelectrochemical perchlorate reduction in a microbial fuel cell. Environ Sci Technol 44:4685–4691

Chaturvedi S, Dave PN (2013) A review on the use of nanometals as catalysts for the thermal decomposition of ammonium perchlorate. J Saudi Chem Soc 17:135–149

Chen R, Luo YH, Chen JX, Zhang Y, Wen LL, Shi LD, Tang Y, Rittmann BE, Zheng P, Zhao HP (2016) Evolution of the microbial community of the biofilm in a methane-based membrane biofilm reactor reducing multiple electron acceptors. Environ Sci Pollut R 23:9540–9548

Chen XM, Liu YW, Peng L, Ni BJ (2017) Perchlorate, nitrate, and sulfate reduction in hydrogen-based membrane biofilm reactor: model-based evaluation. Chem Eng J 316:82–90

Chitrakar R, Makita Y, Hirotsu T, Sonoda A (2012) Montmorillonite modified with hexadecylpyridinium chloride as highly efficient anion exchanger for perchlorate ion. Chem Eng J 191:141–146

Choe JK, Mehnert MH, Guest JS, Strathmann TJ, Werth CJ (2013) Comparative assessment of the environmental sustainability of existing and emerging perchlorate treatment technologies for drinking water. Environ Sci Technol 47:4644–4652

Choi H, Silverstein J (2008) Inhibition of perchlorate reduction by nitrate in a fixed biofilm reactor. J Hazard Mater 159:440–445

Coates JD, Achenbach LA (2004) Microbial perchlorate reduction: rocket-fuelled metabolism. Nat Rev Microbiol 2:569–580

Coates JD, Chakraborty R, Lack JG, O'Connor SM, Cole KA, Bender KS, Achenbach LA (2001a) Anaerobic benzene oxidation coupled to nitrate reduction in pure culture by two strains of Dechloromonas. Nature 411:1039–1043

Coates JD, Chakraborty R, O'Connor SM, Schmidt C, Thieme J (2001b) The geochemical effects of microbial humic substances reduction. Acta Hydrochim Hydrobiol 28:420–427

Crump KS, Gibbs JP (2005) Benchmark calculations for perchlorate from three human cohorts. Environ Health Persp 113:1001–1008

Dasgupta PK, Martinelango PK, Jackson WA, Anderson TA, Tian K, Tock RW, Rajagopalan S (2005) The origin of naturally occurring perchlorate: the role of atmospheric processes. Environ Sci Technol 39:1569–1575

Dong HR, Deng JM, Xie YK, Zhang C, Jiang Z, Cheng YJ, Hou KJ, Zeng GM (2017) Stabilization of nanoscale zero-valent iron (nZVI) with modified biochar for Cr(VI) removal from aqueous solution. J Hazard Mater 332:79–86

Dos Santos AB, Traverse J, Cervantes FJ, Van Lier JB (2005) Enhancing the electron transfer capacity and subsequent color removal in bioreactors by applying thermophilic anaerobic treatment and redox mediators. Biotechnol Bioeng 89:42–52

Eisentraeger A, Klag P, Vansbotter B, Heymann E, Dott W (2001) Denitrification of groundwater with methane as sole hydrogen donor. Water Res 35:2261–2267

Ettwig KF, Butler MK, Le Paslier D, Pelletier E, Mangenot S, Kuypers MMM, Schreiber F, Dutilh BE, Zedelius J, de Beer D, Gloerich J, Wessels HJCT, van Alen T, Luesken F, Wu ML, van de Pas-Schoonen KT, den Camp HJMO, Janssen-Megens EM, Francoijs KJ, Stunnenberg H, Weissenbach J, Jetten MSM, Strous M (2010) Nitrite-driven anaerobic methane oxidation by oxygenic bacteria. Nature 464:543–548

Ettwig KF, Shima S, van de Pas-Schoonen KT, Kahnt J, Medema MH, op den Camp HJM, Jetten MSM, Strous M (2008) Denitrifying bacteria anaerobically oxidize methane in the absence of archaea. Environ Microbiol 10: 3164–3173

