Abstract

The growing need for the characterization of cytochrome P450 (P450) metabolites often necessitates their synthesis up to Gram-scale. This task may in principle be achieved by using various techniques including chemical synthesis, the use of laboratory animals, in vitro P450 systems or microbial biotransformation. However, these approaches are in many instances unfavorable due to low yields, laborious purification, costs of cofactors, or the formation of non-physiologic metabolites. The fission yeast Schizosaccharomyces pombe has previously been shown by others and us to be very well suited for the heterologous expression of human P450s. In this study, we demonstrate whole-cell biotransformation reactions carried out with fission yeast strains that coexpress human cytochrome P450 reductase (CPR) and one of the following P450 isoforms: CYP2B6, CYP2C9, CYP2C19, CYP2D6, or CYP3A4, respectively. These strains could successfully convert their respective standard substrates but showed different responses with respect to incubation pH, the presence of glucose, and temperature, respectively. In addition, the preparative of synthesis of 2.8 g of 4′-hydroxydiclofenac was achieved by whole-cell biotransformation of diclofenac using a CPR-CYP2C9 coexpressing fission yeast strain.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Metabolism typically renders drugs more water soluble so that they can be easily excreted from the body after their desired effect has been exerted. This process primarily occurs in liver hepatocytes and normally results in the formation of metabolites that are inactive and relatively nontoxic; however, in some instances, metabolites may be the source of adverse effects. For this reason, the US Food and Drug Administration has recently published its guidance for industry concerning the safety testing of drug metabolites [1]. According to the FDA, human drug metabolites that can raise a safety concern are those formed at greater than 10% of parent drug systemic exposure at steady state. And while the agency acknowledges the difficulties often associated with the synthesis of specific drug metabolites, it still considers the identification and evaluation of the potential toxicity of drug metabolites to be important for clinical safety. Consequently, there is a strong demand for efficient, robust, and reliable drug metabolite production systems by the pharmaceutical industry. Drug metabolism maybe classified into Phase I (functionalization) and Phase II (conjugation) reactions, with Phase I metabolites in general being more likely to be pharmacologically active. Phase I reactions result in the functionalization of foreign compounds by hydroxylation, dealkylation, deamination, etc. and in most cases are catalyzed by cytochrome P450 monooxygenases (P450s or CYPs). The involvement of other enzymes in the oxidative metabolism of xenobiotics has been recently reviewed [2].

The human P450 isoenzyme superfamily comprises 57 proteins that catalyze the oxidative metabolism of many structurally diverse drugs and chemicals, but also participate in the endogenous metabolism of fatty acids, steroids, eicosanoids, bile acids and fat-soluble vitamins [3]. The human P450s are divided into 18 families and 43 subfamilies and among these, the members of families 1 to 3 mediate 70% to 80% of all phase-I-dependent metabolism of clinically used drugs [4]. To meet the needs of the pharmaceutical industry, large quantities of these enzymes are demanded which cannot be obtained from human liver slices or hepatocytes. Moreover, although human microsomes might be well used for isoform identification and pharmacokinetics, their relative scarcity, batch-to-batch variations and the inherent inhibition problem in order to determine the responsible isoform [5, 6] renders them unsuitable for the preparative synthesis of P450 metabolites. Primary culture of hepatoma cell lines and genetically modified mammalian cell lines often suffer from reduced P450 activity and poor inducibility and are limited to the use in metabolic research, drug–drug interactions or inhibitor screening [7]. Thus, a number of recombinant expression systems for these enzymes were developed that use a range of different hosts such as bacteria, yeasts, and transfected insect cells.

So far, microbial hosts expressing recombinant P450 systems helped to gather a vast amount of information concerning kinetics and reaction mechanism in vitro; hence, they were used as a source for purified enzymes or microsomes rather than being employed for whole-cell biotransformations. However, the preparative metabolite synthesis using isolated microsomes or P450s is cumbersome not only because of the tedious isolation procedure of microsomes or enzymes but also due to poor usability owing to enzyme stability and cofactor regeneration which seriously hamper the long-term activity of the systems [8]. Hence, it would be highly desirable to have a (preferably microbial) system at hand that could combine ease of handing with high biotransformation rates.

We have recently demonstrated the applicability of fission yeast Schizosaccharomyces pombe expressing human P450s for the preparative synthesis of metabolites using whole cells [9–11]. This success prompted us to investigate whether fission yeast might be the expression host of choice for human xenobiotics metabolizing P450s in general. Since the previous studies used fission yeast strains expressing human CYP2B6 and CYP2D6, it was the aim of this study to extend the set to the use of other relevant human liver P450s by functionally expressing the human CYP2C9, CYP2C19, and CYP3A4, respectively, in S. pombe. We tested the activity of all strains using broadly accepted and validated standard substrates [12] with respect to their ability to perform whole-cell biotransformation under different conditions. Notably, all P450s as well as the corresponding Cytochrome P450 reductase (CPR) were expressed using cDNAs that code for unmodified wild-type amino acid sequences (including the respective localization signals). While other groups have previously reported the functional expression of mammalian microsomal P450s in S. pombe for different purposes [13–16], we here focus exclusively on whole-cell biotransformation.

