Abstract

This study deals with a novel model of forced vibrational analysis of nonlocal transversely isotropic thermoelastic nanobeam resonators due to ramp-type heating and due to time varying exponentially decaying load with multi-dual-phase-lag theory of thermoelasticity. The mathematical model is prepared for the nanobeam in a closed form with the application of Euler–Bernoulli (E–B) beam theory using nonlocal generalized thermoelasticity with multi-dual phase lags. The nonlocal nanobeam theory has a nonlocal parameter to depict small-scale effect. The Laplace Transform technique has been used to find the expressions for lateral deflection, conductive temperature, thermal moment, nonlocal axial stress and thermodynamic temperature for (i) clamped–clamped, (ii) simply supported–simply supported, (iii) clamped–simply supported, (iv) clamped–free, and (v) free–free nanobeam in the transformed domain. The general algorithm of the inverse Laplace Transform is developed to compute the results numerically in physical domain. The results exhibit that the amplitude of deflection and thermal moment is attenuated and depends upon the schematic design of the nanobeam being considered. Also, it can be found from both the numerical calculations and the analytic results that nonlocal multi-dual-phase-lag theory of thermoelasticity with two temperatures due to time varying exponentially decaying load has significant effect on deflection and thermal moment. The effect of different theories of nonlocal thermoelasticity, due to time varying exponentially decaying load, has been depicted on the various quantities. Some particular cases have also been deduced.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

In last decade, nanomaterials have gained interest in the field of engineering due to their special properties like electronic, electrical and mechanical. Due to these properties, nano-materials are used in nano-beams as elementary structural components in micro-electromechanical system (MEMS)/nano-electromechanical systems (NEMS) and piezoelectric devices.

Nonlocal theory of elasticity is adopted to deal with many applications in nano-mechanics. Eringen [1,2,3] introduced the theory of nonlocal continuum mechanics to deal with the small-scale structure problems. The theories of nonlocal continuum consider the state of stress at a point as a function of the states of strain of all points in the medium. But in classical continuum mechanics the state of stress at a certain point uniquely depends on the state of strain on that same point. Lu et al. [4] proposed a model on nonlocal plate depending upon nonlocal Kirchhoff and Mindlin plate theories using the Eringen’s theory of nonlocal continuum mechanics.

The thermoelastic damping in a micro-beam resonator by the modified couple stress theory was examined by Ghader et al. [5]. Guo et al. [6] presented the problem of thermoelastic damping in vented MEMS beam with Galerkin finite element and eigenvalue formulation method. Simsek and Reddy [7] and Shaat et al. [8] examined the bending and vibration of functionally graded micro-beams using the modified couple stress theory and higher order beam theory. Allam and Abouelregal [9] investigated the thermoelastic waves prompted by pulsed laser and varying heat of nano-beam. Abouelregal and Zenkour [10] discussed the axially moving micro-beam with combined effects of the pulse-width of thermally originated vibration, varying speed and the transverse excitation. Zenkour [11] discussed the nonlocal elasticity theory for analysing the vibration in a single-layered graphene sheet fixed in viscoelastic medium. Abouelregal and Zenkour [12] studied the linear nonlocal theory for isotropic and semi-infinite medium using an ultra-short pulsed laser heating. Abouelregal [13] presented a new model for thermo-elastic vibrations using fractional derivatives in a nonlocal nanobeams.

Despite these several researchers as Marin [14, 15], Yu et al. [16], Park and Gao [17], Sun et al. [18] Li and Cheng [19], Sharma [20], Chakraborty [21], Lazar and Agiasofitou [22], Abd-Elaziz et al. [23, 24], Zhang and Fu [25], Abbas and Marin [26], Sharma and Kaur [27], Zenkour and Abouelregal [28], Fantuzzi et al. [29], Abouelregal and Zenkour [30], Aksoy [31], Kumar and Devi [32], Riaz et al. [33], Karami et al. [34, 35], Zhang et al. [36], Bhatti et al. [37, 38], Sharma and Marin [39], Sharma and Grover [40], Marin and Craciun [41, 42], AbbasR [43],Lata and Kaur [44,45,46,47,48,49], Bhatti and Michaelides [50] worked on different theory of thermoelasticity.

The present investigation deals with the problem of forced vibrations in a transversely Isotropic thermoelastic thin nanobeam in the context of nonlocal thermoelasticity theory with multi-dual-phase-lag heat transfer due to ramp-type heating and due to time varying exponentially decaying load. The Laplace Transform technique has been used to find the expressions for lateral deflection, conductive temperature, thermal moment, nonlocal axial stress and thermodynamic temperature for (i) clamped–clamped (CC), (ii) simply supported–simply supported (SS), (iii) clamped–simply supported (CS), (iv) clamped–free (CF), and (v) free–free (FF) nanobeam in the transformed domain.

2 Basic equations

Following Eringen [1], Chakraborty [21] the constitutive relation for an anisotropic thermoelastic medium is:

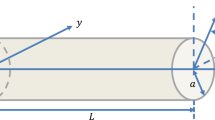

where \(\xi =\left( e_{0}a \right) ^{2}\), a is internal characteristic length and \(e_{0}\) is a constant appropriate to each material, the characteristic length for macro-scale problems is relatively small, i.e. \(\xi =0\), so Eq. (1) changes to classical stress–strain relations. Following Zenkour [51] heat conduction equation with multi-dual-phase-lag heat transfer is:

Here the superimposed dot indicates derivative w.r.t. time variable t and a comma denotes derivative w.r.t. space variable x. The two differential parameters \({L}_{{\theta }}\) and \({L}_{\mathrm {q}}\) are of the form

and

(\(0\le {\tau \theta }<\tau _q\)), and \(\varrho \) is a non-dimension parameter (= 0 or 1 as per the thermoelasticity theory).

where

i is not summed [47].

\(c_{ijkl}\)are elastic parameters and having symmetry due to homogeneous transversely isotropic medium. The basis of these symmetries of \(c_{ijkl}\) is due to the following facts

-

i.

The stress tensor is symmetric, which is only possible if \((c_{ijkl}= c_{jikl})\)

-

ii.

If a strain energy density exists for the material, the elastic stiffness tensor must satisfy \(c_{ijkl}= c_{klij}\)

-

iii.

From stress tensor and elastic stiffness tensor symmetries infer \((c_{ijkl}= c_{ijlk})\) and \(c_{ijkl}= c_{klij}= c_{jikl}= c_{ijlk}\)

3 Formulation of the problem

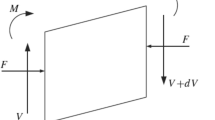

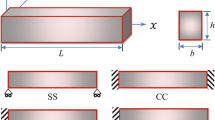

We study a homogeneous TIT rectangular nano-beam (Fig. 1) of length \((0\le x \le L)\), width \(\left( -\frac{b}{2}\le y\le \frac{b}{2} \right) \) and thickness \(\left( -\frac{h}{2}\le z\le \frac{h}{2} \right) ,\) where x, y and z are the Cartesian axes denotes the length, width and thickness of the nano-beam. The x-axis coincides with the nano-beam axis and y, z axis coincide with the end (\(x=0\)) with the origin located at the axis of the beam. In equilibrium, the nano-beam is kept at uniform temperature \(\hbox {T}_{{0,}}\) unstrained and unstressed. Moreover, initially there is no flow of heat along the upper and lower surface of the nanobeam so that

and its axial ends are presumed to be at isothermal conditions.

According to the fundamental E-B theory for small deflection of a simple bending problem, the displacement components are given by Rao (2007)

where \(w\left( x,t \right) \) is the lateral deflection of the nanobeam and t is the time. Also the temperature distribution function T and conductive temperature \(\varphi \) can be expressed as

From Eqs. (3) and (8), we have

According to Eringen’s nonlocal theory of elasticity the one-dimensional constitutive equation obtained from Eq. (1) with the help of Eq. (7) becomes

where \(t_{11}\) is the nonlocal stress, \({\beta }_{1}= {(c}_{11}+c_{13})\alpha _{1}+C_{13}\alpha _{3}\) is the thermoelastic coupling parameter and \(\alpha _{1},\alpha _{3}\) are the coefficient of linear thermal expansion along and perpendicular to plane of isotropy. The thermoelastic parameter \(\beta _{3}= \mathrm {2}c_{13}\alpha _{1}+c_{33}\alpha _{3}\) along z-axis does not appear due to E-B hypothesis.

