Abstract

Cellulose – either in solid form or as a highly hydrophilic chemical derivative of cellulose – can serve multiple and synergistic roles in the preparation of absorbent materials to meet the requirements of diverse absorbent products. Progress in the preparation of nanocellulose products, including nanocrystalline cellulose (CNC), nanofibrillated cellulose (NFC), and bacterial cellulose (BC), is opening up new possibilities for the reinforcement of hydrogels. Conventional cellulosic fibers, including kraft pulp fibers (e.g., fluff pulp), mechanically pulped lignocellulosic fibers, and recycled paper fibers can provide a structure to fine-tune the mechanical and drainage properties of products that can include superabsorbent materials. Carboxymethylcellulose (CMC) is an especially strong candidate for preparation of the swellable phase of a hydrogel. The high content of carboxylic acid groups in CMC gives rise to a strong swelling tendency, especially at neutral to alkaline pH values. The uptake of water can be understood based on concepts of osmotic pressure, in addition to any salinity in the fluid that is being absorbed. The swelling can be adjusted by the choice and amount of a cross-linking agent. Notably, some of the needed cross-linking effect can be optionally provided by nanocellulose or conventional cellulosic fibers. Combinations of solid cellulose entities and water-soluble cellulose-based polyelectrolytes can be used to prepare completely bio-based products that offer an alternative to the presently available disposable absorbents, which are based mainly on petroleum-based superabsorbent hydrogels. Chemical and physical aspects of cellulose and its derivatives also help determine what happens during drying of absorbent products; some swelling ability may be lost irreversibly due to highly organized hydrogen bonding and coalescence of the cellulose-based macromolecular chains. Since cellulose can be involved in both the structural and chemical aspects of highly absorbent products, there will be unique mechanistic roles governing water uptake, water holding, and even the environmental impacts of cellulose-based absorbent products.

Access provided by Autonomous University of Puebla. Download reference work entry PDF

Similar content being viewed by others

Keywords

- Hydrogel

- Carboxymethylcellulose (CMC)

- Osmotic swelling

- Cross-linking

- Biodegradable

- Nanofibrillated cellulose (NFC)

- Cellulose nanocrystals (CNCs)

1 Introduction

The goal of this chapter is to review the main mechanisms by which cellulose and its derivatives can participate in highly water-absorbent products. A key challenge lies in the fact that cellulose itself – either in its native form or after conventional isolation methods – is merely absorbent, but not highly or “super”-absorbent. To qualify as a superabsorbent, a material must have the capacity to take up at least 10 g or water per g of solids [1], and the system also should be resistant to squeezing [2]. Articles considered in this review chapter most often report absorption capacities in the range 100–1000 g water per g of superabsorbent polymer. It has been shown that certain chemical derivatives of cellulose, in particular carboxymethylcellulose (CMC), can indeed be used as a main ingredient of superabsorbent hydrogels [3]. Cellulose itself – in the form of fibers, nanofibrillated cellulose (NFC) and cellulose nanocrystals (CNCs) – can potentially be employed as components in highly absorbent hydrogel systems. So, in considering the mechanistic role of “cellulose,” the present chapter takes a broad view, considering everything from native lignocellulosic fibers, to nanocellulose products, to water-soluble polymeric derivatives of cellulose for use in highly absorbent products. The fact that cellulose can fulfil so many different and overlapping roles in absorbent-related technologies attests to the unique nature of this remarkable macromolecule. The wider topic of superabsorbency also has been addressed in earlier review articles [1, 2, 4, 5].

Daunting challenges need to be overcome if the goal is to replace the currently used superabsorbent products with cellulose-based materials. Over 90% of the superabsorbent polymer (SAP) presently in use is based on acrylic-based polymers, i.e., lightly cross-linked sodium polyacrylate hydrogels. This is the major absorbent material in disposable diapers and feminine pads. Because manufacturing costs for such SAPs are presently much lower in comparison to any natural-based superabsorbent materials , it is reasonable to expect that the acrylate-type SAPs will remain dominant in the market for the foreseeable future. On the other hand, polyacrylates are derived from petroleum resources, which eventually will become depleted. Though the transition from a fossil resource-based economy to a sustainable economy has been slow, it is important to pursue steps in that direction. One of the most important contributions that researchers can make toward more rapid implementation of cellulosic materials in disposable absorbent products is to find ways to lower the costs of manufacturing such products as CMC.

