Abstract

Selection of the ideal microbe is crucial for whole-cell biotransformations, especially if the target reaction intensively interacts with host cell functions. Asymmetric styrene epoxidation is an example of a reaction which is strongly dependent on the host cell owing to its requirement for efficient cofactor regeneration and stable expression of the styrene monooxygenase genes styAB. On the other hand, styrene epoxidation affects the whole-cell biocatalyst, because it involves toxic substrate and products besides the burden of additional (recombinant) enzyme synthesis. With the aim to compare two fundamentally different strain engineering strategies, asymmetric styrene epoxidation by StyAB was investigated using the engineered wild-type strain Pseudomonas sp. strain VLB120ΔC, a styrene oxide isomerase (StyC) knockout strain able to accumulate (S)-styrene oxide, and recombinant E. coli JM101 carrying styAB on the plasmid pSPZ10. Their performance was analyzed during fed-batch cultivation in two-liquid phase biotransformations with respect to specific activity, volumetric productivity, product titer, tolerance of toxic substrate and products, by-product formation, and product yield on glucose. Thereby, Pseudomonas sp. strain VLB120ΔC proved its great potential by tolerating high styrene oxide concentrations and by the absence of by-product formation. The E. coli-based catalyst, however, showed higher specific activities and better yields on glucose. The results not only show the importance but also the complexity of host cell selection and engineering. Finding the optimal strain engineering strategy requires profound understanding of bioprocess and biocatalyst operation. In this respect, a possible negative influence of solvent tolerance on yield and activity is discussed.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Progress in recombinant DNA technology including DNA synthesis and fast and cheap sequencing of industrially relevant microorganisms offer new opportunities in strain selection and engineering for whole-cell redox biocatalysis [14, 32]. Bioprocess performance strongly depends on interactions between the cell and the recombinant system, such as enzyme synthesis and metabolism [30, 39, 45]. Strain selection criteria include general industrially relevant features, such as high growth rates in simple media, suitability for large-scale and high cell density cultivation, availability of genetic manipulation tools and knowledge [39], and more reaction-specific aspects, such as low by-product formation, high tolerance for the substrate and product, and high yields [30].

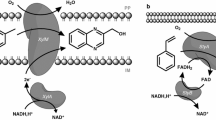

The whole-cell biocatalyst engineering strategy becomes more important for biotransformations with multiple interactions between the host cell and the recombinant reaction. Oxygenase-based reactions, for example, strongly depend on host properties not only on the level of target enzyme synthesis, but also on the level of metabolism owing to their dependence on redox cofactors [5, 24]. For oxygenase catalysis, the application of whole cells is favored over the use of isolated enzymes, because metabolism can be exploited as a powerful cofactor regeneration system and for the degradation of reactive oxygen species originating from uncoupling [15, 27, 51]. This study focuses on the asymmetric epoxidation of styrene to (S)-styrene oxide catalyzed by the NADH-dependent styrene monooxygenase from Pseudomonas sp. strain VLB120 [35]. Efficient whole-cell biocatalysts have been constructed by engineering the wild-type strain, generating the styrene oxide isomerase (StyC) knockout strain Pseudomonas sp. strain VLB120ΔC, wherein product degradation was prevented [38], or based on recombinant Escherichia coli expressing the styrene monooxygenase genes styAB from a plasmid [35, 36]. Interestingly, in activity assays, similar specific activities have been reported for both strains with maxima of 97 and 92 U/gCDW for Pseudomonas sp. strain VLB120ΔC and recombinant E. coli, respectively [37, 38]. Fed-batch cultivation and two-liquid phase biotransformation with bis(2-ethylhexyl)phthalate (BEHP) as the extractive carrier solvent have been identified as the most promising reaction setup [33, 38]. This process has been intensified with respect to productivities and product titers with E. coli as the host [26]. The maximum achievable product titers were restricted by toxification of the E. coli-based biocatalyst by the product (S)-styrene oxide and by the by-product 2-phenylethanol [25, 26, 37]. Pseudomonas sp. strain VLB120 belongs to a group of pseudomonads which are able to tolerate high concentrations of toxic solvents [17, 38]. Hence, the use of this strain deficient in the styrene oxide isomerase gene offers a great opportunity to increase the maximally achievable product titers.

The aim of this study was the comparison of these E. coli and Pseudomonas biocatalysts with respect to their performance in the production of the toxic product (S)-styrene oxide by oxygenase catalysis. Thereby, biotechnological aspects in focus included productivities, specific activities, solvent tolerance, biomass and product yields, and by-product formation.

