Abstract

This study evaluated the effect of four different surface treatments methods on the shear bond strength (SBS) of ceramic and metal brackets to Vita Enamic (VE) CAD/CAM hybrid ceramic. A total of 240 plates (10 mm × 10 mm × 3 mm) were cut from VE ceramic blocks and divided into two groups. In each group, four subgroups were prepared by hydrofluoric acid (HF); phosphoric acid (H3PO4); diamond ceramic grinding bur; and silica coating using CoJet system (CJ). Maxillary central incisor metal (Victory Series) and ceramic (Clarity) brackets were bonded with light-cure composite and then stored in artificial saliva for 1 week and thermocycled. The SBS test was performed, and the failure types were classified with adhesive remnant index scores. Surface morphology of the ceramic was characterized after treatment using a scanning electron microscope. Data were analyzed using two-way ANOVA, Tukey HSD test, and Weibull analysis. SBS was significantly affected by the type of bracket and by type of treatment (P < 0.001). Specimens treated with CJ presented with significantly higher SBS compared to other groups (P < 0.05). Improvements in SBS values (MPa) were found in the following order: CJ > HF > Bur > H3PO4. Ceramic bracket showed higher SBS compared to metal bracket. Adhesive failures between the ceramic and composite resin were the predominant mode of failure in all groups. Surface treatment of VE CAD/CAM hybrid ceramic with silica coating enhanced the adhesion with ceramic and metal brackets.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Adult orthodontic treatment often entails bonding brackets onto different types of dental restorations [1]. In recent years, dental ceramics have increased substantially as restorative materials [2]. Ceramic restorations have several advantages including highly esthetic appearance, wear resistance, biocompatibility, and color stability [2, 3]. Consequently, orthodontists are frequently encountered with the challenge of efficiently bonding orthodontic brackets to different ceramic restorations in adult patients [4, 5].

Optimal bracket adhesion to ceramic restoration requires that orthodontic forces be applied without bond failure throughout treatment and also the ceramic integrity is not affected during treatment [6]. Ceramic is an inert material and consequently, there is difficulty on bonding the currently available adhesive resins to ceramic surface [7]. Consequently, ceramic surfaces require pretreatment to accomplish adequate bond strength [8]. Various surface treatments have been applied to the surface of ceramics to improve its bond strength with orthodontic brackets, including airborne-particle abrasion, roughening with diamond burs, etching with hydrofluoric acid or phosphoric acid, and tribochemical silica coating with varying outcomes [1, 4, 5, 7, 9].

A non-destructive, simple, and applicable method for pre-treating ceramic restorations would be clinically beneficial [10]. As the ceramic restorations remain in the mouth after debonding the brackets, damage to ceramic surface because of excessive roughening of the surface throughout pretreatment or debonding should be avoided [1, 11]. It has been reported that hydrofluoric acid enhanced the adhesion of brackets to ceramics [8, 11, 12]. On the other hand, hydrofluoric acid has been found to be harmful and can irritate the soft tissues [1, 13, 14]. Consequently, clinicians should be cautious while using it in the oral cavity [8]. Mechanical roughening with diamond burs and airborne-particle abrasion are reported to provoke crack initiation and propagation within the ceramic [1, 15, 16]. Nevertheless, in order to achieve an adequate bond between the orthodontic brackets and the ceramic restorations, chemical or mechanical roughening is unavoidable [1, 5, 15, 17, 18]. Tribochemical silica coating is another modality to improve the bond strength between orthodontic brackets and ceramic restorations. It is based on creation of micromechanical retention and sites for chemical adhesion [4]. The mechanical retention is formed by airborne-particle abrasion to the surface with 30 µm grain size aluminum trioxide coated with silica particles. The blasting pressure inserts silica particles on the surface, making it chemically more reactive to resin through silane application [8, 19, 20].

Recently, a novel CAD/CAM hybrid ceramic material for indirect restorations has been developed. It is based on a polymer-infiltrated-ceramic network material (PICN) [21]. The hybrid ceramic consists of a dominant ceramic network (86 wt%) which is reinforced by acrylate polymer network (14 wt%) with both networks fully penetrating one another [22]. It was manufactured by introducing a lower elastic modulus polymeric second phase into ceramic networks [23]. Consequently, the hybrid ceramic combines the positive characteristics of ceramics and composites [22].

