Abstract

Interfaces in rocks, especially grain boundaries in olivine dominated rocks, have been subject to about 40 years of studies. The grain boundary structure to property relation is fundamental to understand the diverging properties of polycrystalline samples compared to those of single crystals. The number of direct structural observations is small, i.e. in range of 100 micrographs, and the number of measurements of properties directly linked to structural observations is even smaller. Bulk aggregate properties, such as seismic attenuation, rheology and electrical conductivity, are sensitive to grain size, and seem to show influences by grain boundary character distributions. In this context we review previous studies on grain boundary structure and composition and plausible relations to bulk properties. The grain boundary geometry is described using five independent parameters; generally, their structural width ranges between 0.4–1.2 nm and the commonly used 1 nm seems a good approximation. This region of enhanced disorder is often enriched in elements that are incompatible in the perfect crystal lattice. The chemical composition of grain boundaries depends on the bulk rock composition. We determined the 5 parameter grain boundary character distribution (GBCD) for polycrystaline Fo\(_{90}\) and studied structure and chemistry at the nm-scale to extend previous measurements. We find that grain boundary planes close to perpendicular to the crystallographic c-direction dominate the grain boundary network. We conclude that linking grain boundary structure in its full geometric parameter space to variations of bulk rock properties is now possible by GBCD determination using EBSD mapping and statistical analyses.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Interfaces in rocks, especially grain boundaries in olivine dominated rocks, have been subject to nearly 40 years of studies. One of the first authors who noted the importance of relating structure to property in further research on the nature and role of grain boundaries was McClay (1977) while reviewing pressure solution and Coble creep in rocks and minerals. 40 years later, the grain boundary structure to bulk rock property relation is still being debated. This contribution is an attempt to review past work and while refraining to claim completeness, we hope to indicate open questions and trigger new studies using newly available methods. Developments with and observations on crystallographically and chemically simpler systems such as ceramics, with relevance for the Earth (e.g. MgO), allow identification of structure-property relations directly.

Olivine incorporates a broad range of elements in traces at ppm and ppb level (e.g. Garrido et al. 2000; Davies et al. 2006; Lee et al. 2007; Drouin et al. 2009; De Hoog et al. 2010; Foley et al. 2011, 2013), including transition metals with variable valance states. Therefore, the structure–property relations are best identified on simplified systems with low porosity (e.g. derived from sol–gel processes, from oxides or from nano-sized precursors). With respect to diffusional properties, the most important element controlling the defect chemistry at given pressure, temperature, oxygen fugacity and silicon activity was shown to be iron (Chakraborty et al. 1994; Chakraborty 1997; Petry et al. 2004). This led to the conclusion that any diffusion-related properties measured on iron free systems cannot be used to model these properties in natural systems. Therefore, we present some new observations and highlight recent developments that offer new possibilities for gaining a more complete understanding of grain boundaries on Fo90. While the examples given for the terminology in the appendix are of general character and, therefore, include observations from ceramics, the main part of this contribution will focus on interfaces in olivine-dominated rocks. In cases where we report results from the ceramics literature, we will mark it in cursive italics.

Rocks are polycrystalline materials (e.g. Lloyd et al. 1997), thus individual crystals joint to each other by a three-dimensional network of internal interfaces − the grain boundary network (e.g. Rohrer 2011b). The principal characteristics of the texture of a ’monomineralic’ rock are the relative areas of different types of grain boundaries and the way that they are connected. Such a description intrinsically includes information on aspect ratio, lattice preferred orientation, relative orientation of neighboring grains (disorientation, to be defined later), but excludes grain size variations.

Single crystal properties (e.g. Durham and Goetze 1977; Durham et al. 1977) are markedly different from bulk rock properties (e.g. Phakey et al. 1972; Goetze and Kohlstedt 1973; Poirier 1985; Karato et al. 1986; Marquardt et al. 2011a, b; Kohlstedt and Hansen 2015). Grain boundaries significantly influence a number of the physical properties of rocks (e.g. Wenk 1985). Their presence influences creep strength in diffusion creep (e.g. Cooper and Kohlstedt 1984; Hirth and Kohlstedt 1995; Sundberg and Cooper 2008; Hansen et al. 2011, 2012a, b, c). Grain boundary diffusion is orders of magnitude faster compared to volume diffusion (for example Farver et al. 1994; Farver and Yund 2000; Milke et al. 2001, 2007; Hayden and Watson 2008; Dohmen and Milke 2010; Demouchy 2010; Marquardt et al. 2011c, d; Gardés et al. 2012). Furthermore, seismic properties are directly influenced by grain boundaries as evidenced by a marked grain size effect found by Jackson et al. (2002, 2004). Electrical conductivity has also been found to be grain size sensitive (ten Grotenhuis et al. 2004, 2005; Dai et al. 2008; Farla et al. 2010; Laumonier et al. 2017). However, some studies conclude opposingly that grain boundaries have no effect on electrical conductivity (Roberts and Tyburczy 1991). The variable grain boundary energy influences the melt distribution and thus indirectly influences bulk properties, which has been proposed by Anderson and Sammis (1970) and Solomon (1972). First experiments with respect to melt networks at olivine interfaces were conducted by Waff and Bulau (1979).

Despite their importance, and despite the amount of studies general relations between olivine grain boundary structure and associated properties are still poorly understood, but are extensively evident in ceramics (summarising works include Sutton and Balluffi 1995; Rohrer 2007, 2011a, 2015; Harmer 2010). Structure property relations have been established using the grain boundary geometry in its full five parameter space: the grain boundary character distribution (GBCD). The key geometrical information directly related to bulk properties appears to be the grain boundary plane distribution (GBPD); it is proportional to the inverse of grain boundary energy distribution [GBPD \(\propto\) 1/GBED, (Olmsted et al. 2009; Rohrer 2011b; Holm et al. 2011; Bean and McKenna 2016)]. Rohrer (2007) further summarises that: ’Grain boundary plane distributions in polycrystals are anisotropic and scale invariant during normal grain growth. This suggests that the GBCD is an intrinsic characteristic of the microstructure. The most common grain boundary planes are those with low surface energies and the grain boundary populations are inversely correlated with the grain boundary energy. These observations indicate that the GBCD develops deterministically based on the relative energies of the boundaries and can be influenced by altering these energies.’.

Furthermore, the volume of the grain boundary region is linked to the GBPD through its positive correlation with grain boundary energy (e.g. Olmsted et al. 2009; Holm et al. 2011; Bean and McKenna 2016). It is observed that the GBPD sensitively changes with varying grain boundary composition (Cho et al. 1999; Pang and Wynblatt 2006), which is explained as a result of changing grain boundary energies (Pang and Wynblatt 2006; Holm et al. 2011). Consequently, the structure of grain boundaries varies with composition, which can thus be regarded as a sixth parameter that affects the 5-parameter space.

Moreover, a positive correlation between grain boundary volume and grain boundary diffusion has been observed in molecular dynamic simulations in forsterite (Adjaoud et al. 2012; Wagner et al. 2016) as well as in many computational studies in ceramics (Olmsted et al. 2009; Holm et al. 2011; Bean and McKenna 2016). The GBPD may therefore, in a first approximation, be linked to the grain boundary volume, energy, viscosity and diffusivity and a true structure to property relations can be established. In this contribution, we review past work on grain boundaries, show new data on the composition and structure of grain boundaries and conclude that quantitative information that encompasses that the full 5–6 parameter space can be obtained using the GBCD and GBPD.

Grain boundary geometry

The term grain boundary defines the interface where two minerals of the same phase are in contact (Fig. 1). The only characteristic that varies between the two grains (crystals) is the orientation of the crystal lattice, this affects the grain boundary energy. In the green grain, a small angle grain boundary intersects the high angle grain boundary of the red grain. The inequality of the dihedral angles is indicative of the lower energy of the small angle grain boundary (sub grain boundary) which has been used to infer the relative energies of low angle grain boundaries (Duyster and Stöckhert 2001).

