Abstract

Biocatalytic reactions performed by cytochrome P450 monooxygenases are interesting in pharmaceutical research since they are involved in human drug metabolism. Furthermore, they are potentially interesting as biocatalysts for synthetic chemistry because of the exquisite selectivity of the chemistry they undertake. For example, selective hydroxylation can be undertaken on a highly functionalized molecule without the need for functional group protection. Recent progress in the discovery of novel P450s as well as protein engineering of these enzymes strongly encourages further development of their application, including use in synthetic processes. The biological characteristics of P450s (e.g., cofactor dependence) motivate the use of whole-cell systems for synthetic processes, and those processes implemented in industry are so far dominated by growing cells and native host systems. However, for an economically feasible process, the expression of P450 systems in a heterologous host with sufficient biocatalyst yield (g/g cdw) for non-growing systems or space-time yield (g/L/h) for growing systems remains a major challenge. This review summarizes the opportunities to improve P450 whole-cell processes and strategies in order to apply and implement them in industrial processes, both from a biological and process perspective. Indeed, a combined approach of host selection and cell engineering, integrated with process engineering, is suggested as the most effective route to implementation.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

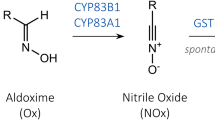

In recent years, enormous progress in the application of enzymes for industrial chemistry has been witnessed, in particular in the pharmaceutical sector (Wohlgemuth 2010; Bornscheuer et al. 2012; Woodley 2008). Among other developments, a much broader range of enzymes has now been implemented [including transaminases (Savile et al. 2010) and enoate reductases (Ma et al. 2010)]. Nevertheless, one class of enzyme that remains particularly challenging is the enzyme family known as cytochrome P450 monooxygenases (so called because of the characteristic peak of the reduced CO-bound complex at 450 nm) or CYPs according to the official nomenclature, including more than 26,000 different enzymes (EC 1.14.X.X) (Bernhardt and Urlacher 2014; Nelson 2009). This enormous diversity also implies that P450s are implicated in a broad range of research fields, not least because of their involvement in human drug metabolism (Rendic and Guengerich 2010; Gillam and Hayes 2013; Martinez and Rupashinghe 2013). However, in this paper, we are focusing on P450s with potential for synthetic production at industrial scale. P450s are, in general, challenging to implement in industry, and there are few examples of the oxidation of non-natural substrates. Perhaps, surprisingly, given the challenges, the scientific literature reports that cytochrome P450 monooxygenases are potentially amongst the most useful of all enzymes to exploit as industrial biocatalysts since they possess the ability to catalyze the selective oxidation of highly functionalized molecules (e.g., oxidation of unactivated hydrocarbons in a stereoselective manner) (De Montellano 2005; Julsing et al. 2008; Schulz et al. 2012). A general reaction scheme is shown in Scheme 1 and examples of possible reactions types in Fig. 1, selected from Sono et al. (1996). The first hydroxylation can also enable further oxidations and other chemical reactions as summarized by Bernhardt and Urlacher (2014). More unusual P450 catalyzed reactions have also been summarized in a recent review (Guengerich and Munro 2013). Interestingly, such selective chemistry is hard to achieve by conventional chemical routes since heterogeneous catalysis and organometallic activation suffer from side reactions and other drawbacks such as high temperature operation (Labinger 2004). The lack of obvious competing chemical processes should therefore make the biocatalytic (P450-based) processes economically interesting. In fact, the selectivity of these enzymes far outcompetes their chemical counterparts, but it is their productivity that has been found limiting. A lot of effort has been put into protein engineering aimed at improving not only selectivity and activity (Seifert et al. 2011; Furuya et al. 2012; Malca 2012) but also screening for P450s performing novel reactions or engineering P450s to perform novel reactions (McIntosh et al. 2014). In the last few years alone, several reviews have been published covering many aspects of the cytochrome P450 family and their potential in biotechnology, the chemical, and pharmaceutical industry (O’Reilly et al. 2011; Urlacher and Girhard 2012; Grogan 2011; Julsing et al. 2008; Jung et al. 2011). The most recent review by Bernhardt and Urlacher (2014) is an excellent summary of the progress made within P450 research for biotechnological applications. Hence, the objective of the current paper is to take this research one step further and present an analysis of improvements that can be made to whole-cell cytochrome P450 monooxygenases systems using both biological and process engineering tools to enable industrial implementation of economically feasible P450 catalyzed production of chemicals and pharmaceuticals. Important steps will be discussed from a process perspective with the intention of bridging the gap between the extensive molecular biology research within the field of P450s and future process implementation. The intention is to identify areas where more research is needed and to guide efforts aimed at developing a process for this group of catalysts, which has more biological than chemical challenges compared to many other biocatalytic processes. This is done by identifying bottlenecks, divided into catalyst-, reaction-, or process-related parameters preventing us from reaching the process targets.

Example of reactions performed by P450s. a Hydroxylation of hydrocarbons exemplified by activation of sp3-hybridized carbons. b Epoxidation of carbon–carbon double bonds. c Aromatic hydroxylation. d Dealkylation. Reactions selected from (Sono et al. 1996) and picture modified from (O’Reilly et al. 2011)

Toward processes for P450-based systems

Types of P450s and properties

The main biological characteristics of cytochrome P450 enzymes are the heme prosthetic group, the requirement for a nicotinamide adenine dinucleotide (phosphate) cofactor, and the corresponding electron transfer proteins. P450s are mainly dependent on NADPH, although NADH is also used by some classes. The use of a given host cell’s cofactor regeneration system can circumvent the use of stoichiometric amounts of cofactor supplied to the reaction, which would otherwise be a major economic limitation. Additionally, the electron transport from the cofactor to the heme active site has, in some cases, been shown to be a limitation to such systems due to difficulties of expression and also the prediction of alternative redox partners in heterologously expressed systems. P450s have been divided into ten classes dependent upon the electron transport chain in a given case (Hannemann et al. 2007) and can be classified into one (classes II, VII, VIII,XI, and X), two (classes V and VI), and three (classes I, III, and IV) component systems. As in many biocatalytic reactions, the limited stability of the catalyst is frequently a challenge to P450 processes, especially for eukaryotic membrane-bound P450s (Braun et al. 2012). Whole-cell systems provide a cofactor regeneration system, possible co-expression of redox partners, and a protected environment to enhance the stability of the biocatalyst. Furthermore, a whole-cell biocatalyst is considerably cheaper than the isolated or immobilized enzyme if the extra cost cannot be justified by catalyst recycle (Tufvesson et al. 2011).

Whole-cell processes

In whole-cell processes, the host plays a crucial role in the overall process structure, and this has been emphasized in an excellent recent review by Schrewe et al. (2013). Exploration of recombinant prokaryotic and eukaryotic expression systems is a key step toward industrial implementation of such biocatalysts. However, a heterologous recombinant host might not be superior to the natural P450 expression host, and high expression levels in the natural host have been suggested to improve the performance. The specific activity of the alkane monooxygenase component AlkB was, e.g., reported to be five to six times higher in the natural host Pseudomonas oleovorans compared to Escherichia coli (Staijen et al. 2000). Despite the possible overexpression in E. coli (2–10-fold), this did not compensate for the lower activity. Indeed, those processes, which have reached industrial maturity, mainly utilize native microorganisms (Liese et al. 2006). There are, however, some exceptions such as the impressive synthetic biology work of an entire pathway, including P450s, leading to production of artemisinic acid, a precursor to the antimalarial artemisinin, by Saccharomyces cerevisiae with a product concentration of 25 g/L (Paddon et al. 2013). This work was funded by Bill and Melinda Gates Foundation, and the drug is being sold on a non-profit basis. Even though the result is very inspiring, for commercial products in general, the development cost has to be accounted for in the overall performance. Another engineered pathway, including several P450s from higher eukaryotes with glucose/ethanol as a substrate in S. cerevisiae, was developed for the production of progesterone and later hydrocortisone (Szczebara et al. 2003; Duport et al. 1998). The reported product concentrations are, however, in the milligram per liter scale. Metabolic pathway engineering has also been applied in E. coli for production of precursors in the synthesis of anticancer drug taxol where a plant P450 is involved in the next step producing taxadien-5α-ol (Ajikumar et al. 2010). However, the P450 catalyzed reaction was shown to be the limiting step in the engineered host, and a titer of 60 mg/L was achieved. Besides native hosts such as Bacillus sp. (Bleif et al. 2012), Pseudomonas sp. (Kuhn et al. 2012), Streptomyces sp. (Park et al. 2003), as well as several different yeast strains [S. cerevisiae (Szczebara et al. 2003), Schizosaccharomyces pombe (Drăgan et al. 2011), Pichia pastoris (Kolar et al. 2007), and Yarrowia lipolytica (Nthangeni et al. 2004)], non-natural P450 expressing hosts exemplified by recombinant E. coli have been used as expression systems for P450s (Scheps et al. 2013; Zhang et al. 2010). E. coli lacks intrinsic P450 genes and heme proteins and hence might require addition of the heme-precursor (δ-aminolevulinic acid), whereas the yeast strains to varying extent have their own P450 expression systems (as well as an internal membrane system) simplifying the expression of eukaryotic membrane bound P450s even though this can be achieved also in E. coli (Richardson et al. 1995).

