Abstract

Objectives

The aim of this study was to assess the influence of surface treatment on the shear bond strength of two different adhesive-coated orthodontic ceramic brackets to computer-aided design/computer-aided manufacturing (CAD/CAM) nanohybrid composite.

Methods

A total of 120 specimens (10 mm × 10 mm × 3 mm) were prepared from each type of CAD/CAM block (Grandio [GR], VOCO Cuxhaven, Germany; Lava Ultimate [LU], 3M ESPE, St. Paul, MN, USA). For each type of CAD/CAM block, the plates were divided into four groups based on the applied surface treatment: hydrofluoric acid (HF), grinding bur (GB), silica coating with CoJet system (CS), and titanium tetrafluoride (TiF4) 2 wt/v%. Maxillary central incisors of adhesive-coated ceramic orthodontic brackets (APC Flash-free Clarity Advanced Ceramic, 3M Unitek, Monrovia, CA, USA) were bonded using Transbond XT Primer (3M Unitek, Monrovia, CA, USA). Shear bond strength was conducted, and the modes of failure were assessed utilizing the adhesive remnant index. Surface roughness and topography of treated CAD/CAM were evaluated. Data were statistically analyzed using two-way analysis of variance (ANOVA) and Tukey’s test. The Weibull analysis was conducted on shear bond strength data.

Results

Surface treatment with 2% TiF4 wt/v revealed significantly higher bond strength (GR, 14.51 ± 2.57 MPa; LU, 11.19 ± 2.17 MPa) than other groups for both types of CAD/CAM restorative materials (p < 0.05). Adhesive failures were the predominant mode of failure. Surface treatment with CS revealed higher surface roughness than other groups (p < 0.05).

Conclusions

Surface treatment with 2% TiF4 wt/v enhanced the adhesion between orthodontic ceramic brackets to GR and LU CAD/CAM composite restorative materials. GR CAD/CAM nanohybrid composite had higher bond strength than LU to ceramic orthodontic brackets.

Zusammenfassung

Zielsetzung

Ziel dieser Studie war es, den Einfluss der Oberflächenbehandlung auf die Scherhaftfestigkeit von 2 verschiedenen adhäsiv beschichteten kieferorthopädischen Keramikbrackets auf einem CAD/CAM-Nanohybridkomposit zu untersuchen.

Methoden

Von jedem CAD/CAM-Block (Grandio [GR], VOCO Cuxhaven, Deutschland; Lava Ultimate [LU], 3M ESPE, St. Paul/MN, USA) wurden insgesamt 120 Probekörper (10 × 10 × 3 mm) hergestellt. Für jeden Typ von CAD/CAM-Block wurden die Platten anhand der angewandten Oberflächenbehandlung in 4 Gruppen eingeteilt: Fluorwasserstoffsäure (HF), Schleifkörper (GB), Siliziumdioxid-Beschichtung mit CoJet-System (CS) und Titantetrafluorid (TiF4) 2 Gew%. Oberkieferschneidezähne von adhäsiv beschichteten keramischen kieferorthopädischen Brackets (APC Flash-free Clarity Advanced Ceramic, 3M Unitek, Monrovia/CA, USA) wurden mit Transbond XT Primer (3M Unitek, Monrovia/CA, USA) verklebt. Die Scherhaftfestigkeit wurde geprüft und die Art des Versagens anhand des ARI („adhesive remnant index“) bewertet. Die Oberflächenrauhigkeit und -topographie der behandelten CAD/CAM wurden bewertet. Die Daten wurden mit Hilfe der Zwei-Wege-Varianzanalyse (ANOVA) und dem Tukey-Test statistisch ausgewertet. Die Weibull-Analyse wurde für die Daten zur Scherhaftfestigkeit durchgeführt.

Ergebnisse

Die Oberflächenbehandlung mit 2% TiF4 wt/v ergab für beide Arten von CAD/CAM-Restaurationsmaterialien eine signifikant höhere Haftfestigkeit (GR, 14,51 ± 2,57 MPa; LU, 11,19 ± 2,17 MPa) als die anderen Gruppen (p < 0,05). Adhäsivversagen war die vorherrschende Versagensart. Die Oberflächenbehandlung mit CS ergab eine höhere Oberflächenrauhigkeit als bei den anderen Gruppen (p < 0,05).

Schlussfolgerungen

Die Oberflächenbehandlung mit 2% TiF4 wt/v verbesserte die Adhäsion zwischen kieferorthopädischen Keramikbrackets und GR- sowie LU-CAD/CAM-Komposit-Restaurationsmaterialien. Das GR CAD/CAM-Nanohybridkomposit hatte eine höhere Haftfestigkeit als LU auf kieferorthopädischen Brackets.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Orthodontists deal with challenges for adults seeking orthodontic treatment with restored teeth [1, 2]. Indirect restorations are widely utilized for durability and natural appearance of dental restorations [1, 2]. It was reported that bonding orthodontic brackets to ceramic restorations has lower bond strength as ceramics have an inert surface [3,4,5,6]. Computer-aided design/computer-aided manufacturing (CAD/CAM)-prepared composite restorative materials are increasingly used due to enhanced properties [7,8,9]. The improvements in CAD/CAM-prepared composite restorative materials include superior physical properties with enhanced edge stability that facilitate the milling process with lower thickness, polishability, and the possibility of intraoral repair due to resin content [10,11,12,13,14,15].