Materials and methods

Strain and cultivation conditions

Pseudomonas sp. strain VLB120ΔC [38] and E. coli JM101 (pSPZ10) [29] were used in this study. The expression plasmid pSPZ10 is based on the pBR322 vector and contains the styrene monooxygenase genes styAB from Pseudomonas sp. strain VLB120 under the control of the alk regulatory system from Pseudomonas putida GPo1 [36].

Kanamycin (50 mg/L) and streptomycin (100 mg/L) were used as selective markers for E. coli JM101 (pSPZ10) and Pseudomonas sp. strain VLB120ΔC, respectively. The strains were grown in lysogeny broth (LB) [3], M9 [43], M9* [34], or RB medium for high cell density cultivation [7]. M9 and M9* media were complemented with 0.5 % (w/v) glucose, 1 mL/L US* trace element solution [34], and 2 mL/L 1 M MgSO4. RB medium was supplemented with 1.5 % (w/v) glucose, 1 mL/L US* trace element solution, and 2.5 mL/L 1 M MgSO4 and adjusted to pH 6.8 using 25 % NH4OH and to pH 7.2 using 10 M NaOH. Additionally, 1 mL/L 1 % (w/v) thiamine solution was added to E. coli cultures.

Resting cell activity assays

Resting cell activity assays were performed as described before [35, 38]. In short, M9* cultures were grown in baffled shake flasks to a cell concentration of 0.10–0.15 gCDW/L, before induction was performed by 0.025 % dicyclopropyl ketone (DCPK) and 2 mM styrene for E. coli and Pseudomonas, respectively. After induction, incubation was continued for 4 h, before the cells were harvested and gently resuspended to a cell concentration of 0.5 gCDW/L in 50 mM potassium phosphate buffer containing 1 % (w/v) glucose. For the assay, 2-mL aliquots of cell suspension were transferred to 15-mL Pyrex tubes and equilibrated to the assay conditions (30 °C, 400 rpm) for 10 min inside a water bath. Then, the biotransformation was started by the addition of the substrate. The reaction was stopped by addition of 2 mL of ice-cold diethyl ether containing 0.2 mM decane as the internal standard. After extraction and phase separation by centrifugation, the ether phase was transferred to GC vials for analysis.

Two-liquid phase biotransformation

Two-liquid phase biotransformations with Pseudomonas sp. strain VLB120ΔC were performed by adapting the procedure optimized for E. coli [24, 25]. A 100-mL M9 shake flask culture grown overnight was used to inoculate a 3-L KLF 2000 reactor (Bioengineering, Wald, Switzerland) containing 900 mL RB medium [7]; 15 g/L glucose was used as the carbon and energy source. The pH was maintained at 7.20 by adding 30 % phosphoric acid and 25 % NH4OH solutions. The latter additionally served as a nitrogen feed. The batch phase lasted approximately 12 h (overnight). Aeration and stirring rate were maintained constant at 1 L/min and 1,500 rpm, respectively. After depletion of the carbon source, a feed consisting of 730 g/L glucose and 19.6 g/L MgSO4·7H2O was started at a rate of 3.3 or 3.7 gglucose/L/h and increased exponentially to sustain a growth rate between 0.15 and 0.25 h−1 until a biomass concentration of approximately 20 g/L was reached. The biotransformation was started by the addition of 1 L organic phase consisting of BEHP and styrene serving as the substrate and inducer of styAB expression. During the biotransformation the feed was kept constant at a rate of 8.8 or 10.4 gglucose/L/h. The dissolved oxygen concentration was kept above 20 % by increasing the stirring speed (to a maximum of 2,800 rpm) and the aeration rate (up to 1.5 L/min). Antifoam A (Sigma-Aldrich Chemie GmbH, Steinheim, Germany) was added in case of excessive foaming. The biotransformation was monitored by taking samples every hour as described previously [34]. For two-liquid phase biotransformations, volumetric rates and concentrations are given per liter of aqueous phase (Laq), organic phase (Lorg), or total volume (Ltot).

Analytics

Concentrations of styrene, styrene oxide, and 2-phenylethanol were measured by a TRACE GC Ultra (Thermo Fisher Scientific Inc., Waltham, MA, USA) equipped with a FactorFour VF-5 ms column (Varian, Inc., Palo Alto, CA, USA). Analytical conditions were identical as published before [26]. Specific epoxidation activities are given in units (U) per gram cell dry weight (CDW), whereby 1 U is defined as the activity forming 1 μmol product per 1 min.

