Abstract

Escherichia coli BL21 as production strain for the production of cytochrome P450 monooxygenase (P450SMO) from Rhodococcus sp. in high yields was developed. The expression was first optimized with a series of flask experiments testing several key parameters for their influence on the expression level and enzyme activity. The optimal process parameters found in the flask experiments were verified in a cultivation process in a 5-L bioreactor. Glycerol proved to be superior over glucose as carbon source. Low dissolved oxygen (DO) concentration (<10%) during expression was found to be critical for active P450s production, resulting in expression level of 400 nM for P450SMO. Intact cells were used to establish an efficient bioconversion system for the production of sulfoxidation product. With p-chlorothioanisole as a representative substrate, the desired product (S-sulfoxide) was afforded with 99% ee and highest production of 130 mg/L within 12 h.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

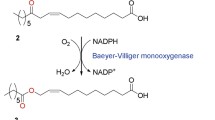

Cytochrome P450s are hemoproteins encoded by a superfamily of genes converting a broad variety of substrates and catalyzing a variety of interesting chemical reactions such as carbon hydroxylation, dealkylation, epoxidation, heteroatom (N, S, P) oxidation, aromatic hydroxylation, reduction and dehalogenation [1]. However, P450 enzyme fermentation levels in the microbial system are often too low, which was very difficult to meet the demand for industrial preparation. Therefore, a sufficient amount of active forms of cytochrome P450 enzymes are demanded for current biotransformation research. Bacterial expression systems have proven to be a valuable tool for high-level expression and are chosen to produce a few commercially available P450s by main manufacturers such as New England Biolabs [2].

Escherichia coli, the most commonly used host, have been used for expressing recombinant proteins in shake flask and more so for large-scale protein production in bioreactors [3, 4]. Recombinant expression in E. coli has emerged as one of the most versatile systems for the expression of active P450s, primarily due to its ease of propagation, well-established genetics, and the absence of any interfering native P450 genes [5–7]. By concomitantly expressing P450 genes using a bicistronic vector, adequate levels of each enzyme can be obtained [8].

In our previous work, we cloned a new P450 monooxygenase (P450SMO) gene from Rhodococcus sp. ECU0066 displaying a novel sulfide oxidation activity [9]. The high sequence homology (73%) to P450RHF from a Rhodococcus sp. NCIMB 9784 indicated that the P450SMO belong to class IV of P450 monooxygenase postulated by Roberts et al. [10]. P450RHF was the first example of a self-sufficient cytochrome P450 that does not possess a primary structural organization akin to that of P450 BM3 [11], these enzymes mediate catalysis in the absence of additional redox proteins [10, 12]. However, the expression level of these enzymes in E. coli was very low. In this study, the expression conditions of P450SMO were optimized and the expression level was greatly improved with high conversion and excellent enantioselectivity for the biosulfoxidation using the expression improved recombinant E. coli.

Materials and methods

Materials

Tryptone and yeast extract were obtained from Oxoid (Shanghai, China), and restriction enzymes were provided by TaKaRa (Dalian, China). Phenyl methyl sulfide was purchased from Shou & Fu Chemical Co., Ltd (Zhejiang, China). p-Tolyl methyl sulfide, p-chlorothioanisole, p-fluorothioanisole and ethyl phenyl sulfide were purchased from Lancaster (Morecambe, UK). p-Methoxythioanisole was purchased from Sigma–Aldrich (Taufkirchen, Germany). All other chemicals were also commercially available with purity of analytic grade.

Vector construction and cloning into E. coli

These steps were performed as described previously [9].