As mentioned earlier, recombinant P450 expressing hosts were rather used as activity sources in vitro and there are few reports on their use as whole-cell catalysts. In several instances, the biotransformation of diclofenac to its hydroxylated metabolites was used as a marker reaction for the assessment of a system’s suitability for larger-scale synthesis of P450 metabolites. Hence, we compared the biotechnological parameters of the whole-cell biosynthesis of 4′-hydroxydiclofenac at gram-scale using a fission yeast strain functionally coexpressing human CPR and CYP2C9 to published results using the same P450 isoform expressed in baculovirus transfected insect cell lines [17] or in Escherichia coli cells [18, 19]. Additionally, we also compared our results to those obtained with two microbial systems that display native 4′-hydroxydiclofenac-generating activities, the fungus Epicoccum nigrum [20] and the bacterium Actinoplanes sp. ATCC 53771 [21].

Materials and Methods

Chemicals and Reagents

Substrates and metabolite standards were obtained from the following sources: Dextromethorphan hydrobromide and dextrorphan tartrate from MP Biomedicals (Irvine, CA, USA), mephenytoin and 4-hydroxymephenytoin from BIOMOL (Hamburg, Germany), tolbutamide and 4-hydroxytolbutamide from SigmaAldrich (Taufkirchen, Germany), bupropion and hydroxybupropion from BD Biosciences (San Jose, CA, USA), 1′-hydroxymidazolam and 4-hydroxymidazolam from Lipomed (Arlesheim, Switzerland), corticosterone from Serva (Feinbiochemica, Heidelberg, Germany), and diclofenac sodium salt from Fagron GmbH & Co. KG (Barsbüttel, Germany). Midazolam was a kind gift from Roche (Mannheim, Germany). Methanol (HPLC grade) was purchased from Fisher Scientific (Pittsburgh, PA, USA), ethyl acetate was from Sigma–Aldrich. Acetonitrile, water (both HPLC grade), and other chemicals (analytical grade) were obtained from E. Merck (Darmstadt, Germany).

Fission Yeast Media and General Techniques

General DNA manipulation methods were performed using standard techniques [22]. Media and genetic methods for studying fission yeast have been described in detail [23, 24]. Briefly, strains were generally cultivated at 30 °C in Edinburgh Minimal Medium (EMM) with supplements of 0.1 g/L final concentration as required. Liquid cultures were kept shaking at 150 rpm. Thiamine was used at a concentration of 5 μM throughout.

cDNA Synthesis

The cDNA sequences for human CYP2B6, CYP2C9, CYP2C19, CYP3A4, and CPR, respectively, were synthesized by Entelechon GmbH (Regensburg, Germany) and code for the respective wild-type enzymes. The cDNA sequence of human CYP2D6 was also wild-type as reported previously [9].

Expression Plasmid Construction

For expression of human CPR and P450s in fission yeast, the integrative vector pCAD1 [25] and the autosomally replicating vector pREP1 [26] were used, respectively. The CPR cDNA was ligated into NdeI/BamHI restricted pCAD1 to yield pCAD1-CPR. All P450 cDNAs were cloned into NdeI/BamHI-digested pREP1 to yield pREP1-CYP2B6, pREP1-CYP2C9, pREP1-CYP2C19, pREP1-CYP2D6, and pREP1-CYP3A4, respectively. The correctness of all expression constructs was confirmed by automated sequencing.

Fission Yeast Strain Construction

Transformation of fission yeast was done either using cryopreserved cells [27] or by the lithium acetate method [28]. Strain NCYC2036 (h − ura4-D18) was transformed with pCAD1-CPR to yield strain CAD62 (all strains are listed in Table 1). Correct chromosomal integration of the pCAD1-CPR construct into the leu1 locus was confirmed by plating colonies on EMM lacking leucine. The resultant strain CAD62 was subsequently subjected to the cryopreservation method [27]. Cryopreserved CAD62 cells were then transformed with pREP1 expression vectors bearing the respective P450 cDNAs to yield five different strains that coexpress CPR and one of the P450s.

Biomass Production

Cells from permanent cultures were streaked on EMM dishes containing leucine and thiamine and grown for 3 days at 30 °C. Cell material from plates was transferred to a 10 mL EMM preculture containing leucine but not thiamine to induce the nmt1 promoter. Culture volumes were scaled up by a factor of 10 to finally yield 100 mL or 1 L cell suspensions. Usually, the final cell density was around 5 × 107 cells/mL or 3 g/L dry weight (d.wt.) with cells usually being in the early stationary growth phase as judged from microscopic observation.

