Abstract

In examining the production of valuable compounds by marine microorganisms, we isolated a novel yeast strain that produces a large amount of squalene and several polyunsaturated fatty acids. Molecular and phylogenetic analyses of the ribosomal DNA suggest that the isolate belongs to the genus Pseudozyma, which comprises ustilaginomycetous anamorphic yeasts. The nucleotide sequence of an internally transcribed spacer region from isolate Pseudozyma sp. JCC207 showed 98% similarity with those of Pseudozyma rugulosa and Pseudozyma aphidis, which are close relatives of the isolate. In considering use of Pseudozyma sp. JCC207 for squalene production, the efficiency of squalene production was investigated under different conditions. Glucose was the best carbon source for the production of squalene. In the presence of yeast extract, squalene production was activated and an optimum ratio of glucose to yeast extract was 4.5. For the optimal squalene production, the concentration of glucose was 40 g l−1 and the best nitrogen source was sodium nitrogen. Pseudozyma sp. JCC207 was shown to produce up to 5.20 g/L of biomass and 340.52 mg/L of squalene. In an optimal condition, the content and yield of squalene produced by Pseudozyma sp. JCC207 were much greater than those obtained from microorganisms previously reported as squalene producers. We identified, classified, and characterized Pseudozyma sp. JCC207 as a novel squalene producer. The squalene production rate of Pseudozyma sp. JCC207 makes it an ideal candidate for the commercialization of microbial squalene.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Squalene is a polyunsaturated aliphatic hydrocarbon containing six isoprene units that provide the backbone for the biosynthesis of cholesterol, bile acids, and steroids (Fig. 1). In addition to its role as a key precursor to isoprene-derived molecules, squalene is essential in our body because it is a natural antioxidant that protects cells from free radicals and reactive oxygen species (Kohno et al. 1995). Although current use of squalene is mainly associated with cosmetic industries as a moisturizing agent and an emollient, it has garnered more attention due to many studies showing its therapeutic effects and possible pharmaceutical applications (for a review, see Newmark 1999; Smith 2000). Most importantly, squalene has significant antitumor activities (Newmark 1999; Smith 2000). Studies have shown that squalene effectively inhibited chemically induced colon, lung, and skin tumorigenesis in animals (Murakoshi et al. 1992; Rao et al. 1998; Smith et al. 1998). Squalene also had a radioprotective effect on mice receiving lethal whole-body doses of radiation (Kamimura et al. 1992; Storm et al. 1993), a cardioprotective effect on experimentally induced myocardial infarction (Aguilera et al. 2005), and a hypocholesterolemic effect in patients (Chan et al. 1996).

These health benefits of squalene have provided its potential as therapeutics. Until now, squalene has been extracted from the liver oil of deep-sea sharks. Conservation of marine ecology as well as high processing costs are currently the major obstacles for massive production of squalene from a limited animal source. In addition, the use of shark liver oil is limited due to environmental pollutants, such as dioxins, PCBs, and heavy metals in shark liver, as well as the unpleasant fishy smell and taste (Storelli et al. 2003; Turoczy et al. 2000). To produce high-quality squalene without the above problems, microbial production of squalene could be an excellent alternative. In fact, production of polyunsaturated fatty acids from oleaginous microorganisms rather than from marine animals, such as fish and seals, is now a reality (for a review, see Ward and Singh 2005). Unfortunately, no known squalene-producing microbial organisms produce enough squalene for commercial applications.

To identify squalene-producing microorganisms, we screened microbial strains from various marine environments. Microbial isolates were screened for their ability to produce large quantities of fatty acids or lipids. Among several squalene-producing strains isolated, we identified a novel yeast strain that produces large amounts of squalene. The squalene production rate of this isolate proved its strong potential as a natural source for the commercial production of high-quality squalene. Here, we show the isolation and characterization of Pseudozyma sp. JCC207, a novel producer of squalene.