To date, no study has evaluated the effect of surface treatments on the shear bond strength of ceramic and metal brackets to the novel CAD/CAM hybrid ceramic restorative material. Therefore, the present study aimed to evaluate the effect of four different surface treatments methods on the shear bond strength of ceramic and metal brackets to CAD/CAM hybrid ceramic, and to determine the mode of failure after debonding.

Materials and methods

A power analysis was conducted to determine the sample size needed using a significance level of 0.05 and a power of 0.90. The resulting sample size was 30 specimens per group.

Specimen preparation

Vita Enamic (VE) (Vita Zahnfabrick, Bad Säckingen, Germany) CAD/CAM hybrid ceramic material was used in this study. A total number of 240 plates (10 mm × 10 mm × 3 mm) were cut from VE blocks using a water cooled diamond blade (Diamond Wafering Blade, Buehler, Lake Bluff, IL, USA) with a low-speed cutting saw (Isomet, Buehler). The specimens were stained and glazed according to the manufacturer’s instructions. After that, the specimens were embedded in acrylic resin blocks (Vertex; Vertex-Dental B.V., Zeist, The Netherlands), leaving one surface of the ceramic plate exposed for surface treatments and bonding.

Grouping of specimens

Two types of orthodontic brackets for maxillary central incisors were used in this study, namely Victory Series metal brackets and Clarity ceramic brackets (3 M Unitek, Monrovia, CA, USA). The ceramic specimens were divided into two groups of 120 for each type of orthodontic bracket materials. Each group was further subdivided into four subgroups (n = 30) according to the surface treatment performed onto the ceramic surface as follows: Group 1: hydrofluoric acid (HF); the specimens were etched with HF (Ultradent Porcelain Etch 9 % Buffered, Ultradent Products, South Jordan, UT) for 1 min, then rinsed for 1 min and air-dried, Group 2: 37 % phosphoric acid (H3PO4); the specimens were etched with 37 % H3PO4 gel (Scotchbond Etchant, 3 M ESPE, St Paul, Minn, USA) for 1 min, then rinsed for 1 min and air-dried, Group 3: roughened with a diamond ceramic grinding bur (VOCO, Cuxhaven, Germany) at 6,000–10,000 rpm under water cooling, and Group 4: silica coating using CoJet system (CJ) (3 M ESPE, St. Paul, MN, USA); the specimens were subjected to air-abrasion with 30 µm aluminum trioxide particles coated with silica that was applied for 4 s at a pressure of 2.5 bar with a distance of 10 mm between the nozzle and the surface. The sand particles remnants were gently air blown.

Bonding procedure

After surface treatments, silane and the adhesive primer (Transbond XT; 3 M Unitek, Monrovia, CA, USA) were applied to the treated ceramic surface. The light cure adhesive paste (Transbond XT; 3 M Unitek) was applied to the base of brackets. Then, the brackets were seated on the ceramic surface and a standardized constant pressure of half kg was applied to the top surface of the bracket using a customized metallic tool to obtain a uniform adhesive thickness [24]. The excess paste was carefully removed from the periphery of the bracket base with an explorer. The adhesive paste was cured for a total of 20 s from two directions using a LED light curing unit (Elipar S10, 3 M ESPE, St. Paul, MN, USA; light output: 1200 mW/cm2). The bonded specimens were stored in SAGF medium artificial saliva (NaCl 125.6 mg L−1; KCl 963.9 mg L−1; KSCN 189.2 mg L−1; KH2PO4 654.5 mg L−1; urea 200.0 mg L−1; NaSO4·10H2O 763.2 mg L−1; NH4Cl 178.0 mg L−1; CaCl2.2H2O 227.8 mg L−1; NaHCO3 630.8 mg L−1) for 1 week at 37 °C [25]. After that, the specimens were subjected to thermocycling between 5 and 55 °C for 1000 cycles with a 30 s dwell time prior to shear bond strength testing [4].