2 Why Cellulose

2.1 General Aspects

Cellulose is highly available, relatively low in cost, and, at least in its native state, highly eco-friendly. The amount of cellulose grown annually on the planet through photosynthesis has been estimated to be in the neighborhood of 1017 g [6]. Though much of the total cellulose that grows each year either decays, is burned for fuel, or is used for wood products, the amounts converted into papermaking fibers, chemical-grade cellulose (dissolving pulp), grown as cotton, etc. are still very large. Table 1 provides some estimates of the amounts of cellulose, in various forms, that are produced in the world each year. Note that the amount of “fluff pulp” shown in the table is highly relevant to the focus of this chapter, since fluff pulp is a major component of typical disposable diapers and other highly absorbent products [7, 8].

Another main component of typical disposable diapers, incontinence pads, tampons, and other such product is superabsorbent polymer (SAP) hydrogels. These currently are mainly based on poly(acrylic acid) or copolymers of acrylic acid and acrylamide, which are nonrenewable, petroleum-based products [8, 14]. A hydrogel will be defined here as a hydrophilic polyelectrolyte having a range of cross-linking that allows it to swell in water but not dissolve. The amount of synthetic SAPs used per year is over 1.5 × 1012 g [5, 12]. By comparing this number with other data shown in Table 1, two things become clear. First, the amount of SAP being produced each year is just a tiny fraction of the amount of cellulose that is being isolated each year in various forms. Second, the amount of SAP is larger than the current worldwide production of carboxymethylcellulose, and it is almost of the same magnitude as the world production of dissolving pulp, which has a variety of current uses. It follows that, if it were decided to replace the present SAP output with cellulose products, the present production capacity for dissolving-grade pulps would not be sufficient.

Perhaps to a greater extent than its abundance, one of the primary reasons that researchers have been motivated to consider cellulose as a source for making highly absorbent products is the environmentally friendly nature of the raw material. Since cellulose is produced naturally by photosynthesis, its usage in place of petroleum-based chemicals has the potential to reduce the net production of carbon dioxide [15]. Based on the assumption that the forests from which wood is obtained are replanted and managed in an efficient and sustainable manner, such practices have the potential to minimize the production of greenhouse gases over the long term.

Although biodegradability has been viewed as an inherent advantage of cellulose-based products, compared to petroleum-derived SAP, a critical examination is needed of each case. On the one hand, native sources of cellulose (e.g., wood, cotton, bacterial cellulose , etc.) all are subject to natural decay [16, 17]. Researchers have shown that various cellulose-based sorbent materials are biodegradable [18,19,20,21,22,23,24,25,26,27]. Acrylamide-based or acrylic acid-based materials generally exhibit slow degradation rates [28,29,30,31]. However, under well-managed composting conditions, favorable rates of decomposition acrylic acid-based disposable diapers, including detoxification, have been reported [32, 33].

Rates of biodegradation of polymers, including natural polymers, will be affected by chemical modifications. For instance, carboxymethylcellulose is readily degraded by cellulase enzymes [34]. But other chemical transformations, such as chemical derivatization and cross-linking (see later sections), sometimes have a negative effect on biodegradation [35]. A further difficulty is that SAP-containing products are often buried under conditions where any degradation is either very slow due to lack of oxygen or where decomposition results in the production of methane, which is a highly potent contributor to global warming [16, 17, 28]. There is a continuing need for environmental impact assessments to compare petroleum-based superabsorbent products and similar products based on CMC or other natural-based materials [36, 37]. Future studies will be needed in order to confirm the working hypothesis here that (a) cellulose-based absorbent products are likely to be more biodegradable than currently used SAP materials and (b) the greater biodegradability can have an important ecological advantage either when using state-of-the-art waste disposal practices. Future alternative processes might be based on composting [32, 33, 38, 39] or anaerobic treatments with efficient retrieval of methane [40, 41]. Incineration is often regarded as unattractive due to the high water content of used SAPs [42].

2.2 Chemical Aspects

Two main aspects of cellulose that are likely to be important for the preparation of absorbent products will be considered in this section – the generally hydrophilic nature of cellulosic materials (with attention to the role of –OH groups) and the ionically charged nature of many cellulosic materials, with particular focus on –COO− groups.

As is well known, pure cellulose is a homopolymer of anhydroglucose units that are joined together by β-glycosidic bonds . Each six-carbon glucose unit contains three –OH groups. Native cellulose from wood commonly has degree of polymerization (DP) values in the range of about 3000–5000 [43]. In woody plant materials, cellulose is present in combination with hemicellulose and lignin, of which the hemicellulose generally causes the mixture to be more hydrophilic [44, 45] and the lignin causes the combined material to be more hydrophobic [46]. Cellulosic plant materials also contain relatively small amounts of extractives, most of which contribute to a hydrophobic tendency [47]. The percentages of these components, in typical wood from temperate climates, fall into ranges of about 40–45% cellulose, 25–35% hemicellulose, 20–30% lignin, and 2–5% extractives [48]. Cotton represents a special case of cellulosic material; as a seed hair material, it consists mainly of cellulose, but in nature it has a hydrophobic coating of wax [49].

