Abstract

The use of yeasts in bioprocesses can be considered one of the most relevant strategies in industrial biotechnology, and their potential is recognized due to the ability of these microorganisms for production of diverse value-added compounds. Yeasts from Ustilaginaceae family have been highlighted in the last years as a promising source of industrial interesting compounds, including enzymes, sugars, lipids, organic acids, and biosurfactants. These compounds may exhibit various applications in pharmaceutical, cosmetic, food, medical, and environmental fields, increasing the scientific attention in the study of ustilaginomycetous for biotechnological purposes. In this mini-review, we provide a comprehensive overview about the biotechnological use of yeasts from Ustilaginaceae family to produce value-added compounds, focusing in recent trends, characteristics of processes currently developed, new opportunities, and potential applications.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Yeasts can be considered the major producers of natural compounds through fermentative processes, and the importance of basidiomycetous and ascomycetous yeasts in industrial production of value-added metabolites has been extensively revised in last years (Johnson 2013a; Johnson 2013b; Azhar et al. 2017). The historical and modern role of yeasts in production of food ingredients (amino acids, pigments, enzymes, flavors), beverages (beer, wine, sake, cachaça), heterologous proteins (hormones, vaccines), and other compounds showed that these microorganisms are economically suitable and offer wide range of potential applications for industrial exploration (Mannazzu et al. 2015; Demain and Martens 2016; Basso et al. 2016; Portugal et al. 2017; Johnson 2013b)

Ustilaginaceae is a family belonging to Ustilaginomycotina subphylum (Basidiomycota, fungi) that comprises several species of smut fungi and may exhibit various morphological characteristics. These microorganisms are mostly dimorphic and present a yeast stage during part of their life cycle, which can comprise unicellular budding cells as well as cultures that might produce hyphae (Begerow et al. 2014; Wang et al. 2015).

Nowadays, researchers have been proposing a taxonomic review of this group based on phylogenetic and multiple gene sequence analysis, resulting on reclassification of some species and description of new genus and classes (Wang et al. 2014; Wang et al. 2015). For example, the strain formerly described as Pseudozyma brasiliensis and known by endoxylanase production characteristics was renamed as Kalmonozyma brasiliensis (Oliveira et al. 2014; Wang et al. 2015). Similarly, the reclassification of the biosurfactant producer Pseudozyma churashimaensis to Dirkmeia churashimaensis was recently suggested (Morita et al. 2011a; Wang et al. 2015). In the case of some species with uncertain phylogenetic positions, it is proposed to use the term pro tempore or pro tem. in abbreviation until its definitive taxonomic classification (Wang et al. 2015).

Ustilaginomycetous yeasts are recognized in agricultural field due to its plant pathogenicity, causing economic losses by damaging important crops, including wheat, maize, barley, oats, sorghum, and sugarcane (Geiser et al. 2014; Matei and Doehlemann 2016). Among all species, Ustilago sp. is the most studied considering that the infection leads to development of large tumors in plant cells and also contamination of edible crops with mycotoxins (Jasso-Robles et al. 2016; Abbas et al. 2017).

Despite these safety concerns on pathogenicity and product spoilage, a wide range of value-added bio-products of commercial interest can be produced by Ustilaginaceae species, including organic acids (L-malic, succinic, itatartaric, itaconic, and 2-hydroxyparaconic acids), polyols (erythritol and mannitol), oligosaccharides, squalene, enzymes (CAZymes, lipases, aminopeptidases), and biosurfactants (mannosylerythritol lipids and ustilagic acid) (Fig. 1) (Feldbrügge et al. 2013; Guevarra and Tabuchi 1990a; Zambanini et al. 2017a; Jeya et al. 2009; Fai et al. 2015a; Chang et al. 2008; Oliveira et al. 2013; Kaupert Neto et al. 2016; Morita et al. 2011b). From innovation point of view, there are patents about the application of ustilaginomycetous yeasts on the most diverse fields, for example, the use of P. aphidis and P. fusiformata as biocontrol agent against several plant pathogens, including Botrytis cinerea, Penicillium digitatum, Alternaria brassicicola, Uromyces appendiculatus, Leveillula taurica, and Sclerotinia sclerotiorum, inhibiting the growth of pathogens and aiding in the preservation of fruits, such as tomato (Levy and Gafni 2011; Zhang et al. 2014). Previously, a patent disclosed the use of a P. rugulosa strain as decolorizing dye agent and suggested its potential use in waste water treatment (Wen 2005). In addition, biotechnological processes for production of erythritol, lipids, enzymes, itaconic acid, and biosurfactants were patented using ustilaginomycetous species such as P. tsukubaensis, P. pruni, P. antarctica, and P. aphidis, respectively (Cho et al. 2002; Leu and Yen 2013; Kitamoto et al. 2011; Kuo et al. 2009; Chen et al. 2015).

Traditional genetic tools and new methods to obtain engineered strains are some of the approaches that are increasing the viability of using yeasts in industrial processes. The aim of these studies is the production of complex compounds from simple, readily available, and inexpensive materials, mainly for production of fuels, chemicals, and pharmaceuticals (Jakočiūnas et al. 2015; Rasool et al. 2016). Nowadays, the genome editing method of clustered regularly interspaced short palindromic repeat, RNA-guided Cas9 nucleases (CRISPR/Cas9) proved to be advantageous compared to the time-consuming sequential transformation steps and has been used in studies for genetic engineering of Saccharomyces cerevisiae (Jakočiūnas et al. 2015).

Regarding ustilaginomycetous yeasts, CRISPR/Cas9 system was already used to disrupt target genes and perform alterations in the genome of the fungal maize pathogen Ustilago maydis (Schuster et al. 2016; Schuster et al. 2017). Moreover, the production of malic acid and itaconic acid could be enhanced after the development of new genetically modified strains and adaptive laboratory evolution processes (Zambanini et al. 2016a; Zambanini et al. 2017a; Zambanini et al. 2017b).

In addition to the production of value-added compounds, the proteins produced by Ustilago sp. can also be explored for biotechnology. The secretome analysis can help to elucidate the mechanisms of plant-pathogen interactions and to identify new enzymes that can be employed for degradation of plant cell wall and lignocellulosic biomass (Mueller et al. 2008; Schuster et al. 2017; Geiser et al. 2013; Geiser et al. 2016c; Couturier et al. 2012). Some of the proteins produced by Ustilago maydis can be used in medical and pharmaceutical industries due to its biological activities (Stock et al. 2012; Terfrüchte et al. 2017).

Thus, considering the potential of these yeasts in diverse fields, in this review, we provide a solid set of information on the employment of ustilaginomycetous yeasts in biotechnological processes for production of value-added compounds, describing production process parameters, results achieved, optimization strategies, and the perspectives for industrial application.

Value-added biotechnological products from ustilaginomycetous yeasts

Enzymes

Enzymes are efficient catalysts for biochemical reactions. Most of them are highly specific, catalyzing only one reaction with a specific substrate. The applications of enzymes can be related to pharmaceutical formulas, agriculture, daily products, food additives, and bioenergy (Adrio and Demain 2014; Schäfer et al. 2007). Here, we will present the biotechnological potential of this group of ustilaginomycetous yeasts based on several recent studies about the secretion and production of diverse enzymes. However, more studies are still required prior to the effective use of these yeasts as enzyme producers in industry, mainly employing statistical and metabolic tools to improve process productivity and reduce production costs.

Carbohydrate-active enzymes

The carbohydrate-active enzymes (CAZymes) are proteins responsible for the synthesis, degradation, and modification of storage and/or structural polysaccharides (Lombard et al. 2014). They can be classified as glycoside hydrolases (GHs), polysaccharide lyases (PLs), carbohydrate esterases (CEs), auxiliary activities (AAs), and glycosyltransferases (GTs) (André et al. 2014).

In the last years, the potential of CAZymes for biofuel production has been reported, mainly from degradation of lignocellulosic materials and agricultural residues, such as sugarcane bagasse and wheat straw, for production of second generation (2G) ethanol (Clark et al. 2012; Sims et al. 2010; Gupta et al. 2016; Couturier et al. 2016). In addition, these enzymes are essential in a wide range of industrial biotechnology processes, on a variety of markets, including textiles and paper, pharmaceuticals, feed, food and beverages, and others (Schückel et al. 2016). Considering the growing number of studies related with CAZymes, the CAZy database (http://www.cazy.org), an online platform available since 1998, was created to support researchers by providing a broad information about these proteins such as its classification, amino acid sequence, three-dimensional structure, and catalytic mechanism (Lombard et al. 2014).

The production of these enzymes by fungi (Fusarium sp., Aspergillus sp., Trichoderma sp., Neurospora sp., and Penicillium sp.) and bacteria (Bacillus sp., Streptomyces sp.) are widely studied; however, examples involving basidiomycete yeasts are rare (Pessôa et al. 2017; Borin et al. 2015; Xiong et al. 2014; Peng et al. 2017; Manzo et al. 2011; Lim et al. 2014). Recently, the production of CAZymes by ustilaginomycetous yeasts has received more attention (Table 1). As it will be described below, the majority of reported enzymes are important to breakdown xylan, a polysaccharide of β-1,4-linked xylose units, the major constituent of hemicellulose of plant cell walls (Kumar and Satyanarayana 2015). Xylanase is the main enzyme responsible for the hydrolysis of internal glycosidic linkages along xylan; β-xylosidase hydrolyzes non-reducing end xylose residues from xylooligosaccharides, and α-arabinofuranosidase catalyzes the hydrolysis of terminal α-L-1,2-, α-L-1,3-, and α-L-1,5-arabinofuranosyl residues present in hemicellulosic polysaccharides (Saha 2000; Collins et al. 2005; Javier et al. 2007; Azelee et al. 2016).