In addition to selection of the host cell, the operating mode is also important for the process (as illustrated in Fig. 2). Two options are possible. In the simpler approach, growing cells (where fermentation and biocatalysis are performed simultaneously) is used. Alternatively, resting cells (where fermentation and biocatalysis can be optimized independently) enables different possibilities for process improvement. Previously, we also discussed the choice of biocatalyst form from a process perspective (Woodley 2006; Wohlgemuth and Woodley 2010) and concluded that decisions need to be made on a case-by-case basis.

a Fermentation and conversion performed in one step with growing cells. b Fermentation and conversion are separated by centrifugation (or filtration) enabling optimum conditions for the fermentation and conversion and use of the cells in a resting state. The proposed figures assume that the product is present in the media or buffer and not associated with the cells. DSP downstream processing

Economic metrics

The economic potential of a biocatalytic process can be described using metrics (Lima-Ramos et al. 2014; Van Dien 2013). Demands on reaction yield (g product/g substrate) and final product concentration (g/L) are general regardless the operating mode. Space-time yield (g product /L/h) are, however, more important to growing cell processes in line with fermentative production of bulk chemicals (Oudshoorn et al. 2010), although with more flexible threshold values due to the higher product value. Besides the final product concentration, important for downstream processing (DSP), the cost of the equipment required to reach desired amounts of product is an important factor in a one-pot growing cell process. This cost is best translated to demands on space-time yield. For scaling of a process, the space-time yield also plays a role in a resting cell process. For a resting cell processes (and for processes where further biocatalyst processing is used) biocatalyst yield (g product/g catalyst) is applied instead. This metric represents the total amount of product that can be produced by the catalyst, similar to a total turnover number. The biocatalyst yield reflects the cost contribution of the catalyst itself, and the target values are influenced by the final cell density and protein expression of the fermentation process. Catalyst recycle is one approach to improve the biocatalyst yield. The requirements for all metrics are dependent upon the product application and market size. The value added by the process is determined by the selling price of the product multiplied with the reaction yield minus the cost of the substrate. Before considering process development, a reaction yield above 90 % is recommended to be able to reach the economic targets. The reason is that the similar properties of substrate and product make DSP difficult. The reaction yield is determined not only by the substrate concentration but also by the specificity of the enzyme. Overoxidation by the P450 of interest or other pathways in the cell as well as oxidation by other P450s will influence the product profile. By-products will strongly contribute to more challenging DSP due to very similar properties of many unwanted by-products compared to the target molecule. Although a reaction yield above 90 % has not been achieved for all whole-cell processes summarized later in this section, there are examples from a resting (Fujii et al. 2009) and growing cell process (Kleser et al. 2012). Furthermore, it is important to minimize by-product formation enabling efficient utilization of the whole cell in terms of, e.g., cofactor availability (further discussed below). Reasonable target values for product concentration is above 20 g/L and space-time yield around 2 g/L/h (growing cells), and these numbers are also fulfilled in successfully implemented industrial biocatalytic processes (Straathof et al. 2002; Oudshoorn et al. 2010; Van Dien 2013). For a resting cell process, with potential additional biocatalyst processing step and recycle, a target value for the biocatalyst yield for pharmaceuticals or high value chemicals is around 10 g/g cell dry weight (g/g cdw). Each metric reflects demands on different steps of the process, and in the case of hydroxylation reactions by P450s, the required reaction yield is expected to influence the DSP cost to a higher extent than in other processes due to very similar properties of the substrate and product. Typical DSP depends on the product localization, if the product is accumulated inside or attached to the cells or soluble in the media, determining if the cells need to be separated or disrupted. Extraction by organic solvents and further purification is a possible scheme and also enables the DSP to be retrofitted to an existing chemical plant.

In Table 1, the typical parameters relevant for whole-cell P450 catalyzed reactions, divided in biocatalyst-related parameters, substrate and product-related parameters, and process-related parameters, are shown and what metric they primarily influence. It should be emphasized that the targets defined for each metric need to be fulfilled for an economical viable process. Furthermore, some of the parameters are intrinsic to the relevant system and thereby set constraints for the process.

Economic assessments regarding catalyst production for application in processes where the biocatalytic reaction is separated from the fermentation step have been made, and these assumptions can be translated to biocatalyst yield targets of at least 10 g product/g dry cell weight for pharmaceuticals and significantly higher numbers for lower value bulk chemicals (Tufvesson et al. 2011). This was calculated on a base case with a protein expression of 6.25 g/L and a cell titer of 50 g cdw/L. To put these numbers into perspective, the highest reported expression of functional P450s to our knowledge is 1.5 g/L with a cell titer of 13 g cdw/L (Pflug et al. 2007). To reach the target product concentration of 20 g/L, a specific activity of 7 μmol substrate converted per gram cell dry weight per minute (U/g cdw) would be required. These calculations are based on numbers from Pflug et al. (2007) (13 g cdw/L; a molecular weight of the substrate, p-nitrophenoxydodecanoic acid, of 138 g/mol and product of 154 g/mol) for a 24-h process with constant activity. Doing similar calculation for a growing cell process based on a space-time yield requirement of 2 g/L/h, the required specific activity would be 17 U/g cdw. Specific activities in this range have been reported and are not unrealistic. For a resting cell process, without cell recycling, 10 g/g cdw corresponds to 45 U/g cdw, indicating that cell recycle might be necessary to cover the extra cost contribution from the biocatalyst processing step (filtration or centrifugation and washing in case of whole cells). However, to assume a constant activity over 24 h is not really realistic in the case of P450s. Several challenges to achieve the required targets for each metrics can be expected, and in the following sections, this will be discussed along with possible solutions, already summarized in Table 2. Tables 1 and 2 have the same basis to simplify the correlation between parameters influencing the reaction and tools to improve the system in order to reach a target metric in the end.

In order to identify and summarize where the P450 research stands in relation to the defined guidelines above, selected growing and resting whole-cell processes have been summarized and are presented in Fig. 3. The best performance among the processes, in relation to the presented targets, is found using an unspecified P450 in a growing natural P450 expressing mutant strain of Candida tropicalis. This uncharacterized P450 is converting n-tridecane to the corresponding dicarboxylic acid in a batch process where fermentation and conversion were separated into two steps, although in the same fermenter (Liu et al. 2004). A step-wise addition of alkane and optimized pH profile, by gradual increase during the production phase, were applied to the process. The process performance is in the same order of magnitude regarding space-time yield and product concentration as the minimum guideline for pharmaceutical processes, while other processes are almost two orders of magnitude behind. As can be seen in Fig. 3b, the resting cell processes are further away from the target, expressed as biocatalyst yield, compared to the growing cells (Fig. 3a) where the target is represented as space-time yield. The main reason for this is that the catalyst is rarely reused in P450 catalyzed processes, which would be required to cover the extra cost arising from the additional biocatalyst processing step (centrifugation or filtration). In lab processes, cell recycle is scarcely considered, and as mentioned, in industrially implemented processes, growing cells has been the preferred operating mode.

a Published growing P450 whole cell processes presented as space-time yield vs product concentrations. b Resting P450 whole-cell processes presented as biocatalyst yield vs product concentration. White square represents reactions performed in bioreactors, and lozenge represents shake flask or test tube processes (growing cells in this figure defined as processes performed in one pot and space-time yields calculated on entire process time)

A whole-cell system is a complex machinery and is dependent on the environment, e.g., the availability of cofactor for the desired biocatalytic reaction and the oxygen consumption by the resting cell strongly depends on the state of the cell. Therefore, it is hard to generalize and immediately present required parameters that need to be fulfilled. To be able to make reasonable calculations and guide the catalyst development in the field, some assumptions need to be made to be able to convert, e.g., specific activity (U/g cdw) to a space-time yield expressed in g/L/h. Furthermore, in order to correlate activities achieved in short enzymatic assays (e.g., using p-nitrophenoxydodecanoic acid) to reactions with a different substrate in whole-cell systems is not straightforward and depends on several parameters. In the case of α-pinene oxyfunctionalization by a BM3-quintuple mutant, the in vitro assay above showed a k cat of 0.7 s−1, and the corresponding value for the non-natural substrate α-pinene in a whole-cell with heterologous cofactor regeneration was 0.17, representing a 4-fold difference in favor of the in vitro assay (Schewe et al. 2008). On the other hand, a more accurate comparison using the same substrate in vitro and in vivo shows the opposite trend meaning higher specific activities for the in vivo systems [2.9-fold for (S)-limonene hydroxylation by CYP153A6 and 3.9-fold for epoxidation of 1-hexene by CYP102A1 F87V] indicating that the intact cell provides a better environment for the enzyme (Cornelissen et al. 2011; Siriphongphaew et al. 2012).

