Abstract

Purpose

Normal soil washing leave high residual pollutant content in soil. The remediation could be improved by targeting the extraction to coarser fractions. Further, a low/high extraction pH and higher temperature enhance the pollutant removal, but these measures are costly. In this study, the utility of NaOH, oxalate–citrate (OC) and dithionite–citrate–oxalate (DCO) solutions for extracting of arsenic, chromium and zinc from contaminated soil were assessed and compared. In addition the effects of NaOH concentration and temperature on NaOH extractions, and those of temperature and pH on OC and DCO extractions, were evaluated.

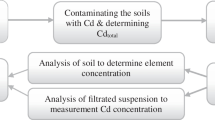

Materials and methods

A two-level, full-factorial design with a centre point was implemented. Two factors, concentration and temperature,were evaluated in NaOH extractions, and pH and temperature for OC and DCO solutions. In all cases, the extraction temperature was 20°C, 30°C and 40°C. The studied NaOH concentrations were 0.05, 0.075 and 0.1 M. The pH in OC solutions was 3, 5 and 7, and in DCO solutions, 4.7, 6.3 and 6.7. Water-washed and medium coarse soil fraction of arsenic, chromium and zinc contaminated soil was agitated for 15 min with the extraction solution.

Results and discussion

In NaOH extractions, the temperature and (less strongly) NaOH concentration significantly affected As and Cr mobilisation, but only the latter affected Zn mobilisation. Both pH and temperature significantly (and similarly) influenced As and Cr mobilisation in OC extractions, while only the pH influenced Zn mobilisation. In contrast, the extraction temperature (but not pH) influenced As, Cr and Zn mobilisation in DCO extractions.

Conclusions

For all extractants, mobilisation was most efficient at elevated temperature (40°C). None of the extractants reduced the soil’s As content to below the Swedish EPA’s guideline value. Use of DCO is not recommended because dithionite has a short lifetime and residual arsenic contents in DCO-extracted soil are relatively high. Instead, sequential extraction with NaOH followed by OC solutions (affording significant reductions in As, Cr and Zn levels in the soil with short extraction times) at 40°C is recommended.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

Multiple metal(loid)-contaminated soils commonly exist due to different anthropogenic activities. For example, in Sweden, among the 80,000 sites potentially contaminated, about 1,400 need to be remediated by year 2050 due to contamination of, among others, As and metals (Skogsjö 2010) which is commonly a result of the utilisation of wood preservatives (Bhattacharya et al. 2002). Several methods are available to remediate contaminated sites, e.g. excavation and landfilling, solidification/stabilisation, containment and capping (Mulligan et al. 2001; United States Environmental Protection Agency 1997). These methods, however, do not reduce satisfactorily environmental risk due to possible metal(loid) leaching from treated soils (Alam and Tokunaga 2006). Beside extractive phytoremediation methods (Arwidsson et al. 2010; Mulligan et al. 2001), soil washing offers one of few permanent treatment solutions to remove metal(loid)s from the soil in a feasible time frame (Dermont et al. 2008). Pollutants such as As are often concentrated in the portions of soil with small particle sizes (Jang et al. 2007; Ko et al. 2005; Legiec et al. 1997), which occupy a small volume of the total bulk soil. Soil washing can be used to separate highly contaminated fine fractions from the clean coarse material, which can be reused. An intermediate fraction may be generated from soil washing which is moderately contaminated and in which pollutants are more loosely bound than in finer fractions (Ko et al. 2005; Legiec et al. 1997). Many studies on As extraction have focused on the highly contaminated fine soil fraction (<2 mm), and while some reductions in As levels have generally been achieved, the residual As concentration in the extracted soil generally remains high after treatment (Bhattacharya et al. 2002; El-Khosht Salama 2001; Van Benschoten et al. 1994). A recent study found NaOH, dithionite–citrate–oxalate (DCO) and oxalate–citrate (OC) to be the most effective extractants for removing arsenic from contaminated soil (Rastas Amofah et al. 2008). Although this study focused on the water-washed coarse soil fractions, all of the methods examined left relatively high residual concentrations of As in the treated soil. The efficiency of arsenic extraction could be improved by multiple sequential extractions of the soil. However, multistage extractions with an extractant at close to room temperature do not significantly improve overall contaminant removal (Alam et al. 2001; Bhattacharya et al. 2002; Jang et al. 2007). By contrast, increasing the extraction temperature can significantly improve As removal (Alam et al. 2001). However, heating the extraction solution can be costly. Furthermore, pH significantly influences the mobility of elements; As [as arsenate, As(V)] is mobile at extremely low and extremely high pHs (Lee et al. 2007; Manning and Goldberg 1997; Xu et al. 1988). Thus, since soil becomes acidic after acid extraction, the treated bulk soil must be neutralized to avoid detrimental effects on soil properties (Ko et al. 2005). Therefore, it is important to identify optimal temperatures and pH to remove As and other pollutant metals derived from chromated zinc arsenate (CZA) efficiently from contaminated soil.

In the present study, the utility of NaOH, OC and DCO solutions for extracting arsenic and related contaminants from a medium coarse and water-washed CZA-contaminated soil were assessed and compared. In addition the effects of NaOH concentration and temperature on NaOH extractions, and those of temperature and pH of near to neutral on OC and DCO extractions, were evaluated.