Shear bond strength test

The shear bond strength (SBS) test was performed in a universal testing machine (Model TT-B, Instron Corp., Canton, MA, USA) at a crosshead speed of 0.5 mm/min. The shearing wedge was positioned at the bracket base [26–28]. The bond strength in megapascals (MPa) was calculated by dividing the fracture load (F) in Newton by the surface area (A) in mm2 [29]. The mean base surface area of the brackets was calculated by measuring length and width with a digital caliper (Digimatic, Mitutoyo Co., Tokyo, Japan) and computing the area [30]. After debonding, the fractured specimen was examined and the adhesive remnant index (ARI) was determined according to Årtun and Bergland [31]:

- 0:

-

no adhesive left on the ceramic surface

- 1:

-

less than half of the adhesive left on the ceramic surface

- 2:

-

more than half of the adhesive left on the ceramic surface

- 3:

-

all adhesive left on the ceramic surface, with distinct impression of the bracket mesh

The ARI scores were used as a more comprehensive means of defining the sites of bond failure between the ceramic, resin, and bracket base. The ARI scores were assessed with an optical stereomicroscope (Olympus SZX-ILLB100; Olympus Optical, Tokyo, Japan) with 20× magnification.

Scanning electron microscopy evaluation

A total number of 12 specimens from VE CAD/CAM hybrid ceramic plates (10 mm × 10 mm × 3 mm) were prepared and grouped (n = 3) as mentioned before. Then, the specimens were mounted on metallic stubs, sputtered with a gold layer (SPI-Module Sputter Coater, Structure Probe Inc., West Chester, PA), and then examined under a scanning electron microscope (SEM) (JEOL, JSM-6510LV, JEOL Ltd., Tokyo, Japan) at magnification of 1000× to observe the features of the treated surfaces.

Statistical analysis

A statistical analysis (SPSS 15.0; Chicago, IL, USA) of the SBS (MPa) data was analyzed using two-way analysis of variance (ANOVA) and a Tukey HSD test, considering 2 factors (type of bracket and surface treatment) and their interaction. The Chi square (χ 2) test was used to determine if there were any significant differences in the ordinal ARI values. Statistical significance was set at the 0.05 probability level. A Weibull analysis was performed on the bond strength data. The description of the Weibull distribution is given by:

where P f is the failure probability, defined by the relation:

κ is the rank in strength from least to greatest. N denotes the total number of specimens in the group, m is the shape parameter (Weibull modulus), σ is the SBS at a given P f, and σ 0 is characteristic strength. The Weibull modulus, characteristic bond strength, correlation coefficient, and the SBS at 5 and 10 % probability of failure were calculated [4, 32].

Results

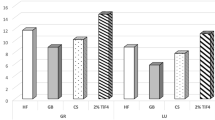

Two-way ANOVA of the SBS (MPa) testing data (type of bracket and type of treatment) revealed that the bond strength was significantly affected by the type of bracket and by type of treatment (P < 0.001). There was no significant interaction between type of bracket and type of treatment (P = 0.112) as presented in Table 1. The mean of the SBS values (MPa) and standard deviations are presented in Table 2. Specimens treated with CJ presented with significantly higher SBS compared to other groups for both types of brackets (P < 0.05). On the other hand, the lowest SBS was with H3PO4 surface treatment for both types of brackets (P < 0.05). In general, improvements in SBS values (MPa) were found in the following order: CJ > HF > Bur > H3PO4 groups as shown in Table 2. For the type of bracket, ceramic bracket showed higher SBS compared to metal bracket in all tested groups (P < 0.05) (Table 2).

The ARI scores for the debonded specimen are given in Table 3. The Chi square test showed that significant differences of ARI scores were present between the type of treatments (χ 2 = 54.356, P < 0.001). The type of bracket did not significantly differ in ARI scores (χ 2 = 2.593, P > 0.05). The ARI results revealed that adhesive failures between the ceramic and composite resin were the predominant mode of failure in all groups (Table 3). Examination of the debonded surfaces showed no damage to the surfaces in any group.

The parameters of the Weibull analysis for each group are presented in Table 4. The Weibull modulus values for ceramic bracket varied with different treatments, showing higher values for CJ (6.89) and HF (6.50) groups, and lower values for H3PO4 (4.96) and bur (5.69) groups. Similarly, for metal bracket, lower Weibull modulus was recorded for H3PO4 (5.22) and bur (5.40) groups than those values of CJ (5.97) and HF (5.53) groups. The cumulative probability of failure plots for the SBS data of the ceramic and metal brackets with the different treatments are shown in Figs. 1, 2, respectively.