Glucose, glycerol, and acetate were separated on an Aminex HPX-87-H column (Bio-Rad Laboratories, Hercules, CA, USA) in a LaChrom Elite HPLC system (Hitachi High Technologies America, Inc., Pleasanton, CA, USA), after extraction of aqueous styrene, styrene oxide, and 2-phenylethanol by BEHP [25]. The flow rate of 5 mM sulfuric acid as the mobile phase was set to 1.0 mL/min. The column temperature was kept constant at 40 °C. Detection of the analytes was done by an L-2420 UV–Vis and an L-2490 refractive index module.

Cell concentrations were determined spectrophotometrically on a Libra S11 spectrophotometer at a wavelength of 450 nm [4].

Results

Two-liquid phase biotransformations

Two-liquid phase styrene biotransformations based on fed-batch cultivated Pseudomonas sp. strain VLB120ΔC cells have been investigated before, whereby 290 mM (=34.8 g/Lorg) (S)-styrene oxide was produced (Table 1) [38]. During this preceding study, the initial styrene concentration and the biomass concentration at induction were low compared to the intensified setup with E. coli JM101 (pSPZ10) [26]. Therefore, two-liquid phase biotransformations were performed with the VLB120ΔC strain according to the E. coli setup aiming at enhanced volumetric productivities and product titers applying higher biocatalyst and substrate concentrations (Fig. 1, Table 1).

Two-liquid phase styrene epoxidation by Pseudomonas sp. strain VLB120ΔC with 80 mL styrene. At t = − 6 h, fed-batch cultivation was started using a feed rate of 3.3 gglucose/h, which was increased exponentially to support a growth rate of 0.15 h−1. At −3.5 h, the feed rate was raised faster for a μ of 0.20 h−1. The feed rate was set constant at 8.8 gglucose/h, 0.5 h before the biotransformation was started by the addition of styrene containing BEHP phase (t = 0 h). a Time course of specific epoxidation activities and styrene and styrene oxide concentrations in the organic phase. b Time course of biomass, glucose, and acetate concentrations, the feed rate, and pO2

After Pseudomonas sp. strain VLB120ΔC was grown in fed-batch mode to a cell concentration of 19.3 g/L, an organic phase consisting of 920 mL BEHP and 80 mL styrene (serving as the substrate and as the inducer) was added to the reactor (t = 0 h) at an organic to aqueous phase ratio of 1:1. After 1 h, the specific activity started to increase quickly to 28–35 U/gCDW, before it steadily decreased with ongoing biotransformation. In contrast, recombinant E. coli maintained high maximum activities of 40–60 U/gCDW until toxification occurred at the end of the biotransformation as indicated by sharply decreasing oxygen and glucose uptake rates [26, 37]. The lower specific epoxidation activity of Pseudomonas sp. strain VLB120ΔC resulted in a longer biotransformation time until the initially added styrene was completely converted. Interestingly and in contrast to recombinant E. coli, Pseudomonas cells remained metabolically active until the end of the biotransformation indicating a higher tolerance to the accumulating styrene oxide.

In order to capitalize on the tolerance of Pseudomonas for such high styrene oxide concentrations, the initial substrate concentration was further increased to 10 % (v/v) in the organic phase. Again, epoxidation started within the second hour after organic phase addition (Fig. 2).

Two-liquid phase styrene epoxidation by Pseudomonas sp. strain VLB120ΔC with 100 mL styrene. At t = − 5.5 h, fed-batch cultivation was started using a feed rate of 3.7 gglucose/h, which was increased exponentially to support a growth rate of 0.25 h−1. The feed rate was set constant at 10.4 gglucose/h, 1.3 h before the biotransformation was started by the addition of styrene containing BEHP phase (t = 0 h). a Time course of specific epoxidation activities and styrene and styrene oxide concentrations in the organic phase. b Time course of biomass, glucose, and acetate concentrations, the feed rate, and pO2

Compared to the experiment presented before, the epoxidation activities were lower with a maximum of 25 U/gCDW being reached after 2.5 h. Again, the epoxidation activities decreased steadily throughout the biotransformation. Although the added 859 mM styrene was completely consumed, the overall productivity was low as a result of the steadily decreasing activities and the long biotransformation time.