The left side shows a schematic illustration of a polycrystalline sample where all grains have different crystallographic orientations, but are of the same phase (drawn after an initial sketch by Gregory S. Rohrer). On the right, the Herring equation with an illustrative sketch is shown. In this form, \(\theta\) indicates the dihedral angles. \(\gamma _{i}\) is the excess free energy of the \(i{\text {th}}\) boundary (surface = s, grain boundary = gb), \(\hat{n}_{i}\) is the unit boundary normal of the \(i{\text {th}}\) boundary and perpendicular to the triple line, \(\hat{I}=\hat{n}_{i}\oplus \hat{t}_{i}\) which is common to all tree adjacent boundaries. The derivative terms are referred to as torque terms, \(\hat{t}_{i}\) and reflect the dependence of interface energy on orientation about the triple junctions at fixed \(\hat{I}\) (e.g. Adams et al. 1999; Rollett and Rohrer 2017)

The grain boundary geometry is given using five macroscopic degrees of freedom (e.g. Mishin and Herzig 1999; Rollett and Rohrer 2017); this is visualised in Fig. 2. The misorientation between two adjacent crystals is described using three Eulerian angles that are given with respect to one of the adjacent crystal lattices, conventionally: \(\sigma\)1, \(\phi\), \(\sigma_2\)(e.g. Wenk 1985). The grain boundary plane is described using the two remaining degrees of freedom with one radial and one azimuthal angle: \(\Phi\) and \(\theta\) (Randle and Engler 2014; Rollett and Rohrer 2017). This description encompasses all types of grain boundaries: low angle grain boundaries, high angle grain boundaries of general and special character, where special generally refers to either geometrically or from a property point of view special (Randle and Davies 2002).

Schematic illustration of a 3D polycrystalline sample, where the full 5 parameters needed for the macroscopic description of the grain boundary geometry are given. Figure is varied from the sketch in the publication (Rohrer 2007)

Low angle grain boundaries are build from periodically spaced dislocations. The small angle grain boundary has the misorientation angle \(\theta\) across the boundary. For small misorientations, this can be approximated using the burgess vector \(\bar{b}\) of the dislocation and their spacing h as:

The low angle tilt grain boundary misorientaion can be related to the grain boundary energy (Read and Schockley 1950):

where \(\nu\) is the Poisson’s ration and A the elastic strain energy resulting from the lattice distortions around the dislocation cores, and G the shear modulus. Such distortions around individual dislocations forming low angle grain boundaries have been mapped using TEM (Johnson et al. 2004). TEM investigations on low angle grain boundaries date back to at least (Phakey et al. 1972; Goetze and Kohlstedt 1973; Durham et al. 1977; Durham and Goetze 1977). Modern TEM methods allow to obtain full 3D data on dislocations by tomography (Mussi et al. 2014). This formulation applies to low angle grain boundaries. It is not applicable to high angle grain boundaries, because as soon as the cores of the dislocations overlap, we cannot distinguish individual dislocations anymore. This misorientation defines the onset of large angle grain boundaries, nevertheless the energy should remain proportional to the minimum geometrically necessary dislocation densities (Rohrer 2011a). Heinemann et al. (2005) observed that this transition occurs above 20\(^{\circ }\) misorientation in forsterite. A relation to the larger lattice parameters in silicates in comparison to metals was speculated to be the cause. They showed that the Read and Schockley (1950) model is well applicable even though the initial approximations are derived for cubic crystal system. This was further supported by molecular dynamic simulation studies by Adjaoud et al. (2012) and Wagner et al. (2016). For small angle twist grain boundaries, a similar treatment is suitable (Read and Schockley 1950).

High angle grain boundaries used to be described using geometrical models. The coincidence side lattice (CSL) model yields the three-dimensional lattice site density (Chan and Balluffi 1986; Sutton and Balluffi 1995). The \(\Sigma\) value gives the inverse of the coincidence site density at the grain boundary plane (Vonlanthen and Grobety 2008) such that an actual physical meaning of the CSL theory could be obtained. In principle, all planar grain boundaries must be periodic—because they are interfaces between two periodic crystals. However, the past two decades of grain boundary studies in ceramics show that the \(\Sigma\) notation has no significant meaning besides its short-hand notation; furthermore, these so-called ‘special’ grain boundaries are not particularly common in polycrystals (e.g. Saylor et al. 2003, 2004; Vonlanthen and Grobety 2008; Rohrer 2007), a situation referred to as the ‘Sigma enigma’ (Randle and Davies 2002). Also in olivine, Marquardt et al. (2015) found no preference for special (low \(\Sigma\) CSL) grain boundaries of any type, which is probably enhanced by the relatively low symmetry of olivine. Therefore, we will not further consider this model in this overview.

Of all the relations between the geometry of high angle grain boundaries and their properties, the most fundamental relation is that of geometry to grain boundary energy, \(\gamma\), see Eq. 2. If we consider only interfacial energies, the vector (\(\mathbf {b}\)) sum of the forces must be zero in equilibrium:

If we rearrange Eq. 3, we obtain the Young equation (sine law):

If the energies of the three interfaces are known, the dihedral angles can be computed. However, this is only viable for isotropic systems (for example soap bubbles)—for anisotropic systems, thus all crystals, the torque terms—as illustrated in Fig. 1—have to be taken into account and the full Herring equation (Eq. 5) is appropriate for usage (its reduction yields again the Young equation):

In polycrystalline samples Marquardt et al.’s (2015), observations indicate that grain boundary energy minimisation is controlled by surface energy reduction of the individual grains in contact and not by adapting the grain boundary plane orientation of special atomic configuration across the interface. This is in agreement with many studies on ceramics (Saylor 2001; Sano et al. 2003, 2005; Saylor et al. 2004; Pang and Wynblatt 2006; Dillon et al. 2010). Thus, the ideal shape or minimum surface energy of each crystal in these polycrystal depends on the material the individual crystal is in contact with, e.g. another crystal, melt, fluid, or segregated elements.

The five parameter grain boundary character distribution (GBCD)

The GBCD is sometimes referred to as interface character distribution (ICD, Fang et al. 2016) and used to be reduced to one or three parameters. The disorientation angle, which is one single parameter, is often called misorientation in geological literature. We will use disorientation here, Fig. 5a. The axis and angle of disorientation (e.g. Lloyd et al. 1997; Fliervoet et al. 1999) includes three parameters (Fig. 5b). These simplifications were necessary, because the full geometrical parameter space discretised in for example steps as large as 10\(^{\circ }\) results in approx. 60 × 103 geometrically distinct grain boundaries in the orthorhombic crystal system (Rohrer 2011b; Marquardt et al. 2015). This number increases for finer discretisation or lower crystal symmetries. Therefore, the numbers of previous grain boundary observations are small compared to realistic number of geometrically distinct grain boundaries.

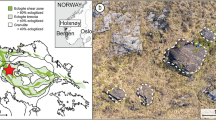

The grain boundary plane distribution (GBPD) is part of the GBCD and given by the remaining two parameters. One radial and one azimuthal angle: \(\Phi\) and \(\theta\), frequently displayed independently of misorientation as in Fig. 5c. The new developments in EBSD techniques allow to statistically extract these two parameters. The anisotropic distribution of the grain boundary plane at a specific disorientation about a specific axis means, in other words that if the disorientation of two adjacent crystals is constant, particular grain boundary plane orientations are more common than others and thus energetically favourable. In Fig. 5d, e, the grain boundary plane distributions represent the relative areas of different grain boundary planes at specific disorientation about specific axis, here 60\(^{\circ }\) about [100] and 90\(^{\circ }\) about [001]. The plots in c–d are stereographic projections in the crystal reference frame. All data in Fig. 5 are obtained from a sol–gel Fo\(_{90}\) sample, with minor amounts of Ti partitioned to the grain boundaries. The results will be discussed below and in full detail and in comparison to other GBCD in a following publication.

The number of published direct observations on grain boundaries amounts to about 100 transmission electron micrographs for olivine grain boundaries. Most observations stem from the works of Phakey et al. (1972); Goetze and Kohlstedt (1973); Durham and Goetze (1977); Durham et al. (1977); Vaughan et al. (1982); Kohlstedt (1990); de Kloe (2001); Hiraga et al. (2002, 2003); Adjaoud et al. (2012); Burnard et al. (2015) and the various studies of the ANU group (Faul et al. 1994; Drury and Fitz Gerald 1996; Cmíral et al. 1998; Faul 2000; Jackson et al. 2004; Faul et al. 2004) as well as from the study of Fei et al. (2016).

It should be noted that the recent development of high-speed electron backscatter diffraction (EBSD) mapping now allows for characterisation of large numbers of grain boundaries in their five parameter space (four parameters from 2D sections and the fifth calculated using stereology, or directly five parameters are obtained by serial sectioning). The number of grain boundaries characterised using EBSD amount to 104, 105 in individual studies (e.g. Adams et al. 1993; Zaefferer and Wright 2009; Marquardt et al. 2015).