Materials and methods

Microorganisms

Pseudozyma sp. JCC207 was isolated from seawater near Guam, USA in October 2004. We collected seawater 10 km from the coast and 100 m below the water surface. The seawater was cultured on streptomycin-containing ATCC790 medium (glucose 0.5%, peptone 0.1%, yeast extract 0.1%, sea salt 3%). After incubation at 25°C for 7 days, we isolated Pseudozyma sp. JCC207 as the producer of squalene and fatty acids by screening using gas chromatography. Pseudozyma sp. JCC207 is available from Jinis Culture Collection (JCC, Chonju, Korea) and the Korea Agricultural Culture Collection (KACC 91307). The microorganisms were cultured at 25°C on ATCC790 agar plates. They were stored at 4°C and renewed every 4 weeks.

Molecular and phylogenetic analyses

Genomic DNA was isolated from a pure culture of isolate JCC207 as described previously (Hoffman and Winston 1987). The DNA fragments used for phylogenetic analyses contained the ITS1, 5.8S rDNA, ITS2, and D1/D2 domains of LSU rDNA. The DNA fragments were amplified with primers NS5 and LR7 (White et al. 1990; Vilgalys and Hester 1990). The primers used for sequencing of the ITS region, including 5.8S rDNA, were ITS5, ITS3, ITS2, and ITS4 (White et al. 1990). LR0R, LR3R, LR5, and LR7 were used for sequencing of the LSU rDNA (Vilgalys and Hester 1990; Moncalvo et al. 1993).

The resulting sequence data were searched using NCBI BLAST, and the sequences were aligned with the ClustalX program. Phylogenetic relationships were constructed using the neighbor-joining method in PAUP*4.0b10. The distances between sequence pairs were calculated using Kimura’s two-parameter model, and bootstrap analyses were performed with 1,000 random resampling events.

The rRNA sequences of the isolate are available in GenBank. The GenBank accession numbers for the nucleotide sequences of the 26S rRNA gene and the ITS1, 5.8S rRNA, ITS2 gene are DQ178644 and DQ178645, respectively.

Morphological, physiological, and biochemical characteristics

The morphological and physiological characteristics of the strain were determined using standard yeast techniques (Yarrow 1998).

Media preparation and culture conditions

To study the squalene production, single colonies from agar slants were inoculated in SC1 medium (glucose 0.9%, yeast extract 0.2%, and sea salt (Sigma, S9883) 2.5%) for marine-derived microbial culture. Seed culture was carried out at 25°C for 42 h on an orbital shaker at 150 rpm. 1.5 ml of seed culture was transferred into 50 ml of SC1 in a 100-ml flask and incubated at 25°C for 6 days at 150 rpm. In the main cultures, ATCC790 was also used for comparison.

To investigate the effect of carbon sources and nitrogen sources on squalene production, some conditions of cultivation were slightly modified from the above cultivation. Seed cultures were prepared by incubating at 25°C for 48 h at 180 rpm. Three milliliters of seed cultures were transferred into 100 ml of main media in a 250-ml flask and incubated at 25°C at 160 rpm. The composition of SC1 medium was altered with different carbon and nitrogen sources for each experiment as indicated in the results. In order to examine squalene production and cell growth using optimal media composition by time course analysis, the media used in main cultivation were SC4 (glucose 4%, yeast extract 0.2%, and sea salt 2.5%) and SC41 (glucose 4%, yeast extract 0.2%, NaNO3 0.1% and sea salt 2.5%). SC1 was also used for comparison.

Squalene analyses

The production of squalene and fatty acids by Pseudozyma sp. JCC270 was analyzed by gas chromatography and mass spectroscopy (GC/MS). An aliquot from each culture was sampled and harvested. The samples were directly transmethylated as described previously (Grayburn et al. 1992), with slight modifications. Two milliliters of 2% sulfuric acid in methanol were added to the samples and heated to 100°C for 1 h. The samples were vortexed before and after heating. The boiled samples were then cooled to room temperature, and 2 ml of n-hexan and distilled water were added. Samples were next vortexed vigorously for 1 to 2 min. After pulse centrifugation, the organic upper phase was transferred to a new tube and subjected to analysis by GC/MS.