Ettwig KF, van Alen T, van de Pas-Schoonen KT, Jetten MSM, Strous M (2009) Enrichment and molecular detection of denitrifying methanotrophic bacteria of the NC10 phylum. Appl Environ Microb 75:3656–3662

Ettwig KF, Zhu BL, Speth D, Keltjens JT, Jetten MSM, Kartal B (2016) Archaea catalyze iron-dependent anaerobic oxidation of methane. P Natl Acad Sci USA 113:12792–12796

Finster K, Liesack W, Thamdrup B (1998) Elemental sulfur and thiosulfate disproportionation by Desulfocapsa sulfoexigens sp. nov., a new anaerobic bacterium isolated from marine surface sediment. Appl Environ Microb 64:119–125

Fonseca AD, Crespo JG, Almeida JS, Reis MA (2000) Drinking water denitrification using a novel ion-exchange membrane bioreactor. Environ Sci Technol 34:1557–1562

Ford CL, Park YJ, Matson EM, Gordon Z, Fout AR (2016) A bioinspired iron catalyst for nitrate and perchlorate reduction. Science 354:741–743

Fox S, Bruner T, Oren Y, Gilron J, Ronen Z (2016) Concurrent microbial reduction of high concentrations of nitrate and perchlorate in an ion exchange membrane bioreactor. Biotechnol Bioeng 113:1881–1891

Freguia S, Rabaey K, Yuan ZG, Keller J (2008) Sequential anode-cathode configuration improves cathodic oxygen reduction and effluent quality of microbial fuel cells. Water Res 42:1387–1396

Gao M, Wang S, Jin C, She Z, Zhao C, Zhao Y, Zhang J, Ren Y (2015) Autotrophic perchlorate reduction kinetics of a microbial consortium using elemental sulfur as an electron donor. Environ Sci Pollut R 22:9694–9703

Giblin TL, Herman DC, Frankenberger WT (2000) Removal of perchlorate from ground water by hydrogen- utilizing bacteria. J Environ Qual 29:1057–1062

Gingras TM, Batista JR (2002) Biological reduction of perchlorate in ion exchange regenerant solutions containing high salinity and ammonium levels. J Environ Monitor 4:96–101

Glombitza F (2001) Treatment of acid lignite mine flooding water by means of microbial sulfate reduction. Waste Manag 21:197–203

Guan XY, Xie YX, Wang JF, Wang J, Liu F (2015) Electron donors and co-contaminants affect microbial community composition and activity in perchlorate degradation. Environ Sci Pollut R 22:6057–6067

Guo J, Zhang C, Lian J, Lu C, Chen Z, Song Y, Guo Y, Xing Y (2017) Effect of thiosulfate on rapid start-up of sulfur-based reduction of high concentrated perchlorate: a study of kinetics, extracellular polymeric substances (EPS) and bacterial community structure. Bioresour Technol 243:932–940

Hatzinger PB (2005) Perchlorate biodegradation for water treatment. Environ Sci Technol 39:239a–247a

Hu SH, Zeng RJ, Burow LC, Lant P, Keller J, Yuan ZG (2009) Enrichment of denitrifying anaerobic methane oxidizing microorganisms. Env Microbiol Rep 1:377–384

Huang LP, Regan JM, Quan X (2011) Electron transfer mechanisms, new applications, and performance of biocathode microbial fuel cells. Bioresour Technol 102:316–323

Huang YH, Zhang TC, Shea PJ, Comfort SD (2003) Effects of oxide coating and selected cations on nitrate reduction by iron metal. J Environ Qual 32:1306–1315

Hutchison JM, Poust SK, Kumar M, Cropek DM, MacAllister IE, Arnett CM, Zilles JL (2013) Perchlorate reduction using free and encapsulated Azospira oryzae enzymes. Environ Sci Technol 47:9934–9941

Jiang C, Yang Q, Wang D, Zhong Y, Chen F, Li X, Zeng G, Li X, Shang M (2017) Simultaneous perchlorate and nitrate removal coupled with electricity generation in autotrophic denitrifying biocathode microbial fuel cell. Chem Eng J 308:783–790

