Abstract

Objectives

To evaluate the effect of surface treatments and flash-free adhesive on the shear bond strength of ceramic orthodontic brackets bonded to materials used for the fabrication of CAD/CAM provisional crowns.

Materials and methods

Specimens (n = 160) from each provisional material (CAD-Temp and C-Temp) were categorized into four groups according to the surface treatment methods: C (no surface treatment), HP (37% H3PO4), DB (mechanical roughening by diamond bur), and SB (mechanical roughening by blasting). Maxillary central incisor ceramic brackets (Clarity™ Advanced ceramic brackets, 3 M Unitek) were bonded to the conditioned provisional materials according to the used adhesive system (n = 20), APC PLUS or APC flash-free. All specimens were evaluated for shear bond strength testing (SBS) and the adhesive remnant index (ARI). Data were analyzed using Kruskal–Wallis and Mann–Whitney U tests.

Results

C-Temp significantly recorded higher SBS than CAD-Temp (24.0 and 16.0 MPa, respectively) (p < 0.001). DB and SB groups utilizing flash-free adhesive significantly recorded higher SBS (18.2 and 24.0 MPa, respectively) (P < 0.05) compared to other groups in the tested materials. Higher ARI scores were recorded in CAD-Temp and flash-free adhesive.

Conclusions

Mechanical surface treatments and flash-free adhesive would enhance SBS of ceramic orthodontic brackets to CAD/CAM provisional materials. The higher ARI scores reported with CAD-Temp and flash-free adhesive reduce chair time for excess removal.

Clinical relevance

Bonding of orthodontic brackets to provisional restorations is a challenge for orthodontists in adult comprehensive cases that could be improved by an appropriate provisional material, surface treatments, and adhesive system.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Provisional restoration is an important element in fixed prosthodontics, which protects dental surfaces from various oral environmental hazards until delivering the definitive restoration [1]. In addition, it could be used for long-term cases such as oral implantation treatment, periodontal therapy, and orthodontic therapy or in situations involving comprehensive occlusal reconstructions [2]. Consequently, the challenge of effective orthodontic brackets bonding to provisional restorations may encounter orthodontists in adult comprehensive cases [3, 4].

Different types of provisional materials are available in the market. Recently, using CAD/CAM is of a great interest as to fabricate provisional restorations and to improve material properties compared to conventional polymerization [5]. The provisional material type [6,7,8], thermocycling [4, 9], surface treatment [4, 8, 9], and adhesive type [10] are among the aspects that could influence bond strength of orthodontic brackets. A weak bond between orthodontic brackets and provisional restorations will lead to the high failure rate with adverse concerns on the cost and the patient comfort [4, 9]. However, simple and appropriate means for pre-treating provisional restorations would be clinically encouraging to avoid debonding [11, 12].

Two bonding systems are being utilized when directly placing orthodontic brackets, either by manual application or by a pre-coated bracket system in which orthodontic adhesive applied to the bracket base. In both systems, flash removal step is needed to prevent the formation of rough surface and plaque accumulation that could consequently interfere with effective bonding [13, 14]. Thus, 3 M Unitek has developed a novel flash-free adhesive coated appliance system to minimize flash amounts, to improve bond strength, and to reduce the microleakage [15,16,17]. It is composed of a low viscosity resin applied to non-woven polypropylene mesh that attached to the orthodontic bracket base [17]. The bond strength of flash-free adhesive to CAD/CAM provisional material has not been investigated previously. It must be kept in mind that bonding of orthodontic brackets to provisional restorations as well as debonding is a challenge for orthodontists in adult comprehensive cases. Thus, selecting the appropriate adhesive, surface treatments, and provisional material is of prime importance.

Therefore, this study aimed to evaluate the effect of surface treatments and flash-free adhesive on the shear bond strength of ceramic orthodontic brackets to CAD/CAM provisional materials. In addition, the adhesive remnant index (ARI) was evaluated. The null hypotheses tested were (1) the type of surface treatment, (2) the type of CAD/CAM provisional material, and (3) the type of adhesive do not affect shear bond strength.

Materials and methods

Two types of CAD/CAM provisional materials, polyacrylate polymer (CAD-Temp, VITA Zahnfabrik, BadSäckingen, Germany) and fiberglass-reinforced polymer (C-Temp, KaVo, Biberach, Germany), as well as two types of maxillary central incisor pre-coated orthodontic ceramic brackets (APC PLUS and APC flash-free) were used in the study (Table 1). A sample size of 20 specimens in each group was required to give a 0.95 power using 0.05 level of significance according to the conducted power analysis (size effect = 2.34, α-two tailed = 0.05).