Cultivation in flasks

Test tubes with 3 mL of LB medium were inoculated from a single colony and incubated over night at 37 °C on a shaker at 180 rpm. The antibiotics kanamycin (50 mg mL−1) was used as selection marker for the vectors pET28a (+). The next morning 250 mL flasks with 50 mL of different media (depending on the experiment) and the appropriate antibiotic were inoculated with the overnight culture resulting in a start OD600 of 0.01 and cells were allowed to grow at 37 °C to an OD600 of about 0.6 after which 0.5 mM FeCl3 were added to the culture. After further incubation for 10 min at 25 °C, the cultures were induced with 0.5 mM IPTG and re-incubated at 25 °C for 20 h. For the optimization of expression, numerous expression conditions were tested. The following media were tested during the work: LB medium (per liter deionized water: 10.0 g tryptone, 5.0 g yeast extract, 10.0 g NaCl), TB medium (per liter deionized water: 12.0 g tryptone, 24.0 g yeast extract, 4.0 mL (v/v) glycerol, 2.31 g KH2PO4, 12.54 g K2HPO4).

Cultivation in fermenter

For all experiments a 5-L bioreactor (Bao xing, Shanghai, China) containing 3 L of LB medium and the construct E. coli BL21-pET28a-P450SMO were used. Test tubes with 3 mL of LB medium were inoculated with freshly transformed E. coli BL21-pET28a-P450SMO from a single colony on a LB-agar plate. The cells were incubated analogous to the flask experiments. This preculture was used to inoculate 500 mL flasks containing 150 mL of LB medium, and incubated at 37 °C and 180 rpm on an orbital shaker until an OD600 of 2–3 was reached. Cultivation in the bioreactor was started by inoculation from the second preculture resulting in a start OD600 of 0.05–0.1. The medium contained 10 g L−1 of glucose for the initial growth of the cells in the cases when glucose was used as the sole carbon source and 5 g L−1 of glycerol in the case of glycerol based cultivations. The pH was maintained at 7.0 throughout the process using 2 M NaOH and 2 M H2SO4. The temperature was controlled at 37 °C during growth and 25 °C after the induction of expression with IPTG (0.5 mM). The dissolved oxygen content of the culture broth was regulated by the variation of airflow and agitation speed.

Preparation of the resting cells

The cells were harvested by centrifugation and washed with 50 mM sodium phosphate buffer (50 mM, pH 7.4) three times. The washed cells were re-collected by centrifugation. Resting cells obtained were employed as the whole cell biocatalysts and stored at 4 °C prior to use.

Carbon monoxide difference spectra analysis

Resting cells were resuspended and disrupted by sonication in sodium phosphate buffer (50 mM, pH 7.5). The lysates were centrifuged to remove insoluble fractions. The supernatant was employed for spectroscopic measurement. The CO difference spectra were measured as follows: the crude extracts were reduced by adding several grains of sodium dithionite. Samples were dispensed into two cuvettes and a baseline spectrum was spectrophotometrically recorded (Shimadzu UV–Vis Spectrophotometer UVmini-1240) in the range of 350–500 nm. One cuvette was then gently gassed with carbon monoxide for 1 min, after which a difference spectrum was immediately monitored in the same spectral range and subsequently baseline-corrected. The concentration of P450SMO in the aqueous solution was determined by the CO difference spectrum with a molar extinction difference of 91 mM−1 cm−1 between 450 and 490 nm [13].

Whole-cell biotransformation

The cells were washed twice with sterile sodium phosphate buffer (50 mM, pH 7.4) and resuspended in the same buffer and then 5 μl of 200 mM p-chlorothioanisole in methanol was added to give a final concentration of 1 mM. Biotransformation was performed in 10 mL glass vials with screw caps with 1 mL cell suspension (0.05 g wet cell/mL) at 30 °C. After incubation for 30 min, the reaction mixture was saturated with NaCl and extracted with ethyl acetate by vigorous shaking. The layers were separated by centrifugation. The organic layers were dried over anhydrous sodium sulfate and prepared for GC/HPLC analysis.

Product analysis

The product analysis was performed as described by Li et al. [14] with minor modification. Briefly, GC (GC-14C, Shimadzu, Japan) with a column (AT·SE-54 30 × 0.25 mm × 0.33 μm) and an FID detector was used to determine the quantity of sulfoxide formed. GC analysis conditions were: injector 280 °C; detector 280 °C and oven 180 °C. Enantiomeric excess (ee) of product was determined with HPLC (LC-10AT, Shimadzu, Japan) with a chiral column (Chiralcel OD-H, Daicel Co., Japan, 250 mm × Φ4.6 mm), which was eluted using hexane/isopropanol (93:7, v/v, 1.0 mL/min) and detected at 254 nm. Authentic standard for each enantiomer of every sulfoxide was prepared by the method previously established [14].

