Abstract

Biological denitrification was reviewed regarding its potential application to treating nitrate in industrial wastewater. Although heterotrophic denitrification is an efficient and well-developed process, some carbon content in wastewater is essential to maintain bacterial activity. Because of the high operating cost of heterotrophic denitrification caused by the required addition of a carbon source and potential “carbon breakthrough”, the study of autotrophic denitrification has attracted the interest of numerous researchers. Many advances in autotrophic processes have been made in the application of novel concepts and reaction schemes. While the main advantage of autotrophic bacteria rests on the reduction of operating costs by the replacement of an external carbon source with a cheaper electron donor, further decrease in cost requires additional refinement of these processes, including further improvement of reactor structure and optimization of reaction conditions. In the long term, new concepts are required for a compact wastewater treatment process. This review addresses the state of the art of each electron donor candidate for its potential application to the treatment of industrial wastewater containing nitrate.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Nitrate and/or nitrite contamination of water and groundwater is an increasingly serious problem in many developed and developing countries (Hiscock et al. 1991; Devlin et al. 2000; Kimura et al. 2002; Almasri 2007). The regulations for nitrate concentrations in drinking water have been set lower to 10 NO3 −-N mg/l for the USA, Japan, and Korea, and 11.3 NO3 −-N mg/l for the European Union (Jang et al. 2005; McAdam and Judd 2006) and this change has spurred the search for and study of better treatment processes. Among the various methods available for nitrate treatment, such as ion exchange, adsorption, chemical treatment, and membrane technology, biological treatment has been widely used. Ion exchange and adsorption processes have been developed mainly for the production of high purity water and generate concentrated brine that needs additional treatment, often involving adsorption resins whose capacity is rapidly reached by these concentrates, thus requiring frequent replacement or regeneration. Membrane technology (i.e., reverse osmosis) is a concentrating method which needs a posttreatment of the brine before discharging out of the process, and chemical treatment is inefficient in treating the low nitrate concentrations of wastewater and requires a continuous and large supply of chemicals (Croll and Hayes 1988; Hiscock et al. 1991; Annouar et al. 2004; McAdam and Judd 2006). As shown in Table 1, biological denitrification is a well-developed and widely used method, one technically and economically superior compared to other competing methods (De Lucas et al. 2005) and involves a microbial respiration which uses nitrate as a final electron acceptor under anoxic conditions instead of oxygen in oxic conditions. Metabolically, denitrifying bacteria use an enzymatic pathway consisting of four steps or reactions successively involving nitrate reductase, nitrite reductase, nitric oxide reductase, and nitrous oxide reductase in the periplasmic and/or inner membrane (Mellor et al. 1992; Shapleigh et al. 1987). The proposed mechanisms for these enzymes and the related genes are well explained by Tavares et al. (2006) and Zumft (1997), and the illustration for the locations and reactions of these enzymes is shown in Fig. 1. As these oxidoreductases need an electron donor, NADH should be regenerated to maintain their activities. Thus, maintenance of useful levels of an electron donor for microbial denitrification is the main concern for efficient denitrification. Because the microbes with denitrification ability utilize a variety of electron donors, such as carbon, sulfur, hydrogen, etc., many processes have been developed for each kind of donor. The detailed progress with the merits and demerits of each process will be addressed in this review.

Organization of the anaerobic electron transfer chain of Pseudomonas stutzeri. The shaded areas represent the components of the constitutive aerobic respiratory chain consisting of an NADH dehydrogenase complex (DH), quinone cycle (Q, QH 2), cytochrome bc1 complex (Cyt bc1), and the cytochrome cb terminal oxidase complex (Cyt cb). The denitrification system comprises respiratory nitrate reductase (NAR), nitrite reductase (NIR), NO reductase (NOR), and N2O reductase (N 2OR). The enzyme is modeled according to the situation with Ralstonia eutropha and Paracoccus denitrificans. FeS iron-sulfur centers, b heme B, c heme C, d1 heme D1, cyt c unspecified c-type cytochromes accepting electrons from the bc1 complex and acting on N2OR and NOR, cyt c551 cytochrome c551, AP postulated nitrate/nitrite antiporter (Zumft 1997)

Heterotrophic denitrification

Heterotrophic denitrification is a process that uses various carbon compounds as energy and electron sources and is mediated by a number of bacterial genera including Pseudomonas, Paracoccus, Flavobacterium, Alcaligenes, and Bacillus spp. (Koren et al. 2000). In municipal wastewater and dairy-farming wastewater, where enough carbon sources for denitrification usually exist, control of the carbon to nitrogen (C/N) ratio is not a major concern for the process. Factors controlling the removal efficiency in this system are influent concentration, microbial concentration, the retention times of the sludge and wastewater, reactor configuration, etc. The influent to the treatment system in this kind of wastewater occasionally also contains ammonia, which requires aerobic oxidation to nitrate and/or nitrite (nitrification) before it can be denitrified, making control of the oxygen concentrations another concern and a contributing factor to the operational and capital costs of this approach.

Newly discovered microbiological activities can be used independently or in combination with conventional nitrification/denitrification for treating nitrogen compounds in wastewater. Methods based on new concepts, including a single reactor system for high ammonium removal over nitrite (Hellinga et al. 1998), anaerobic ammonium oxidation (van de Graaf et al. 1995), completely autotrophic nitrogen removal over nitrite (Strous et al. 1997), and oxygen limited autotrophic nitrification–denitrification (Kuai and Verstraete 1998), have been commercialized or tested in pilot-scale plants which demonstrated the efficient removal of nitrogen from water with a very low organic load, in a reduced space, and with a low energy requirement (Third et al. 2001; Fux et al. 2002), although the operational conditions and/or sludge development at the early stage of the processing are not easily constructed (Ahn 2006).

In contrast to municipal wastewater, wastewater containing very low concentrations of carbon compounds, often no carbon at all, together with high concentration of nitrate are produced in various industrial plants, such as mineral processing, electroplating, semiconductor manufacturing, and power plants (Buchheister et al. 2000; Kasia et al. 2005; Gabaldón et al. 2007). With high concentrations of nitrate with insufficient carbon sources flowing into the treatment system, a conventional biological denitrification treatment process requires additional carbon sources to match the maximum contaminant level (De Lucas et al. 2005).

A supply of carbon such as methanol, acetate, and ethanol is the first choice for a solution to this problem. Stoichiometric reaction equations for some carbons are shown in Table 2. Since the construction of the first full-scale water denitrification plant in 1983, many pilot- or full-scale plants have been constructed (Matějů et al. 1992). The basic concept of these processes, such as “Biodenit”, “Nitrazur”, and other packed-bed processes, are the same. Clay, ceramic, or gravel were used as an immobilization matrix for the microbes and carbon sources, such as methanol, acetic acid, or ethanol, were supplied together with phosphate to keep the nitrite level low. As the unused carbon source might cause a second contamination (carbon breakthrough) and microbes might detach from the matrix, all of these processes required posttreatments such as coagulation, adsorption, and disinfection (Holló and Czakó 1987; Matějů et al. 1992).

In addition to packed-bed reactors, a fluidized-bed reactor was also applied to the denitrification process in a pilot-scale plant. The German process “Denipor” and other similar reactors demonstrated high removal rates with a volumetric base more than ten times and sometimes 50 times faster than a packed-bed reactor (Matějů et al. 1992). Also fluidized-bed processes could reduce clogging and channeling problems, which are often encountered in packed-bed type reactors and decrease reactor performance. However, control and operability issues still hinder wider applications of these processes in a commercial-scale operation.