Various surface treatments have been applied to indirect restorations to increase the bond strength of orthodontic brackets [3, 16,17,18]. On the other hand, it is essential to avoid damaging the surface of indirect esthetic restorations when debonding brackets [1]. Consequently, a nondestructive and applicable technique for bonding orthodontic brackets to indirect esthetic restoration would be desirable for the clinic [17, 19, 20]. It is crucial that orthodontists select the appropriate surface treatment for each restorative material when bonding orthodontic brackets.

Different applications of titanium tetrafluoride (TiF4) in dentistry have been assessed comprising a varnish to protect enamel and dentin from erosion, for caries prevention, and as an etching agent for ceramics and titanium with various outcomes [21,22,23,24,25]. Recently, a nanohybrid CAD/CAM restorative material (Grandio blocs [GR]; VOCO, Cuxhaven, Germany) was introduced to the dental market. The GR blocs consist of 86 wt% inorganic fillers embedded in a polymer matrix [26]. Resin nanoceramic (Lava Ultimate [LU]; 3M ESPE; St Paul, MN, USA) is another type of machinable CAD/CAM polymer-based restorative material [27, 28]. Given that the GR CAD/CAM restorative material is rather new in the dental market, studies on its performance in bonding properties are ongoing. For adult patients having crown restorations and requiring orthodontic treatment, the bonding performance of ceramic brackets to these newly developed CAD/CAM restorations remains ambiguous [29]. According to the authors’ knowledge, no study has evaluated the bond strength of ceramic brackets to the newly developed CAD/CAM nanohybrid composite. Consequently, the aim of this study was to assess the influence of various surface treatments on the shear bond strength of adhesive-coated ceramic brackets to CAD/CAM nanohybrid composites. The null hypothesis was that the surface treatment and type of CAD/CAM would not influence the adhesion between ceramic brackets and the CAD/CAM restorative materials.

Materials and methods

Power analysis to estimate the appropriate sample size was based on the results of a previous study [17]. The effect size was hypothesized to be 0.27. Accordingly, with the constraints of α = 0.05, the required sample size needed was 30 specimens per group (GPower v3.1.3 software; University of Düsseldorf; Düsseldorf, Germany) with power 0.95.

Two types of CAD/CAM restorative materials were used in this study: GR (VOCO, Cuxhaven, Germany) and LU (3M ESPE; St Paul, MN, USA). The specimens from each type of CAD/CAM were produced (10 × 10 × 3 mm) using a low-speed cutting machine (Isomet, Buehler, Lake Bluff, IL, USA). The bonding surface of the specimens was polished with silicon carbide paper (240, 400, 600, 800, and 1000 grit). The specimens were ultrasonically cleaned and then placed in autopolymerizing acrylic resin blocks (Vertex; Vertex-Dental B. V., Zeist, The Netherlands) with the polished surface exposed for surface treatment and bonding [16, 17].

Surface treatment

The exposed surface of each CAD/CAM restorative material was divided into 4 sectors/groups according to the surface treatment as follows:

-

Hydrofluoric acid (HF): specimens were conditioned with 9% HF (Ultradent Products, South Jordan, UT, USA) for 1 min, then rinsed and air-dried.

-

Grinding bur (GB): specimens were roughened using a diamond ceramic grinding bur (VOCO, Cuxhaven, Germany) at 6000–10,000 rpm under water cooling.

-

Silica coating with CoJet system (CS): specimens were air-abraded with 30 µm aluminum trioxide particles for 4 s at 2.5 bar pressure.

-

Titanium tetrafluoride (2% TiF4 wt/v): specimens were treated with 2% TiF4 wt/v (Aldrich Chemical Company; Milwaukee, WI, USA) for 1 min.

Shear bond strength

A total of 120 specimens from each type of CAD/CAM restorative material were surface treated (n = 30/group) as mentioned. A primer (Transbond XT Primer; 3M Unitek, Monrovia, CA, USA) was applied to the treated CAD/CAM surfaces. Then, flash-free adhesive-coated brackets (APC Flash-free Clarity Advanced Ceramic, 3M Unitek, Monrovia, CA, USA) for maxillary central incisors were bonded to the treated CAD/CAM surface applying a standardized force of 5 N [30, 31]. The bonded specimens were cured (Ortholux™ Luminous Curing Light; 3M Unitek, light output 1600 mW/cm2) according to the manufacturer’s instructions. The bonded specimens were stored in SAGF medium artificial saliva for 1 week at 37 °C [32]. After that, the specimens were thermal cycled for 10,000 cycles between 5 and 55 °C and a 30 s dwell time [18].