An Agilent GC/MS (Hewlett Packard Co.) was used, which was equipped with a model 5890 gas chromatograph, a model 5973 mass selective detector, and an Agilent G1701CA chemstation. A capillary column coated with DB-5 cross-linked 5% phenylmethylsilicon was used. Helium served as the carrier gas; its flow rate was 1 ml/min. The initial oven temperature was 70°C, which was maintained for 3 min and then increased to 300°C at a rate of 10°C/min and held for 8 min. The injector temperature was 280°C, the transfer line temperature was 270°C, and the detector temperature was 200°C. The injection volume was 1 μl and the split ratio was 1:12. The mass spectrometer was operated at 70 eV in the electron impact mode with SCAN. Identification of compounds, including squalene, was tentatively verified using a mass spectral library (Wiley 7n.L mass spectral database). Squalene was further identified using a commercial standard (98% squalene, Sigma S3626). Heptadecanoic acid (C18, Sigma H-4515) was used as an internal standard for the quantification of squalene.

The growth curve of Pseudozyma sp. JCC207

The growth of Pseudozyma sp. JCC207 was determined by measuring the cellular dry weight. Cultures were periodically sampled and harvested by centrifugation at 3,200 rpm for 20 min. To determine the cellular dry weight, harvested cells were washed with distilled water and dried at 80°C in a vacuum oven for 48 h.

Results

Molecular and phylogenetic analyses of Pseudozyma sp. JCC207

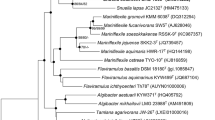

Molecular analyses based on the D1/D2 domain of the 26S rDNA and ITS region from isolate JCC207 indicated that phylogenetically, it was closely related to several species of the basidiomycetous anamorphic yeasts Pseudozyma (Fig. 2; tree based on D1/D2 domain of 26S rDNA is not shown; Boekhout 1995; Begerow and Bauer 2000; Fell et al. 2000). The closest relatives of the isolate were Pseudozyma aphidis and Pseudozyma rugulosa. Partial sequences of the 26S rDNA of the isolate were identical to those of P. aphidis and P. rugulosa, except for a single-nucleotide substitution in P. rugulosa strain CBS 170.88. Isolate JCC207 differed from P. aphidis and P. rugulosa by five to six nucleotide substitutions and six gaps in the ITS region. The nucleotide sequences of ITS1 and ITS2 from isolate JCC207 showed 98% similarity to those of P. aphidis and P. rugulosa. Based on molecular and phylogenetic analyses, we named isolate JCC207 “Pseudozyma sp. JCC207.”

The phylogenetic trees of Pseudozyma sp. JCC207 with its Ustilaginales relatives. The trees were constructed based on nucleotide sequences of ITS1, 5.8S rRNA, ITS2 by neighbor-joining methods. Bootstrap percentages from 1,000 bootstrap replicates are shown (values under 50% are not given.) Rhodotorula taiwaniana and Rhodotorula acheniorum were used as outgroups

Morphological and physiological characteristics

Pseudozyma sp. JCC207 formed a yeast-like vegetative cell that was ovoid to cylindrical and had septate and hyaline hyphae (Fig. 3). Pseudozyma sp. JCC207 produced fusiform blastoconidia on a sterigma-like structure along the hyphae. Pseudozyma sp. JCC207 was positive in DBB and urease activity tests, and did not produce extracellular starch-like compound (Table 1). These morphological and physiological characteristics are common features of the Pseudozyma classified by Boekhout (1995). We investigated the growth of the strain on various carbon and nitrogen sources, and under various temperatures and osmotic stresses, all of which are necessary for yeast identification and taxonomy (Table 1). The chemotaxanomic data differentiated Pseudozyma sp. JCC207 from other known species of Pseudozyma (Table 2). Pseudozyma sp. JCC207 was differentiated from P. aphidis by its ability to assimilate ethanol, glycerol, erythritol and d-gluconate. In addition, Pseudozyma sp. JCC207 differs from P. rugulosa in its ability to assimilate l-sorbose, lactose, melibiose, and methanol.