Processing of cellulosic materials can change their chemical composition greatly. For example, the kraft pulping of wood and other materials such as sugarcane bagasse and bamboo is intended to remove mainly the lignin portion, along with most of the extractives and a portion of the hemicellulose [48, 50]. By contrast, mechanical pulping of wood typically achieves separation of the fibers from each other while maintaining a yield of over 90% of the original solids. Processing of cotton typically entails removal of the natural wax [49].

2.2.1 Hydrophilic –OH Groups

Due to its polar nature and its ability to participate in hydrogen bonding, the –OH group is well known to contribute to the water-loving nature of many organic compounds [51]. The greater electronegative character of the oxygen atom, compared to that of hydrogen, creates a dipole of approximately 1.7–2.5 D [52]. In aqueous solutions, such dipoles contribute to a transient (pico-second duration) lining up of –OH groups belonging to the water, as well as to other compounds [53], and the energy of such interactions contributes to wetting and solubilization of various materials in water. Due to its partly crystalline structure (see later), the cellulose does not dissolve, though it is generally agreed that the polar interactions are favorable for the swelling of cellulosic materials in water [54].

A second way that –OH groups can contribute to hydrophilic character is via hydrogen bonding. The hydrogen atom is unique in nature in having only one electron per atom. When a hydrogen atom is covalently bonded to oxygen, a more electronegative atom, the pair of electrons participating in bonding (or the density of the wave function) tends to spend a disproportionate amount of time or be enriched near to the oxygen [55]. This leaves the hydrogen nucleus (a proton) relatively exposed and available for secondary interactions with the lone pairs of electrons on the oxygen atoms of other water molecules in the neighborhood. The hydrogen bonds thus formed have energies ranging from about 1.4 to 7 kcal/mole [56]. The lifetime of an individual hydrogen bond in the bulk phase of water is about 0.4 × 10−12 s [57]. The ability of hydrogen bonds to very rapidly form and detach from each other, in a continually shifting structure, helps to account for the strong cohesive forces within water, in combination with an ability to flow as a liquid, if not frozen. Figure 1 provides a pictorial representation of an –OH group-rich cellulosic surface with a “snapshot” of possible orientations of water molecules as they participate in transient preferential orientations with the surface groups and as clusters with each other [53].

Though there are three –OH groups for each anhydroglucose unit that comprises cellulose, only a small portion of such groups are typically available for interaction with the surroundings, including water molecules. That is because a large proportion of such groups will be arranged in highly organized patterns of intramolecular and intermolecular hydrogen bonding within the cellulose phase [58]. Typical native celluloses have crystalline contents in a range of about 40–80% [59], and it is clear that –OH groups located in the interior of such regions have essentially no ability to participate in interactions with water molecules [60].

2.2.2 Charged –COO− Groups

Native cellulose, in its raw forms, is of neutral charge in aqueous suspension. However, ionic functional groups attached to cellulose chains can play a large role in the ability of cellulosic materials to swell in water. To begin with, hemicellulose macromolecules of various types either already contain carboxylic acid functionalities or they contain acetate groups that can be easily converted to charged form by hydrolysis reactions [61]. Further amounts of –COO− groups are provided by lignin structures [48] and by various extractives, such as fatty acids and resin acids [47, 48]. Table 2 provides some typical values for the amounts of –COO− groups within native woods, compared to those in a cellulose derivative and polyacrylate.

The energy associated with the interaction of a –COO− group (in its Na+ salt form) with surrounding polar water molecules is approximately 4 kcal/mole [65]. This value may at first suggest that ionic groups will have a large influence on swelling and absorbency properties of cellulosic materials. But that will be true only when the densities of such groups are either naturally high (e.g., due to the presence of hemicellulose) or that there has been chemical derivatization of the cellulosic material. Common cellulosic fiber materials have carboxylic acid contents ranging from just 5 μeq/g in the case of cotton to about 44–66 in the case of bleached hardwood kraft pulps [62]. These are very low values in comparison to SAPs, as shown in Table 2. Thus, for purposes of achieving high absorbency of water, there is a strong motivation to consider chemical derivatization as a means of increasing the charge density and increasing the absorption capacity of native cellulose.