The shear bond strength test was conducted using a universal testing machine (Model TT‑B, Instron Corp., Canton, MA, USA). The shearing blade was placed vertically at the base of the bracket at a crosshead speed of 0.5 mm/min and the bond strength was calculated in megapascals (MPa) [1, 16, 17, 33].

Adhesive remnant index

After debonding, the fractured specimens were examined using a stereomicroscope (Olympus, SZX9, Tokyo, Japan) at 25 × magnification to determine the adhesive remnant index (ARI) as follows [17, 31, 34]:

-

0—no adhesive remained on the CAD/CAM surface,

-

1—less than half of the adhesive remained on the CAD/CAM surface,

-

2—more than half of the adhesive remained on the CAD/CAM surface, and

-

3—all adhesive remained on the CAD/CAM surface, with a visible impression of the bracket mesh.

Scanning electron microscopy

The surface of the treated CAD/CAM specimens (n = 10/group) was examined using a scanning electron microscopy (SEM) at 500 × (Evo LS10, Carl Zeiss, Oberkochen, Germany) to determine the changes in the surface due to the applied treatment. The specimens were sputter-coated with gold (Hummer II, Anatech, Springfield, VA, USA).

Surface roughness

The surface roughness of the treated CAD/CAM specimens (n = 30/group) was evaluated using a profilometer (Perthometer M2; Mahr, Göttingen, Germany) with 0.25 mm/s driving speed for a 1.25 mm length. For each specimen, five measurements were taken, and the average (Ra, µm) was calculated.

Statistical analysis

The data of shear bond strength and surface roughness were statistically analyzed (SPSS software; Version 17, SPSS Inc., Chicago, IL, USA) using two-way analysis of variance (ANOVA) considering two factors (type of surface treatment and type of CAD/CAM material) and their interactions at the 0.05 level of significance. The Chi-square (χ2) test was performed to test the difference in frequency distributions of the ARI values. Multiple comparisons were performed using Tukey’s test. The Weibull analysis (SuperSMITH software; Fulton Findings, Torrance, CA, USA) was conducted on the shear bond strength data.

Results

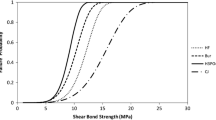

The means of the shear bond strength values (MPa) and standard deviations are shown in Table 1 and Fig. 1. Two-way ANOVA showed that the bond strength was significantly influenced by the type of CAD/CAM restorative material (F = 146.16, p < 0.001) and the type of treatment (F = 94.05, p < 0.001). There was no significant interaction between the type of CAD/CAM restorative material and the type of treatment (p = 0.557). Surface treatment with 2% TiF4 wt/v revealed significantly higher bond strength (GR, 14.51 ± 2.57 MPa; LU, 11.19 ± 2.17 MPa) than the other groups for both types of CAD/CAM restorative material (p < 0.05). On the other hand, the specimens treated with GB revealed significantly lower bond strength (GR, 8.87 ± 1.26 MPa; LU, 5.81 ± 0.78 MPa; p < 0.05). Surface treatments with CS (GR, 10.18 ± 1.97 MPa; LU, 7.81 ± 1.69 MPa) and HF (GR, 11.78 ± 1.98 MPa; LU, 8.89 ± 1.87 MPa) showed no significant difference in bond strength (p > 0.05). The ranking for the bond strength values was as follows: 2% TiF4 wt/v > HF > CS > GB.

Shear bond strength (MPa) of ceramic brackets to Grandio (GR) and Lava Ultimate (LU) computer-aided design/computer-aided manufacturing (CAD/CAM) restorative materials with different surface treatments: hydrofluoric acid (HF), grinding bur (GB), silica coating with CoJet system (CS), and titanium tetrafluoride (TiF4) 2 wt/v%

Scherhaftfestigkeit (MPa) von keramischen Brackets auf Grandio (GR) und Lava Ultimate (LU) CAD/CAM-Restaurationsmaterialien mit unterschiedlichen Oberflächenbehandlungen: Fluorwasserstoffsäure (HF), Schleifkörper (GB), Siliziumdioxid-Beschichtung mit CoJet-System (CS) und Titantetrafluorid (TiF4) 2 Gew%

Table 2 shows the ARI scores of the debonded specimens. There was no significant difference in frequency distributions of the ARI scores between the different types of treatment (χ2 = 6.562, p = 0.363). Similarly, the type of CAD/CAM restorative material did not significantly differ in frequency distributions of the ARI scores (χ2 = 3.173, p = 0.205). The main modes of failure were observed to happen with an ARI score 0.