Whole-Cell Biotransformations in Deep-Well MTPs

Following biomass production, cells were harvested by centrifugation (3,000×g, 5 min, 4 °C), washed with cold, deionized water and finally resuspended in biotransformation medium as indicated. Depending on the experimental design the biotransformation was carried out in either 100 mM sodium acetate/acetic acid buffer (for pH 3 to 5) or in 100 mM NaH2PO4/Na2HPO4 (for pH 6 to 10). Supplements like glucose (2% w/v) and substrates (1 mM) were added as either aqueous or ethanolic solutions. The assay cell density was set to 2 × 108 cells/mL throughout. All assays were conducted in deep well microtiter well plates (MTPs) containing 1 mL of cell suspension per well. The substrates were chosen according to a list of validated P450 marker substrates of human P450 isoenzymes [12] which are: bupropion for CYP2B6, tolbutamide for CYP2C9, mephenytoin for CYP2C19, dextromethorphan for CYP2D6, and midazolam for CYP3A4. The incubation time was 8 h and the agitation was done at 750 rpm.

To monitor the influence of temperature on the bioconversion rate, assays were conducted in 250 mL Erlenmeyer flasks filled with a cell suspension volume of 10 mL as described [25]. Initial activity tests were also done under these conditions whereby the pH was set to 8 for all strains.

Preparative Synthesis of 4′-Hydroxydiclofenac by Whole-Cell Biotransformation

All cultures were incubated at 30 °C in EMM. Cells from strains CAD68 were grown in 10 mL cultures for 24 h and subsequently transferred to 300 mL of medium in a 2.5 L Erlenmeyer flask. After a growth period of 24 h, the culture volume was expanded to 1 l by adding 700 mL medium. After an incubation period of 48 h, biomass from four one liter cultures was centrifuged (3,000×g, 20 min, 4 °C) and resuspended in 1 L 100 mM NaH2PO4/Na2HPO4 buffer pH 7 with 20 g/L glucose. The resulting d.wt. biomass concentration was approximately 8 g/L. An amount of 10 mL of a 200 mM diclofenac stock solution (in 70% ethanol) was added to reach a final substrate concentration of 2 mM. The biotransformation was carried out at 30 °C. Six individual incubations were performed and samples were generally taken at 0 and 96 h to determine product concentrations and biomass dry weight. In some cases, sampling was done more frequently in order to monitor the reaction progress.

After the biotransformation, each liter of cell suspension was extracted three times with 1 L of ethyl acetate. The organic phase was subsequently concentrated at 47 °C and 240 mbar (24 kPa) using a IKA RV 10 control rotary evaporator with integrated heating bath (VWR, Darmstadt, Germany) to approximately 10 mL. The concentrated organic phases were combined and separated on a flash chromatography system consisting of a Labomatic pump MD 80/100 (Allschwil, Switzerland), a Chromabond® MN 240 SiOH 130 g column (Macherey-Nagel, Düren, Germany) and a Biotronik BT8200 UV/Vis detector equipped with a preparative detection cell (Biotronik wissenschaftliche Geräte GmbH, Maintal, Germany). The isocratic mobile phase consisted of hexane:ethyl acetate:acetic acid (73.5%:24.5%:2% v/v) pumped at a flow rate of 80 mL/min; detection was done at 280 nm. Prior to sample injection, the system was equilibrated for 20 min. Fractions containing 4′-hydroxydiclofenac were collected (approximately 200 mL of solution for each liter of cell suspension) and subsequently evaporated to approximately 10 mL in a rotary evaporator under the same conditions as above. Eventually, the concentrated solutions were lyophilized using the Christ Beta 2–8 LD (Martin Christ Gefriertrocknungsanlagen GmbH, Osterode am Harz, Germany) at −80 °C and 0.2 mbar (2 Pa).

Sample Preparation

Samples gained from Erlenmeyer or MTP experiments were centrifuged (8,000×g, 5 min, 4 °C) and supernatants were transferred to autosampler vials and fivefold diluted (v/v) with a mixture (60:40, v/v) of 50 mM aqueous ammonium formate adjusted to pH 3.5 with formic acid (eluent A) and acetonitrile with 0.1% formic acid (eluent B). Aliquots (25 μL) of the diluted supernatants were injected into the liquid chromatography-tandem mass spectrometer (LC-MS/MS) system.

Samples consisting of 500 μL of cell suspension that were taken during the biosynthesis of 4′-hydroxydiclofenac were mixed with 12.5 μL of a 10 mM ethanolic corticosterone solution as internal standard. The cell suspension was then extracted with 1 mL of ethyl acetate and the upper 900 μL were evaporated in a 1.5-mL reaction cap. One milliliter of methanol was added to the evaporated sample which was then centrifuged (104×g, 5 min, 4 °C). The upper 800 μL were transferred to HPLC vials and analyzed by HPLC.

Analysis of Whole-Cell Biotransformations

The LC-MS/MS system was as follows: Shimadzu integrated HPLC system consisting of a Shimadzu CBM 20 A controller, two Shimadzu LC 20AD pumps including a degasser, a Shimadzu SIL 20AC autosampler, and a Shimadzu CTO 20AC column oven; Applied Biosystems 3200 Q TRAP Linear Ion Trap Quadrupole Mass Spectrometer equipped with a Turbo V Ion Source operated in the electron spray ionization (ESI) mode and controlled by Analyst Software (Version 1.4.2).