Specimen preparation and grouping

One hundred sixty specimens (10 × 10 × 3 mm) were cut from each type of CAD/CAM provisional material with an ISOMET (Techcut4, Allied, USA). Digital caliper (Mitutoyo Corporation, Tokyo, Japan) was used to ensure uniform specimen thickness. Different grit sizes (600–2000 grits) of silicone carbide papers were used to finish the bonded surfaces of specimens under copious water cooling followed by a 3-min ultrasonic cleaning with distilled water. The specimens were embedded in acrylic resin blocks (Paladur, Heraeus-Kulzer, Hanau, Germany) exposing one surface for surface treatment methods and bonding. Specimens were categorized into four groups (n = 40) according to the surface treatment methods performed on the provisional material surfaces: C, no treatment (control); HP, surfaces were etched for 1 min with 37% H3PO4 gel (Scotchbond™ Universal Etchant, 3 M ESPE, St Paul, MN, USA) and then rinsed for 1 min; DB, surfaces were ground using a high-speed handpiece and medium grit abrasive diamond bur (Komet Dental, GmbH& Co, KG, Germany) under water cooling, rotated at 45,000 rpm for 8 s [18]; and SB, surfaces were airborne particle abraded with 50-μm aluminum oxide (LEMAT NT4, Wassermann, Germany) for 10 s at a distance of 10 mm with a pressure of 0.55 MPa and then air-dried for 20 s [4]. Transbond Plus self-etching primer (3 M Unitek) was applied to the treated surfaces according to the manufacturers’ instructions.

Bracket bonding procedure

Maxillary central incisor ceramic brackets (Clarity™ Advanced ceramic brackets, 3 M Unitek) were bonded to the conditioned provisional materials by a single operator according to the used adhesive system (n = 20), APC PLUS or APC flash-free. The adhesive coated ceramic brackets were selected; their blister tab lids were peeled back, lightly placed on the specimens’ surface, and then firmly adjusted to its final position. Half-kilogram customized metallic tool was applied to the bracket top surface as a standardized constant pressure to attain a uniform adhesive thickness. An explorer was used to remove the adhesive resin excess only in APC PLUS adhesive pre-coated bracket group. Ortholux Luminous Curing Light (3 M Unitek; Monrovia, California, USA, light output: 1600 mW/cm2) was used to polymerize all adhesive resin for 12 s from two directions (6 s for each one). To allow complete polymerization of the bonding material, specimens were kept in distilled water at 37 °C for 24 h. Then all the groups were 1000 times thermocycled (SD Mechatronic GmbH, Feldkirchen Westerham, Germany) between 5 and 55 °C with a 30-s dwell time before shear bond strength testing.

Shear bond strength (SBS) test

SBS test was conducted using a universal testing machine (AGS-1000A; Shimadzu CO., Kyoto, Japan). Specimens were fixed in the lower jaw of the machine so that the bonded bracket base was parallel to the shear force direction. Specimens were subjected to a compressive loading at a crosshead speed of 0.5 mm/min [19, 20]. Stainless steel rod with mono-beveled chisel configuration that attached to the upper movable compartment of testing machine was positioned exactly onto the bracket base (Fig. 1) [20, 21]. The shear force at fracture (the force level at which debonding of the specimen occurred) was captured via a 2.5-kN load cell connected to a computer and was displayed by the testing machine in Newton (N). The SBS in megapascals (MPa) was calculated by dividing the fracture load (F) in Newton by the surface area (A) in square millimeter. The bracket bond area was calculated by measuring length and width using digital caliper (Mitutoyo Corporation, Tokyo, Japan) and computing the area [20]. Our approach departed from the provisions of DIN 13,990–1/-2 [22,23,24,25] in that we used 0.5 mm/min crosshead speed and shearing wedge blade instead of 1 mm/min and stainless steel blade with a square-cut aperture of the side length around the bracket exactly onto the bracket base respectively. After debonding, the residual adhesive on provisional restoration surfaces was assessed by examining the fractured specimen using an optical stereomicroscope (Olympus SZ61, Tokyo, Japan) at × 20 magnification. The assessment was determined using the modified ARI as described by Bishara and Trulove [26] and graded on a scale between 1 and 5 (1 all adhesive left on the provisional material surface with a distinct impression of the bracket mesh; 2 more than 90% of adhesive left; 3 more than 10% of the adhesive left but less than 90%; 4 less than 10% of adhesive left; 5 no adhesive left). The ARI scores were used to determine bond failure sites between the provisional materials, adhesive resin, and bracket base.