After 11 and 13 h of biotransformation, the aqueous (S)-styrene oxide concentration reached 2.9 and 3.1 mM, respectively, levels which are known to be toxic for E. coli [37]. In contrast to E. coli-based biotransformations [25, 26], Pseudomonas sp. strain VLB120ΔC was able to tolerate these high product concentrations for another 5–7 h as indicated by the low pO2 in the culture broth and high glucose uptake rates. Furthermore, biotransformation continued. After 14.6 h of biotransformation, the glucose feed was stopped for 20 min resulting in a halt of bioconversion, which continued after feed resumption. The energy starvation introduced by the feed interruption may have triggered the breakdown of metabolism observed after 18 h of biotransformation. By-products were not detected by HPLC analysis with the exception of small amounts of acetic acid (<0.15 g/L).

For the first time, product titers comparable to those reached with recombinant E. coli were achieved with a Pseudomonas strain. However, the productivity was clearly lower with the latter strain.

Investigation of product degradation in activity assays

No 2-phenylethanol was detected during biotransformations with Pseudomonas sp. strain VLB120ΔC. This by-product was produced by E. coli JM101 (pSPZ10) at a rate accounting for 10 % of the styrene oxide formation rate [38]. The excellent styrene oxide yield on styrene of 91 % previously observed for Pseudomonas sp. strain VLB120ΔC was lower with the higher substrate and cell concentrations and longer biotransformation times applied in this study (Table 1). The substrate balance was not closed during the two-liquid phase biotransformations reported here (Figs. 1, 2). This points to a loss of substrate over time by evaporation and/or substrate/product degradation. Styrene stripping from the strongly aerated reactor is known to occur during these biotransformations [26, 38], although the loss was minimized by using an off-gas cooling system. Furthermore, Pseudomonas strains are known for their versatility in degrading diverse aromatic compounds [2, 12]. Therefore, degradation of styrene and/or styrene oxide was investigated in more detail by means of resting cell activity assays.

First, the degradation of styrene oxide was tested. Neither Pseudomonas sp. strain VLB120ΔC nor E. coli JM101 (pSPZ10) was able to convert styrene oxide (Table 2). Styrene degradation may involve the intermediate formation of phenyl acetaldehyde, which was observed as a by-product during styrene epoxidation by isolated styrene monooxygenase [20, 42]. Therefore, the two strains also were investigated for phenyl acetaldehyde conversion (Table 2).

Wild-type E. coli JM101 and induced E. coli JM101 (pSPZ10) converted phenyl acetaldehyde to 2-phenylethanol at identical rates (Table 2). In accordance with the results of two-liquid phase biotransformations, Pseudomonas sp. strain VLB120ΔC did not accumulate 2-phenylethanol. Phenyl acetaldehyde was degraded without detectable accumulation of intermediates. The rate of phenyl acetaldehyde degradation was independent of induction by styrene. Acetophenone, the secondary ketone, remained unconverted with all investigated strains. In cell-free KPi buffer, no conversion of styrene, styrene oxide, phenyl acetaldehyde, and acetophenone was observed except for slow epoxide hydrolysis to the respective diol at a reduced pH of 5.5. The conversions of phenyl acetaldehyde described above can hence be ascribed to background activities within the E. coli and Pseudomonas biocatalysts.

For Pseudomonas sp. strain VLB120ΔC, degradation of phenyl acetaldehyde formed from styrene as a by-product is expected to reduce styrene oxide yields on styrene (Fig. 3).

Discussion

By-product formation

Unwanted side reactions during oxygenase catalysis include multiple oxidation at different sites due to low regiospecificities and overoxidation of the same carbon atom, when the product (alcohol) also serves as substrate [8, 47]. Styrene epoxidation by recombinant E. coli comes with the formation of the by-product 2-phenylethanol at approximately 10 % of the (S)-styrene oxide formation rate [36, 37]. 2-Phenylethanol is most likely formed from phenyl acetaldehyde, a by-product which was observed during the application of isolated styrene monooxygenase [20, 42]. Attack by the semiquinone radical on styrene oxide was proposed as a mechanism [42]. Externally added styrene oxide, however, remained unconverted in activity assays with whole cells (Table 2). Phenyl acetaldehyde was not detected during application of recombinant E. coli, which can be explained by its reduction to 2-phenylethanol as was observed when phenyl acetaldehyde was provided as the substrate. Such unspecific alcohol dehydrogenase activities have been observed before with recombinant E. coli, catalyzing aromatic aldehyde reduction [9, 28, 31].