New techniques to measure the full five parameter space of grain boundaries

The study of grain boundaries in polycrystals went through a drastic change since the availability of automated EBSD mapping, which allows to sample the immense parameter space of the grain boundary character. EBSD techniques are well described in several text books (e.g. Zhou and Wang 2007; Zaefferer and Wright 2009; Randle and Engler 2014; Rollett and Rohrer 2017) and an efficient overview is given by Rohrer (2011b) new developments are discussed in Marquardt et al. (2017). To measure the GBCD, two main approaches have been used: 3D serial sectioning and stereological analyses of two-dimensional orientation maps (e.g. Randle and Davies 2002; Rohrer et al. 2004). Stereology is, while being much simpler than sectioning, only applicable to materials without significant orientation texture or lattice preferred orientation (LPO). The stereological concept has been applied to many different materials; many comparisons of different research groups to 3D sectioning proved its applicability (e.g. Adams et al. 1993; Randle and Davies 2002; Kim et al. 2006; Reed et al. 2012).

Grain boundary energy, structure and width

The grain boundary structure is changing on the atomic scale to minimise the respective surface energies, resulting in locally different grain boundary geometries. The grain boundary structure can be studied at the nm-scale using HRTEM in combination with electron exit wave reconstruction (e.g. Adjaoud et al. 2012). True atomically resolved micrographs of olivine grain boundaries have not been published as yet. It should be noted that the observed grain boundary structure of not perfectly straight grain boundaries varies on the scale of less than 100 nm, visible in HRTEM micrographs. Thus, every few tens to hundreds of nm we can define a new grain boundary structure. Steps and facets on grain boundaries are necessary to accommodate a particular grain boundary plane orientation. Instead of straight facets, grain boundaries are also observed to be curved in two orthogonal dimensions, again facilitated by unit cell sized steps. The unit cell criterion arises because charge neutrality is required and it has been observed in evaporation experiments, that no leaching layer forms—thus, evaporation occurs in stoichiometric ratios. But roughness and steps may also arise from dislocations or sub-grain boundaries intersecting the grain boundary.

The atoms at grain boundaries are less ordered relative to the olivine crystal interior but because they are influenced by the close proximity of the adjacent crystals they are more ordered than pure melt. This is reflected in the faster diffusion along grain boundaries compared to the crystal volume, and slower diffusion than that in melt. Furthermore, grain boundaries show higher viscosity than melt. Molecular dynamic simulations inferred a relation of diffusivity and viscosity to surface energy (e.g. Gurmani et al. 2011) and crystal orientations with higher surface energy show lower self-diffusion coefficients of all ionic species. The relation between viscosity, diffusion and self diffusion for ionic liquids is simple and given by the Nerst–Einstein equation, it is discussed by Avramov (2009), but unfortunately not applicable to silicate melts as they are non-ionic liquids. Other approaches to obtain the grain boundary viscosity from molecular dynamic simulations can be obtained from the Green–Kubo relation expressing the viscosity as function of the stress tensor time correlation function as exploited by Mantisi et al. (2017). Note that the surface energies given in Gurmani et al. (2011) were calculated in contact with vacuum rather than in contact with melt and are very similar to the energies calculated by Watson et al. (1997). Other simulation methods yield varying surface energies, also affected by the contact medium (de Leeuw et al. 2000a, b; King et al. 2010; Bruno et al. 2014, 2016).

In the following, we review and examine the structural width and the effective width of grain boundaries in experimentally produced polycrystalline olivine aggregates of samples of different origin and composition. We summarise previous findings, the terminology and end with the observation that the width of grain boundaries requires further clarifying studies.

The width of grain boundaries, \(\delta\), is subjected to debates for several decades. Generally, it appears that it is necessary to distinguish the structural (or physical) grain boundary width, \(\delta _{\mathrm{{struc}}}\) defined as the distance between neighbouring crystal lattices and the effective grain boundary width, \(\delta _{\mathrm{{eff}}}\), which is the width active to enhance a specific process occurring at the grain boundary. The effective width may be different for different processes and is an empirical parameter used in the absence of physically easily observable differences.

The structural grain boundary width, \(\delta _{\mathrm{{struc}}}\), is defined as the distance between two adjacent perfect crystal lattices. While some studies find that the lattice planes of neighbouring crystals are directly in contact, they abut, without an intervening disordered region (Kohlstedt 1990; Hiraga et al. 2002; Vaughan et al. 1982), others find a disordered region between the two adjacent crystal lattices with a width of about 1 nm (Drury and Fitz Gerald 1996; Tan et al. 2001; Faul et al. 2004). As both results are obtained from imaging, they both yield the structural width. The structural width of low-angle grain boundaries has been determined by Ricoult and Kohlstedt (1983) to be three to four times smaller than the dislocation spacing and approx. in the range of 5–8 nm. Furthermore, the importance of hydrated grain boundaries was greatly emphasised for tectonites, including quartz and peridotite mylonites (e.g. White and White 1981). They observe that a grain boundary region of 10–30 nm is more susceptible to electron beam damage compared to the crystal interior and conclude that this region has generally different properties caused by the presence of a fluid and/or a highly distorted crystal structure layer. White and White (1981) suggest that the grain boundary width of olivine grain boundaries is orientation dependent. For hydrated grain boundaries in halides width of up to 2 \(\upmu\)m where discussed (Mistler and Coble 1974).

The effective grain boundary width, \(\delta _{\mathrm{{eff}}}\), in contrast is defined as the zone around a grain boundary where a specific process is enhanced. The effective grain boundary width may be orders of magnitude larger compared to the structural width, and may not be directly observed using SEM; in TEM \(\delta _{\mathrm{{eff}}}\), if caused by lattice distortions, may be imaged using geometrical phase analyses as exemplified on low angle grain boundaries in olivine by Johnson et al. (2004). It has been observed that element segregation (max. 7 nm Hiraga et al. 2002) and diffusion along a grain boundary can occur at an effectively larger region; this was attributed to lattice strain and/or a space charge layers associated with grain boundaries in ionic crystals (e.g. Kliewer and Koehler 1965; Cinibulk et al. 1993; Kleebe 2002). Such strained and/or charged layers allow for variations in polaron conduction or element diffusion rates. Determining the effective grain boundary width, \(\delta _{\mathrm{{eff}}}\), during deformation or diffusion from the respective formulas results in width estimates ranging from approx. 1 nm to regions as wide as several \(\upmu\)m (e.g. Mistler and Coble 1974; Hirth and Kohlstedt 2003; Marquardt et al. 2011d; Hashim 2016). Constituting equations for diffusional or rheological processes include the effective grain boundary width, as an imperative parameter (e.g. Farver et al. 1994; Kaur et al. 1995; Dillon and Harmer 2007).

The effective grain boundary width and the width of the region elements partition to (segregate) are affected by: (1) lattice misfit of the adjacent grains, (2) misfit lattice strain due to the difference between the size of a solute ion and that of the ideal strain-free lattice site (Hiraga and Kohlstedt 2007; Hiraga et al. 2007; Marquardt et al. 2011d; Lejček 2010), and (3) in ionic crystals a space charge layer can be present (e.g. Lehovec 1953; Kliewer and Koehler 1965; Kingery 1974). These effects can be visualised for example by depicting the displacement of atoms with respect to the place they would occupy in a perfect crystal lattice; examples have been calculated with molecular dynamic simulations (e.g. Ghosh and Karki 2014; Wagner et al. 2016; Mantisi et al. 2017). Furthermore, the effective width of element diffusion of a specific element along a specific interface might be as large as 10–30 nm (White and White 1981; Marquardt et al. 2011d). In contrast, Farver et al. (1994) highlighted that the average effective grain boundary width for Mg grain boundary diffusion in forsterite is in good agreement with the structural grain boundary width determined from HRTEM micrographs, which is in the range of 1 nm.

Concepts to explain these large variations were suggested by Peterson (1983), who stated that the values for \(\delta _{\mathrm{{eff}}}\) that are obtained thought diffusion studies are too large depending on whether or not grain boundary diffusion occurs parallel or perpendicular to the grain boundary. Where diffusion is parallel to the grain boundary, (\(D^{\parallel }_{\mathrm{{gb}}}\)) the process depends on \(D_{\mathrm{{gb}}}\delta\), or where diffusion occurs across the grain boundary \(D^{\perp }_{\mathrm{{gb}}}\) the process depends on \(D^{\perp }_{\mathrm{{gb}}}\delta {^{-1}}\), e.g. grain boundary migration. Therefore, Peterson (1983) concluded that even though direct observations are easily interpreted, kinetic techniques may be more appropriate for the interpretation of the various grain boundary widths. Furthermore, Ricoult and Kohlstedt (1983) suggested that impurities will significantly slow down grain boundary migration (\(D^{\perp }_{\mathrm{{gb}}}\delta ^{-1}\)) and will have little effect on grain boundary diffusion (\(D^{\parallel }_{\mathrm{{gb}}}\)).