Improving specific activity to give increased space-time yield (g/L/h) or biocatalyst yield (g/g biocatalyst)

The specific activity, expressed as U/g cdw, is affecting the space-time yield (g/L/h) for a growing cell process and the biocatalyst yield (g/g cdw) for a resting cell process. There are two main factors that contribute to the specific activity: enzyme expression (mol P450/g cdw) and enzyme activity, k cat (s−1, turnover per active site and second). However, an increased enzyme activity in vitro does not necessarily translate directly to corresponding activity in vivo due to the many factors influencing a P450 catalyzed reaction such as cofactor supply, electron transport, and proximity and stability of the catalytic components.

Fermentation cell density, enzyme expression, and host cell physiology

The fermentation performance is, as discussed earlier, of key importance for the economy of the process, especially in the case of resting cells. To lower the cost contribution of the catalyst, it is of special importance to reach reasonable cell densities in the fermentation process. When the guideline for biocatalyst yield (g/g cdw) was calculated, a base case density of 50 g cdw/L was assumed, which is reasonable for a fed-batch fermentation process (Tufvesson et al. 2011). Overexpression of proteins constitutes a burden to the host cell, and for P450 expression, heme depletion has been shown to cause a major stress (Michener et al. 2012). In a reasonably successful fermentation process, an overexpressed protein content of 12.5 % of the cell dry weight can be assumed (Tufvesson et al. 2011), and when expressing CYP102A1 in E. coli, similar values (11 %) were reported (Pflug et al. 2007). Dependent on the requirement of overexpression of electron transfer proteins in a given case, this gives different potentials for expression of the P450 itself and might limit the total potential activity of the cell (specific activity). This has been exemplified by Schewe et al. (2009) when co-expressing glucose facilitator and dehydrogenase and achieving comparable product concentrations with half the P450 expression.

Cell physiology has in several cases been shown to have a crucial impact on the reaction performance. By changing the host strain from P. putida GPo12 to P. putida KT2440 and the carbon source from octane to citrate, a 6-fold improved productivity (g/L/h) was achieved in the hydroxylation of (S)-limonene to (S)-perillyl alcohol (Cornelissen et al. 2011). Further work on the same system showed the importance of host background for the formation of by-products, which were decreased from 26 to 8 % by changing host again to E. coli W3110 (Cornelissen et al. 2013). Metabolic engineering of the host cell can also influence the performance of the whole-cell system as indicated by an improved product per glucose yield from 0.5 to 1.71 (mol/mol), as a result of more efficient utilization of the cofactor and increased specific activity from 9 to 26 U/g cdw in a resting cell biocatalytic conversion of propane to propanol (Fasan et al. 2011). In a growing NADPH-dependent styrene epoxidation, on the other hand, the cofactor availability limited the reaction above 21 U/g cdw, probably due to increased consumption of glucose by stress-induced processes and NADPH being used inefficiently by the enzyme (Bühler et al. 2008), suggesting metabolic engineering to increase redox biocatalysis. This supports the fact that synthesis and presence of active NADPH decrease growth yields and reduce growth rate and metabolic activity (Bühler et al. 2006).

Direct comparisons of growing and resting processes are not straight forward. First, the basis of the comparison needs to be determined, e.g., the cost driving metric in a specific case needs to be identified. Second, the catalyst concentration in a growing cell process will vary, and in a resting cell process, the chosen catalyst concentration will influence space-time yield and final product concentration and is an important factor in the comparison. Not many examples can be found in the literature where direct comparisons based on process performance have been done, and the operating mode has a big influence on process design and should be investigated further. Despite this, in an attempt to compare the two operating modes, E. coli overexpressing NADPH-dependent cyclohexanone monooxygenase for production of caprolactone using a resting cell process showed 20-fold higher space-time yields (0.79 g/L/h over 10 h) compared to growing cells, although it could be explained by different cell concentrations and the specific activity of the growing cells were higher than the resting cells (Walton and Stewart 2002, 2004). The main limitation was shown to be the stability of the monooxygenase and substrate transport across the cell membrane. It was also shown that glucose-fed non-growing cells were not limited by cofactor regeneration (intracellular NADPH concentration after 12 h reaction was 180 μM). On the other hand, E. coli W3110 growing in the presence of yeast extract were shown to be more resistant to n-octane compared to resting cells without yeast extract, and this lead to a 5-fold increase in the final product concentration (Favre-Bulle and Witholt 1992). It has also been suggested that resting cells are more sensitive to product inhibition compared to growing cells in styrene oxidation (Julsing et al. 2012).

Enzyme activity

The highest activity reported to our knowledge is 363 s−1 reached by a one-component CYP102A1 mutant (Eiben et al. 2006). However, this number is outstanding, and reported activities above 1 s−1 are scarce with the exception of BM3 and P450cam systems, which are the most explored P450s, and a few other one component systems (P450nor and reductase-independent eukaryotic systems; search on BRENDA 2012-08) (Scheer et al. 2011). In order to reach the lowest target for pharmaceuticals, specified above, of 10 g product/g dry cell weight, assuming an expression of 11 % enzyme per g cdw and a cell density of 13 g/L, a molecular weight of the enzyme of 118 kDa and a molecular mass of the product of 154 g/mol (numbers taken from Pflug et al. 2007), the required turnover number for a process lasting 24 h (without cell recycling) would be <1 s−1. This implies that the activities reached for most systems are in the range of activities required for a successful industrial process and specially the P450 systems in four families (CYP102, CYP101, P450nor, and independent eukaryotic systems). The enzyme activity can furthermore be improved by directed evolution and site-directed mutagenesis, and the extensive work done with the most explored P450, P450 BM3, has been summarized up to June 2011 in a review by Whitehouse et al. (2012). In general, these techniques have evolved extensively in recent years, and a 10-fold (or even 100-fold) improvement of the enzyme activity is reasonable to achieve (Malca 2012; Lewis and Arnold 2009). To achieve the same improved performance of the enzyme in a whole-cell system as achieved in vitro, the enzyme activity would have to be the limiting factor. However, this is, according to calculations above, not the case as long as the assumed stability is fulfilled and, therefore, a direct translation of rates between in vitro and in vivo is only valid when no other limitations are present.

Cofactor regeneration

In theory, cofactor regeneration for redox catalysis of metabolically active cells has been calculated to be in the range of 500–1000 U/g cdw (Duetz et al. 2001; Meyer et al. 2006; Blank et al. 2008). However, in practice, maximum specific activities for oxygenases (although not P450 monooxygenases) achieved in whole cells are around 200 U/g cdw (Bühler and Schmid 2004), and the cofactor regeneration has, in several cases, been shown to limit the activity. Cellular processes such as increased maintenance demand of the cell under biocatalytic conditions as well as by-product formation and uncoupling (discussed in the following section) can be part of the explanation why the theoretical value has not been reached. Furthermore, growing cells tend to utilize the cofactors for better growth rather than the desired biocatalytic reaction, implying that resting cells would be the better operating mode from this point of view. In order to avoid the need for addition of the required cofactor in stoichiometric concentrations, which would make any process uneconomic, several regeneration approaches have been developed. Heterologous coexpression of, e.g., glucose dehydrogenase (NADPH), improving the specific activity from 0.39 to 3.59 U/g cdw and 0.96 to 1.47 U/g cdw, respectively (Schewe et al. 2008; Siriphongphaew et al. 2012), or glycerol dehydrogenase (NADH) (Mouri et al. 2006), has been used in several cases to improve the cofactor regeneration. Another approach is to couple permeabilized cells, expressing the enzymes of interest, done in the case with NADPH-dependent ketoreductase and glucose dehydrogenase used for the production in the gram per liter scale with specific regeneration activities of 61 U/g cdw (Zhang et al. 2009). Recent metabolic engineering approaches for better NADPH regeneration during glycolysis have been reviewed by Lee et al. (2013), in the best cases showing a 6-fold improvement of catalytic performance (final product concentration or specific activity) in engineered E. coli. Another approach to tackle the dependence of the more expensive and less stable cofactor NADPH is to change the cofactor specificity to NADH. This was done by site-directed mutagenesis for hydroxylation of myristic acid by CYP102A1 (free enzyme with cofactor regeneration by formate dehydrogenase) yielding a total turnover number of 30,000 and a space-time yield of 153 mg/L/h (Maurer et al. 2005).