Results and discussion

Improvement of P450 monooxygenase production by optimization of expression conditions with shake flask experiments

Initial fermentation development to examine the impact of IPTG concentration, temperature and inoculum age, as well as post-induction time, was conducted in shake flasks. The results showed that the IPTG concentration of 0.5 mM was favorable for the expression of P450SMO and that IPTG concentrations above 0.5 mM did not result in the increased of protein expression (Fig. 1a). It is recommended by the manufacturer of the pET system to lower the temperature during expression for the production of more soluble enzyme. As seen in Fig. 1b, an expression temperature of 25 °C turned out to be more efficient than other temperatures. The inoculum age at OD600 (0.45–0.7) was favorable for expression of P450, and higher OD600 decreases the P450SMO production. Long induction time may improve the incorporation rate of heme to the protein. So we further prolonged the induction time. As shown in Fig. 2a, the highest P450SMO production was obtained at 18 h of induction. Supplementation of media with FeCl3, which obviously improved the protein expression and the activity of P450SMO increased about 10% compared with that of control (Fig. 2b). Under optimal flask fermentation conditions with LB medium maximum titers of 298 nmol P450SMO/L were obtained.

TB medium is the most frequently reported medium for its use in the production of recombinant P450 enzymes in E. coli [15, 16]. In this study, experiments with TB medium for the production of P450SMO were also studied under the optimal flask fermentation conditions. The maximum titers of 369.9 nmol P450SMO/L were obtained, but the activity of the protein was not higher in TB medium (1.20 μmol min−1 g−1 DCW) compared with that in LB medium (1.18 μmol min−1 g−1 DCW). In Simon Pflug’ work [17], similar results was obtained, and they concluded that any unknown components included in the TB medium or by-products of the metabolism formed during growth that interfere with the activity of P450 monooxygenase. Considering the expensive cost of TB medium, the LB medium was further used in the next fermentations.

Improvement of P450 monooxygenase production in batch fermentation

Glucose is a rather cheap carbon source, can be easily metabolized by E. coli and is widely used for cell cultivation. To improve the P450 monooxygenase production in fermentor, the glucose as carbon source was added into the LB medium, and cell density increased very quickly (Fig. 3a). However, the active P450 production was much lower than that of flask fermentation, and the best P450 production reached only 120 nmol/L (Fig. 3b). High amounts of acetate produced appeared to be a major limitation for the improvement of P450SMO expression [17].

Time profiles of cell density (OD600) (a) and concentration of P450SMO (b) during fermentation process. Filled square glucose as carbon source, filled diamond glycerol as carbon source without DO concentration control, filled triangle glycerol as carbon source with the DO concentration control (<10%)

To solve the problem of acetate formation during expression, glycerol as an alternative carbon source was studied. In many cases, the use of glycerol resulted in better production of recombinant proteins in E. coli than glucose [18]. Moreover, E. coli does not produce significant amounts of acetate while growing on glycerol [3]. With glycerol as carbon source and DO not controlled, the initial growth rate of the culture rose evidently, and only modest amounts of active P450SMO were produced (Fig. 3b). In contrast, with the DO controlled (<10%), P450SMO expression and cell density increased proportionately. A twofold increase in overall P450 expression levels was observed. The expression level of P450SMO was increased to 400 nmol/L and the activity of recombinant strain whole cells reached 1.5 μmol min−1g−1DCW (Fig. 4).

After batch fermentation, the production of active P450SMO was significantly improved, however, the cell density reached only about OD600 8 which was much lower than other P450s. To improve the cell density, the fed-batch fermentation was further examined, and the concentrated feed medium with glycerol was added after the beginning of stationary phase. With the feeding, the cell densities of about OD600 20 was reached, but only moderate active P450SMO was produced (<200 nmol/L) with little activity. Large amounts of by-products of the metabolism formed during growth may be the main reasons that interfered with the activity of P450 monooxygenase.

