Abstract

Mercury (Hg)-contaminated soils from anthropogenic activities pose significant challenges to ecosystems and their biotic and abiotic components. Among many treatment methods for the remediation of Hg-contaminated soils, soil washing has been practiced as an effective treatment. This study investigated Hg removal efficiencies by using different combinations of washing solutions, including organic acids (humic, citric, oxalic, tartaric acids), surfactants (Tween 80, sodium dodecyl sulfate (SDS)), and electrolyte solution (NaCl). Moreover, the optimal conditions of the soil-washing process also were pointed out. The results showed that the experiment performed by a combination of citric acid + Tween 80 with SDS provided the highest Hg removal efficiency (94%). Organic acids show potential in Hg-contaminated soil washing with relatively high removal efficiency, particularly humic acid, with a removal efficiency of 79%. Surfactants show a role in enhancing Hg removal efficiency when combined with organic acids. Surfactants have been shown to play a role in enhancing Hg removal efficiency, while electrolytes have not yet when combined with organic acids as the washing solutions. Therefore, further studies are needed when using electrolytes in soil-washing solutions. Mercury-contaminated soil washing is most effective at operating conditions of pH = 4, liquid-to-solid ratio = 5:1, and stirring speed = 1500 rpm. The liquid-to-solid ratio played a significant effect (P < 0.05) on the Hg removal efficiency. The results from this study show the potential of green soil washing technology using less toxic, biodegradable, environmentally friendly, and low-cost chemicals.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

Mercury (Hg) is considered the most toxic ubiquitous environmental pollutant (Raj & Maiti, 2019). Anthropogenic activities like Hg mining, coal combustion, power plant, and industrial process become a reason to increase Hg levels in soil (Guney et al., 2020; He et al., 2015). Mercury leaching from soils may contaminate waters, air, ecosystems, and human health through the food chain (Caballero-Gallardo et al., 2022; Piccolo et al., 2021). It has been observed that Hg2+ effectively causes kidney and lung impairment, while the organomercuric form impairs brain function (Li et al., 2017). Therefore, mercury has been progressively designated a high-priority pollutant by international agencies in light of its bioaccumulation and toxicity (Raju et al., 2019). The World Health Organization (WHO) enlisted Hg as one of the “ten leading chemicals of concern” (Xu et al., 2015). In this context, Hg-contaminated soil should be treated through diverse remediation processes to control its transmission and toxic effects on the environment and human health.

In the previous decades, Hg-contaminated soil has been treated employing several techniques, including soil replacement/filling, soil stabilization, thermal desorption, phytoremediation, electrokinetic, and biological remediation (Bolan et al., 2014; Vargas-Garcia et al., 2012). However, these methods primarily concentrate on the restoration of soil contaminated in a certain context, are not adequate for an extended level of contamination, relatively involve high cost, and require a long period (Ali et al., 2013; Beiyuan et al., 2017). Instead, previous studies have shown that soil-washing technology has become a promising approach for removing Hg from contaminated soil based on cost and time savings (Feng et al., 2020). A fundamental characteristic of soil washing is its complexity, which is demonstrated not only by its phenomenon but also by its mechanisms. Therefore, choosing an effective soil-washing solution for Hg removal from contaminated soil is a matter of concern (Wei et al., 2018). Additionally, there are still some uncertainties about the conditions and the factors that affect its performance. It is therefore necessary to conduct studies on soil-washing solutions and factors that can increase heavy metal removal from contaminated soils.

Several studies have examined the influence of soil washing conditions and washing agents on Hg removal efficiency (Kwon et al., 2020). Mercury removal efficiency from contaminated soil is less than 10% when using deionized water as a washing solution. As Hg has a relatively higher octanol-water partition coefficient (Kow = 4.17 for metallic Hg), it would be tightly sorbed onto the soil particles (Chen et al., 2018). In order to make it easier to remove Hg from contaminated soils, using chemicals as washing solutions has become popular (Wang et al., 2014). In the study of Wasay et al. (2001), chemical extraction has been used to upsurge the effectiveness of soil washing to remove Hg. Chemical agents that are normally used to solubilize Hg include acids, alkalis, salt solutions, and chelating agents (Wasay et al., 1995). A variety of inorganic acids (H2SO4, HNO3) and saline solutions (KI, Na2S2O3) are studied to remove Hg from contaminated soils (Ray and Selvakumar, 2000). A major disadvantage of soil washing using inorganic acids as washing solutions is to loss of nutrients in the soil and negative influence on the soil structure (Jiang et al., 2017) as well as the strong acids may affect the soil microbiology and fertility (Ko et al., 2005). In soil-washing processes, aminopolycarboxylate chelates like EDTA have been commonly tested due to their ability to form metal-ligand coordination compounds (Qiao et al., 2017). However, the EDTA is poorly biodegradable and can form stable complexes with metals as it may persist in soil for longer periods. The use of EDTA might be harmful to microorganisms and plants, as well as contaminating groundwater (Leštan et al., 2008). Low molecular weight organic acids (LMWOAs) are particularly useful for heavy metal mobilization due to their metal chelating and complexing properties (Cao et al., 2018). Different organic acids may affect the interaction between metals and soil in different ways. Metal dissolution is most commonly caused by hydrogen ions released by carboxylic acid groups (Burckhard et al., 1995). In soil environments, LMWOA is easily biodegradable, but heavy metals are less readily removed with organic acids alone (Ren et al., 2015). A surfactant-based washing is more effective when metals and organic contaminants are closely associated. This has been proven in many previous studies (Mulligan et al., 1999). Tween 80 and SDS are considered to be the most cost-effective and promising solutions because they are relatively low in toxicity and have low critical micelles concentrations (CMC) and are relatively easily dissolved (Colacicco et al., 2010). Despite their lack of impact on soil structure, these washing solutions are effective in washing heavy metal-contaminated soil. Besides, previous studies have also shown that the electrolyte supports the soil-washing process. Some previous studies reported that chlorides had an effect on Hg mobilization. Schuster (1991) indicated that the pH of the soil solution plays a significant role when adding salt as a washing solution. The highest Hg dissolution was achieved from pH 5 and 11, reaching up to 0.3% of the total Hg (Xu et al., 2014).

In order to increase the removal efficiency of heavy metals from contaminated soil, combined chemicals used as washing solutions were studied (Issaro et al., 2009). Combined chemicals, for instance, acid + salt, salt + oxidant/reducing, salt + acid, or salt + chelating agent, used in metal-contaminated soil washing were reported to be more effective compared to individual chemicals (Biester & Scholz, 1997; Subires-Munoz et al., 2011). However, studies using combined chemicals as washing solutions to remove Hg from contaminated soil are still limited. Especially, there have been no studies on the combination of organic acids, surfactants, and electrolyte solutions before, although there have been numerous studies on the role of surfactants and electrolyte solutions in enhancing the mobility of mercury (Jing et al., 2007; You et al., 2016). Therefore, studies using this method to remove Hg from contaminated soil are highly recommended.

Flotation is a physicochemical separation technique, which introduces air bubbles in a suspension, and is widely used in mineral ore (Dermont et al., 2008; Vanthuyne & Maes, 2002). This technology has received much less research than other soil-washing techniques like chemical extraction (Dermont et al., 2010). In froth flotation, to separate contaminants from the soil matrix, a hydrophobic difference mechanism is employed (Tran et al., 2022). In addition to chemical and physical parameters, bubble hydrodynamics also play an influential role in froth flotation removal efficiency (Zhang et al., 2001). In spite of this, there is limited research on the interaction between organic acid, surfactants, and electrolytes during heavy metal removal from contaminated soil.