Scanning electron microscopy evaluation

Three additional representative specimens from each group were produced in the same manner as in SBS test and cleaned with 96% ethanol in an ultrasonic bath for 2 min, and then air-dried. Specimens were mounted on metallic stubs, gold sputter-coated, and then were evaluated under an SEM (Jeol-JSM-6510, Tokyo, Japan) with original magnification × 500 to detect topography of the treated surfaces.

Statistical analysis

The normality and equal of variance assumptions were not fulfilled according to the Shapiro–Wilk test and Levene’s test. Kruskal–Wallis test was conducted to compare SBS data regarding surface treatment groups. Dun’s pairwise tests with corrected p values were used for post-hoc comparisons. The SBS values between the two adhesives as well as the two materials in each surface treatment group were compared by using Mann–Whitney U test. The level of significance was set at 5% for all statistical tests. The Chi-square (χ2) and Monte Carlo test as a correction for Chi-square when more than 25% of cells count less than 5 were used to determine significant differences in the ARI scores at the 5% level of significance.

Additionally, SBS data were entered into a Weibull analysis using MS Excel 2010 to calculate Weibull modulus (m), characteristic bond strength (σ0), correlation coefficient (r), and SBS at 95, 90, and 5% survival probability (Ps) as follows: first, SBS data were ascendingly ordered. Evaluation of the percentage of specimens’ failure was calculated using the median ranks according to the following formula, \({p}_{f}\)(\(i\)) = \((i-0.3)/(N+0.4)\), where \(i\) is the rank order and N is the total number of data points. Modeling the data using Weibull analysis requires adding analysis toolpak add-in into excel. Second, Weibull parameters were obtained using the simple linear regression analysis. Third, from the regression output, the Weibull reliability was performed to illustrate the survival probabilities of each group of various numbers of stress levels. Fourth, the survival probability curves were obtained by entering Weibull parameter data into Wolfram Mathematica 7 program. The Weibull distribution is given by Ps = EXP [-(σ/σ0) m] where Ps is the survival probability at any shear stress, σ is the SBS at a given Ps, σ0 is the characteristic strength, and m is the shape parameter (Weibull modulus). Ps is obtained by the relation, Ps = k / (N + 1), where k is the rank order and N is the group specimen numbers.

Results

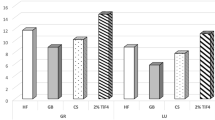

The median, minimum, maximum, and means ± SD of SBS values (MPa) for all groups are presented in Table 2. Kruskal–Wallis test showed significant differences among the four surface treatment groups for CAD-Temp in APC PLUS adhesive (p < 0.001), C-Temp in APC PLUS adhesive (p < 0.001), CAD-Temp in APC flash-free (p < 0.001), and C-Temp in APC flash-free (p < 0.001). Dun’s pairwise tests showed that DB and SB groups recorded significantly higher SBS medians (p < 0.001) compared to other groups (C and HP) for both types of materials either in APC PLUS or in flash-free adhesive. No significant difference (p ˃ 0.05) was detected between C and HP groups either in APC PLUS or flash-free adhesive for both types of materials. The SBS median values were significantly higher ( p < 0.001) in C-Temp in comparison to CAD-Temp in all surface treatment groups as revealed by Mann–Whitney U test. In addition, Mann–Whitney U test revealed that flash-free adhesive showed statistically significant SBS values with CAD-Temp in DB group (p = 0.049) and with C-Temp in SB group ( p < 0.001), in comparison to APC PLUS adhesive (Table 3). Concurrently, the independent variables (material type, surface treatment methods, and adhesive type) were significantly affecting SBS values.

The type of material (χ2 = 28.8, p < 0.001), the surface treatments (Monte Carlo test, p < 0.001), and the type of adhesive (Monte Carlo test, p < 0.001) significantly affect ARI scores (Tables 4 and 5). In a closer look at the data in Tables 4 and 5, C-Temp revealed high incidence of scores 1 and 2 more than CAD-Temp (41.9% and 23.8%, respectively). However, CAD-Temp recorded high incidence of scores 4 and 5 more than C-Temp (48.7% and 34.4%, respectively). Regarding surface treatment methods, DB and SB groups showed higher incidence of scores 1 and 2 (58.7% and 71.3%, respectively) than C and HP groups (0.0% and 1.2%, respectively). However, the highest incidence of scores 1 and 2 in (DB and SB groups) is more pronounced with C-Temp (63.5%) than CAD-Temp (36.5%). In addition, there was a greater incidence of ARI scores 1 and 2 within APC PLUS more than APC flash-free adhesive (37.5% and 28.1%, respectively). Flash-free adhesive also showed a greater incidence of ARI scores 4 and 5 more than APC PLUS adhesive (61.3% and 36.2%).