The Weibull analysis showed that surface treatment of GR and LU CAD/CAM with 2% TiF4 wt/v revealed the highest characteristic bond strength (σ0, 23.68 and 17.37; respectively) and Weibull modulus (m, 4.92 and 4.61; respectively) compared with other surface treatments (Table 1; Fig. 2). On the other hand, the GB surface treatment resulted in the lowest σ0 (14.19 and 9.82; respectively). The Weibull plot for GR and LU with different surface treatments is shown in Fig. 2.

Weibull plot of shear bond strength (MPa) for the Grandio (GR) and Lava Ultimate (LU) computer-aided design/computer-aided manufacturing (CAD/CAM) materials with different surface treatments. The characteristic bond strength is represented by the dotted line. 2% TiF4 wt/v of GR and LU CAD/CAM revealed higher characteristic bond strength than other treatments. GB surface treatment showed the lowest characteristic bond strength. HF hydrofluoric acid, GB grinding bur, CS silica coating with CoJet system, TiF4 titanium tetrafluoride 2 wt/v%

Weibull-Plot der Scherhaftfestigkeit (MPa) für die CAD/CAM-Materialien Grandio (GR) und Lava Ultimate (LU) mit unterschiedlichen Oberflächenbehandlungen. Die charakteristische Haftfestigkeit ist durch die gepunktete Linie dargestellt. Die Behandlungen mit 2% TiF4 wt/Volumengewicht von GR und LU CAD/CAM zeigten eine höhere charakteristische Haftfestigkeit als andere. Die niedrigste charakteristische Haftfestigkeit wurde bei der GB-Oberflächenbehandlung festgestellt. HF Fluorwasserstoffsäure, GB Schleifkörper, CS Siliziumdioxid-Beschichtung mit CoJet-System, TiF4 Titantetrafluorid 2 wt/v%

The mean of the surface roughness values (Ra, µm) and standard deviations are shown in Table 1 and Fig. 3. Two-way ANOVA showed that the surface roughness was significantly influenced by the type of CAD/CAM restorative material (F = 32.35, p < 0.001) and the type of treatment (F = 52.18, p < 0.001). There was a significant interaction between the type of CAD/CAM restorative material and the type of treatment (p = 0.003). Surface treatment with CS revealed higher surface roughness (GR, 3.23 ± 0.35 μm; LU, 2.89 ± 0.25 μm) compared with the other groups for both types of CAD/CAM restorative material (p < 0.05). There was no significant difference in the surface roughness between HF and 2% TiF4 wt/v treatment (p > 0.05).

Surface roughness (μm) of Grandio (GR) and Lava Ultimate (LU) computer-aided design/computer-aided manufacturing (CAD/CAM) restorative materials with different surface treatments: hydrofluoric acid (HF), grinding bur (GB), silica coating with CoJet system (CS), and titanium tetrafluoride (TiF4) 2 wt/v%

Oberflächenrauhigkeit (μm) von Grandio (GR) und Lava Ultimate (LU) CAD/CAM-Restaurationsmaterialien mit unterschiedlichen Oberflächenbehandlungen: Fluorwasserstoffsäure (HF), Schleifkörper (GB), Siliziumdioxid-Beschichtung mit CoJet-System (CS) und Titantetrafluorid (TiF4) 2 wt/v%

The effect of surface treatment on the microstructures of the CAD/CAM restorative materials is presented in Fig. 4. Surface treatment with HF showed surface remarkable irregularities for the GR CAD/CAM restorative material (Fig. 4a), while treatment of LU revealed a smoother surface with formation of pores (Fig. 4b). GB surface treatment revealed deep grooves on the surfaces of the GR and LU CAD/CAM restorative materials (Fig. 4c, d, respectively). Roughening with CS showed prominent microsized areas with white spots on the surface, which represent silica particles (Fig. 4e, f, respectively). The surfaces of specimens treated with 2% TiF4 wt/v revealed a layer-like structure formed on the surface of the CAD/CAM restorative materials (Fig. 4g, h, respectively).

Representative SEM images (500 ×) of Grandio (GR; left) and Lava Ultimate (LU; right) computer-aided design/computer-aided manufacturing (CAD/CAM) restorative materials after various surface treatments. a,b hydrofluoric acid (HF), c,d grinding bur (GB), e,f silica coating with CoJet system (CS), and g,h titanium tetrafluoride (TiF4) 2 wt/v%

Repräsentative REM-Aufnahmen (500:1) von Grandio (GR; links) und Lava Ultimate (LU; rechts) CAD/CAM-Restaurationsmaterialien nach verschiedenen Oberflächenbehandlungen: a,b Fluorwasserstoffsäure (HF), c,d Schleifkörper (GB), e,f Siliziumdioxid-Beschichtung mit CoJet-System (CS), g,h Titantetrafluorid (TiF4) wt/Volumengewicht

Discussion

The purpose of the current study was to assess the most efficient surface treatment for bonding ceramic brackets onto newly developed CAD/CAM nanohybrid composite material. The specimens were thermal cycled to simulate oral conditions to determine the durability of the bonded surfaces under changing thermal conditions [17]. The null hypothesis that the surface treatments and type of CAD/CAM would not influence the adhesion between ceramic brackets and CAD/CAM restorative materials was rejected.