This last statement seems unlikely based on the growing body on grain boundary diffusion studies in ceramics and metals that rather suggest that both grain boundary migration and grain boundary diffusion can increase or decrease with different types of impurities that segregated to grain boundaries (e.g. Ching and Xu 1999; Cho et al. 1999; Dillon and Harmer 2007; Palmero et al. 2012; Raabe et al. 2014; Homer et al. 2015).

Grain boundary chemistry: partitioning/segregation to grain boundaries

It is now generally accepted that high angle grain boundaries are enriched in trace elements that are relatively incompatible in the crystal interiors (e.g. Tan et al. 2001; Hiraga et al. 2002, 2003, 2004; Faul et al. 2004). Drury and Fitz Gerald (1996) were the first to measure grain boundary compositions in olivine but in relation to melt films. Some early studies found no enrichment at grain boundaries (Kohlstedt 1990); this was later explained as related to the substantial capability drawbacks in transmission electron microscopic methods in these days. In this context De Kloe et al. (2000) pointed out that the absence of a compositional difference between intra- and inter-granular areas might related to the positioning difficulties of a condensed beam, which could further cause irradiation damage.

The enrichment of trace elements at high angle grain boundaries is a result of segregation (partitioning), where elements that do not fit into the structure of the adjacent crystals partition/segregate to the grain boundary (Hiraga et al. 2002, 2007; Faul et al. 2004; Hiraga and Kohlstedt 2007), a process analogous to element partitioning between melt and crystal (and similarly inferred to be temperature and pressure dependent). Grain boundaries may thus serve as a container for incompatible elements in the Earth’s interior (Hiraga et al. 2004; Sommer et al. 2008). However, Eggins et al. (1998) show in their ICP-MS and microbeam (EMP, LA-ICP-MS) study on peridotites that all trace element content can be accounted for without accessory minerals or grain boundaries for grain sizes above μm-sizes. An exception might be noble gases; solubility experiments for He in olivine. Parman et al. (2005) show measurable quantities of helium interpreted to be trapped between grains or adsorbed on grain boundaries.

The grain boundary energy is influenced through chemical segregation, where the grain boundary energy in most observations in ceramics decreases, but occasionally increases; the latter results in creep resistance reduction (Yasuda et al. 2004; Raabe et al. 2014). In ceramics, the prevailing consensus is that segregation influences grain boundary diffusivity, and in consequence bulk viscosity in diffusion creep. It can be hypothesised that the creep resistance in rocks is influenced through grain boundary segregation.

Pre-melting

Based on the observation that grain boundaries often have a different composition and are more disordered compared to grain interiors, the concept of ’pre-melting’ has been proposed. Its occurrence was recently described for geological materials (Levine et al. 2016). Pre-melting involves the formation of nanometer-scale intergranular films with liquid-like properties, such as static and dynamic disorder, below the bulk melting point [the same as surface or interface melting (Mott 1951)]. Consequently, diffusion rates within this region are higher than normal grain boundary diffusivities and approach those in a liquid (e.g. Kaplan et al. 2013). Material science melting studies in mono-mineralic substances of high purity and on single crystals show that melting occurs along grain boundaries and grain surfaces below the actual bulk-melting temperature (Dash 1999; Alsayed et al. 2005; Mei and Lu 2007; Han et al. 2010; Bhogireddy et al. 2014). Pre-melting can begin at temperatures of 90 \(\%\) of the bulk melting temperature, as observed in simulations and studies of ceramics (Luo et al. 2005; Mellenthin et al. 2008; Luo and Chiang 2008; Dillon et al. 2010).

Levine et al. (2016) summarised evidence for pre-melting and shows its existence in gneiss. This study summarises the causes for pre-melting at dislocations (also applicable to grain boundaries) as: (1) a lowering of the activation energy as a result of stored strain energy, (2) an increased abundance of weakened bonds located within sub-grain boundaries, thus less energy is required to weaken the remaining bonds (Hartmann et al. 2008), (3) enhanced diffusion rates along the sub-grain boundaries and (4) a local lowering of the melting temperature due to ‘water and water-derived species’.

Pre-melting is related to, but should not be confused with early partial melting (EPM), a process where point-defect condensation leads to small melt factions that are unusually enriched in SiO\(_{2}\), not expected to occur in thermodynamic equilibrium. This has been described in the system olivine-pyroxene [e.g. Doukhan et al. 1993; Raterron et al. 1995, 1997] and Raterron et al. (2000) concluded that the process can be well explained by sluggish point-defect equilibration using the model of Nakamura and Schmalzried (1983).

Melt distribution to study grain boundary energy

The distribution of the melt phase at the grain scale is a function of grain boundary energy [e.g. Bulau et al. (1979); Vaughan et al. (1982); Cooper and Kohlstedt (1982); Toramaru and Fujii (1986a, b); Wanamaker and Kohlstedt (1991) and Bagdassarov et al. (2000)]. For example, while basaltic melt penetrates deeply into high angle olivine grain boundaries (a small dihedral angle), sub-grain boundaries show a large dihedral angle, indicating their much lower grain boundary energy [Fig. 4d in Cmíral et al. (1998); Duyster and Stöckhert (2001)]. A static model is frequently used to determine the relative grain boundary energies by measuring the dihedral angle at the contact of two grains with melt (Waff and Bulau 1979; Bulau et al. 1979). In the case of a melt-bearing polycrystal, using the assumption of isotropic grain boundary energies, \(\gamma _{gb}\) and isotropic liquid-crystal energies, \(\gamma _{sl}\), the Herring relations can be reduced to

The dihedral angle is the angle enclosing the second phase, i.e. the melt. This is shown in Fig. 3 and is a specific case of surface energy relations between the same crystal phases as displayed in Fig. 1.

Schematic illustration of a 3-D isotropic polycrystalline sample, with two melts with different wetting properties, left non-wetting, right, wetting along triple junctions. No examples for wetted grain boundaries are given. It is important to remember that such illustrations are based on static hypothetic considerations. This does not account for dynamic reorganisation where wetted grain boundaries and melt pools at quadrupole junctions form transient features (e.g. Walte et al. 2005). Figure was inspired by a sketch in the PhD thesis of Rene de Kloe (de Kloe 2001)

Because of the simplicity of the dihedral angle measurements compared to interfacial energy determination, dihedral angles have been measured for a range of systems (an overview is given in Faul (2000); Laporte and Provost (2000); Bagdassarov et al. (2000)). Dihedral angles \(>0^{\circ }\) up to \(60^{\circ }\) yield interconnected melt without wetting grain boundaries in the isotropic theory. For dihedral angles \(>60^{\circ }\), the formation of an interconnected melt network requires increasing melt contents. The idealised isotropic model is self-similar, i.e. independent of grain size. A grain size dependance of the melt distribution enters only in the models of Takei and Holtzman (2009b), Holtzman and Kendall (2010).

Instead of the true dihedral angle, which requires 3D observations (e.g. Cmíral et al. 1998), the distribution of the melt is frequently described using the distribution of apparent dihedral angles measured from 2D sections (e.g. Jurewicz and Jurewicz 1986). This approach assumes isotropic surface energies; however, the surface energy anisotropy of olivine is non-negligible (e.g. Cooper and Kohlstedt 1982; Watson et al. 1997; de Leeuw et al. 2000a, 2010; Faul et al. 2004; King et al. 2010; Gurmani et al. 2011; Adjaoud et al. 2012).

Surface energies also depend on the composition of the melt as shown by Wanamaker and Kohlstedt (1991). Using the sessile drop technique (i.e. an additional liquid–vapour interface), they showed that the wetting angle (obtained from a variation of Herrings relations) increases with increasing silica content. Wanamaker and Kohlstedt (1991) conclude that the interfacial energy increases with increasing silica content, but for different Ca, Na, K containing silica melts and different crystallographic surfaces the relations become more complex. Similar to Wanamaker and Kohlstedt (1991), Schäfer and Foley (2002) used the sessile drop technique to study the variation of mineral-melt interfacial energy for the minerals olivine, enstatite, diopside, and spinel ad found that surface energy increases in that order. Finally, it should be noted that the grain boundary energy can be determined from grooved triple junctions of grain boundaries that arise from thermal etching or from internal triple junctions (e.g. Rohrer et al. 2004; Rohrer 2011b).