The flexural moment of the cross section of the nanobeam following Rao [52] is given by

Multiply Eq. (10) by z and integrate w.r.t z and by using Eq. (11) we obtain

where

\({M}_\mathrm{T}\) is the thermal moment of inertia of the nano-beam and \(\beta _{1}M_\mathrm{T}\) is the thermal moment of the nano-beam. In addition, \(I=\frac{bh^{3}}{\mathrm {12}}\) is the moment of inertia of cross section and \(c_{11}I \) is the flexural rigidity of the nano-beam.

The equation of transverse motion of the nano-beam is given by Rao [52]

where \(A=bh\) is the area of cross section and q(x, t) represents the load acting on the nano-beam along the thickness direction. Using Eq. (12) in Eq. (14), we get

According to Lifshitz and Roukes [53] no thermal gradient exists in the y-direction. Therefore, Eq. (1) under such situation using Eq. (7) becomes

To facilitate the solution, the following dimensionless quantities are introduced:

Now applying the dimensionless quantities from (17) in Eqs. (12) and (13), after, suppressing the prime, we get

where

The nonlocal axial stress defined in Eq. (10) after using Eq. (9) and the dimensionless quantities defined by Eq. (17) and suppressing primes become

For a very thin nano-beam, assuming that the increase in temperature varies along the thickness of the nano-beam as function of \(\sin \frac{\pi z}{h}\) (i.e. varies sinusoidally) given by

The temperature in Eq. (9) after using dimensionless quantities and suppressing primes and using (21) becomes

Using Eq. (21) in Eq. (20) gives nonlocal axial stress as

Using Eq. (9) in Eq. (13) and then using Eq. (21)

where \(\delta _{3}=\frac{2h^{2}}{\pi ^{2}}\left\{ \left( 1+a_{3}\frac{\pi ^{2}}{h^{2}} \right) \right\} ,\delta _{4}=-\frac{2h^{2}a_{1}}{\pi ^{2}}.\)

Now using the value of \({ M}_\mathrm{T}\) from Eq. (24) in (18) we get

Using Eq. (21) in Eq. (19) and multiplying by z and integrating both sides w.r.t z for \(\frac{-h}{2}\le z\le \frac{h}{2},\) gives

Let us take the Laplace transform defined by

By applying Laplace Transform defined by Eq. (27) in Eqs. (21) and (22), we get

Which implies

By applying Eq. (27) in Eq. (24)–(26), we get

where

Now consider a dimensionless time varying exponentially decaying load of the form

where \(q_{0}\) is the dimensionless magnitude of the point load and \({\Omega }\) represents the dimensionless frequency of the applied load. For uniformly distributed load we take \(\delta =0\). Taking Laplace transform of Eq. (34), we have

Therefore Eq. (31) using Eq. (34) becomes

Eliminating \(\bar{\Theta }\) from Eqs. (33) and (36), we get

where

For simplification of solution let us take \(q_{0}=0\), i.e. load on nano-beam is assumed to be zero.

The differential equation governing the lateral deflection \({\bar{w}}\left( x,s \right) ,\) Eq. (37) can take the form

where \(\pm \lambda _{1}, \pm \lambda _{2}\) and \(\pm \lambda _{3}\) are the characteristics roots of the equation \(\lambda ^{6}-p\lambda ^{4}+q\lambda ^{2}-r=0\) and hence,

Let the lateral deflection \({\bar{w}}\left( x,s \right) \) is given by

where \(A_{i}=A_{i}(s)\) and \(A_{i+3}=A_{i+3}(s), \mathrm {i}=1,2,3\).

Now using Eq. (32) in Eq. (35) gives

where \(\zeta _{1}=\frac{\delta _{7}^{2}}{\beta _{1}\delta _{8}^{2}\delta _{4}-\delta _{3}\delta _{7}\delta _{8}\beta _{1}},\zeta _{2}=\frac{-\left( \delta _{7}^{2}\delta _{5}+\delta _{4}\delta _{6}\delta _{7}\beta _{1} \right) }{\beta _{1}\delta _{8}^{2}\delta _{4}-\delta _{3}\delta _{7}\delta _{8}\beta _{1}},\zeta _{3}=\frac{\delta _{3}\delta _{6}\delta _{7}\beta _{1}-\delta _{4}\delta _{6}\delta _{8}\beta _{1}-s^{2}\xi \delta _{7}^{2}}{\beta _{1}\delta _{8}^{2}\delta _{4}-\delta _{3}\delta _{7}\delta _{8}\beta _{1}}{,\zeta }_{4}=\frac{-s^{2}\delta _{7}^{2}}{\beta _{1}\delta _{8}^{2}\delta _{4}-\delta _{3}\delta _{7}\delta _{8}\beta _{1}}\)

The general solution for Eq. (39) using Eq. (38) is given by

where \(B_{i}=\left( \zeta _{2}\lambda _{i}^{4}+\zeta _{3}\lambda _{i}^{2}{+\zeta }_{4} \right) , i=1,2,3.\)

Using Eq. (41) in Eq. (28) the expression for conductive temperature is given by

By putting the value of \(\bar{\Theta }\left( x,s \right) \) from Eq. (41) in Eq. (31), we get thermal moment of inertia of the nano-beam which is \(\bar{M}_\mathrm{T}\left( x,s \right) \) as

where

The expression for thermal moment of nano-beam is \(\beta _{1}\bar{M}_\mathrm{T}\left( x,s \right) \) as

using (23) and (27) the nonlocal axial stress \(\bar{t}_{11}\left( x,z,s \right) \) can be written as

Using Eqs. (39) and (41) in Eq. (42) gives

where \(D_{i}=\left\{ \frac{1}{a_{R}^{2}\xi }z\lambda _{i}^{2}+ \frac{\beta _{1}}{\xi }\sin \frac{\pi z}{h}B_{i}\left[ \left( 1+a_{3}\frac{\pi ^{2}}{h^{2}} \right) -a_{1}\lambda _{i}^{2} \right] \right\} ,\xi =\left( e_{0}a \right) ^{2}, i=1,2,3\).

Solving Eq. (44) gives nonlocal axial stress as

where \(E_{1},E_{2}\) are constants.

The expression for thermodynamic temperature from Eq. (30) and (41) is given by

where \(F_{i}=B_{i}\left[ \left( 1+a_{3}\frac{\pi ^{2}}{h^{2}} \right) -a_{1}\lambda _{i}^{2} \right] \) and \(B_{i}=\left( \zeta _{2}\lambda _{i}^{4}+\zeta _{3}\lambda _{i}^{2}{+\zeta }_{4} \right) , i=1,2,3\).