In order to overcome the aforementioned challenges, this study presented the technically effective method in consideration to efficiently identify the adequate chemical combination for Hg remediations from contaminated soil. The combined chemicals, including organic acids, Tween 80, sodium dodecyl sulfate (SDS), and electrolyte, to form different washing recipes are employed to survey Hg desorption performance. After that, three influencing factors are considered in an experiment to determine the optimal washing conditions: pH, liquid-to-solid ratio, and stirring speed. Flotation machines were selected to use in the experiments. The selection of a combination of organic acids, Tween 80, SDS, and electrolytes in various recipes offers efficient green soil washing technology with short processing times and less soil structure effect. The findings can serve as valuable information and technical support for developing green soil-washing technology to remediate Hg-contaminated soils.

2 Materials and Methods

2.1 Soil Samples and Wet Screening Process

In this study, the contaminated soil was collected from a derelict chlor-alkali plant in Tainan City, in southern Taiwan. Through wet screening (adding water to the screen), the undersized material (non-soil part) was efficiently removed by taking into account the specified particle size. In pursuance of carrying out the wet screening process, the ASTM E276-13 approach was implemented. A total of 50 kg Hg-contaminated soil having a particle size range of 10–300 µm was homogeneously mixed and separated into 300 g for each experimental unit. The soil samples were further analyzed to determine the physicochemical soil properties. The physicochemical analysis results displayed the following: composition (clay 20.5%, silt 23.0%, and sand 56.5%), organic matter (OM) content 0.85%, and electrical conductivity (EC) 2.04 dS/m. The Physicochemical properties of the contaminated soil analysis method and instruments were enlisted in the supplementary materials in Table S1.

2.2 Chemicals and Instruments

The surfactant sodium dodecyl sulfate (SDS) and Tween 80 were supplied by Sigma-Aldrich, Germany. The high-purity citric acid (99.5~100%), sodium chloride (99.8%), and sodium hydroxide (95%) were purchased from Nihon Shiyaku Industries Ltd. (Taiwan). Industrial-grade oxalic acid (98% purity), tartaric acid (99% purity), and industrial-grade humic acid (99% purity) were purchased from Alfa Aesar (UK).

In this study, the Denver D12 laboratory scale flotation machine (XFD3III, JXSC Mine Machinery Factory) was employed (Dermont et al., 2008). Separation is performed based on the hydrophobic properties of particle surfaces (Vanthuyne et al., 2003). The purpose of this instrument is to separate minerals from soil using different washing solutions. It is commonly used in the mining industry. The specification of flotation machines was enlisted in the supplementary materials Table S2. In this work, a flotation machine was placed in a closed chamber to limit mercury losses to the external environment through evaporation. The closed chamber was designed with a cartridge to absorb the evaporating Hg. The washing solution combination and diagram of the flotation machine are depicted in Fig. 1.

2.3 Experimental Setup

The experiment performed is divided into two main stages. In the first stage, the feasibility of different washing solutions is investigated. The deionized (DI) water and different washing solutions were used to conduct experiments during this stage. The first stage includes four treatments to appraise Hg’s removal efficacy. Firstly, experiments on the feasibility of organic acids were conducted. Subsequently, experiments on the use of surfactants (Tween 80) to enhance organic acids during soil washing were carried out. After that, SDS was added to support organic acids and Tween 80 to remove Hg. Finally, experiments on the combination of surfactants and electrolyte solutions to enhance soil washing by organic acid will be conducted. There are 16 experiments conducted in the first stage, as shown in Table 1. These experiments were conducted at pH 4, a stirring speed of 1500 rpm, and a liquid-to-solid ratio of 5:1. After completing these 16 experiments, the most effective washing recipes were chosen to investigate the effects of different experimental conditions in the second stage.

In the second stage, influential factors were considered, including liquid-to-solid ratio, pH, and stirring speed at room temperature. The most effective washing was used to investigate the effects of different experimental conditions. The Taguchi method was employed to design experiments for this stage. The Taguchi method has been proven to be one of the fastest techniques. In Taguchi’s design, response variables are tested for their sensitivity to a set of control parameters by considering experiments in an orthogonal array. An orthogonal array provides the best-balanced set with the least number of experiments (Flores et al., 2018). Taguchi L9 orthogonal arrays were implemented, aiming to identify the optimal conditions of the soil-washing process. Nine experiments were carried out based on the variation of three parameters, including liquid-to-solid ratio, pH, and stirring speed, with three levels presented in Table 2. Generally, there are three methods to calculate S/N ratios, including HB (higher or larger is better), NB (nominal is better), and LB (lower is better) (Asgari et al., 2016). The experimental design is carried out using an L9 orthogonal array selected by employing Minitab statistical software package.

After the wet screening process, 50 kg of mercury-contaminated soil with a particle size ranging from 10 to 300 µm were homogeneously mixed and then weighed 300 g of mercury-contaminated soil for each experiment. From this 300 g soil, 50 g was stored in the refrigerator (40 C) to analyze the initial concentration of mercury in the soil (C0); 250 g was put into the container of a flotation machine for the washing process. During experiments, the foams, water, and sediment samples were collected after 10 min of each flotation period. After collecting the foam and water samples, the remaining solution was drained and collected using a vacuum pump. Thirty grams of soil was taken from four corners and the center of the container. All samples were refrigerated at 4 ℃ until further analysis.

2.4 Analysis of Soil, Water, and Foam Samples

The analysis was performed by following the procedures described by the National Institute of Environmental Analysis, Taiwan (NIEA). In this process, foam, water, and sediment samples were collected from the flotation machine. Both solid and liquid samples were detected following Taiwan EPA methods (NIEA M318.01C and US EPA Method 7473). The Hg analyzer (MA 2000, NIC) was implemented to observe the detection line. After the inception of the detection line, the absolute weight of Hg was calculated using the obtained peak height or sample area and inspection line. This sample contains moisture, so the moisture content was determined using a soil and sediment moisture content determination method of an environmental laboratory-gravimetric method (NIEA S280, ISO 11465). The specifications Hg analyzers can be found in the supplementary materials Table S2.

2.4.1 QA/QC

The quality assurance and quality control (QA/QC) were examined based on the detection method described by the National Institute of Environmental Analysis, Taiwan (NIEA) that was followed to perceive the total amount of mercury in sediment, foam, and liquid samples. As well as before the scrutiny of Hg, all glassware was washed with distilled water, soaked in 30% nitric acid, and air-dried for further utilization. Additionally, all the recovery values in triplicated experiments were found in the 91.6–107.3% range and within the acceptable range of 80–120% for mercury analysis. The relative standard deviation (RSD) values obtained for samples ranged from 3.9 to 10.2%, which was ≤15% RSD under the required control limits. These values indicated the analytical method with the necessary accuracy and precision.

3 Results and Discussion

3.1 Organic Acids as a Washing Agent

Experiments using water as soil washing solution to remove Hg from contaminated soil showed low removal efficiency (around 10%). This may be because the Hg species is very strongly bound with organic compounds and sulfides in the soil to form the insoluble complex compound (Ma et al., 2015). Therefore, chemical washing solutions are required to enhance Hg desorption from the contaminated soil. Recent studies have demonstrated that natural organic acids are ideal for soil washing. In addition to being biodegradable and environmentally friendly, natural organic acids can also prevent secondary pollution caused by the soil-washing process (Zou et al., 2019). The results highlighted that the Hg removal efficiencies using organic acids (0.2 M) as soil washing solutions were improved compared to water. As shown in Fig. 1a, the Hg removal efficiencies were found at around 79%, 70%, 68%, and 37% when using humic acid, citric acid, tartaric acid, and oxalic acid, respectively. Low molecular weight organic acids (LMWOAs) contain different functional groups, which have a high capacity to bind with Hg, leading to higher Hg removal efficiency (Jiang et al., 2017).