To solve the problem of contamination of denitrified water by microbes, the immobilization of microbes has been studied (Matějů et al. 1992). Although the advantages of using pure immobilized bacterial isolates are high denitrification rates as well as the prevention of leaching microbes out of the system, decreases in the effective rate mainly due to the limited mass transfer through the immobilization matrix and the limited stability of the matrix itself are the concerns that need to be addressed (Matějů et al. 1992). In addition, the control of the C/N ratio to remove nitrate completely without producing nitrite and without carbon breakthrough is another persistent problem, especially when the fluctuation of influent concentrations is great (Her and Huang 1995; Kim et al. 2002a). Another concern of C/N ratio is the toxicity of carbon sources such as methanol, ethanol, and benzoic acid. They gave harmful effects on the process when excess amount was added and could give harmful effects on the environment if they were released from the process (Her and Huang 1995).

Since the nitrate removal efficiency afforded by methanol is similar to other soluble carbon sources (Table 3), the choice of carbon source is mainly determined by cost (Soares 2000; Kesserü et al. 2002). Although methanol is the cheapest carbon source among widely known carbon substrates, the large amounts of methanol required for wastewater treatment has led researchers to search for even cheaper substrates (Bilanovic et al. 1999). Many kinds of cheap and insoluble carbon sources including cotton, wheat straw, newspaper, sawdust, starch, and vegetable oil have been studied (Volokita et al. 1996a, b; Soares et al. 2000; Hunter 2001; Kim et al. 2002b). Among them, cotton seems to be the most technically feasible material due to its high cellulose content and high denitrification rate compared to other insoluble carbon, although the cost of this substrate based on the removal amount of nitrate was similar to methanol (Soares et al. 2000). Unfortunately, as a replacement of methanol, cotton is still inferior to methanol in the denitrification rate and has a comparable cost (Tables 3 and 4).

Because the denitrification rate when using an insoluble carbon source is low compared to methanol, application of insoluble substrates has been concentrated on the removal of nitrate from underground water (Robertson and Anderson 1999; Hunter 2001, 2003). As soluble carbon sources cause operational difficulties due to films of microbes plugging the small channels by which water and substrates were delivered (Hunter 2001), an insoluble substrate was suggested as an alternative, in which a solid carbon source was used as both a supporting material for microbes and as a carbon substrate. Although the supply rate of carbon was slow from this kind of carbon source and thus slow nitrate removal rate as shown in Table 3, the constant supply of carbon could reduce the maintenance and operating costs compared to soluble substrates such as methanol and acetic acid, which require additional apparatus for delivery, such as pumps, reservoirs, and injection wells. A pilot-scale reactor using cotton was operated successfully for 6 months (Soares et al. 2000), but unfortunately, high pressures in the reactor compressed the cotton-bed, decreasing the removal rate and limiting the height of the reactor. Although the highest removal rate was maintained for only a short time because of the compression, its stable removal efficiency and high microbial concentration demonstrated its potential usefulness.

Other cheap sources of carbon have been studied, including mixed volatile organic acids from anaerobic digesters (Table 5; Bilanovic et al. 1999; Elefsiniotis et al. 2004) and agrofood industrial wastewater whose toxicity to microbes are negligible (De Lucas et al. 2005). Since these carbon sources were proven efficient in removing nitrates and no other costs were involved for obtaining these materials, they could be a good substitute for the methanol where they were easily obtainable.

When pesticides were cocontaminants with nitrate in groundwater, the pesticides were removed by the addition of carbon sources, probably by way of cometabolic pathways, and nitrate was simultaneously transformed to nitrogen gas (Aslan 2005; Aslan and Türkman 2005). Because the metabolic pathways utilized to degrade these two pollutants are not apparently related, no correlation was found between these two activities. Only the effects of carbon dosage on each pollutant were reported in these studies. Moreover, although the high efficiencies of pesticide removal were achieved, the final concentrations were still unacceptable for drinking water and required a further treatment, such as adsorption (Aslan and Türkman 2005).

One thing worth mentioning under the topic of heterotrophic denitrification is aerobic denitrification as performed by Paracoccus denitrificans (Lukow and Diekmann 1997). Although denitrification is mainly known as an anaerobic respiration process, this unusual aerobic process exists in many microorganisms (Chen et al. 2003; Takaya et al. 2003). In aerobic conditions, instead of nitrogen gas as in anaerobic processes, these microbes produce nitrous oxide, which is toxic to the microbes and also a stronger greenhouse gas than carbon dioxide due to its longer half-life (Takaya et al. 2003).

Autotrophic denitrification

While the replacement of the carbon source has been widely studied, the use of inorganic electron donors was suggested to overcome the problems related to the usage of organic carbon and in preventing carbon and microbial breakthrough, all of which caused increased operating costs for maintaining high removal rates. Inorganic electron donors such as hydrogen and sulfur can provide electrons for autotrophic microbial processes, and thus, autotrophic denitrification was thought to be superior to the carbon-addition processes, considering the reduction in operating costs afforded by eliminating the need for an external carbon source and the lower handling costs of decreased sludge production (Zhang and Lampe 1999). Lower sludge production (expressed as C5H7NO2) per unit mole of removed nitrate for autotrophic denitrification compared to heterotrophic denitrification is also shown in Table 2.

Reduced sulfur compounds

Autotrophic denitrification using sulfur compounds is a microbial activity which utilizes an inorganic reduced sulfur (the element or a compound) as an electron source instead of the carbon compounds used in heterotrophic denitrification (Batchelor and Lawrence 1978; Jang et al. 2005). Inorganic sulfur compounds include sulfide (S2 −), elemental sulfur (S), thiosulfate (S2O3 2−), tetrathionate (S4O6 2−), and sulfite (SO3 2−). As is shown in Table 4, since the price of elemental sulfur is much cheaper than the cost of carbon sources such as methanol and acetate, the operational cost of the denitrification process could be reduced (Batchelor and Lawrence 1978; Jang et al. 2005). This microbial ability and related water treatment processes have been known for over 50 years (Baalsrud and Baalsrud 1954; Batchelor and Lawrence 1978) and have presently regained their usefulness in reducing the high cost of biological denitrification. Elemental sulfur was studied most extensively mainly because of its low price, high sulfur content to mass ratio among the reduced sulfur compounds, and ease of handling (Hashimoto et al. 1987; Batchelor and Lawrence 1978). Moreover, the amount of sulfate produced in the process is least when using elemental sulfur (Kimura et al. 2002). Although promising elemental sulfur appears to be as a substrate for denitrification, its low solubility could severely limit its availability to microorganisms, presenting an inherent weak point in this strategy. Hashimoto et al. (1987) also paid attention to the difficulty of using isolated microorganisms such as Thiobacillus denitrificans in the wastewater treatment system where it is usually hard to maintain pure populations. Feasibility tests revealed that the sequential adaptation of the sludge acclimated the microbes to using elemental sulfur and increased the denitrification to a rate similar to the theoretical rate. Although the denitrification rate was lower than has been previously reported mainly due to the oxygen concentrations, denitrification using elemental sulfur was able to operate in a continuous culture at over 95% removal efficiency. However, the low solubility of the elemental sulfur remained the main obstruction to the application of this process in wastewater treatment systems. By analyzing kinetic studies, Koenig and Liu (2001) concluded the dissolution rate of solid sulfur was the limiting factor in and cause of low sulfur autotrophic denitrification. The energy yields for elemental sulfur or thiosulfate are almost the same (91.15 and 92.97 kJ/electron equivalent, respectively) and are just below that of methanol (109.18 kJ/e−-eq). This conclusion was reasonably inferred by the observation of a sevenfold increase in the specific denitrification rate when a stoichiometric amount of thiosulfate was added to the same culture of Thiobacillus denitrificans and was confirmed by a separate experiment in which an immediate increase in rate was observed when thiosulfate was added to the sulfur-using culture (Koenig and Liu 2001). Similar high rates were also observed in other experiments (Claus and Kutzner 1985; Yamamoto-Ikemoto et al. 2000; Table 5).