Representative SEM images of the treated VE CAD/CAM hybrid ceramic material are presented in Fig. 3. The analysis showed a variation in the surface microstructures of the VE hybrid ceramic with the surface treatments. Specimens treated with HF showed a change in surface texture with formation of numerous irregular and randomly distributed gaps and micropores (Fig. 3a). HF acid treatment appeared to partially dissolve the polymer and glassy phases of VE hybrid ceramic that possibly served for micromechanical bonding. On the other hand, H3PO4 surface treatment showed random surface peeling and erosions on the surface (Fig. 3b). Roughening with bur showed deep grooves with uniform peeling or an erosive appearance with undercuts (Fig. 3c). The surfaces of specimens treated by CJ (silica coating) showed a well define micro-sized elevated and depression areas with crevices and a crater-like appearance. Additionally, white spots appeared on the surfaces which are silica particles (Fig. 3d).

Discussion

The aim of this study was to determine the most reliable surface treatment for bonding ceramic and metal brackets onto recently introduced VE CAD/CAM hybrid ceramic material. The specimens were subjected to thermocycling as a screening procedure for the performance of the bonded interfaces under standardized hydrothermal stresses. SBS test was used in this study to evaluate the bond strength between VE CAD/CAM hybrid ceramic and brackets. Shear testing is the most commonly laboratory method used for assessing the SBS of brackets [26, 33]. SBS test was performed using a standardized protocol as described previously [27, 28]. It has been reported that the optimal bracket bonding force is 6–8 MPa [34]. In the present study, all groups showed bond strength values above 6 MPa and consequently could be considered sufficient for clinical applications. Ceramic brackets have demonstrated higher bond strengths when compared to metallic brackets and this finding is in agreement with the previous studies [35–37]. This result might be in part due to the larger surface area of the ceramic bracket bases which is 14.6 mm2 compared to 11.9 mm2 of the metal bracket [38]. In addition, the ceramic bracket base technology that uses the polycrystalline alumina with a rough base comprised of either randomly oriented sharp crystals or spherical glass particles which provides micromechanical interlocking with the orthodontic adhesive [39].

The application of silica coating on the bonding surface of VE CAD/CAM hybrid ceramic material enhanced the adhesion for both types of brackets compared to the other surface treatments. Silica coating system is based on deposition of alumina particles coated with silica on the substrate surface using chairside airborne-particle abrasion. This treatment changed the VE CAD/CAM hybrid ceramic surface by creating a well defines micro-sized elevated and depression areas with crevices and a crater-like appearance (Fig. 3d). Then, the surface is coated with a silane coupling agent that forms covalent bonds among the alumina and silica particles and the adhesive [40]. It has been reported that this technique enhanced the bond strength between resins and ceramics [41]. This finding is in agreement with previous studies [1, 4, 8, 19]. Moreover, the microstructure of VE CAD/CAM hybrid ceramic consists of a feldspar ceramic network that is fully infiltrated with a polymer network (Fig. 4) [22]. Consequently, it could be anticipated that the methoxy groups of silane bonds chemically with both the SiO2 and the infiltrated polymer components of VE CAD/CAM hybrid ceramic. Also, the methoxy groups of the silane molecules react with the methacrylate groups of resin composite [41], and accordingly, improve the bond strength.

The HF surface treatment modifies the microstructures of VE CAD/CAM hybrid ceramic surface by partial dissolution of the polymer and glassy phases of the ceramic as shown in Fig. 3a. HF acid forms microporosity on the ceramic surface, increases the surface area, and enhances the establishment of mechanical interlocking with the adhesive resin which is sufficient for brackets adhesion [26, 42]. Despite the bond strength achieved with HF acid etching was adequate; some orthodontists might hesitate to use it due to its potential detrimental effects and might prefer a safer alternative conditioning method [8]. In the present study, buffered HF was used as it has been recommended due to its reduced toxicity and hazardous effect [26, 43].

Among the surface treatments tested, acid etching with 37 % H3PO4 that showed significantly lower SBS compared to other surface treatments for both types of brackets. It has been reported that H3PO4 is rather ineffective for enhancing mechanical retention on ceramics when they are used in combination with the resin composite [44]. This finding is in agreement with previous studies [44, 45]. On the other hand, roughening with diamond bur enhanced the bond strength. Surface preparation with diamond bur creates deep grooves and streaks which form macro- and microretentive areas (Fig. 3c) [5, 45].