The different molecular structures of LMWOAs might lead to differences in the strength of their interactions with heavy metals in the soil during chelating or ion exchange reactions (Yang et al., 2006). Moreover, there is competition among heavy metals to combine with the active sites on washing solutions (Di Palma & Mecozzi, 2007). Therefore, there was a difference in Hg removal efficiency when different organic acids were used as washing solutions. Humic acid (0.2 M) presented the highest removal efficiency of Hg (79%). Humic acid is one of the most stable organic compounds (Xu et al., 2015). The presence of soluble humic acids noticeably increased Hg mobility by transferring Hg from the solid phase to the liquid phase (Cattani et al., 2009). It contains a large number of functional groups that have a high capacity to interact with Hg, such as -OH, -COOH, and -SH (Yang & Hodson, 2019). It means humic acid has more binding sites for heavy metal ions than other organic acids allowing them to form outer or inner-sphere complexes (Begum et al., 2012). In contrast, oxalic acid showed the lowest Hg removal efficiency due to its low molecular weight and less complexing capability (Jing et al., 2007; Ponizovskii & Mironenko, 2001).

Some previous studies also reported the effectiveness of organic acids in removing Hg from contaminated soil through soil washing (Jiang et al., 2017). However, organic acids showed lower soil washing efficiency compared with inorganic acids. For instance, Xu et al. (2014) showed that Hg removal efficiency reached 80–97% when using HCl and HNO3 as washing solutions. Although using inorganic acids as washing solutions can achieve high Hg removal efficiency, generating secondary pollutants from the washing process and destroying soil structure are significant problems (Meng et al., 2017). Meanwhile, organic acids are known to be environmentally friendly chemicals with high biodegradability within the soil environment (Wen et al., 2009). Using organic acids as a washing solution might limit the occurrence of secondary pollutants and effects on soil structure, leading to a promising green soil washing technology. The Hg removal efficiency when using organic acids as a washing solution can be improved by combining it with environmentally friendly surfactants.

Organic acids can enhance metal mobility in soil profiles by reducing soil pH and forming complexes with heavy metals (Jing et al., 2007). In this study, non-humified organic acid and humified organic acid are used to remove mercury from contaminated soil. The LWMOA used in this study exhibit the mechanisms which are as follows: (i) positively charged complexes are formed directly with heavy metals, (ii) complex formation between organic acid functional groups, and (iii) formation of highly soluble complexes with heavy metals after adsorption onto the soil surface (Ash et al., 2016). The different organic acids may affect the interactions between metals and soil differently in different ways. Hydrogen ions released by carboxylic groups are essential for metal dissolution. Metal complexation and leaching are influenced by the positions and types of functional groups in organic acids (Renella et al., 2004). All of these factors affected the characteristics of Hg2+ adsorption in soils. Soil surfaces may be less adsorbent to Hg2+ by adding organic acids that chelate with Hg2+ and HgOH+. Generally, the stronger the chelator, the less Hg2+ is adsorbed, and correspondingly, the more Hg2+ is desorbed (Krishnamurti et al., 1997), as citric acids have two or three -COOH groups, allowing them to form chelates with a five- or six-membered ring structure. So, as compared to the monodentate complexes, these chelates are much more stable (Qin et al., 2004).

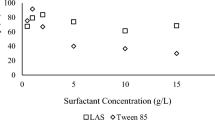

3.2 Organic Acids and Tween 80

Rather than using a single reagent, an artificial non-ionic surfactant, Tween 80, was used in combination with natural organic acids to investigate the enhancement of Hg removal efficiencies. This complex was intended to promote the transformation and dissolution of metals from soils to solutions. Tween 80 is a potentially cost-effective and promising solution because of its low critical micelles concentration (CMC), toxicity, and relative water solubility (Colacicco et al., 2010). The outstanding properties of the complex of organic acids and Tween 80 are biodegradable and eco-friendly (Pazos et al., 2013).

The combination of organic acids and Tween 80 mostly provided higher Hg removal efficiency compared to a single washing solution. Specifically, the Hg removal efficiencies were 89%, 78%, 77%, and 68% when combining Tween 80 with humic acid, oxalic acid, citric acid, and tartaric acid, respectively. The addition of Tween 80 to the water-sediment system resulted in the solubilization/elution of organic matter and its Hg complexes (Falciglia et al., 2016). In solution, non-ionic surfactants have lower critical micelle concentration (CMC) values and a weaker ability to flocculate clay particles. Therefore, the surfactant has a higher solubilizing activity for pollutants and a lower sorption activity leading to improving the Hg removal efficiencies (Lindman et al., 2016). Thus, Tween 80 and the organic acid combination can intrinsically boost the desorption of heavy metals from sediments (Hahladakis et al., 2014). Also, these mixed washing solutions could reduce the treatment cost and secondary pollution to the environment by removing heavy metals at a lower concentration. According to these results, the combination of Tween 80 and organic acids offers a substantial potential for the practical application of surfactant-enhanced soil washing.

3.3 Organic Acids, Tween 80, and SDS

The non-ionic surfactants do not carry charges, so they cannot participate in the counter-ion binding and ion-exchange processes (Liu et al., 2021). Therefore, the addition of anionic surfactants, SDS, to the washing solution is intended to promote ion exchange and binding to achieve higher Hg removal efficiencies. SDS segregates into Na+ and DS- in the washing solution. Yet, these ions can extract heavy metals weakly bound to soil organic matter (Yun et al., 2015). The complexation in the ternary surface of DS- and oxides with metals has efficiently boosted the chelation by SDS, which pertinently enhances the metal extraction from contaminated soils. Thus, as shown in Fig. 2c, Hg removal efficiencies were significantly improved when using the complex organic acids, Tween 80, and SDS as washing solution compared to only organic acid and organic acids + Tween 80, in which the combination of citric acid, Tween 80, and SDS reported the highest Hg removal efficiency (94%). Sulfur-containing groups in SDS molecules facilitate the desorption of heavy metals (Mao et al., 2015). The anionic surfactants (SDS) recovered higher mercury at low concentrations than Tween 80; this may be due to the electrostatic interaction between negatively charged functional groups (sulfate in SDS) and mercury ions (Hg2+) resulting in the formation of a complex (Chen et al., 2011). The highest heavy metal removal rate from contaminated soil was obtained using SDS alone, with the removal rate reaching 70% (Shin & Barrington, 2005). Ramamurthy et al. (2008) reported that with the addition of SDS, the most effective removal of Cu(II) and Zn(II) was achieved compared with using individual surfactants. More details related to the desorption efficiency of different heavy metals based on different washing agents are critically summarized in Table 3.

The results also showed that SDS exerts a synergistic effect on citric acid and tartaric acid to enhance Hg removal efficiency. Meanwhile, the treatment efficiency showed a slight decrease in the case of using SDS in combination with complex humic acid + Tween 80 and oxalic acid + Tween 80. This result is also similar to some previous study results. For instance, the study by Chen et al. (2016) reported the same result for Zn2+ removal by adding SDS to complex non-ionic surfactant and organic acids (citric acids, tartaric acid, and oxalic acid) in a washing solution. The results from this study reported that complex SDS, non-ionic surfactant, and oxalic acid did not improve Zn2+ removal efficiency, even with enhanced reaction time. Different effects of surfactants in combination with organic acids on metal removal efficiency were mainly based on the physicochemical features of organic acids and various interactions in the complex soil-liquid systems. Thus, the combination of surfactants provides better performance (low CMC and adsorption loss), thus reducing remediation costs and surfactant application amounts.