It is crucial to improve the adhesion between the ceramic brackets and the CAD/CAM-prepared composite restorative materials to avoid debonding during orthodontic treatment. There are different techniques to enhance the adhesion between orthodontic brackets and indirect restorative materials, including HF, phosphoric acid, bonding agents, grinding, and airborne-particle abrasion [16, 17].

Surface treatment with 2% TiF4 wt/v enhanced the adhesion of the ceramic brackets on the GR and LU CAD/CAM materials the most compared with the other treatments. In the present study, a 2% wt/v concentration of TiF4 was chosen as it was reported that higher concentrations reduced the bond strength of composite cement with the GR CAD/CAM restorative material [23]. The aqueous solution of TiF4 improved the adhesion of luting agents to fiber posts, ceramics, and titanium [25, 35, 36]. The TiF4 solution has a high acidity [37] that modifies the surface of the GR and LU CAD/CAM, which enhanced the mechanical retention with the adhesive-coated ceramic brackets. All groups revealed higher bond strength values than the promoted optimal bracket bonding strength, ranging from 6–8 MPa [38] and accordingly could be considered sufficient for clinical applications [17]; only LU treated with GB showed lower bond strength (5.81 ± 0.78 MPa). Adequate bond strength of orthodontic brackets with the restorative material is essential for minimizing accidentally debonding of brackets and substrate fracture when removing the brackets [2, 39].

Both CS and HF surface treatments revealed comparable bond strength. The CS surface treatment created micromechanical retention by alumina-particles coated with silica on the surfaces of the GR and LU CAD/CAM materials (Fig. 4e, f, respectively). The surfaces were then coated with the primer that formed covalent bonds between the alumina and silica particles and the adhesive-coated ceramic brackets [40]. However, the CS surface treatment may cause microcracks on the surface of the CAD/CAM restorative materials, which may lower the bond strength [28, 41]. Surface treatment using HF altered the surfaces of the GR and LU restorative materials by forming surface irregularities and pores (Fig. 4a, b) that might increase the surface area and improve the adhesion with the ceramic brackets. However, the potential detrimental effect of HF as a conditioning method requires caution for the safety of patients [42]. On the other hand, TiF4 solution has been used for orthopedic implant surface modification to induce bioactivity [43]. It was considered less hazardous for intraoral ceramic etching, mainly for ceramic repair [25]. It has been suggested that TiF4 solution might be used for creating an etching effect without compromising the health of the surrounding soft tissues [25].

Surface modification of the GR and LU CAD/CAM with GB revealed lower bond strength than in the other groups. The diamond bur creates deep grooves on the surface of the specimens that might causes cracks that lower the bond strength (Fig. 4c, d). Surface treatments with 2% TiF4 wt/v and HF revealed lower surface roughness than CS and GB. However, the former surface treatments enhanced the bond strength with the ceramic brackets in comparison with CS and GB treatments.

GR revealed greater bond strength with the ceramic brackets than LU. It could be postulated that the microstructure of the GR CAD/CAM nanohybrid composite enhanced the bond strength with the adhesive-coated ceramic brackets. The GR blocs consisted of 86 wt% inorganic fillers embedded in a polymer matrix [23, 26], whereas the LU is composed of 80 wt% nanoceramic and 20 wt% resin [23]. In addition, GR presented a higher surface roughness than LU [23], which might enhance the micromechanical retention with the ceramic brackets. It has been shown that if the bond strength between the adhesive resin and the ceramic is greater than 13 MPa, the ceramic is prone to fracture [44]. In the present study, only GR specimens treated with 2% TiF4 wt/v showed bond strength values higher than 13 MPa (14.51 ± 2.57 MPa). According to the finding of the ARI scores, the adhesive mode of failure (score 0) was the predominant type. It should be emphasized that the adhesive mode of failure between the CAD/CAM restorative material and the adhesive interface is the most favorable to avoid CAD/CAM fractures during the debonding of ceramic brackets [17, 18]. The surface of the CAD/CAM materials did not show any damage after debonding in any group. It is essential to keep the surface of the CAD/CAM restorative material free of any damage as this might affect the durability and esthetic appearance of the restoration [45].

The findings of the Weibull analysis supported the results of the bond strength measurements. The GR and LU CAD/CAM materials treated with 2% TiF4 wt/v showed a higher characteristic bond strength (σ0) and Weibull modulus (m) compared with the other surface treatments, which indicates higher bonding effectiveness and more reliable treatment [46]. On the other hand, the GB surface treatment revealed the lowest σ0 (14.19 and 9.82; respectively).