2 Materials and methods

2.1 Soil sampling

The soil used in the experiments originated from a wood impregnation site in Forsmo, northern Sweden (63°10′10″ N, 17°17′57″ E), where CZA has been used for wood treatment (Nordberg and Stenberg 2005). Contaminated soil at this site had been previously excavated, transported and stored in an open-air pile at a landfill site. A composite sample was collected randomly from this pile and homogenised by mixing with a spade. The studied soil has been investigated in earlier studies (Kumpiene et al. 2009; Lidelöw et al. 2007), in which more detailed information of the soil characteristics is given. The soil was dried at room temperature and sieved through an 8-mm followed by a 0.25-mm sieving mesh. The 0.25–8-mm fraction was placed on a 0.25-mm sieve and rinsed under running tap water for several minutes, then the soil was dried in an oven at 50°C before use. This water-sieved soil fraction is henceforth referred to as “composite soil” and is the focus of this study. The composite soil was subsampled by using fractional shovelling and a rotating sectional splitter containing eight receiving sectors (Gerlach and Nocerino 2003). The soil was analysed to determine: organic matter, measured by loss on ignition at 550°C according to Swedish standard SS 028113 (Swedish Standards Institute SIS 1981); grain size distribution, following Swedish standard SS 027124 (Swedish Standards Institute SIS 1992); and pH, after equilibrating the soil in deionised water for 10 min at a soil-to-water ratio of 1:1 (Thomas 1996). The metal content of the soil was determined by a modified version of the method described in Andersson et al. (1991). Soil samples (4 g) were digested with 40 ml of 7 M HNO3 on a sand bath at 70°C for 30 min then at 100°C for 2 h. After cooling, the solutions were filtered through a filter paper (OOR), made up to a volume of 100 ml, filtered through a 0.45-μm membrane filter and stored at 4°C prior to analysis. All analyses were in triplicate.

2.2 Extraction experiment design

The batch extraction process was studied using a two-level, full-factor design, focusing on two factors—concentration and temperature—when using NaOH as the extractant, and pH and temperature when using oxalic/citric acid (OC) or Na2S2O4 (Na dithionite)/Na citrate/Na oxalate (DCO, Table 1). The chemicals used were of pro-analysis grade and were supplied by Merck, and all glasswares were acid washed before usage. The pH of the OC solutions was adjusted with NaOH while that of the DCO solutions was adjusted with NaOH or HCl as appropriate. Experiments corresponding to the corner points were run in duplicate, while the centre point was run in triplicate. Extraction tests were performed by agitating 10 g of soil with 50 ml of the appropriate extractant solution in a 125-ml glass flask. With the exception of the tests conducted at room temperature, all of the extraction solutions were heated to 10°C above the test temperature (see Table 1) prior to the experiment. The agitation was effected in a water bath, resulting in an extraction temperature of 20°C, 30°C and 40°C, with linear mixing for 15 min. After agitation, the temperature, pH and redox potential of the extraction solution were measured. Samples were filtered through a 0.45-μm filter and stored at 4°C prior to analysis.

2.3 Metal contents of the extracted soil

The extraction solution was decanted from each soil sample, which was then rinsed twice with 125 ml distilled water by adding water to the flask and decanting after several minutes. The soil sample was then collected from the flask and dried at 50°C in a crucible. Residual metal contents in the soil after extraction by each of the three extractants, under the conditions that proved most efficient for removing As, were determined as described in Section 2.1.

2.4 Extraction analysis, statistical evaluation and modelling

The samples’ pH and redox potential were measured with a WTW pH 330 meter and a PHM95 pH/ION meter (Radiometer, Copenhagen), respectively. The total metal concentrations (in the soil samples prior and after extraction) were analysed with ICP-OES (Perkin Elmer Optima 2000DV). Arsenic, Fe and Al concentrations in the extraction solutions were analysed with ICP-AES according to EPA 200.7. Copper and Cr concentrations in the extraction solutions were analysed with ICP-SFMS according to EPA 200.8. The analysis of the extraction solutions was conducted at the accredited laboratory of ALS Scandinavia in Luleå, Sweden. MODDE software (Umetrics AB, Sweden) was used for data evaluation. Experimental data for As, Cr, Zn, Fe and Al were fitted using partial least squares. VMINTEQ ver 2.53, a chemical equilibrium programme (Gustafsson 2007) based on MINTEQA2, was used for geochemical modelling. The elemental concentrations, temperature, pH and redox potential of the extraction solutions were used to determine chemical speciation and potential solid phases within the extraction solutions.

3 Results

3.1 Soil characteristics

Following pH, sieving and metal analyses, the soil was classified as moderately acidic gravelly sand (Table 2), with 2.5 times more Fe than Al (11,800 vs 4,600 mg/kg) and 56 times more Fe than Mn. In addition, it contained 147, 26 and 62 mg/kg As, Cr and Zn, respectively.

3.2 Sodium hydroxide extraction

The first model constructed, designated the aggregate model, focused on the overall mobilisation of five elements (As, Zn, Cr, Fe, and Al). The importance of each factor and their interactions in this model are summarised in the variable influence on projection (VIP) plot shown in Fig. 1a. The only terms with VIP >0.7 were temperature and concentration, so these two variables are the most significant in this model. The other variables are less important in the aggregate model, but some are important for predicting the mobilisation of individual elements; the main and interactive factors affecting mobilisation of As, Zn, Cr, Fe and Al individually are shown in Table 3. Both the concentration of the NaOH solution and the extraction temperature significantly influenced the mobilisation of all five elements. The temperature had a greater effect than extractant concentration for all elements other than Zn; the difference between the effects was significant for As, Cr, Fe and Al. The concentration–temperature interaction was significant only for Zn; temperature had a greater effect on Zn mobilisation at the higher extractant concentration. For As, Zn, Cr, Fe and Al, models including only three terms (concentration, temperature and the interaction between them) had R 2 and Q 2 values of >0.80 (except for Zn, for which the Q 2 was 0.75).