The surfactant helps in the desorption or dispersion of contaminants by forming micelles and reducing the concentration of Hg2+ adsorbed to the soil surface, which increases the chelator’s strength (Liu et al., 2022). Surfactants can enhance the removal of heavy metals through mechanisms such as ion exchange, counter-ion binding, and dissolution precipitation (Rouse et al., 2004). In the case of SDS, it is possible for SDS to remove heavy metal from soil alone through ion exchange with sodium cations and electrostatic attraction between negatively-charged DS-micelles (Shin & Barrington, 2005). By complexing with metals (competing with OH-) and competing for sorption sites on the solid phase with cations, electrolyte solutions can improve the mobility of metals in soil solution (Lee et al., 2008).

3.4 Organic Acids, Tween 80, SDS, and NaCl

Chloride ions play a role in the improvement of the soluble chloro-complexes formation, which favors heavy metal solubilization in an acidic medium (Guemiza et al., 2015). There is also another reason for this, which is the modification of the CMC, which facilitates the solubilization of pollutants. (Lopez et al., 2004). Therefore, NaCl was added to the mixture of organic acids + Tween 80 + SDS to investigate Hg removal efficiencies. However, in the results of this study, the mixture of NaCl + organic acids + Tween 80 + SDS did not show higher Hg removal efficiencies compared to other recipes. The results shown that the removal efficiency reached 78%, 74%, 71%, and 44% when using the mixture NaCl + humic acid + Tween 80 + SDS, NaCl + oxalic acid + Tween 80 + SDS, citric acid + Tween 80 + SDS, and tartaric acid + Tween 80 + SDS, respectively (Fig. 2d).

The reason behind the reduction in removal efficiency is maybe the reduction of the surfactant concentration. Compared to prior treatments with this combination, the low concentration of Tween 80 and SDS (0.25% v/v) has proven less effective. A nonionic surfactant’s solubilization is relatively unaffected by salinity, whereas adding salt to an anionic surfactant solution can decrease its CMC (Bai et al., 1998). However, some researchers have shown that increasing salinity decreases the solubility of inorganic pollutant and spreads the distribution of pollutants to soil phases due to interactions between the surfactant and salt that makes it difficult for pollutants to incorporate into the hydrophobic core of micelles (Tremblay et al., 2005). In addition, some previous studies reported that chlorides had little effect on Hg mobilization. The pH of the soil solution plays a very important role when adding salt as a washing solution (Schuster, 1991). The highest Hg dissolution was achieved from pH 5 and 11, reaching up to 0.3% of the total Hg (Xu et al., 2014). In addition to the other reagents, NaCl is also relatively non-toxic or can be treated with ordinary sewage treatment systems (Zheng et al., 2022).

Furthermore, the reagent used in this study is less toxic and biodegradable. The low molecular weight organic acid was used in this study to remove potential metals from the soil while also being biodegradable and not causing secondary pollution (Di Palma & Mecozzi, 2007). Additionally, SDS and Tween 80 are less toxic and biodegradable than other synthetic surfactants, such as toothpaste and body wash, which often contain SDS. As Tween 80 concentration is 0.5% v/v, it can be added to ice cream for edible use. NaCl is salt, so these chemicals are considered relatively non-harmful to the environment or can be dealt with by ordinary sewage treatment procedures (Zheng et al., 2022). So, using these washing agents is less disruptive to soil structure and less detrimental to soil microbial ecology (Wen et al., 2009).

3.5 Effect of Parameters on Mercury Desorption

To determine the influence of different operational parameters for removing Hg from contaminated soil, the most efficient washing recipe, citric acid + Tween 80 + SDS, was chosen for the survey. Many factors may influence the performance of the soil washing process, including pH, solid-to-liquid ratio, and stirring speed. To examine the optimal operational conditions for the washing process, we explored the influence of these factors on the Hg removal rates from contaminated soil samples.

Among the different remediation technologies available, physical remediation methods require the least amount of time to complete the remediation of a polluted site, so they are considered the most effective (Dermont et al., 2008). Chemical remediation techniques are also fast, but their effectiveness varies with metal, soil, and chemical type. The combination of physical and chemical remediation is quite effective as compared to the individual soil washing technology (Vu et al., 2017). The flotation machine is known to take less time to remove the contaminant. The high rotating speed of the flotation machine reduces the time frame as the soil particles in the solution collide with each other, and the reagent makes complexes with heavy metals quickly (Blais et al., 2010). The purpose of using a flotation machine is to reduce the time period normally taken in the soil washing process. So, in this context, Taguchi design is used to find out the optimal parameters. Figure 3 shows the variation trends of Hg removal rates with the change of pH value in a flotation cell. The Hg removal efficiency decreased as the pH value of the solution increased. The minimum Hg removal efficiency was observed at pH = 6 due to an alkaline environment (higher pH value) which might effectively reduce heavy metal desorption capabilities and weaken the performance of washing solutions (Kulikowska et al., 2015). At pH 4 soil, heavy metal cations are complex with H+ for the adsorption of soil colloids. The greater carbonate solubility allows washing reagents to access carbonate-bound metals (Chen et al., 2018; Chen et al., 2016). Overall, these results indicate the pH variation could influence the Hg removal in the presence of washing agents.

Another important factor in the soil-washing process is the liquid-to-solid ratio. The desorption of Hg increase with the increase in the liquid-to-solid ratio. Liquid-to-solid ratios greatly influence washing reactions, as metals-to-reagents molar ratios determine extraction efficiencies (Zhang et al., 2013). In spite of increased removal rates for heavy metals, when the liquid-to-solid ratio is increased, the washing equipment would necessarily experience greater operation pressure. The highest removal efficiency was observed at L/S ratio of 5:1. Experiments showed that the Hg desorption rate increased with an increase in the liquid-to-solid ratio. At high liquid-to-solid ratios, the washing solutions contain a huge number of functional groups that serve as binding sites for heavy metal ions (Xu et al., 2022). Low liquid-to-solid ratios resulted in a small formulation volume and dense foam. Getting soil particles out of dense foam is a pretty difficult task. Furthermore, a low liquid-to-soil ratio expedites a deficient mixing of soil and washing agents, which critically curtail the removal efficacy (Son & Jung, 2011).

The appropriate stirring speed could facilitate stripping the crusted or adsorbed contaminants. According to the survey, the Hg removal efficiency reached the highest value at the stirring speed of 1500 rpm. The noticeable decreasing trend of Hg removal efficiencies was noted at too low and high stirring speeds. The excessive stripping speeds reduce relative movement and collision between soil particles, resulting in a lower removal efficiency (Amofah et al., 2011). An increase in the stirring speed will cause the slurry to move in bulk formation, movement is limited, and collision is reduced, leading to lower removal efficiency.

Furthermore, to determine the optimal conditions, the signal-to-noise ratio (SNR) represents each parameter's impact on the removal rate based on three classifications: “normal value is better,” “small is better,” and “larger is better” (Googerdchian et al., 2018). The “larger is the better” condition was selected in this work to compute the removal efficiencies. The effect of varying experimental conditions on the removal efficiency of Hg from contaminated soil is depicted in Fig. 3. The maximum removal rate of Hg was achieved at pH = 4, the liquid-to-solid ratio of 5:1, and a 1500-rpm stirring speed.

The analysis variance (ANOVA) for the Taguchi approach is conducted (the results showed in Table S3). ANOVA was performed to determine which factors are significantly influencing the washing process and what are the contribution of each factor to the Hg removal rate. In other words, this analysis allows a better understanding of each parameter's significance in assessing the reliability of observed results. These results revealed that the liquid-to-solid ratio (P = 0.017) was highly persuasive on removal rate, followed by pH and stirring speed. The P-values of the liquid-to-solid ratio are less than 0.05, indicating this factor is statistically noteworthy. However, when it comes to removing Hg, the rotation speed is the least imperative aspect. Among the three parameters, pH value has the least impact on Hg desorption rate.