One of the first studies about CAZymes in basidiomycetes described a novel yeast strain, capable of producing xylanase in high amounts, also detecting low levels of α-arabinofuranosidase and β-xylosidase activities (Bastawde et al. 1994). Moreover, Gokhale et al. (1998) showed that the supernatant of a culture broth in that the yeast was cultivated with xylan or wheat bran and was able to hydrolyze the hemicellulose fraction of different agricultural waste residues, including corn cob, jute fibers, and sugarcane bagasse pulp. This microbial producer was subsequently identified as Pseudozyma hubeiensis pro tem., and in a study perfomed by Adsul et al. (2009), two distinct xylanases were purified: PhX33, protein of 33.3 kDa with α-helix structure, and PhX20, of 20.1 kDa containing predominantly β-sheets. Recently, the enzyme responsible for the β-xylosidase activity was isolated and characterized. Mhetras et al. (2016) showed that P. hubeiensis pro tem. produces only one β-xylosidase, denominated PhXyl. The molecular weight of the enzyme was found to be 112.3 kDa, and it presented the highest β-xylosidase activity reported so far from yeast strains. PhXyl also showed low inhibition by xylose and ethanol, which suggests that this enzyme is a good option to be used in industrial processes, such as the production of 2G ethanol.

The biotechnological production of xylanases by other ustilaginomycetous strains also has been reported. In this context, Borges et al. (2014) described the production of a xylanase by Kalmonozyma brasiliensis, with molecular weight of 24 kDa and a secondary structure predominantly composed of β-sheets. It was presented that the enzyme activity was greater in cultures grown in xylan than xylose and exhibited a higher specific activity, when compared with several other eukaryotic xylanases, including those derived from filamentous fungi. To deepen into the knowledge about how K. brasiliensis secretes these enzymes and break down polysaccharides, Kaupert Neto et al. (2016) characterized, for the first time to this group, the secretome of this species grown on distinct carbon sources. In total, 20 CAZymes (13 GHs, 3 CEs, and 4 AAs) were identified. Authors showed that K. brasiliensis has the potential to hydrolyze xylan, mannan, cellobiose, and other polysaccharides; therefore, it may be the source of different enzymes with biotechnological potential.

Furthermore, Watanabe et al. (2015) showed that two strains of Moesziomyces antarcticus produced a xylanase of 33 kDa with high yield using lignocellulosic bioethanol distillery wastewater, derived from rice straw hydrolysate as substrate. These enzymes were more inducible on xylose, and this difference in relation to the xylanase from K. brasiliensis may be due to the nature of xylanase, since the xylanases characterized of M. antarcticus are from GH10 family and the K. brasiliensis from GH11. Curiously, the genome of M. antarcticus codifies for one GH11 (not characterized), ortholog of K. brasiliensis GH11, but the latter has no GH10 xylanases (Morita et al. 2013a; Saika et al. 2014; Oliveira et al. 2013). This difference can support the recent classification of these yeasts in distinct genera (Wang et al. 2015).

There are some studies that also describe the production of enzymes to degrade pectin (a heteropolysaccharide contained in the cell walls), such as polygalacturonases (Buzzini and Martini 2002; Oliveira et al. 2009; Trindade et al. 2002). Although they had not purified and characterized the enzymes, the corresponding activity was verified in M. antarcticus, K. fusiformata, and other Pseudozyma sp., and all of them showed a good production, reinforcing the biotechnological importance of these species.

Another CAZyme produced by this group of yeast is amylase. Specialized to catalyze the endohydrolysis of 1,4-α-D-glycosidic linkage in polysaccharides, this enzyme is used in the production of high glucose syrup and plays an important role in bread production, developing crust color and flavor, increasing loaf volume, preparation of open crumb structure, and extension of shelf life. Hirose et al. (2009) screened yeasts able to produce this enzyme and identified a M. aphidis strain. The enzyme (55 kDa) was purified, characterized, and tested on bread making, resulting in an improvement of bread taste and elasticity.

A recent study investigated the enzymatic arsenal of yeast and characterized, for the first time, a ustilaginomycetous hyaluronidase producer (Smirnou et al. 2015). This enzyme predominantly degrades hyaluronan and can be applied therapeutically, or in cosmetic and pharmaceutical products of hyaluronan oligomers (Buhren et al. 2016; Stern and Jedrzejas 2006). The hyaluronidase of M. aphidis showed a high thermostability (95% activity after 1 h at 37°C), which may be advantageous for commercial applications.

Cutinases have easier access to the substrate and do not depend on interfacial activation. Shinozaki et al. (2013b) used several plastic sources to produce cutinase-like enzymes from M. antarcticus, and the best yield was reached under pH 9.5 and 40 °C, using emulsified PBSA (Bionolle® EM-301). This enzyme can be used in a set of applications, such as laundry products, chemical synthesis, and also for farmers. Watanabe et al. (2014) showed that xylose induces cutinase-like enzyme production in 11 different strains of M. antarcticus. The strain M. antarcticus GB-4(1)W achieved the best results in terms of enzyme production (1.8 U/mL). This enzyme was tested into PBSA emulsion, PBS film, and commercial biodegradable plastic, presenting high solubility.

Another enzyme that can be industrially applied is an esterase, and it is used to hydrolyze polymeric structural component of plant cuticles, which is a waxy waterproof film, composed of fatty acids and acyl lipids. This structure covers the wall of epidermal cells of plants, creating a hydrophobic layer protecting plants against desiccation (Yeats et al. 2012; Yeats and Rose 2013). Despite being a poor habitat for microorganisms, due to the low amount of plant’s exudates, strains of this group are often found on leaf surfaces (Kurtzman et al. 2011; Souza et al. 2016). In study performed by Alex et al. (2014a), esterases from Pseudozyma sp. NII 08165 were immobilized on magnetic nanoparticles to produce biodiesel from sunflower oil. A low yield was observed, but a higher enzyme dosage and an improved condition may reach better results. Moreover, the purified esterase exhibited tolerance in methanol, and this can be considered an advantage due to the possibility of application in detergent formulations or for biodiesel production (Alex et al. 2014b).

Lipases

Lipase and esterase act very similarly by hydrolyzing carboxyl-ester bonds, but the first is not classified in CAZy. The main difference is that lipase is active against long-chain fatty acids, and esterase catalyzes the hydrolysis of short-chain triglycerides (Chahinian et al. 2002). Microorganisms are the main sources of lipases, and the interest on these enzymes has been increased due to their potential application in the production of biodiesel. The production of this enzyme is reported in P. hubeiensis pro tem. and M. antarcticus (Bussamara et al. 2010). This latter specie is capable to produce lipase A and B. The lipase B is active in low temperatures with transesterification activity, and the lipase A differs from others by its much lower acyltransfer activity, displaying a catalytic behavior, close to classical lipases (Neang et al. 2014). According to Jan et al. (2016), based on structural models involved with the lipase A from M. antarcticus, it could improve the stability of other lipases. In this way, it will be possible to improve the synthesis of aminolysis and acylated peptide that can be used in the production of biodiesel.

Aminopeptidase

Many applications of enzymes are associated with the food industry, such as the aminopeptidases, and these catalysts are useful for the processing of high-protein foods. The reaction is based on the release of the amino acid residues from the N-terminal end of the proteins. Recently, it has been shown that P. hubeiensis pro tem. strain 31-B secretes an aminopeptidase of 75.3 kDa, which can be applied in the dairy industry enhancing flavor development in liquid seasonings, yogurt, and cheese ripening (Isshiki et al. 2017).

There is still much information to be discovered about the yeasts of this group. Although they are not the best enzyme producers in terms of quantity, they are capable of producing a wide range of enzymes that can be applied in many different industries. Therefore, the obtaining of these products with improved yield is the next step to the development of a financially applicable technology for the benefit of society.

Carbohydrates

In the past years, some studies have highlighted the use of yeasts from Ustilaginaceae family in the biotransformation of compounds for sugar production such as oligosaccharides, polysaccharides, and polyols. The development of such processes becomes relevant as the demand for bio-based products has increased in recent times by the needs to replace fossil resources currently used as raw material and to establish new value chains from biomass to energy and chemicals (Straathof 2014). In order to substitute chemical processes that have high costs, extreme conditions, and low yields, biotechnological strategies based on microbial fermentation are most advantageous, even with its own challenges such as isolation of high producing strains, optimization of culture conditions, metabolic engineering tools, and the use of low cost substrates (Park et al. 2016).

Within the Ustilaginaceae family, the most recent studies contemplate the production of galactooligosaccharides, exopolysaccharides (EPS), and polyols by Pseudozyma sp. and Sporisorium sp. erythritol producers in amounts of potential commercial interest (Jeya et al. 2009; Sajna et al. 2013a; Fai et al. 2015a; Fai et al. 2015b; Geiser et al. 2014).

Two studies report in more details the production of galactooligosaccharides (GOSs) by Pseudozyma yeasts. GOSs are carbohydrates formed by 2 to 20 monosaccharides (galactoses and a terminal glucose, most of the time), usually not digested by enzymes present in the human body, which leads to metabolism only by bacteria in the gut microbiota. Therefore, they can be considered as compounds of prebiotic activity (Muñiz-Marquez et al. 2016). Fai et al. (2015a) described the optimization of culture conditions in the GOS synthesis by P. tsukubaensis pro tem. through statistical data treatment and response surface methodology. In a lactose culture medium with yeast extract and urea, the P. tsukubaensis pro tem. transgalactosylation activity leads to the best GOS concentration of 73.71 g/L and yield of 28.35 g GOS/100 g lactose after 24 h. In a second study, the researchers described the integrated GOS and biosurfactant production from P. tsukubaensis pro tem. Initially, cassava wastewater was used as substrate for biomass growth and biosurfactant production; then, the same biomass was transferred to a medium containing 40% lactose (w/v). This integrated process resulted in 73.12 g/L GOS production and yielded 18.28% (w/w) at 24 h of process (Fai et al. 2015b).