In contrast to E. coli, Pseudomonas sp. strain VLB120ΔC degrades phenyl acetaldehyde without the accumulation of any by-product via the native styrene degradation pathway, which is present except for the styrene isomerase StyC [35]. The avoidance of by-product formation can be considered beneficial for the overall biocatalytic performance, because accumulation of toxic 2-phenylethanol is prevented. Beside the avoidance of related inhibitory effects, this simplifies downstream processing.

E. coli also tends to form acetic acid, when glucose is used as the carbon and energy source [7, 37, 41]. Acetic acid formation has been shown to be triggered by styrene oxide [37], and concentrations of 3–10 g/L were observed during two-liquid phase biotransformations with E. coli [25, 26, 37]. Acetic acid formation reduces the cofactor regeneration yield per glucose consumed and negatively affects the proton gradient across the cytoplasmic membrane [1, 5, 38]. In contrast, the acetic acid levels remained below 0.15 g/L applying Pseudomonas sp. strain VLB120ΔC (Table 1). This low tendency for organic acid formation is a clear advantage of using Pseudomonas as the host for biocatalytic oxidations, because efficient regeneration of reduction equivalents is crucial for cofactor-dependent biocatalysis and inhomogeneities in large-scale reactors might further amplify acetic acid formation by E. coli [11, 16].

Solvent tolerance

Solvents with a log P O/W (logarithm of octanol–water partition coefficient) between 1 and 5 are generally considered to be toxic to most microorganisms [19, 22]. However, several members of the genus Pseudomonas were found to tolerate these solvents to a high extent [12, 21, 22, 35, 40, 52]. Pseudomonas sp. strain VLB120 belongs to this remarkable group of solvent-tolerant bacteria [17, 38]. Tolerance of low log P O/W solvents is an enormous advantage in biocatalysis involving low log P O/W compounds [13] including the epoxidation of styrene (log P O/W 2.8) to styrene oxide (log P O/W 1.6). Whereas the metabolic activity of E. coli JM101 (pSPZ10) was severely affected by aqueous styrene oxide concentrations in the range of 2–3 mM, Pseudomonas sp. strain VLB120ΔC was able to maintain metabolic activities (glucose catabolism, respiration) under these adverse conditions for extended time periods (Figs. 1, 2), giving evidence for its higher tolerance to these toxic solvents.

Specific activities and productivities

Styrene epoxidation activities of Pseudomonas sp. strain VLB120ΔC were generally lower compared to E. coli and steadily decreased with ongoing biotransformation (Figs. 1, 2). The biocatalytic potential of the VLB120ΔC strain was shown to be equal to that of E. coli in short-term resting cell assays, in which activities in the range of 60–100 U/gCDW were found with both strains [37, 38]. Maximal activities reported amount to 97 and 92 U/gCDW, respectively. It should be noted that process conditions in two-liquid phase biotransformations differ from resting cell assay conditions in terms of substrate availability, product concentrations, and physiological state of the cells [5, 8]. Regarding substrate availability, oxygen was present at a concentration above 20 % of saturation at all time. These levels are considered to be sufficient for both growth and oxygenase catalysis [10, 15]. According to whole-cell kinetics derived from continuous two-liquid phase cultivations [38], the low epoxidation activities of the VLB120ΔC strain observed during two-liquid phase fed-batch cultivations should not be due to styrene limitation. The substrate concentrations in the organic phase were well above the apparent K S of 18.8 mM for this two-liquid phase system. It is noteworthy the mentioned kinetic data were recorded in the presence of lower styrene and styrene oxide concentrations. Specific epoxidation activities of the solvent-tolerant VLB120ΔC strain might be restricted in the presence of higher styrene and styrene oxide concentrations by two physiological effects. First, solvent defense mechanisms, namely the efflux pumps, actively remove solvents from the cells. This lowers intracellular styrene concentrations, which might become limiting for the styrene monooxygenase [6]. The observed decrease in activity over time may be explained by stronger induction of solvent tolerance genes with rising styrene oxide concentrations. A similar effect may have led to lower maximum activities with higher initial styrene concentrations.