Further clinical trials are required to evaluate the performance of ceramic orthodontic brackets bonded to GR and LU CAD/CAM restorative materials after 2% TiF4 wt/v surface treatment. The oral environment and masticatory movements during the orthodontic treatment might affect possible bracket loss [1]. It has been reported that TiF4 could also be used as a prophylactic agent during orthodontic treatment [47]. Thus, it is postulated that 2% TiF4 wt/v surface treatment could be used as a possible standard technique for treating the CAD/CAM composite restorative materials in orthodontic practice if it was clinically verified to be safe and effective for CAD/CAM composite restorations during the debonding procedure.

Conclusion

Within the limitations of this study, the following conclusions were drawn:

-

Surface treatment with 2% TiF4 wt/v enhanced the adhesion between flash-free adhesive-coated orthodontic ceramic bracket to Grandio (GR) and Lava Ultimate (LU) computer-aided design/computer-aided manufacturing (CAD/CAM) composite restorative materials.

-

Surface treatment with CS (silica coating with CoJet system) increased surface roughness compared with the other treatments for both types of CAD/CAM restorative materials.

-

The GR CAD/CAM nanohybrid composite revealed higher bond strength than LU to flash-free adhesive-coated orthodontic ceramic brackets.

References

Zhang ZC, Qian YF, Yang YM, Feng QP, Shen G (2016) Bond strength of metal brackets bonded to a silica-based ceramic with light-cured adhesive: influence of various surface treatment methods. J Orofac Orthop 77:366–372. https://doi.org/10.1007/s00056-016-0044-2

Di Guida LA, Benetti P, Corazza PH, Della Bona A (2019) The critical bond strength of orthodontic brackets bonded to dental glass-ceramics. Clin Oral Investig 23:4345–4353. https://doi.org/10.1007/s00784-019-02881-5

Abu Alhaija ES, Abu AlReesh IA, AlWahadni AM (2010) Factors affecting the shear bond strength of metal and ceramic brackets bonded to different ceramic surfaces. Eur J Orthod 32:274–280. https://doi.org/10.1093/ejo/cjp098

Zarif Najafi H, Oshagh M, Torkan S, Yousefipour B, Salehi R (2014) Evaluation of the effect of four surface conditioning methods on the shear bond strength of metal bracket to porcelain surface. Photomed Laser Surg 32:694–699. https://doi.org/10.1089/pho.2014.3782

Abdelnaby YL (2011) Effects of cyclic loading on the bond strength of metal orthodontic brackets bonded to a porcelain surface using different conditioning protocols. Angle Orthod 81:1064–1069. https://doi.org/10.2319/030211-151.1

Falkensammer F, Freudenthaler J, Pseiner B, Bantleon HP (2012) Influence of surface conditioning on ceramic microstructure and bracket adhesion. Eur J Orthod 34:498–504. https://doi.org/10.1093/ejo/cjr034

Edelhoff D, Beuer F, Schweiger J, Brix O, Stimmelmayr M, Guth JF (2012) CAD/CAM-generated high-density polymer restorations for the pretreatment of complex cases: a case report. Quintessence Int 43:457–467

Stawarczyk B, Krawczuk A, Ilie N (2015) Tensile bond strength of resin composite repair in vitro using different surface preparation conditionings to an aged CAD/CAM resin nanoceramic. Clin Oral Investig 19:299–308. https://doi.org/10.1007/s00784-014-1269-3

Goracci C, Özcan M, Franchi L, Di Bello G, Louca C, Vichi A (2019) Bracket bonding to polymethylmethacrylate-based materials for computer-aided design/manufacture of temporary restorations: influence of mechanical treatment and chemical treatment with universal adhesives. Korean J Orthod 49:404–412. https://doi.org/10.4041/kjod.2019.49.6.404

Alt V, Hannig M, Wöstmann B, Balkenhol M (2011) Fracture strength of temporary fixed partial dentures: CAD/CAM versus directly fabricated restorations. Dent Mater 27:339–347. https://doi.org/10.1016/j.dental.2010.11.012

Göncü Başaran E, Ayna E, Vallittu PK, Lassila LV (2011) Load-bearing capacity of handmade and computer-aided design—computer-aided manufacturing-fabricated three-unit fixed dental prostheses of particulate filler composite. Acta Odontol Scand 69:144–150. https://doi.org/10.3109/00016357.2010.545034

Stawarczyk B, Ender A, Trottmann A, Özcan M, Fischer J, Hämmerle CH (2012) Load-bearing capacity of CAD/CAM milled polymeric three-unit fixed dental prostheses: effect of aging regimens. Clin Oral Investig 16:1669–1677. https://doi.org/10.1007/s00784-011-0670-4

Stawarczyk B, Özcan M, Trottmann A, Schmutz F, Roos M, Hämmerle C (2013) Two-body wear rate of CAD/CAM resin blocks and their enamel antagonists. J Prosthet Dent 109:325–332. https://doi.org/10.1016/S0022-3913(13)60309-1

Stawarczyk B, Sener B, Trottmann A, Roos M, Özcan M, Hämmerle CH (2012) Discoloration of manually fabricated resins and industrially fabricated CAD/CAM blocks versus glass-ceramic: effect of storage media, duration, and subsequent polishing. Dent Mater J 31:377–383. https://doi.org/10.4012/dmj.2011-238