Sajna et al. (2013a) reported the production of EPS by ustilaginomycetous anamorphic yeast Pseudozyma sp. NII 08165. According to the authors, this was the first characterization report of EPS molecule synthesized by microorganisms of this genus. Exopolysaccharides have various applications such as thickeners, emulsifiers, and stabilizer in food industry and potential to be used in therapeutic and pharmaceutical fields. After inoculation in basal medium for 6 days, cell growth and quantification of EPS produced were evaluated. The best results were obtained when the medium was composed of 4% glucose, leading to a 3.5 g/L EPS concentration. In addition, the compound had a maximum viscosity of 63 mPa and was mainly responsible for the viscosity change in the medium that occurred during the process. Structural analysis showed defined monomers of glucose, galactose, and mannose, and molecular weight of 1.7 MDa, which demonstrates great potential of rheological use in food industries.

Polyols are natural sugars that can be employed as a sweetener food additive. They are similar to carbohydrates but with a hydroxyl group instead of aldehyde or ketone one (Grembecka 2016). Its production by yeasts from Ustilaginaceae family has also been studied in recent years, especially the production of erythritol, both for its potential noncariogenic sweetener and associated with other compounds generating biosurfactant activity (Jeya et al. 2009). As an active participant into the pentose phosphate pathway in microorganisms, its biological route has been increasingly studied to establish a commercially viable fermentation process instead of existing chemical and enzymatic processes (Moon et al. 2010; Park et al. 2016).

In a study carried by Jeya et al. (2009), the potential of a P. tsukubaensis pro tem. strain in the erythritol fermentation, as well as the process scale-up, was evaluated. After isolating the microorganism from 1037 strains, the results show an average potential of producing 240 g/L erythritol in pilot plant scale in medium containing 400 g/L glucose, with a 61% conversion yield. This response demonstrates that production of erythritol by P. tsukubaensis pro tem. has a great capacity for industrialization, becoming one attractive natural-obtained product alternative for the consumer market.

Studies up to this date involving sugars and sugar alcohol synthesis by ustilaginomycetous yeasts show that there is a great potential to be explored. The scarcity of studies published in this area emphasizes the need for great efforts into this theme, so that the potential demonstrated until now can be evidenced in fact. Market demand is also an important assessment factor, as well as the use of by-products from other processes, making this economically viable and environmentally sustainable.

Lipids

The single cell oils (SCOs) produced in the form of triacylglycerols (TAGs) by microorganisms can be a sustainable and promising source for biodiesel production for the replacement of commonly used oilseed crops from agriculture, such as soybeans, rapeseed, and palm (Slininger et al. 2016; Takakuwa et al. 2013). In addition, these products have broad potential for use in the food industry as an alternative to common oils and can also be applied in the production of biosurfactants, solvents, plastics, lubricants, and waxes, among others (Béligon et al. 2016; Ayadi et al. 2016). Thus, this area has received significant interest from sustainable energy researchers (Tanimura et al. 2016).

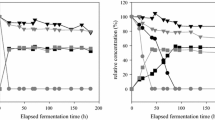

Lipid accumulation by oleaginous yeast has been well studied over the years and depends primarily on physiology, nutrient limitation, and environmental conditions of the microorganism (Beopoulos et al. 2009). Several genera are already recognized as potential lipid producers and are commonly used in the literature, such as Yarrowia sp., Cryptococcus sp., Rhodotorula sp., and Lipomyces sp., among others, which may allow the future production of microbial lipids on an industrial scale (Bellou et al. 2016; Gong et al. 2016; Lorenz et al. 2017; Xavier et al. 2017; Ageitos et al. 2011). The potential of these strains is considerably greater than conventional strains, for example, Rhodotorula spp. and C. curvatus are able to accumulate from 40 to 70% of lipids, whereas Saccharomyces cerevisiae or Candida utilis only 5–10% of these compounds when grown under the same conditions (Meng et al. 2009). The use of biocatalysts belonging to the Ustilaginaceae family for the production of microbial lipids is also advantageous although unexploited. In addition, a diversity of fatty acids can be found as components of the lipid fraction produced by these microorganisms using different substrates as a carbon source, demonstrating their metabolic versatility (Fig. 2) (Tanimura et al. 2016; Areesirisuk et al. 2015a).

The production of squalene through biotechnological processes is an important approach that is growing in recent years, and the use of ustilaginomycetous yeasts also has been reported for this purpose. This compound is a polyunsaturated aliphatic hydrocarbon containing six isoprene units that provide the backbone for the biosynthesis of cholesterol, bile acids, and steroids (Fig. 3) (Chang et al. 2008). In addition, squalene is essential for human body as it is a natural antioxidant able to protect cells from free radicals and reactive oxygen species (Kohno et al. 1995). Industrial application of this compound includes its use as moisturizing agent and an emollient in cosmetic, therapeutic effects, and possible pharmaceutical applications (Newmark 1999).

According to Xiao et al. (2016), the currently available sources of squalene are from animal origin such as liver oils of deep-sea sharks and from plant oils including olive oils and soybean oils. However, considering environmental concerns related to preservation of marine animals, the obtaining of squalene from sharks has been drastically decreasing, and the production from plant resources is limited by seasonal factors and high costs associated to the extraction and purification processes (Xiao et al. 2016). Thus, the microbial production of squalene is a potential alternative to be exploited, although the biotechnological process still needs to be improved, in terms of final product concentration and optimization of the purification steps before industrial-scale production becomes a reality (Chen et al. 2010; Fan et al. 2010; Hoang et al. 2014; Rasool et al. 2016; Xu et al. 2016).

Some studies are successfully employing genetic engineered strains of Saccharomyces cerevisiae to obtain higher squalene amounts, when compared to the wild-type parental strains (Mantzouridou and Tsimidou 2010; Spanova and Daum 2011; Rasool et al. 2016). Similarly, the results obtained using ustilaginomycetous yeasts demonstrated an important possibility of using a non-genetic modified microorganism (GMM) for squalene production and can offer a novel strategy to improve the potential of biotechnology for this purpose.

In this approach, a Pseudozyma sp. JCC207 strain was able to produce up to 340.52 mg/L of squalene and 5.20 g/L of biomass, after analyzing the effects of carbon and nitrogen sources on squalene production. Optimized conditions included the concentration of 40 g/L of glucose and sodium nitrate as the best nitrogen source, after 120 h of process and under 160 rpm of agitation. This was possibly the first report associating this strain with the production of squalene (Chang et al. 2008). The ability of the Pseudozyma sp. SD301 to produce a high concentration of squalene was reported. The strain was isolated from mangrove ecosystem and evaluated in batch and fed-batch system under previous optimized conditions: the culture media contained 60 g/L of glucose, 20 g/L of yeast extract, and 15 g/L of artificial sea salt concentration, under cultivation conditions of pH 6.0 and 25 °C. When subjected to these conditions, squalene productivity reached 0.039 g/L h in batch fermentation, while the maximum squalene concentration of 2.445 g/L was obtained in fed-batch fermentation after 80 h of process. The newly isolated strain presented a great potential for production of squalene, being one of the largest already reported through fermentative approach (Song et al. 2015). These squalene levels produced by ustilaginamycetous were lower than those recently obtained in biotechnological processes using Aurantiochytrium sp. strains in which the production ranged from 900 mg/L to 21.2 g/L (Kaya et al. 2011; Chen et al. 2010; Nakazawa et al. 2014; Fan et al. 2010), but were better than those obtained with some S. cerevisiae strains reported by Kamimura et al. (1994) and Mantzouridou et al. (2009) in that the squalene production ranged from 18 to 20.7 mg/L, respectively.

Another potential use of yeasts from Ustilaginaceae family that can be evidenced in the literature is in obtaining lipids for the subsequent production of biodiesel. In a study performed by Takakuwa et al. (2013), the strain Pseudozyma sp. TYC-2187 was used for TAG production using crude glycerol as carbon source and targeting this product for biodiesel production. These authors optimized culture conditions and process parameters reaching 15.7 g/L of TAG after 48 h of process, working with 80 g/L of glycerol and 10 g/L of yeast extract, under 25 °C of temperature and pH 6.0. An important data for the potential application of this TAG in biodiesel production is that the product complied with biodiesel standards, considering fatty acid composition, iodine value, and cetane number, among others (Takakuwa et al. 2013).

In a screening study, a P. parantarctica CHC28 was selected as a potential lipid producer. Process was conducted in batch fermentation, where biomass and total lipids reached 14.33 ± 0.35 and 5.72 ± 0.26 g/L, after 5 days of process. Results for lipid content showed a decrease from the first to the fifth day, varying from 43.45 ± 11.11 to 39.89 ± 1.06%, respectively. It was observed that the major fatty acids in the lipids of this yeast strain were C16 and C18, with a composition very similar with conventional vegetable oils (Areesirisuk et al. 2015a). The same strain was studied using glucose as the main carbon source, in order to investigative growth parameters, production rate, and fatty acid composition profile. Authors evaluated no significantly inhibitory effect at 100 g/L of glucose, where working in this concentration reached 10.99 g/L and 49.66% of dry weight of oil production and oil content, respectively. Within this composition, it was evaluated the majority presence of long-chain fatty acids (C16–C18) ranging between approximately 86 and 90%, which had their content increased as the glucose concentration increased (Areesirisuk et al. 2015b).