The isotropic model together with melt fraction for the description of such solid–liquid systems is still a common procedure, despite the clear advantage of the description using contiguity as introduced by Takei (1998):

Contiguity is defined as the ratio between the length of solid–solid interfaces \(L_{\mathrm{{ss}}}\) and the total grain boundary length. The factor 2 is a result of the two surfaces that form the grain boundary. Note that the contiguity for anisotropic materials is a tensor which is by definition symmetric: \(\varphi _{ij}\) = \(\varphi _{ij}\) (Takei 1998). Contiguity (the contact area) can also be expressed as wetness, which is the inverse: \(\psi =1-\varphi\).

Most early studies used relatively low resolution to measure the dihedral angle. However, the resolution is critical because thin layers on grain boundaries contribute a lot to wetness but little to melt total fraction. For the system of olivine with a basaltic melt, dihedral angles between in the range of 20\(^{\circ }\)–50\(^{\circ }\) have been measured with light and low-resolution SEM microscopy (von Bargen and Waff 1986; Beeman and Kohlstedt 1993; Hirth and Kohlstedt 1995). At low resolution, the grain boundary wetness is underestimated. High-resolution studies by scanning electron microscopy and TEM yield lower dihedral angle values of about 10\(^{\circ }\) (e.g. Cmíral et al. 1998; Faul and Scott 2006).

In situ observations on analogue materials (Walte et al. 2003, 2005, 2011) show that ’non-equilibrium’ wetted grain boundaries are a consequence of steady-state grain growth (Walte et al. 2003, 2005, 2011). Layers on grain boundaries in olivine partial melts have been observed on 2-D images for example by (Faul et al. 1994; Faul and Fitz Gerald 1999; Mu and Faul 2016) and were confirmed by (Garapic et al. 2013) to represented wetted grain boundaries by serial sectioning. Implications of a more complex melt distribution characterised by contiguity, with implications for rheology (Mu and Faul 2016), and seismic velocity and electrical conductivity, are summarised in review by Takei (2017). The observed complex melt distribution relative to the predictions of the simple isotropic model shows that not all grain boundaries are equal, establishing the need to characterise the different grain boundaries and their distribution.

Grain growth

Grain growth is a result of Gibbs-free energy (\(\Delta G\)) minimisation of the total system where interfacial energies are included (e.g. Burke and Turnbull 1952; Rollett and Rohrer 2017). A brief review is given by Rollett et al. (2004) who notes that ’the challenge is to establish a reliable structure–property relationship that includes all the relevant parameters such as temperature, composition and crystallographic type.’ The main conclusion of this short review is, however, that ’simple models of grain boundary mobility do not provide an adequate description of the phenomenon.’ This results in a continuous flow of studies on grain growth with the objective to describe both the coarsening rate and the grain size distribution with mathematical functions.

Full mathematically simulation of grain growth including the contribution of the interfacial energy reduction to the minimisation of the total Gibbs-free energy of the system is available in multi-phase field models, reviewed by Steinbach (2009). In these and other models, the individual energy contributions can be incorporated—still anisotropy is only very seldom included (e.g. level-set method, Ghanbarzadeh et al. 2014). Many experimental studies have empirically determined the parameters for olivine grain growth under static conditions. Different factors were investigated: water (Karato 1989; Ohuchi and Nakamura 2007), oxygen fugacity (Nichols and Mackwell 1991), melt (Cabane et al. 2005; Faul and Scott 2006) and secondary phases, e.g. pores (Karato 1989; Nichols and Mackwell 1991), secondary phases such as orthopyroxenes (Hiraga et al. 2010; Tasaka et al. 2013) and clinopyroxenes (Ohuchi and Nakamura 2007) and cation exchange (Ohuchi et al. 2010).

Abnormal grain growth can have different causes, but there must always be an energy or mobility advantage of the abnormally growing grain. Energy advantages can consist of a greater driving force for growth, for example through stored elastic or plastic strain energy, but also a lower surface energy causes faster growth. Mobility advantages mean that the abnormally growing grain has interfaces that are more mobile. This can be caused by an intrinsic structure of the grain boundary or by extrinsic solutes (incompatible elements) or particles on the grain boundary (e.g. chemical segregation, or particles, e.g. Fig. 12). Abnormal growth occurs only when the growth advantage can persist while the grain grows into its neighbouring grains. Abnormal grain growth appears to be very rare; it is still observed in natural olivine aggregates (e.g. Drury and Urai 1990; Drury 2005; Heilbronner and Tullis 2006), in highly deformed aggregates during recrystallisation in both ceramics (Rollett 2004) and olivine Boneh et al. (2017). In the latter case, it is taken responsible for orientation and magnitude of crystallographic preferred orientation and may influence the distribution and magnitudes of seismic wave velocities and anisotropies.

Rheology

Viscous regime

Convection in the Earth causes continuous, grain-scale deformation. Constitutive models for grain scale deformation can be derived for diffusion creep, where diffusion occurs either through the grain interior (Nabarro–Herring creep) or along grain boundaries (Cobble creep), and dislocation creep which includes glide and climb (e.g. Poirier 1985). Experimentally the two mechanisms are distinguished by (a) grain size dependence and linear stress dependence of diffusion creep, and (b) grain size independence and a power-law stress dependence of dislocation creep. Dislocation accommodated grain boundary sliding is grain size dependent but has a non-linear stress dependence (Hansen et al. 2011, 2012a).

Dislocation creep leads to grain size reduction through recrystallisation (accumulation of dislocations in subgrain boundaries, followed by rotation) where the recrystallised grain size is stress dependent (Karato et al. 1980; Van der Wal et al. 1993). Glide of dislocations includes a rotational component and consequent alignment of crystalline grains to produce crystallographic preferred orientation (CPO).

The rheology of partially molten rocks was investigated both experimentally Hirth and Kohlstedt (e.g. 1995, 2000, 2007) and by modeling (e.g. Takei and Holtzman 2009b). Currently constitutive laws of deformation including grain boundary processes are phenomenological with parameters that are not directly linked to atomic scale quantities. Obtaining models that expand pure diffusion mechanisms to include grain boundary mechanisms (e.g. Ashby et al. 1970; Raj and Ashby 1971; Ashby 1972; Langdon 2006) is a current goal of research (e.g. Cordier et al. 2014; Sun et al. 2016).

In diffusion creep, grain boundary sliding is a major strain producing mechanism necessary to explain equiaxed grain shapes even after large strains [superplasticity, Miyazaki et al. (2013)]. To explain power-law creep that is grain size dependent, similarly grain boundary sliding is invoked (e.g. Hirth and Kohlstedt 2003). Grain boundary mechanisms can relax the von Mises criterion (the need for five independent slip systems) in dislocation creep, as can the movement of grain boundaries, maybe facilitated by grain boundary disclinations (Cordier et al. 2014; Sun et al. 2016). In the case where grain boundary properties are strongly anisotropic, grain boundary mechanisms should allow energetically favourable interfaces to orient themselves to minimise the total viscosity of the aggregate (Maruyama and Hiraga 2017a, b). Grain boundary deformation mechanisms are sensitive to the grain boundary structure (Cahn et al. 2006), and consequently also to the grain boundary viscosity (Maruyama and Hiraga 2017a, b). Grain boundary structure in this context includes the roughness of the boundary, i.e. steps/facetts as mentioned in section “Grain boundary energy, structure and width”.

Anelastic regime

While large strain deformation changes the grain scale microstructure, the microstrains due to the propagation of seismic waves interrogate the grain boundary properties without changing the microstructure. The model of accommodation of microstrains due to grain boundary sliding by Raj and Ashby (1971) includes two sequential processes: first, sliding of grain boundaries accommodated by elastic strain at grain corners or steps on grain boundaries. Due to the high elastic moduli, the resulting strains are very small, particularly for small grain sizes.

Second, after the maximum sliding due to elastic accommodation has taken place, the resulting stress concentration at grain corners will drive diffusion, which leads to a redistribution of stresses along grain boundaries towards the state of stress for macroscopic diffusion creep. This transient redistribution of stresses was termed diffusionally assisted grain boundary sliding by Morris and Jackson (2009) to distinguish it from macroscopic diffusionally accommodated grain boundary sliding.

Elastically accommodated grain boundary sliding and diffusionally assisted grain boundary sliding are both anelastic processes as the strain is recovered with a time delay on removal of the applied stress. Again grain boundary sliding is not directly observed in the experiments but inferred from the observed grain size dependence. An implicit assumption in the Raj–Ashby model is that grain boundaries are substantially weaker than grain interiors, consistent with the much higher grain boundary diffusivity. Diffusionally assisted grain boundary sliding is inferred to account for the attenuation observed in torsional forced oscillations tests (Tan et al. 1997, 2001; Gribb and Cooper 1998; Jackson et al. 2002), see the review by Faul and Jackson (2015). Grain boundary viscosities derived from small strain experiments in the anelastic regime are more than 5 orders of magnitude lower than steady-state viscosities measured in diffusion creep (Faul et al. 2004).