The autosampler was cooled to 15 °C and operated without rinsing. Isocratic elution was performed on a GRACE mixed-mode C18/cation exchange column (5 μm, 150 × 4.6 mm) as stationary phase. The column temperature was 30 °C. The mobile phase composition (A:B, v/v) was 45:55 for analysis of dextromethorphan/dextrorphan and tolbutamide/4-hydroxytolbutamide, 70:30 for analysis of bupropion/hydroxybupropion, 35:65 mephenytoin/4-hydroxymephenytoin, and 40:60 for analysis of midazolam, 4-hydroxymidazolam and 1′-hydroxymidazolam, respectively. Flow rate and run time were 1 mL/min and 5 min, respectively. Before use, the mobile phases were degassed for 30 min in an ultrasonic bath, and during use, the mobile phase was degassed by the integrated degasser.

For detection and quantification, the following ESI inlet conditions were used: gas 1, nitrogen (50 psi; 344.7 kPa); gas 2, nitrogen (50 psi; 344.7 kPa); ion spray voltage, 5,500 V; ion source temperature, 700 °C, curtain gas, nitrogen (10 psi; 68.9 kPa). Samples were analyzed in positive ion mode. The MS was operated in MRM mode with Q1 and Q3 being operated in unit resolution with the following settings: collision gas was set at medium; the dwell time was set at 150 ms. All other settings were analyte-specific and were determined using Analyst software in quantitative optimization mode. Two transitions were monitored per analyte, one target transition (t) for quantification and one qualifier transition. The monitored transitions are reported in Table 2. The resulting concentrations were used to compute the respective metabolite formation rates.

Analysis of 4′-Hydroxydiclofenac

The LC system was composed of an Alliance 2695 HPLC module equipped with an inline degasser, a column oven and a 966 diode array detector. The separation was carried out using a Nucleosil 100 RP-18 5 μm 125 × 4 mm column at 40 °C, the eluents water (A) and methanol (B), and the elution profile: 0 to 1 min 20% A, 1 to 8 min linear transition to 55% A, 8 to 12.5 min hold at 55% A, 12.5 to 16 min at 70% A, 16 to 20 min at 20% A. Monitoring was done at 245 nm for corticosterone and 280 nm for diclofenac and 4′-hydroxydiclofenac. The injected sample volume was 20 μL. To assess the 4′-hydroxydiclofenac concentration in the biotransformation samples, different diclofenac concentrations were extracted in presence of internal standard from cell suspensions with similar biomass densities as used in biotransformations. This calibration was used to estimate the concentration of 4′-hydroxydiclofenac.

For structural confirmation of the purified 4′-hydroxydiclofenac by NMR, solutions were prepared in CD3OD (7.1 mg/mL) and 1HNMR (500 MHz) spectra were recorded on a Bruker Avance 500 at 300 K. The chemical shifts are given in δ values (ppm) relative to TMS. The purity of 4′-diclofenac was assessed using the LC-system described for the analysis of diclofenac bioconversion under isocratic conditions (60% water, 40% methanol) and aggregated DAD signals from 200 to 400 nm.

Results and Discussion

Strain Construction

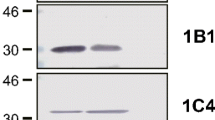

We adopted a previously described cloning strategy [18, 29, 30] whereby CPR expression is directed from an integrative, chromosomal element while the P450 is expressed from an autosomally replicating plasmid. Integration of the human CPR cDNA into the fission yeast genome was done by transforming the parent strain NCYC2036 with linearized pCAD1-CPR. The resulting clones were tested for correct integration into the leu1 locus by replica plating on EMM dishes containing thiamine and phloxine B. One of the correct integrands was designated CAD62 and subjected to the preparation of cryocompetent cells [27]. Transformation of CAD62 with autosomally replicating pREP1 plasmids bearing cDNAs that code for the human microsomal P450s yielded strains CAD64 to CAD68 (see Table 1). The growth of all strains was only mildly affected by the expression of the human P450 systems (data not shown). Moreover, biomass generation was unproblematic and did not require special care about oxygen levels during the growth phase which is in stark contrast to E. coli-based systems where strict absence of oxygen is a necessity for the formation of active P450 systems [18]. In contrast to earlier reports on biotransformations by fission yeast strains solely expressing human microsomal CYP2D6 [9], human CYP17 [31], and human CYP21 [32], it was found here to be necessary to coexpress human CPR due to barely detectable activities of CYP2B6, CYP2C9, CYP2C19, and CYP3A4 expressing strains without such a coexpression (data not shown). Except for CYP2D6, these findings were consistent with data reported on baker’s yeast where CPR overexpression was also crucial for the detection of P450 activity either in vivo [33] and in vitro [29, 34].