The use of low cost substrates on SCO production can be considered an interesting approach; however, few studies describe this strategy using ustilaginomycetous yeasts. In this context, a broad screening with 1189 oleaginous yeast strains was conducted aiming to evaluate the simultaneous utilization of glucose (20 g/L), xylose (10 g/L), and L-arabinose (5 g/L) in artificial hydrolysate as substrates. During trials, analysis involved the measurement of remaining sugar concentration in the culture medium and lipid concentration accumulated into the cells. From the total of isolates, only 12 were able to co-ferment the sugars used, and interestingly, all selected strains belonged to the Ustilaginales order, expanding their potential for biodiesel production. In addition, the yeast P. hubeiensis pro tem. IPM1-10 was capable of consuming the complex substrate sugars simultaneously with a sugar consumption rate of 94.1% and high lipid concentration (reaching almost 2 g/L after 10 days of process). Despite the lower productivity, this strain seems a potential biocatalyst for the conversion of hydrolysate of lignocellulosic biomass into second-generation biodiesel (Tanimura et al. 2016).

Therefore, the process development of microbial lipid production using these biocatalysts can be considered as a good alternative to the conventional production, although it still requires several advances due to the scarcity of data in this promising area.

Organic acids

The production of organic acids by biotechnological routes is an advantageous approach for obtaining these building block chemicals from renewable carbon sources (Sauer et al. 2008). Additionally, these compounds serve as versatile precursors for a variety of important commercial chemicals and polymers representing a potential alternative to the manufacture via chemical synthesis (Mattey 1992; Sanchez-Riera 2010). Thus, due to their wide field of application, the organic acids represent an important class of compounds for economical purposes and industrial applications, such as pharmaceutical, food, and cosmetic industries (Wieschalka et al. 2013; Klement and Büchs 2013).

Among the main biotechnological applications of the microorganisms belonging to Ustilaginaceae family are the production of value-added organic acids, such as itaconic, L-malic, succinic, itatartaric, and 2-hydroxyparaconic acids, among others (Fig. 4) (Geiser et al. 2014; Geiser et al. 2016a; Zambanini et al. 2017a; Guevarra and Tabuchi 1990a; Guevarra and Tabuchi 1990b). It is well known that the total acid production, as well as the ratio of the different acids, is strongly influenced by the strain used and by culture conditions such as pH, temperature, aeration, and the growth-limiting nutrient (Klement et al. 2012).

Itaconic acid, an unsaturated dicarboxylic acid, is recognized as one of the most versatile chemical building blocks derived from biomass, greatly enhancing its biotechnological interest and its field of application (Geiser et al. 2016b; Saha 2017). The wide range of application of the itaconic acid includes the production of resins, plastics, adhesives, elastomers, and coatings, among others (Willke and Vorlop 2001; Ramos et al. 2016). Therefore, the annual production of itaconic acid reaches more than 80,000 t (Okabe et al. 2009). In the recent years, itaconic acid has gained more interest as future bio-based platform chemical for production of biofuels (Klement and Büchs 2013). This compound was still identified as a metabolite produced in mammals with antimicrobial activity (Geiser et al. 2016b).

The metabolic pathways and the factors that influence itaconic acid production have been investigated in greater detail using Aspergillus terreus strains, whereas studies focused in ustilaginomycetous yeasts have grown considerably only in recent years (Klement and Büchs 2013; Saha 2017).

In fact, the first reports of the use of Ustilago sp. for organic acid production are not recent. Itaconic acid production was reported in the 1950s using strains of Ustilago zeae. This product was quantified by bromine-iodine method reaching 15 g/L, and it was generated in a mixture together with a glycoside of mannose and erythritol (Haskins et al. 1955).

Permeabilized cells of Ustilago cynodontis K320, when incubated for 7 days at 30 °C and 220 rpm of agitation, produced a mixture of organic acids including itaconic, L-malic, and succinic acids, in addition to two products identified as itatartaric and 2-hydroxyparaconic acids. This was one of the first reports on the production of itatartarate and 2-hydroxyparaconate using the genus Ustilago. Based on these findings, the authors analyzed that they were produced with itaconic acid and proposed that 2-hydroxyparaconic is an intermediate in the metabolic pathway of obtaining itatartarate (Guevarra and Tabuchi 1990a). Optimization experiments were conducted, revealing the positive influence of temperature (25 °C), aeration, and addition of metal ions (5 ppm of FeSO4 and 0.5 ppm of ZnSO4) on production of acids by U. cynodontis K320. In this experiment, from 1 L of filtrate, 49 g of 2-hydroxyparaconic acid was recovered as a crystalline mass with approximately 96% of purity (Guevarra and Tabuchi 1990b).

In a screening procedure, 68 Ustilaginaceae strains from 13 different species were evaluated for production of valuable chemicals, such as organic acids, polyols, and glycolipids using glucose as substrate. Among them, U. cynodontis, U. maydis, U. avenae, and Sporisorium exsertum were identified as the most promising strains producing itaconate, malate, succinate, and erythritol, respectively. Additionally, the pH variation showed a strong correlation with the acid production; selected strains exhibit final pH of 5.3 ± 0.2 for U. maydis 2229, 4.6 ± 0.1 for U. maydis 2162, and 3.3 ± 0.5 for U. cynodontis 2217, due to the higher malate and itaconate production. This work also used the two first strains for further controlled batch fermentations in a working volume of 0.5 L, leading to the confirmation of products obtained in the screening trial. The batch fermentations led to more than 47 g/L of total acid concentration, presenting the broad potential of strains U. maydis 2229 and U. maydis 2162 for itaconate, succinate, and malate production (Geiser et al. 2014).

Among the main works and advances in itaconic acid production, it is remarkable the potential of the strain U. maydis, due to its ability to produce this acid from biomass-derived sugar monomers and polymers (Maassen et al. 2014). The great trend in the use of renewable lignocellulosic biomass for production of biofuels and other added-value compounds has led to investigations of the interference of pretreatment of these materials with the subsequent fermentation steps by U. maydis. For that, the characterization of the cultivation and itaconic production was performed in laboratory scale, using glucose as substrate. Moreover, three pretreated biomass fractions were evaluated as substrate: cellulose hydrolyzed enzymatically in seawater, monomeric hemicellulose from fractionated beech wood, and cellulose hydrolyzed via salt-assisted. It was observed that the production of itaconic acid was achieved on first and second substrates, and it was only affected by high osmolarities up to 3.5 osmol/L as well as to 0.1 M of oxalic acid. This study proved the versatility of this strain and its potential for use in the biorefinery concept (Klement et al. 2012).

This potential of U. maydis for industrial itaconate production was further investigated by Maassen et al. (2014), who worked in batch fermentations with a working volume between 2 and 2.5 L and varying medium composition. The production of itaconic acid reached 44.5 g/L at a maximum rate of 0.74 g/L h, using 200 g/L glucose and 75 mM ammonium, at 30 °C and pH 6.0 due to the strong influence of nitrogen source observed in this production (Maassen et al. 2014; Klement et al. 2012). However, with low concentrations of carbon and nitrogen sources, 50 g/L glucose, and 30 mM ammonium, respectively, the yield of itaconic acid reached 0.34 g/g. Despite collecting interesting results on this scale, authors highlighted the importance of optimization of U. maydis through metabolic engineering in order to achieve an economically feasible and competitive process with the industrial production of this compound, currently performed by Aspergillus terreus (Maassen et al. 2014).

In this approach, Geiser et al. (2016b) suggested the metabolic pathway of U. maydis for production of itaconic acid. This microorganism evolved to the utilization of an alternative pathway through the decarboxylation of the toxic intermediate trans-aconitate, the thermodynamically favored isomer of cis-aconitate. Also, authors identified a gene cluster that contains all genes involved in itaconic acid pathway formation. In more details, the overexpression of the cytochrome P450 monooxygenase gene cyp3, which lies adjacent to U. maydis itaconate cluster, led to a drastic decrease of itaconate production. In contrast, deletion of cyp3 resulted in a slight but not significant increase (Geiser et al. 2016b). In this case, authors proposed that the possible underlying mechanism was suggested to be the oxidation of itaconate to 2-hydroxyparaconate by cyp3. However, the exact action and role of cyp3 in relation to itaconate and 2-hydroxyparaconate production remains to be unclear (Geiser et al. 2016a; Geiser et al. 2016b).

Another chemical compound of great industrial interest obtained by Ustilago sp. strains is malic acid. This compound is extensively used in the pharmaceutical and food industries, in this last case used in many products as an acidulant (Battat et al. 1991; Tsao et al. 1999). This acid can also be an important C4 platform chemical, with potential to replace the petroleum-derived commodity chemical maleic anhydride (Sauer et al. 2008).

Aiming to investigate new possible utilizations for crude glycerol, Zambanini et al. (2016a) proposed the production of malic acid by U. trichophora TZ1 using this low-value waste stream obtained during biodiesel manufacture. The microorganism used was identified in a screening of 74 Ustilaginaceae strains as the best potential acid malic producer, in a strategy based on growth in solid glycerol medium and later on liquid cultures containing 50 g/L of glycerol. Laboratory adaptive evolution led to the increasing of 2.5- and 6.6-fold of growth and production rate, respectively, while medium optimization led to 0.82 g mal/g gly and 0.39 g/L h of yield and overall production rate, respectively. Under these optimized conditions, with 250 g/L glycerol as starting concentration, final acid malic concentration reached 196 g/L after 504 h of process. These results indicate the high potential of U. trichophora TZ1 for the industrial production of malic acid (Zambanini et al. 2016a).