Methods

Which sample type or preparation method is most appropriate for experimental studies has been debated for decades and regularly culminates in strong dissent between different research groups. The question is how a sample should be best prepared to best simulate natural samples, while having small grain sizes, mosaic (foam) texture, indicative of steady state grain growth, often referred to as equilibrium texture (technically wrong, but descriptive for the sluggish grain coarsening) and controlled impurities. Depending on the question to be addressed, the different samples preparation methods all have their advantages and disadvantages. Natural samples are too coarse-grained; the presumably representative composition led to samples that are reconstituted from ground and hand-sorted grains to have both small grain sizes and natural composition. The compositional range is variable depending on the source materials and quality of sorting. The grinding may cause the introduction of dislocations. It is often critically commented that reconstituted samples may not reach micro-structural “equilibrium” before the actual experiments are performed (e.g. Mcdonnell and Spiers 2002; Sano et al. 2006; Koizumi et al. 2010). Sol–gel samples (e.g. Edgar 1973; Jackson et al. 2002) and vacuum sintered samples (e.g. Koizumi et al. 2010) can result in very fine-grained and micro-structurally “equilibrated” samples. However, the applicability of experimental observations on iron-free systems to natural systems is highly debated, since diffusion mechanisms differ strongly in the iron-free and iron-bearing systems (Chakraborty et al. 1994; Chakraborty 1997; Petry et al. 2004). While vacuum sintered samples are still iron free, sol–gel samples with and without iron and representative trace element impurities (e.g. Faul et al. 2016) have been prepared. Note that Chakraborty (1997) concluded that the iron-related point defect-dependent diffusion mechanism, at constant P, T, \(f_{\mathrm{{O}}_{2}}\) and \(a_{\mathrm{{Si}}}\) is dominating over all trace-element-related point defect diffusion mechanisms. Therefore, the sole presence of representative amounts of iron and defined P, T, \(f_{\mathrm{{O}}_{2}}\) and \(a_{\mathrm{{Si}}}\) might suffice to simulate natural diffusion-related processes. Nevertheless, studying the effect of iron and individual trace elements simplifying the final interpretation is necessary to prove this assumption. Finally, for the study of grain boundaries bicrystals can be synthesised, where the interface has the orientation of choice (e.g. Heinemann et al. 2005; Hartmann et al. 2010; Marquardt et al. 2011c, d). In the following, we examined different samples of different preparation origin to compare the grain boundaries at the nm-scale using transmission electron microscopy.

Reconstituted rocks (RR) Samples for deformation or attenuation experiments are produced by selecting olivine crystals of several mm in size that are as inclusion-free as possible. These crystals are then crushed and sorted by size before being cold pressed to 200 MPa and hot pressed in a cylindrical shape for deformation. Typical sample sizes of 10–11.5 mm in diameter and 20–30 mm in length require substantial amounts of starting material. Even careful hand-picking of the original grains as well as of the crushed fragments under a binocular microscope typically does not reliably remove all incorporated other phases. The resulting sample aggregates contain variable amounts of melt at high temperatures (\(\sim\)1250 \(^{\circ }\)C) and low pressure ranging from 0.01 wt.% or less (Tan et al. 2001; Faul et al. 2004) to \(\sim\) 1 wt.% (Karato et al. 1986; Hirth and Kohlstedt 1995; Mei and Kohlstedt 2000).

Solution gelation derived samples (SG) Fully synthetic samples are produced from reagent grade nitrites and ethanol solutions, which are reacted and fired to produce fine-grained starting materials (Jackson et al. 2002, 2004). These materials are consistently melt free at the TEM scale (Faul et al. 2004). The deformation experiments discussed below were conducted in a Paterson gas-medium apparatus at 300 MPa confining pressure. The experimental procedures are detailed in Faul and Jackson (2007). Sample 1623 contains 396 ppm Ti/Si, 780 ppm H/Si, and has an average grain size of 21 \(\upmu\)m.

Vacuum sintered samples (VS) Nano-sized powders of colloidal SiO\(_{2}\) and highly dispersed Mg(OH)\(_{2}\) with particle size of less than 50 nm were used as chemical sources for MgO and SiO\(_{2}\). They were cold-pressed and vacuum sintered to obtain highly dense and fine-grained polycrystalline samples (Koizumi et al. 2010), the transmission electron microscope study was performed on one of the samples from a different study (Fei et al. 2016) and more details are available in this study.

Wafer bonded bicrystals One sample was produced using the wafer bonding method (Heinemann et al. 2001, 2003, 2005; Hartmann et al. 2010; Marquardt et al. 2011c, d), where two epi-polishe forsterite surfaces saturated with pure adsorbed water are brought into contact without force. Additional annealing establishes atomic bonds across the interface. The forsterite was grown at the institute for crystal synthesis (IKZ-Institut für Krizstallzüchtung Berlin) using the Czochralski method (Czochralski 1918). Here, we produced a 60\(^{\circ }\) [100]/(011) grain boundary.

Analysis

Generally, all samples were investigated with a combination of methods ranging from light microscopy, microprobe wavelength dispersive spectroscopy (WDS) and energy dispersive spectroscopy (EDS) in both scanning electron microscopy (SEM) and transmission electron microscopy (TEM).

Prior to EBSD measurements, the studied samples were chemo-mechanically polished for 2–8 h using an alkaline solution of colloidal silica on a soft substrate. The crystallographic orientation measurements were carried out on 3–6 nm carbon-coated samples using automated indexing routines commercially available. EBSD analyses were conducted using an FEI Scios FEG dual beam machine at Bayerisches Geoinstitute. The system is equipped with an EDAX-TSL Digiview IV EBSD detector and the OIM software incorporated in the TEAM 8 user interface. Simultaneous acquisition of energy dispersive X-ray spectra for each orientation measurement point allowed to exclude pyroxene from the indexing routine, because we only analysed the olivine GBCD form these data. We simply excluded all data points where the Si to Mg ratio was closer to 1:1 than 1:2. Our mappings where conducted at accelerating voltage of 20 kV, beam current of 3.2 nA and working distance of 10–14 mm. We used step sizes of at least 1/10th of the grain size, thus varying from 0.2 to 1 μm using a hexagonal mapping grid. Olivine was indexed in space group Pbnm using the lattice constants a = 4.762 \(\AA\), b = 10.225 \(\AA\), and c = 5.994 \(\AA\).

Data treatment From EBSD maps, we reconstructed the grain boundaries using the OIM analyses 8. Grains were defined with a minimum disorientation of 3\(^{\circ }\), and this fixes the lower limit for the smallest grain boundary disorientation. We did two runs exporting the grain boundary segments, once including the low angle grain boundaries (3-20\(^{\circ }\) disorientation), once we only considered grain boundaries with disorientations larger than 20\(^{\circ }\). This follows the observation that individual dislocations can be distinguished for disorientation angles as large a 20\(^{\circ }\) (Heinemann et al. 2005), which defines the transition from low- to high-angle grain boundaries.

The quality of the indexing of the Kikuchi patterns is expressed as confidence index (CI) ranging from 0 to 1, where values above 0.2 are sufficient for correct indexing. Our CI values were generally higher than 0.2. Generally, we obtained maps with very high indexing fractions (\(\sim\)95\(\%\) of the pixels), and little misindexing. We performed a clean-up procedure to remove unindexed and misindexed pixels: First, we applied a correction for pseudo-symmetry, e.g. 60\(^{\circ }\) about [100]. Furthermore, we dilated grains to absorb points not belonging to any grain (defined as a minimum of 2 neighbouring points with the same orientation within 3\(^{\circ }\)) which frequently occur along grain boundaries where two Kikuchi pattern overlap. For pixels at boundaries, the isolated point becomes part of the grain that surrounds the majority of the point; if two grains surround the individual points equally, the point becomes part of the grain with the highest average CI. The absorbed point takes orientation and CI of the neighbouring grain with highest CI. Dilatation was set to result in a minimum of 3 rows of a minimum of 3 pixels each, which did not affect the average grain size determined before and after this procedure. Note, that the grains considered for further analyses were chosen to have a minimum size of 25 pixels over at least three rows. The grain boundary traces are reconstructed into segments. Triple junctions are identified and a straight line is drawn between them. The segments are dissected into shorter segments. The tolerance between the reconstructed line and the actual grain boundary is less than twice the step size used for mapping, a schematic explanation is given by others (Edax OIM analyses 8 manual). Subsequently, the exported grain boundary line segments were evaluated using the scripts developed at the Carnegie Mellon University, Pittsburgh (Rohrer et al. 2004).