Aside from regeneration of the cofactor by the host cell and heterologous enzymatic regeneration options, non-enzymatic options to regenerate cofactors and direct regeneration of the monooxygenase active site have been reported and reviewed (Hollmann et al. 2006). NADPH has, e.g., been substituted by zinc dust and cobalt(III)sepulchrate, reaching 20 % of the rate achieved using NADPH in vitro for hydroxylation of p-nitrophenoxydodecanoic acid (Schwaneberg et al. 2000). In the case of P450s, an alternative mechanism for the reaction is the use of the peroxide shunt pathway as a source of both electrons and oxygen, which was exemplified by hydroxylation of naphthalene by a P450cam mutant showing a 20-fold improvement in activity over the wild-type enzyme (Joo et al. 1999). Cumene hydroperoxide-driven dextromethorphan demethylation by CYP2D6 resulted in 210 % of the product concentration achieved by the natural cofactors (NADPH/CPR) after 1 h in vitro assay, however, with decreased stability but comparable total turnover numbers (Chefson et al. 2006). The field of peroxide-driven P450 catalysis is extensively covered with patents by Cirino and Arnold (2008).

Electron transport and coupling efficiency

The electron transfer from the cofactor to the heme active site is, in many cases, the rate-limiting step and thereby has been the target for biocatalytic improvement. This has also been suggested to be the reason for observing equal activity in an overexpressed engineered system as in the native host with a lower enzyme concentration (Duetz et al. 2001). Optimization of the flux of electrons is crucial to utilize the full capacity of the biocatalyst to the targeted reaction, and the importance has also been emphasized in the review by Bernhardt and Urlacher (2014). Approaches with fusion constructs have been published, and besides constructs with the reductase domain of BM3, the reductase domain of CYP116B2 (P450RhF) is a promising alternative (Bordeaux et al. 2011; Robin et al. 2009). This field with a lot of potential for the application of P450s has recently been reviewed (Sadeghi and Gilardi 2013). The length and also structure of the linker within the fusion constructs have been shown to be important for electron transport (Munro et al. 2007b; Robin et al. 2009). Activity can also be reconstituted with more component systems, especially for eukaryotic systems with unknown redox partners, even though the redox partners are commonly known for eukaryotic systems in contrast to prokaryotic ones. The choice of heterologous redox partners is firstly determined by the class of P450 but has proven not to be that straight forward, and optimization of the electron transfer has been shown to be beneficial, e.g., by a modified ferredoxin (Bell et al. 2012). Putidaredoxin reductase with putidaredoxin (Kim and Ortiz de Montellano 2009) and adrenodoxin reductase with adrenodoxin (Zehentgruber et al. 2010a; Hollmann et al. 2006; Ewen et al. 2012; Hakki et al. 2008) have been the most commonly used redox partners for heterologous expression. Non-enzymatic transfer of electrons to the heme-active site has also been explored, including direct chemical reduction or electrochemical reduction (Hlavica 2009) as well as light driven catalysis exemplified by hydroxylation of lauric acid by P450 BM3 (Tran et al. 2013).

The catalytic efficiency is among others affected by uncoupling, when reducing equivalents are lost to by-product formation without substrate oxidation (O’Reilly et al. 2011). Uncoupling is affected by the physical position of the electron transporting chain (i.e., can be improved by the design of fusion constructs) but especially by the binding of the substrate in the active site and is therefore a particular challenge for efficient catalysis of non-natural substrates. A systematic domain-based directed evolution strategy was used to engineer P450 BM3 towards the non-natural substrate propane (Fasan et al. 2007). This resulted in total turnover number of 45,800 and increased coupling efficiency from 17.4 to 98.2 % in vitro.

Improving catalyst stability for increased biocatalyst yield (g/g cdw) and final product concentration (g/L)

As already mentioned, a sufficient stability over 24 h is assumed in calculations setting a threshold for enzyme activity. If the stability would only allow for an 8 h reaction, the demand on all rates would be three times higher. This forms thereby a prerequisite and is of major importance. In addition to the stability of the host cell, the stability of the monooxygenase and also the corresponding electron transport proteins are critical to achieve the defined process targets. As stated above, a supplement of cofactors gives severe economic consequences for a scaled process, and the cofactor regeneration is one of the motivations for a whole-cell process. The native cofactor regeneration system is, however, not adapted to the activity of an overexpressed enzyme, and, besides the regeneration, the stability of cofactors can thereby become a limitation in systems with high turnover numbers and stable enzymes. Total turnover numbers of up to 1300 for NAD(P)+ and 300 for NAD+ have been reached in an in vitro P450 BM3 biphasic system using formate dehydrogenase (Maurer et al. 2005). In the case of ketoreductase with a glucose dehydrogenase cofactor regeneration approach, the overall turnover number for NADPH recycling reached 3400 with a specific activity of 61 U/g cdw (Zhang et al. 2009).

When uncoupling occurs, hydrogen peroxide is produced, decreasing the stability of the enzyme by heme degradation (Cirino and Arnold 2003). The stability of P450 BM3 towards hydrogen peroxide has been explored by Cirino and Arnold (2003), and the total turnover number was increased 11-fold for a hydrogen peroxide (5 mM) driven P450 BM3 heme domain by protein engineering, although the enzyme was inactivated within 5 min in the presence of 10 mM hydrogen peroxide and is far from industrially suitable. Six additional rounds of directed evolution of this enzyme resulted in a 250 times longer half-life at 57.5 °C compared to the holoenzyme of the wild type with 50 % remaining activity of the peroxide-driven parent (Salazar et al. 2003). The reductase domain of CYP102A1 is known to be less stable than the monooxygenase domain (Munro et al. 2007a). When the reductase domain of CYP102A1 was replaced with the more stable reductase domain of CYP102A3, the stability was improved (10-fold longer half-life at 50 °C) even though the activity was decreased (Eiben et al. 2007).

When designing a whole-cell biocatalytic process with the knowledge that solvents most probably will be used, this should be considered when choosing the host and screening for desired enzymatic characteristics. In general, Gram-negative bacteria are known to be more solvent tolerant than their Gram-positive counterparts. Variations in solvent tolerance can be explained by different membrane composition and efflux pumps and varies not only between different bacterial strains but can also vary between different strains of the same species (Ramos et al. 2002).

The stability of P450 BM3 in the presence of co-solvents added to increase the solubility of the substrates has been increased by directed evolution yielding mutants with 10- and 6-fold increased specific activities compared to the parent mutant F87A in the presence of 2 % THF and 25 % DMSO, respectively (Seng Wong et al. 2004). The improved tolerance was also seen for other co-solvents (acetone, acetonitrile, DMF, and ethanol). P450 BM3 mutants have also been constructed by site-directed mutagenesis for the hydroxylation of cyclohexane in a biphasic system containing 50 % cyclohexane as substrate and organic phase and 50 % aqueous buffer (Maurer et al. 2005). The best double mutant was shown to be active for 100 h when stabilized by catalase and BSA with a total turnover number of 12,850. Similarly, octane (used as substrate and second phase) and myristic acid in dodecane showed total turnover numbers of 2200 and 3300, demonstrating applicability of biphasic reaction systems.

Immobilization as a means to increase the stability of P450s has also been explored, although to be implemented in industry, this requires improved biocatalyst yield to cover the additional cost added to the process. Mainly purified enzymes have been immobilized, and in this case, cofactor regeneration has to be addressed. Sol–gel matrix showed to be the best amongst several matrices tested when immobilizing BM3 mutants with immobilized formate dehydrogenase for cofactor regeneration (Maurer et al. 2003). The storage stability was improved measured as the half-life at 25 °C from 5 days (with glycerol) to 29 days. Reusability of the catalyst was also shown. The immobilization of the heme domain of BM3 on mesoporous molecular sieves using hydrogen peroxide as electron and oxygen source was also investigated by Weber et al. (2010). However, the activity towards n-octane was only twice as high compared to the free enzyme and still quite low reaching in total 62 nmol product per milligram P450. A fusion protein between the plant CYP71B1 and its reductase showed 10-fold improved activity compared to the free enzyme when immobilized in colloidal liquid aphrons (CLA) (Lamb et al. 1998). Another immobilization approach, taking the importance of proximity of the electron transfer chain for efficient electron transfer into close consideration, called PUPPET, where P450cam, putidaredoxin, and putidaredoxin reductase where fused to monomers of proliferating cell nuclear antigen (PCNA) forming a trimeric ring structure (Hirakawa and Nagamune 2010). This lead to an increase in initial activity by two orders of magnitude measured by O2 consumption and NADH consumption compared to the mixture of the free enzymes leading to a specific activity of 500 min−1.

Cell-free extracts of E. coli expressing CYP105D1 immobilized on the anion exchange resin DE52 only showed activities of one third to half of the free enzyme but showed activity up to 36 h using formate dehydrogenase for cofactor regeneration (Taylor et al. 2000). Flocculent yeast Saccharomyces diasticus expressing a fused P450 enzyme was immobilized within reticulated polyurethane foam biomass particles in a fluidized bed reactor enabling production in five batch cycles, each lasting 8 h with higher final product concentration and production rate than freely suspended cells (Liu et al. 1998).

Even though the stability is shown to be increased by protein engineering and immobilization, from a process perspective, it is important that the stability under process relevant conditions is considered (agitation, temperature, concentration of reactants, etc.).