Results of present study give us appropriate instruction for practical applications. The most effective washing agents as well as the optimum soil to solution ratio were derived from the results of present study. This information can be used to improve the decision-making process concerning the selection of the most efficient factors in washing of multi metal-polluted soils.

4 Conclusions

This study used a combined physicochemical method to investigate the Hg removal efficiencies from contaminated soil by soil washing. In particular, washing solutions are a combination of chemicals that are less toxic to the environment, including organic acids, surfactants (Tween 80 and SDS), and electrolyte solutions (NaCl). The results indicated that humic acid showed higher Hg removal efficiency than acetic acid, tartaric acid, and oxalic acid. Using surfactants in combination with organic acids provides the pre-eminent average removal rate. Among them, the recipe citric acid + Tween 80 + SDS shows the highest Hg removal efficiency (94%). Electrolytes have not been shown to enhance removal efficiency; therefore, further studies are needed. The different environmental conditions were examined in the second experimental stage to figure out the optimal conditions. The optimal conditions were shown at pH of 4, a liquid-to-solid ratio of 5:1, and a stirring speed of 1500 rpm. The liquid-to-solid ratio (P = 0.017) was highly significant on Hg removal rate, followed by pH and stirring speed. The results from this study show the potential of green soil washing technology using less toxic, biodegradable, environmentally friendly, and low-cost chemicals.

Data Availability

Data will be made available under the request

References

Ali, H., Khan, E., & Sajad, M. A. (2013). Phytoremediation of heavy metals-concepts and applications. Chemosphere, 91(7), 869–881. https://doi.org/10.1016/j.chemosphere.2013.01.075

Amofah, L. R., Maurice, C., Kumpiene, J., & Bhattacharya, P. (2011). The influence of temperature, pH/molarity and extractant on the removal of arsenic, chromium and zinc from contaminated soil. Journal of Soils and Sediments, 11(8), 1334–1344. https://doi.org/10.1007/s11368-011-0411-y

Asgari, G., Feradmal, J., Poormohammadi, A., Sadrnourmohamadi, M., & Akbari, S. (2016). Taguchi optimization for the removal of high concentrations of phenol from saline wastewater using electro-Fenton process. Desalination and Water Treatment, 57(56), 27331–27338. https://doi.org/10.1080/19443994.2016.1170635

Ash, C., Tejnecký, V., Borůvka, L., & Drábek, O. (2016). Different low-molecular-mass organic acids specifically control leaching of arsenic and lead from contaminated soil. Journal of Contaminant Hydrology, 187, 18–30.

Bai, G., Brusseau, M. L., & Miller, R. M. (1998). Influence of cation type, ionic strength, and pH on solubilization and mobilization of residual hydrocarbon by a biosurfactant. Journal of Contaminant Hydrology, 30(3–4), 265–279. https://doi.org/10.1016/S0169-7722(97)00043-0

Begum, Z. A., Rahman, I. M. M., Tate, Y., Sawai, H., Maki, T., & Hasegawa, H. (2012). Remediation of toxic metal contaminated soil by washing with biodegradable aminopolycarboxylate chelants. Chemosphere, 87(10), 1161–1170. https://doi.org/10.1016/j.chemosphere.2012.02.032

Beiyuan, J. Z., Tsang, D. C. W., Valix, M., Zhang, W. H., Yang, X., Ok, Y. S., & Li, X. D. (2017). Selective dissolution followed by EDDS washing of an e-waste contaminated soil: extraction efficiency, fate of residual metals, and impact on soil environment. Chemosphere, 166, 489–496. https://doi.org/10.1016/j.chemosphere.2016.09.110

Biester, H., & Scholz, C. (1997). Determination of mercury binding forms in contaminated soils: mercury pyrolysis versus sequential extractions. Environmental Science & Technology, 31(1), 233–239. https://doi.org/10.1021/es960369h

Blais, J.-F., Meunier, N., & Mercier, G. (2010). New technologies for toxic metals removal from contaminated sites. Recent Patents on Engineering, 4(1), 1–6.

Bolan, N., Kunhikrishnan, A., Thangarajan, R., Kumpiene, J., Park, J., Makino, T., Kirkham, M. B., & Scheckel, K. (2014). Remediation of heavy metal(loid)s contaminated soils - to mobilize or to immobilize? Journal of Hazardous Materials, 266, 141–166. https://doi.org/10.1016/j.jhazmat.2013.12.018

Burckhard, S., Schwab, A., & Banks, M. K. (1995). The effects of organic acids on the leaching of heavy metals from mine tailings. Journal of Hazardous Materials, 41(2–3), 135–145.

Caballero-Gallardo, K., Palomares-Bolanos, J., & Olivero-Verbel, J. (2022). Mercury concentrations in water, sediments, soil, and fish around ancestral afro-descendant territories impacted by gold mining in the Cauca Department. Colombia. Water Air and Soil Pollution, 233(9), 393. https://doi.org/10.1007/s11270-022-05779-3

Cao, Y. R., Zhang, S. R., Zhong, Q. M., Wang, G. Y., Xu, X. X., Li, T., Wang, L. L., Jia, Y. X., & Li, Y. (2018). Feasibility of nanoscale zero-valent iron to enhance the removal efficiencies of heavy metals from polluted soils by organic acids. Ecotoxicology and Environmental Safety, 162, 464–473. https://doi.org/10.1016/j.ecoenv.2018.07.036

Cattani, I., Zhang, H., Beone, G. M., Del Re, A. A. M., Boccelli, R., & Trevisan, M. (2009). The role of natural purified humic acids in modifying mercury accessibility in water and soil. Journal of Environmental Quality, 38(2), 493–501. https://doi.org/10.2134/jeq2008.0175

Chen, H.-R., Chen, C.-C., Reddy, A. S., Chen, C.-Y., Li, W. R., Tseng, M.-J., Liu, H.-T., Pan, W., Maity, J. P., & Atla, S. B. (2011). Removal of mercury by foam fractionation using surfactin, a biosurfactant. International Journal of Molecular Sciences, 12(11), 8245–8258.

Chen, Y., Zhang, S. R., Xu, X. X., Yao, P., Li, T., Wang, G. Y., Gong, G. S., Li, Y., & Deng, O. P. (2016). Effects of surfactants on low-molecular-weight organic acids to wash soil zinc. Environmental Science and Pollution Research, 23(5), 4629–4638. https://doi.org/10.1007/s11356-015-5700-3

Chen, S. C., Lin, W. H., Chien, C. C., Tsang, D. C. W., & Kao, C. M. (2018). Development of a two-stage biotransformation system for mercury-contaminated soil remediation. Chemosphere, 200, 266–273. https://doi.org/10.1016/j.chemosphere.2018.02.085

Cheng, S. L., Lin, Q. T., Wang, Y. P., Luo, H. Y., Huang, Z. F., Fu, H. Y., Chen, H. R., & Xiao, R. B. (2020). The removal of Cu, Ni, and Zn in industrial soil by washing with EDTA-organic acids. Arabian Journal of Chemistry, 13(4), 5160–5170. https://doi.org/10.1016/j.arabjc.2020.02.015

Cho, K., Myung, E., Kim, H., Park, C., Choi, N., & Park, C. (2020). Effect of soil washing solutions on simultaneous removal of heavy metals and arsenic from contaminated soil. International Journal of Environmental Research and Public Health, 17(9), 3133. https://doi.org/10.3390/ijerph17093133