The Weibull parameters for each group are presented in Table 6. The Weibull modulus values for each material varied with surface treatments and adhesive type, showing higher values for sandblasted group in CAD-Temp and C-Temp. The survival probability plots for different groups are presented in Figs. 2 and 3.

The treated surfaces of CAD-Temp and C-Temp under SEM showed variations in the surface microstructures (Fig. 4). Specimens treated with phosphoric acid showed random surface erosions (Figs. 4b and f). Roughening with a bur showed the uniform erosive appearance with undercuts (Figs. 3c and g). Sandblasted group showed well-defined micro-sized elevated and depressed areas (Figs. 4d and h). The effect of mechanical roughening including bur and blasting was more homogenous, uniform, and well oriented with C-Temp.

Discussion

To be clinically successful, the shear bond strength of the orthodontic brackets to provisional material should be adequately strong to prevent bracket debonding during the treatment. Accordingly, the aims of this study were to evaluate the bond strength of ceramic orthodontic brackets bonded to two different categories of CAD/CAM provisional materials based on the most reliable surface treatment methods and on the adhesive systems for optimal bonding. In addition, adhesive remnant index (ARI) was evaluated.

Surface treatments have been reported to enhance the bond strength of provisional materials [2]. Micromechanical retention can be provided through mechanical roughening with diamond bur and blasting, or acid etching [2, 9, 27]. Although 24-h bond strength of orthodontic brackets is important since debonding can occur soon due to arch wires stresses, there is a definite need to test bonding effectiveness of adhesives under clinically relevant circumstances [28]. While most previous studies have not included thermocycling regimens before testing [29,30,31], other studies performed 500 [21, 23, 24] or 1000 cycles [20, 32, 33] of thermocycling for all specimens to evaluate the SBS of orthodontic brackets to indirect restorations under clinically relevant circumstances. The primary bond strength testing protocol in the present study was tested 24-h after performing 1000 times thermocycling [20, 32, 33]. This was followed based on previous studies (20,32,33). The 1000 times thermocycling was performed for testing the performance of the bonded interface in wet environmental conditions under standardized hydrothermal stresses after 24-h [20]. In addition, studies performed no or limited thermocycling yielded high bond strengths that do not correspond to chair-side experiences and therefore should be evaluated with caution [32].

For standardization, two types of pre-coated ceramic orthodontic brackets were used in this study: one with a novel adhesive system (APC flash-free) that does not need removal of resin flash and one with traditional adhesive (APC plus) that needs flash removal [15,16,17]. Shear testing is considered the most common laboratory method used to evaluate the shear bond strength of brackets [15, 34, 35]. SBS denotes the loading modes rather than the nature of bonding failure stresses. The distribution of stresses at the bonded interface is influenced by the geometry of the loading device (chisel, orthodontic-looped wire, and stainless steel tape systems). It has to be noted that chisel causes severe tensile stress concentration in the load application area than wire loop and stainless steel tape allowed more uniform stress distribution at the bond interface [36, 37]. Stainless steel rod with mono-beveled chisel configuration was the shearing wedge blade used in this study, according to ISO/TR-11405 specified test [21]. This method is preferable at crosshead speeds of 0.5 and 1.00 mm/min, due to its superior sensitivity to subtle differences and the high prevalence of adhesive failures. In addition, this method is practical, faster, and less sensitive to handling during setting.

Although the debonding forces applied in vivo are more likely to be applied to the bracket wings, in this in vitro study, the shearing wedge was positioned exactly onto the bracket base to avoid more rotational stresses [19, 25]. Klocke et. al [19] evaluated the effect of three in vitro debonding force location on the generated stresses in the adhesive layer. They reported that the recorded shear bond strength dropped when the debonding force moved from a position close to the bracket base to the ligature groove. Moreover, an additional decrease in bond strength was found when forces were applied to the bracket wings.

It is worth to be mentioned that, due to the great heterogeneity within various research teams, the DIN-13990–2:2009–05 standard was introduced in 2009, updated in 2017 to the DIN 13,990:2017–04. This standard utilizes a stainless steel blade with a square-cut aperture of the side length that placed around the bracket exactly onto the bracket base to assure correct position and avoiding rotational stresses when applying the debonding force either on the bracket body or wings [25].