4 Initial conditions

The homogeneous nanobeam is initially at rest, is undeformed state and is at uniform temperature \(T_{0}\). Thus the dimensionless initial conditions will be

Using the Laplace transform defined by Eq. (27) in the boundary conditions (45) yields

5 Mechanical boundary conditions

Consider the ends of the nanobeam are subjected to (i) clamped–clamped (CC), (ii) simply supported–simply supported (SS), (iii) clamped–simply supported (CS), (iv) clamped–free (CF), and (v) free–free (FF) conditions. Thus at its dimensionless ends \(x=0\) and \(x=1\), the boundary conditions are:

- Case I:

-

Clamped–clamped (CC) or pinned or hinged nanobeam

At the fixed ends the lateral deflection and the slope of lateral deflection are zero.

$$\begin{aligned} \left. w\left( x,t \right) \right| _{x=0,1}=\left. \frac{\partial w\left( x,t \right) }{\partial x} \right| _{x=0,1}=0, \end{aligned}$$(51)Using the Laplace transform defined by Eq. (27) in the boundary conditions (51) yields

$$\begin{aligned} \left. {\bar{w}}\left( x,s \right) \right| _{x=0,1}=\left. \frac{\partial {\bar{w}}\left( x,s \right) }{\partial x} \right| _{x=0,1}=0, \end{aligned}$$(52) - Case II:

-

Simply supported–simply supported (SS) nanobeam. Here the transverse lateral deflection and bending moment are zero at the ends.

$$\begin{aligned} \left. w\left( x,t \right) \right| _{x=0,1}=\left. \frac{\partial ^{2}w\left( x,t \right) }{\partial x^{2}} \right| _{x=0,1}=0, \end{aligned}$$(53)Using the Laplace transform defined by Eq. (27) in the boundary conditions (53) yields

$$\begin{aligned} \left. {\bar{w}}\left( x,s \right) \right| _{x=0,1}=\left. \frac{\partial ^{2}{\bar{w}}\left( x,s \right) }{\partial x^{2}} \right| _{x=0,1}=0, \end{aligned}$$(54) - Case III:

-

Clamped–simply supported (CS) nanobeam.

At the fixed ends the transverse lateral deflection and the slope of lateral deflection are zero and at simply supported end the transverse displacement and bending moment are zero. If the beam is clamped at \(x=0\) and simply supported at \(x=1\), then boundary conditions can be written as

$$\begin{aligned} \left. w\left( x,t \right) \right| _{x=0,1}=\left. \frac{\partial w\left( x,t \right) }{\partial x} \right| _{x=0}=\left. \frac{\partial ^{2}w\left( x,t \right) }{\partial x^{2}} \right| _{x=1}, \end{aligned}$$(55)Using the Laplace transform defined by Eq. (27) in the boundary conditions (55) yields

$$\begin{aligned} \left. {\bar{w}}\left( x,s \right) \right| _{x=0,1}=\left. \frac{\partial w\left( x,s \right) }{\partial x} \right| _{x=0}=\left. \frac{\partial ^{2}{\bar{w}}\left( x,s \right) }{\partial x^{2}} \right| _{x=1}, \end{aligned}$$(56) - Case IV:

-

Clamped–free (CF)/cantilever nanobeam. The bending moment and shear force are zero at the free end and at the fixed ends the transverse lateral deflection and the slope of displacement are zero. If the nanobeam is fixed at \(x=0\) and free at \(x=1\), then the boundary conditions are:

$$\begin{aligned} \left. w\left( x,t \right) \right| _{x=0}=\left. \frac{\partial w\left( x,t \right) }{\partial x} \right| _{x=0}=\left. \frac{\partial ^{2}w\left( x,t \right) }{\partial x^{2}} \right| _{x=1}=\left. \frac{\partial ^{3}w\left( x,t \right) }{\partial x^{3}} \right| _{x=1}, \end{aligned}$$(57)Using the Laplace transform defined by Eq. (27) in the boundary conditions (57) yields

$$\begin{aligned} \left. {\bar{w}}\left( x,s \right) \right| _{x=0}=\left. \frac{\partial {\bar{w}}\left( x,s \right) }{\partial x} \right| _{x=0}=\left. \frac{\partial ^{2}{\bar{w}}\left( x,s \right) }{\partial x^{2}} \right| _{x=1}=\left. \frac{\partial ^{3}{\bar{w}}\left( x,s \right) }{\partial x^{3}} \right| _{x=1}, \end{aligned}$$(58) - Case V:

-

Free–free (FF) nanobeam The bending moment and shear force are zero at the ends in this case.

$$\begin{aligned} \left. \frac{\partial ^{2}w\left( x,t \right) }{\partial x^{2}} \right| _{x=0,1}=\left. \frac{\partial ^{3}w\left( x,t \right) }{\partial x^{3}} \right| _{x=0,1}=0, \end{aligned}$$(59)Using the Laplace transform defined by Eq. (27) in the boundary conditions (59) yields

$$\begin{aligned} \left. \frac{\partial ^{2}{\bar{w}}\left( x,s \right) }{\partial x^{2}} \right| _{x=0,1}=\left. \frac{\partial ^{3}{\bar{w}}\left( x,s \right) }{\partial x^{3}} \right| _{x=0,1}=0, \end{aligned}$$(60)

6 Applications: thermal boundary conditions

Consider the nanobeam is thermally loaded on the boundary \(x=0\). Therefore by Eq. (21) we have

where \(\theta _{0}\) is a constant and \(f\left( x,t \right) \) is a ramp-type function given by

where \(t_{0}\) is ramp-type parameter. The temperature at the boundary \(x=1\) is given by

Using the Laplace transform defined by Eq. (27) in the thermal boundary conditions defined by (61)–(63) yields

By applying the mechanical boundary conditions and thermal boundary conditions, we have

- Case I:

-

Substituting the values of \({\bar{w}}\) and \(\bar{\Theta }\) from Eqs. (39) and (41) in the mechanical and thermal boundary conditions (52), (64) and (65), we obtain the value of \(A_{i}\) as

$$\begin{aligned} A_{i}=\frac{{\Delta }_{i}}{{\Delta }} , i=1,2,3,4,5,6. \end{aligned}$$(66)and

$$\begin{aligned} {\Delta =}\left| {\begin{array}{*{20}c} {\begin{array}{*{20}c} {1} &{} {1} &{} {1}\\ \mathrm {e}^{{{-\lambda }}_{{1}}} &{} \mathrm {e}^{{{-\lambda }}_{{2}}} &{} \mathrm {e}^{{{-\lambda }}_{{3}}}\\ -{\lambda }_{{1}} &{} -{\lambda }_{{2}} &{} -{\lambda }_{{3}}\\ \end{array}} &{} {\begin{array}{*{20}c} {1} &{} {1} &{} {1}\\ \mathrm {e}^{{\lambda }_{{1}}} &{} \mathrm {e}^{{\lambda }_{{2}}} &{} \mathrm {e}^{{\lambda }_{{3}}}\\ {\lambda }_{{1}} &{} {\lambda }_{{2}} &{} {\lambda }_{{3}}\\ \end{array}}\\ {\begin{array}{*{20}c} -{\lambda }_{{1}}\mathrm {e}^{{{-\lambda }}_{{1}}} &{} -{\lambda }_{{2}}\mathrm {e}^{{{-\lambda }}_{{2}}} &{} -{\lambda }_{{3}}\mathrm {e}^{-{\lambda }_{{3}}}\\ B_{1} &{} B_{2} &{} B_{3}\\ B_{1}\mathrm {e}^{-{\lambda }_{{1}}} &{} B_{2}\mathrm {e}^{{{-\lambda }}_{{2}}} &{} B_{3}\mathrm {e}^{{{-\lambda }}_{{3}}}\\ \end{array}} &{} {\begin{array}{*{20}c} {\lambda }_{{1}}\mathrm {e}^{{\lambda }_{{1}}} &{} {\lambda }_{2}\mathrm {e}^{{\lambda }_{{2}}} &{} {\lambda }_{3}\mathrm {e}^{{\lambda }_{{3}}}\\ B_{1} &{} B_{2} &{} B_{3}\\ B_{1}\mathrm {e}^{{\lambda }_{{1}}} &{} B_{2}\mathrm {e}^{{\lambda }_{{2}}} &{} B_{3}\mathrm {e}^{{\lambda }_{{3}}}\\ \end{array}}\\ \end{array}} \right| \end{aligned}$$\({\Delta }_{i}(i=1,2,3,\ldots ,6)\) are obtained by replacing the columns by \(\left[ {\begin{array}{*{20}c} {\begin{array}{*{20}c} {0,} &{} {0,} &{} {0,}\\ \end{array} } &{} {\begin{array}{*{20}c} {0,} &{} \bar{G}\left( s \right) -\zeta _{1}Q{,} &{} 0\\ \end{array}}\\ \end{array}} \right] \) in \({\Delta }\).