Whole-cell biocatalysis

Whole cell was often used as biocatalyst, because the whole-cell approaches have been applied not only to single enzyme conversion process but also to biotransformations requiring cofactor regeneration, such as reductions with NADH or NADPH [19].

With the improved production of P450SMO, the recombinant E. coli whole cells were further used for asymmetric sulfoxidation. First, we optimized the reaction conditions. Similar to the purified enzyme [9], the recombinant strain showed maximum activity at 30 °C, and at higher temperatures the conversion began to decrease significantly (Fig. 5a). The optimum pH was 7.5. When the pH was below 7.0 or over 8.0, the enzyme activity decreased drastically (Fig. 5b).

Solubilization of the mostly monooxygenase substrate requires at least small amounts of organic solvents. So the effect of different organic co-solvents on the conversion of sulfide was further investigated. As shown in Fig. 6a, DMSO was the more favorable co-solvent due to its less deleterious effect on sulfoxidation activity of monooxygenase. The effect of different concentrations of DMSO on the whole-cell conversion showed that 1% (v/v) was more efficient than other concentrations (Fig. 6b).

Effect of different co-solvent (a) and different DMSO concentrations (b) on whole-cell biotransformation. The reaction mixture (1 mL) comprised 1 mM substrate, 50 mg/mL of E. coli cells in 0.05 M sodium phosphate buffer (pH 7.5). Samples were incubated at 30 °C for 6 h. All experiments were performed in duplicate

Glucose as a carbon source of E. coli can be metabolized by E. coli enzymes with a small amount of NADPH regenerated during the biotransformation process, thus further improving the conversion of sulfide substrate. As shown in Fig. 7, with the amount of glucose increased, the sulfide conversion was also increased, and the highest conversion rate was obtained when 10 mM glucose was added. When glucose was increased to 20 mM, no evident conversion rate was increased. Moreover, the sulfide conversion was decreased when glucose was increased to 30 mM.

Different sulfide substrates were employed for biotransformation with the recombinant strain whole cell under the optimal conditions obtained above. As shown in Table 1, essentially variable conversions between 70.0 and 97.0% were obtained with 12 h reaction, and in no case was the corresponding sulfone formed. With the recombinant strain whole-cell reactions, almost enantiopure (S)-sulfoxides (99.0% ee) was achieved except for p-methoxythioanisole for which only 83.4% ee was obtained. The results (excellent enantioselectivity and high conversion) obtained were much better than that of purified enzyme [9]. We speculate that the eligible environment in vivo may be more benefitial for substrate combination, and the NADPH regeneration by cell metabolism further promoted the reaction conversion rate.

With the optimized conditions, the reaction was performed in a 500 mL reactor with 100 mL cell suspension (0.05 g wet cell/mL) to which 150 mg/L p-chlorothioanisole was added. The result showed that the highest productivity of 130 mg/L of desired product (S-sulfoxide) was achieved within 12 h with 99% ee.

Conclusions

In summary, E. coli BL21 as production strain for the production of P450SMO from Rhodococcus sp. in high yields was developed. With the optimized expression conditions, the expression of P450SMO reached 400 nM in 3 L fermentation. The recombinant E. coli-catalyzed sulfoxidation was carried out under optimal conditions, and sulfide conversion and product enantiomeric excess were significantly enhanced.

References

Werck-Reichhart D, Feyereisen R (2000) Cytochromes P450: a success story. Genome Biol 1:3003.1–3003.9

Wu ZL, Qiao J, Zhang ZG, Guengerich FP, Liu Y, Pei XQ (2009) Enhanced bacterial expression of several mammalian cytochrome P450 s by codon optimization and chaperone coexpression. Biotechnol Lett. doi:10.1007/s10529-009-0059-5

Lee SY (1996) High cell-density culture of Escherichia coli. Trends Biotechnol 14:98–105

Baneyx F (1999) Recombinant protein expression in Escherichia coli. Curr Opin Biotechnol 10:411–421