Variable influence on projection (VIP) plot for the mobilisation of As, Cr, Zn, Fe and Al from the soil using a NaOH, b oxalate–citrate and c dithionite–citrate–oxalate solutions. The plot summarises the importance of each factor, factor interaction and the square term on the total model. Temp temperature, Conc concentration

At room temperature, doubling (NaOH) from 0.05 to 0.1 M increased As mobilisation by a factor of <2 (Table 4); using 0.1 M NaOH, 48 mg As/kg was mobilised, corresponding to 33% removal. At the lower concentration, raising the extraction temperature from 20°C to 41 ± 1°C increased the mobilisation of As from 28 to 78 mg/kg. When extracting at 40°C and the higher NaOH concentration, 102 mg/kg of As was mobilised. Amounts of Cr extracted with NaOH varied between 0.8 and 2.6 mg/kg (3–10%), depending on the conditions. Using 0.05 M NaOH, 0.8–0.9 mg/kg of Zn was mobilised; the extraction temperature had very little influence. By contrast, using a 0.1-M NaOH solution, 2.0 mg/kg of Zn was mobilised at 40°C, compared to 1.2 mg/kg at 20°C. Depending on the conditions, the Zn removal varied between 1.4% and 3.3%. The amount of Fe mobilised using NaOH was 11–27 mg/kg, and Al mobilisation was 189–535 mg/kg.

The pH of the extract solutions after agitation varied from 11.8 to 12.8, with lower extraction temperatures resulting in higher pH values (Table 5). Extracts obtained at 20°C had considerably higher redox potentials than those obtained at elevated temperature.

3.3 Oxalate–citrate solution extraction

The VIP plot (see Fig. 1b) for the aggregate model shows that pH and temperature are the most significant variables (VIP >0.8) when using oxalate–citrate as the extractant, the factor squared and interaction terms being less important (VIP values 0.7 and <0.6, respectively). Including either of these terms (especially temperature squared) improved simple pH and temperature-based extraction models (based on R 2 and Q 2 values). The temperature, pH and temperature-squared terms were all significant in the As, Cr, Fe and Al mobilisation models (see Table 3). Of these terms, pH and temperature were the most important, and their effects on As, Cr, Fe and Al mobilisation were identical at the 95% confidence level. For Zn, only the pH term was significant.

At 20°C, decreasing the pH of the OC solution from 7 to 3 increased the elements’ mobility more than fivefold (with the exception of Zn; see Table 4). For example, the amount of As mobilised rose from 6.3 to 57 mg/kg. The maximum As mobility with OC was 111 mg/kg, using a pH 3 solution at 43 ± 1°C. Under most conditions examined, ≤2.2 mg/kg Cr was mobilised, but using an OC solution of pH 3 at ∼40°C, 5.6 mg/kg was mobilised, corresponding to 22% removal. The maximum Zn mobilisation was 16–17 mg/kg (corresponding to ∼26% reduction), at pH 3; Zn mobilisation was relatively insensitive to changes in the extraction temperature. At pH 3 and ∼40°C, the OC solution mobilised large amounts of Fe (1,050 mg/kg) and Al (607 mg/kg) corresponding to 9% and 13% removal, respectively. At pH 7, <1% and <4% of the Fe and Al were removed, respectively.

The oxalate and citrate ions in the OC solution served as efficient buffers, maintaining the solutions’ pH at 3.1, 5.2 and 7.2, as appropriate (see Table 5). The redox potentials of the solutions were 150–500 mV.

3.4 Dithionite solution extraction

As shown in the VIP plot (see Fig. 1c), the main factors in the DCO extraction aggregate model were temperature and pH, both of which had a VIP >0.7. The VIP of the temperature-squared and interaction terms were 0.7 and 0.64, respectively. An extraction at pH 6.7 and high temperature gave an anomalous result; this outlier was excluded from the model. A simplified aggregate model using only the main factors and the interaction term gave a better fit than one using the main factors and the temperature-squared term, based on the models R 2 and Q 2 values. The coefficients for each of the five elements from the model using the main factors and the interaction term are shown in Table 3. Temperature was significant for all five elements and had the greatest effect on their mobilisation. For As and Cr, the interaction term was significant; at the higher pH, temperature affected their mobilisation more than at the lower pH. The pH term was significant only for Al.

At room temperature, 47 and 32 mg/kg of As was mobilised at pH 4.7 and 6.7, respectively. Increasing the temperature from 20°C to 40°C increased As mobilisation at pH 6.7 nearly threefold to 93 mg/kg. The amount of Cr mobilised was below 4 mg/kg under all conditions examined, except at pH 6.7 and 42 ± 1°C, with a maximum value of ∼4.6 mg/kg. Zn mobilisation was not significantly affected by changes in pH, with mobilisations of 9–10 mg/kg at room temperature. At 40°C, the mobilisation was 35 mg/kg, corresponding to a 57% reduction. The amount of Fe mobilised varied between 341 and 709 mg/kg, and Al mobilisation was 113–338 mg/kg.