The production of hydrogen ions during denitrification has been observed to alter the pH of the medium (Table 2), but in the process, this caused the accumulation of nitrite and decreased removal rates (Furumai et al. 1996). Nitrite is a precursor of nitrosoamine which is a carcinogen and a cause of infant methemoglobinemia (blue-baby syndrome; Matějů et al. 1992). The production of nitrite during water treatment is a significant problem that decreases the process efficiency of biological treatment methods (Foglar et al. 2005). Since the removal rate for nitrate is higher than that of nitrite, high concentrations of nitrate could induce nitrite accumulation, and many other factors such as the sulfur to nitrogen (S/N) ratio, nutrients, pH, etc. also induce nitrite accumulation (Hunter, 2003; Campos et al. 2008). To maintain pH and to compensate for the theoretical alkalinity, which is equivalent to 4.8 mg CaCO3/mg N-NO3 − removed, limestone was added to the reactor. The addition of limestone not only creates the needed alkalinity but also provides inorganic carbon for autotrophic denitrifying bacteria and is thus called the “sulfur-limestone autotrophic denitrification” (Zhang and Lampe 1999). This process does not require an external organic carbon source, and less sludge is produced compared to heterotrophic denitrification. These factors also provide additional benefits when considering secondary contamination which might result from “carbon breakthrough” (Zhang 2004). Although study of this process started in 1970s, it has gained much attention due to the need for safe nitrate-free groundwater (Driscoll and Bisogni 1978; Zhang 2004). Because lime and sulfur are solid materials, they could be easily combined into a permeable reactive barrier for the in situ treatment of groundwater by this microbial process (Moon et al. 2004). Monitoring of nitrite formation, particularly when the influent concentration of nitrate was changed, revealed that the process required adaptation time, but after that time, high removal efficiencies could be maintained. In this kind of process, more experimentation together with reactor modeling and a deeper understanding of the mechanisms involved are still required to obtain proper quantitative data for the design of large-scale reactors (Zhang 2004; Zeng and Zhang 2005). Another concern for facilitating this process was the rapid formation of a microbial film on the surface of the elemental sulfur. Recently, granular biofilms with pellet-like morphology, formed through acclimation of the microbes to thiosulfate, was used as an inoculum, accelerating arrival at a steady state of system operation and achieving more than 95% removal efficiency, which was maintained continuously until the nitrate loading reached maximum (Sierra-Alvarez et al. 2007).

Another method of controlling a system’s pH was the combination of autotrophic denitrification with heterotrophic denitrification that produces carbon dioxide (Lee et al. 2001). When sulfide was supplied to the reactor with carbon sources, acetate, or methanol, the reaction rate was greatly increased to about ten times faster than the reaction using autotrophic bacteria alone (Table 5; Gommers et al. 1988; Lee et al. 2001; Kim et al. 2002a). Higher reaction rates were thought to be achievable only from heterotrophic denitrification, not from autotrophic denitrification.

Since Thiobacillus denitrificans does not agglomerate, it is hard to maintain a sludge during processing and to prevent the microbes from leaving the system. Immobilization of the microorganisms using elemental sulfur itself is the natural solution here because film formation on the surface of the sulfur is an efficient means for the microbes to ingest a low solubility substrate, an effect that has caused elemental sulfur to be studied widely for these applications (Lee et al. 2001; Soares 2002; Jang et al. 2005). Sulfur fluidized-bed reactors instead of sulfur packed-bed reactors resulted in higher loading rates of nitrate compared to the latter one, although frequently increases in effluent nitrate concentration revealed the problems under actual operating conditions (Kim et al. 2004). Membrane technology was occasionally combined with autotrophic denitrification (McAdam and Judd 2006). Due to the low specific growth rate of the autotrophic bacteria, it is hard to maintain at a considerable population within the reactor system, while biological growth and leakage along with soluble microbial by-products is also a concern for the development and utility of this process (Kimura et al. 2002). The combination of sulfur-using bacteria with membrane technology was expected to overcome these problems with effective denitrification (McAdam and Judd 2006). Ultrafiltration membranes (75,000 Da) prevented the leakage of bacteria, which has occasionally happened in other sulfur-based denitrification processes (Kimura et al. 2002), but the leakage of assimilable organic carbon over the recommended concentration (10 μg/l) indicated the necessity for process modification. Other by-products of sulfur such as sulfide could be released if produced (Kimura et al. 2002).

Sulfate was a main product along with nitrogen gas in the above processes and, since the mean concentration of sulfate in sea water is 2,700 mg/l, direct discharge into sea water is not a problem. However, normally 200 mg/l is a recommended concentration for drinking water and higher concentrations of sulfate can cause corrosion problems and can act as a laxative. Therefore, discharge into freshwater might require posttreatment processing (Soares 2000; Kimura et al. 2002).

Autotrophic denitrification using sulfur is known to be carried out by Thiobacillus denitrificans and/or Thiomicrospira denitrificans (Zhang and Lampe 1999). However, 16S rDNA analysis of a microbial biofilm community revealed that, when a biofilm developed on the surface of the sulfur, other heterotrophic bacteria were part of the community and probably also took a part in the denitrification (Koenig et al. 2005). Thiobacillus versutus, Thiobacillus thyasiris, Paracoccus denitrificans, and Paracoccus pantotrophus (formal name was Thiosphaera pantotropha) can grow under autotrophic or heterotrophic conditions (Oh et al. 2001). Among them, Paracoccus pantotrophus is a unique species which can convert ammonia to nitrogen gas via nitrate under aerobic conditions, is able to use various substrates and to oxidize reduced sulfur compounds while also nitrifying ammonia, can apparently perform nitrification/denitrification using various electron donors, and preferentially uses sulfur instead of carbon sources (Gupta 1997).

Overall, sulfur-utilizing denitrification processes seem to be adequate for the removal of nitrates from underground water and low concentration of nitrate wastewater due to its low nitrate removal rate. For treatment of industrial wastewater, more sophisticated methods for the protection of the biofilm, which is needed on the elemental sulfur surfaces, in high flow rate conditions would be required to handle large amounts of wastewater, and a facilitating method to solubilize elemental sulfur is also required. Furthermore, the needed improvements in reaction efficiency together with improved costs relative to the removed nitrate should be worked out in the near future.

Hydrogen

Hydrogen is also a promising electron donor for denitrification because of its high selectivity for nitrate removal and the lack of a harmful by-product (Chang et al. 1999). Rhodopseudomonas sphaeroides was reported first as a nonsulfur autotrophic bacterium with denitrification abilities (Shen and Hirayama 1991; Satoh et al. 1976). Studies of denitrifying bacteria using hydrogen as an electron donor were done mainly on Paracoccus denitrificans, Alcaligenes eutrophus, and Pseudomonas pseudoflava (Matějů et al. 1992; Chang et al. 1999), although most work has been done using mixed populations of microbes, whose population dynamics could change with the conditions. For example, monitoring of microbial populations revealed that Paracoccus denitrificans diminished in a hydrogen-dependent denitrification reactor where Ochrobactrum anthropi, Pseudomonas stutzeri, and Paracoccus pantotrophus increased and were thus in charge of denitrification (Szekeres et al. 2002). Because hydrogen gas and the reaction products (nitrogen gas and water) are harmless to humans, hydrogen could be the best choice for the treatment of drinking water compared to organic carbons and reduced sulfur (Chang et al. 1999).