Production of squalene by Pseudozyma sp. JCC207 in ATCC790 and SC1 media

GC/MS analysis of the n-hexan portion from cell extracts of Pseudozyma sp. JCC207 indicated that, while it produced squalene as a major peak, it also produced useful polyunsaturated fatty acids, including hexadecanoic acid, 9,12-octadecadienoic acid, 9-octadecenoic acid, and octadecanoic acid (Fig. 4). We investigated the squalene yield and content of Pseudozyma sp. JCC207 cultivated in ATCC790 and SC1 by time course analysis (Fig. 5). The yield and content of squalene were much greater in SC1 than in ATCC790. The yield of squalene reached the highest at 48 h in ATCC790 but 96 h in SC1. Maximum production of squalene was achieved in SC1 in which squalene yield was about four times of that in ATCC790. The content of squalene in biomass showed similar pattern. The squalene content reached maximum at 48 h in ATCC790 but 96 h in SC1. Maximum content of squalene was achieved at 96 h in SC1 in which squalene was about 2.5 times of that in ATCC790. Overall, SC1 medium was better than ATCC790 for squalene production using Pseudozyma sp. JCC207.

Squalene yield and content of Pseudozyma sp. JCC207 cultured in ATCC790 and SC1. Pseudozyma sp. JCC207 was cultured in 50 ml of ATCC790 broth (open squares) and SC1 broth (closed squares) at 25°C for 144 h on an orbital shaker at 150 rpm. Squalene yield and content were measured periodically by GC/MS analysis. a Squalene yield per liter of cell culture. b Squalene content per gram of dry cell weight. The values are the mean ± standard deviation of two replicates

Optimization of cultivation conditions for the production of squalene

After preliminary culture study with two common culture media for marine-derived cell, culture condition for the maximum production of squalene was investigated. In order to address the influence of carbon sources on squalene production, Pseudozyma sp. JCC207 was cultured with various common carbon sources, including glucose, sucrose, galactose, glycerol, acetic acid, and soybean oil (Fig. 6). The maximum production of squalene occurred after 96 h of cultivation when glucose was used as a carbon source; although galactose reached significant level of squalene production earlier, 72 h of cultivation. The carbon sources for the production of squalene seemed to be glucose and galactose. Optimization of culture media with Pseudozyma sp. JCC207 was further investigated with other nutrients, including yeast extract, peptone, corn steep, and cottonseed flour, called proflo (Fig. 7). The greatest amount of squalene production occurred in cultures with yeast extract compared to the cultures containing corn steep, proflo, or peptone. The optimum ratio of glucose to yeast extract for the squalene production was also examined (Fig. 8). When the ratio of glucose to yeast extract was 4.5, Pseudozyma sp. JCC207 produced the highest amount of squalene both after 72 and 96 h of cultivation. The concentration of carbon source also greatly affected the production of squalene (Fig. 9). Glucose-rich media, containing 20–40 g/L, resulted in about two times increase in squalene production compared to the basal media with glucose of 9 g/L. Regarding inorganic nitrogen sources on the production of squalene, common nitrogen sources including sodium nitrate, ammonium nitrate, ammonium chloride, and ammonium sulfate were investigated with Pseudozyma sp. JCC207 (Fig. 10). Pseudozyma sp. JCC207 culture containing NaNO3 showed the highest level of squalene compared to ammonium nitrate, ammonium chloride, and ammonium sulfate.

The effects of carbon sources on squalene production by Pseudozyma sp. JCC207. Pseudozyma sp. JCC207 was cultured with different carbon sources at 25°C on an orbital shaker at 160 rpm. The cultures were sampled after 72 and 96 h of cultivation, respectively, and squalene production was analyzed by GC/MS. The carbon sources used were added at 0.9% to SC1. Glu: Glucose; Suc: Sucrose; Gal: Galactose; Gly: Glycerol. The values are the mean ± standard deviation of two replicates

The effects of some nutrients on squalene production by Pseudozyma sp. JCC207. Pseudozyma sp. JCC207 was cultured with different organic nitrogen sources at 25°C on an orbital shaker at 160 rpm. The cultures were sampled after 72 and 96 h cultivation, respectively, and squalene production of the samples was analyzed by GC/MS. The nutrients used were added at 0.2% to SC1. The values are the mean ± standard deviation of two replicates

The effects of glucose/yeast extract ratios on squalene production by Pseudozyma sp. JCC207. Pseudozyma sp. JCC207 was cultured with different ratios of glucose to yeast extract (glucose/yeast extract = 1, 2, 3, 4.5) at 25°C on an orbital shaker at 160 rpm. The cultures were sampled after 72 and 96 h cultivation, respectively, and squalene production of the samples was analyzed by GC/MS. The values are the mean ± standard deviation of two replicates