The second possible influence of solvent tolerance on the biocatalytic reaction involves the competition of energy metabolism and oxygenase for reduction equivalents [6]. Several studies showed that the energy metabolism is significantly increased in solvent-tolerant strains encountering toxic compounds indicating a high energy demand to sustain solvent tolerance. Proteome analyses of P. putida S12 and DOT-T1E revealed a strong upregulation of TCA-cycle enzymes upon exposure to toluene [46, 49], which was suggested as being part of the cellular strategy to maintain adequate NAD(P)H levels. Metabolic flux analysis of P. putida DOT-T1E confirmed the high TCA-cycle activity leading to an eightfold increase in the NAD(P)H regeneration rate in the presence of toxic octanol compared to reference conditions [6, 23, 44]. The styrene monooxygenase has to compete with the high demand of solvent tolerance mechanisms for energy and reduction equivalents in order to catalyze styrene epoxidation, the rate of which was heavily reduced with recombinant P. putida DOT-T1E in the presence of a second octanol phase [6]. Such a competition is expected to increase when the VLB120ΔC strain is exposed to rising styrene oxide concentrations and thus may contribute to the steady decrease of specific epoxidation activity. Thus, the results obtained in this study indicate a trade-off between high specific epoxidation activities and volumetric productivities, as achieved with recombinant E. coli, and tolerance of high product titers enabling high process durability, as achieved with the Pseudomonas sp. strain VLB120ΔC.

Yields on glucose

Next to the potential impact on oxygenase activities, the high maintenance energy demand as a result of exposure to toxic solvents also affects the biomass yield on glucose [6, 49]. The biomass yield decreased with increasing biotransformation times and styrene oxide concentrations. From an economic perspective, high yields on the carbon and energy source are crucial for industrial processes [18, 48, 50]. In the case of (S)-styrene oxide production by recombinant E. coli, glucose was found to be the second most important raw material cost factor after the organic phase BEHP [25, 26]. This indicates that a Pseudomonas-based biocatalyst can only be competitive if comparable yields on the carbon source are reached. Hence, the obvious advantage of solvent tolerance needs to be weighed against the disadvantage of the high energy demand of these defense mechanisms.

The key to the application of solvent-tolerant pseudomonads is a better understanding of the underlying mechanisms of their metabolic versatility and exceptional solvent tolerance. Such knowledge is necessary for systematic engineering approaches. Tackling the challenges of low yields on energy source and lower activities in the presence of toxic solvents is essential for bioprocessing based on solvent-tolerant Pseudomonas strains.

References

Axe DD, Bailey JE (1995) Transport of lactate and acetate through the energized cytoplasmic membrane of E. coli. Biotechnol Bioeng 47(1):8–19

Beltrametti F, Marconi AM, Bestetti G, Colombo C, Galli E, Ruzzi M, Zennaro E (1997) Sequencing and functional analysis of styrene catabolism genes from Pseudomonas fluorescens ST. Appl Environ Microbiol 63(6):2232–2239

Bertani G (1951) Studies on lysogenesis I. The mode of phage liberation by lysogenic E. coli. J Bacteriol 62(3):293–300

Blank LM, Ebert BE, Bühler B, Schmid A (2008) Metabolic capacity estimation of E. coli as platform for redox biocatalysis: constraint based modeling and experimental verification. Biotechnol Bioeng 100(6):1050–1065

Blank LM, Ebert BE, Bühler K, Bühler B (2010) Redox biocatalysis and metabolism: molecular mechanisms and metabolic network analysis. Antioxid Redox Signal 13(3):349–394

Blank LM, Ionidis G, Ebert BE, Bühler B, Schmid A (2008) Metabolic response of P. putida during redox biocatalysis in the presence of a second octanol phase. FEBS J 275(20):5173–5190

Bühler B, Bollhalder I, Hauer B, Witholt B, Schmid A (2003) Use of the two-liquid phase concept to exploit kinetically controlled multistep biocatalysis. Biotechnol Bioeng 81(6):683–694

Bühler B, Schmid A (2004) Process implementation aspects for biocatalytic hydrocarbon oxyfunctionalization. J Biotechnol 113(1–3):183–210

Bühler B, Schmid A, Hauer B, Witholt B (2000) Xylene monooxygenase catalyzes the multistep oxygenation of toluene and pseudocumene to corresponding alcohols, aldehydes, and acids in E. coli JM101. J Biol Chem 275(14):10085–10092

Bühler B, Straathof AJJ, Witholt B, Schmid A (2006) Analysis of two-liquid-phase multistep biooxidation based on a process model: indications for biological energy shortage. Org Process Res Dev 10(3):628–643

Bylund F, Collet E, Enfors SO, Larsson G (1998) Substrate gradient formation in the large-scale bioreactor lowers cell yield and increases by-product formation. Bioprocess Eng 18(3):171–180

Cruden DL, Wolfram JH, Rogers RD, Gibson DT (1992) Physiological properties of a Pseudomonas strain which grows with p-xylene in a two-phase (organic-aqueous) medium. Appl Environ Microbiol 58(9):2723–2729

de Bont JAM (1998) Solvent-tolerant bacteria in biocatalysis. Trends Biotechnol 16(12):493–499