Early work for autotrophic denitrification using hydrogen was done by Kurt et al. (1987), where nitrate was removed by a mixed culture in a fluidized bed to which hydrogen was supplied by a bubble absorption tank located in a recycle line. A hydrogen-utilizing denitrification process was scaled up to commercial scale at Rasseln, Germany (Gros et al. 1988). Called “Denitropur”, the process was a fixed-bed reactor and compressed hydrogen was supplied together with carbon dioxide and phosphate, and the resulting nitrate removal rate was reduced only by half compared to the lab-scale reactor (Kurt et al. 1987; Dries et al. 1988; Gros et al. 1988). A fluidized-bed reactor with an immobilized and isolated microbe, A. eutrophus, has also been tested and produced better rates but exhibited some limitations. Nitrate reductase and nitrite reductase suffered an inhibitory effect under 0.1 and 0.2 mg/l hydrogen, respectively, while hydrogen solubility in water is 1.6 mg/l. It was concluded that low hydrogen concentration caused nitrite accumulation and that phosphate concentration was also an important factor for nitrite control (Chang et al. 1999).

In these processes, hydrogen was supplied by gas absorption but was not fully consumed in the system such that residual hydrogen within the effluent could create an explosive atmosphere (Lee and Rittmann 2002; Terada et al. 2006). As previously mentioned, at low hydrogen concentrations, nitrite formation was induced, making the maintenance of appropriate hydrogen levels an important issue. To feed the required amount of hydrogen to microbes, biofilm formation was allowed on a gas diffusing membrane, through which hydrogen was supplied. By the adoption of fibrous membranes, high amounts of biomass could be built up in a system, possibly countering the previously discussed disadvantage of these slow growing autotrophic bacteria (Kurt et al. 1987). A hollow-fiber membrane/biofilm reactor was set up (Lee and Rittmann 2000) in which hydrogen was fed through the membrane to the biofilm on the surface of the membrane and by the control of the hydrogen pressure, the removal rate of hydrogen together with the nitrate removal efficiency was able to be controlled while minimizing the wastage of hydrogen. This process demonstrated that high denitrification rates and high hydrogen utilizing flux could be achieved and the removal efficiency of the system could be manipulated by changes of hydrogen pressure. Since the inlet concentration was usually 10 to 20 mg NO3 −-N/l in hollow-fiber membrane treatment processes in an early stage (Lee and Rittmann 2000, 2002; Haugen et al. 2002), a test of the stability of the system under a high concentration of nitrate needed to be done before it could be applied to industrial wastewater, and since the biofilm formed on the outside of the membrane, posttreatment water sterilization was required, which is normally not the case for other membrane microbial reactors. The removal efficiency of the system was sensitive to the pH, which caused the precipitation of CaCO3 (Lee and Rittmann 2003), normally a negligible problem in a short-term reaction, but the authors mentioned the precipitation needed to be monitored in long-term operations (Lee and Rittmann 2003; Grommen et al. 2006).

To treat high concentrations of nitrate wastewater, a microbial community was adapted to the high concentrations by a step-wise increase (Shin et al. 2005). The denitrification reactor was incorporated with another hollow-fiber membrane/biofilm reactor for nitrification. Although the denitrification rate per membrane unit was low compared to the previous results, volumetric rate of throughput was increased enormously by using bundles of membranes together with an acclimated microbial community (Table 5). Other trials of the combination of a continuous, stirred, tank reactor (CSTR) with a hollow-fiber membrane reactor for an even distribution of nitrate to the biofilm also showed promise with a steady removal of nitrate for 300 days. The volumetric rate, however, was decreased in this reactor, probably due to shear forces on the biofilm and low surface area of membrane compared to the tank volume required to facilitate stirring (Shin et al. 2008).

The long period of the acclimation (several tens of days) for the microbes means a long start-up time is required, a common problem using autotrophic bacteria. This time could be reduced by the usage of fibrous slag around the gas-permeable membrane (Terada et al. 2006), providing additional support (slag) for biofilm, such that the fully grown microbial film could be obtained within 10 days and maintain their morphology for more than 2 months, with the process operating steadily all the while. Although other conclusions for the beneficial role of slag, which is principally the prevention of biofilm detachment, seem appropriate, the experimental proof of these was not provided. An interesting conclusion from this study was that the excess supply of hydrogen was not only beneficial in the view point of wasting hydrogen but it also produced favorable conditions for the growth of sulfate reducing bacteria by lowering the oxidation reduction potential.

Different types of membrane reactors other than hollow-fiber membrane reactors were studied by Rezania et al. (2007). An anaerobic submerged membrane bioreactor, where hydrogen-saturated water was supplied, could be operated without the addition of an external scouring gas by recycling of the generated nitrogen.

A new concept which combines two different electron donors, sulfur and hydrogen, has been invented (Wang and Qu 2003), in which the hydrogen ion, formed in the lower part of the reactor by sulfur autotrophic denitrification, was consumed in the upper part of the reactor through hydrogen formation on the cathode during the electrolysis of water. The produced hydrogen acts as another electron donor in the upper part, so that pH of the media did not change and the increase of water hardness, usually caused by the use of limestone, did not occur. Although the sulfate formation problem in this system was not solved and long acclimation times were still needed, good denitrification efficiency was obtained.

By the help of various configurations, membrane technology has advanced enormously in removing the main disadvantages of fouling and the difficulty of increasing the size to full-scale processing. Since most of the research, except one full-scale project, were carried out in lab-scale reactors, a cost analysis and feasibility study for the applicability of this technique at the industrial scale is needed to assess the possibility of commercialization (McAdam and Judd 2006).

Until now, hydrogen-using denitrification combined with membrane technology has been thought to be relevant for the production of drinking water quality. For the application of wastewater, kinetic studies of the reactor design and the understanding of reaction mechanisms need to be gained in order to improve reactor efficiency. For example, the limiting substrate, which was presumed to be nitrate with sufficient hydrogen concentrations (Lee and Rittmann 2002), is still not certain and the working interrelationship between them is also uncertain.

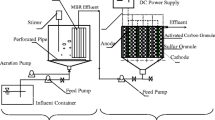

Novel concept: bioelectrochemical method

Although the denitrification process using hydrogen as an electron donor has been proven feasible, the major drawback is the hydrogen resource and the cost of hydrogen, which is about three times more expensive than methanol per unit mass. On the other hand, although the cost of hydrogen per unit mass is higher than that of methanol, the cost of hydrogen per unit nitrate removed is lower than methanol (Table 4). However, most hydrogen was not consumed by the microbes and left the system, even in a membrane reactor (Terada et al. 2006). If a stoichiometric amount of hydrogen was used, the cost could be comparable with methanol or even lower (Grommen et al. 2006). The low solubility and dissolution rate of hydrogen were other disadvantages of this system (Prosnansky et al. 2002). To reduce wastage of hydrogen, a new concept which combines an electrochemical method with biological treatment in a bioelectro reactor (BER) was exploited by Sakakibara and Kuroda (1993). A biofilm formed on the cathode could denitrify nitrate by the help of hydrogen produced on the electrode (cathode) by electrolysis. Through their pioneering work with this novel concept and other studies, including continuous treatment using this system (Sakakibara et al. 1997), cotreatment of nitrate with ammonia (Kuroda et al. 1996), and cotreatment of nitrate with organic pollutants (Kuroda et al. 1997), the authors have proven the feasibility of this denitrification process.