The effects of glucose concentration on squalene production by Pseudozyma sp. JCC207. Pseudozyma sp. JCC207 was cultured with different concentration of glucose at 25°C on an orbital shaker at 160 rpm. The cultures were sampled after 96 h of cultivation, and squalene production of the samples was analyzed by GC/MS. The values are the mean ± standard deviation of two replicates

The effects of inorganic nitrogen sources on squalene production by Pseudozyma sp. JCC207. Pseudozyma sp. JCC207 was cultured with NaNO3, NH4NO3, NH4Cl and (NH4)2SO4 at 25°C on an orbital shaker at 160 rpm. The nitrogen sources used were added at 0.1% to SC1. The cultures were sampled after 96 h of cultivation, and squalene production of the samples was analyzed by GC/MS. The values are the mean ± standard deviation of two replicates

After optimizing the effects of carbon and nitrogen sources on squalene production, we have tested cultivation conditions such as alteration of the rotational speed used for seed and main cultivation and cultivation time for seed cultures. The rotational speed for seed and main cultivation was optimized to 180 and 160 rpm, respectively, and the seed cultures were prepared by incubating at 25°C for 48 h. The yield and content of squalene greatly increased after 96 h of growth to 116.81 mg/L and 30.33 mg/g, respectively (Fig. 11, SC1). For further optimization, 40 g/L glucose was added into SC1, yielding SC4. Next, sodium nitrate was added into SC4, yielding SC41. Maximum level of squalene content and production, 340.52 mg/L and 70.32 mg/g, occurred after 120 h of incubation in SC4 which contained 40 g/L glucose but no sodium nitrate.

Squalene yield and content of Pseudozyma sp. JCC207 cultured in optimized culture condition and media. For optimized cultivation, the seed culture was prepared by incubating at 25°C for 48 h on an orbital shaker at 180 rpm and then transferring into 100 ml of SC1 (triangles), SC4 (squares) and SC41 (diamonds) media. The main cultivation was carried out for 168 h on an orbital shaker at 160 rpm. Squalene yield and content were measured periodically by GC/MS analysis. a Squalene yield per liter of cell culture. b Squalene content per gram of dry cell weight. The values are the mean ± standard deviation of two replicates

The cell growth of Pseudozyma sp. JCC207 was investigated by measuring dry cell weights from cultures grown in optimized media and cultivation conditions (Fig. 12). Pseudozyma sp. JCC207 in SC4 and SC41 reached maximum growth after 120 h of cultivation with a maximum biomass of 4.88 g/L and 5.20 g/L, respectively.

The cell-growth curves of Pseudozyma sp. JCC207 cultured in optimized culture condition and media. Pseudozyma sp. JCC207 was cultured in SC1 (triangles), SC4 (squares) and SC41 (diamonds) with optimized culture conditions for squalene production at 25°C for 168 h. Cell growth was determined by measuring the dry cell weight of Pseudozyma sp. JCC207. The values are the mean ± standard deviation of three replicates

Discussion

Marine oils, such as polyunsaturated fatty acids and squalene, have been an important nutrient for the maintenance of human health. Famous Eskimo studies proved that polyunsaturated fatty acids, such as omega 3, provide strong cardiovascular effects. Therefore, consumption of fish oils as dietary supplements is recommended (Dyerberg and Bang 1982). However, ever-increasing pollution in marine products as well as the limited source of marine animals necessitates the identification of a natural source of marine oils without heavy metal contamination or inconsistencies. Microbial production of high-quality oil could be an excellent alternative, since omega 3 and squalene are produced from oleaginous microorganisms in the sea but not from fish or shark. In fact, microbial omega 3 containing DHA has been successfully commercialized for infants and pregnant women through the development of an industrial strain for mass production of omega 3 (Ward and Singh 2005).

Accumulated studies examining squalene have confirmed its strong antioxidant as well as anticancer activity through the ras-oncogene pathway, suggesting its therapeutic potential. However, the limited production of squalene from deep-sea shark, as well as its inconsistence and contamination, has created difficulties with its mass production and commercialization. Therefore, the identification of an industrial strain of squalene-producing microorganism has been the subject of increasing commercial attention. In this study, marine samples were screened for squalene production and a candidate strain JCC207 was identified and classified as Pseudozyma sp. JCC207. For the selection of appropriate strains for mass production, important considerations included the specific growth rate, the biomass production, the total lipid content, and the squalene content of the lipid. Pseudozyma sp. JCC207 produces the greatest amount of squalene, both in quantity and in proportion to total cellular lipid.