- Case II:

-

Substituting the values of \({\bar{w}}\) and \(\bar{\Theta }\) from Eqs. (39) and (41) in the mechanical and thermal boundary conditions (54), (64) and (65), we obtain the value of \(A_{i}\) as

$$\begin{aligned} A_{i}=\frac{{\Delta }_{i}}{{\Delta }} , i=1,2,3,4,5,6. \end{aligned}$$(67)and

$$\begin{aligned} {\Delta } =\left| {\begin{array}{*{20}c} {\begin{array}{*{20}c} {1} &{} {1} &{} {1}\\ \mathrm {e}^{{{-\lambda }}_{{1}}} &{} \mathrm {e}^{{{-\lambda }}_{{2}}} &{} \mathrm {e}^{{{-\lambda }}_{{3}}}\\ {\lambda }_{{1}}^{{2}} &{} {\lambda }_{{2}}^{{2}} &{} {\lambda }_{{3}}^{{2}}\\ \end{array} } &{} {\begin{array}{*{20}c} {1} &{} {1} &{} {1}\\ \mathrm {e}^{{\lambda }_{{1}}} &{} {e}^{{\lambda }_{{2}}} &{} \mathrm {e}^{{\lambda }_{{3}}}\\ {\lambda }_{{1}}^{{2}} &{} {\lambda }_{{2}}^{{2}} &{} {\lambda }_{{3}}^{{2}}\\ \end{array}}\\ {\begin{array}{*{20}c} {\lambda }_{{1}}^{{2}}\mathrm {e}^{{{-\lambda }}_{{1}}} &{} {\lambda }_{{2}}^{{2}}\mathrm {e}^{{{-\lambda }}_{{2}}} &{} {\lambda }_{{3}}^{{2}}\mathrm {e}^{-{\lambda }_{{3}}}\\ B_{1} &{} B_{2} &{} B_{3}\\ B_{1}\mathrm {e}^{-{\lambda }_{{1}}} &{} B_{2}\mathrm {e}^{{{-\lambda }}_{{2}}} &{} B_{3}\mathrm {e}^{{{-\lambda }}_{{3}}}\\ \end{array}} &{} {\begin{array}{*{20}c} {\lambda }_{{1}}^{{2}}\mathrm {e}^{{\lambda }_{{1}}} &{} {\lambda }_{{2}}^{{2}}\mathrm {e}^{{\lambda }_{{2}}} &{} {\lambda }_{{3}}^{{2}}\mathrm {e}^{{\lambda }_{{3}}}\\ B_{1} &{} B_{2} &{} B_{3}\\ B_{1}\mathrm {e}^{{\lambda }_{{1}}} &{} B_{2}\mathrm {e}^{{\lambda }_{{2}}} &{} B_{3}\mathrm {e}^{{\lambda }_{{3}}}\\ \end{array}}\\ \end{array}} \right| \end{aligned}$$\({\Delta }_{i}(i=1,2,3,\ldots ,6)\) are obtained by replacing the columns by \(\left[ {\begin{array}{*{20}c} {\begin{array}{*{20}c} {0,} &{} {0,} &{} {0,}\\ \end{array} } &{} {\begin{array}{*{20}c} {0,} &{} \bar{G}\left( s \right) -\zeta _{1}Q{,} &{} 0\\ \end{array}}\\ \end{array}} \right] \) in \({\Delta }\).

- Case III:

-

Substituting the values of \({\bar{w}}\) and \(\bar{\Theta }\) from Eqs. (39) and (41) in the mechanical and thermal boundary conditions (56), (64) and (65), we obtain the value of \(A_{i}\) as

$$\begin{aligned} A_{i}=\frac{{\Delta }_{i}}{{\Delta }} , i=1,2,3,4,5,6. \end{aligned}$$(68)and

$$\begin{aligned} {\Delta =}\left| {\begin{array}{*{20}c} {\begin{array}{*{20}c} {1} &{} {1} &{} {1}\\ \mathrm {e}^{{{-\lambda }}_{{1}}} &{} \mathrm {e}^{{{-\lambda }}_{{2}}} &{} \mathrm {e}^{{{-\lambda }}_{{3}}}\\ -{\lambda }_{{1}} &{} -{\lambda }_{{2}} &{} -{\lambda }_{{3}}\\ \end{array}} &{} {\begin{array}{*{20}c} {1} &{} {1} &{} {1}\\ \mathrm {e}^{{\lambda }_{{1}}} &{} \mathrm {e}^{{\lambda }_{{2}}} &{} \mathrm {e}^{{\lambda }_{{3}}}\\ {\lambda }_{{1}} &{} {\lambda }_{{2}} &{} {\lambda }_{{3}}\\ \end{array}}\\ {\begin{array}{*{20}c} \mathrm {\lambda }_{{1}}^{{2}}\mathrm {e}^{{{-\lambda }}_{{1}}} &{} {\lambda }_{{2}}^{{2}}\mathrm {e}^{{{-\lambda }}_{{2}}} &{} {\lambda }_{{3}}^{{2}}\mathrm {e}^{-{\lambda }_{{3}}}\\ B_{1} &{} B_{2} &{} B_{3}\\ B_{1}\mathrm {e}^{-{\lambda }_{{1}}} &{} B_{2}\mathrm {e}^{{{-\lambda }}_{{2}}} &{} B_{3}\mathrm {e}^{{{-\lambda }}_{{3}}}\\ \end{array} } &{} {\begin{array}{*{20}c} {\lambda }_{{1}}^{{2}}\mathrm {e}^{{\lambda }_{{1}}} &{} {\lambda }_{{2}}^{{2}}\mathrm {e}^{{\lambda }_{{2}}} &{} {\lambda }_{{3}}^{{2}}\mathrm {e}^{{\lambda }_{{3}}}\\ B_{1} &{} B_{2} &{} B_{3}\\ B_{1}\mathrm {e}^{{\lambda }_{{1}}} &{} B_{2}\mathrm {e}^{{\lambda }_{{2}}} &{} B_{3}\mathrm {e}^{{\lambda }_{{3}}}\\ \end{array}}\\ \end{array}} \right| \end{aligned}$$\({\Delta }_{i}(i=1,2,3,\ldots ,6)\) are obtained by replacing the columns by \(\left[ {\begin{array}{*{20}c} {\begin{array}{*{20}c} {0,} &{} {0,} &{} {0,}\\ \end{array} } &{} {\begin{array}{*{20}c} {0,} &{} \bar{G}\left( s \right) -\zeta _{1}Q{,} &{} 0\\ \end{array}}\\ \end{array}}\right] \) in \({\Delta }\).

- Case IV:

-

Substituting the values of \({\bar{w}}\) and \(\bar{\Theta }\) from Eqs. (39) and (41) in the mechanical and thermal boundary conditions (58), (64) and (65), we obtain the value of \(A_{i}\) as

$$\begin{aligned} A_{i}=\frac{{\Delta }_{i}}{{\Delta }} ,i=1,2,3,4,5,6. \end{aligned}$$(69)and