Colacicco, A., De Gioannis, G., Muntoni, A., Pettinao, E., Polettini, A., & Pomi, R. (2010). Enhanced electrokinetic treatment of marine sediments contaminated by heavy metals and PAHs. Chemosphere, 81(1), 46–56. https://doi.org/10.1016/j.chemosphere.2010.07.004

Dermont, G., Bergeron, M., Mercier, G., & Richer-Lafleche, M. (2008). Soil washing for metal removal: a review of physical/chemical technologies and field applications. Journal of Hazardous Materials, 152(1), 1–31. https://doi.org/10.1016/j.jhazmat.2007.10.043

Dermont, G., Bergeron, M., Richer-Lafleche, M., & Mercier, G. (2010). Remediation of metal-contaminated urban soil using flotation technique. Science of the Total Environment, 408(5), 1199–1211. https://doi.org/10.1016/j.scitotenv.2009.11.036

Di Palma, L., & Mecozzi, R. (2007). Heavy metals mobilization from harbour sediments using EDTA and citric acid as chelating agents. Journal of Hazardous Materials, 147(3), 768–775. https://doi.org/10.1016/j.jhazmat.2007.01.072

Effendi, A. J., Lestari, V., & Irsyad, M. (2020). Optimizing soil washing remediation of mercury contaminated soil using various washing solutions and solid/liquid ratios. E3S Web of Conferences,

Falciglia, P. P., Malarbi, D., & Vagliasindi, F. G. A. (2016). Removal of mercury from marine sediments by the combined application of a biodegradable non-ionic surfactant and complexing agent in enhanced-electrokinetic treatment. Electrochimica Acta, 222, 1569–1577. https://doi.org/10.1016/j.electacta.2016.11.142

Feng, W. J., Zhang, S. R., Zhong, Q. M., Wang, G. Y., Pan, X. M., Xu, X. X., Zhou, W., Li, T., Luo, L., & Zhang, Y. Z. (2020). Soil washing remediation of heavy metal from contaminated soil with EDTMP and PAA: properties, optimization, and risk assessment. Journal of Hazardous Materials, 381, 120997. https://doi.org/10.1016/j.jhazmat.2019.120997

Flores, R. A. C., Garcia, F. P., Sanchez, E. M. O., Miro, A. M. B., & Sandoval, O. A. A. (2018). Pyrolysis optimization of agricultural waste using Taguchi L9 orthogonal array design. Bulgarian Journal of Agricultural Science, 24(2), 263-273. <Go to ISI>://WOS:000448983600013

Gao, J. B., Zhao, J., Dong, C. X., Wu, L. H., & Hu, P. J. (2018). Remediation of metal-contaminated paddy soils by chemical washing with FeCl3 and citric acid. Journal of Soils and Sediments, 18(3), 1020–1028. https://doi.org/10.1007/s11368-017-1759-4

Googerdchian, F., Moheb, A., Emadi, R., & Asgari, M. (2018). Optimization of Pb(II) ions adsorption on nanohydroxyapatite adsorbents by applying Taguchi method. Journal of Hazardous Materials, 349, 186–194. https://doi.org/10.1016/j.jhazmat.2018.01.056

Guemiza, K., Mercier, G., & Blais, J. F. (2015). Pilot-scale decontamination of small-arms shooting range soil polluted with copper, lead, antimony, and zinc by acid and saline leaching. Journal of Environmental Engineering, 141(1), 04014054. https://doi.org/10.1061/(Asce)Ee.1943-7870.0000887

Guney, M., Akimzhanova, Z., Kumisbek, A., Beisova, K., Kismelyeva, S., Satayeva, A., Inglezakis, V., & Karaca, F. (2020). Mercury (Hg) contaminated sites in Kazakhstan: review of current cases and site remediation responses. International Journal of Environmental Research and Public Health, 17(23), 8936. https://doi.org/10.3390/ijerph17238936

Gusiatin, Z. M., & Klimiuk, E. (2012). Metal (Cu, Cd and Zn) removal and stabilization during multiple soil washing by saponin. Chemosphere, 86(4), 383–391. https://doi.org/10.1016/j.chemosphere.2011.10.027

Hahladakis, J. N., Lekkas, N., Smponias, A., & Gidarakos, E. (2014). Sequential application of chelating agents and innovative surfactants for the enhanced electroremediation of real sediments from toxic metals and PAHs. Chemosphere, 105, 44–52. https://doi.org/10.1016/j.chemosphere.2013.11.022

Han, C., Wang, H., Xie, F., Wang, W., Zhang, T. A., & Dreisinger, D. (2019). Feasibility study on the use of thiosulfate to remediate mercury-contaminated soil. Environmental Technology, 40(7), 813–821. https://doi.org/10.1080/09593330.2017.1408693

He, F., Gao, J., Pierce, E., Strong, P. J., Wang, H. L., & Liang, L. Y. (2015). In situ remediation technologies for mercury-contaminated soil. Environmental Science and Pollution Research, 22(11), 8124–8147. https://doi.org/10.1007/s11356-015-4316-y

Issaro, N., Abi-Ghanem, C., & Bermond, A. (2009). Fractionation studies of mercury in soils and sediments: a review of the chemical reagents used for mercury extraction. Analytica Chimica Acta, 631(1), 1–12. https://doi.org/10.1016/j.aca.2008.10.020

Jiang, J. G., Yang, M., Gao, Y. C., Wang, J. M., Li, D. A., & Li, T. R. (2017). Removal of toxic metals from vanadium-contaminated soils using a washing method: reagent selection and parameter optimization. Chemosphere, 180, 295–301. https://doi.org/10.1016/j.chemosphere.2017.03.116

Jing, Y. D., He, Z. L., & Yang, X. E. (2007). Effects of pH, organic acids, and competitive cations on mercury desorption in soils. Chemosphere, 69(10), 1662–1669. https://doi.org/10.1016/j.chemosphere.2007.05.033

Kim, T. (2020). On-site treatment of soil contaminated by heavy metals and petroleum using relocatable soil washing equipment. International journal of advanced smart convergence, 9(1), 19–28.

Ko, I., Chang, Y. Y., Lee, C. H., & Kim, K. W. (2005). Assessment of pilot-scale acid washing of soil contaminated with As, Zn and Ni using the BCR three-step sequential extraction. Journal of Hazardous Materials, 127(1–3), 1–13. https://doi.org/10.1016/j.jhazmat.2005.06.041

Krishnamurti, G., Cieslinski, G., Huang, P., & Van Rees, K. (1997). Kinetics of cadmium release from soils as influenced by organic acids: implication in cadmium availability (0047-2425).

Kulikowska, D., Gusiatin, Z. M., Bulkowska, K., & Kierklo, K. (2015). Humic substances from sewage sludge compost as washing agent effectively remove Cu and Cd from soil. Chemosphere, 136, 42–49. https://doi.org/10.1016/j.chemosphere.2015.03.083

Kwon, Y. S., Park, S. Y., Koh, I. H., Ji, W. H., Lee, J. S., & Ko, J. I. (2020). A study on applicability of mercury-contaminated tailing and soil remediation around abandoned mines using washing process. Economic and Environmental Geology, 53(4), 337–346.

Lee, D.-H., Chang, H.-W., & Kim, C. (2008). Mixing effect of NaCl and surfactant on the remediation of TCB contaminated soil. Geosciences Journal, 12(1), 63–68.

Leštan, D., Luo, C.-L., & Li, X.-D. (2008). The use of chelating agents in the remediation of metal-contaminated soils: a review. Environmental Pollution, 153(1), 3–13.