Demain AL (2000) Microbial biotechnology. Trends Biotechnol 18(1):26–31

Duetz WA, van Beilen JB, Witholt B (2001) Using proteins in their natural environment: potential and limitations of microbial whole-cell hydroxylations in applied biocatalysis. Curr Opin Biotechnol 12(4):419–425

Enfors SO, Jahic M, Rozkov A, Xu B, Hecker M, Jürgen B, Krüger E, Schweder T, Hamer G, O’Beirne D, Noisommit-Rizzi N, Reuss M, Boone L, Hewitt C, McFarlane C, Nienow A, Kovacs T, Trägardh C, Fuchs L, Revstedt J, Friberg PC, Hjertager B, Blomsten G, Skogman H, Hjort S, Hoeks F, Lin HY, Neubauer P, van der Lans R, Luyben K, Vrabel P, Manelius A (2001) Physiological responses to mixing in large scale bioreactors. J Biotechnol 85(2):175–185

Halan B, Schmid A, Buehler K (2011) Real-time solvent tolerance analysis of Pseudomonas sp. strain VLB120ΔC catalytic biofilms. Appl Environ Microbiol 77(5):1563–1571

Heijnen JJ, van Dijken JP (1992) In search of a thermodynamic description of biomass yields for the chemotropic growth of microorganisms. Biotechnol Bioeng 39(8):833–858

Heipieper HJ, Neumann G, Cornelissen S, Meinhardt F (2007) Solvent-tolerant bacteria for biotransformations in two-phase fermentation systems. Appl Microbiol Biotechnol 74(5):961–973

Hofstetter K, Lutz J, Lang I, Witholt B, Schmid A (2004) Coupling of biocatalytic asymmetric epoxidation with NADH regeneration in organic-aqueous emulsions. Angew Chem Int Ed 43(16):2163–2166

Inoue A, Horikoshi K (1989) A Pseudomonas thrives in high concentrations of toluene. Nature 338(6212):264–266

Isken S, de Bont JAM (1998) Bacteria tolerant to organic solvents. Extremophiles 2(3):229–238

Isken S, Derks A, Wolffs PF, de Bont JA (1999) Effect of organic solvents on the yield of solvent-tolerant P. putida S12. Appl Environ Microbiol 65(6):2631–2635

Kuhn D, Blank LM, Schmid A, Bühler B (2010) Systems biotechnology: rational whole-cell biocatalyst and bioprocess design. Eng Life Sci 10(5):384–397

Kuhn D, Julsing MK, Heinzle E, Bühler B (2012) Systematic optimization of a biocatalytic two-liquid phase oxyfunctionalization process guided by ecological and economic assessment. Green Chem 14:645–653

Kuhn D, Kholiq MA, Heinzle E, Bühler B, Schmid A (2010) Intensification and economic and ecological assessment of a biocatalytic oxyfunctionalization process. Green Chem 12(5):815–827

Leak DJ, Sheldon RA, Woodley JM, Adlercreutz P (2009) Biocatalysts for selective introduction of oxygen. Biocatal Biotransform 27(1):1–26

Maruyama T, Iida H, Kakidani H (2003) Oxidation of both termini of p- and m-xylene by E. coli transformed with xylene monooxygenase gene. J Mol Catal B Enzym 21(4–6):211–219

Messing J (1979) A multi-purpose cloning system based on the single stranded bacteriophage M13. Recomb DNA Tech Bull 79–99(2):43–48

Meyer D, Bühler B, Schmid A (2006) Process and catalyst design objectives for specific redox biocatalysis. Adv Appl Microbiol 59:53–91

Meyer D, Witholt B, Schmid A (2005) Suitability of recombinant E. coli and P. putida strains for selective biotransformation of m-nitrotoluene by xylene monooxygenase. Appl Environ Microbiol 71(11):6624–6632

Otero JM, Nielsen J (2010) Industrial systems biology. Biotechnol Bioeng 105(3):439–460

Panke S, Held M, Wubbolts MG, Witholt B, Schmid A (2002) Pilot-scale production of (S)-styrene oxide from styrene by recombinant E. coli synthesizing styrene monooxygenase. Biotechnol Bioeng 80(1):33–41

Panke S, Meyer A, Huber CM, Witholt B, Wubbolts MG (1999) An alkane-responsive expression system for the production of fine chemicals. Appl Environ Microbiol 65(6):2324–2332