Ju X, Field JA, Sierra-Alvarez R, Salazar M, Bentley H, Bentley R (2007) Chemolithotrophic perchlorate reduction linked to the oxidation of elemental sulfur. Biotechnol Bioeng 96:1073–1082

Ju X, Sierra-Alvarez R, Field JA, Byrnes DJ, Bentley H, Bentley R (2008) Microbial perchlorate reduction with elemental sulfur and other inorganic electron donors. Chemosphere 71:114–122

Kim K, Logan BE (2001) Microbial reduction of perchlorate in pure and mixed culture packed-bed bioreactors. Water Res 35:3071–3076

Knittel K, Boetius A (2009) Anaerobic oxidation of methane: Progress with an unknown process. Annu Rev Microbiol 63:311–334

Knowles R (2005) Denitrifiers associated with methanotrophs and their potential impact on the nitrogen cycle. Ecol Eng 24:441–446

Koenig A, Liu LH (2001) Kinetic model of autotrophic denitrification in sulphur packed-bed reactors. Water Res 35:1969–1978

Kroon AGM, van Ginkel CG (2004) Biological reduction of chlorate in a gas-lift reactor using hydrogen as an energy source. J Environ Qual 33:2026–2029

Lai C, Li BS, Chen M, Zeng GM, Huang DL, Qin L, Liu XG, Cheng M, Wan J, Du CY, Huang FL, Liu SY, Yi H (2018) Simultaneous degradation of P-nitroaniline and electricity generation by using a microfiltration membrane dual-chamber microbial fuel cell. Int J Hydrogen Energ 43:1749–1757

Laurinavicius V, Razumiene J, Ramanavicius A, Ryabov AD (2004) Wiring of PQQ-dehydrogenases. Biosens Bioelectron 20:1217–1222

Li JJ, Gao MM, Zhang G, Wang XH, Wang SG, Song C, Xu YY (2015) Perchlorate reduction in microbial electrolysis cell with polyaniline modified cathode. Bioresour Technol 177:74–79

Liamleam W, Annachhatre AP (2007) Electron donors for biological sulfate reduction. Biotechnol Adv 25:452–463

Lian J, Tian X, Guo J, Guo Y, Song Y, Yue L, Wang Y, Liang X (2016) Effects of resazurin on perchlorate reduction and bioelectricity generation in microbial fuel cells and its catalysing mechanism. Biochem Eng J 114:164–172

Lian J, Tian X, Li Z, Guo J, Guo Y, Yue L, Ping J, Duan L (2017) The effects of different electron donors and electron acceptors on perchlorate reduction and bioelectricity generation in a microbial fuel cell. Int J Hydrogen Energ 42:544–552

Lin YJ, Fang QL, Chen BL (2014) Perchlorate uptake and molecular mechanisms by magnesium/aluminum carbonate layered double hydroxides and the calcined layered double hydroxides. Chem Eng J 237:38–46

Liu JY, Choe JK, Sasnow Z, Werth CJ, Strathmann TJ (2013) Application of a Re-Pd bimetallic catalyst for treatment of perchlorate in waste ion-exchange regenerant brine. Water Res 47:91–101

Liu JY, Choe JK, Wang Y, Shapley JR, Werth CJ, Strathmann TJ (2015) Bioinspired complex-nanoparticle hybrid catalyst system for aqueous perchlorate reduction: rhenium speciation and its influence on catalyst activity. ACS Catal 5:511–522

Logan BE (2001) Assessing the outlook for perchlorate remediation. Environ Sci Technol 35:482a–487a

London MR, De Long SK, Strahota MD, Katz LE, Speitel GE (2011) Autohydrogenotrophic perchlorate reduction kinetics of a microbial consortium in the presence and absence of nitrate. Water Res 45:6593–6601

London MR, Wahman DG, Katz LE, Speitel GE (2013) Zero-valent iron/biotic treatment system for perchlorate-contaminated water: lab-scale performance, modeling, and full-scale implications. J Environ Eng 139:1361–1367

Luo YH, Chen R, Wen LL, Meng F, Zhang Y, Lai CY, Rittmann BE, Zhao HP, Zheng P (2015) Complete perchlorate reduction using methane as the sole electron donor and carbon source. Environ Sci Technol 49:2341–2349