Electron microprobe analyses (EMPA) Microprobe analyses were performed at the MIT Electron Microprobe Facility on the JEOL-JXA-8200 with 15 kV acceleration potential and a beam current of 10 nA and a beam diameter of \(\sim\) 1 \(\upmu\)m. Counting times were 20–40 s per element, resulting in counting precisions of 0.5–1.0 \(\%\) 1-\(\sigma\) standard deviations. The raw data were corrected for matrix effects with the CITZAF program (Armstrong 1995).

Transmission electron microscopy (TEM) TEM samples were prepared by conventional Ar-ion milling using a a Gatan PIPS II or using focused ion beam side specific sample preparion (e.g. Wirth 2004; Marquardt and Marquardt 2012). TEM investigations were performed with an FEI TitanTM G2 80–200 microscope at Bayerisches Geoinstitut Bayreuth, using conventional TEM, high resolution (HR)-TEM as well as scanning (S)-TEM modes. The microscope was operated at an acceleration voltage of 200 kV with an electron beam generated by an extreme brightness field emission gun (X-FEG) Schottky electron source. The point resolution is 0.24. The TEM is equipped with a post-column Gatan imaging filter (GIF QuantumRSE). Analytical TEM was performed in STEM. The probe size after careful optimisation is 160 pm, and the final image resolution in STEM results from pixel size and probe size. The signal is acquired using a high angle annular dark field detector (HAADF), with the camera length optimised to yield Z-contrast. Energy dispersive X-ray spectra were acquired using a windowless SuperX-EDS detector with 4 Si-drift detectors (SDDs) inclined towards the sample in a superimposed circle, resulting in 0.7 srad solid angle for collection. This configuration allows acquisition of high numbers of X-rays and facilitates to obtain reliable peak to background ratios, thus overcoming previous difficulties. The EDS analyses are point analyses, smart line profiles (Sader et al. 2010; Marquardt et al. 2011d), a method largely comparable to the elliptical beam analyses of previous studies (e.g. Drury and Fitz Gerald 1996). The area measured is usually wider than the grain boundary region, so that the resulting analysis is a mixture of grain boundary and grain interior volumes. This means that the absolute compositions of the grain boundaries can only be obtained through lengthly extrapolations by measurements with different beam sizes and extrapolating down to the width of the grain boundary. As the current paper is a compilation of previous results and aims at a qualitative summary extended with new data, we refrain from quantitative analyses. The map in Fig. 14, the area of interest, was scanned for 2 h continuously; the spectra at each pixel are summed. Each pixel has a size of 4 nm.

High resolution transmission electron microscopy (HRTEM) To image the structural width of a grain boundary using HRTEM, the grain boundary has to be parallel to the electron beam (edge-on condition). This condition can be tested using the appearance of fresnel fringes when bringing the sample in an out of the minimum contrast condition. Note that delocalisation is more pronounced for large reciprocal space vectors (i.e. small lattice spacing). Dark or bright fresnel fringes appear on both sides of the grain boundary at the same distance when changing the defocus; however, if the grain boundary is not edge-on the fresnel fringes will have different gray values on either side of the interface and may also have different widths and distances from the interface (Fig. 4). It was previously pointed out (Hiraga et al. 2002) that a grooved surface, even in the absence of a glass film, can produce Fresnel fringes with contrast stronger than that produced by a glass film at a grain boundary (Rasmussen et al. 1989). Thus, the Fresnel fringe method is not the best to determine whether or not an amorphous film is present, but assuming that such grooves are relatively symmetric they are still suitable to test the inclination of the interface. The defocus is chosen to lie between Scherzer (for maximum resolution) and 0 to minimise delocalisation (Williams and Carter 2009; Fultz 2001). This is the optimal focus for direct image interpretation for uncorrected transmission electron microcopy to image interfaces.

Lattice planes can only be resolved by high-resolution transmission electron microscopy (HREM) if they are close to fulfil the Bragg criterion and thus waves interact constructively. The contrast can be interpreted directly up to the point resolution of the microscope. Interpretation of higher frequencies requires image simulation and exits wave reconstruction (e.g. Fultz 2001; Williams and Carter 2009; Marquardt et al. 2011d).

High-resolution TEM images of grain boundary that changes inclination with respect to the incident electron beam. The fresnel fringes vary in intensity and gray scale where the grain boundary plane is strongly inclined with respect to the incidence beam direction. The Fresnel fringes change width at a less inclined areas of the interface

To use the resolution of the microscope to its point resolution while minimising delocalisation, we used a virtual aperture of \(\sim 3.33\) nm\(^{-1}\) by post-processing to remove frequencies that result in delocalisation greater than 0.9 nm. To observe lattice planes on both sides of a grain boundary and simultaneously have the grain boundary plane parallel to the beam, the grain boundary must be oriented in a relatively low index zone common to both crystals; this is a relatively rare condition that is not met for the vast majority of grain boundaries. The orientation requirement for the grain boundary plane is quite stringent: Vaughan et al. (1982) pointed out that in order to resolve a 1 nm wide layer, the grain boundary has to be oriented with an accuracy of better than 2\(^{\circ }\) for a 30 nm thick TEM foil. Therefore, several authors previously gave direct recipes on how to acquire best HRTEM images of interfaces Clarke (1979a); Vaughan et al. (1982); Hiraga et al. (2002). In short, they contain the following steps:

-

1.

Find a thin grain boundary in good orientation to fulfil the above-mentioned criteria.

-

2.

Correct astigmatism of the condenser and objective lenses close to the region of interest.

-

3.

The chosen diffracted beams of both crystals must be accurately centred in the objective aperture and remain on the optical axis of the microscope; you may follow the illustrated examples given in Vaughan et al. (1982).

-

4.

Allow the frequencies necessary for imaging to pass through the aperture, preferably up to the inverse of point resolution for uncorrected microscopes. The optimum can be calculated using equation 28.72 in Williams and Carter (2009).

-

5.

Acquire a through-focus series to subsequently choose the image with the optimum defocus conditions.

Note, if a sample allows for acquisition of HRTEM images at different defocus values, and thus reconstruction of the exit-wave is possible, phase images with minimised delocalisation can be calculated. Alternatively, spherical aberration (Cs)-corrected microscopy allows acquisition of images that are nearly free of delocalisation. Other STEM-based methods to retrieve the thickness and orientation of interfacial layers have been proposed (Koch et al. 2006; Kiss et al. 2016). If beam damage is not an issue, these have significant advantages, for example that they result in little delocalisation.

Deformation experiments were conducted in a Paterson-type gas-medium apparatus (Paterson 1990). The samples were tri-axially compressed at a confining pressure of 300 MPa. The temperature was controlled using a Eurotherm controller and a type R Pt-Rh thermocouple. The load cell was calibrated and for jacket corrections samples of mild steel were deformed that have similar composition as the here-used mild steel jackets. More details are described in Faul and Jackson (2007).

Results

GBCD of sol–gel derived Fo\(_{90}\)

The full five parameter grain boundary character for the sol–gel derived Fo\(_{90}\) sample, with less than 2 vol.% of pyroxene, was determined using EBSD mapping and stereological analyses of over 200.000 grain boundary segments. The most important observations of the sample are summarised in Fig. 5a–d. In Fig. 5a, the disorientation distribution as a function of the total measured grain boundary length is displayed. The measured disorientations between adjacent crystals are plotted in red and compared to the calculated Mackenzie distribution for randomly oriented orthorhombic crystals in blue (Mackenzie 1958). Our sample shows perfect agreement with the calculated random distribution and orientation distribution functions yield no LPO. In Fig. 5b, the axes angle distribution, e.g. three independent parameters for each grain boundary, is displayed. All axes of rotation for the disorientation angles 10\(^{\circ }\), 60\(^{\circ }\), 90\(^{\circ }\) and 110\(^{\circ }\) are displayed. No marked preference for any specific axis of disorientations is observed for 10\(^{\circ }\), 90\(^{\circ }\) and 110\(^{\circ }\) disorientations; only 60\(^{\circ }\) disorientations show a preference of being rotated around the [100] axis, similar to previous observations (Faul and Fitz Gerald 1999; Marquardt et al. 2015). This is after correcting for all pseudo-symmetric misindexing.