Li, F., Zhang, J. D., Jiang, W., Liu, C. Y., Zhang, Z. M., Zhang, C. D., & Zeng, G. M. (2017). Spatial health risk assessment and hierarchical risk management for mercury in soils from a typical contaminated site. China. Environmental Geochemistry and Health, 39(4), 923–934. https://doi.org/10.1007/s10653-016-9864-7

Lindman, B., Medronho, B., & Karlstrom, G. (2016). Clouding of nonionic surfactants. Current Opinion in Colloid & Interface Science, 22, 23–29. https://doi.org/10.1016/j.cocis.2016.01.005

Liu, J. W., Wei, K. H., Xu, S. W., Cui, J., Ma, J., Xiao, X. L., Xi, B. D., & He, X. S. (2021). Surfactant-enhanced remediation of oil-contaminated soil and groundwater: a review. Science of the Total Environment, 756, 144142. https://doi.org/10.1016/j.scitotenv.2020.144142

Liu, C., Kwon, J.-H., Prabhu, S. M., Ha, G.-S., Khan, M. A., Park, Y.-K., & Jeon, B.-H. (2022). Efficiency of diesel-contaminated soil washing with different Tween 80 surfactant concentrations, pH, and bentonite ratios. Environmental Research, 214, 113830.

Lopez, J., Iturbe, R., & Torres, L. G. (2004). Washing of soil contaminated with PAHs and heavy petroleum fractions using two anionic and one ionic surfactant: effect of salt addition. Journal of Environmental Science and Health Part a-Toxic/Hazardous Substances & Environmental Engineering, 39(9), 2293–2306. https://doi.org/10.1081/lesa-200026266

Ma, F. J., Peng, C. S., Hou, D. Y., Wu, B., Zhang, Q., Li, F. S., & Gu, Q. B. (2015). Citric acid facilitated thermal treatment: an innovative method for the remediation of mercury contaminated soil. Journal of Hazardous Materials, 300, 546–552. https://doi.org/10.1016/j.jhazmat.2015.07.055

Mao, X. H., Jiang, R., Xiao, W., & Yu, J. G. (2015). Use of surfactants for the remediation of contaminated soils: a review. Journal of Hazardous Materials, 285, 419–435. https://doi.org/10.1016/j.jhazmat.2014.12.009

Meng, F., Yuan, G. D., Wei, J., Bi, D. X., Ok, Y. S., & Wang, H. L. (2017). Humic substances as a washing agent for Cd-contaminated soils. Chemosphere, 181, 461–467. https://doi.org/10.1016/j.chemosphere.2017.04.127

Moghal, A. A. B., Mohammed, S. A., Almajed, A., & Al-Shamrani, M. A. (2020). Desorption of heavy metals from lime-stabilized arid-soils using different extractants. International Journal of Civil Engineering, 18(4b), 449–461. https://doi.org/10.1007/s40999-019-00453-y

Mulligan, C. N., Yong, R. N., & Gibbs, B. F. (1999). On the use of biosurfactants for the removal of heavy metals from oil-contaminated soil. Environmental Progress, 18(1), 50–54.

Pazos, M., Iglesias, O., Gomez, J., Rosales, E., & Sanroman, M. A. (2013). Remediation of contaminated marine sediment using electrokinetic-Fenton technology. Journal of Industrial and Engineering Chemistry, 19(3), 932–937. https://doi.org/10.1016/j.jiec.2012.11.010

Piccolo, A., De Martino, A., Scognamiglio, F., Ricci, R., & Spaccini, R. (2021). Efficient simultaneous removal of heavy metals and polychlorobiphenyls from a polluted industrial site by washing the soil with natural humic surfactants. Environmental Science and Pollution Research, 28(20), 25748–25757. https://doi.org/10.1007/s11356-021-12484-x

Ponizovskii, A. A., & Mironenko, E. V. (2001). Mechanisms of lead(II) sorption in soils. Eurasian Soil Science, 34(4), 371-381. <Go to ISI>://WOS:000168327100005

Qi, M., Zhang, Y. J., & Peng, D. (2017). Desorption of mercury from contaminated soil using sodium sulfite. Water Air and Soil Pollution, 228(1), 27. https://doi.org/10.1007/s11270-016-3213-4

Qiao, J. B., Sun, H. M., Luo, X. H., Zhang, W., Mathews, S., & Yin, X. Q. (2017). EDTA-assisted leaching of Pb and Cd from contaminated soil. Chemosphere, 167, 422–428. https://doi.org/10.1016/j.chemosphere.2016.10.034

Raj, D., & Maiti, S. K. (2019). Sources, toxicity, and remediation of mercury: an essence review. Environmental Monitoring and Assessment, 191(9), 566. https://doi.org/10.1007/s10661-019-7743-2

Raju, A., Singh, A., Srivastava, N., Singh, S., Jigyasu, D. K., & Singh, M. (2019). Mapping human health risk by geostatistical method: a case study of mercury in drinking groundwater resource of the central ganga alluvial plain, northern India. Environmental Monitoring and Assessment, 191, 298. https://doi.org/10.1007/s10661-019-7427-y

Ramamurthy, A. S., Vo, D., Li, X. J., & Qu, J. (2008). Surfactant-enhanced removal of Cu(II) and Zn(II) from a contaminated sandy soil. Water Air and Soil Pollution, 190(1–4), 197–207. https://doi.org/10.1007/s11270-007-9592-9

Ray, A. B., & Selvakumar, A. (2000). Laboratory studies on the remediation of mercury contaminated soils. Remediation Journal, 10(4), 49–56. https://doi.org/10.1002/rem.3440100406

Ren, X. H., Yan, R., Wang, H. C., Kou, Y. Y., Chae, K. J., Kim, I. S., Park, Y. J., & Wang, A. J. (2015). Citric acid and ethylene diamine tetra-acetic acid as effective washing agents to treat sewage sludge for agricultural reuse. Waste Management, 46, 440–448. https://doi.org/10.1016/j.wasman.2015.07.021

Renella, G., Landi, L., & Nannipieri, P. (2004). Degradation of low molecular weight organic acids complexed with heavy metals in soil. Geoderma, 122(2–4), 311–315.

Rouse, J. D., Bjornen, K. K., Taylor, R. W., & Shiau, B.-J. (2004). Surfactant-based technologies applicable to remediation of mercury pollution in the subsurface. Environmental Practice, 6(2), 157–164.

Schuster, E. (1991). The behavior of mercury in the soil with special emphasis on complexation and adsorption processes-a review of the literature. Water Air & Soil Pollution, 56(1), 667–680.

Shin, M., & Barrington, S. (2005). Effectiveness of the iodide ligand along with two surfactants on desorbing heavy metals from soils. Water, Air, and Soil Pollution, 161(1), 193–208.