DCO solutions with pH values of 4.7, 6.3 and 9.2 were evaluated as extractants. The pH of the basic solution decreased from 9.2 to around 6.7 after contact with the soil but then remained constant during agitation. Contact with the soil did not change the pH of the other solutions. Increasing the extraction temperature from 20°C to 40°C raised the redox potentials of the pH 4.7 and 6.7 solutions from −200 to +200 mV and from −340 to +35 mV, respectively.

3.5 Metal content of the soil after extraction

Having identified optimal conditions for treating the soil with each of the three extractants (0.1 M NaOH at 40°C, OC at pH 3 and 40°C, and DCO at pH 6.7 and 40°C), residual element contents of soil extracted under these optimal conditions were investigated (Table 6). The residual As and Zn concentrations in soil extracted with OC under optimised conditions were less than half of those in soil treated with NaOH or DCO. The Cr concentration was also considerably lower in the OC-treated soil.

4 Discussion

4.1 Contaminants in the studied soil

The As content of the untreated soil was six times greater than the Swedish EPA’s guideline value for “less sensitive land use” (“MKM”), 25 mg/kg (EPA 2009). Thus, the soil is clearly contaminated with As. The soil’s Cr and Zn contents were substantially below the guideline values of 150 and 500 mg/kg, respectively (EPA 2009), but somewhat higher than typical contents of Swedish mor layers and topsoil (Berggren Kleja et al. 2006). In slightly acidic and oxidised soils, As(V) is the most stable form of As (Gräfe et al. 2008; Hopp et al. 2008; Masscheleyn et al. 1991) and is mainly adsorbed to Fe, Al and Mn (hydr)oxides (Livesey and Huang 1981; Sadiq 1997). In a previous study (Rastas Amofah et al. 2008), only ∼10% of the total As in the studied soil was mobilised by phosphate at pH 5. The soil studied contains much more Fe and Al than Mn (see Table 2). Therefore, the As in the studied soil was expected to be mainly in the As(V) oxidation state, tightly adsorbed to Fe and Al (hydr)oxides. The chromium in CZA solution exists in the Cr(VI) oxidation state but can be reduced to Cr(III) during wood impregnation (Solo-Gabriele et al. 2003) or in the soil (Song et al. 2006). Cr(VI) is reduced by organic matter or Fe2+, and the Cr(III) thus formed is retained as the trivalent oxide or through precipitation of Fe,Cr(OH)3 in the soil (Fendorf 1995; Hopp et al. 2008). The untreated soil contains substantial amounts of Fe and 2% organic matter. Thus, most of the Cr in the untreated soil was expected to be in Fe,Cr(OH)3 precipitates in the Cr(III) oxidation state. Zn is a rather mobile element in acidic and oxidised soils (McBride 1994). The arsenic contaminating the soil originated from a solution that also contained Zn and Cr(VI). Arsenic has been shown to co-locate with Fe, Cr, Cu and Zn–Fe in CCA-contaminated soil (Gräfe et al. 2008; Hopp et al. 2008) and combines with Zn to form adamite-like and koritnigite-like precipitates on goethite surfaces (Gräfe and Sparks 2005). Thus, arsenic in the untreated soil could also be present as a co-precipitate with Zn on the surface of Fe/Al (hydr)oxides and (Cr,Fe) hydroxides.

4.2 NaOH extraction

Doubling the NaOH concentration from 0.05 to 0.10 M increased removal of As from the contaminated soil only moderately (1.3–1.7-fold), possibly because of the negligible difference in pH between the solutions (see Table 5). Other studies have also found that As mobilisation is not generally significantly enhanced by increasing the NaOH concentration (or the pH) when the pH of the extraction solution is <12–13 (Jang et al. 2002, 2005; Lee et al. 2007). At room temperature, the overall removal in the present study was low compared to results from other studies (≤33% vs. 48–100%) (Jang et al. 2005; Lee et al. 2007; Rastas Amofah et al. 2008), possibly due to the shorter contact time in the present study (15 min vs. 0.5–6 h), since longer contact times generally improve As mobilisation (Jang et al. 2005). In addition, VMINTEQ simulations indicated that the NaOH solutions after extraction were saturated with Ba arsenates (see Electronic supplementary material, Fig. 1), which may have reduced the mobilisation of As. Arsenic co-locates with Fe, Cu and Zn–Fe (Gräfe et al. 2008) and forms precipitates with Zn on goethite surfaces (Gräfe and Sparks 2005). Thus, in addition to the effect of ligand exchange with OH−, the As mobilisation from CZA-contaminated soil is likely to be facilitated by dissolution of these precipitated metal hydroxides, which have low solubility at high pH (>12). Thus, the relatively low mobilisation of arsenic may be related to the low mobilisation of Cr, Zn and Fe under these conditions.

Raising the temperature from 20°C to ∼40°C increased As mobilisation ≥2-fold, resulting in up to 70% removal of the arsenic at the high NaOH concentration, presumably due to increased activities and reaction rates at higher temperatures. At 40°C, the removal when using a 0.1-M solution of NaOH was comparable to values reported in previous studies (Jang et al. 2005; Lee et al. 2007). Thus, by increasing the extraction temperature, the leaching time could be decreased from hour(s) to 15 min without reducing extraction efficiency. The increased Zn mobilisation at the higher extractant concentration may be related to differences in the solubility constants of Zn hydroxide at high and low temperatures, which are greater at higher extractant concentrations (Reichle et al. 1975).