Lv PL, Zhong L, Dong QY, Yang SL, Shen WW, Zhu QS, Lai CY, Luo AC, Tang Y, Zhao HP (2018) The effect of electron competition on chromate reduction using methane as electron donor. Environ Sci Pollut R 25:6609–6618

Ma H, Bonnie NA, Yu M, Che S, Wang Q (2016) Biological treatment of ammonium perchlorate-contaminated wastewater: a review. J Water Reuse Desal 6:82–107

Maree JP, Hulse G, Dods D, Schutte CE (1991) Pilot plant studies on biological sulphate removal from industrial effluent. Iwa Publishing

Martin KJ, Nerenberg R (2012) The membrane biofilm reactor (MBfR) for water and wastewater treatment: principles, applications, and recent developments. Bioresour Technol 122:83–94

Matos CT, Velizarov S, Crespo JG, Reis MAM (2006) Simultaneous removal of perchlorate and nitrate from drinking water using the ion exchange membrane bioreactor concept. Water Res 40:231–240

Mieseler M, Atiyeh MN, Hernandez HH, Ahmad F (2013) Direct enrichment of perchlorate-reducing microbial community for efficient electroactive perchlorate reduction in biocathodes. J Ind Microbiol Biot 40:1321–1327

Miller LG, Baesman SM, Carlstrom CI, Coates JD, Oremland RS (2014) Methane oxidation linked to chlorite dismutation. Front Microbiol 5:275

Modin O, Aulenta F (2017) Three promising applications of microbial electrochemistry for the water sector. Environ Sci-Water Res Technol 3:391–402

Moore AM, De Leon CH, Young TM (2003) Rate and extent of aqueous perchlorate removal by iron surfaces. Environ Sci Technol 37:3189–3198

Nerenberg R, Kawagoshi Y, Rittmann BE (2006) Kinetics of a hydrogen-oxidizing, perchlorate-reducing bacterium. Water Res 40:3290–3296

Nerenberg R, Kawagoshi Y, Rittmann BE (2008) Microbial ecology of a perchlorate-reducing, hydrogen-based membrane biofilm reactor. Water Res 42:1151–1159

Nerenberg R, Rittmann BE (2004) Hydrogen-based, hollow-fiber membrane biofilm reactor for reduction of perchlorate and other oxidized contaminants. Water Sci Technol 49:223–230

Nerenberg R, Rittmann BE, Iwa Programme C (2002) Perchlorate as a secondary substrate in a denitrifying, hollow-fiber membrane biofilm reactor. In: 2nd World Water Congress: Drinking Water Treatment, vol 2. Water Science and Technology: Water Supply, vol 2. pp 259–265

Okeke BC, Frankenberger WT (2005) Use of starch and potato peel waste for perchlorate bioreduction in water. Sci Total Environ 347:35–45

Ontiveros-Valencia A, Tang Y, Krajmalnik-Brown R, Rittmann BE (2013) Perchlorate reduction from a highly contaminated groundwater in the presence of sulfate-reducing bacteria in a hydrogen-fed biofilm. Biotechnol Bioeng 110:3139–3147

Park JY, Yoo YJ (2009) Biological nitrate removal in industrial wastewater treatment: which electron donor we can choose. Appl Microbiol Biot 82:415–429

Patel A, Zuo G, Lehman SG, Badruzzaman M, Clifford DA, Roberts DJ (2008) Fluidized bed reactor for the biological treatment of ion-exchange brine containing perchlorate and nitrate. Water Res 42:4291–4298

Perlmutter MW, Britto R, Cowan JD, Jacobs AK (2001) In situ biotreatment of perchlorate and chromium in groundwater vol 6. Bioremediation of Inorganic Compounds, vol 9

Pous N, Balaguer MD, Colprim J, Puig S (2018) Opportunities for groundwater microbial electro-remediation. Microb Biotechnol 11:119–135

Prosnansky M, Sakakibara Y, Kuroda M (2002) High-rate denitrification and SS rejection by biofilm-electrode reactor (BER) combined with microfiltration. Water Res 36:4801–4810