The results of ARI scores showed that the majority of specimens presented with adhesive failures between the ceramic and composite resin (score 0). This finding reveals that the bond strength between the composite and bracket and the cohesive strength of the composite was higher than the bond strength between the composite and ceramic [4]. The adhesive failures at the ceramic-composite interface are more favorable to avoid ceramic fractures during debonding [4, 46]. There was no damage to the debonded ceramic surfaces in any group. It has been reported that if the bond between ceramic and adhesive resin is higher than 13 MPa, the ceramic will fracture [47]. In this study, only specimens treated with CJ presented with values higher than 13 MPa for both types of brackets; however, no damage was observed to the debonded ceramic surfaces. This finding is significant as damage to ceramic surface could influence the strength and esthetic appearance of the ceramic restoration [9]. Specimens treated with HF, bur, and CJ required further treatment to remove adhesive remnants from the ceramic surfaces. This procedure could probably cause damage to the surface of ceramic restorations [9]. In clinical practice, the prevalence of ceramic damage while debonding the brackets was reported to be very low or not to happen at all, and it did not depend on the formerly used bonding technique [1, 12]. This could be contributed probably to the clinically appropriate and safe debonding techniques with adequate peeling forces which are different from shear testing in the laboratory [44, 48, 49]. Nevertheless, the probability of ceramic fractures cannot be excluded [49, 50]. Consequently, it is unfeasible to anticipate the possibility of VE CAD/CAM hybrid ceramic damage will be higher in clinical situation when the CJ, HF, or bur methods are utilized [1].

Weibull analysis was performed as it relates the survival in clinical trials to data obtained from laboratory tests [28, 51]. This type of analysis does not entail normally distributed samples and focuses on the information relating to the distribution and the lower values that may be more crucial clinically [28, 52, 53]. It has been suggested that the use of bond strength for 5 % chance of failure as an appropriate level for the evaluation of bond strength [54]. It was proposed that the bond strength with a 5 % chance of failure should be at least 5.4 MPa [54]. In the present study, shear bond strength values were higher than 5.4 MPa at the 5 % probability of failure for all groups. This finding suggests that the obtained bond strength was adequate for all groups.

The present study suggests that the use of silica coating as a surface treatment for VE CAD/CAM hybrid ceramic may effectively enhance the bond strength between the ceramic and orthodontic brackets tested. However, other factors found in the oral environment could influence the bond strength of orthodontic brackets to VE CAD/CAM hybrid ceramic such as the presence of proteins, water, minerals, temperature changes, and differences in pH levels [6]. Additionally, only one brand of adhesive resin was tested; the findings related to this product may not be extrapolated to other types of adhesive materials. Furthermore, evaluation of the clinical performance is required to provide reliable recommendations for orthodontists.

Conclusions

Based on the results presented, the following conclusions can be made:

-

1.

Surface treatment of VE CAD/CAM hybrid ceramic with silica coating enhanced the adhesion with ceramic and metal brackets.

-

2.

Ceramic bracket provided higher bond strength compared to metal bracket.

References

Schmage P, Nergiz I, Herrmann W, Özcan M. Influence of various surface-conditioning methods on the bond strength of metal brackets to ceramic surfaces. AM J Orthod Dentofac Orthop. 2003;123:540–6.

Yadav S, Upadhyay M, Borges GA, Roberts WE. Influence of ceramic (feldspathic) surface treatments on the micro-shear bond strength of composite resin. Angl Orthod. 2010;80:577–82.

Siervo S, Pampalone A, Siervo P, Siervo R. Where is the gap? Machinable ceramic systems and conventional laboratory restorations at a glance. Quintessence Int. 1994;25:773–9.

Saraç YS, Külünk T, Elekdağ-Türk S, Saraç D, Türk T. Effects of surface-conditioning methods on shear bond strength of brackets bonded to different all-ceramic materials. Eur J Orthod. 2011;33:667–72.

Türk T, Saraç D, Saraç YS, Elekdağ-Türk S. Effects of surface conditioning on bond strength of metal brackets to all-ceramic surfaces. Eur J Orthod. 2006;28:450–6.

Kukiattrakoon B, Samruajbenjakul B. Shear bond strength of ceramic brackets with various base designs bonded to aluminous and fluorapatite ceramics. Eur J Orthod. 2010;32:87–93.

Abu Alhaija ES, Abu AlReesh IA, AlWahadni AM. Factors affecting the shear bond strength of metal and ceramic brackets bonded to different ceramic surfaces. Eur J Orthod. 2010;32:274–80.