Islam and Suidan (1998) studied a continuous flow BER in which the nitrate removal efficiency was kept stable through a year of operation, without adding any carbon source, and the rate was dependent on the current applied. A lower efficiency of 85–87% and colorization of the medium by anode erosion were problems. A system using two separate reactors, one for the generation of hydrogen by electrolysis and the other a packed-bed reactor for denitrification, was tried and operated for 1 year (Szekeres et al. 2001). Although the stability was demonstrated to be acceptable, the low reaction rate, probably due to the low solubility of hydrogen, revealed that in situ hydrogen production and consumption could be advantageous. This solubility problem was compensated for by counter-current flow between the hydrogen-containing liquid and the nitrate-containing liquid, creating a removal rate comparable to a reactor using hollow-fiber membranes (Smith et al. 2005).

Other trials to increase the removal rate involved the introduction of three-dimensional structure to the electrode design in the reactor, increasing the surface area per unit volume. The first trial of this new electrode concept, done by Prosnansky et al. (2002), used a multiwall cathode made of stainless steel packed with porous, granular, activated carbon, which increased the surface area of electrode and the area for biofilm formation. The result was the best of all results previously reported (Table 5). The rate was increased about tenfold and the reactor performed steadily for 1 year. However, the increased removal rate required large amounts of CO2 and the rate was high only within small retention times, especially under 2 h where the efficiency was low. These small retention times were determined as an optimum reaction conditions to be competitive with other treatment methods such as ion exchange and reverse osmosis. The authors, however, concluded that this new process was superior to the ion exchange and reverse osmosis, which both require posttreatment of concentrated brine. The problem of an adequate CO2 supply was reduced by using activated carbon packed between activated carbon fibers as the anode so that the CO2 produced at the anode (rather than O2) could be used in the denitrification process (Wang and Qu 2003; Zhou et al. 2007). After the biofilm was developed on the expanded surface, heterotrophic nitrification together with autotrophic nitrification greatly increased the current efficiency. However, in the report, the mentioned 227% of current efficiency was not a meaningful value because both heterotrophic and autotrophic denitrification were working together, although the increased area might have enhanced the efficiency (Zhou et al. 2007).

The indirect advantage of the bioelectrode reaction is that easily reducible toxic compounds such as heavy metals could be removed simultaneously, although the process needs adaptation time to be fully operational (Skadberg et al. 1999; Watanabe et al. 2001). Carbon electrodes in a cylindrical arrangement were utilized in a BER used to treat acidic wastewater containing nitrate and heavy metals. Nitrate was removed by autotrophic and heterotrophic denitrification and heavy metals were removed simultaneously, although extra carbon, as acetate, was needed to facilitate the denitrification and it was not determined whether the mechanism of heavy metal removal was accomplished by electrochemical reaction, chemical precipitation, or biosorption.

Although the cost of electrochemically generated hydrogen and its quantitative usage in the reactor diminished the cost of hydrogen by 80% compared to hydrogen in compressed form, the cost of this process is still similar to using methanol if stoichiometric amounts of hydrogen are used (Grommen et al. 2006). Therefore, more optimization and development of the electrodes and the reactor structure are required.

Hydrogen production by electrochemical methods had been considered as a main mechanism for autotrophic denitrification in BERs, but analysis of the production rate of hydrogen by electricity revealed that the electricity consumed by hydrogen production was five orders of magnitude lower than the electricity consumed by microbes performing denitrification (Gregory et al. 2004). This implies that direct electron transfer from the electrode to the microbes could be possible so that microbes would be able to reduce nitrate without using a carbon source. The possibility was demonstrated by Park et al. (2005) where a biofilm on the electrode surface removed nitrate for 60 days without needing a carbon source. Unfortunately, the fact that denitrification was carried out at zero current implied that other removal mechanisms existed in the system.

Another bioelectro-denitrification process was suggested which used electricity as an electron donor instead of a carbon source (Choi et al. 2006; Kim et al. 2007). In this strategy, the denitrification reaction was performed by permeabilized Ochrobactrum anthropi SY509, which acted as a biocatalyst containing denitrifying enzymes, which demonstrated the transfer of electron to the enzymes inside the microbe by mediators, methyl viologen (Choi et al. 2004, 2006). By using the dead cells as catalysts, the problems of long start-up times and carbon-related issues could be solved because the fast-growing heterotrophic bacteria were cultivated separately and used in the process without a carbon source. Furthermore, the permeabilization treatment was able to increase the accessibilities of nitrate and other mediators to the intracellular enzymes and thus improved the nitrate removal efficiency (Choi et al. 2004; Kim et al. 2007).

BERs have been studied extensively for the treatment of drinking water. However, the feasibility for application to the wastewater treatment is not yet determined although the process combined with heterotrophic denitrification has been applied to synthetic wastewater simulating electroplating wastewater (Watanabe et al. 2001), and again, the economic evaluation in a full-scale reactor must be determined through future studies. The summary of advantages and disadvantages for all electron donors is presented in Table 6.

There are few trials which utilize ferrous ions to remove nitrate. Abiotic hydrogen formation in anaerobic corrosion can reduce nitrate (Matějů et al. 1992; Shin and Cha 2008). Although in these studies nitrate transformation is observed to be quite fast, the formation of ammonia as a main product that then should be treated further is the main problem for this technology as it relates to wastewater treatment (Devlin et al. 2000). A modification of this process, suggested by Rocca et al. (2006), involved zero-valent iron, instead of ferrous ions, producing hydrogen gas in a permeable reactive barrier, while oxygen consumption during the hydrogen formation made a favorable environment for heterotrophic denitrification. Carbon dioxide production from heterotrophic denitrification also facilitated autotrophic denitrification activity (Rocca et al. 2007). Although ammonia was produced in a reduced level at the outlet, probably due to the consumption of ammonia by heterotrophs, it was still produced at over 20 mg/l. Very low nitrite formation was a promising feature of this process when the inlet concentration of nitrate was 110 mg/l. Other autotrophic denitrification by chloric compound-utilizing bacteria has not been studied extensively and hence not considered in this paper (Matějů et al. 1992; Chang et al. 1999).