Influence of pH on Activity

We previously observed an influence of the initial incubation pH on the biotransformation activity of the CYP2D6 expressing fission yeast strain CAD58 [9]. Hence, in this study we tested for this effect on the new strains CAD64 to CAD68 in whole-cell biotransformations carried out in deep well MTPs over 8 h using an initial pH range from 3 to 10 (Fig. 1). Marked differences between low and high pH values with transitions from not detectable to considerable rates occurring at 5 < pH < 6 were observed for nearly all strains except for CAD65 (expressing CYP2B6) (Fig. 1a). The course of the pH-dependent metabolite formation rate profile was dependent on the CYP isoform used and could be roughly assigned to two major types. The first was characterized by a rise in activity to a maximum level that remained constant under increasing pH (Fig. 1a, c and e) while the second profile peaked at a certain pH and then decreased (Fig. 1d) or raised again at pH 10 (Fig. 1b). Based on these data, we determined the apparent optimal pH values to be used in whole-cell biotransformations with the marker substrates used here as follows: pH 8 for bupropion conversion by CAD65 (CYP2B6), pH 7 for tolbutamide conversion by CAD68 (CYP2C9), pH 9 for mephenytoin conversion by CAD66 (CYP2C19), pH 7 for dextromethorphan conversion by CAD64 (CYP2D6), and pH 9 for the midazolam conversion by CAD67 (CYP3A4).

Dependence of metabolite formation rates on initial medium pH determined for whole-cell biotransformation carried out with fission yeast strains functionally expressing human CYP systems. Means of two independent assays with respective standard deviations are shown after determining the supernatant metabolite concentrations as described in the Materials and Methods section. Assay conditions: The cell density was 2 × 108 cells/mL, buffers were 100 mM sodium acetate/acetic acid for pH < 6 or 100 mM NaH2PO4/Na2HPO4 for pH ≥ 6, incubation was done for 8 h at 750 rpm in deep-well MTPs; the substrate concentration was 1 mM. The substrates were bupropion (CYP2B6), tolbutamide (CYP2C9), mephenytoin (CYP2C19), dextromethorphan (CYP2D6), and midazolam (CYP3A4), respectively

Influence of Glucose Presence on Biotransformation

Having obtained the apparent optimal pH values, the influence of the presence of glucose on whole-cell biotransformation was assessed next. For this purpose, biotransformations were carried out in deep well MTPs over 8 h using buffer solutions with or without 2% (w/v) glucose (Fig. 2). This experiment shows that, in principle, the presence of glucose in the incubation medium does not significantly influence the rate of biotransformation with the notable exception of strain CAD68 (two-sided t test, n = 5, α = 0.05, P = 6 × 10−4).

Influence of the presence of 2% glucose in the incubation buffer on metabolite formation rates of recombinant fission yeast strains. Mean metabolite formation rates with respective standard deviations (five independent assays) calculated as described in the Materials and Methods section were normalized to values gained in absence of glucose. Assay conditions: The cell density was 2 × 108 cells/mL, buffers were 100 mM NaH2PO4/Na2HPO4 with pH 8 (CAD65), pH 7 (CAD68), pH 9 (CAD66), pH 7 (CAD64) and pH 9 (CAD67), incubation was done for 8 h at 750 rpm in deep-well MTPs; the substrate concentration was 1 mM. The substrates were bupropion (CYP2B6), tolbutamide (CYP2C9), mephenytoin (CYP2C19), dextromethorphan (CYP2D6), and midazolam (CYP3A4), respectively

Effect of Elevated Temperature on Whole-Cell Biotransformation

Since we expressed human enzymes in a yeast environment, we wanted to compare the effect of an elevated incubation temperature (37 °C) on the biotransformation activity in comparison to the generally used fission yeast incubation temperature of 30 °C. For this purpose, whole-cell biotransformations were carried out as above for a period of 72 h at the two indicated incubation temperatures (Fig. 3). Surprisingly, these experiments demonstrated that the influence of temperature on bioconversion activity was strongly isoform-dependent and varied to a much greater extent than in the case of the pH value.

Influence of elevated incubation temperature on biotransformation. Means of metabolite concentrations of three independent assays with respective standard deviations are shown that were measured as described in the Methods section. Assay conditions: The cell density was 2 × 108 cells/mL, buffers were 100 mM NaH2PO4/Na2HPO4 with pH 8 (CAD65), pH 7 (CAD68), pH 9 (CAD66), pH 7 (CAD64), and pH 9 (CAD67), incubation was done for 72 h at 150 rpm in 250 mL Erlenmeyer flasks; the substrate concentration was 1 mM. The substrates were bupropion (CYP2B6), tolbutamide (CYP2C9), mephenytoin (CYP2C19), dextromethorphan (CYP2D6), and midazolam (CYP3A4), respectively

Strain CAD65 (expressing CYP2B6) displayed a somewhat higher initial bioconversion rate at 37 °C (within the first 10 h), after which the values for both temperatures did not significantly differ any more (Fig. 3a). Almost the same is true for strain CAD64 (expressing CYP2D6) which does not seem to be affected by the temperature change at all (Fig. 3d). By contrast, the effect of the elevated incubation temperature on activity was most pronounced in CAD68 (expressing CYP2C9, Fig. 3b) where it led to a more than twofold increase in metabolite formation (Fig. 3b). A completely different behavior was displayed by strain CAD66 (expressing CYP2C19), as its biotransformation activity decreased more than twofold when incubated at 37 °C (Fig. 3c). Under these conditions, mephenytoin conversion slowed down considerably after 8 h. In case of strain CAD67 (expressing CYP3A4), bioconversion seemed to halt within several hours after a steep but relatively short initial bioconversion period, which was somewhat more pronounced at the higher incubation temperature of 37 °C (Fig. 3e).