Karan S, Büyükyılmaz T, Toroğlu MS. Orthodontic bonding to several ceramic surfaces: are there acceptable alternatives to conventional methods? Am J Orthod Dentofac Orthop. 2007;132(144):e7–14.

Trakyali G, Malkondu O, Kazazoğlu E, Arun T. Effects of different silanes and acid concentrations on bond strength of brackets to porcelain surfaces. Eur J Orthod. 2009;31:402–6.

Piascik JR, Wolter SD, Stoner BR. Development of a novel surface modification for improved bonding to zirconia. Dent Mater. 2011;27:e99–105.

Gillis I, Redlich M. The effect of different porcelain conditioning techniques on shear bond strength of stainless steel brackets. Am J Orthod Dentofac Orthop. 1998;114:387–92.

Zachrisson YO, Zachrisson BU, Büyükyilmaz T. Surface preparation for orthodontic bonding to porcelain. Am J Orthod Dentofac Orthop. 1996;109:420–30.

Barbosa VLT, Almeida MA, Chevitarese O, Keith O. Direct bonding to porcelain. Am J Orthod Dentofac Orthop. 1995;107:159–64.

Bourke BM, Rock WP. Factors affecting the shear bond strength of orthodontic brackets to porcelain. Br J Orthod. 1999;26:285–90.

Kocadereli I, Canay S, Akça K. Tensile bond strength of ceramic orthodontic brackets bonded to porcelain surfaces. Am J Orthod Dentofac Orthop. 2001;119:617–20.

Peterson IM, Pajares A, Lawn BR, Thompson VP, Rekow ED. Mechanical characterization of dental ceramics by hertzian contacts. J Dent Res. 1998;77:589–602.

Pannes DD, Bailey DK, Thompson JY, Pietz DM. Orthodontic bonding to porcelain: a comparison of bonding systems. J Prosthet Dent. 2003;89:66–9.

Harari D, Shapira-Davis S, Gillis I, Roman I, Redlich M. Tensile bond strength of ceramic brackets bonded to porcelain facets. Am J Orthod Dentofac Orthop. 2003;123:551–4.

Özcan M, Vallittu PK, Peltomäki T, Huysmans MC, Kalk W. Bonding polycarbonate brackets to ceramic: effects of substrate treatment on bond strength. Am J Orthod Dentofac Orthop. 2004;126:220–7.

Matinlinna JP, Vallittu PK. Silane based concepts on bonding resin composite to metals. J Contemp Dent Pract. 2007;8:1–8.

Coldea A, Swain MV, Thiel N. Mechanical properties of polymer-infiltrated-ceramic-network materials. Dent Mater. 2013;29:419–26.

Vita enamic. Vita enamic concept brochure. https://www.vita-zahnfabrik.com/datei.php?src=portal/sap/dateien/c/cc0/Prospekte/10024/10024-Version-3/VITA_10024E_ENAMIC_PS_EN_V03.pdf.

Coldea A, Swain MV, Thiel N. In-vitro strength degradation of dental ceramics and novel PICN material by sharp indentation. J Mech Behav Biomed Mater. 2013;26:34–42.

Al Jabbari YS, Al Taweel SM, Al Rifaiy M, Alqahtani MQ, Koutsoukis T, Zinelis S. Effects of surface treatment and artificial aging on the shear bond strength of orthodontic brackets bonded to four different provisional restorations. Angl Orthod. 2014;84:649–55.

Gal JY, Fovet Y, Adib-Yadzi M. About a synthetic saliva for in vitro studies. Talanta. 2001;53:1103–15.

Falkensammer F, Freudenthaler J, Pseiner B, Bantleon HP. Influence of surface conditioning on ceramic microstructure and bracket adhesion. Eur J Orthod. 2012;34:498–504.

Klocke A, Kahl-Nieke B. Influence of force location in orthodontic shear bond strength testing. Dent Mater. 2005;21:391–6.

Klocke A, Kahl-Nieke B. Influence of cross-head speed in orthodontic bond strength testing. Dent Mater. 2005;21:139–44.

Ishida K, Endo T, Shinkai K, Katoh Y. Shear bond strength of rebonded brackets after removal of adhesives with Er, Cr:YSGG laser. Odontology. 2011;99:129–34.

Cozza P, Martucci L, De Toffol L, Penco SI. Shear bond strength of metal brackets on enamel. Angl Orthod. 2006;76:851–6.