Improving substrate- and product-related parameters

The biocatalyst can be changed and modified in several ways as discussed above. However, the substrate and product are generally fixed, and challenges associated with the reactant(s) and/or product(s) needs to be circumvented by other means. Typical substrates and products of P450 catalyzed reactions have poor water solubility, which is a challenge when the whole-cell catalyst is present in the aqueous phase. The transport of the poorly water soluble substrate can limit the space-time yield (g/L/h) if it is lower than the reaction rate and also influences the product concentration (g/L) achievable. Inhibition and toxicity can limit the final product concentration (g/L) and biocatalyst yield (g/g cdw) achievable. Volatility of the substrate or product could potentially limit the reaction yield, especially considering the supply of gaseous oxygen. This is, however, not considered to be a challenge for high value molecules relevant for P450-catalyzed processes due to the large molecular weight of substrates and products and thereby in general also low volatility.

Transport limitations—across the cell membrane

Dependent upon the physical properties of the substrate, transport across the cell membrane has, in some cases, been shown to limit the reaction. Three different mechanisms of hydrocarbon uptake by bacteria have been described in the scientific literature: uptake from aqueous phase, uptake of solubilized substrate in an apolar solvent, and from direct contact with organic droplets (Schneider et al. 1998). The membrane needs to allow transport of desired compounds but still be intact enough not to affect the viability of the cell. In general, whole-cell biocatalysis is one to two orders of magnitude slower that isolated enzymes due to transport limitations across the cell walls and membranes (Chen 2007). Different permeabilization methods (physical, chemical, and molecular engineering approaches) can be applied depending on the microorganism (eukaryotic or prokaryotic, Gram-positive or Gram-negative) and characteristics of the compound (hydrophilic or hydrophobic) and have been reviewed previously (Chen 2007). Zehentgruber et al. (2010b) demonstrated that, for steroid transport across the cell membrane in fission yeast, permeabilization by Tween 80 increased the activity by 50 % but hexadodecyl trimethyl ammonium bromide (CTAB) extinguished the activity instead, probably due to toxicity to the biocatalyst. Microbial engineering strategies to improve the uptake of hydrophobic substrates by bacteria was applied in the case of dodecanoic acid methyl ester oxygenation in E. coli W3110, and a 28-fold increase in maximal specific activity was achieved by co-expression of the AlkL membrane protein (Julsing et al. 2012). Application of a biphasic system further increased the activity (62-fold). However, the expression of AlkL decreased the stability of the cell. The same approach has been taken for alkanes (n-dodecane) in E. coli GEC137 (Grant et al. 2011). The examples above are applied to the alkane monooxygeanse system from Pseudomonas putida GPo1 and not a P450. Regarding P450s, the fatty acid transport (pentadecanoic acid) was improved in resting E. coli K27 by expression of the same gene encoded on pGEc47 from P. oleovorans from 0.7 to 1.3 U/g cdw (Schneider et al. 1998). The productivity was further improved 3-fold by the use of cell-free extract, although NADPH was added in this case. The AlkL transport protein was also applied in the well-studied limonene hydroxylation by CYP153A6 expressed in E. coli W3110 resulting in an increased hydroxylation rate from 7.1 to 16.6 U/g cdw (Cornelissen et al. 2013).

Change of the heterologous expression host can also improve the substrate transport. Utilization of B. megaterium MS941 instead of E. coli avoided the inability of E. coli to transport acids with terpene structure (Bleif et al. 2012). Similarly, hydroxylation of testosterone and diclofenac by human P450s CYP3A4 and CYP2C9, respectively, expressed in E. coli showed higher specific activity in the form of isolated membranes compared to whole cells indicating transport limitation (Vail et al. 2005). Another option to circumvent the transport limitation across the cell membrane is to express the enzyme by surface display. CYP106A2 from Bacillus megaterium (Schumacher et al. 2012) and human CYP3A4 (Schumacher and Jose 2012) was expressed on the outer membrane of E. coli and showed hydroxylation of deoxycorticosterone and testosterone, respectively. It should, however, be noted that the advantages with using the whole-cell system were lost, and cofactor and electron transporting proteins need to be added externally. The transport limitations can also imply that the product is accumulated inside the cell (Shimizu et al. 2003) and needs to be recovered through cell lysis, thereby ruling out cell recycle.

Solubility of reactants

Many substrates for reactions catalyzed by P450 have limited water solubility. For example, medium chain alkanes (C5–C16) are water soluble up to around 40 mg/L, and likewise, fatty acids with the same chain length are soluble in the range of 7 mg/L to 19 g/L. In these cases, the transport of the substrate to the water phase containing the catalyst requires an immiscible or miscible organic solvent to facilitate faster transport. Two-phase systems with immiscible solvents are of particular interest (Schewe et al. 2009; Cornelissen et al. 2011). There are many parameters to consider when choosing a solvent: availability and price, the biocompatibility towards the enzymes and the host, low water solubility, substrate and product capacity, flammability, low emulsion forming tendency, and, in cofactor-dependent reactions, low NADPH consumption rate (Schewe et al. 2009). The solvent used also needs to be industrially applicable, environmentally friendly, as well as non-hazardous. Generally, biocatalysis is better in organic solvents with an octanol/water partition coefficient (logP) >4 (Laane et al. 1987). All the mentioned criteria lead to the options of using solvents such as hexadecane and bis(2-ethylhexyl)phthalate like in the case of styrene oxidation (Panke et al. 2000). Ethyl oleate was applied as a second phase in 1.5 L bioreactors to circumvent the low solubility of the substrate in the case of progesterone hydroxylation by CYP3A4 expressed in Y. lipolytica, increasing the final product concentration 5-fold to around 230 μM corresponding to 80 mg/L (Braun et al. 2012). On the other hand, the viscosity of phthalates can prevent the dispersion of the substrate and decrease the overall activity by diffusion limitations as well as the oxygen transfer rate at a given power input (Panke et al. 2002). The use of solvents also brings the concern about safety into the picture, especially in combination with high oxygen supply, and to address this, explosive proof reactors have been designed at pilot scale (Schmid et al. 1998a).

Inhibition and toxicity

In reactions catalyzed by P450s, not only the potential solvent but also the substrate and product are in many cases hydrophobic and toxic to the cells and inhibitory to the enzyme. The host selection should be done carefully, exemplified by Bacillus subtilis 3C5N showing significantly higher tolerance towards the substrate 1-hexene compared to E. coli DH5α (Siriphongphaew et al. 2012). An efflux pump knock-out E. coli, enabling heme and substrate accumulation inside the cell improved the stability and reaction performance (up to 7-fold increase of product concentration) in the case of hydroxylation of compactin, vitamin D3, and 4-cholesten 3-one (Fujii et al. 2009). In a study of 10 recombinant P450s belonging to CYP1, CYP2, and CYP3 families, 13 substrates were tested of which 6 showed substrate inhibition in the range of 5–24 μM corresponding to 2–9 mg/L (Lin et al. 2001). Assuming a batch process with no engineering solutions applied, the tolerance would have to be improved by three orders of magnitude. Depending on the chemical properties of the molecules, different approaches can be taken. Inhibition by the substrate can be overcome by in situ substrate supply (ISSS) using continuous supply of the substrate by a feeding strategy or by resins or solvents. Regarding the product, in situ product removal (ISPR) can be applied by similar approaches (Lye and Woodley 1999; Woodley et al. 2008; Dafoe and Daugulis 2014). Product removal by resins was applied to steroid hydroxylation by CYP106A2 and enabled reuse of the catalyst (Zehentgruber et al. 2010a). Extractive fermentation with isopropyl myristate was applied in the case of artemisinic acid production by S. cerevisiae, reaching a product concentration of 25 g/L, an improvement by 10 g/L due to change of feed composition and introduction of the second phase (Paddon et al. 2013).

Improving space-time yield (g/L/h) by effective reactor operation

Transport limitations between phases in a two-phase system

Other parameters that have been addressed in the use of two-phase systems are the maximum transfer rates of the hydrophobic compounds between the organic and aqueous phase. The transfer rates of n-heptane, n-octane, and n-decane to the aqueous phase were determined to be 79, 64, and 18 mmol/L/h, respectively (Schmid et al. 1998b). Calculated in g/L/h, these numbers are in the same order of magnitude (lowest value corresponding to 1.8 g/L/h) as the target space-time yield of 2 g/L/h. However, addition of the surfactant bis(2-ethylhexyl) sulfosuccinate sodium salt (AOT) to a two-phase hexane/water emulsion increased the initial rates of the hydroxylation of camphor by P450cam using yeast alcohol dehydrogenase for cofactor regeneration, indicating transport limitations between the phases in the hexane buffer system (Ryan and Clark 2008). Total turnover numbers achieved for the monooxygenase was 28,900 and for YADH regenerating NADH, 11,800.