Panke S, Witholt B, Schmid A, Wubbolts MG (1998) Towards a biocatalyst for (S)-styrene oxide production: characterization of the styrene degradation pathway of Pseudomonas sp. strain VLB120. Appl Environ Microbiol 64(9):2032–2043

Panke S, Wubbolts MG, Schmid A, Witholt B (2000) Production of enantiopure styrene oxide by recombinant E. coli synthesizing a two-component styrene monooxygenase. Biotechnol Bioeng 69(1):91–100

Park JB, Bühler B, Habicher T, Hauer B, Panke S, Witholt B, Schmid A (2006) The efficiency of recombinant E. coli as biocatalyst for stereospecific epoxidation. Biotechnol Bioeng 95(3):501–512

Park JB, Bühler B, Panke S, Witholt B, Schmid A (2007) Carbon metabolism and product inhibition determine the epoxidation efficiency of solvent-tolerant Pseudomonas sp. strain VLB120C. Biotechnol Bioeng 98(6):1219–1229

Park JH, Lee SY, Kim TY, Kim HU (2008) Application of systems biology for bioprocess development. Trends Biotechnol 26(8):404–412

Ramos JL, Duque E, Huertas MJ, Haidour A (1995) Isolation and expansion of the catabolic potential of a P. putida strain able to grow in the presence of high concentrations of aromatic hydrocarbons. J Bacteriol 177(14):3911–3916

Rothen SA, Sauer M, Sonnleitner B, Witholt B (1998) Biotransformation of octane by E. coli HB101[pGEc47] on defined medium: octanoate production and product inhibition. Biotechnol Bioeng 58(4):356–365

Ruinatscha R, Dusny C, Bühler K, Schmid A (2009) Productive asymmetric styrene epoxidation based on a next generation electroenzymatic methodology. Adv Synth Catal 351(14–15):2505–2515

Sambrook J, Russell DW (2001) Molecular cloning–a laboratory manual, 3rd edn. Cold Spring Harbor Laboratory Press, New York, NY, USA

Santos PM, Blatny JM, Di Bartolo I, Valla S, Zennaro E (2000) Physiological analysis of the expression of the styrene degradation gene cluster in Pseudomonas fluorescens ST. Appl Environ Microbiol 66(4):1305–1310

Schmid A, Dordick JS, Hauer B, Kiener A, Wubbolts M, Witholt B (2001) Industrial biocatalysis today and tomorrow. Nature 409(6817):258–268

Segura A, Godoy P, van Dillewijn P, Hurtado A, Arroyo N, Santacruz S, Ramos JL (2005) Proteomic analysis reveals the participation of energy- and stress-related proteins in the response of P. putida DOT-T1E to toluene. J Bacteriol 187(17):5937–5945

van Beilen JB, Duetz WA, Schmid A, Witholt B (2003) Practical issues in the application of oxygenases. Trends Biotechnol 21(4):170–177

Verduyn C, Stouthamer AH, Scheffers WA, Vandijken JP (1991) A theoretical evaluation of growth yields of yeasts. Anton Leeuw Int J G 59(1):49–63

Volkers RJM, de Jong AL, Hulst AG, van Baar BLM, de Bont JAM, Wery J (2006) Chemostat-based proteomic analysis of toluene-affected P. putida S12. Environ Microbiol 8(9):1674–1679

von Stockar U, Maskow T, Liu JS, Marison IW, Patino R (2006) Thermodynamics of microbial growth and metabolism: an analysis of the current situation. J Biotechnol 121(4):517–533

Walton AZ, Stewart JD (2004) Understanding and improving NADPH-dependent reactions by nongrowing E. coli cells. Biotechnol Progr 20(2):403–411

Weber FJ, Ooijkaas LP, Schemen RMW, Hartmans S, Debont JAM (1993) Adaptation of P. putida S12 to high concentrations of styrene and other organic solvents. Appl Environ Microbiol 59(10):3502–3504

Acknowledgments

This work was supported by the Ministry of Innovation, Science, Research and Technology of North Rhine-Westphalia (Bio.NRW, Technology Platform Biocatalysis, RedoxCell).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Kuhn, D., Bühler, B. & Schmid, A. Production host selection for asymmetric styrene epoxidation: Escherichia coli vs. solvent-tolerant Pseudomonas . J Ind Microbiol Biotechnol 39, 1125–1133 (2012). https://doi.org/10.1007/s10295-012-1126-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10295-012-1126-9