In order to optimize the culture conditions for squalene production, the effects of carbon and nitrogen sources on squalene production were investigated. Glucose and galactose were the best carbon sources for squalene production. With the addition of yeast extract, the amount of squalene further increased. Maximum level of squalene content and production, 340.52 mg/L and 70.32 mg/g, occurred after 120 h of incubation in SC4, which contained 40 g/L glucose. The sharp decrease of squalene after running through its maximum may be resulted from depletion of carbon source that is precursor for squalene biosynthesis. Also, the sharp depletion of squalene would be caused by the consumption or degradation of the squalene in the cell. In considering use of media for the squalene production by Pseudozyma sp. JCC207, SC4 as well as SC41 could be excellent candidates.

In addition to the media composition, the slight changes in the rotational speed and time of seed cultivation greatly affected the squalene production of the main cultures. In optimal culture conditions, the maximum amount of squalene produced from a culture of Pseudozyma sp. JCC207 was 70.32 mg/g of dry cell weight and 340.52 mg/L in culture. These values are much greater than previous values observed for Saccharomyces cerevisiae (0.041 mg/g), Schizochytrium mangrovei (0.162 mg/g; 1.313 mg/L) and Thraustochytrid ACEM 6063 (1.5 mg/g; Bhattacharjee et al. 2001; Jiang et al. 2004; Lewis et al. 2001).

Molecular and phylogenetic analyses of the rDNA region from the isolate indicated that the species belongs to the genus Pseudozyma, a taxon comprising the anamorphic yeasts of the Ustilaginales (Boekhout 1995). The phylogenetic tree between JCC207 and its Ustilaginales relatives showed that Pseudozyma JCC207 formed a well-supported cluster consisting of P. aphidis, P. rugulosa, Pseudozyma antarctica and P. parantarctica, together with Moesziomyces bullatus and Macalpinomyces eriachnes. No species of Pseudozyma show ITS region sequences that are identical to those of isolate, whereas partial sequences of the 26S rDNA of the isolate were almost identical to those of P. aphidis and P. rugulosa. The nucleotide sequences of ITS1 and ITS2 showed 2% dissimilarity to those of P. aphidis and P. rugulosa, the closest relatives of isolate JCC207. The chemotaxonomic analysis showed that Pseudozyma JCC207 differs from other known species in the utilization of several compounds. Although Pseudozyma sp. JCC207 showed some chemotaxonomic differences compared to its closest relatives, P. aphidis and P. rugulosa, these were not sufficient to identify it as a new species separate from P. aphidis and P. rugulosa. Further studies are needed to confirm whether Pseudozyma sp. JCC207 is a new species or a variant of P. rugulosa or P. aphidis.

The Pseudozyma species have been known to generate various bio-active compounds. It was reported that P. flocculosa produces fatty acids and novel glycolipids that have antifungal activity. (Avis and Bélanger 2002; Mimee et al. 2005). Moreover, P. fusiformata was reported to produce glycolipids with antifungal activity (Kulakovskaya et al. 2003) and P. tsukubaensis was reported to produce mycocin (Golubev et al. 2006). More interestingly, some species of Pseudozyma, including P. aphidis, P. antarctica, and P. rugulosa, have been intensively investigated for the production of mannosylerythritol lipid, a biosurfactant used in a broad range of industrial applications (Kitamoto et al. 2002; Morita et al. 2006; Rau et al. 2005). In this study, Pseudozyma sp. JCC207 was identified and selected for its ability to produce a large amount of squalene. We believe that Pseudozyma sp. JCC207 could be an excellent candidate strain as a novel producer for commercialization of microbial squalene.