4.3 Oxalate–citrate extraction

The pH of the OC solution significantly influenced mobilisation of As, Cr, Zn, Al and Fe from the soil (see Table 3). For example, at the low temperature, reducing the pH from 7 to 3 increased mobilisation of As and Fe ninefold (see Table 4). Similar regarding effects of pH on the dissolution of Fe (Mohapatra et al. 2005; Shi et al. 2008; Zhang et al. 1985; Zinder et al. 1986) and Al oxides (Furrer and Stumm 1986) by oxalic and/or citric acid have been observed. Arsenic was mobilised somewhat less efficiently at pH 3 in this study than in previous extractions of CCA-contaminated soil using acidic oxalate solutions (39% vs. 35–79%) (Bhattacharya et al. 2002; Girouard and Zagury 2009), possibly due to use of a shorter contact time (Girouard and Zagury 2009) and lower concentration of oxalate (Bhattacharya et al. 2002) in this study.

Temperature significantly influenced mobilisation of As, Cr, Fe and Al; raising the temperature from 20°C to ∼40°C increased mobilisation ≥2-fold at both pH levels. However, at ∼40°C, arsenic removal was far more greater at the low pH (76% vs. 19% at the higher pH), presumably because pH (and temperature) affects the dissolution of metal (hydr)oxides (Cornell and Schwertmann 2003). At low pH, more of the ligand can adsorb to the metal (hydr)oxides in the soil, and the extent of dissolution is proportional to the extent of this adsorption (Furrer and Stumm 1986; Zhang et al. 1985). High temperature enhances the rate of detachment of metal–ligand complexes from oxide surfaces (Zhang et al. 1985), a process that often requires high activation energy. Furthermore, the presence of citrate and oxalate reduces rates of readsorption of arsenic on fresh (hydr)oxide surfaces (Grafe et al. 2002; Shi et al. 2008), and the extent of the reduction is greater at pH 3 than at pH 7. The arsenic removal achieved in this study when using OC at the low pH and high temperature levels compares very favourably to that obtained in previous studies (Bhattacharya et al. 2002; Girouard and Zagury 2009). By performing the extraction at pH 3 and elevated temperature, the contact time could be decreased from hour(s) to 15 min without reducing the efficiency of arsenic removal.

4.4 Dithionite extraction

The acidity of the DCO solution used for extraction had no significant effect on the mobilisation of As, Cr and Fe (see Table 3), possibly due to the relatively limited range of acidities examined here (see Table 5). For example, in previous studies, a difference in dissolution rates of goethite of 120 s−1 was recorded when pH of dithionite–citrate solutions from 4.5 to 9.0 were used, but just 40 s−1 when pH of 4.7–6.7 were used (Rueda et al. 1992), and mobilisation of Fe was 2.5 times greater at pH 1.5–8 than at pH 4.5–8 when oxalate was used to dissolve hematite (Zhang et al. 1985). In the present study, the tested pH altered because of lack of buffering and the acidity of the soil: after contact with soil, the solution pH was decreased from 9.2 to 6.7 at high pH level.

The extraction temperature significantly affected mobilisation of As, Cr, Zn, Fe and Al. Increasing the temperature from 20°C to 40°C increased As mobilisation ≥2-fold; this effect was most pronounced at the higher pH. At pH 6.7 and 40°C, 63% of the arsenic was removed. The improved mobilisation at elevated temperatures may be due to the high activation energy of dissolution of Fe (hydr)oxides (Rueda et al. 1992). Interestingly, the pH–temperature interaction term was significant in DCO extractions: at the low temperature, the mobilisation of As and Cr was greater at the lower pH, while at the high temperature, their mobilisation was greater at the higher pH (see Table 4). This may be due to the decomposition of dithionite, which is accelerated at low pH (6 vs. 10) and high temperature (32°C vs. 4°C) (Devaney and Guess 1982), and accompanying increases in the solution’s redox potential (see Table 5). A low redox potential accelerates dissolution of Fe (hydr)oxides (Cornell and Schwertmann 2003), thus enhancing release of As (and Cr). However, the interaction term was not significant for Fe mobilisation (p = 0.09). VMINTEQ simulations indicate that this may be due to saturation of the extractant solution with some Fe minerals at the higher temperatures (see Electronic supplementary material, Fig. 2), which could have reduced the concentration of Fe in the extracted solution. An alternative explanation for the significance of the interaction term for As extraction is that As may have been mobilised via mechanisms other than the reductive dissolution of Fe (hydr)oxides. It has been reported that As(V) is selectively reduced to As(III) by dithionite (Tsang et al. 2007), which does not occur at room temperature but proceeds to completion within 1 h at 50°C and 10 min at 80°C. Therefore, some of the As may have been mobilised via reduction of As(V) to As(III) in the high temperature and high pH extractions.