Following, the same process using U. trichophora TZ1 was analyzed in fed-batch bioreactors with working volume of 1.25 L, at 30 °C, pH 6.5, and 1 vvm of aeration. The best results presented reached 200 g/L of malic acid produced from glycerol, reaching a maximal production rate of 1.94 g/L h. This seems one of the highest concentrations already reported for malic acid production, enabling U. trichophora TZ1 to become competitive with highly engineered strains (Zambanini et al. 2016b).

Genetic analysis revealed all essential genes for malate production from glycerol contributing to metabolic engineering for improving malate production (Zambanini et al. 2016c). Thus, further optimization of U. trichophora TZ1 focused on metabolic engineering making it possible to boost the flux from pyruvate to malic acid and to reduce by-product formation, improving this process for malic acid production from biodiesel-derived crude glycerol (Zambanini et al. 2017a).

Therefore, yeasts from Ustilaginaceae family have shown a great potential for industrial biotechnology, although many efforts are still required aiming the selection of new strains belonging to this genus, optimization and scale-up processes, and also the involvement of genetic engineering techniques that could be great drivers for the production of organic acids for the future of modern industry.

Biosurfactants

Biosurfactants are amphiphilic compounds able to reduce the surface and interfacial tension in liquids or multi-phasic systems that can be produced by several microorganisms, including bacteria, fungi, and yeast strains (Cameotra and Makkar 2010; Souza et al. 2017). These compounds have been considered a suitable alternative to synthetic surfactants due to low toxicity, stability in wide range of temperature, pH, and ionic strength conditions (Varvaresou and Iakovou 2015; Soberón-Chávez and Maier 2011).

Many studies describe the production of biosurfactants by yeasts, obtaining mainly glycolipids such as sophorolipids, cellobiose lipids, and mannosylerythritol lipids (Jiménez-Peñalver et al. 2016; Yang et al. 2013; Niu et al. 2017). The high amounts of biosurfactants achieved in different fermentation strategies make yeasts belonging of the Candida genus and Ustilaginaceae family extremely attractive when compared to bacteria strains such as Bacillus sp. traditionally recognized by lipopeptides biosurfactants (e.g., surfactin) (Campos-Takaki et al. 2010; Amaral et al. 2010; Morita et al. 2009a; Almeida et al. 2017; Souza et al. 2017). According to Souza et al. (2017), the generally regarded as safe (GRAS) status attributed to most of these yeasts, the application of natural products from secondary metabolism, including biosurfactants, can be considered favorable in food and pharmaceutical industries.

The use of ustilaginomycetous yeasts for biosurfactant production has been reported as an interesting approach due to its metabolic capacity to form two types of glycolipids, cellobiose lipids (CLs) and mannosylerythritol lipids (MELs), generally using low-cost substrates (e.g., vegetable oils) as carbon source (Fig. 5). Table 2 comprises some studies that show the biotechnological potential of ustilaginomycetous yeasts in the production of MELs and CLs using different substrates. Furthermore, other glycolipid biosurfactants, mannosylribitol lipid (MRL), mannosylarabitol lipid (MAL), and mannosylmannitol lipid (MML) can be obtained from the ustilaginomycetous yeast P. parantarctica JCM 11752T when supplemented with C5(D-ribitol and D-arabitol) and C6 (mannitol) sugar alcohols in presence of vegetable oil (Morita et al. 2012; Morita et al. 2009b).

Cellobiose lipids are biosurfactants produced by some ustilaginomycetous yeasts such as Ustilago maydis, Pseudozyma fusiformata, P. flocculosa, P. graminicola, P. aphidis, and P. hubeiensis pro tem. and consist of a hydrophilic moiety composed by disaccharide cellobiose that is linked through O-glycosidic bond to long or medium-chain fatty acid, which may contain hydroxyl groups in different positions (Boothroyd et al. 1956; Kulakovskaya and Mironov 2016; Yang et al. 2013; Kulakovskaya et al. 2005; Mimee et al. 2009; Golubev et al. 2008; Morita et al. 2013b). In addition, acetyl groups can be found in the cellobiose portion allowing the formation of different analogs (CL-A, CL-B, and CL-C) (Morita et al. 2013b).

MELs are glycolipid biosurfactants that contain 4-O-β-D-mannopyranosyl-meso-erythritol or 1-O-β-D-mannopyranosylerythritol as the hydrophilic moiety and a fatty acid chain that can present different chemical characteristics as an unsaturation and hydroxyl groups (Morita et al. 2015). These glycolipids have one or two acetyl groups at C-4′ and/or C-6′ of the mannose moiety and are classified as MEL-A (di-acetylated), MEL-B (monoacetylated at C-6′), MEL-C (monoacetylated at C-4′), and MEL-D (deacetylated) (Sajna et al. 2013b). The biotechnological production of MELs has been reported by several species of ustilaginomycetous yeasts, including P. tsukubaensis pro tem., P. churashimaensis, P. antarctica, P. aphidis, P. hubeiensis pro tem., P. crassa, P. siamensis, and some strains of Ustilago genus (Yamamoto et al. 2013; Morita et al. 2011a; Bhangale et al. 2013; Fukuoka et al. 2008; Konishi et al. 2008; Konishi et al. 2011; Arutchelvi and Doble 2011; Morita et al. 2008a; Faria et al. 2015; Morita et al. 2011b).

Among these glycolipid biosurfactants, MELs are more advantageous because of their potential applications in environmental, cosmetic, and medical fields, besides being obtained in high yields using low-cost substrates in its production, while few studies are found for CLs. In terms of biological properties, antibacterial and fungicidal activities were reported to CLs (flocculosin and ustilagic acid), and for MELs, several studies reported antioxidant, antiinflammatory, and antimicrobial activities (Mimee et al. 2005; Hammami et al. 2008; Kulakovskaya et al. 2009; Takahashi et al. 2012; Morita et al. 2011c; Morita et al. 2013b; Morita et al. 2015).

Concerning the biotechnological processes, the production of CLs by ustilaginomycetous yeasts was described in some studies, however, with scarce information about the yield and amounts obtained. In study performed by Kulakovskaya et al. (2005), eight wild strains of P. fusiformata isolated from natural sources (grass leaves, forest litter, and cauliflower) were able to produce mainly ustilagic acid. These microorganisms were cultivated in mineral medium (0.1% (NH4)2SO4, 0.005% MgSO4) containing 1.0% glucose, 0.05% of yeast extract, and 0.73% of citric acid, for 30 days at 24 °C. The production of flocculosin was described using similar minimal medium composition by P. flocculosa incubated at 28 °C and 150 rpm for 48 h (Mimee et al. 2009). In this study, the antimicrobial activity was evaluated against several gram-positive (including Staphylococcus aureus methicillin-resistant and vancomycin-resistant strains) and gram-negative microorganisms with good results of susceptibility for most of the gram-positive strains tested (MIC values < 100 μg/mL).

Morita et al. (2013b) performed a screening study with potential for CL production, using eleven Pseudozyma species and one strain of U. maydis. These microorganisms were cultivated in an experimental medium composed of 2% soybean oil, 5% glucose, 0.3% NaNO3, 0.03% MgSO4, 0.03% KH2PO4, and 0.1% yeast extract at 25 °C, pH 6.0 for 7 days. Interesting results were achieved to four strains, including U. maydis (0.27 g/L), P. aphidis (0.32 g/L), P. graminicola (0.62 g/L), and P. hubeiensis pro tem. (0.29 g/L). In addition, it was also verified the specificity of cyp1 gene for CL biosynthesis based in the results obtained from deduced translation product of the gene fragments of the better CL producers (P. aphidis and P. hubeiensis pro tem.) which shared identity range of 78 to 99% with the cyp1 gene of U. maydis. This result about the importance of cyp1 gene is consistent with those found by Teichmann et al. (2007) and Marchand et al. (2009) for U. maydis and P. flocculosa and consists in a potential way for application of genetic engineering tools to construction of CL producers for industrial purposes (Morita et al. 2013b).

The growing interest in sustainable surfactants with remarkable characteristics of toxicity and biodegradability has made the study of glycolipid biosurfactants gain more attention in recent years (Paulino et al. 2016). In this sense, MELs are considered promising, and many studies describe the production of this glycolipid biosurfactant by ustilaginomycetous yeasts using different low-cost substrates as carbon sources, including honey, sugarcane juice, vegetable, and mineral oils (Bhangale et al. 2013; Morita et al. 2011b; Kitamoto et al. 2001; Fan et al. 2014).

High amounts of MELs may be produced using vegetable oils, with studies reporting processes in which concentrations above 160 g/L by P. aphidis, 140 g/L by P. rugulosa, and 100 g/L by P. parantarctica were achieved using soybean oil as carbon source (Rau et al. 2005; Morita et al. 2006; Morita et al. 2008b). Although it is suggested that the use of vegetable oils is the ideal substrates to achieve high yields of MEL, one of the major drawbacks of this approach is the coexistence of by-products, such as fatty acids, that make the extraction and purification process more complex and expensive (Morita et al. 2007a; Morita et al. 2009a). Thus, studies using different water-soluble carbon sources were performed in the last years, and important results were reported using ustilaginomycetous yeasts.