Reymus M, Roos M, Eichberger M, Edelhoff D, Hickel R, Stawarczyk B (2019) Bonding to new CAD/CAM resin composites: influence of air abrasion and conditioning agents as pretreatment strategy. Clin Oral Investig 23:529–538. https://doi.org/10.1007/s00784-018-2461-7

Buyuk SK, Kucukekenci AS (2018) Effects of different etching methods and bonding procedures on shear bond strength of orthodontic metal brackets applied to different CAD/CAM ceramic materials. Angle Orthod 88:221–226. https://doi.org/10.2319/070917-455.1

Elsaka SE (2016) Influence of surface treatments on bond strength of metal and ceramic brackets to a novel CAD/CAM hybrid ceramic material. Odontology 104:68–76. https://doi.org/10.1007/s10266-014-0188-8

Saraç YS, Külünk T, Elekdağ-Türk S, Saraç D, Türk T (2011) Effects of surface-conditioning methods on shear bond strength of brackets bonded to different all-ceramic materials. Eur J Orthod 33:667–672. https://doi.org/10.1093/ejo/cjq132

Piascik JR, Wolter SD, Stoner BR (2011) Development of a novel surface modification for improved bonding to zirconia. Dent Mater 27:e99–105. https://doi.org/10.1016/j.dental.2011.01.005

Gonzalez-Serrano C, Phark JH, Fuentes MV, Albaladejo A, Sanchez-Monescillo A, Duarte S Jr, Ceballos L (2021) Effect of a single-component ceramic conditioner on shear bond strength of precoated brackets to different CAD/CAM materials. Clin Oral Investig 25:1953–1965. https://doi.org/10.1007/s00784-020-03504-0

Magalhaes AC, Comar LP, Rios D, Delbem AC, Buzalaf MA (2008) Effect of a 4 % titanium tetrafluoride (TiF4) varnish on demineralisation and remineralisation of bovine enamel in vitro. J Dent 36:158–162. https://doi.org/10.1016/j.jdent.2007.12.001

Magalhaes AC, Romanelli AC, Rios D, Comar LP, Navarro RS, Grizzo LT, Aranha AC, Buzalaf MA (2011) Effect of a single application of TiF4 and NaF varnishes and solutions combined with Nd:YAG laser irradiation on enamel erosion in vitro. Photomed Laser Surg 29:537–544. https://doi.org/10.1089/pho.2010.2886

Elsaka SE, Elnaghy AM (2020) Effect of surface treatment and aging on bond strength of composite cement to novel CAD/CAM nanohybrid composite. J Adhes Dent 22:195–204. https://doi.org/10.3290/j.jad.a44284

Klosa K, Boesch I, Kern M (2013) Long-term bond of glass ceramic and resin cement: evaluation of titanium tetrafluoride as an alternative etching agent for lithium disilicate ceramics. J Adhes Dent 15:377–383. https://doi.org/10.3290/j.jad.a29381

Cömlekoğlu ME, Dündar M, Güngör MA, Sen BH, Artunç C (2009) Preliminary evaluation of titanium tetrafluoride as an alternative ceramic etchant to hydrofluoric acid. J Adhes Dent 11:447–453. https://doi.org/10.3290/j.jad.a18138

Pfeilschifter M, Preis V, Behr M, Rosentritt M (2018) Edge strength of CAD/CAM materials. J Dent 74:95–100. https://doi.org/10.1016/j.jdent.2018.05.004

Alp G, Subasi MG, Johnston WM, Yilmaz B (2018) Effect of different resin cements and surface treatments on the shear bond strength of ceramic-glass polymer materials. J Prosthet Dent 120:454–461. https://doi.org/10.1016/j.prosdent.2017.12.016

Elsaka SE (2014) Bond strength of novel CAD/CAM restorative materials to self-adhesive resin cement: the effect of surface treatments. J Adhes Dent 16:531–540. https://doi.org/10.3290/j.jad.a33198

Özarslan MM, Üstün Ö, Buyukkaplan US, Barutcigil Ç, Türker N, Barutcigil K (2018) Assessment the bond strength of ceramic brackets to CAD/CAM nanoceramic composite and interpenetrating network composite after different surface treatments. Biomed Res Int 2018:1871598. https://doi.org/10.1155/2018/1871598

Eslamian L, Borzabadi-Farahani A, Mousavi N, Ghasemi A (2011) A comparative study of shear bond strength between metal and ceramic brackets and artificially aged composite restorations using different surface treatments. Eur J Orthod 34:610–617. https://doi.org/10.1093/ejo/cjr044

Proença MAM, Carvalho EM, Silva e Silva A, Ribeiro GAC, Ferreira PVC, Carvalho CN, Bauer J (2020) Orthodontic resin containing bioactive glass: preparation, physicochemical characterization, antimicrobial activity, bioactivity and bonding to enamel. Int J Adhes Adhes 99:102575. https://doi.org/10.1016/j.ijadhadh.2020.102575