References

Aguilera Y, Dorado ME, Prada FA, Martínez JJ, Quesada A, Gutiérrez VR (2005) The protective role of squalene in alcohol damage in the chick embryo retina. Exp Eye Res 80:535–543

Avis TJ, Bélanger RR (2002) Mechanisms and means of detection of biocontrol activity of Pseudozyma yeasts against plant-pathogenic fungi. FEMS Yeast Res 2:5–8

Begerow D, Bauer R (2000) Phylogenetic placements of ustilaginomycetous anamorphs as deduced from nuclear LSU rDNA sequences. Mycol Res 104(1):53–60

Bhattacharjee P, Shukla VB, Singhal RS, Kulkarni PR (2001) Studies on fermentative production of squalene. World J Microbiol Biotechnol 17:811–816

Boekhout T (1995) Pseudozyma Bandoni emend. Boekhout, a genus for yeast-like anamorphs of Ustilaginales. J Gen Appl Microbiol 41:359–366

Boekhout T, Fell JW (1998) Pseudozyma Bandoni emend. Boekhout and a comparison with the yeast state of Ustilago maydis (De Candolle) Corda. In: Kurtzman CP, Fell JW (eds) The yeasts, a taxonomic study. 4th edn. Elsevier, Amsterdam, pp 790–797

Chan P, Tomlinson B, Lee CB, Lee YS (1996) Effectiveness and safety of low-dose pravastatin and squalene, alone and in combination, in elderly patients with hypercholesterolemia. J Clin Pharmacol 36:422–427

Dyeberg J, Bang HO (1982) A hypothesis on the development of acute myocardial infarction in Greenlanders. Scand J Clin Lab Invest Suppl 161:7–13

Fell JW, Boekhout T, Fonseca A, Scorzetti G, Statzell-Tallman A (2000) Biodiversity and systematics of basidiomycetous yeasts as determined by large subunit rDNA D1/D2 domain sequences analysis. Int J Syst Evol Microbiol 50:1351–1371

Golubev WI, Pfeiffer I, Golubeva EW (2006) Mycocin production in Pseudozyma tsukubaensis. Mycopathologia 162:313–316

Grayburn WS, Collins GB, Hildebrand DF (1992) Fatty acid alteration by a delta 9 desaturase in transgenic tobacco tissue. Biotechnology 10(6):675–678

Hoffman CS, Winston F (1987) A ten-minute DNA preparation from yeast efficiently releases autonomous plasmids for transformation of Escherichia coli. Gene 57(2–3):267–272

Jiang Y, Fan KW, Wong RT, Chen F (2004) Fatty acid composition and squalene content of the marine microalga Schizochytrium mangrovei. J Agric Food Chem 52(5):1196–1200

Kamimura H, Koga N, Oguri K, Yoshimura H (1992) Enhanced elimination of theophylline, phenobarbital and strychnine from the bodies of rats and mice by squalene treatment. J Phamacobiodyn 15(5):215–221

Kitamoto D, Isoda H, Nakahara T (2002) Functions and potential applications of glycolipid biosurfactants—from energy-saving materials to gene delivery carriers. J Biosci Bioeng 94:187–201

Kohno Y, Egawa Y, Itoh S, Nagaoka S, Takahashi M, Mukai K (1995) Kinetic study of quenching reaction of singlet oxygen and scavenging reaction of free radical by squalene in n-butanol. Biochim Biophys Acta 1256(1):52–56

Kulakovskaya TV, Kulakovskaya EV, Golubev WI (2003) ATP leakage from yeast cells treated by extracellular glycolipids of Pseudozyma fusiformata. FEMS Yeast Res 3:401–404

Lewis TE, Nichols PD, McMeekin TA (2001) Sterol and squalene content of a docosahexaenoic acid producing Thraustochytrid: influence of culture age, temperature, and dissolved oxygen. Mar Biotechnol 3:439–447

Mimee B, Labbé C, Pelletier R, Bélanger RR (2005) Antifungal activity of flocculosin, a novel glycolipid isolated from Pseudozyma flocculosa. Antimicrob Agents Chemot 49:1597–1599

Moncalvo JM, Rehner SA, Vilgalys R (1993) Systematics of Lyophyllum section Difformia based on evidence from culture studies and ribosomal DNA sequences. Mycologia 85:788–794

Morita T, Konishi M, Fukuoka T, Imura T Kitamoto D (2006) Discovery of Pseudozyma rugulosa NBRC 10877 as a novel producer of the glycolipid biosurfactants, mannosylerythritol lipids, based on rDNA sequences. Appl Microbiol Biotechnol 73:305–313