In this context, Morita et al. (2011a) described the production of a mixture of MELs, including a novel tri-acetylated derivative (MEL-A2), using glucose as carbon source by a wild strain of P. churashimaensis. The MEL production was carried in Erlenmeyer flasks containing 20 mL of a basal medium composed of 10% glucose, 0.3% NaNO3, 0.03% MgSO4, 0.03% KH2PO4, and 0.1% yeast extract at pH 6.0 and 200 rpm of agitation in aerobic conditions, for 5 days. After purification, this novel MEL derivative exhibited low critical micelle concentration value (CMC), around of 0.0011 g/L, and surface tension of 29.2 mN/m at CMC. Previously, using similar culture conditions and glucose, sucrose, and olive oil at 10% as carbon source, a comparative study for MEL production was performed evaluating the potential of 10 different Pseudozyma species, including P. antarctica, P. aphidis, P. flocculosa, P. fusiformata, P. parantarctica, P. prolifica, P. rugulosa, P. siamensis, P. thailandica, and P. tsukubaensis pro tem. and two Ustilago species (U. maydis and U. scitaminea) (Morita et al. 2009c). The results showed that two strains were able to produce different concentrations of MEL-A, P. antarctica JCM 10317 achieved 1.61, 1.97, and 12.98 g/L, while U. maydis NBRC 5346 produced 1.35, 2.32, and 2.6 g/L using glucose, sucrose, and olive oil, respectively. The production of MEL-B was observed to U. scitaminea NBRC 32730 with concentrations around 6 g/L using glucose and sucrose and 8.29 g/L using olive oil. The production of MEL-C was only verified to one strain, P. siamensis CBS 9960, with concentrations varying to 1.08 g/L using glucose, 1.94 g/L to sucrose, and 1.35 g/L to olive oil. Finally, it was observed that the surfactant properties (CMC values and surface tension reduction) of sucrose-derived MELs were very similar to those exhibited by MELs produced using vegetable oil (Morita et al. 2009c).

Other study reported the efficient use of honey from red dwarf honey bees (Apis Florea) in MEL production by P. antarctica ATCC 32657 (Bhangale et al. 2013). In this case, 5.61 g/L of biosurfactant was achieved when 14% (w/v) of honey was added as sole carbon source in mineral medium after 200 h of cultivation at 25 °C and 210 rpm. The crude MEL was able to reduce the surface tension of water from 72 to 29.5 mN/m with CMC value of 66 mg/L.

Regarding to water-soluble carbon sources, the assimilation of pentoses (D-xylose and L-arabinose) and glucose by P. antarctica PYCC 5048T, P. aphidis PYCC 5535T, and P. rugulosa PYCC 5537T and its influence into production of MELs was evaluated in a recent study performed by Faria et al. (2014a). The screening of the best carbon source was carried out using YNB medium with ammonium as nitrogen source supplemented with 20 g/L of carbon source (pentoses or glucose). After 7 days of cultivation at 28 °C and 150 rpm, it was observed that all strains exhibited similar maximum specific growth rates, regardless of the source of carbon used, but the MEL production was only verified in the medium supplemented with D-xylose and D-glucose. In terms of production, MELs were produced at concentration between 1.2 and 5.4 g/L by the three ustilaginomycetous yeasts using D-xylose, D-glucose, and their mixture (1:1 w/w). The best titers were achieved to P. antarctica PYCC 5048T with MEL concentration of 4.8 g/L to D-xylose, 5.4 g/L to glucose, and 4.9 g/L to their mixture.

More recently, and based in the results described above, Faria et al. (2015) assessed the potential of P. antarctica PYCC 5048T and P. aphidis PYCC 5535T for production of cellulolytic and hemicellulolytic enzymes and consequently their capacity to degradation of lignocellulosic polysaccharides (cellulose and xylan) aiming at the development of a consolidated bioprocess for MEL production. In this study, only xylan was hydrolyzed and used as a carbon and energy source, with best results to P. antarctica PYCC 5048T able to produce 1.3 g/L of MELs from xylan (40 g/L) in batch process and 2.0 g/L in fed-batch experiment, both after 10 days of cultivation.

However, up to date, the best results in MEL production using hydrophilic substrates and yeasts belonging the Ustilaginaceae family have been reported applying glycerol and sugarcane juice as a carbon source, reaching amounts of around 16.3 and 25 g/L, respectively (Morita et al. 2007b; Morita et al. 2011b). In addition, the lower concentrations of MEL produced using hydrophilic substrates compared to vegetable oils can be due to the increase of osmotic pressure in culture broth that affects the metabolic pathways and enzymes involved in carbohydrate assimilation and biosurfactant biosynthesis (Bhangale et al. 2013; Kitamoto et al. 1998; Faria et al. 2014b). In addition, it can be assumed that in processes using vegetable oils, these would be available directly for beta-oxidation processes and hence into the precursor pool of glycolipids, while sugars from water-soluble carbon sources have to be converted to acetyl-CoA before of the synthesis via the fatty acid generation route.

The use of ustilaginomycetous yeasts in the biotechnology of biosurfactants is therefore a great field to be explored, with great industrial and commercial potential. The major challenges, however, are the development of processes that make the recovery and purification steps more efficient when vegetable oils are used as substrates and the improve of production for processes with water-soluble carbon substrates. In addition, further efforts should be made to evaluate other biological properties and novel applications of the biosurfactants produced by this yeast from Ustilaginaceae family.

Conclusion and perspectives

The metabolic versatility of the yeasts of the Ustilaginaceae family has made them the target in the last years of a large and growing number of studies for production of natural compounds with economic potential. The ability to produce a wide variety of enzymes, such as CAZymes, squalene as well as biosurfactants and organic acids, mainly itaconic acid, makes it evident that these microorganisms can provide a new front in biotechnology, with new opportunities to exploration and application in different fields as pharmaceutical, food, environmental, and medical. The major challenges for use of ustilaginomycetous as an alternative producer to conventional biocatalysts currently used in industrial processes are in the establishment of processes with high yields, with low cost of production and easy recovery of the compound of interest. Thus, further studies focusing in the application of statistical methods for optimization and molecular and genetic tools for obtaining of engineered ustilaginomycetous can be considered promising approaches to novel works. In addition, the present mini-review exposed the broad spectrum of possibilities in biotechnology of ustilaginomycetous, the most important developments for production of value-added chemicals and the necessity of multi-disciplinary efforts to improve the process characteristics for insertion of these yeasts in industrial biotechnology.

References

Abbas HK, Shier WT, Plasencia J, Weaver MA, Bellaloui N, Kotowicz JK, Butler AM, Accinelli C, de la Torre-Hernandez ME (2017) Mycotoxin contamination in corn smut (Ustilago maydis) galls in the field and in the commercial food products. Food Control 71:57–63. https://doi.org/10.1016/j.foodcont.2016.06.006

Adrio JL, Demain AL (2014) Microbial enzymes: tools for biotechnological processes. Biomolecules 4:117–139. https://doi.org/10.3390/biom4010117

Adsul MG, Bastawde KB, Gokhale DV (2009) Biochemical characterization of two xylanases from yeast Pseudozyma hubeiensis producing only xylooligosaccharides. Bioresour Technol 100:6488–6495. https://doi.org/10.1016/j.biortech.2009.07.064

Ageitos JM, Vallejo JA, Veiga-Crespo P, Villa T (2011) Oily yeasts as oleaginous cell factories. Appl Microbiol Biotechnol 90:1219–1227. https://doi.org/10.1007/s00253-011-3200-z

Alex D, Mathew A, Sukumaran RK (2014a) Esterases immobilized on aminosilane modified magnetic nanoparticles as a catalyst for biotransformation reactions. Bioresour Technol 167:547–550. https://doi.org/10.1016/j.biortech.2014.05.110

Alex D, Shainu A, Pandey A, Sukumaran RK (2014b) Esterase active in polar organic solvents from the yeast Pseudozyma sp. NII 08165. Enzyme Res 1–10 https://doi.org/10.1155/2014/494682

Almeida DG, Silva RCFS, Luna JM, Rufino RD, Santos V, Sarubbo LA (2017) Response surface methodology for optimizing the production of biosurfactant by Candida tropicalis on industrial waste substrates. Front Microbiol 8:157. https://doi.org/10.3389/fmicb.2017.00157

Amaral PF, Coelho MA, Marrucho IM, Coutinho JA (2010) Biosurfactants from yeasts: Characteristics, production and application. Adv Exp Med Biol 672:236–249. https://doi.org/10.1007/978-1-4419-5979-9_18

André I, Potocki-Véronèse G, Barbe S, Moulis C, Remaud-Siméon M (2014) CAZyme Discovery and design for sweet dreams. Curr Opin Chem Biol 19:17–24. https://doi.org/10.1016/j.cbpa.2013.11.014

Areesirisuk A, Chiu CH, Yen TB, Liu CH, Guo JH (2015a) A novel oleaginous yeast strain with high lipid productivity and its application to alternative biodiesel production. Applied Biochem Microbiol 51:411–418. https://doi.org/10.1134/s0003683815030035

Areesirisuk A, Chiu CH, Yen TB, Liu CH, Pongswat S, Guo JH (2015b) Influence of substrate concentration on microbial oil production by Pseudozyma parantarctica CHC28 and its fatty acid characterization. In: International Conference on Science and Technology. https://doi.org/10.1109/ticst.2015.7369349

Arutchelvi JI, Doble M (2011) Mannosylerythritol lipids: microbial production and their applications. In: Soberón-Chávez G (ed) Biosurfactants, Microbiology Monographs 20. Springer-Verlag. Berlin, Germany, pp 121–149. https://doi.org/10.1007/978-3-642-14490-5_6