Based on Kruskal–Wallis and Mann–Whitney U tests, the three independent variables (material type, surface treatment methods, and type of adhesive) revealed a statically significant effect (p < 0.001, p < 0.001, and p < 0.05, respectively) on the SBS values. Consequently, the three null hypotheses were rejected.

It has been reported that 6–8 MPa is the optimal bracket bond strength [38]. In the present study, mechanically surface roughened groups (DB and SB groups) in both materials showed bond strength values above 8 MPa and subsequently could provide a clinical acceptable application. Mechanical surface treatments provide beneficial mechanical interlocking with pronounced effect for the SB group as they provide small valleys and protruding peaks for additional bonding [4]. Roughening with a diamond bur creates deep grooves with macro- and microretentive areas [39]. In addition, HP group recorded significantly lower SBS compared to DB and SB groups. This could be attributed to the weak nature of phosphoric acid in comparison to diamond bur or to aluminum oxide particle abraded surface treatment methods [40].

Adhesive conditioning without mechanical roughened surface treatment did not give acceptable SBS values in CAD-Temp. This could be attributed to the insufficient residual monomer in the industrially polymerized material to permit co-polymerization with the adhesive [18, 41]. The results of the current study revealed that the C-Temp significantly recorded higher SBS than CAD-Temp in all groups (Table 2). This could be attributed to the high-performance, endless molecular polymer chain plastic, and the higher fiber glass content as shown in Fig. 3e [42, 43]. These results also are in agreement with the Wiegand et al. study [18] that stated the higher SBS with C-Temp could be attributed to the penetration of the adhesive into the surface irregularities, which are created by fiberglass and thus improving retention.

APC flash-free adhesive recorded higher SBS values with mechanical surface-treated groups (Table 2). The mechanical surface treatments have been reported to improve the SBS by increasing the surface energy of the substrate and induce surface irregularities for micromechanical retention [4, 7, 9]. Moreover, the resin utilized in APC flash-free adhesive is unique among orthodontic adhesives. It is a low viscosity adhesive resin and has a surface tension designed to wet and penetrate surface readily and consequently improving wettability and adhesion [17].

The amount of residual adhesive after debonding is an important factor in the selection of orthodontic adhesives and can be assessed with ARI scoring system, both the original (4-point scale) and modified (5-point scale) versions. The modified ARI is one of the most frequently used indices in orthodontic adhesive testing. It is a five-scaled scoring method. A direct comparison between the 4- and 5-point ARI scales could not be made since the number/range of scores is not similar [44]. Within the modified ARI, higher ARI scores (more adhesive left on the brackets) appear to be favorable if chair time has to be reduced, but on the other hand, they can cause restoration fractures as most of the debonding force is acting on the interface between the restoration and adhesive [26]. The lower ARI scores (more adhesive left on the provisional material) ensure few episodes of brackets dislodgement during orthodontic treatment [9]. It has to be mentioned that using higher or lower ARI as an argument is also misleading; therefore, these results should be interpreted with caution. The majority of brackets failures in CAD-Temp material utilizing flash-free adhesive occurred within scores 4 and 5 which reveal adhesive failure between provisional material and adhesive in pre-coated ceramic brackets. The adhesive failures are more favorable to avoid fracture of provisional materials during debonding. These findings are in accordance with the previous studies [15, 16] that showed higher ARI scores with flash-free adhesives. The higher ARI score could be attributed to the slightly compressible non-woven polypropylene fiber positioned on the bracket base to hold back the excess adhesive, which is squeezed out during bracket application [17].

Mechanically surface-treated specimens in C-Temp showed lower ARI scores, which require further handling to remove adhesive remnant from the provisional material surface. During the shear test, in the SB group flash-free adhesive, two brackets of the twenty brackets experienced a partial bracket base fracture, i.e., part of the ceramic bracket remained attached to the C-Temp surface. On the other hand, all ceramic brackets bonded to CAD-Temp were deboned without any bracket fracture. This might be due to higher SBS value related to C-Temp group.

The reliability of the obtained laboratory data for clinical application was confirmed by Weibull analysis as it has been approved as a powerful approach for evaluating fracture behavior based on the distribution of the data rather than on their mean values [45]. Considering the suggested value for clinically minimum bond strength [38] (6–8 MPa), it could be interpreted that shear stress in all C-Temp groups (8.4–19.2 MPa) and mechanically surface-treated groups in CAD-Temp (6.4–11.8 MPa) showed satisfactory stress values at 95% probability of survival. Moreover, survival probability of APC flash-free adhesive is higher than APC PLUS adhesive especially in mechanically surface-treated groups.