Årtun J, Bergland S. Clinical trials with crystal growth conditioning as an alternative to acid-etch enamel pretreatment. Am J Orthod. 1984;85:333–40.

Ban S, Anusavice KJ. Influence of test method on failure stress of brittle dental materials. J Dent Res. 1990;69:1791–9.

Oilo G. Bond strength testing—what does it mean? Int Dent J. 1993;43:492–8.

Reynolds IR. A review of direct orthodontic bonding. Br J Orthod. 1975;2:171–8.

Harris AM, Joseph VP, Rossouw E. Comparison of shear bond strengths of orthodontic resins to ceramic and metal brackets. J Clin Orthod. 1990;24:725–8.

Joseph VP, Rossouw E. The shear bond strengths of stainless steel and ceramic brackets used with chemically and light-activated composite resins. Am J Orthod Dentofac Orthop. 1990;97:121–5.

Odegaard J, Segner D. Shear bond strength of metal brackets compared with a new ceramic bracket. Am J Orthod Dentofac Orthop. 1988;94:201–6.

Blakey R, Mah J. Effects of surface conditioning on the shear bond strength of orthodontic brackets bonded to temporary polycarbonate crowns. Am J Orthod Dentofac Orthop. 2010;138:72–8.

Eliades T, Lekka M, Eliades G, Brantley WA. Surface characterization of ceramic brackets: a multitechnique approach. Am J Orthod Dentofac Orthop. 1994;105:10–8.

Özcan M. The use of chairside silica coating for different dental applications: a clinical report. J Prosthet Dent. 2002;87:469–72.

Özcan M, Vallittu PK. Effect of surface conditioning methods on the bond strength of luting cement to ceramics. Dent Mater. 2003;19:725–31.

El Zohairy AA, De Gee AJ, Mohsen MM, Feilzer AJ. Microtensile bond strength testing of luting cements to prefabricated CAD/CAM ceramic and composite blocks. Dent Mater. 2003;19:575–83.

Schiettecatte D, Mullie G, Depoorter M. Treatment of hydrofluoric acid burns. Acta Chir Belg. 2003;103:375–8.

Cochran D, O’Keefe KL, Turner DT, Powers JM. Bond strength of orthodontic composite cement to treated porcelain. Am J Orthod Dentofac Orthop. 1997;111:297–300.

Bayram M, Yesilyurt C, Kusgoz A, Ulker M, Nur M. Shear bond strength of orthodontic brackets to aged resin composite surfaces: effect of surface conditioning. Eur J Orthod. 2011;33:174–9.

Smith GA, McInnes-Ledoux P, Ledoux WR, Weinberg R. Orthodontic bonding to porcelain–bond strength and refinishing. Am J Orthod Dentofac Orthop. 1988;94:245–52.

Ozden AN, Akaltan F, Can G. Effect of surface treatments of porcelain on the shear bond strength of applied dual-cured cement. J Prosthet Dent. 1994;72:85–8.

Sinha PK, Nanda RS. The effect of different bonding and debonding techniques on debonding ceramic orthodontic brackets. Am J Orthod Dentofac Orthop. 1997;112:132–7.

Jost-Brinkmann PG, Bohme A. Shear bond strengths attained in vitro with light-cured glass ionomers vs composite adhesives in bonding ceramic brackets to metal or porcelain. J Adhes Dent. 1999;1:243–53.

Winchester L. Direct orthodontic bonding to porcelain: an in vitro study. Br J Orthod. 1991;18:299–308.

Sargison AE, McCabe JF, Gordon PH. An ex vivo study of self-, light-, and dual-cured composites for orthodontic bonding. Br J Orthod. 1995;22:319–23.

Eliades T, Brantley WA. The inappropriateness of conventional orthodontic bond strength assessment protocols. Eur J Orthod. 2000;22:13–23.

Fox NA, McCabe JF, Buckley JG. A critique of bond strength testing in orthodontics. Br J Orthod. 1994;21:33–43.

Littlewood SJ, Mitchell L, Greenwood DC. A randomized controlled trial to investigate brackets bonded with a hydrophilic primer. J Orthod. 2001;28:301–5.

Conflict of interest

The author declares that there is no conflict of interest.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Elsaka, S.E. Influence of surface treatments on bond strength of metal and ceramic brackets to a novel CAD/CAM hybrid ceramic material. Odontology 104, 68–76 (2016). https://doi.org/10.1007/s10266-014-0188-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10266-014-0188-8