4.5 Improving the extraction

As, Cr and Zn mobilisation with all extractants was maximal at ∼40°C, but for OC, NaOH and DCO, optimal results were obtained using solutions of pH 3, 0.1 M and pH 6.7, respectively (Fig. 2a–c). Although the three extractants all afforded similar mobilisations (100 ± 10 mg/kg) of As under optimal conditions, the residual As content was ≤2-fold lower in the OC-treated soil than in both the NaOH- and DCO-treated soil (see Table 6). Furthermore, residual levels of several other metals were lowest in the OC-treated soil. The relatively poor efficiency of NaOH and DCO extractions may be partly due to readsorption of As from residual extraction solution trapped between soil particles after the extraction solution has been poured away, and the pH decreased and the redox potential raised when rinsing water is added.

Reduction of a As, b Cr and c Zn (in percent) after 15 min agitation with NaOH, oxalate–citrate (OC) or dithionite–citrate–oxalate (DCO) solutions. For NaOH solutions, the concentrations used were 0.05, 0.075 and 0.1 M; for OC solutions, the pH values were 3.1, 5.1 and 7.1; and for DCO solutions, the pH values were 4.7, 6.3 and 6.7. In all cases, the temperatures were 20°C, ∼30°C and ∼40°C. One of three centre points for the NaOH extractions and one of the corner points (1,1) for the DCO extractions were excluded

The residual As content of the OC-treated soil exceeded the Swedish EPA’s guideline value for “less sensitive land use” (“MKM”) by 25 mg/kg (EPA 2009). The mechanism of As mobilisation depends on the extractant used: ligand exchange with NaOH solution, ligand-enhanced dissolution of (hydr)oxides with OC solution and reductive dissolution of Fe (hydr)oxides with DCO solution. Overall As removal is not significantly improved by multiple extractions with the same extractant (Alam et al. 2001; Bhattacharya et al. 2002; Jang et al. 2007). However, sequential extractions with different extractants, targeting different As pools in the soil, may be more effective, hopefully allowing high As removal without impairing the soil. For example, Kuhlman and Greenfield (1999) suggested a two-step acid/base extraction procedure for removing As from contaminated soil. The first extraction could be performed with 0.1 M NaOH and the second with a pH 5 OC solution (in this order because NaOH is cheaper and mobilises a similar amount of As but much less Fe and Al than an OC solution of pH 3). Furthermore, the OC solution will dissolve any zinc arsenates and Cr,Fe(OH)3 that may be present in the soil, and after the extraction, the pH of the soil would be approximately neutral, with a low residual As content. Extraction in two steps instead of one means an increased cost for extraction, but the second extraction step could be regarded as a polishing step, hence a solution with lower oxalate and citrate concentrations could be used than in the present study, thereby reducing costs of the two-step extraction. Another advantage of using acid and alkaline extraction agents sequentially is that the extraction solutions could be quenched simply by mixing them together, yielding a solution of approximately neutral pH, which in turn would reduce the mobility of the dissolved arsenic (Jang et al. 2007). It may be advantageous to perform the extractions at 40°C, which would allow high As removal with short contact times.

Despite the relatively efficient removal of As when using dithionite at pH 7 and 40°C, use of this extractant is not recommended due to its relatively short lifetime and high residual As levels in the extracted soil (see Table 6). Furthermore, use of this extractant risks reduction of As(V) to As(III), a more harmful form of arsenic.

5 Conclusions

In NaOH extractions the temperature and (less strongly) NaOH concentration and temperature significantly influenced mobilisation of As and Cr, while the NaOH concentration, but not the temperature, influenced Zn mobilisation. At elevated temperature (40°C), NaOH removed 70% of the arsenic, but little of the Cr and Zn were mobilised using NaOH. In oxalate–citrate extractions, the pH and temperature strongly (and similarly) influenced As and Cr mobilisation, while the temperature-squared term had weaker but significant effects. In contrast, the pH was the only significant factor for Zn mobilisation with OC solutions. Extraction using the oxalate–citrate solution under acidic conditions at elevated temperature mobilised 76%, 12% and 26% of the As, Cr and Zn, respectively. It was only possible to study a narrow range of acidities for extractions with dithionite solution. Consequently, the extraction temperature was the only significant factor for the removal of As, Cr and Zn using this extractant; at neutral pH and elevated temperature, 63%, 18% and 57% of the As, Cr and Zn, respectively, were removed by dithionite extraction. For all three extractants, As was most efficiently mobilised when the extraction temperature was 40°C. None of the examined extractants reduced residual As contents of the soil to below the Swedish EPA’s guideline value. Based on these results, we recommend a two-step extraction protocol, involving initial NaOH extraction followed by extraction with oxalate–citrate (both at elevated temperature). This should efficiently remove As, Cr and Zn from the soil with short contact times, without causing soil deterioration. Using dithionite as an extractant is not recommended because of its short lifetime and the high residual As content of DCO-treated soil. Further investigations to determine the optimal concentration of oxalate–citrate for extractions are needed to minimise the quantity of extractant required and thus reduce extraction costs.