The present study suggests that using mechanical surface treatments and flash-free adhesive would enhance the bond strength of ceramic orthodontic brackets to CAD-Temp without liability of fracture during debonding. The recorded SBS is considered sufficient for orthodontic procedures. In addition, the higher ARI scores reduce chair time for excess removal. Regarding C-Temp, it is better not to perform mechanical surface treatments. The untreated surface gives sufficient and acceptable results for orthodontic treatment procedures. Although mechanical surface treatments increased bond strength than CAD-Temp, the liability of fracture during debonding could occur in sandblasted group and the lower ARI scores require more chair time for excess removal.

One of the limitations of this study is the visual inspections of the residual adhesive flash. We tried to assess and quantify the definite mount of adhesive flash remained around the bracket base with × 30 scanning electron microscope, but the adhesive margins could not be envisioned to obtain reliable measurements. Some other limitations do also exist, such as other oral environmental factors that could influence the bond strength; saliva components; and differences in pH levels. Furthermore, clinical performance assessment is required to provide reliable recommendations for orthodontists.

Conclusion

Within the limitations of the methodology, it could be concluded that APC flash-free adhesive would enhance SBS to CAD-Temp than APC PLUS adhesive in mechanical roughening methods. The higher ARI scores reported with CAD-Temp and flash-free adhesive reduce chair time for excess removal. On the other hand, C-Temp gives sufficient and acceptable results for orthodontic treatment procedures without the need for mechanical surface treatments.

References

Patras M, Naka O, Doukoudakis S et al (2012) Management of provisional restorations’ deficiencies: a literature review. J Esthet Restor Dent 24:26–38. https://doi.org/10.1111/j.1708-8240.2011.00467.x

Lodding DW (1997) Long-term esthetic provisional restorations in dentistry. Curr Opin Cosmetic Dent 4:16–21

Proffit WR (2000) Contemporary orthodontics. Adjunctive treatment for adults, 3rd edn. Mosby, Chicago, pp 616–674

Al Jabbari YS, Al Taweel SM, Al Rifaiy M et al (2014) Effect of surface treatment and artificial aging on the shear bond strength of orthodontic brackets bonded to four different provisional restorations. Angle Orthod 84:649–655. https://doi.org/10.2319/090313-649.1

Stawarczyk B, Ender A, Trottmann A et al (2012) Load-bearing capacity of CAD/CAM milled polymeric three-unit fixed dental prostheses: effect of aging regimens. Clin Oral Investig 16:1669–1677. https://doi.org/10.1007/s00784-011-0670-4

Maryanchik I, Brendlinger EJ, Fallis DW et al (2010) Shear bond strength of orthodontic brackets bonded to various esthetic pontic materials. Am J Orthod Dentofacial Orthop 137:684–689. https://doi.org/10.1016/j.ajodo.2008.06.031

Blakey R, Mah J (2010) Effects of surface conditioning on the shear bond strength of orthodontic brackets bonded to temporary polycarbonate crowns. Am J Orthod Dentofacial Orthop 138:72–78. https://doi.org/10.1016/j.ajodo.2008.08.030

Wan Abdul Razak WS, Sherriff M, Bister D et al (2017) Bond strength of stainless steel orthodontic brackets bonded to prefabricated acrylic teeth. J Orthod 44:105–109. https://doi.org/10.1080/14653125.2017.1296636

Chay SH, Wong SL, Mohamed N et al (2007) Effects of surface treatment and aging on the bond strength of orthodontic brackets to provisional materials. Am J Orthod Dentofacial Orthop 132:7–11. https://doi.org/10.1016/j.ajodo.2004.01.024

Rambhia S, Heshmati R, Dhuru V et al (2009) Shear bond strength of orthodontic brackets bonded to provisional crown materials utilizing two different adhesives. Angle Orthod 79:784–789. https://doi.org/10.2319/060908-298.1

De Almeida JX, Depra MB, Marquezan M et al (2013) Effects of surface treatment of provisional crowns on the shear bond strength of brackets. Dental Press J Orthod 18:29–34. https://doi.org/10.1590/s2176-94512013000400006

Viwattanatipa N, Jermwiwatkul W, Chintavalakorn R et al (2010) The effect of different surface preparation techniques on the survival probabilities of orthodontic brackets bonded to nanofill composite resin. J Orthod 37:162–173. https://doi.org/10.1179/14653121043065

Armstrong D, Shen G, Petocz P et al (2007) Excess adhesive flash upon bracket placement. Angle Orthod 77:1101–1108. https://doi.org/10.2319/081506-334.1