Ravnjak M, Vrtovsek J, Pintar A (2013) Denitrification of drinking water in a two-stage membrane bioreactor by using immobilized biomass. Bioresour Technol 128:804–808

Ricardo AR, Carvalho G, Velizarov S, Crespo JG, Reis MAM (2012) Kinetics of nitrate and perchlorate removal and biofilm stratification in an ion exchange membrane bioreactor. Water Res 46:4556–4568

Rikken GB, Kroon AGM, Ginkel CGV (1996) Transformation of (per)chlorate into chloride by a newly isolated bacterium: reduction and dismutation. Appl Microbiol Biot 45:420–426

Ryu HW, Nor SJ, Moon KE, Cho KS, Cha DK, Rhee KI (2012) Reduction of perchlorate by salt tolerant bacterial consortia. Bioresour Technol 103:279–285

Sahu AK, Conneely T, Nusslein K, Ergas SJ (2009) Hydrogenotrophic denitrification and perchlorate reduction in ion exchange brines using membrane biofilm reactors. Biotechnol Bioeng 104:483–491

Schaefer CE, Fuller ME, Condee CW, Lowey JM, Hatzinger PB (2007) Comparison of biotic and abiotic treatment approaches for co-mingled perchlorate, nitrate, and nitramine explosives in groundwater. J Contam Hydrol 89:231–250

Seraj S, Kunal P, Li H, Henkelman G, Humphrey SM, Werth CJ (2017) PdAu alloy nanoparticle catalysts: effective candidates for nitrite reduction in water. ACS Catal 7:3268–3276

Shea C, Clauwaert P, Verstraete W, Nerenberg R (2008) Adapting a denitrifying biocathode for perchlorate reduction. Water Sci Technol 58:1941–1946

Shrout JD, Parkin GF (2006) Influence of electron donor, oxygen, and redox potential on bacterial perchlorate degradation. Water Res 40:1191–1199

Shrout JD, Scheetz TE, Casavant TL, Parkin GF (2005a) Isolation and characterization of autotrophic, hydrogen-utilizing, perchlorate-reducing bacteria. Appl Microbiol Biot 67:261–268

Shrout JD, Williams AGB, Scherer MM, Parkin GF (2005b) Inhibition of bacterial perchlorate reduction by zero-valent iron. Biodegradation 16:23–32

Son A, Lee J, Chiu PC, Kim BJ, Cha DK (2006) Microbial reduction of perchlorate with zero-valent iron. Water Res 40:2027–2032

Son AJ, Schmidt CJ, Shin HJ, Cha DK (2011) Microbial community analysis of perchlorate-reducing cultures growing on zero-valent iron. J Hazard Mater 185:669–676

Song W, Gao B, Wang H, Xu X, Xue M, Zha M, Gong B (2017) The rapid adsorption-microbial reduction of perchlorate from aqueous solution by novel amine-crosslinked magnetic biopolymer resin. Bioresour Technol 240:68–76

Srinivasan A, Viraraghavan T (2009) Perchlorate: health effects and technologies for its removal from water resources. Int J Env Res Public Health 6:1418–1442

Srinivasan R, Sorial GA (2009) Treatment of perchlorate in drinking water: a critical review. Sep Purif Technol 69:7–21

Steinberg LM, Trimble JJ, Logan BE (2005) Enzymes responsible for chlorate reduction by Pseudomonas sp are different from those used for perchlorate reduction by Azospira sp. FEMS Microbiol Lett 247:153–159

Sun J, Li W, Li Y, Hu Y, Zhang Y (2013) Redox mediator enhanced simultaneous decolorization of azo dye and bioelectricity generation in air-cathode microbial fuel cell. Bioresour Technol 142:407–414

Tang Y, Ontiveros-Valencia A, Feng L, Zhou C, Krajmalnik-Brown R, Rittmann BE (2013) A biofilm model to understand the onset of sulfate reduction in denitrifying membrane biofilm reactors. Biotechnol Bioeng 110:763–772

Tang Y, Zhao H, Marcus AK, Krajmalnik-Brown R, Rittmann BE (2012) A steady-state biofilm model for simultaneous reduction of nitrate and perchlorate, part 1: model development and numerical solution. Environ Sci Technol 46:1598–1607