Oxygen requirements

Hydroxylations by P450s require equimolar amounts of oxygen. One oxygen atom is introduced to the substrate, and one is reduced to water. For the reaction to take place, it is of utmost importance that molecular oxygen is available and that it can be supplied at a sufficient rate. Even though potential oxygen limitation has not been studied to a large extent within the field of P450s, intact E. coli expressing recombinant P450 for the hydroxylation of progesterone has been suggested to be limited by molecular oxygen (Shet et al. 1997). Nevertheless, this study was conducted in milliliter scale without agitation, and the P450 catalyzed reaction was only responsible for 1.5 % of the total oxygen utilized by the cell. Already in 1947, resting cells without nitrogen source were suggested to consume 45 % of what cells in the same state consumed in the presence of nitrogen source (Armstrong and Fisher 1947). This could be explained by the higher K m of oxygenases (10–60 μM) compared to the electron-transfer chain (1 μM), meaning that, at low oxygen concentrations, the oxygen will be used for respiration instead of the catalytic reaction (Duetz et al. 2001). Optimization of biomass and activity will be one important step in the process development, and this has been done in the case of whole-cell Baeyer–Villiger oxidation (Baldwin and Woodley 2006). This is illustrated by optimizing the height of the gray area in Fig. 4, assuming that the O2 supply is sufficient. Besides the overall reaction rate, dissolved oxygen concentrations can also effect the reaction in terms of regioselectivity (Schneider et al. 1998).

Oxygen demand vs biocatalyst concentration in whole-cell biocatalytic oxidation process. Dashed line represents possible O2 supply from industrial sized fermenters, the lower solid line represents O2 requirements for cell metabolism, and the higher solid line the total O2 demand for cell metabolism and P450 catalyzed reaction. (Reconstructed from Baldwin and Woodley 2006)

As a rule of thumb, oxygen transfer rates in industrial size fermenters are 100 mmol L−1 h−1 and that would be able to transfer oxygen to 1670 U/L. Assuming a product with 154 g/mol in molecular weight, this activity corresponds to a space-time yield of 15.4 g/L/h if the supplied oxygen is solely used for the catalytic reaction (and with 100 % reaction yield). Keeping the target for space-time yield in mind, 2 g/L/h, efficient use of oxygen is required since 13 % of supplied oxygen has to be used for the reaction. This leaves the remaining 87 % for the metabolism or growth of the cell, and it is clear that there is no room for poor coupling efficiency consuming oxygen without product formation. Depending on the specific requirement of oxygen of the resting cell, the oxygen availability also set the requirements for the specific activity of the cell and thereby also on enzyme activity and expression levels. The oxygen requirements in combination with solubility issues leading to high oxygen pressures and solvents in combination consist of a safety problem as discussed above.

There are, however, alternatives to increase the oxygen transfer rate to the aqueous media if the specific activity per gram cell dry weight and catalyst concentration cannot be optimized enough in relation to oxygen supply. This can be done by increased oxygen pressure in the reactor by elevated pressure, supply of pure oxygen instead of air, modified oxygen supply configuration, and complete reactor configurations. For example, the use of a bubble column, where air is released in fine bubbles through a sintered glass in the bottom of the reactor, increased the activity of a whole-cell Baeyer–Villiger oxidation reaction (Hilker et al. 2004). Another example is bubble-free aeration using membranes of which the mass transfer characteristics have been described and equations presented (Cote et al. 1988). The technique was exemplified in a biocatalytic reaction, enabling a reduction of the reactant feed rate with one third while still keeping the same reaction rate (Lynch et al. 1997). A circulation loop with a glass tube containing dead-end hollow gas-permeable fibers controlling the dissolved oxygen tension (DOT) with the oxygen pressure inside the fibers was used to prevent the volatile substrate fluorobenzene from evaporation.

Perspectives

There is no doubt that P450 monooxygenases perform excellent chemistry and, based on that, have huge potential within white biotechnology. Despite this fact and that lots of research have been done within the field, not many industrial processes with P450s have been implemented. P450s are a good example of where chemists, biologists, and chemical engineers need to work together in order to reach industrial implemented processes and that the idea of process development and identification of bottlenecks at an early stage can help to direct efforts. In order to improve a process that does not meet the requirements for being economically viable, the bottlenecks first need to be identified. However, it is not easy to distinguish between parameters that, at first glance, depend on each other. The biological parameters important for whole-cell P450 catalyzed reactions are summarized in Table 3, and numbers achieved for P450 systems are presented. As can be seen in the table, the prerequisites of successful whole-cell P450 biocatalytic (Maurer et al. 2005; Eiben et al. 2007; Salazar et al. 2003) processes are sufficient to reach target metrics (final product concentration and space-time yield or biocatalyst yield) when parameters are analyzed individually. However, an efficient use of resources available is required.

In Fig. 5, the importance of the weakest chain in the reaction system is illustrated and the influence it has on the economic potential illustrated by space-time yield and final product concentration. The biological parameters influencing specific activity are summarized in the lower left graph in the figure, and following the figure clockwise, the influence of these parameters on economic metrics are presented. The specific activity in combination with the cell concentration determines the space-time yield, which, along with the stability of the cell, influences the final product concentration. The final product concentration along with applied catalyst concentration subsequently determines the biocatalyst yield for a resting cell process where the number of recycles also needs to be accounted for. What also can be seen is that stability of the system plays a crucial role, and once again, it should be stressed that it is the stability under process relevant conditions that matters.

Influence of the typical biological parameters presented in P450 whole-cell processes on economic important parameters and limitations. Starting in the lower left corner the rate-related parameters are listed (enzyme expression, enzyme turnover number, electron transport, and coupling efficiency) influencing the specific activity that in the upper left corner together with the cell concentration results in the space-time yield. The space-time yield can be limited by the possible oxygen supply by the reactor and the transport of reactants between phases or across the cell membrane. From the space-time yield, the possible final product concentration is determined by the stability of the whole-cell system including the host cell, the monooxygenase, reductase, and cofactors, shown in the upper right corner. The lower right corner illustrates how the cell concentration together with the final product concentration determines the biocatalyst yield for a resting cell process where the number of recycles also needs to be accounted for. Thick lines indicate the limits to the metrics

Guidelines

Biological limitations of P450-catalyzed whole-cell reactions have previously been discussed in individual studies. In this review, we have made quantitative comparisons of individual parameters in relation to economic metrics to guide the development of economically feasible processes. Recommendations for successful development of P450-catalyzed processes for synthetic applications can be summarized as follows:

General:

-

The main target for P450 catalyzed reactions are recommended to be high value molecules (fine chemicals and pharmaceuticals), complementary to existing chemical routes. For these high value products, k cat values for many P450s are promising, assuming no other limitations. However, if the process is aiming for production of low-range bulk chemicals, the activity requirements of the enzyme increase by two orders of magnitude and only the P450s with the highest turnover numbers reported so far would be sufficient.

Biological:

-

The stability of the catalyst is crucial, both in terms of cell, enzyme and cofactor. It can be concluded that turnover numbers in the higher range of what has been published would be enough if they could be achieved in vivo and stable over 24 h. A lower stability, meaning that product concentrations and biocatalyst yields need to be reached in a shorter time, would inevitably translate into higher demands on rates.

-

Carefully selected host cell systems (e.g., natural P450 expressing hosts) for a robust host able to handle expression, reactive oxygen species, and simplify transport across membrane are recommended.

-

Cell and metabolic engineering to various extents (tuning expression especially in multicomponent systems, balancing of redox cofactors and energy metabolites) to fully utilize the potential of the catalyst. However, this approach is very resource demanding, and the extent of the work needs to be carefully balanced to the gain expected. Approaches and tools for development of optimal industrial strains have recently been summarized by (Van Dien 2013).

-

The coupling efficiency needs to be maximized to utilize available cofactor efficiently, minimize toxic by-products and economical use of oxygen supplied.

Process:

-

Product localization determines product recovery, and if cell disruption is necessary, a growing cell process is favored due to the higher economic demands on the resting cell process. Growing or resting cells needs to be determined on a case-by-case basis, and factors like stability and product profile can also influence the decision.

-

Using process knowledge and constraints gained from substrate and product properties regarding solubility, toxicity, and transport should be taken into account when designing the overall process from the beginning, instead of designing a process purely based on the P450 in mind as illustrated in Fig. 6.