$$\begin{aligned} {\Delta =}\left| {\begin{array}{*{20}c} {\begin{array}{*{20}c} {1} &{} {1} &{} {1}\\ {\lambda }_{{1}}^{{2}}\mathrm {e}^{{{-\lambda }}_{{1}}} &{} {\lambda }_{{2}}^{{2}}\mathrm {e}^{{{-\lambda }}_{{2}}} &{} {{\lambda }_{{3}}^{{2}}\mathrm {e}}^{{{-\lambda }}_{{3}}}\\ -{\lambda }_{{1}} &{} -{\lambda }_{{2}} &{} -{\lambda }_{{3}}\\ \end{array} } &{} {\lambda }_{{1}}^{{2}}{\begin{array}{*{20}c} {1} &{} {1} &{} {1}\\ \mathrm {e}^{{\lambda }_{{1}}} &{} {\lambda }_{{2}}^{{2}}\mathrm {e}^{{\lambda }_{{2}}} &{} {{\lambda }_{{3}}^{{2}}\mathrm {e}}^{{\lambda }_{{3}}}\\ {\lambda }_{{1}} &{} {\lambda }_{{2}} &{} {\lambda }_{3}\\ \end{array}}\\ {\begin{array}{*{20}c} {{-\lambda }}_{{1}}^{{3}}\mathrm {e}^{{{-\lambda }}_{{1}}} &{} -{\lambda }_{{2}}^{{3}}\mathrm {e}^{{{-\lambda }}_{{2}}} &{} {{-\lambda }}_{{3}}^{3}\mathrm {e}^{-{\lambda }_{{3}}}\\ B_{1} &{} B_{2} &{} B_{3}\\ B_{1}\mathrm {e}^{-{\lambda }_{{1}}} &{} B_{2}\mathrm {e}^{{{-\lambda }}_{{2}}} &{} B_{3}\mathrm {e}^{{{-\lambda }}_{{3}}}\\ \end{array} } &{} {\begin{array}{*{20}c} {\lambda }_{{1}}^{3}\mathrm {e}^{{\lambda }_{{1}}} &{} {\lambda }_{{2}}^{{3}}\mathrm {e}^{{\lambda }_{{2}}} &{} {\lambda }_{{3}}^{{3}}\mathrm {e}^{{\lambda }_{{3}}}\\ B_{1} &{} B_{2} &{} B_{3}\\ B_{1}\mathrm {e}^{{\lambda }_{{1}}} &{} B_{2}\mathrm {e}^{{\lambda }_{{2}}} &{} B_{3}\mathrm {e}^{{\lambda }_{{3}}}\\ \end{array}}\\ \end{array} } \right| \end{aligned}$$\({\Delta }_{i}(i=1,2,3,\ldots ,6)\) are obtained by replacing the columns by \(\left[ {\begin{array}{*{20}c} {\begin{array}{*{20}c} {0,} &{} {0,} &{} {0,}\\ \end{array} } &{} {\begin{array}{*{20}c} {0,} &{} \bar{G}\left( s \right) -\zeta _{1}Q{,} &{} 0\\ \end{array}}\\ \end{array}} \right] \) in \({\Delta }\).

- Case V:

-

Substituting the values of \({\bar{w}}\) and \(\bar{\Theta }\) from Eqs. (39) and (41) in the mechanical and thermal boundary conditions (60), (64) and (65), we obtain the value of \(A_{i}\) as

$$\begin{aligned} A_{i}=\frac{{\Delta }_{i}}{{\Delta }} , i=1,2,3,4,5,6. \end{aligned}$$(70)and

$$\begin{aligned} {\Delta =}\left| {\begin{array}{*{20}c} {\begin{array}{*{20}c} {\lambda }_{{1}}^{{2}} &{} {\lambda }_{{2}}^{{2}} &{} {\lambda }_{{3}}^{{2}}\\ {{\lambda }_{{1}}^{{2}}\mathrm {e}}^{{{-\lambda }}_{{1}}} &{} {{\lambda }_{{2}}^{{2}}\mathrm {e}}^{{{-\lambda }}_{{2}}} &{} {{\lambda }_{{3}}^{{2}}\mathrm {e}}^{{{-\lambda }}_{{3}}}\\ -{\lambda }_{{1}}^{{3}} &{} -{\lambda }_{{2}}^{{3}} &{} {{-\lambda }}_{{3}}^{{3}}\\ \end{array} } &{} {\begin{array}{*{20}c} {\lambda }_{1}^{{2}} &{} {\lambda }_{2}^{{2}} &{} {\lambda }_{{3}}^{{2}}\\ {{\lambda }_{{1}}^{{2}}\mathrm {e}}^{{\lambda }_{{1}}} &{} {\lambda }_{{2}}^{{2}}\mathrm {e}^{{\lambda }_{{2}}} &{} {{\lambda }_{{3}}^{{2}}\mathrm {e}}^{{\lambda }_{{3}}}\\ {\lambda }_{{1}}^{{3}} &{} {\lambda }_{{2}}^{{3}} &{} {\lambda }_{{3}}^{{3}}\\ \end{array}}\\ {\begin{array}{*{20}c} {{-\lambda }}_{{1}}^{{3}}\mathrm {e}^{{{-\lambda }}_{{1}}} &{} {{-\lambda }}_{{2}}^{{3}}\mathrm {e}^{{{-\lambda }}_{{2}}} &{} {{-\lambda }}_{{3}}^{3}\mathrm {e}^{-{\lambda }_{\mathrm {3}}}\\ B_{1} &{} B_{2} &{} B_{3}\\ B_{1}\mathrm {e}^{-{\lambda }_{{1}}} &{} B_{2}\mathrm {e}^{{{-\lambda }}_{{2}}} &{} B_{3}\mathrm {e}^{{{-\lambda }}_{{3}}}\\ \end{array} } &{} {\begin{array}{*{20}c} {\lambda }_{{1}}^{3}\mathrm {e}^{{\lambda }_{{1}}} &{} {\lambda }_{{2}}^{3}\mathrm {e}^{{\lambda }_{{2}}} &{} {\lambda }_{{3}}^{{3}}\mathrm {e}^{{\lambda }_{{3}}}\\ B_{1} &{} B_{2} &{} B_{3}\\ B_{1}\mathrm {e}^{{\lambda }_{{1}}} &{} B_{2}\mathrm {e}^{{\lambda }_{{2}}} &{} B_{3}\mathrm {e}^{{\lambda }_{{3}}}\\ \end{array}}\\ \end{array}} \right| \end{aligned}$$\({\Delta }_{i}(i=1,2,3,\ldots ,6)\) are obtained by replacing the columns by \(\left[ {\begin{array}{*{20}c} {\begin{array}{*{20}c} {0,} &{} {0,} &{} {0,}\\ \end{array} } &{} {\begin{array}{*{20}c} {0,} &{} \bar{G}\left( s \right) -\zeta _{1}Q{,} &{} 0\\ \end{array}}\\ \end{array}}\right] \) in \({\Delta }\).

7 Inversion of Laplace transform

To find the solution of the problem in physical domain, we must invert the transforms in equations (40), (42), (43), (46)–(48), (66)–(70). These equations are functions of x, the parameter of Laplace transform s and hence, are of the form \({\bar{f}}\left( x,s \right) \). To get the function \(f\left( x,t \right) \) in the physical domain, first we invert the Laplace transform using

The integral in Eq. (71) is evaluated using the method described in Press et al. [54].

8 Particular cases

-

i.

If we take \(q_{0}=0\), in equations (39), (42), (44), (47) and (48) we obtain expressions for lateral deflection, conductive temperature, thermal moment, nonlocal axial stress and thermodynamic temperature of a transversely isotropic thermoelastic nanobeam for nonlocal thermoelasticity with free vibrations and two temperatures for all the five mechanical boundary conditions.

-

ii.

If we take \(q_{0}=0{, }c_{11}=c_{33}=\lambda +2\mu , c_{12}=c_{13}=\lambda ,c_{44}=\mu ,a_{1}=a_{3}=a,\beta _{{1}}=\beta _{{3}}=\beta {,} \alpha _{1}=\alpha _{3}=\alpha ^{'}, K_{1}=K_{3}=K,K_{1}^{*}=K_{3}^{*}=K^{*}\), in equations (39), (42), (44), (47) and (48), we obtain expressions for lateral deflection, conductive temperature, thermal moment, nonlocal axial stress and thermodynamic temperature of an isotropic thermoelastic nanobeam for nonlocal thermoelasticity with free vibrations and two temperatures for all the five mechanical boundary conditions.

-

iii.

If we take \(c_{11}=c_{33}=\lambda +2\mu , c_{12}=c_{13}=\lambda ,c_{44}=\mu ,a_{1}=a_{3}=a,\beta _{{1}}=\beta _{{3}}=\beta {,} \alpha _{1}=\alpha _{3}=\alpha ^{'}, K_{1}=K_{3}=K,K_{1}^{*}=K_{3}^{*}=K^{*}\), in equations (39), (42), (44), (47) and (48), we obtain expressions for lateral deflection, conductive temperature, thermal moment, nonlocal axial stress and thermodynamic temperature of an isotropic thermoelastic nanobeam for nonlocal thermoelasticity with forced vibrations and two temperatures for all the five mechanical boundary conditions.