Sukontapatipark W, El-Agroudi MA, Selliseth NJ et al (2001) Bacterial colonization associated with fixed orthodontic appliances: a scanning electron microscopy study. Eur J Orthod 23:475–484. https://doi.org/10.1093/ejo/23.5.475

Lee M, Kanavakis G (2016) Comparison of shear bond strength and bonding time of a novel flash-free bonding system. Angle Orthod 86:265–270. https://doi.org/10.2319/011715-37.1

Foersch M, Schuster C, Rahimi RK et al (2016) A new flash-free orthodontic adhesive system: A first clinical and steriomicroscopic study. Angle Orthod 86:260–264. https://doi.org/10.2319/050415-302.1

APC Flash-free (2018) 3M™ APC™ Flash-Free Adhesive. IOP Publishing Physics Web. https://multimedia.3m.com/mws/media/871437O/3m-apc-flash-free-adhesive-a-technical-overview.pdf. Accessed 29 Aug 2020

Wiegand A, Stucki L, Hoffmann R et al (2015) Repairability of CAD/CAM high-density PMMA- and composite-based polymers. Clin Oral Invest 19:2007–2013. https://doi.org/10.1007/s00784-015-1411-x

Klocke A, Kahl-Nieke B (2005) Influence of force location in orthodontic shear bond strength testing. Dent Mater 21:391–396. https://doi.org/10.1016/j.dental.2004.07.004

Elsaka SE (2016) Influence of Surface Treatments on Bond Strength of Metal and Ceramic Brackets to a Novel CAD/CAM Hybrid Ceramic Material. Odontology 104(1):68–76. https://doi.org/10.1007/s10266-014-0188-8

Dental materials - testing of adhesion to tooth structure. 2nd ed. Switzerland: 2003. Technical specification ISO/TS 11405

Richter C, Jost-Brinkmann PG (2015) Shear Bond Strength of Different Adhesives Tested in Accordance with DIN 13990–1/-2 and Using Various Methods of Enamel Conditioning. J Orofac Orthop 76(2):175–187. https://doi.org/10.1007/s00056-014-0281-1

Deutsches Institut für Normung e. V. (2009) DIN 13990–1. Zahnheilkunde— Prüfverfahren für die Scherhaftfestigkeit von Adhäsiven für kieferorthopädische Befestigungselemente—Teil 1: Verbund der Grenzflächen Adhäsiv-Befestigungselement und Adhäsiv-Zahnschmelz. Beuth, Berlin

Deutsches Institut für Normung e. V. (2009) DIN 13990–2. Zahnheilkunde-Prüfverfahren für die Scherhaftfestigkeit von Adhäsiven für kieferorthopädische Befestigungselemente—Teil 2: Gesamtverbund Befestigungselement-Adhäsiv-Zahnschmelz. Beuth, Berlin

Daratsianos N, Schütz B, Reimann S et al (2019) The influence of enamel sandblasting on the shear bond strength and fractography of the bracket-adhesive-enamel complex tested in vitro by the DIN 13990:2017–04 standard. Clin Oral Investig 23(7):2975–2985. https://doi.org/10.1007/s00784-018-2692-7

Bishara SE, Trulove TS (1990) Comparisons of different debonding techniques for ceramic brackets: an in vitro study. Part I. Background and methods. Am J Orthod Dentofacial Orthop 98:145–153. https://doi.org/10.1016/0889-5406(90)70008-z

Peumans M, Hikita K, De Munck J et al (2007) Effects of ceramic surface treatments on the bond strength of an adhesive luting agent to CAD-CAM ceramic. J Dent 35:282–288. https://doi.org/10.1016/j.jdent.2006.09.006

Van Meerbeek B, Peumans M, Poitevin A et al (2010) Relationship Between Bond-Strength Tests and Clinical Outcomes. Dent Mater 26(2):e100–e121. https://doi.org/10.1016/j.dental.2009.11.148

Gillis I, Redlich M (1998) The effect of different porcelain conditioning techniques on shear bond strength of stainless-steel brackets. Am J Orthod Dentofacial Orthop 114:387–392. https://doi.org/10.1016/s0889-5406(98)70183-0

Huang TH, Kao CT (2001) The shear bond strength of composite brackets on porcelain teeth. Eur J Orthod 23:433–439. https://doi.org/10.1093/ejo/23.4.433

Cochran D, O’Keefe KL, Turner DT et al (1997) Bond strength of orthodontic composite cement to treated porcelain. Am J Orthod Dentofacial Orthop 111:297–300. https://doi.org/10.1016/s0889-5406(97)70188-4