References

Ajikumar PK, Xiao W, Tyo KEJ, Wang Y, Simeon F, Leonard E, Mucha O, Phon TH, Pfeifer B, Stephanopoulos G (2010) Isoprenoid pathway optimization for taxol precursor overproduction in Escherichia coli. Science (Washington, DC, U S) 330:70–74

Armstrong FH, Fisher KC (1947) The oxygen consumption associated with growth in Escherichia coli and the effect of sulfathiazole and of n-propyl carbamate on it. J Gen Physiol 30:279–289

Baldwin CVF, Woodley JM (2006) On oxygen limitation in a whole cell biocatalytic Baeyer–Villiger oxidation process. Biotechnol Bioeng 95:362–369

Bell SG, McMillan JH, Yorke JA, Kavanagh E, Johnson EO, Wong L (2012) Tailoring an alien ferredoxin to support native-like P450 monooxygenase activity. Chem Commun 48:11692–11694

Bernhardt R, Urlacher VB (2014) Cytochromes P450 as promising catalysts for biotechnological application: chances and limitations. Appl Microbiol Biotechnol 98:6185–6203

Blank LM, Ebert BE, Bühler B, Schmid A (2008) Metabolic capacity estimation of Escherichia coli as a platform for redox biocatalysis: constraint‐based modeling and experimental verification. Biotechnol Bioeng 100:1050–1065

Bleif S, Hannemann F, Zapp J, Hartmann D, Jauch J, Bernhardt R (2012) A new Bacillus megaterium whole-cell catalyst for the hydroxylation of the pentacyclic triterpene 11-keto-β-boswellic acid (KBA) based on a recombinant cytochrome P450 system. Appl Microbiol Biotechnol 93:1135–1146

Bordeaux M, Galarneau A, Fajula F, Drone J (2011) A regioselective biocatalyst for alkane activation under mild conditions. Angew Chem Int Ed 123:2123–2127

Bornscheuer U, Huisman G, Kazlauskas R, Lutz S, Moore J, Robins K (2012) Engineering the third wave of biocatalysis. Nature 485:185–194

Braun A, Geier M, Bühler B, Schmid A, Mauersberger S, Glieder A (2012) Steroid biotransformations in biphasic systems with Yarrowia lipolytica expressing human liver cytochrome P450 genes. Microb Cell Fact 11:106–121

Bühler B, Schmid A (2004) Process implementation aspects for biocatalytic hydrocarbon oxyfunctionalization. J Biotechnol 113:183–210

Bühler B, Straathof AJJ, Witholt B, Schmid A (2006) Analysis of two-liquid-phase multistep biooxidation based on a process model: indications for biological energy shortage. Org Process Res Dev 10:628–643

Bühler B, Park JB, Blank LM, Schmid A (2008) NADH availability limits asymmetric biocatalytic epoxidation in a growing recombinant Escherichia coli strain. Appl Environ Microbiol 74:1436–1446

Chefson A, Zhao J, Auclair K (2006) Replacement of natural cofactors by selected hydrogen peroxide donors or organic peroxides results in improved activity for CYP3A4 and CYP2D6. Chembiochem 7:916–919

Chen RR (2007) Permeability issues in whole-cell bioprocesses and cellular membrane engineering. Appl Microbiol Biotechnol 74:730–738

Cirino PC, Arnold FH (2003) A self‐sufficient peroxide‐driven hydroxylation biocatalyst. Angew Chem Int Ed 115:3421–3423

Cirino PC, Arnold FH (2008) Polymorphic monooxygenase comprising mutation in heme domain of a secondary structural element and enhanced heat stability; improved peroxide-driven hydroxylation. US7465567 B2

Cornelissen S, Liu S, Deshmukh AT, Schmid A, Bühler B (2011) Cell physiology rather than enzyme kinetics can determine the efficiency of cytochrome P450-catalyzed C–H-oxyfunctionalization. J Ind Microbiol Biotechnol 38:1359–1370

Cornelissen S, Julsing MK, Volmer J, Riechert O, Schmid A, Bühler B (2013) Whole‐cell‐based CYP153A6‐catalyzed (S)‐limonene hydroxylation efficiency depends on host background and profits from monoterpene uptake via AlkL. Biotechnol Bioeng 110:1282–1292

Cote P, Bersillon JL, Huyard A, Faup G (1988) Bubble-free aeration using membranes: process analysis. J Water Pollut Control Fed 60:1986–1992

Dafoe JT, Daugulis AJ (2014) In situ product removal in fermentation systems: improved process performance and rational extractant selection. Biotechnol Lett 36:443–460

De Montellano PRO (2005) Cytochrome P450: structure, mechanism, and biochemistry. Plenum, New York

Drăgan CA, Peters FT, Bour P, Schwaninger AE, Schaan SM, Neunzig I, Widjaja M, Zapp J, Kraemer T, Maurer HH (2011) Convenient gram-scale metabolite synthesis by engineered fission yeast strains expressing functional human P450 systems. Appl Biochem Biotechnol 163:965–980

Duetz WA, Van Beilen JB, Witholt B (2001) Using proteins in their natural environment: potential and limitations of microbial whole-cell hydroxylations in applied biocatalysis. Curr Opin Biotechnol 12:419–425

Duport C, Spagnoli R, Degryse E, Pompon D (1998) Self-sufficient biosynthesis of pregnenolone and progesterone in engineered yeast. Nat Biotechnol 16:186–189

Eiben S, Kaysser L, Maurer S, Kühnel K, Urlacher VB, Schmid RD (2006) Preparative use of isolated CYP102 monooxygenases—a critical appraisal. J Biotechnol 124:662–669

Eiben S, Bartelmäs H, Urlacher VB (2007) Construction of a thermostable cytochrome P450 chimera derived from self-sufficient mesophilic parents. Appl Microbiol Biotechnol 75:1055–1061

Ewen KM, Ringle M, Bernhardt R (2012) Adrenodoxin—a versatile ferredoxin. IUBMB Life 64:506–512

Fasan R, Chen MM, Crook NC, Arnold FH (2007) Engineered alkane‐hydroxylating cytochrome P450BM3 exhibiting nativelike catalytic properties. Angew Chem Int Ed 119:8566–8570

Fasan R, Crook NC, Peters MW, Meinhold P, Buelter T, Landwehr M, Cirino PC, Arnold FH (2011) Improved product‐per‐glucose yields in P450‐dependent propane biotransformations using engineered Escherichia coli. Biotechnol Bioeng 108:500–510

Favre-Bulle O, Witholt B (1992) Biooxidation of n-octane by a recombinant Escherichia coli in a two-liquid-phase system: effect of medium components on cell growth and alkane oxidation activity. Enzyme Microb Technol 14:931–937

Fujii T, Fujii Y, Machida K, Ochiai A, Ito M (2009) Efficient biotransformations using Escherichia coli with tolC acrAB mutations expressing cytochrome P450 genes. Biosci Biotechnol Biochem 73:805–810

Furuya T, Arai Y, Kino K (2012) Biotechnological production of caffeic acid by bacterial cytochrome P450 CYP199A2. Appl Environ Microbiol 78:6087–6094

Gillam EMJ, Hayes MA (2013) The evolution of cytochrome P450 enzymes as biocatalysts in drug discovery and development. Curr Top Med Chem 13:2254–2280

Grant C, Woodley JM, Baganz F (2011) Whole-cell bio-oxidation of n-dodecane using the alkane hydroxylase system of P. putida GPo1 expressed in E. coli. Enzyme Microb Technol 48:480–486

Grogan G (2011) Cytochromes P450: exploiting diversity and enabling application as biocatalysts. Curr Opin Chem Biol 15:241–248

Guengerich FP, Munro AW (2013) Unusual cytochrome p450 enzymes and reactions. J Biol Chem 288:17065–17073

Hakki T, Zearo S, Dragan C, Bureik M, Bernhardt R (2008) Coexpression of redox partners increases the hydrocortisone (cortisol) production efficiency in CYP11B1 expressing fission yeast Schizosaccharomyces pombe. J Biotechnol 133:351–359

Hannemann F, Bichet A, Ewen KM, Bernhardt R (2007) Cytochrome P450 systems—biological variations of electron transport chains. BBA-Gen Subjects 1770:330–344

Hilker I, Alphand V, Wohlgemuth R, Furstoss R (2004) Microbial transformations, 56. Preparative scale asymmetric Baeyer–Villiger oxidation using a highly productive “Two‐in‐One” resin‐based in situ SFPR concept. Adv Synth Catal 346:203–214

Hirakawa H, Nagamune T (2010) Molecular assembly of P450 with ferredoxin and ferredoxin reductase by fusion to PCNA. ChemBioChem 11:1517–1520

Hlavica P (2009) Assembly of non-natural electron transfer conduits in the cytochrome P450 system: a critical assessment and update of artificial redox constructs amenable to exploitation in biotechnological areas. Biotechnol Adv 27:103–121

Hollmann F, Hofstetter K, Schmid A (2006) Non-enzymatic regeneration of nicotinamide and flavin cofactors for monooxygenase catalysis. Trends Biotechnol 24:163–171

Joo H, Lin Z, Arnold FH (1999) Laboratory evolution of peroxide-mediated cytochrome P450 hydroxylation. Nature (London) 399:670–673

Julsing MK, Cornelissen S, Bühler B, Schmid A (2008) Heme-iron oxygenases: powerful industrial biocatalysts? Curr Opin Chem Biol 12:177–186