-

iv.

If \(\tau _{\theta },\tau _{q}\rightarrow 0, \tau _{0}>0 \) and \({\varrho =1}\), in equations (39), (42), (44), (47) and (48) we obtain expressions for lateral deflection, conductive temperature, thermal moment, nonlocal axial stress and thermodynamic temperature of a transversely isotropic thermoelastic nanobeam for nonlocal thermoelasticity with forced vibrations and two temperatures with Lord-Shulman (LS) theory for all the five mechanical boundary conditions.

-

v.

If \(\tau _{\theta }=\tau _{q}=\tau _{0}=0 \) and \({\varrho =1, }\) in equations (39), (42), (44), (47) and (48), we obtain expressions for lateral deflection, conductive temperature, thermal moment, nonlocal axial stress and thermodynamic temperature of a transversely isotropic thermoelastic nanobeam for nonlocal thermoelasticity with forced vibrations and two temperature with Coupled Theory of Thermoelasticity (CTE) for all the five mechanical boundary conditions.

-

vi.

If \(\tau _{0}\rightarrow \tau _{q} ,\mathrm {R}_{{1}}=\mathrm {R}_{{2}}=1 \) and \({\varrho =1}\), in equations (39), (42), (44), (47) and (48), we obtain expressions for lateral deflection, conductive temperature, thermal moment, nonlocal axial stress and thermodynamic temperature of a transversely isotropic thermoelastic nanobeam for nonlocal thermoelasticity with forced vibrations and two temperatures with dual phase-lag theory for all the five mechanical boundary conditions.

-

vii.

If \(\tau _{0}\rightarrow \tau _{q} ,\mathrm {R}_{{1}}=1,\mathrm {R}_{{2}}=2\) and \(\varrho =1\), in Eqs. (39), (42), (44), (47) and (48) we obtain expressions for lateral deflection, conductive temperature, thermal moment, nonlocal axial stress and thermodynamic temperature of a transversely isotropic thermoelastic nanobeam for nonlocal thermoelasticity with forced vibrations and two temperatures with refined multi-dual-phase-lag heat transfer theory and more refinement may be obtained by taking higher values of \(\mathrm {R}_{{1}}\) and \(\mathrm {R}_{\mathrm {2}}\) for all the five mechanical boundary conditions.

9 Numerical results and discussion

In order to illustrate our theoretical results in the proceeding section and to show the effect of different theories of nonlocal thermoelasticity, we now present some numerical results. Cobalt material is chosen from Dhaliwal and Singh [55] for the purpose of numerical calculation, which is transversely isotropic. Physical data for a single crystal of cobalt is given by:

The following five cases are considered in numerical computations for dimensionless lateral deflection, thermal moment, conductive temperature and thermodynamic temperature studied with various theories of thermoelasticity (like LS, CTE, DPL and MDPL) by taking \(\xi =0.1,h=0.1,a_{1}=0.03, a_{3}=0.06\), and \(0<L<1\).

- Case I:

-

Clamped–clamped (CC) or pinned or hinged nanobeam

- Case II:

-

Simply supported–simply supported (SS) nanobeam.

- Case III:

-

Clamped–simply supported (CS) nanobeam.

- Case IV:

-

Clamped–free (CF)/cantilever nanobeam.

- Case V:

-

Free–free (FF) nanobeam

The numerical results are obtained and graphically presented in Figs. 2, 3, 4, 5, 6, 7, 8, 9, 10, 11, 12, 13, 14, 15, 1617, 18, 19, 20 and 21. In the graphs, the solid red line with centre symbol circle represents CTE Theory and solid black line represents LS theory, the solid blue line with centre symbol diamond represents DPL Theory and the solid green line with centre symbol circle represents MDPL Theory.

Case I: Clamped–clamped (CC) or pinned or hinged nanobeam

Figure 2 shows the variation in the lateral deflection w w.r.t. length of the beam for various theories of thermoelasticity (like LS, CTE, DPL and MDPL). It is found that the DPL has the highest effect and CTE theory has the least effect on the lateral deflection w. Lateral deflection decreases gradually and reaches to zero for all the theories of thermoelasticity. Figure 3 illustrates the variation of thermal moment w.r.t. length of the beam for various theories of thermoelasticity (like LS, CTE, DPL and MDPL). It is found that the DPL has the highest effect and CTE theory has the least effect on the thermal moment. Thermal moment decreases gradually and reaches to zero for all the theories of thermoelasticity.

Figure 4 demonstrates the variation of conductive temperature w.r.t. length of the beam for various theories of thermoelasticity (like LS, CTE, DPL and MDPL). It is found that the DPL has the highest effect and MPDL theory has the least effect on the conductive temperature. Conductive temperature decreases gradually and reaches to zero for all the theories of thermoelasticity.

Figure 5 exhibits the variation of thermodynamic temperature w.r.t. length of the beam for various theories of thermoelasticity (like LS, CTE, DPL and MDPL). It is found that the DPL has the highest effect and CTE theory has the least effect on the thermodynamic temperature. Thermodynamic temperature decreases gradually and reaches to zero for all the theories of thermoelasticity.

Case II: Simply supported–simply supported (SS) nanobeam

Figures 6, 7, 8 and 9 show the variation in the lateral deflection, thermal moment, conductive temperature and thermodynamic temperature w.r.t. length of the beam for various various theories of thermoelasticity (like LS, CTE, DPL and MDPL). It is found that the CTE has the highest effect and MDPL theory of thermoelasticity has the least effect on lateral deflection, thermal moment, conductive temperature in simply supported–simply supported (SS) nanobeam, whereas DPL has the highest effect and CTE theory of thermoelasticity has the least effect thermodynamic temperature. All these parameters decrease gradually and reach to zero for all the theories of thermoelasticity.

Case III: Clamped–simply supported (CS) nanobeam

Figures 10, 11, 12 and 13 show the variation in the lateral deflection, thermal moment, conductive temperature and thermodynamic temperature w.r.t. length of the beam for various various theories of thermoelasticity (like LS, CTE, DPL and MDPL). It is found that the LS has the highest effect and CTE theory of thermoelasticity has the least effect on these parameters in clamped–simply supported (CS) nanobeam, whereas DPL and MDPL have approximately equal effect on these parameters.

Case IV: Clamped–free (CF)/cantilever nanobeam

Figures 14, 15, 16 and 17 show the variation in the lateral deflection, thermal moment, conductive temperature and thermodynamic temperature w.r.t. length of the beam for various theories of thermoelasticity (like LS, CTE, DPL and MDPL). It is found that the LS has the highest effect on lateral deflection and thermal moment and DPL theory of thermoelasticity has the highest effect on conductive temperature and thermodynamic temperature in clamped–simply supported (CS) nanobeam, whereas MDPL has approximately lowest effect on these parameters.

Case V: Free–free (FF) nanobeam

Figures 18, 19, 20 and 21 show the variation in the lateral deflection, thermal moment, conductive temperature and thermodynamic temperature w.r.t. length of the beam for various various theories of thermoelasticity (like LS, CTE, DPL and MDPL). It is found that the CTE has the highest effect and MDPL theory of thermoelasticity has the least effect on these parameters in free–free (FF) nanobeam. All these parameters decrease gradually and reach to zero for all the theories of thermoelasticity.

10 Conclusions

-

The proposed model is designed to predict the thermomechanical response of transversely isotropic thermoelastic thin nanobeam in the context of nonlocal and multi-dual-phase-lag theories of thermoelasticity with two temperatures due to time varying exponentially decaying load and due to ramp-type heating at the end \(x=0\) by using E–B Beam theory and Laplace transform technique.

-

The ends of the nanobeam are subjected to: clamped–clamped (CC), simply supported–simply supported (SS), clamped–simply supported (CS), clamped–free (CF), free–free (FF) boundary conditions.

-

Sinusoidally varying conductive temperature has been considered.