Grain boundary planes dominating the interfacial network are displayed in Fig. 5c. Grain boundaries close to perpendicular to the c-axis dominate the distribution, with a maximum near (012)-planes. Generally, the grain boundary planes show a preference for planes along the edge [001] to [010] of the standard triangle for orthorhombic crystal systems. Therefore, (0kl)-type planes make up the largest portion of the surface area of olivine crystalls in this polycrystal. The planes most frequently brought into contact by a 60\(^{\circ }\) rotation about the [100]-direction are displayed in Fig. 5d. In agreement with the high occurrence of (0kl)-type boundaries, this specific axis angle pair favourably involves planes of (0kl)-type.

Different representations of information about grain boundaries in sol–gel derived Fo\(_{90}\), all from the same data. a Single parameter disorientation distribution in red, each grain boundary is reduced to its minimum disorientation angle, disregarding its disorientation axis. The random distribution is shown in blue for comparison. b Three independent parameters for each boundary are given in the axis angle representation of the disorientation. Two parameters for the axis direction and one for the rotation angle. Each point in 3D space represents one grain boundaries that is distinct from the next. In each of the layers of the axis angle space, all possible axis are presented. Each layer corresponds to a different rotation angle which varies at non-constant intervals along the vertical direction. Note that there are only very slight preferences for specific rotation about specific angles. The 60\(^{\circ }\) rotations mostly occur around the [100] and 10–20\(^{\circ }\) rotations have a preference for [100] and/or [210]. It should be noted that only a very small fraction of all grain boundaries of this sample are low angle grain boundaries; consequently, the statistical relevance of the information obtained for this range is limited. c, d Poles to planes plotted in a stereological projection in the crystal reference frame. c Grain boundary plane distribution irrespective of disorientation. It yields an approximate average crystal habit. d For any particular axis angle combinations, a specific grain boundary plane distribution exists; here, it is shown for 60\(^{\circ }\) about the [100] direction. We chose to display only planes in 60\(^{\circ }\) about the [100], because only planes with this specific disorientation angle show a significant preference for a specific axis of rotation. The color code in the stereographic plots gives values in multiples of random distribution (MRD) and the respective area \(\%\)

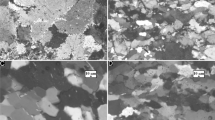

Direct micrographs of grain boundaries

To obtain the most representative information about variable grain boundary structures, grain boundaries were chosen arbitrarily (with the only criterion of being at the thinnest areas of the TEM-lamellae). The grain boundary was oriented parallel to the beam and subsequently rotated about the axis perpendicular to the grain boundary until lattice fringes could be observed. This procedure often results in images where lattice fringes with frequencies (d-spacings) that do not suffer from delocalisation are visible only in one of the grains, as most of the time the second grain is in an orientation where none of the planes with large d-spacings is parallel to the beam (Figs. 6d, 7, 8a, b). The width of the grain boundary region in the resulting images ranges up to 1 nm. In some micrographs, the grain boundary region does not display any lattice fringes and appears amorphous. These grain boundary images are subsequently called ’amorphous’ type. The imaged width of ’amorphous’ appearing grain boundaries is independent of sample type (i.e. synthetic Fo\(_{100}\), Fig. 6d, synthetic Fo\(_{90}\), Fig. 8a, or San Carlos derived reconstituted rocks, Fig. 8c). The presence of melt in a sample similarly does not influence the width of the grain boundary region of non-wetted grain boundaries in the micrographs (Fig. 8b). Similar images were also published Faul et al. (2004) from sol–gel samples with added melt and Mei and Kohlstedt (2000) from experimental samples with olivine of natural origin.

HRTEM micrograph of vacuum sintered Fo\(_{100}\) from the Hiraga Lab. The grain boundary is parallel to the incident beam; lattice fringes are obtained for both crystals. a The contrast changes along the grain boundary with increasing sample thickness towards the bottom of the image. Frequencies corresponding to d-spacings of less than 0.24 nm are removed using a Fourier filter, because they suffer from delocalisation. The original images are displayed in Fig. 18 of the “Appendix”. This procedure is analogous to placing an objective aperture in the back focal plane of the objective lens. In b and c, the lattice planes of the adjacent crystal lattices are in ’contact’. In c, a facet at the centre of the micrograph results in a double line along the interface. The region between the fresnel fringes in d might appear amorphous if a too large aperture was used. HRTEM micrographs of Fei et al. (2016) stem from the same sample

HRTEM micrograph of a vacuum sintered sample. The grain boundary is parallel to the incident beam; lattice fringes are obtained for both crystals, even though those on the left crystal have such small d-spacings that they are nearly not resolved anymore. The right grain has relatively large d-spacings. In the upper part of the micrograph, the grain boundary thus appears very smooth

Figure 7 shows a straight grain boundary with varying grain boundary outline from top, with a smooth grain boundary, to bottom, with a stepped/facetted appearance. Note that the right grain has relatively large d-spacings, which generates the impression of steps at the interface. This impression is, however, misleading, because other crystallographic planes, less easily identified by eye because of there smaller d-spacing are continuous and more parallel to the grain boundary. In the upper part of the micrograph, where these d-spacings are better visible the grain boundary appears very smooth.

High resolution TEM images of grain boundaries in polycrystalline olivine aggregates. The width of the grain boundaries (oriented parallel to the electron beam) is about 1 nm for all samples (note that the scale of the each image is different). a Melt-free sol–gel sample 6381 with lattice fringes resolved in the left grain (Jackson et al. (2002)). b Melt-added sol–gel sample 6384 with lattice fringes resolved in the left grain (Faul et al. (2004)). c San Carlos olivine sample 6261 with a melt content < 0.01% (Tan et al. (2001); Jackson et al. (2002))

Figure 8 shows a compilation of previous micrographs published as indicated in the figure caption. The two melt-free grain boundaries in Fig. 8a, b appear similar even though the former is from a melt-free sol–gel sample, while the latter is from a melt-added sol–gel sample. Therefore, the images by themselves provide no indication of the provenance or state (melt vs. no melt) of the sample.

In contrast, Figs. 6b, c, 9, 10a show directly abutting lattice planes for both olivine grain boundaries and olivine enstatite phase boundaries, where similar micrographs were also published in Vaughan et al. (1982); Hiraga et al. (2002), subsequently called ’crystalline’. Note that both appearances of grain boundaries micrographs can be obtained from the same grain boundary as shown in Fig. 6. In 6b and c, the grain boundary appears ’crystalline’, while in Fig. 6d it appears ’amorphous’. The different appearance is a consequence of contrast that depends on defocus setting and sample thickness. Note that the ’crystalline’ interpretation is more appropriate, as ’amorphous’ is observed in sample regions more easily biased by imaging artefacts (e.g. thicker sample). Note that the grain boundary displayed in Fig. 6 is mostly straight, except for Fig. 6c where a facet is observed, that causes the boundary to appear as a double fringe in the centre of the micrograph.

The grain boundary planes in the synthetic forsterite bicrystal of Fig. 9 are the (011) planes with respect to both adjacent crystals. The planes are brought into contact by a 60.8\(^{\circ }\) rotation about the common [100] axis. The here-imaged grain boundary is facetted on the nm-scale. Two inclined areas are visible. The structural width of the grain boundary at places oriented parallel to the electron beam is less than 1 nm. The adjacent crystal planes are in direct contact.

HRTEM micrograph of the synthetic forsterite bicrystal; the grain boundary plane is the (011) with respect to both adjacent crystals. The grain boundary was traced in transparent white and the inclined facets are indicated by shaded regions—the traces were then shifted with respect to the grain boundary to allow the reader to have a better view of the structure. The structural width of the grain boundary is less than 1 nm, the boundary appears “crystaline”. The adjacent crystal planes are in direct contact

HRTEM micrograph at slightly different positions along the wedge-shaped sol–gel sample 6793, see Table 1. The changing sample thicknesses influence which lattice planes are more apparent in the image. The inset in a is a selected area diffraction (SAD) pattern of the olivine. In centre of the micrograph, c a small dark area is visible. Generally, the lattice fringes of enstatite (bottom) and olivine (top) are in direct contact. No amorphous layer is observed

Scanning transmission electron micrographs of an olivine grain boundary and two olivine–enstatite phase boundaries. Sol–gel sample 6793, see Table 1. a BF, b DF, c HAADF. d schematic of the phase assemblage; ol-ol-grain boundary, orange; ol-en-interphase boundary, blue-gray; enstatite in green with twin lamellae; olivine, colourless