Ayadi I, Kamoun O, Trigui-Lahiani H, Hdiji A, Gargouri A, Belghith H, Guerfali M (2016) Single cell oil production from a newly isolated Candida viswanathii Y-E4 and agro-industrial by-products valorization. J Ind Microbiol Biotechnol 43:901–914. https://doi.org/10.1007/s10295-016-1772-4

Azelee NIW, Jahim JM, Ismail AF, Fuzi SFZM, Rahman RA, Illias RM (2016) High xylooligosaccharides (XOS) production from pretreated kenaf stem by enzyme mixture hydrolysis. Ind Crops Prod 81:11–19. https://doi.org/10.1016/j.indcrop.2015.11.038

Azhar SHM, Abdulla R, Jambo SA, Marbawi H, Gansau JA, Faik AAM, Rodrigues KF (2017) Yeasts in suitainable bioethanol production: a review. Biochem Biophys Rep 10:52–61. https://doi.org/10.1016/j.bbrep.2017.03.003

Basso RF, Alcarde AR, Portugal CB (2016) Could non-Saccharomyces yeasts contribute on innovative brewing fermentations? Food Res Int 86:112–120. https://doi.org/10.1016/j.foodres.2016.06.002

Bastawde KB, Puntambekar US, Gokhale DV (1994) Optimization of cellulase-free xylanase production by a novel yeast strain. J Ind Microbiol 13:220–224. https://doi.org/10.1007/bf01569752

Battat E, Peleg Y, Bercovitz A, Rokem JS, Goldberg I (1991) Optimization of L-malic acid production by Aspergillus flavus in a stirred fermentor. Biotechnol Bioeng 37:1108–1116. https://doi.org/10.1002/bit.260371117

Begerow D, Schäfer AM, Kellner R, Yurkov A, Kemler M, Oberwinkler F, Bauer R (2014) 11 Ustilaginomycotina. In: Esser K (ed) The Mycota-Systematics and Evolution- Part A. Springer Berlin Heidelberg, Berlin, Germany, pp 295–329. https://doi.org/10.1007/978-3-642-55318-9_11

Béligon V, Christophe G, Fontanille P, Larroche C (2016) Microbial lipids as potential source to food supplements. Curr Opin Food Sci 7:35–42. https://doi.org/10.1016/j.cofs.2015.10.002

Bellou S, Triantaphyllidou IE, Mizerakis P, Aggelis G (2016) High lipid accumulation in Yarrowia lipolytica cultivated under double limitation of nitrogen and magnesium. J Biotechnol 234:116–126. https://doi.org/10.1016/j.jbiotec.2016.08.001

Beopoulos A, Cescut J, Haddouche R, Uribelarrea JL, Molina-Jouve C, Nicaud JM (2009) Yarrowia lipolytica as a model for bio-oil production. Prog Lipid Res 48:375–387. https://doi.org/10.1016/j.plipres.2009.08.005

Bhangale A, Wadekar S, Kale S, Pratap A (2013) Optimization and monitoring of water soluble substrate for synthesis of mannosylerythritol lipids by Pseudozyma antarctica (ATCC 32657). Biothecnol Bioprocess Eng 18:679–685. https://doi.org/10.1007/s12257-012-0647-4

Boothroyd B, Thorn JA, Haskins RH (1956) Biochemistry of the ustilaginales: XII. Characterization of extracellular glycolipids produced by Ustilago sp. Biochem Cell Biol 34:10–14. https://doi.org/10.1139/o56-003

Borges TA, De Souza AT, Squina FM, Riaño-Pachón DM, Dos Santos RAC, Machado E, Oliveira JVC, Damásio ARL, Goldman GH (2014) Biochemical characterization of an endoxylanase from Pseudozyma brasiliensis sp. nov. strain GHG001 isolated from the intestinal tract of Chrysomelidae larvae associated to sugarcane roots. Process Biochem 49:77–83. https://doi.org/10.1016/j.procbio.2013.10.004

Borin GP, Sanchez CC, Souza AP, Santana ES, Souza AT, Leme AFP, Squina FM, Buckeridge M, Goldman GH (2015) Comparative secretome analysis of Trichoderma reesei and Aspergillus niger during growth on sugarcane biomass. PLoS ONE 10:1–20. https://doi.org/10.1371/journal.pone.0129275

Buhren BA, Schrumpf H, Hoff NP, Bӧlke E, Hilton S, Gerber PA (2016) Hyaluronidase: from clinical applications to molecular and cellular mechanisms. Eur J Med Res 21:1. https://doi.org/10.1186/s40001-016-0201-5

Bussamara R, Dall’Agnol L, Schrank A, Fernandes KF, Vainstein MH (2012) Optimal conditions for continuous immobilization of Pseudozyma hubeiensis (strain HB85A) lipase by adsorption in a packed-bed reactior by response surface methodology. Enzyme Res 2012:1-12. https://doi.org/10.1155/2012/329178

Bussamara R, Fuentefria AM, Oliveira ES, Broetto L, Simcikova M, Valente P, Schrank A, Vainstein MH (2010) Isolation of a lipase-secreting yeast for enzyme production in a pilot-plant scale batch fermentation. Bioresour Technol 101:268–275. https://doi.org/10.1016/j.biortech.2008.10.063

Buzzini P, Martini A (2002) Extracellular enzymatic activity profiles in yeast and yeast-like strains isolated from tropical environments. J Appl Microbiol 93:1020–1025. https://doi.org/10.1046/j.1365-2672.2002.01783.x

Cameotra SS, Makkar RS (2010) Biosurfactant-enhanced bioremediation of hydrophobic pollutants. Pure Appl Chem 82:97–116. https://doi.org/10.1351/pac-con-09-02-10

Campos-Takaki GM, Sarubbo LA, Albuquerque CD (2010) Environmentally friendly biosurfactant produced by yeasts. Adv Exp Med Biol 672:250–262. https://doi.org/10.1007/978-1-4419-5979-9_19

Chahinian H, Nini L, Boitard E, Dubès JP, Comeau LC, Sarda L (2002) Distinction between esterases and lipases: a kinetic study with vinyl esters and TAG. Lipids 37:653–662. https://doi.org/10.1007/s11745-002-0946-7

Chang MH, Kim HJ, Jahng KY, Hong SC (2008) The isolation and characterization of Pseudozyma sp. JCC 207, a novel producer of squalene. Appl Microbiol Biotechnol 78:963–972. https://doi.org/10.1007/s00253-008-1395-4

Chauhan PS, Puri N, Sharma P, Gupta N (2012) Mannanases: microbial sources, production, properties and potential biotechnological applications. Appl Microbiol Biotechnol 93:1817–1830. https://doi.org/10.1007/s00253-012-3887-5

Chen G, Fan KW, Lu FP, Li Q, Aki T, Chen F, Jiang Y (2010) Optimization of nitrogen source for enhanced production of squalene from thraustochytrid Aurantiochytrium sp. N Biotechnol 27:382–389. https://doi.org/10.1016/j.nbt.2010.04.005

Chen Q, Niu Y, Fan L, Li H, Dong Y (2015) Method for synthesizing MELs (mannosylerythritol lipids) through bioconversion of kitchen waste oil. CN104805160

Cho CH, Kim SY, Lee JG (2002) Erythritol fermentation method by a novel strain, Pseudozyma tsukubaensis. South Korea KR20020035051 A

Clark JH, Luque R, Matharu AS (2012) Green chemistry, biofuels, and biorefinery. Annu Rev Chem Biomol Eng 3:183–207. https://doi.org/10.1146/annurev-chembioeng-062011-081014

Collins T, Gerday C, Feller G (2005) Xylanases, xylanase families and extremophilic xylanases. FEMS Microbiol 29:3–23. https://doi.org/10.1016/j.femsre.2004.06.005

Couturier M, Navarro D, Olivé C, Chevret D, Haon M, Favel A, Lesage-Meessen L, Henrissat B, Coutinho PM, Berrín JG (2012) Post-genomic analyses of fungal lignocellulosic biomass degradation reveal the unexpected potential of the plant pathogen Ustilago maydis. BMC Genomics 13:57. https://doi.org/10.1186/1471-2164-13-57

Couturier M, Bennati-Granier C, Urio MB, Ramos LP, Berrin JG (2016) Fungal enzymatic degradation of cellulose. In: Soccol CR, Brar SK, Faulds C, Ramos LP (eds) Green Fuels Technology: Biofuels. Springer International, Switzerland, pp 133–146. https://doi.org/10.1007/978-3-319-30205-8_6

De Souza PM, de Oliveira e Magalhães P (2010) Application of microbial α-amylase in industry- A review. Braz J Microbiol 41:850–861. https://doi.org/10.1590/s1517-83822010000400004

Demain AL, Martens E (2016) Production of valuable compounds by molds and yeasts. J Antibiot 70:347–360. https://doi.org/10.1038/ja.2016.121

Fai AEC, Simiqueli APR, Andrade CJ, Ghiselli G, Pastore GM (2015a) Optimized production of biosurfactant from Pseudozyma tsukubaensis using cassava wastewater and consecutive production of galactooligosaccharides: an integrated process. Biocatal Agric Biotechnol 4:535–542. https://doi.org/10.1016/j.bcab.2015.10.001

Fai AEC, Simiqueli APR, Ghiselli G, Pastore GM (2015b) Sequential optimization approach for prebiotic galactooligosaccharides synthesis by Pseudozyma tsukubaensis and Pichia kluyveri. LWT – Food Sci Technol 63:1214–1219. https://doi.org/10.1016/j.lwt.2015.04.064