Preparative Synthesis of 4′-diclofenac by Whole-Cell Biotransformation

In order to demonstrate the applicability of our recombinant fission yeast strains for the preparative synthesis of human Phase I metabolites, we used strain CAD68 (expressing CYP2C9) to synthesize 4′-hydroxydiclofenac from diclofenac (Fig. 4a). Figure 4b exemplarily shows the time course of a single diclofenac bioconversion run in a 2.5 L Erlenmeyer for 94 h carried out in phosphate buffer with 20 g/L glucose. Product formation proceeded constantly for 48 h with a rate of about 450 μM/d and then decreased somewhat. In this experiment, the glucose was consumed to non detectable levels at 26.5 h while the biomass density was nearly constant throughout the bioconversion period with values of 8.3 ± 0.3 g/L at 0 h and 7.8 ± 0.2 g/L at 94 h (data not shown). From this biomass density, an overall d.wt.-normalized metabolite formation rate of 56 μmol/(d × g) was calculated. The result of HPLC analysis of samples taken at 0 h and 94 h is shown in Fig. 4c; it demonstrates that the majority of diclofenac was converted to 4′-hydroxydiclofenac. After purification was carried out as described in the “Materials and Methods” section, 480 mg of purified 4′-hydroxydiclofenac were obtained from this bioconversion run.

Preparative synthesis of 4′-hydroxydiclofenac by whole-cell biotransformation with recombinant fission yeast strain CAD68 (CYP2C9). The hydroxylation reaction was carried out in 2.5 L Erlenmeyer shaking flasks containing 1 L of 100 mM NaH2PO4/Na2HPO4 pH 7 containing 8.3 ± 0.3 g/L CAD68 biomass, 20 g/L glucose and 2 mM diclofenac sodium salt. a Reaction scheme. b Exemplary time course of 4′-hydroxydiclofenac formation during a 94 h biotransformation. c HPLC chromatograms of samples taken at 0 h and 94 h from the biotransformation run shown in panel b. d UV/Vis purity determination of the final lyophilized 4′-hydroxydiclofenac using aggregated DAD signals (200 to 400 nm). For analytical HPLC conditions refer to the “Materials and Methods” section

In total, six biotransformation runs were performed. In order to allow for a more efficient conversion of the substrate, the biotransformation runtime for each vessel was increased individually based on the present 4′-hydroxydiclofenac concentration measured via HPLC after approximately 72 h. The total amount of purified 4′-hydroxydiclofenac was 2.8 g, which corresponds to an average of 470 mg of product per run per 150 h of biotransformation period. Thus, 12 mmol of solid diclofenac were converted to 9 mmol of purified metabolite yielding an overall molar conversion efficiency of 75%. The purification scheme including an initial ethyl acetate extraction, two evaporation steps, one flash chromatography step, and a final lyophilization was simple and reproducible as confirmed by HPLC analysis of every metabolite batch (data not shown). The final product was lyophilized and subjected to 1H-NMR (7.1 mg/mL in CD3OD, see carbon atom numbering in Fig. 4a) yielding δ 7.17 ppm (d, 1H, H-C6), δ 7.02 ppm (t, 1H, H-C4), δ 6.87 ppm (2, 2H, H-C3′ + H-C5′), δ 6.8 ppm (t, 1H, H-C5), δ 6.26 (d, 1H, H-C3), and δ 3.71 ppm (s, 2H, CH2) in agreement with previous 1H-NMR data of 4′-diclofenac [35]. A UV/Vis purity of 98.5% was determined using an isocratic separation and aggregated DAD signals (200 to 400 nm; Fig. 4d).

Comparison of Published Whole-Cell Biotransformations for the Synthesis of 4′-Hydroxydiclofenac

Several studies on the biological production and purification of 4′-hydroxydiclofenac were published to date which made use of either native or recombinant microorganisms or insect cells [17, 19–21]. A comparison of our approach to the published reports with respect to several biotechnological parameters is displayed in Table 3. Of course, the different processes are only comparable to a certain extent, as they differ in many aspects. For instance, the volumetric scale of the processes ranges from 100 mL (for the Sf21 system) to 20 L (for the Epiccocum nigrum system) and the incubation vessels were as different as Erlenmeyer and automated fermenters. Also, substrate concentrations cover a span of more than one order of magnitude with the highest value (5 mM) used in the Actinoplanes sp. ATCC 53771 process and the lowest (250 μM) in the Sf21 process. By contrast, incubation temperatures were more or less equal, while the agitation speeds reflect the requirements of the specific host, like oxygen demand in the E. coli process or low speeds for the Sf21 cell culture. The different runtimes seem to reflect the aim of a complete substrate turnover, with the initial biotransformation rate being typically higher than the overall rate [17, 19]. The synthesized and purified amounts of 4′-hydroxydiclofenac were all well below the gram range except for the fission yeast process that yielded almost 3 g of product. Of course, these figures dependent on the productive volume used and a comparison of space-time yields sees the Actinoplanes sp. ATCC 53771 process ahead of the field with 1,017 mg/(L × d). The fission yeast process shows a value of 75 mg/(L × d) and is still somewhat more efficient than, for instance, the E. coli process. This is remarkable since the biomass used in the E. coli process showed relatively a high P450 titer of approximately 103 nmol/L culture [19], which can be readily assumed to be at least two orders of magnitude higher than in fission yeast [36]. A general process efficiency dependent on the biotransformation capacity of the host and the efficiency of the purification scheme but independent on the volumetric scale can be derived by considering the molar ratio of substrate to isolated product. In this regard, the most efficient process is clearly described in this study where 75% of the initial molar amount of diclofenac could be converted to 4′-hydroxydiclofenac.