References

Alam M, Tokunaga S (2006) Chemical extraction of arsenic from contaminated soil. J Environ Sci Health A Tox Hazard Subst Environ Eng 41:631–7643

Alam MGM, Tokunaga S, Maekawa T (2001) Extraction of arsenic in a synthetic arsenic-contaminated soil using phosphate. Chemosphere 43:1035–1041

Andersson A, Nilsson Å, Håkansson L (1991) Metal concentration of the mor layer. Report 3990:85, Swedish Environmental Protection Agency

Arwidsson Z, Johansson E, von Kronhelm T, Allard B, van Hees P (2010) Remediation of metal contaminated soil by organic metabolites from fungi I—production of organic acids. Water Air Soil Pollut 205:215–226

Berggren Kleja D, Elert M, Gustafsson JP, Jarvis N, Norrström A-C (2006) Mobility of metals in soil. Report 5536, Swedish Environmental Protection Agency. Stockholm, Sweden

Bhattacharya P, Mukherjee AB, Jacks G, Nordqvist S (2002) Metal contamination at a wood preservation site: characterisation and experimental studies on remediation. Sci Total Environ 290:165–180

Cornell R, Schwertmann U (2003) The iron oxides: structure, properties, reactions, occurrences and uses. Wiley, Weinheim, pp 664

Dermont G, Bergeron M, Mercier G, Richer-Laflèche M (2008) Soil washing for metal removal: a review of physical/chemical technologies and field applications. J Hazard Mater 152:1–31

Devaney AM, Guess RG (1982) Sodium thiosulphate in hydrosulphite bleaching. Pulp Paper Can 83:TR60–64

El-Khosht Salama N (2001) Utilization of surfactants or organic acids with/without chelating agents for the removal of arsenic from contaminated soil. Doctoral Thesis, Oklahoma States University

Swedish Environmental Protection Agency (Swedish EPA) (2009) Generic guideline values for contaminated soils—model description and guidance. Report 5976, Swedish Environmental Protection Agency, Stockholm

Fendorf SE (1995) Surface reactions of chromium in soils and waters. Geoderma 67:55–71

Furrer G, Stumm W (1986) The coordination chemistry of weathering: I. Dissolution kinetics of δ-Al2O3 and BeO. Geochim Cosmochim Acta 50:1847–1860

Gerlach RW, Nocerino JM (2003) Guidance for obtaining representative laboratory analytical subsamples from particulate laboratory samples. EPA/600/R-03/027.134, United States Environmental Protection Agency

Girouard E, Zagury GJ (2009) Arsenic bioaccessibility in CCA-contaminated soils: influence of soil properties, arsenic fractionation, and particle-size fraction. Sci Total Environ 407:2576–2585

Gräfe M, Sparks DL (2005) Kinetics of zinc and arsenate co-sorption at the goethite–water interface. Geochim Cosmochim Acta 69:4573–4595

Grafe M, Eick MJ, Grossl PR, Saunders AM (2002) Adsorption of arsenate and arsenite on ferrihydrite in the presence and absence of dissolved organic carbon. J Environ Qual 31:1115–1123

Gräfe M, Tappero RV, Marcus MA, Sparks DL (2008) Arsenic speciation in multiple metal environments II. Micro-spectroscopic investigation of a CCA contaminated soil. J Colloid Interface Sci 321:1–20

Gustafsson JP (2007) Visual MINTEQ version 2.53. http://www.lwr.kth.se/English/OurSoftware/vminteq/. Accessed 20 Aug 2007

Hopp L, Nico PS, Marcus MA, Peiffer S (2008) Arsenic and chromium partitioning in a podzolic soil contaminated by chromated copper arsenate. Environ Sci Technol 42:6481–6486

Jang Y, Townsend T, Ward M, Bitton G (2002) Leaching of arsenic, chromium, and copper in a contaminated soil at a wood preserving site. Bull Environ Contam Toxicol 69:808–816

Jang M, Hwang JS, Choi SI, Park JK (2005) Remediation of arsenic-contaminated soils and washing effluents. Chemosphere 60:344–354

Jang M, Hwang JS, Choi SI (2007) Sequantial soil washing techniques using hydrochloric acid and sodium hydroxide for remediating arsenic-contaminated soils in abandoned iron-ore mines. Chemosphere 66:8–17

Ko I, Chang Y-Y, Lee C-H, Kim K-W (2005) Assessment of pilot-scale acid washing of soil contaminated with As, Zn and Ni using the BCR three-step sequential extraction. J Hazard Mater 127:1–13

Kuhlman M, Greenfield T (1999) Simplified soil washing processes for a variety of soils. J Hazard Mater 66:31–45

Kumpiene J, Ragnvaldsson D, Lövgren L, Tesfalidet S, Gustavsson B, Lättström A, Leffler P, Maurice C (2009) Impact of water saturation level on arsenic and metal mobility in the Fe-amended soil. Chemosphere 74:206–215

Lee M, Sung Paik I, Do W, Kim I, Lee Y, Lee S (2007) Soil washing of As-contaminated stream sediments in the vicinity of an abandoned mine in Korea. Environ Geochem Health 29:319–329

Legiec IA, Griffin LP, Walling PD Jr, Breske TC, Angelo MS, Isaacson RS, Lanza MB (1997) DuPont soil washing technology program and treatment of arsenic contaminated soils. Environ Prog 16:29–34

Lidelöw S, Ragnvaldsson D, Leffler P, Tesfalidet S, Maurice C (2007) Field trials to assess the use of iron-bearing industrial by-products for stabilisation of chromated copper arsenate-contaminated soil. Sci Total Environ 387:68–78

Livesey NT, Huang PM (1981) Adsorption of arsenate by soils and its relation to selected chemical properties and anions. Soil Sci 131:88–94

Manning BA, Goldberg S (1997) Arsenic(III) and arsenic(V) adsorption on three California soils. Soil Sci 162:886–895

Masscheleyn PH, Delaune RD, Patrick WH Jr (1991) Effect of redox potential and pH on arsenic speciation and solubility in a contaminated soil. Environ Sci Technol 25:1414–1419