-

Variation in the lateral deflection, thermal moment, conductive temperature and thermodynamic temperature with various theories of nonlocal thermoelasticity (like LS, CTE, DPL and MDPL with two temperatures) due to time varying exponentially decaying load are studied and shown graphically to depict the effects successfully.

-

From the analysis, it is observed that the nonlocal multi-dual-phase-lag theory of thermoelasticity with two temperatures due to time varying exponentially decaying load has significant effect on lateral deflection, thermal moment, conductive temperature and thermodynamic temperature. In addition, for the change in boundary conditions at the ends of the nanobeam, there is significant effect on the lateral deflection, thermal moment, conductive temperature and thermodynamic temperature with different theories.

-

A novel mathematical solutions has been given for the thin nanobeam in the context of nonlocal and multi-dual-phase-lag theories of thermoelasticity with two temperatures due to time varying exponentially decaying load, which is consequently easier for design and construction of beam-type MEMS/NEMS, accelerometers, sensors, resonators and other branches of engineering.

Abbreviations

- \(\delta _{ij}\) :

-

Kronecker delta

- \(T_{0}\) :

-

Reference temperature

- \(\beta _{ij}\) :

-

Thermal elastic coupling tensor

- \(\tau _{q}\) :

-

Phase lag of heat flux

- \(c_{ijkl}\) :

-

Elastic parameters

- \(\varphi \) :

-

conductive temperature

- T :

-

Absolute temperature

- \(e_{ij}\) :

-

Strain tensors

- \(C_\mathrm{E}\) :

-

Specific heat

- \(\rho \) :

-

Medium density

- \(u_{i}\) :

-

Components of displacement

- \(a_{ij}\) :

-

Two temperature parameters

- \(\alpha _{ij}\) :

-

Linear thermal expansion coefficient

- \(K_{ij}\) :

-

Thermal conductivity

- \({\Omega }\) :

-

Frequency of the applied load

- \(\vec {u}\) :

-

Displacement vector

- \(\delta (x)\) :

-

Dirac delta function

- \(\xi \) :

-

Nonlocal parameter

- \(t_{ij}\) :

-

Stress tensors

- \(\tau _{\theta }\) :

-

Phase lag of temperature gradient

- \(\tau _{0}\) :

-

Relaxation time

- I :

-

Moment of inertia

References

Eringen, A.C.: Theory of nonlocal thermoelasticity. Int. J. Eng. Sci. 12, 1063–1077 (1974). https://doi.org/10.1016/0020-7225(74)90033-0

Eringen, A.C.: On differential equations of nonlocal elasticity and solutions of screw dislocation and surface waves. J. Appl. Phys. 54, 4703–4710 (1983). https://doi.org/10.1063/1.332803

Eringen, A.C.: Nonlocal Continuum Field Theories. Springer, New York (2004)

Lu, P., Zhang, P., Lee, H., Wang, C., Reddy, J.: Non-local elastic plate theories. Proc. R. Soc. A Math. Phys. Eng. Sci. 463, 3225–3240 (2007). https://doi.org/10.1098/rspa.2007.1903

Rezazadeh, G., Vahdat, A.S., Tayefeh-rezaei, S., Cetinkaya, C.: Thermoelastic damping in a micro-beam resonator using modified couple stress theory. Acta Mech. 223, 1137–1152 (2012). https://doi.org/10.1007/s00707-012-0622-3

Guo, X., Yi, Y.-B., Pourkamali, S.: A finite element analysis of thermoelastic damping in vented MEMS beam resonators. Int. J. Mech. Sci. 74, 73–82 (2013). https://doi.org/10.1016/j.ijmecsci.2013.04.013

Şimşek, M., Reddy, J.N.: Bending and vibration of functionally graded microbeams using a new higher order beam theory and the modified couple stress theory. Int. J. Eng. Sci. 64, 37–53 (2013). https://doi.org/10.1016/j.ijengsci.2012.12.002

Shaat, M., Mahmoud, F.F., Gao, X.-L., Faheem, A.F.: Size-dependent bending analysis of Kirchhoff nano-plates based on a modified couple-stress theory including surface effects. Int. J. Mech. Sci. 79, 31–37 (2014). https://doi.org/10.1016/j.ijmecsci.2013.11.022

Allam, M.N.M., Abouelregal, A.E.: The thermoelastic waves induced by pulsed laser and varying heat of inhomogeneous microscale beam resonators. J. Therm. Stress. 37, 455–470 (2014). https://doi.org/10.1080/01495739.2013.870858

Abouelregal, A.E., Zenkour, A.M.: Effect of phase lags on thermoelastic functionally graded microbeams subjected to ramp-type heating. Iran. J. Sci. Technol. Trans. Mech. Eng. 38, 321–335 (2014). https://doi.org/10.22099/ijstm.2014.2498

Zenkour, A.M.: Free vibration of a microbeam resting on Pasternak’s foundation via the Green-Naghdi thermoelasticity theory without energy dissipation. J. Low Freq. Noise Vib. Act. Control. (2016). https://doi.org/10.1177/0263092316676405

Abouelregal, A.E., Zenkour, A.M.: Nonlocal thermoelastic semi-infinite medium with variable thermal conductivity due to a laser short-pulse. J. Comput. Appl. Mech. 50, 90–98 (2019). https://doi.org/10.22059/jcamech.2019.276608.366

Abouelregal, A.E.: The effect of temperature-dependent physical properties and fractional thermoelasticity on nonlocal nanobeams. Open Access J. Math. Theor. Phys. (2018). https://doi.org/10.15406/oajmtp.2018.01.00009

Marin, M.: The Lagrange identity method in thermoelasticity of bodies with microstructure. Int. J. Eng. Sci. 32, 1229–1240 (1994). https://doi.org/10.1016/0020-7225(94)90034-5

Marin, M.: On existence and uniqueness in thermoelasticity of micropolar bodies. Comptes Rendus Acad. Sci. Paris Ser. II. 321, 475–480 (1995)

Yu, T.X., Yang, J.L., Reid, S.R., Austin, C.D.: Dynamic behaviour of elastic–plastic free–free beams subjected to impulsive loading. Int. J. Solids Struct. 33, 2659–2680 (1996). https://doi.org/10.1016/0020-7683(95)00169-7

Park, S.K., Gao, X.-L.: Bernoulli–Euler beam model based on a modified couple stress theory. J. Micromech. Microeng. 16, 2355–2359 (2006). https://doi.org/10.1088/0960-1317/16/11/015

Sun, Y., Fang, D., Saka, M., Soh, A.K.: Laser-induced vibrations of micro-beams under different boundary conditions. Int. J. Solids Struct. 45, 1993–2013 (2008). https://doi.org/10.1016/j.ijsolstr.2007.11.006

Li, Y., Cheng, C.-J.: A nonlinear model of thermoelastic beams with voids, with applications. J. Mech. Mater. Struct. 5, 805–820 (2010). https://doi.org/10.2140/jomms.2010.5.805

Sharma, J.N.: Thermoelastic damping and frequency shift in micro/nanoscale anisotropic beams. J. Therm. Stress. 34, 650–666 (2011). https://doi.org/10.1080/01495739.2010.550824

Chakraborty, A.: Wave propagation in anisotropic media with non-local elasticity. Int. J. Solids Struct. 44, 5723–5741 (2007). https://doi.org/10.1016/j.ijsolstr.2007.01.024

Lazar, M., Agiasofitou, E.: Screw dislocation in nonlocal anisotropic elasticity. Int. J. Eng. Sci. 49, 1404–1414 (2011). https://doi.org/10.1016/j.ijengsci.2011.02.011

Abd-Elaziz, E.M., Othman, M.I.A.: Effect of Thomson and thermal loading due to laser pulse in a magneto-thermo-elastic porous medium with energy dissipation. ZAMM J. Appl. Math. Mech. (2019). https://doi.org/10.1002/zamm.201900079

Abd-Elaziz, E., Marin, M., Othman, M.: On the effect of Thomson and initial stress in a thermo-porous elastic solid under G–N electromagnetic theory. Symmetry (Basel). 11, 413 (2019). https://doi.org/10.3390/sym11030413