Ozcan M, Vallittu PK, Peltomaki T et al (2004) Bonding polycarbonate brackets to ceramic: effects of substrate treatment on bond strength. Am J Orthod Dentofacial Orthop 126:220–227. https://doi.org/10.1016/j.ajodo.2003.06.015

Şinasi Saraç Y, Külünk T, Elekdağ-Türk S et al (2011) Effects of Surface-Conditioning Methods on Shear Bond Strength of Brackets Bonded to Different All-Ceramic Materials. Eur J Orthod 33(6):667–672. https://doi.org/10.1093/ejo/cjq132

Jurubeba JEP, Costa AR, Correr-Sobrinho L et al (2017) (2017) Influence of Thermal Cycles Number on Bond Strength of Metallic Brackets to Ceramic. Braz Dent J 28:206–209. https://doi.org/10.1590/0103-6440201701217

Klocke A, Kahl-Nieke B (2005) Influence of cross-head speed in orthodontic bond strength testing. Dent Mater 21:139–144. https://doi.org/10.1016/j.dental.2004.03.004

Braga RR, Meira JB, Boaro LC et al (2010) Adhesion to tooth structure: a critical review of “macro” test methods. Dent Mater 26(2):e38-49. https://doi.org/10.1016/j.dental.2009.11.150

DeHoff PH, Anusavice KJ, Wang Z (1995) Three-dimensional finite element analysis of the shear bond test. Dent Mater 11(2):126–131. https://doi.org/10.1016/0109-5641(95)80047-6

Reynolds IR (1975) A review of direct orthodontic bonding. Br J Orthod 2:171–178. https://doi.org/10.1080/0301228X.1975.11743666

Bayram M, Yesilyurt C, Kusgoz A et al (2011) Shear bond strength of orthodontic brackets to aged resin composite surfaces: effect of surface conditioning. Eur J Orthod 33:174–182. https://doi.org/10.1093/ejo/cjq048

Lise DP, Van Ende A, De Munk J et al (2017) Microtensile Bond Strength of Composite Cement to Novel CAD/CAM Materials as a Function of Surface Treatment and Aging. Oper Dent 42:73–81. https://doi.org/10.2341/15-263-L

Stawarczyk B, Basler T, Ender A et al (2012) Effect of surface conditioning with airborne-particle abrasion on the tensile strength of polymeric CAD/CAM crowns luted with self-adhesive and conventional resin cements. J Prosthet Dent 107:94–101. https://doi.org/10.1016/S0022-3913(12)60031-6

Everest C-Temp provisional restoration (2016) KaVo Elements for KaVo ARCTICA and KaVo Everest. The foundation for reliable long-term temporary applications: C-Temp. IOP Publishing Physics Web. http://dinamed.by/media/Instrukcii2014/ARCTICA_en_Material.pdf. Accessed 29 Aug 2020

Everest C-Temp provisional restoration (2016) Material processing instructions for KaVo CAM systems. IOP Publishing Physics Web. http://www.scribd.com/document/332436930/Arctica-Engine-Kavo. Accessed 29 Aug 2020

Cehreli SB, Polat-Ozsoy O, Sar C, Cubukcu HE, Cehreli ZC (2012) A comparative study of qualitative and quantitative methods for the assessment of adhesive remnant after bracket debonding. Eur J Orthod 34(2):188–192. https://doi.org/10.1093/ejo/cjq191

Fox NA, Mccabe JF, Buckley JG (1994) A critique of bond strength testing in orthodontics. Br J Orthod 21:33–43. https://doi.org/10.1179/bjo.21.1.33

Acknowledgements

The authors would like to appreciate the great contributions of the 3M Unitek Dental Products (Monrovia, CA, USA), for providing the pre-coated orthodontic ceramic brackets used in this study. Also, the authors would like to appreciate the great effort of professor Mousataf Elsyad for his contributions in doing the statistical analysis in this study. Furthermore, the authors would like to appreciate the great effort of Dr. Eman Mohamed Raffat for her contributions in collecting the data.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Ethics approval

This article does not contain any studies with human participants or animals performed by any of the authors.

Conflict of interest

The authors declare no competing interests.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Soliman, T.A., Ghorab, S. & Baeshen, H. Effect of surface treatments and flash-free adhesive on the shear bond strength of ceramic orthodontic brackets to CAD/CAM provisional materials. Clin Oral Invest 26, 481–492 (2022). https://doi.org/10.1007/s00784-021-04022-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00784-021-04022-3