The comparison of the various efficiency parameters described above illustrates that an evaluation of different biological systems that aim at metabolite production at Gram scale cannot be done based on a single parameter. Although space-time yield is crucial to the process per se, further parameters such as scalability and versatility also need to be considered. The scalability of the Sf21 process might be problematic due to the dynamic nature of the virus-based system [37] while in case of the Actinoplanes sp. ATCC 53771 process the scalability remains unclear as only very low volumes were used [21]. Higher production scales was employed in the studies that used E. nigrum IMI 354292, E. coli, or S. pombe, respectively, where the last process displayed the best results in terms of molar product yield and space–time yield. With respect to versatility, difficulties may arise when using native microbial activities, since the microbial enzymes typically reflect mammalian P450 activity only with respect to certain substrates; in addition, they often generate the mammalian metabolites as well as metabolites unique to their genus [38]. Thus, an established process using native microbial activities that yields one CYP2C9 metabolite (such as 4′-hydroxydiclofenac) will probably not produce other CYP2C9 metabolites, and additional time needs to be spent for the screening of other suitable strains. This point is clearly a strong advantage for the recombinant systems, as the relevant mammalian P450s are typically known when a metabolite needs to be produced at Gram scale. Another important point is that the host organism stays the same, which facilitates process design and development.

Conclusions

Our results presented here demonstrate that fission yeast is a very suitable host for the recombinant expression of the major human microsomal P450s. We expressed functional CPR-P450 systems that readily performed the isoform-specific standard reactions. The dependence of the conversion rate on different assay parameters such as pH, the presence of glucose and incubation temperatures was investigated and in many instances found to be distinctly isoform-specific. As an example of Gram scale metabolite production, the preparative synthesis and purification of 2.8 g of 4′-hydroxydiclofenac was demonstrated. Our results are set in comparison to several other biological metabolite production systems that make use of either native or recombinant cells, and the relative strengths and weaknesses of these are discussed.

Abbreviations

- P450:

-

Cytochrome P450

- CPR:

-

Cytochrome P450 reductase

- DAD:

-

Diode array detector

- EMM:

-

Edinburgh Minimal Medium

- d.wt.:

-

Dry weight

- LC-MS/MS:

-

Liquid chromatography-tandem mass spectrometer

- MRM:

-

Multiple reaction monitoring

- MTP:

-

Microtiter plate

- NaPi:

-

Sodium phosphate buffer

- TMS:

-

Tetramethylsilane

References

FDA. (2008). Guidance for industry: Safety testing of drug metabolites in U.S. Department of Health and Human Services, F. a. D. A., Center for Drug Evaluation and Research (CDER) (Ed).

Strolin Benedetti, M., Whomsley, R., & Baltes, E. (2006). Expert Opinion on Drug Metabolism & Toxicology, 2, 895–921.

Bernhardt, R. (2005). Cytochrome P-450. In W. Lennarz, M. Lane, P. Modrich, J. Dixon, E. Carafoli, J. Exton, & D. Cleveland (Eds.), Encyclopedia of Biological Chemistry (pp. 544–549). New York: Academic.

Ingelman-Sundberg, M. (2004). Trends in Pharmacological Sciences, 25, 193–200.

Guengerich, F. P. (2006). The AAPS Journal, 8, E101–E111.

Jia, L., & Liu, X. (2007). Current Drug Metabolism, 8, 822–829.

Donato, M. T., Lahoz, A., Castell, J. V., & Gomez-Lechon, M. J. (2008). Current Drug Metabolism, 9, 1–11.

Urlacher, V. B., Lutz-Wahl, S., & Schmid, R. D. (2004). Applied Microbiology and Biotechnology, 64, 317–325.

Peters, F. T., Dragan, C. A., Wilde, D. R., Meyer, M. R., Zapp, J., Bureik, M., et al. (2007). Biochemical Pharmacology, 74, 511–520.

Peters, F. T., Dragan, C. A., Kauffels, A., Schwaninger, A. E., Zapp, J., Bureik, M., et al. (2009). Journal of Analytical Toxicology, 33, 190–197.

Peters, F. T., Dragan, C. A., Schwaninger, A. E., Sauer, C., Zapp, J., Bureik, M., et al. (2009). Forensic Science International, 184, 69–73.

Walsky, R. L., & Obach, R. S. (2004). Drug Metabolism and Disposition, 32, 647–660.