Conclusion

Nitrate in many industrial wastewaters has been discharged to the environment. Ammonia from sewage and waste disposal site drainage is oxidized to nitrate that also contributes to nitrate contamination of groundwater. Because of globally increasing concern for nitrate in the environment, the regulations for nitrate release are being strengthened. Biological denitrification to treat these waters is considered to be the most economic process available and among these biological processes, heterotrophic denitrification, which uses a carbon source as an electron donor, has proven feasible for wastewater treatment if there are readily usable internal or external sources of carbon such as fermentation by-products. However, the high operating costs of wastewater treatment which does not contain carbon sources and the related secondary contamination problems resulting from the residual carbon content have raised the need of research utilizing autotrophic denitrification. The advantages of autotrophic denitrification include the lack of a need for a carbon source, which reduced the operating cost, and the lowered possibility of “carbon breakthrough”. In contrast, the sulfur-utilizing process combined with lime could be a reasonable choice for the treatment of small amount of wastewater containing low concentration of nitrate, and the hydrogen-utilizing process could be the solution for processing capable of producing drinking quality water. In industrial applications, although the cost of substrates such as sulfur and hydrogen could be an attractive choice, large-scale application of autotrophic denitrification still needs further study to become an industrially available process. A detailed cost analysis of the sulfur-utilizing process is unavailable. Cost analysis of using electrically generated hydrogen revealed that the cost of hydrogen-utilizing denitrification is not lower than heterotrophic denitrification mainly due to its low denitrification rate in volumetric base and low hydrogen usage in the process. The hydrogen-using process combined with membranes and/or bioelectric reactors requires further study for proper scale-up and extensive modeling analysis to find the key control factors for each part of the system. Novel reactor and electrode designs for efficient H2 production and three-dimensional removal of nitrate that are being examined currently are key tools for improving these technologies. Preventing nitrite accumulation remains a general concern for all biological denitrification processes. Optimum operating conditions, especially when high concentrations of nitrate enters the treatment system and/or when other inhibiting chemicals are present, should be set up for a specific target wastewater type after the above mentioned variables or issues have been settled. Recently, a new method which uses permeabilized microbes was suggested and, although this process was just set up in concept, the usage of heterotrophic denitrification bacteria by direct electron transfer could be a solution for the denitrification process of wastewater. Overall, research for new concept/technologies regarding autotrophic denitrification is still required and especially for the membrane/hydrogen-utilizing processes and BER technologies.

References

Ahn YH (2006) Sustainable nitrogen elimination biotechnologies: A review. Process Biochem 41:1709–1721

Almasri MN (2007) Nitrate contamination of groundwater: a conceptual management framework. Environ Impact Assess Rev 27:220–242

Annouar S, Mountadar M, Soufiane A, Elmidaoui A, Sahli MAM, Kahlaoui M (2004) Denitrification of underground water by chemical adsorption and by electrodialysis. Desalination 168:185

Aslan Ş (2005) Combined removal of pesticides and nitrates in drinking waters using biodenitrification and sand filter system. Process Biochem 40:417–424

Aslan Ş, Türkman A (2005) Combined biological removal of nitrate and pesticides using wheat straw as substrates. Process Biochem 40:935–943

Baalsrud K, Baalsrud KS (1954) Studies on Thiobacillus denitrificans. Archiv Mikrobiol 20:34–62

Batchelor B, Lawrence AW (1978) A kinetic model for autotrophic denitrification using elemental sulfur. Water Res 12:1075–1084

Bilanovic D, Battistoni P, Cecchi F, Pavan P, Mata-Alvarez J (1999) Denitrification under high nitrate concentration and alternating anoxic conditions. Water Res 33(15):3311–3320

Boley A, Müller WR, Haider G (2000) Biodegradable polymer as solid substrate and biofilm carrier for denitrification in recirculated aquaculture systems. Aquac Eng 22:75–85

Buchheister F, Schuch R, Winter J (2000) Biological nitrogen removal from wastewater of the metal-working industry. Chem Eng Technol 23:967–971

Campos JL, Carvalho S, Portela R, Mosquera-Corral A, Méndez R (2008) Kinetics of denitrification using sulphur compounds: effects of S/N ratio, endogenous and exogenous compounds. Bioresour Technol 99:1293–1299

Chang CC, Tseng SK, Huang HK (1999) Hydrogenotrophic denitrification with immobilized Alcalligenes eutrophus for drinking water treatment. Bioresour Technol 69:53–58

Chen F, Xia Q, Ju LK (2003) Aerobic denitrification of Pseudomonas aeruginosa Monitored by online NAD(P)H fluorescence. Appl Environ Microbiol 69(11):6715–6722

Choi KO, Song SH, Yoo YJ (2004) Permeabilization of Ochrobactrum anthropi SY509 cells with organic solvents for whole cell biocatalyst. Biotechnol Bioprocess Eng 9:147–150

Choi KO, Song SH, Kim YH, Park DH, Yoo YJ (2006) Bioelectrochemical denitrification using permeabilized Ochrobactrum anthropi SY509. J Microbiol Biotechnol 16:678–682

Claus G, Kutzner HJ (1985) Autotrophic denitrification by Thiobacillus denitrificans in a packed bed reactor. Appl Microbiol Biotechnol 22:289–296

Croll BT, Hayes CR (1988) Nitrate and water supplies in the United Kingdom. Environ Pollut 50:163–187

De Lucas A, Rodriguez L, Villaseñor J, Fernádez FJ (2005) Denitrification potential of industrial wastewaters. Water Res 39:3715–3726

Devlin JF, Eedy R, Butler BJ (2000) The effects of electron donor and granular iron on nitrate transformation rates in sediments from a municipal water supply aquifer. J Contam Hydrol 46:81–97

Dries D, Liessens F, Verstraete W, Stevens P, de Vos P, de Ley J (1988) Nitrate removal from drinking water by means of hydrogenotrophic denitrifiers in a polyurethane carrier reactor. Water Supply 6:181–192

Driscoll CT, Bisogni JJ (1978) The use of sulphate and sulfide in packed bed reactors for autotrophic denitrification. J Water Pollut Control Fed 50:569–577

Elefsiniotis P, Wareham DG, Smith MO (2004) Use of volatile fatty acids from an acid-phase digester for denitrification. J Biotechnol 114:289–297

Foglar L, Briški F, Sipos L, Vuković M (2005) High nitrate removal from synthetic wastewater with the mixed bacterial culture. Bioresour Technol 96:879–888

Francis CW, Malone CD (1977) Anaerobic column denitrification of high nitrate wastewater. Prog Water Technol 9:678

Furumai H, Tagui H, Fujita K (1996) Effects of pH and alkalinity on sulphur-denitrification in a biological granular filter. Water Sci Technol 34(1–2):355–362

Fux C, Boehler M, Huber P, Brunner I, Siegrist H (2002) Biological treatment of ammonium-rich wastewater by partial nitritation and subsequent anaerobic ammonium oxidation (anammox) in a pilot plant. J Biotechnol 99:295–306

Gabaldón C, Izquierdo M, Martínez_Soria V, Marzal P, Penya-roja JM, Alvarez-Hornos FJ (2007) Biological nitrate removal from wastewater of a metal-finishing industry. J Hazard Mater 148:485–490

Ghafari S, Hasan M, Aroua MK (2008) Bio-electrochemical removal of nitrate from water and wastewater—a review. Bioresour Technol 99(10):3965–3974

Gommers PJF, Buleveld W, Kuenen JG (1988) Simultaneous sulfide and acetate oxidation in a denitrifying fluidized bed reactor I: start-up and reactor performance. Water Res 22(9):1075–1083

Gregory KB, Bond DR, Lovley DR (2004) Graphite electrodes as electron donors for anaerobic respiration. Environ Microbiol 6(6):596–604

Grommen R, Verhaege M, Verstraete W (2006) Removal of nitrate in aquaria by means of electrochemically generated hydrogen gas as electron donor for biological denitrification. Aquac Eng 34:33–39

Gros H, Schnoor G, Rutten P (1988) Biological denitrification process with hydrogen-oxidizing bacteria for drinking water treatment. Water Supply 6:193–198

Gupta AB (1997) Thiosphaera pantotropha: a sulphur bacterium capable of simultaneous heterotrophic nitrification and aerobic denitrification. Enz Microb Technol 21:589–595