Son, H. O., & Jung, M. C. (2011). Relative extraction ratio (RER) for arsenic and heavy metals in soils and tailings from various metal mines, Korea. Environmental Geochemistry and Health, 33, 121–132. https://doi.org/10.1007/s10653-010-9356-0

Subires-Munoz, J. D., Garcia-Rubio, A., Vereda-Alonso, C., Gomez-Lahoz, C., Rodriguez-Maroto, J. M., Garcia-Herruzo, F., & Paz-Garcia, J. M. (2011). Feasibility study of the use of different extractant agents in the remediation of a mercury contaminated soil from Almaden. Separation and Purification Technology, 79(2), 151–156. https://doi.org/10.1016/j.seppur.2011.01.032

Torres, L. G., Lopez, R. B., & Beltran, M. (2012). Removal of As, Cd, Cu, Ni, Pb, and Zn from a highly contaminated industrial soil using surfactant enhanced soil washing. Physics and Chemistry of the Earth, 37–39, 30–36. https://doi.org/10.1016/j.pce.2011.02.003

Tran, H. T., Lin, C., Hoang, H. G., Bui, X. T., Le, V. G., & Vu, C. T. (2022). Soil washing for the remediation of dioxin-contaminated soil: a review. Journal of Hazardous Materials, 421, 126767. https://doi.org/10.1016/j.jhazmat.2021.126767

Tremblay, L., Kohl, S. D., Rice, J. A., & Gagné, J.-P. (2005). Effects of temperature, salinity, and dissolved humic substances on the sorption of polycyclic aromatic hydrocarbons to estuarine particles. Marine Chemistry, 96(1–2), 21–34. https://doi.org/10.1016/j.marchem.2004.10.004

Vanthuyne, M., Maes, A., & Cauwenberg, P. (2003). The use of flotation techniques in the remediation of heavy metal contaminated sediments and soils: an overview of controlling factors. Minerals Engineering, 16(11), 1131–1141. https://doi.org/10.1016/j.mineng.2003.06.012

Vanthuyne, M., & Maes, A. (2002). The removal of heavy metals from contaminated soil by a combination of sulfidisation and flotation. Science of the Total Environment, 290(1-3), 69-80. Pii S0048-9697(01)01064-6 https://doi.org/10.1016/S0048-9697(01)01064-6

Vargas-Garcia, M. D., Lopez, M. J., Suarez-Estrella, F., & Moreno, J. (2012). Compost as a source of microbial isolates for the bioremediation of heavy metals: in vitro selection. Science of the Total Environment, 431, 62–67. https://doi.org/10.1016/j.scitotenv.2012.05.026

Vu, C. T., Lin, C., Hung, W., Huang, W.-Y., Kaewlaoyoong, A., Yotapukdee, S., Chen, J.-R., & Shen, Y.-H. (2017). Ultrasonic soil washing with fish oil extract to remove polychlorinated dibenzo-p-dioxins (PCDDs), dibenzofurans (PCDFs) from highly contaminated field soils. Water, Air, & Soil Pollution, 228(9), 1–11.

Wang, G. Y., Zhang, S. R., Xu, X. X., Li, T., Li, Y., Deng, O. P., & Gong, G. S. (2014). Efficiency of nanoscale zero-valent iron on the enhanced low molecular weight organic acid removal Pb from contaminated soil. Chemosphere, 117, 617–624. https://doi.org/10.1016/j.chemosphere.2014.09.081

Wasay, S. A., Arnfalk, P., & Tokunaga, S. (1995). Remediation of a soil polluted by mercury with acidic potassium-iodide. Journal of Hazardous Materials, 44(1), 93–102. https://doi.org/10.1016/0304-3894(95)00059-4

Wasay, S. A., Barrington, S., & Tokunaga, S. (2001). Organic acids for the in situ remediation of soils polluted by heavy metals: soil flushing in columns. Water Air and Soil Pollution, 127(1–4), 301–314. https://doi.org/10.1023/A:1005251915165

Wei, M., Chen, J., & Wang, Q. (2018). Remediation of sandy soil contaminated by heavy metals with Na(2)EDTA washing enhanced with organic reducing agents: element distribution and spectroscopic analysis. European Journal of Soil Science, 69(4), 719–731. https://doi.org/10.1111/ejss.12560

Wen, J., Stacey, S. P., McLaughlin, M. J., & Kirby, J. K. (2009). Biodegradation of rhamnolipid, EDTA and citric acid in cadmium and zinc contaminated soils. Soil Biology & Biochemistry, 41(10), 2214–2221. https://doi.org/10.1016/j.soilbio.2009.08.006

Xu, J. Y., Kleja, D. B., Biester, H., Lagerkvist, A., & Kumpiene, J. (2014). Influence of particle size distribution, organic carbon, pH and chlorides on washing of mercury contaminated soil. Chemosphere, 109, 99–105. https://doi.org/10.1016/j.chemosphere.2014.02.058

Xu, J. Y., Bravo, A. G., Lagerkvist, A., Bertilsson, S., Sjoblom, R., & Kumpiene, J. (2015). Sources and remediation techniques for mercury contaminated soil. Environment International, 74, 42–53. https://doi.org/10.1016/j.envint.2014.09.007

Xu, L., Dai, H. P., Skuza, L., Xu, J. M., Shi, J. C., & Wei, S. H. (2022). Co-high-efficiency washing agents for simultaneous removal of Cd, Pb and As from smelting soil with risk assessment. Chemosphere, 300, 134581. https://doi.org/10.1016/j.chemosphere.2022.134581

Yang, T., & Hodson, M. E. (2019). Investigating the use of synthetic humic-like acid as a soil washing treatment for metal contaminated soil. Science of the Total Environment, 647, 290–300. https://doi.org/10.1016/j.scitotenv.2018.07.457

Yang, J. Y., Yang, X. E., He, Z. L., Li, T. Q., Shentu, J. L., & Stoffella, P. J. (2006). Effects of pH, organic acids, and inorganic ions on lead desorption from soils. Environmental Pollution, 143(1), 9–15. https://doi.org/10.1016/j.envpol.2005.11.010

You, R., Liang, L., Qin, C. Q., Deng, H., & Wang, D. Y. (2016). Effect of low molecular weight organic acids on the chemical speciation and activity of mercury in the soils of the water-level-fluctuating zone of the Three Gorges Reservoir. Huan Jing Ke Xue, 37(1), 173-179. https://www.ncbi.nlm.nih.gov/pubmed/27078955

Yun, S. M., Kang, C. S., Kim, J., & Kim, H. S. (2015). Evaluation of soil flushing of complex contaminated soil: An experimental and modeling simulation study. Journal of Hazardous Materials, 287, 429–437. https://doi.org/10.1016/j.jhazmat.2015.01.062

Zhang, L., Somasundaran, P., Ososkov, V., & Chou, C. C. (2001). Flotation of hydrophobic contaminants from soil. Colloids and Surfaces a-Physicochemical and Engineering Aspects, 177(2–3), 235–246. https://doi.org/10.1016/S0927-7757(00)00681-6

Zhang, T., Liu, J.-M., Huang, X.-F., Xia, B., Su, C.-Y., Luo, G.-F., Xu, Y.-W., Wu, Y.-X., Mao, Z.-W., & Qiu, R.-L. (2013). Chelant extraction of heavy metals from contaminated soils using new selective EDTA derivatives. Journal of Hazardous Materials, 262, 464–471.

Zheng, X.-J., Li, Q., Peng, H., Zhang, J.-X., Chen, W.-J., Zhou, B.-C., & Chen, M. (2022). Remediation of heavy metal-contaminated soils with soil washing: a review. Sustainability, 14(20), 13058.

Zou, Q., Gao, Y. C., Yi, S., Jiang, J. G., Aihemaiti, A., Li, D. A., & Yang, M. (2019). Multi-step column leaching using low-molecular-weight organic acids for remediating vanadium- and chromium-contaminated soil. Environmental Science and Pollution Research, 26(15), 15406–15413. https://doi.org/10.1007/s11356-019-04915-7

Funding

This research is financially supported by the Ministry of Science and Technology (MOST) Taiwan (MOST-108-2221-E-992-052-MY2).

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of Interest

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Below is the link to the electronic supplementary material.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Ahsan, W.A., Hoang, HG., Zhang, QJ. et al. Solvent-Based Soil Washing of Mercury-Contaminated Soil with Eco-friendly Washing Agents. Water Air Soil Pollut 234, 69 (2023). https://doi.org/10.1007/s11270-023-06093-2

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11270-023-06093-2