Friedberg T, Pritchard MP, Bandera M, Hanlon SP, Yao D, Mclaughlin LA, Ding S, Burchell B, Wolf CR (1999) Merits and limitations of recombinant models for the study of human P450-mediated drug metabolism and toxicity: an intralaboratory comparison. Drug Metab Rev 31:523–544

Gillam EMJ (1998) Human cytochrome P450 enzymes expressed in bacteria: reagents to probe molecular interactions in toxicology. Clin Exp Pharmacol Physiol 25:877–886

Guengerich FP (2002) Cytochrome P450 enzymes in the generation of commercial products. Nat Rev Drug Discov 1:359–366

Parikh A, Gillam EMJ, Guengerich FP (1997) Drug metabolism by Escherichia coli expressing human cytochromes P450. Nat Biotechnol 15:784–788

Zhang JD, Li AT, Yang Y, Xu JH (2010) Sequence analysis and heterologous expression of a new cytochrome P450 monooxygenase from Rhodococcus sp. for asymmetric sulfoxidation. Appl Microbiol Biotechnol 85:615–624

Roberts GA, Grogan G, Greter A, Flitsch SL, Turner NJ (2002) Identification of a new class of cytochrome P450 from a Rhodococcus sp. J Bacteriol 184:3898–3908

Roberts GA, Celik A, Hunter DJ, Ost TW, White JH, Chapman SK, Turner NJ, Flitsch SL (2003) A self-sufficient cytochrome P450 with a primary structural organization that includes a flavin domain and a [2Fe–2S] redox center. J Biol Chem 278:48914–48920

Liu L, Schmid RD, Urlacher VB (2006) Cloning, expression, and characterization of a self-sufficient cytochrome P450 monooxygenase from Rhodococcus ruber DSM 44319. Appl Microbiol Biotechnol 72:876–882

Omura T, Sato R (1964) The carbon monoxide-binding pigment of liver microsomes. I. Evidence for its hemoprotein nature. J Biol Chem 239:2370–2378

Li AT, Zhang JD, Xu JH, Lu WY, Lin GQ (2009) Isolation of Rhodococcus sp. ECU0066: a new sulfide monooxygenase producing strain for asymmetric sulfoxidation. Appl Environ Microbiol 75:551–556

Farinas ET, Schwaneberg U, Glieder A, Arnold FH (2001) Directed evolution of a cytochrome P450 monooxygenase for alkane oxidation. Adv Synth Catal 343:601–606

Gustafsson MCU, Roitel O, Marshall KR, Noble MA, Chapman SK, Pessegueiro A, Vail RB, Homann MJ, Hanna I, Zaks A (2005) Preparative synthesis of drug metabolites using human cytochrome P450 s 3A4, 2C9 and 1A2 with NADPH-P450 reductase expressed in Escherichia coli. J Ind Microbiol Biotechnol 32:67–74

Simon P, Sven MR, Vlada BU (2007) Development of a fed-batch process for the production of the cytochrome P450 monooxygenase CYP102A1 from Bacillus megaterium in E. coli. J Biotechnol 129:481–488

Choi JH, Lee SJ, Lee SJ, Lee SY (2003) Enhanced production of insulin like growth factor I fusion protein in Escherichia coli by coexpression of the down-regulated genes identified by transcriptome profiling. Appl Environ Microb 69:4737–4742

Endo T, Koizumi S (2001) Microbial conversion with cofactor regeneration using genetically engineered bacteria. Adv Synth Catal 343:521–526

Acknowledgments

This work was financially supported by the National Natural Science Foundation of China (Grant Nos. 20773038 and 20902023), Ministry of Science and Technology, P.R. China (Grant Nos. 2009CB724706 and 2009ZX09501-016), China National Special Fund for State Key Laboratory of Bioreactor Engineering (Grant No. 2060204) and Shanghai Leading Academic Discipline Project (No. B505).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Zhang, JD., Li, AT. & Xu, JH. Improved expression of recombinant cytochrome P450 monooxygenase in Escherichia coli for asymmetric oxidation of sulfides. Bioprocess Biosyst Eng 33, 1043–1049 (2010). https://doi.org/10.1007/s00449-010-0429-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00449-010-0429-3