Haugen KS, Semmens MJ, Novak PJ (2002) A novel in situ technology for the treatment of nitrate contaminated groundwater. Water Res 36:3497–3506

Hashimoto S, Furukawa K, Shioyama M (1987) Autotrophic denitrification using elemental sulphur. J Ferment Technol 65(6):683–692

Hellinga C, Schellen AAJC, Mulder JW, van Loosdrecht MCM, Heijnen JJ (1998) SHARON proess: an innovative method for nitrogen removal from ammonium-rich waste water. Water Sci Technol 37(9):135–142

Her J, Huang JS (1995) Influences of carbon source and C/N ratio on nitrate/nitrite denitrification and carbon breakthrough. Bioresour Technol 54:45–51

Hiscock KM, Lloyd JW, Lerner DN (1991) Review of natural and artificial denitrification of groundwater. Water Res 25(9):1099–1111

Holló J, Czakó L (1987) Nitrate removal from drinking water in a fluidized-bed biological denitrification bioreactor. Acta Biotechnol 7(5):417–423

Hunter WJ (2001) Use of vegetable oil in a pilot-scale denitrifying barrier. J Contam Hydrol 53:119–131

Hunter WJ (2003) Accumulation of nitrite in denitrifying barriers when phosphate is limiting. J Contam Hydrol 66:79–91

Islam S, Suidan MT (1998) Electrolytic denitrification: long term performance and effect of current intensity. Water Res 32(2):528–536

Jang AM, Bum M, Kim S, Ahn Y, Kim IS, Bishop PL (2005) Assessment of characteristics of biofilm formed on autotrophic denitrification. J Microbiol Biotechnol 15(3):455–460

Kasia JM, Duncan JR, Burgess JE (2005) Biological removal of nitrogen species from metal-processing wastewater. Water SA 31:407–412

Kesserü P, Kiss I, Bihari Z, Polyák B (2002) Investigation of the denitrification activity of immobilized Pseudomonas butanovora cells in the presence of different organic substrates. Water Res 36:1565–1571

Kim IS, Oh SE, Bum MS, Lee JL, Lee ST (2002a) Monitoring the denitrification of wastewater containing high concentrations of nitrate with methanol in a sulfur-packed reactor. Appl Microbiol Biotechnol 59:91–96

Kim Y-S, Nakano K, Lee T-J, Kanchanatawee S, Matsumura M (2002b) On-site nitrate removal of groundwater by an immobilized Psychrophilic denitrifier using soluble starch as a carbon source. J Biosci Bioeng 93(3):303–308

Kim HL, Lee IS, Bae JH (2004) Performance of a sulphur-utilizing fluidized bed reactor for post-denitrification. Process Biochem 39:1591–1597

Kim YH, Park YJ, Song SH, Yoo YJ (2007) Nitrate removal without carbon source feeding by permeabilized Ochrobactrum anthropi SY509 using electrochemical bioreactor. Enzyme Microb Technol 41:663–668

Kimura K, Nakamura M, Watanabe Y (2002) Nitrate removal by a combination of elemental sulphur-based denitrification and membrane filtration. Water Res 36:1758–1766

Koenig A, Liu LH (2001) Kinetic model of autotrophic denitrification in sulphur packed-bed reactors. Water Res 35(8):1969–1978

Koenig A, Zhang T, Liu LH, Fang HHP (2005) Microbial community and biochemistry process in autosulfurotrophic denitrifying biofilm. Chemosphere 58:1041–1047

Koren DW, Gould WD, Bédard P (000)) Biological removal of ammonia and nitrate from simulated mine and mill effluents. Hydrometallurgy 56:127–144

Kuai L, Verstraete W (1998) Ammonium removal by the oxygen-limited autotrophic nitrification-denitrification system. Appl Environ Microbiol 64(11):4500–4506

Kuroda M, Watanabe T, Umeda Y (1996) Simultaneous oxidation and reduction treatments of polluted water by a bio-electro reactor. Water Res 34(9):101–108

Kuroda M, Watanage T, Umeda Y (1997) Simultaneous cod removal and denitrification of wastewater by bio-electro reactors. Water Res 35(8):161–168

Kurt M, Dunn J, Bourne JR (1987) Biological denitrification of drinking water using autotrophic organisms with H2 in a fluidized-bed biofilm reactor. Biotechnol Bioeng 29:493–501

Lee KC, Rittmann BE (2000) A novel hollow-fibre membrane biofilm reactor for autohydrogenotrophic denitrification of drinking water. Water Sci Technol 41(4–5):219–226

Lee KC, Rittmann BE (2002) Applying a novel autohydrogenotrophic hollow-fiber membrane biofilm reactor for denitrification of drinking water. Water Res 36:2040–2052

Lee KC, Rittmann BE (2003) Effects of pH and precipitation on autohydrogenotrophic denitrification using the hollow-fiber membrane-biofilm reactor. Water Res 37:1551–1556

Lee DU, Lee IS, Choi YD, Bae JH (2001) Effects of external carbon source and empty bed contact time on simultaneous heterotrophic and sulfur-utilizing autotrophic denitrification. Process Biochem 36:1215–1224

Lemoine D, Jouenne T, Junter GA (1988) Reduction of nitrate by Pseudomonas putrefaciens entrapped in composite agar layer/microporous membrane structures. Biotechnol Lett 10(6):399–402

Lukow T, Diekmann H (1997) Aerobic denitrification by a newly isolated heterotrophic bacterium strain TL1. Biotechnol Lett 19(11):1157–1159

Matějů V, Čižinská S, Krejčí J, Janoch T (1992) Biological water denitrification—a review. Enzyme Microb Technol 14:170–183

McAdam EJ, Judd SJ (2006) A review of membrane bioreactor potential for nitrate removal from drinking water. Desalination 196:135–148

Mellor RB, Ronnennberg J, Campbell HW, Diekmann S (1992) Reduction of nitrate and nitrite in water by immobilized enzymes. Nature 355:717–719

Moon HS, Ahn KH, Lee S, Nam K, Kim JY (2004) Use of autotrophic sulphur-oxidizers to remove nitrate from bank filtrate in a permeable reactive barrier system. Environ Pollut 129:499–507

Oh SE, Yoo YB, Young JC, Kim IS (2001) Effect of organics on sulphur-utilizing autotrophic denitrification under mixotrophic conditions. J Biotechnol 92:1–8

Ovez B, Ozgen S, Yuksel M (2006) Biological denitrification in drinking water using Glycyrrhiza globra and Arunda donax as the carbon source. Process Biochem 41:1539–1544

Park HI, Kim DK, Choi YJ, Pak D (2005) Nitrate reduction using an electrode as direct electron donor in a biofilm-electrode reactor. Process Biochem 40:3383–3388

Prosnansky M, Sakakibara Y, Kuroda M (2002) High-rate denitrification and SS rejection by biofilm-electrode reactor (BER) combined with microfiltration. Water Res 36:4801–4810

Rahmani H, Rols JL, Capdeville B, Cornier JC, Deguin A (1995) Nitrite removal by a fixed culture in a submerged granular biofilter. Water Res 29:1745–1753

Rajapakse JP, Scutt JE (1999) Denitrification with natural gas and various new growth media. Water Res 33:3723–3734

Rezania B, Oleszkiewicz JA, Cicek N (2007) Hydrogen-dependent denitrification of water in an anaerobic submerged membrane bioreactor coupled with a novel hydrogen delivery system. Water Res 41:1074–1080

Robertson WD, Anderson MR (1999) Nitrogen removal from landfill leachate using an infiltration bed coupled with a denitrification barrier. Ground Water Monit Rem 19(4):73–80