McBride MB (1994) Environmental chemistry of soils. Oxford University Press, New York

Mohapatra D, Singh P, Zhang W, Pullammanappallil P (2005) The effect of citrate, oxalate, acetate, silicate and phosphate on stability of synthetic arsenic-loaded ferrihydrite and Al-hydrite. J Hazard Mater B124:95–100

Mulligan CN, Yong RN, Gibbs BF (2001) Remediation technologies for metal-contaminated soils and groundwater: an evaluation. Eng Geol 60:193–207

Nordberg D, Stenberg J (2005) Remediation of wood impregnation sites. Master’s thesis, Luleå University of Technology

Rastas Amofah L, Maurice C, Bhattacharya P (2008) Extraction of arsenic from soils contaminated with wood preservation chemicals. Soil Sediment Contam 19:142–159

Reichle RA, McCurdy KG, Hepler LG (1975) Zinc hydroxide: solubility product and hydroxy-complex stability constants from 12.5–75°C. Can J Chem 53:3841–3845

Rueda EH, Ballesteros MC, Grassi RL, Blesa MA (1992) Dithionite as a dissolving reagent for goethite in the presence of EDTA and citrate. Application to soil analysis. Clays Clay Miner 40:575–585

Sadiq M (1997) Arsenic chemistry in soils: an overview of thermodynamic predictions and field observations. Water Air Soil Pollut 93:117–136

Shi R, Jia Y, Wang C, Yao S (2008) Mechanism of arsenate mobilisation from goethite by aliphatic carboxylic acid. J Hazard Mater 163:1129–1133

Skogsjö E (2010) Status report of remediation in the country 2009. Swedish Environmental Protection Agency, Stockholm

Solo-Gabriele H, Khan B, Townsend T, Song J-K, Jambeck J, Dubey B, Yang Y-C, Cai Y (2003) Arsenic and chromium speciation of leachates from CCA-treated wood, Florida Center, Gainesville

Song J, Townsend T, Solo-Gabriele H, Jang Y-C (2006) Hexavalent chromium reduction in soils contaminated with chromated copper arsenate preservative. Soil Sediment Contam 15:387–399

Swedish Standards Institute (SIS) (1981) Determination of dry matter and ignition residue in water, sludge and sediment. SS 028113, SIS, Stockholm

Swedish Standards Institute (SIS) (1992) Geotechnical tests—particle size distribution—sedimentation, hydrometer methods. SS 027124, SIS, Stockholm

Thomas GW (1996) Soil pH and soil acidity. In: Sparks DL (eds) Methods of soil analysis. Part 3. Chemical methods. SSSA Book series No. 5. SSSA, Madison, pp 475–490

Tsang S, Phu F, Baum MM, Poskrebyshev GA (2007) Determination of phosphate/arsenate by a modified molybdenum blur method and reduction of arsenate by S2O 2−4 . Talanta 71:1560–1568

United States Environmental Protection Agency (1997) Engineering bulletin: technology alternatives for the remediation of soils contaminated with As, Cd, Cr, Hg, and Pb. EPA/540/S-97/500, U.S. Environmental Protection Agency, Office of Emergency and Remedial Response, and Research and Development. Cincinnati, U.S.

Van Benschoten JE, Reed BE, Matsumoto MR, McGarvey PJ (1994) Metal removal by soil washing for an iron oxide coated sandy soil. Water Environ Res 66:168–174

Xu H, Allard B, Grimvall A (1988) Influence of pH and organic substance on the adsorption of As(V) on geologic materials. Water Air Soil Pollut 40:293–305

Zhang Y, Kallay N, Matijevic E (1985) Interaction of metal hydrous oxides with chelating agents. 7. Hematite-oxalic acid and citric acid systems. Langmuir 1:201–206

Zinder B, Furrer G, Stumm W (1986) The coordination chemistry of weathering: II. Dissolution of Fe(III) oxides. Geochim Cosmochim Acta 50:1861–1869

Acknowledgements

The Swedish Research Council for Environment, Agricultural Sciences and Spatial Planning (ID 2006-25-6874-34), the European Union Structural Funds, the Northern Sweden Soil Remediation Centre, EDF Objective 2, Contract MCN IO No 43173 and The J Gust Richert Memorial Fund are acknowledged for the financial support of this study.

Author information

Authors and Affiliations

Corresponding author

Additional information

Responsible editor: Jean-Paul Schwitzguébel

Electronic supplementary material

Below is the link to the electronic supplementary material.

Fig. 1

VMINTEQ simulation result for extraction using 0.1 M NaOH solution at 40°C—saturation indices for minerals. Red text indicates oversaturation of mineral species, blue text undersaturation and green text equilibrium (JPEG 109 kb)

Fig. 2

VMINTEQ simulation result for extraction using dithionite–citrate–oxalate solution at pH 6.3 and 30°C—saturation indices for minerals. Red text indicates oversaturation of mineral species, blue text undersaturation and green text equilibrium (JPEG 109 kb)

Rights and permissions

About this article

Cite this article

Rastas Amofah, L., Maurice, C., Kumpiene, J. et al. The influence of temperature, pH/molarity and extractant on the removal of arsenic, chromium and zinc from contaminated soil. J Soils Sediments 11, 1334–1344 (2011). https://doi.org/10.1007/s11368-011-0411-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11368-011-0411-y