Fan KW, Aki T, Chen F, Jiang Y (2010) Enhanced production of squalene in the thraustochytrid Aurantiochytrium mangrovei by medium optimization and treatment with terbinafine. World J Microbiol Biotechnol 26:1303–1309. https://doi.org/10.1007/s11274-009-0301-2

Fan LL, Dong YC, Fan YF, Zhang J, Chen QH (2014) Production and identification of mannosylerythritol lipid-A homologs from the ustilaginomycetous yeast Pseudozyma aphidis ZJUDM34. Carbohydr Res 392:1–6. https://doi.org/10.1016/j.carres.2014.04.013

Faria NT, Marques S, Fonseca C, Ferreira FC (2015) Direct xylan conversion into glycolipid biosurfactants, mannosylerythritol lipids, by Pseudozyma antarctica PYCC 5048(T). Enzyme Microb Technol 71:58–67. https://doi.org/10.1016/j.enzmictec.2014.10.008

Faria NT, Santos M, Ferreira C, Marques S, Ferreira FC, Fonseca C (2014b) Conversion of cellulosic materials into glycolipid biosurfactants, mannosylerythritol lipids, by Pseudozyma spp. under SHF and SSF processes. Microb Cell Fact 13:155. https://doi.org/10.1186/s12934-014-0155-7

Faria NT, Santos MV, Fernandes P, Fonseca LL, Fonseca C, Ferreira FC (2014a) Production of glycolipid biosurfactants, mannosylerythritol lipids, from pentoses and D-glucose/D-xylose mixtures by Pseudozyma yeast strains. Process Biochem 49:1790–1799. https://doi.org/10.1016/j.procbio.2014.08.004

Feldbrügge M, Kellner R, Schipper K (2013) The biotechnological use and potential of plant pathogenic smut fungi. Appl Microbiol Biotechnol 97:3253–3265. https://doi.org/10.1007/s00253-013-4777-1

Frautz B, Lang S, Wagner F (1986) Formation of cellobiose lipids by growing and resting cells of Ustilago maydis. Biotechnol Lett 8:757–762. https://doi.org/10.1007/BF01020817

Fukuoka T, Kawamur M, Morita T, Imura T, Sakai H, Abe M, Kitamoto D (2008) A basidiomycetous yeast, Pseudozyma crassa, produces novel diastereomers of conventional mannosylerythritol lipids as glycolipid biosurfactants. Carbohydr Res 343:2947–2955. https://doi.org/10.1016/j.carres.2008.08.034

Fukuoka T, Morita T, Konishi M, Imura T, Kitamoto D (2007) Characterization of new types of mannosylerythritol lipids as biosurfactants produced from soybean oil by a basidiomycetous yeast, Pseudozyma shanxiensis. J Oleo Sci 56:435–442. https://doi.org/10.5650/jos.56.435

Geiser E, Przybilla SK, Engel M, Kleineberg W, Büttner L, Sarikaya E, Hartog T, Klankermayer J, Leitner W, Bölker M, Blank LM, Wierckx N (2016a) Genetic and biochemical insights into the itaconate pathway of Ustilago maydis enable enhanced production. Metab Eng 38:427–435. https://doi.org/10.1016/j.ymben.2016.10.006

Geiser E, Wierckx N, Zimmermann M, Blank LM (2013) Identification of an endo-1,4-beta-xylanase of Ustilago maydis. BMC Biotechnol 13:59. https://doi.org/10.1186/1472-6750-13-59

Geiser E, Reindl M, Blank LM, Feldbrügge M, Wierckx N, Schipper K (2016c) Activating intrinsic carbohydrate-active enzymes of the smut fungus Ustilago maydis for the degradation of plant cell wall components. Appl Environ Microbiol 82:5174–5185. https://doi.org/10.1128/AEM.00713-16

Geiser E, Przybilla SK, Friedrich A, Buckel W, Wierckx N, Blank LM, Bölker M (2016b) Ustilago maydis produces itaconic acid via the unusual intermediate trans-aconitate. Microb Biotechnol 9:116–126. https://doi.org/10.1111/1751-7915.12329

Geiser E, Wiebach V, Wierckx N, Blank LM (2014) Prospecting the biodiversity of the fungal family Ustilaginaceae for the production of value-added chemicals. Fungal Biol Biotechnol 1:2. https://doi.org/10.1186/s40694-014-0002-y

Gokhale DV, Patil SG, Bastawde KB (1998) Potential application of yeast cellulase-free xylanase in agrowaste material treatment to remove hemicellulose fractions. Bioresour Technol 63:187–191. https://doi.org/10.1016/s0960-8524(97)00062-x

Golubev WI, Kulakovskaya TV, Shashkov AS, Kulakovskaya EV, Golubev NV (2008) Antifungal cellobiose lipid secreted by the epiphytic yeast Pseudozyma graminicola. Microbiology 77:171–175. https://doi.org/10.1134/s0026261708020082

Gong Z, Zhou W, Shen H, Zhao ZK, Yang Z, Yan J, Zhao M (2016) Co-utilization of corn stover hydrolysates and biodiesel-derived glycerol by Cryptococcus curvatus for lipid production. Bioresour Technol 219:552–558. https://doi.org/10.1016/j.biortech.2016.08.021

Grembecka M (2016) Sugar alcohols as sugar substitutes in food industry. In: Mérillon JM, Ramawat KG (eds) Sweeteners, reference series in phytochemistry. Springer International Publishing, Switzerland, pp 1–27

Guevarra ED, Tabuchi T (1990a) Accumulation of itaconic, 2-hydroxyparaconic, itatartaric, and malic acids by strains of the genus Ustilago. Agric Biol Chem 54:2353–2358. https://doi.org/10.1080/00021369.1990.10870333

Guevarra ED, Tabuchi T (1990b) Production of 2-hydroxyparaconic and itatartaric acids by Ustilago cynodontis and simple recovery process of the acids. Agric Biol Chem 54:2359–2365. https://doi.org/10.1271/bbb1961.54.2359

Gupta VK, Kubicek CP, Berrin JG, Wilson DW, Couturier M, Berlin A, Filho EXF, Ezeji T (2016) Fungal enzymes for bio-products from sustainable and waste biomass. Trends Biochem Sci 41:633–645. https://doi.org/10.1016/j.tibs.2016.04.006

Hammami W, Labbé C, Chain F, Mimee B, Bélanger RR (2008) Nutritional regulation and kinetics of flocculosin synthesis by Pseudozyma flocculosa. App Microbiol Biotechnol 80:307–315. https://doi.org/10.1007/s00253-008-1541-z

Haskins RH, Thorn JA, Boothroyd B (1955) Biochemistry of the Ustilaginales: XI. Metabolic products of Ustilago zeae in submerged culture. Can J Microbiol 1:749–756. https://doi.org/10.1139/m55-089

Hirose E, Izawa N, Adachi J, Mori S, Mase T (2009) Purification, characterization and application of α-amylase from Pseudozyma aphidis I-8. J Appl Glycosci 56:207–124. https://doi.org/10.5458/jag.56.207

Hoang MH, Ha NC, Thom LT, Tam LT, Anh HTL, Thu NTH, Hong DD (2014) Extraction of squalene as value-added product from the residual biomass of Schizochytrium mangrovei PQ6 during biodiesel producing process. J Biosci Bioeng 118:632–639. https://doi.org/10.1016/j.jbiosc.2014.05.015

Isshiki S, Shitasue S, Mase T, Kondo T, Kamino S, Kamei Y (2017) Characterization of an aminopeptidase from Pseudozyma hubeiensis 31-B and potential applications. Mycoscience 58:60–67. https://doi.org/10.1016/j.myc.2016.10.001

Jakočiūnas T, Bonde I, Herrgård M, Harrison SJ, Kristensen M, Pedersen LE, Jensen MK, Keasling JD (2015) Multiplex metabolic pathway engineering using CRISPR/Cas9 in Saccharomyces cerevisiae. Metab Eng 28:213–222. https://doi.org/10.1016/j.ymben.2015.01.008

Jan AH, Subileau M, Deyrieux C, Perrier V, Dubreucq E (2016) Elucidation of a key position for acyltransfer activity in Candida parapsilosis lipase/acyltransferase (CpLIP2) and in Pseudozyma antarctica lipase A (CAL-A) by rational design. Biochim Biophys Acta 1864:187–194. https://doi.org/10.1016/j.bbapap.2015.11.006

Jasso-Robles FI, Jiménzez-Bremont JF, Becerra-Flora A, Juárez-Montiel M, Gonzalez ME, Pieckenstain FL (2016) Inhibition of polyamine oxidase activity affects tumor development during the maize-Ustilago maydis interaction. Plant Phydiol Biochem 102:115–124. https://doi.org/10.1016/j.plaphy.2016.02.019

Javier PI, Oscar G, Sanz-Aparicio J, Díaz P (2007) Xylanases: molecular properties and applications. In: Polaina J, MacCabe A (eds) Industrial Enzymes. Springer, Netherlands, pp 65–82

Jayani RS, Saxena S, Gupta R (2005) Microbial pectinolytic enzymes: a review. Process Biochem 40:2931–2944. https://doi.org/10.1016/j.procbio.2005.03.026

Jeya M, Lee KM, Tiwari MK, Kim JS, Gunasekaran P, Kim SW, Kim IW, Lee JK (2009) Isolation of a novel high erythritol-producing Pseudozyma tsukubaensis and scale-up of erythritol fermentation to industrial level. Appl Microbiol Biotechnol 83:225–231. https://doi.org/10.1007/s00253-009-1871-5