Rocca CD, Belgiorno V, Meriç S (2006) An heterotrophic/autotrophic denitrification (HAD) approach for nitrate removal from drinking water. Process Biochem 41:1022–1028

Rocca CD, Belgiorno V, Meriç S (2007) Heterotrophic/autotrophic denitrification (HAD) of drinking water: prospective use for permeable reactive barrier. Desalination 210:194–204

Sakakibara Y, Kuroda M (1993) Electric prompting and control of denitrification. Biotechnol Bioeng 42:535–537

Sakakibara Y, Araki K, Watanabe T, Kuroda M (1997) The denitrification and neutralization performance of an electrochemically activated biofilm reactor used to treat nitrate-contaminated groundwater. Water Res 36(1):61–68

Satoh T, Hoshino Y, Kitamura H (1976) Rhodopseudomonas sphaeroides forma sp. denitrificants, a denitrifying strain as a subspecies of Rhodopseudomonas sphaeroides. Arch Microbiol 108:265–269

Sauthier N, Grasmick A, Blancheton JP (1998) Biological denitrification applied to a marine closed aquaculture system. Water Res 32(6):1932–1938

Schipper LA, Vojvodić-Vuković M (2000) Nitrate removal from groundwater and denitrification rates in a porous treatment wall amended with sawdust. Ecol Eng 14:269–278

Shapleigh JP, Davies KJP, Payne WJ (1987) Detergent inhibition of nitric-oxide reductase activity. Biochim Biophys Acta 911:334–340

Shen J, Hirayama O (1991) Hydrogen photoproduction and denitrification by photosynthetic bacteria isolated from lake Nakaumi and its vicinity. J Ferment Bioeng 72(5):338–342

Shin K-H, Cha DK (2008) Microbial reduction of nitrate in the presence of nanoscale zero-valent iron. Chemosphere 72:257–262. doi:https://doi.org/10.1016/j.chemosphere.2008.01.043

Shin J-H, Sang B-I, Chung Y-C, Choung Y-k (2005) The removal of nitrogen using a n sutotrophic hybrid hollow-fiber membrane biofilm reactor. Desalination 183:447–454

Shin J-H, Sang B-I, Chung Y-C, Choung Y-k (2008) A novel CSTR-type of hollow fiber membrane biofilm reactor for consecutive nitrification and denitrification. Desalination 221:526–533

Sierra-Alvarez R, Cardoso RB-, Salazar M, Gómez J, Flores ER, Field JA (2007) Chemolithotrophic denitrification with elemental sulphur for groundwater treatment. Water Res 41:1253–1262

Skadberg B, Geoly-horn SL, Sangamalli V, Flora JRV (1999) Influence of pH, current and copper on the biological dechlorination of 2,6-dichlorophenol in an electrochemical cell. Water Res 33(9):1997–1999

Smith RL, Buckwalter SP, Repert DA, Miller DN (2005) Small-scale, hydrogen-oxidizing-denitrifying bioreactor for treatment of nitrate-contaminated drinking water. Water Res 39:2014–2023

Soares MIM (2000) Biological denitrification of groundwater. Water Air Soil Pollut 123:183–193

Soares MIM (2002) Denitrification of groundwater with elemental sulfur. Water Res 36:1392–1395

Soares MIM, Brenner A, Yevzori A, Messalem R, Leroux Y, Abeliovich A (2000) Denitrification of groundwater: pilot-plant testing of cotton-packed bioreactor and post-microfiltration. Water Sci Technol 42(1):353–359

Strous M, van Gerven E, Kuenen JG, Jetten M (1997) Effect of aerobic and microaerobic conditions on anaerobic ammonium-oxidizing (anammox) sludge. Appl Environ Microbiol 63(6):2446–2448

Szekeres S, Kiss I, Bejerano TT, Soares MIM (2001) Hydrogen-dependent denitrification in a two-reactor bio-electrochemical system. Water Res 35(3):715–719

Szekeres S, Kiss I, Kalman M, Soares MIM (2002) Microbial population in a hydrogen-dependent denitrification reactor. Water Res 36:4088–4094

Takaya N, Catalan-Sakairi MAB, Sakaguchi Y, Kato I, Zhou Z, Shoun H (2003) Aerobic denitrifying bacteria that produce low levels of nitrous oxide. Appl Environ Microbiol 69(6):3152–3157

Tavares P, Pereira AS, Moura JJG, Moura I (2006) Metalloenzymes of the denitrification pathway. J Inorg Biochem 100:2087–2100

Terada A, Kaku S, Matsumoto S, Tsuneda S (2006) Rapid autohydrogenotrophic denitrification by a membrane biofilm reactor equipped with a fibrous support around a gas-permeable membrane. Biochem Eng J 31:84–91

Third KA, Sliekers AO, Kuenen JG, Jetten MSM (2001) The CANON system (completely autotrophic nitrogen-removal over nitrite) under ammonium limitation: interaction and competition between three groups of bacteria, system. Appl Microbiol 24:588–596

van de Graaf AA, Mulder A, de Bruijn P, Jetten MSM, Robertson LA, Kuenen JG (1995) Anaerobic oxidation of ammonium is a biologically mediated process. Appl Environ Microbiol 61(4):1246–1251

Volokita M, Abeliovich A, Soares MIM (1996a) Denitrification of groundwater using cotton as energy source. Water Sci Technol 34(1–2):379–385

Volokita M, Belkin S, Abeliovich A, Soares MIM (1996b) Biological denitrification of drinking water using newspaper. Water Res 30(4):965–971

Wang H, Qu J (2003) Combined bioelectrochemical and sulfur autotrophic denitrification for drinking water treatment. Water Res 37:3767–3775

Wąsik E, Bohdziewicz J, Blaszczyk M (2001) Removal of nitrates from ground water by a hybrid process of biological denitrification and microfiltration membrane. Process Biochem 37:57–64

Watanabe T, Motoyama H, Kuroda M (2001) Denitrification and neutralization treatment by direct feeding of an acidic wastewater containing copper ion and high-strength nitrate to a bio-electrochemical reactor process. Water Res 35(17):4102–4110

Yamamoto-Ikemoto R, Komori T, Nomura M, Ide Y, Matsukami T (2000) Nitrogen removal from hydroponic culture wastewater by autotrophic denitrification using thiosulfate. Water Sci Technol 42(3–4):369–376

Zeng H, Zhang TC (2005) Evaluation of kinetic parameters of a sulfur-limestone autotrophic denitrification biofilm process. Water Res 39:4941–4952

Zhang TC (2004) Denitrification processes for treatment of nitrate-contaminated groundwater in small communities. Final project report, Midwest Technology Assistance Center (MTAC)

Zhang TC, Lampe DG (1999) Sulfur: limestone autotrophic denitrification processes for treatment of nitrate-contaminated water: batch experiments. Water Res 33(3):599–608

Zhou M, Fu W, Gu H, Lei L (2007) Nitrate removal from groundwater by a novel three-dimensional electrode biofilm reactor. Electrochim Acta 52:6052–6059

Zumft WG (1997) Cell biology and molecular basis of denitrification. Micobiol Mol Biol Rev 61(4):533–616

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Park, J.Y., Yoo, Y.J. Biological nitrate removal in industrial wastewater treatment: which electron donor we can choose. Appl Microbiol Biotechnol 82, 415–429 (2009). https://doi.org/10.1007/s00253-008-1799-1

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00253-008-1799-1