Julsing MK, Schrewe M, Cornelissen S, Hermann I, Schmid A, Bühler B (2012) Outer membrane protein AlkL boosts biocatalytic oxyfunctionalization of hydrophobic substrates in Escherichia coli. Appl Environ Microbiol 78:5724–5733

Jung ST, Lauchli R, Arnold FH (2011) Cytochrome P450: taming a wild type enzyme. Curr Opin Biotechnol 22:809–817

Kim D, Ortiz de Montellano PR (2009) Tricistronic overexpression of cytochrome P450 cam, putidaredoxin, and putidaredoxin reductase provides a useful cell-based catalytic system. Biotechnol Lett 31:1427–1431

Kleser M, Hannemann F, Hutter M, Zapp J, Bernhardt R (2012) CYP105A1 mediated 3-hydroxylation of glimepiride and glibenclamide using a recombinant Bacillus megaterium whole-cell catalyst. J Biotechnol 157:405–412

Kolar NW, Swart AC, Mason JI, Swart P (2007) Functional expression and characterisation of human cytochrome P45017α in Pichia pastoris. J Biotechnol 129:635–644

Kuhn D, Bühler B, Schmid A (2012) Production host selection for asymmetric styrene epoxidation: Escherichia coli vs. solvent-tolerant Pseudomonas. J Ind Microbiol Biotechnol 39:1125–1133

Laane C, Boeren S, Vos K, Veeger C (1987) Rules for optimization of biocatalysis in organic solvents. Biotechnol Bioeng 30:81–87

Labinger JA (2004) Selective alkane oxidation: hot and cold approaches to a hot problem. J Mol Catal A Chem 220:27–35

Lamb SB, Lamb DC, Kelly SL, Stuckey DC (1998) Cytochrome P450 immobilisation as a route to bioremediation/biocatalysis. FEBS Lett 431:343–346

Lee W, Kim M, Jin Y, Seo J (2013) Engineering of NADPH regenerators in Escherichia coli for enhanced biotransformation. Appl Microbiol Biotechnol 97:2761–2772

Lewis JC, Arnold FH (2009) Catalysts on demand: selective oxidations by laboratory-evolved cytochrome P450 BM3. CHIMIA Int J Chem 63:309–312

Liese A, Seelbach K, Wandrey C (2006) Industrial biotransformations. Wiley-VCH Verlag GmbH & Co. KGaA, Weinheim, Germany

Lima-Ramos J, Tufvesson P, Woodley JM (2014) Application of environmental and economic metrics to guide the development of biocatalytic processes. Green Proc Synth 3:195–213

Lin Y, Lu P, Tang C, Mei Q, Sandig G, Rodrigues AD, Rushmore TH, Shou M (2001) Substrate inhibition kinetics for cytochrome P450-catalyzed reactions. Drug Metab Dispos 29:368–374

Liu Y, Kondo A, Ohkawa H, Shiota N, Fukuda H (1998) Bioconversion using immobilized recombinant flocculent yeast cells carrying a fused enzyme gene in an ‘intelligent’ bioreactor. Biochem Eng J 2:229–235

Liu S, Li C, Fang X, Cao Z (2004) Optimal pH control strategy for high-level production of long-chain α, ω-dicarboxylic acid by Candida tropicalis. Enzyme Microb Technol 34:73–77

Lye GJ, Woodley JM (1999) Application of in situ product-removal techniques to biocatalytic processes. Trends Biotechnol 17:395–402

Lynch RM, Woodley JM, Lilly MD (1997) Process design for the oxidation of fluorobenzene to fluorocatechol by Pseudomonas putida. J Biotechnol 58:167–175

Ma SK, Gruber J, Davis C, Newman L, Gray D, Wang A, Grate J, Huisman GW, Sheldon RA (2010) A green-by-design biocatalytic process for atorvastatin intermediate. Green Chem 12:81–86

Malca S (2012) Bacterial CYP153A monooxygenases for the synthesis of omega-hydroxylated fatty acids. Chem Commun 48:5115–5117

Martinez CA, Rupashinghe SG (2013) Cytochrome P450 bioreactors in the pharmaceutical industry: challenges and opportunities. Curr Top Med Chem 13:1470–1490

Maurer SC, Schulze H, Schmid RD, Urlacher V (2003) Immobilisation of P450 BM‐3 and an NADP cofactor recycling system: towards a technical application of heme‐containing monooxygenases in fine chemical synthesis. Adv Synth Catal 345:802–810

Maurer SC, Kühnel K, Kaysser LA, Eiben S, Schmid RD, Urlacher VB (2005) Catalytic hydroxylation in biphasic systems using CYP102A1 mutants. Adv Synth Catal 347:1090–1098

McIntosh JA, Farwell CC, Arnold FH (2014) Expanding P450 catalytic reaction space through evolution and engineering. Curr Opin Chem Biol 19:126–134

Meyer D, Buehler B, Schmid A (2006) Process and catalyst design objectives for specific redox biocatalysis. Adv Appl Microbiol 59:53–91

Michener JK, Nielsen J, Smolke CD (2012) Identification and treatment of heme depletion attributed to overexpression of a lineage of evolved P450 monooxygenases. Proc Natl Acad Sci U S A 109:19504–19509

Mouri T, Michizoe J, Ichinose H, Kamiya N, Goto M (2006) A recombinant Escherichia coli whole cell biocatalyst harboring a cytochrome P450cam monooxygenase system coupled with enzymatic cofactor regeneration. Appl Microbiol Biotechnol 72:514–520

Munro AW, Girvan HM, McLean KJ (2007a) Variations on a (t) heme—novel mechanisms, redox partners and catalytic functions in the cytochrome P450 superfamily. Nat Prod Rep 24:585–609

Munro AW, Girvan HM, McLean KJ (2007b) Cytochrome P450—redox partner fusion enzymes. BBA-Gen Subjects 1770:345–359

Nelson DR (2009) The cytochrome P450 homepage. Hum Genomics 4:59–65

Nthangeni M, Urban P, Pompon D, Smit M, Nicaud J (2004) The use of Yarrowia lipolytica for the expression of human cytochrome P450 CYP1A1. Yeast 21:583–592

O’Reilly E, Köhler V, Flitsch SL, Turner NJ (2011) Cytochromes P450 as useful biocatalysts: addressing the limitations. Chem Commun 47:2490–2501

Oudshoorn A, van den Berg C, Roelands C, Straathof A, Van der Wielen L (2010) Short-cut calculations for integrated product recovery options in fermentative production of bio-bulk chemicals. Process Biochem 45:1605–1615

Paddon C, Westfall P, Pitera D, Benjamin K, Fisher K, McPhee D, Leavell M, Tai A, Main A, Eng D (2013) High-level semi-synthetic production of the potent antimalarial artemisinin. Nature 496:528–532

Panke S, Wubbolts MG, Schmid A, Witholt B (2000) Production of enantiopure styrene oxide by recombinant Escherichia coli synthesizing a two‐component styrene monooxygenase. Biotechnol Bioeng 69:91–100

Panke S, Held M, Wubbolts MG, Witholt B, Schmid A (2002) Pilot‐scale production of (S)‐styrene oxide from styrene by recombinant Escherichia coli synthesizing styrene monooxygenase. Biotechnol Bioeng 80:33–41

Park JW, Lee JK, Kwon TJ, Yi DH, Kim YJ, Moon SH, Suh HH, Kang SM, Park YI (2003) Bioconversion of compactin into pravastatin by Streptomyces sp. Biotechnol Lett 25:1827–1831

Pflug S, Richter SM, Urlacher VB (2007) Development of a fed-batch process for the production of the cytochrome P450 monooxygenase CYP102A1 from Bacillus megaterium in E. coli. J Biotechnol 129:481–488

Ramos JL, Duque E, Gallegos MT, Godoy P, Ramos-González MI, Rojas A, Terán W, Segura A (2002) Mechanisms of solvent tolerance in Gram-negative bacteria. Annu Rev Microbiol 56:743–768

Rendic S, Guengerich FP (2010) Update information on drug metabolism systems—2009, part II. Summary of information on the effects of diseases and environmental factors on human cytochrome P450 (CYP) enzymes and transporters. Curr Drug Metab 11:4–84

Richardson TH, Jung F, Griffin KJ, Wester M, Raucy JL, Kemper B, Bornheim LM, Hassett C, Omiecinski CJ, Johnson EF (1995) A universal approach to the expression of human and rabbit cytochrome P450s of the 2C subfamily in Escherichia coli. Arch Biochem Biophys 323:87–96

Robin A, Roberts GA, Kisch J, Sabbadin F, Grogan G, Bruce N, Turner NJ, Flitsch SL (2009) Engineering and improvement of the efficiency of a chimeric [P450cam-RhFRed reductase domain] enzyme. Chem Comm:2478–2480

Ryan JD, Clark DS (2008) P450cam biocatalysis in surfactant‐stabilized two‐phase emulsions. Biotechnol Bioeng 99:1311–1319