Yamazaki, S., Sato, K., Suhara, K., Sakaguchi, M., Mihara, K., & Omura, T. (1993). Journal of Biochemistry, 114, 652–657.

Yasumori, T. (1997). Expression of a human cytochrome P450 form in Schizosaccharomyces pombe: Comparison with expression in Saccharomyces cerevisiae. In Y. Giga-Hama & H. Kumagai (Eds.), Foreign gene expression in fission yeast Schizosaccharomyces pombe (pp 111–121). New York: Springer.

Yasumori, T., Chen, L. S., Li, Q. H., Ueda, M., Tsuzuki, T., Goldstein, J. A., et al. (1999). Biochemical Pharmacology, 57, 1297–1303.

Takanashi, K., Tainaka, H., Kobayashi, K., Yasumori, T., Hosakawa, M., & Chiba, K. (2000). Pharmacogenetics, 10, 95–104.

Rushmore, T. H., Reider, P. J., Slaughter, D., Assang, C., & Shou, M. (2000). Metabolic Engineering, 2, 115–125.

Hanlon, S. P., Friedberg, T., Wolf, C. R., Ghisalba, O., & Kittelmann, M. (2007). Recombinant yeast and bacteria that express human P450s: Bioreactors for drug discovery, development, and biotechnology. In R. D. Schmid & V. B. Urlacher (Eds.), Modern biooxidation: Enzymes, reactions and applications (pp 233–252). Chichester: Wiley.

Vail, R. B., Homann, M. J., Hanna, I., & Zaks, A. (2005). Journal of Industrial Microbiology & Biotechnology, 32, 67–74.

Webster, R., Pacey, M., Winchester, T., Johnson, P., & Jezequel, S. (1998). Applied Microbiology and Biotechnology, 49, 371–376.

Osorio-Lozada, A., Surapaneni, S., Skiles, G. L., & Subramanian, R. (2008). Drug Metabolism and Disposition, 36, 234–240.

Sambrook, J., & Russell, D. W. (2001). Molecular cloning: A laboratory manual (3rd ed.). Cold Spring Harbor: Cold Spring Harbor Press.

Moreno, S., Klar, A., & Nurse, P. (1991). Methods Enzymol, 194, 795–823.

Alfa, C., Fantes, P., Hyams, J., McLeod, M., & Warbrick, E. (1993). Experiments with fission yeast. A laboratory course manual. Cold Spring Harbor Press, Cold Spring Harbor, NY.

Dragan, C. A., Zearo, S., Hannemann, F., Bernhardt, R., & Bureik, M. (2005). FEMS Yeast Research, 5, 621–625.

Maundrell, K. (1993). Gene, 123, 127–130.

Suga, M., & Hatakeyama, T. (2005). Yeast, 22, 799–804.

Okazaki, K., Okazaki, N., Kume, K., Jinno, S., Tanaka, K., & Okayama, H. (1990). Nucleic Acids Research, 18, 6485–6489.

Cheng, J., Wan, D. F., Gu, J. R., Gong, Y., Yang, S. L., Hao, D. C., et al. (2006). Protein Expression and Purification, 47, 467–476.

Masimirembwa, C. M., Otter, C., Berg, M., Jonsson, M., Leidvik, B., Jonsson, E., et al. (1999). Drug Metabolism and Disposition, 27, 1117–1122.

Dragan, C. A., Hartmann, R. W., & Bureik, M. (2006). Journal of Enzyme Inhibition and Medicinal Chemistry, 21, 547–556.

Dragan, C. A., Blank, L. M., & Bureik, M. (2006). Yeast, 23, 779–794.

Truan, G., Cullin, C., Reisdorf, P., Urban, P., & Pompon, D. (1993). Gene, 125, 49–55.

Peyronneau, M. A., Renaud, J. P., Truan, G., Urban, P., Pompon, D., & Mansuy, D. (1992). European Journal of Biochemistry, 207, 109–116.

Shen, S., Marchick, M. R., Davis, M. R., Doss, G. A., & Pohl, L. R. (1999). Chemical Research in Toxicology, 12, 214–222.

Bureik, M., Schiffler, B., Hiraoka, Y., Vogel, F., & Bernhardt, R. (2002). Biochemistry, 41, 2311–2321.

Paine, M. J., Gilham, D., Roberts, G. C., & Wolf, C. R. (1996). Archives of Biochemistry and Biophysics, 328, 143–150.

Huang, H., Yang, X., Li, Q., Sun, L., & Zhong, D. (2006). Applied Microbiology and Biotechnology, 72, 486–491.

Losson, R., & Lacroute, F. (1983). Cell, 32, 371–377.

Acknowledgements

This work was supported by a grant (ChemBioTec 13220-32) from the Deutsche Bundesstiftung Umwelt (DBU).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Drăgan, CA., Peters, F.T., Bour, P. et al. Convenient Gram-Scale Metabolite Synthesis by Engineered Fission Yeast Strains Expressing Functional Human P450 Systems. Appl Biochem Biotechnol 163, 965–980 (2011). https://doi.org/10.1007/s12010-010-9100-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12010-010-9100-3