Murakoshi M, Nishino H, Tokuda H, Iwashima A, Okuzumi J, Kitano H, Iwasaki R (1992) Inhibition by squalene of the tumor-promoting activity of 12-O-tetradecanoylphorbol-13-acetate in mouse-skin carcinogenesis. Int J Cancer 1992 52(6):950–952

Newmark HL (1999) Squalene, olive oil, and cancer risk: review and hypothesis. Ann NY Acad Sci 889:193–203

Rao CV, Newmark HL, Reedy BS (1998) Chemopreventive effect of squalene on colon cancer. Carcinogenesis 19:287–290

Rau U, Nguyen LA, Schulz S, Wray V, Nimtz M, Roeper H, Koch H, Lang S (2005) Formation and analysis of mannosylerythritol lipids secreted by Pseudozyma aphidis. Appl Microbiol Biotechnol 66(5):551–559

Smith TJ (2000) Squalene: potential chemopreventive agent. Exp Opin Invest Drugs 9(8):1841–1848

Smith TJ, Yang GY, Seril DN, Liao Q, Kim S (1998) Inhibition of 4-(methylnitrosamino)-1-(3-pyridyl)-1-butanone-induced lung tumorigenesis by dietary olive oil and squalene. Carcinogenesis 19:703–706

Storelli MM, Ceci E, Storelli A, Marcotrigiano GO (2003) Polychlorinated biphenyl, heavy metal and methylmercury residues in hammerhead sharks: contaminant status and assessment. Mar Pollut Bull 46:1035–1039

Storm HM, Oh SY, Kimler BF, Norton S (1993) Radioprotection of mice by dietary squalene. Lipids 28(6):555–559

Sugita T, Takashima M, Poonwan N, Mekha N, Malaithao K, Thungmuthasawat B, Prasarn S, Luangsook P, Kudo T (2003) The first isolation of ustilaginomycetous anamorphic yeasts, Pseudozyma species, from patients’ blood and a description of two new species: P. parantarctica and P. thailandica. Microbiol Immunol 47(3):183–190

Turoczy NJ, Laurenson LJ, Allinson G, Nishikawa M, Lambert DF, Smith C, Cottier JP, Irvine SB, Stagnitti F (2000) Observations on metal concentrations in three species of shark (Deania calcea, Centroscymnus crepidater, and Centroscymnus owstoni) from southeastern Australian waters. J Agric Food Chem 48:4357–4364

Vilgalys R, Hester M (1990) Rapid genetic identification and mapping enzymatically amplified ribosomal DNA from several Cryptococcus species. J Bacteriol 172(8):4238–4246

Wang QM, Jia JH, Bai FY (2006) Pseudozyma hubeiensis sp. nov. and Pseudozyma shanxiensis sp. nov., novel ustilaginomycetous anamorphic yeast species from plant leaves. Int J Syst Evol Microbiol 56:289–293

Ward OP, Singh A (2005) Omega-3/6 fatty acids: alternative sources of production. Process Biochem 40:3627–3652

White TJ, Bruns T, Lee S, Taylor J (1990) Amplification and direct sequencing of fungal ribosomal genes for phylogenetics. In: Innis MA, Gelfand DH, Sninsky JJ, White TJ (eds) PCR protocols, a guide to methods and applications. Academic, New York, pp 315–322

Yarrow D (1998) Methods for the isolation, maintenance, classification and identification of yeast. In: Kurtzman CP, Fell JW (eds) The yeasts, a taxonomic study. 4th edn. Elsevier, Amsterdam, pp 75–200

Acknowledgements

We thank Dr. So Young Kim (Chosun University) and Dr. Yun Cho Chung (Center for University-wide Research Facilities) for critical advice regarding the phylogenetic analysis of the rDNA and the analysis of squalene, respectively. This study was supported by the Research Center for Industrial Development of BioFood Materials at Chonbuk National University, Chonju, Korea.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Chang, MH., Kim, HJ., Jahng, KY. et al. The isolation and characterization of Pseudozyma sp. JCC 207, a novel producer of squalene. Appl Microbiol Biotechnol 78, 963–972 (2008). https://doi.org/10.1007/s00253-008-1395-4

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00253-008-1395-4