Thrash JC, Van Trump JI, Weber KA, Miller E, Achenbach LA, Coates JD (2007) Electrochemical stimulation of microbial perchlorate reduction. Environ Sci Technol 41:1740–1746

Ucar D, Cokgor EU, Sahinkaya E (2016a) Evaluation of nitrate and perchlorate reduction using sulfur-based autotrophic and mixotrophic denitrifying processes. Water Sci Tech-W Sup 16:208–218

Ucar D, Ubay Cokgor E, Sahinkaya E (2016b) Simultaneous nitrate and perchlorate reduction using sulfur-based autotrophic and heterotrophic denitrifying processes. J Chen Technol Biot 91:1471–1477

Upadhyaya G, Kotlarz N, Togna P, Raskin L (2015) Carbohydrate-based electron donor for biological nitrate and perchlorate removal. J Am Water Works Ass 107:674–684

Van der Zee FR, Cervantes FJ (2009) Impact and application of electron shuttles on the redox (bio)transformation of contaminants: a review. Biotechnol Adv 27:256–277

Van Ginkel SW, Ahn CH, Badruzzaman M, Roberts DJ, Lehman SG, Adham SS, Rittmann BE (2008) Kinetics of nitrate and perchlorate reduction in ion-exchange brine using the membrane biofilm reactor (MBfR). Water Res 42:4197–4205

Van Ginkel SW, Tang Y, Rittmann BE (2011) Impact of precipitation on the treatment of real ion-exchange brine using the H-2-based membrane biofilm reactor. Water Sci Technol 63:1453–1458

Van Trump JI, Coates JD (2009) Thermodynamic targeting of microbial perchlorate reduction by selective electron donors. ISME J 3:466–476

Velizarov S, Rodrigues CM, Reis MA, Crespo JG (2000) Mechanism of charged pollutants removal in an ion exchange membrane bioreactor: drinking water denitrification. Biotechnol Bioeng 71:245–254

Wan D, Liu Y, Niu Z, Xiao S, Li D (2016) Perchlorate reduction by hydrogen autotrophic bacteria and microbial community analysis using high-throughput sequencing. Biodegradation 27:47–57

Wan D, Liu Y, Wang Y, Li Q, Jin J, Xiao S (2019) Sulfur disproportionation tendencies in a sulfur packed bed reactor for perchlorate bio-autotrophic reduction at different temperatures and spatial distribution of microbial communities. Chemosphere 215:40–49

Wan D, Liu Y, Wang Y, Wang H, Xiao S (2017) Simultaneous bio-autotrophic reduction of perchlorate and nitrate in a sulfur packed bed reactor: kinetics and bacterial community structure. Water Res 108:280–292

Wang C, Lippincott L, Meng XG (2008) Kinetics of biological perchlorate reduction and pH effect. J Hazard Mater 153:663–669

Wang DB, Wang YL, Liu YW, Ngo HH, Lian Y, Zhao JW, Chen F, Yang Q, Zeng GM, Li XM (2017a) Is denitrifying anaerobic methane oxidation-centered technologies a solution for the sustainable operation of wastewater treatment plants? Bioresour Technol 234:456–465

Wang Y, Jin L, Deshusses MA, Matsumoto MR (2013) The effects of various amendments on the biostimulation of perchlorate reduction in laboratory microcosm and flowthrough soil columns. Chem Eng J 232:388–396

Wang YL, Wang DB, Yang Q, Zeng GM, Li XM (2017b) Wastewater opportunities for denitrifying anaerobic methane oxidation. Trends Biotechnol 35:799–802

Wang ZC, Gao MC, Zhang Y, She ZL, Ren Y, Wang Z, Zhao CC (2014) Perchlorate reduction by hydrogen autotrophic bacteria in a bioelectrochemical reactor. J Environ Manag 142:10–16

Weijma J, Chi TM, Pol LWH, Stams AJM, Lettinga G (2003) The effect of sulphate on methanol conversion in mesophilic upflow anaerobic sludge bed reactors. Process Biochem 38:1259–1266