Gal J‑Y, Fovet Y, Adib-Yadzi M (2001) About a synthetic saliva for in vitro studies. Talanta 53:1103–1115. https://doi.org/10.1016/S0039-9140(00)00618-4

Goto S, Hasegawa Y, Miyagawa Y, Endo T (2020) Effects of contact compressive force on bracket bond strength and adhesive thickness : study using orthodontic resins with different viscosities. J Orofac Orthop 81:79–88. https://doi.org/10.1007/s00056-019-00202-9

Årtun J, Bergland S (1984) Clinical trials with crystal growth conditioning as an alternative to acid-etch enamel pretreatment. Am J Orthod 85:333–340. https://doi.org/10.1016/0002-9416(84)90190-8

Elsaka SE, Elnaghy AM (2019) Bonding durability of titanium tetrafluoride treated glass fiber post with resin cement. Dent Mater J 38:189–195. https://doi.org/10.4012/dmj.2018-054

Elsaka SE (2018) Effectiveness of titanium tetrafluoride on the bond strength of composite cement to titanium. J Adhes Dent 20:143–149. https://doi.org/10.3290/j.jad.a40297

van Rijkom H, Ruben J, Vieira A, Huysmans MC, Truin GJ, Mulder J (2003) Erosion-inhibiting effect of sodium fluoride and titanium tetrafluoride treatment in vitro. Eur J Oral Sci 111:253–257. https://doi.org/10.1034/j.1600-0722.2003.00031.x

Reynolds IR (1975) A review of direct orthodontic bonding. Br J Orthod 2:171–178. https://doi.org/10.1080/0301228X.1975.11743666

Basalamah A, Maher A, Whba AH, Scribante A, Sfondrini MF, Montasser MA (2021) Effects of fluorosed enamel on orthodontic bracket bonding : an in vitro study. J Orofac Orthop. https://doi.org/10.1007/s00056-021-00342-x

Özcan M (2002) The use of chairside silica coating for different dental applications: a clinical report. J Prosthet Dent 87:469–472. https://doi.org/10.1067/mpr.2002.124365

Peumans M, Valjakova EB, De Munck J, Mishevska CB, Van Meerbeek B (2016) Bonding effectiveness of luting composites to different CAD/CAM materials. J Adhes Dent 18:289–302. https://doi.org/10.3290/j.jad.a36155

Zachrisson YO, Zachrisson BU, Buyukyilmaz T (1996) Surface preparation for orthodontic bonding to porcelain. Am J Orthod Dentofacial Orthop 109:420–430. https://doi.org/10.1016/s0889-5406(96)70124-5

Shimizu K, Imai H, Hirashima H, Tsukuma K (1999) Low-temperature synthesis of anatase thin films on glass and organic substrates by direct deposition from aqueous solutions. Thin Solid Films 30:220–224. https://doi.org/10.1016/S0040-6090(99)00084-X

Ozden AN, Akaltan F, Can G (1994) Effect of surface treatments of porcelain on the shear bond strength of applied dual-cured cement. J Prosthet Dent 72:85–88. https://doi.org/10.1016/0022-3913(94)90216-x

Trakyali G, Malkondu O, Kazazoğlu E, Arun T (2009) Effects of different silanes and acid concentrations on bond strength of brackets to porcelain surfaces. Eur J Orthod 31:402–406. https://doi.org/10.1093/ejo/cjn118

Bielen V, Inokoshi M, Munck JD, Zhang F, Vanmeensel K, Minakuchi S, Vleugels J, Naert I, Van Meerbeek B (2015) Bonding effectiveness to differently sandblasted dental zirconia. J Adhes Dent 17:235–242. https://doi.org/10.3290/j.jad.a34401

Büyükyilmaz T, Tangugsorn V, Ogaard B, Arends J, Ruben J, Rølla G (1994) The effect of titanium tetrafluoride (TiF4) application around orthodontic brackets. Am J Orthod Dentofacial Orthop 105:293–296. https://doi.org/10.1016/S0889-5406(94)70124-5

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

S. Elsaka, A. Hassan and A. Elnaghy declare that they have no competing interests.

Ethical standards

For this article no studies with human participants or animals were performed by any of the authors. All studies mentioned were in accordance with the ethical standards indicated in each case.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Elsaka, S., Hassan, A. & Elnaghy, A. Effectiveness of surface treatment on bond strength of ceramic brackets to two types of CAD/CAM-prepared nanohybrid composites. J Orofac Orthop 84 (Suppl 2), 123–132 (2023). https://doi.org/10.1007/s00056-022-00377-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00056-022-00377-8

Keywords

- Computer-aided design/computer-aided manufacturing

- Orthodontic appliances, fixed

- Shear bond strength

- Surface roughness

- Titanium tetrafluoride