Zhang, J., Fu, Y.: Pull-in analysis of electrically actuated viscoelastic microbeams based on a modified couple stress theory. Meccanica 47, 1649–1658 (2012). https://doi.org/10.1007/s11012-012-9545-2

Abbas, I.A., Marin, M.: Analytical solution of thermoelastic interaction in a half-space by pulsed laser heating. Phys. E Low-Dimens. Syst. Nanostruct. 87, 254–260 (2017). https://doi.org/10.1016/j.physe.2016.10.048

Sharma, J.N., Kaur, R.: Transverse vibrations in thermoelastic-diffusive thin micro-beam resonators. J. Therm. Stress. 37, 1265–1285 (2014). https://doi.org/10.1080/01495739.2014.936252

Zenkour, A.M., Abouelregal, A.E.: Thermoelastic vibration of an axially moving microbeam subjected to sinusoidal pulse heating. Int. J. Struct. Stab. Dyn. 15, 1450081 (2015). https://doi.org/10.1142/S0219455414500813

Fantuzzi, N., Trovalusci, P., Dharasura, S.: Mechanical behavior of anisotropic composite materials as micropolar continua. Front. Mater. 6, 1–11 (2019). https://doi.org/10.3389/fmats.2019.00059

Abouelregal, A.E., Zenkour, A.M.: Thermoelastic response of nanobeam resonators subjected to exponential decaying time varying load. J. Theor. Appl. Mech. 55, 937–948 (2017). https://doi.org/10.15632/jtam-pl.55.3.937

Aksoy, H.G.: Wave propagation in heterogeneous media with local and nonlocal material behavior. J. Elast. 122, 1–25 (2016). https://doi.org/10.1007/s10659-015-9530-9

Kumar, R., Devi, S.: Interactions of thermoelastic beam in modified couple stress theory. Appl. Appl. Math. Int. J. 12, 910–923 (2017)

Riaz, A., Ellahi, R., Bhatti, M.M., Marin, M.: Study of heat and mass transfer in the Eyring–Powell model of fluid propagating peristaltically through a rectangular compliant channel. Heat Transf. Res. 50, 1539–1560 (2019). https://doi.org/10.1615/HeatTransRes.2019025622

Karami, B., Janghorban, M., Tounsi, A.: Nonlocal strain gradient 3D elasticity theory for anisotropic spherical nanoparticles. Steel Compos. Struct. 27, 201–216 (2018). https://doi.org/10.12989/scs.2018.27.2.201

Karami, B., Janghorban, M., Rabczuk, T.: Forced vibration analysis of functionally graded anisotropic nanoplates resting on Winkler/Pasternak-foundation. Comput. Mater. Contin. 62, 607–629 (2020). https://doi.org/10.32604/cmc.2020.08032

Zhang, L., Bhatti, M.M., Michaelides, E.E.: Thermally developed coupled stress particle-fluid motion with mass transfer and peristalsis. J. Therm. Anal. Calorim. (2020). https://doi.org/10.1007/s10973-020-09871-w

Bhatti, M.M., Ellahi, R., Zeeshan, A., Marin, M., Ijaz, N.: Numerical study of heat transfer and Hall current impact on peristaltic propulsion of particle-fluid suspension with compliant wall properties. Mod. Phys. Lett. B. 33, 1950439 (2019). https://doi.org/10.1142/S0217984919504396

Bhatti, M.M., Yousif, M.A., Mishra, S.R., Shahid, A.: Simultaneous influence of thermo-diffusion and diffusion-thermo on non-Newtonian hyperbolic tangent magnetised nanofluid with Hall current through a nonlinear stretching surface. Pramana 93, 88 (2019). https://doi.org/10.1007/s12043-019-1850-z

Sharma, K., Marin, M.: Reflection and transmission of waves from imperfect boundary between two heat conducting micropolar thermoelastic solids. Analele Univ. “Ovidius” Constanta Ser. Mater. 22, 151–176 (2014). https://doi.org/10.2478/auom-2014-0040

Sharma, J.N., Grover, D.: Thermoelastic vibrations in micro-/nano-scale beam resonators with voids. J. Sound Vib. 330, 2964–2977 (2011). https://doi.org/10.1016/j.jsv.2011.01.012

Marin, M., Craciun, E.M.: Uniqueness results for a boundary value problem in dipolar thermoelasticity to model composite materials. Compos. B Eng. 126, 27–37 (2017). https://doi.org/10.1016/j.compositesb.2017.05.063

Marin, M., Craciun, E.M., Pop, N.: Some results in green—lindsay thermoelasticity of bodies with dipolar structure. Mathematics (2020). https://doi.org/10.3390/math8040497

Abbas, I.A.: Free vibrations of nanoscale beam under two-temperature Green and Naghdi model. Int. J. Acoust. Vib. 23, 289–293 (2018). doi.org/10.20855/ijav.2018.23.31051

Lata, P., Kaur, I.: A study of transversely isotropic thermoelastic beam with Green–Naghdi type-II and type-III theories of thermoelasticity. Appl. Appl. Math. Int. J. 14, 270–283 (2019)

Kaur, I., Lata, P.: Rayleigh wave propagation in transversely isotropic magneto-thermoelastic medium with three-phase-lag heat transfer and diffusion. Int. J. Mech. Mater. Eng. 14, 5–6 (2019). https://doi.org/10.1186/s40712-019-0108-3

Kaur, I., Lata, P.: Stoneley wave propagation in transversely isotropic thermoelastic medium with two temperature and rotation. GEM Int. J. Geomath. 11, 1–17 (2020). https://doi.org/10.1007/s13137-020-0140-8

Kaur, I., Lata, P., Singh, K.: Effect of Hall current in transversely isotropic magneto-thermoelastic rotating medium with fractional-order generalized heat transfer due to ramp-type heat. Indian J. Phys. (2020). https://doi.org/10.1007/s12648-020-01718-2

Kaur, I., Lata, P.: Effect of hall current on propagation of plane wave in transversely isotropic thermoelastic medium with two temperature and fractional order heat transfer. SN Appl. Sci. 1, 5–9 (2019). https://doi.org/10.1007/s42452-019-0942-1

Kaur, I., Lata, P.: Transversely isotropic thermoelastic thin circular plate with constant and periodically varying load and heat source. Int. J. Mech. Mater. Eng. (2019). https://doi.org/10.1186/s40712-019-0107-4

Bhatti, M.M., Michaelides, E.E.: Study of Arrhenius activation energy on the thermo-bioconvection nanofluid flow over a Riga plate. J. Therm. Anal. Calorim. (2020). https://doi.org/10.1007/s10973-020-09492-3

Zenkour, A.M.: Magneto-thermal shock for a fiber-reinforced anisotropic half-space studied with a refined multi-dual-phase-lag model. J. Phys. Chem. Solids 137, 109213 (2019). https://doi.org/10.1016/j.jpcs.2019.109213

Rao, S.S.: Vibration of Continuous Systems. Wiley, NJ (2007)

Lifshitz, R., Roukes, M.L.: Thermoelastic damping in micro- and nanomechanical systems. Phys. Rev. B. 61, 5600–5609 (2000). https://doi.org/10.1103/PhysRevB.61.5600

Press, W.H., Teukolsky, S.A., Flannery, B.P.: Numerical Recipes in Fortran. Cambridge University Press, Cambridge (1980)

Dhaliwal, R.S., Singh, A.: Dynamic Coupled Thermoelasticity. Hindustan Publication Corporation, New Delhi (1980)

Funding

No fund/grant/scholarship has been taken for the research work.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Kaur, I., Lata, P. & Singh, K. Study of transversely isotropic nonlocal thermoelastic thin nano-beam resonators with multi-dual-phase-lag theory. Arch Appl Mech 91, 317–341 (2021). https://doi.org/10.1007/s00419-020-01771-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00419-020-01771-7

Keywords

- Transversely isotropic thermoelastic

- Nanobeam

- Multi-dual-phase-lag theory of thermoelasticity

- Time varying load

- Nonlocal nanobeam

- Laplace transform