Wen LL, Yang Q, Zhang ZX, Yi YY, Tang Y, Zhao HP (2016) Interaction of perchlorate and trichloroethene bioreductions in mixed anaerobic culture. Sci Total Environ 571:11–17

Wen LL, Zhang Y, Chen JX, Zhang ZX, Yi YY, Tang Y, Rittmann BE, Zhao HP (2017) The dechlorination of TCE by a perchlorate reducing consortium. Chem Eng J 313:1215–1221

Wu XQ, Yang Q, Xu DC, Zhong Y, Luo K, Li XM, Chen HB, Zeng GM (2013) Simultaneous adsorption/reduction of bromate by nanoscale zerovalent iron supported on modified activated carbon. Ind Eng Chem Res 52:12574–12581

Xie D, Yu H, Li C, Ren Y, Wei C, Feng C (2014) Competitive microbial reduction of perchlorate and nitrate with a cathode directly serving as the electron donor. Electrochim Acta 133:217–223

Xie T, Yang Q, Winkler MKH, Wang D, Zhong Y, An H, Chen F, Yao F, Wang X, Wu J, Li X (2018) Perchlorate bioreduction linked to methane oxidation in a membrane biofilm reactor: performance and microbial community structure. J Hazard Mater 357:244–252

Xu X, Gao B, Jin B, Zhen H, Wang X, Dai M (2015a) Physicochemical characteristics of epichlorohydrin, pyridine and trimethylamine functionalized cotton stalk and its adsorption/desorption properties for perchlorate. J Colloid Interf Sci 440:219–228

Xu X, Gao B, Jin B, Zhen H, Wang X, Dai M (2015b) Study of microbial perchlorate reduction: considering of multiple pH, electron acceptors and donors. J Hazard Mater 285:228–235

Yang Q, Yao FB, Zhong Y, Wang DB, Chen F, Sun J, Hua S, Li SB, Li XM, Zeng GM (2016) Catalytic and electrocatalytic reduction of perchlorate in water—a review. Chem Eng J 306:1081–1091

Yao FB, Zhong Y, Yang Q, Wang DB, Chen F, Zhao JW, Xie T, Jiang C, An HX, Zeng GM, Li XM (2017) Effective adsorption/electrocatalytic degradation of perchlorate using Pd/Pt supported on N-doped activated carbon fiber cathode. J Hazard Mater 323:602–610

Yazdani SS, Gonzalez R (2007) Anaerobic fermentation of glycerol: a path to economic viability for the biofuels industry. Curr Opin Biotech 18:213–219

Ye L, You H, Yao J, Su HL (2012) Water treatment technologies for perchlorate: a review. Desalination 298:1–12

Yu XY, Amrhein C, Deshusses MA, Matsumoto MR (2006) Perchlorate reduction by autotrophic bacteria in the presence of zero-valent iron. Environ Sci Technol 40:1328–1334

Yu XY, Amrhein C, Deshusses MA, Matsumoto MR (2007) Perchlorate reduction by autotrophic bacteria attached to zerovalent iron in a flow-through reactor. Environ Sci Technol 41:990–997

Zhang HS, Bruns MA, Logan BE (2002) Perchlorate reduction by a novel chemolithoautotrophic, hydrogen-oxidizing bacterium. Environ Microbiol 4:570–576

Zhang Y, Chen JX, Wen LL, Tang Y, Zhao HP (2016) Effects of salinity on simultaneous reduction of perchlorate and nitrate in a methane-based membrane biofilm reactor. Environ Sci Pollut Res Int 23:24248–24255

Zhao HP, Ilhan ZE, Ontiveros-Valencia A, Tang Y, Rittmann BE, Krajmalnik-Brown R (2013a) Effects of multiple electron acceptors on microbial interactions in a hydrogen-based biofilm. Environ Sci Technol 47:7396–7403

Zhao HP, Ontiveros-Valencia A, Tang Y, Kim BO, Ilhan ZE, Krajmalnik-Brown R, Rittrnann BE (2013b) Using a two-stage hydrogen-based membrane biofilm reactor (MBfR) to achieve complete perchlorate reduction in the presence of nitrate and sulfate. Environ Sci Technol 47:1565–1572