Figure 2 depicts the main reaction for the preparation of carboxymethylcellulose (CMC), usually starting with dissolving pulp (e.g., highly delignified wood pulp) [66]. Commercial grades of CMC are widely available. The degree of substitution (per anhydroglucose unit) can range from about 0.4 to about 2.2 [18, 63, 64]. A DS value of 0.4 is generally high enough to allow solubilization of the polymeric material, as long as the pH is high enough to dissociate the carboxylic acid groups. But it is the relatively high-DS CMC products, with their correspondingly higher swelling tendency and strong solubility in water, which are regarded as promising components of highly absorbent hydrogels [18]. Such hydrogels are often cross-linked by application of gamma radiation [16, 18, 19, 64, 67]. Though highly absorbent materials also can be obtained with other ethers and esters of cellulose, the results generally have not been as favorable as those achieved with CMC [68].

An alternative way to increase the level of carboxylic acid groups at the cellulose surface is by grafting. For example, Gurdag et al. [69] and Margutti et al. [70] carried out pioneering work in the grafting of acrylic acid chains to cellulose. The resulting structures from such reactions show greatly enhanced water-absorbing capabilities.

Another chemical reaction that has important implications for cellulose-based absorbent products is formation of sulfate ionic groups, which are often referred to as sulfate half-esters [71]. As will be described more in Sect. 2.3.4, treatment with concentrated sulfuric acid is widely used for the preparation of cellulose nanocrystals (CNCs) . In addition to liberating the crystals, such treatment yields cellulosic surfaces that are covered with –OSO3− ionic groups. Since sulfuric acid is a strong acid, such groups maintain their negative charge throughout the range of pH values considered by most investigators. Zhang et al. [72] showed that sulfate half-ester groups can be especially effective in increasing the water retention value [73] of bleached kraft fibers.

2.3 Structural Aspects

Absorbency typically involves swelling of an absorbent material, i.e., a change of it dimensions as the liquid enters. It follows that structural aspects of cellulosic materials, including their ability to expand or their tendency to restrain expansion, can affect absorption performance.

Some aspects of cellulose material structure are determined by its chemical composition, while others are related to details of plant growth. Yet others are related to the higher-level organization of cellulose, hemicellulose, and lignin into fibers and larger parts of woody plants. Further structural details depend on how the cellulosic material may have been separated into component fibers (i.e., pulping) or subsequently converted to nanofibrillated or nanocrystalline forms. These structures, if present, may affect properties of the absorbed products, so some aspects will be considered here.

2.3.1 Inherent Structural Tendencies of Cellulose

Cellulose is inherently fibrillar. This characteristic becomes clear if one attempts to prepare spherical cellulose structures at a nanoscale [74]. When cellulose is precipitated from solution, usually by introducing a non-solvent or otherwise changing the conditions of the medium, the precipitated matter is generally in the form of fibers or an extruded filament or sheet composed of fibrillar elements at the nanoscale [75]. This behavior can be attributed, at least in part, to details of cellulose’s molecular structure – which is linear, free of branches, and having –OH groups in a suitable position to form both intra-chain and interchain hydrogen bonds [58]. The intramolecular bonds tend to hold the molecules in a straight-line position. The tendency for linear alignment is reinforced by the action of hydrogen bonding that can develop between adjacent cellulose molecules, especially if the chains are lined up in parallel. The molecular conformation, including the participation of hydrogen bonds in that conformation, has been confirmed by X-ray crystallography [58] as well as by molecular dynamics simulations [76].

During biosynthesis of cellulose, there is evidence that individual cellulose chains are formed from glucose in six-sided rosette-shaped proteinaceous structures in the cell walls of plants [77] and that the extruded chains somehow come together in a parallel, proto-crystalline form [78]. The result, in typical plant materials, is the formation of crystalline zones having widths of about 3–8 nm [79]. In woody plants, these crystalline zones are enmeshed within a matrix of noncrystalline components, mainly consisting of hemicellulose and lignin [48]. In addition, X-ray crystallography consistently indicates that some of the cellulose is also present in either a noncrystalline (amorphous) form or at least having defects in the pattern of crystallinity [79]. For instance, Nishiyama et al. [80] found evidence that sequences of approximately 4–5 anhydroglucose subunits tend to deviate from crystallinity within native cellulose material and that the adjacent parts of the chains are within crystalline zones. It is widely believed that these noncrystalline zones of cellulose have an enhanced tendency to interact with water [60, 81, 82].

At nano-dimensions, the ability of cellulosic materials to swell and accommodate water is generally attributed to either (a) swelling of noncrystalline zones or (b) opening up of spaces between crystalline zones, i.e., a form of partial nanoscale delamination.

2.3.2 Fibers

A typical softwood kraft fiber of the “fluff pulp” type [7] will readily take up about 12 g or water per g of solid matter [1, 5]. Though this value is high enough to meet Kabiri’s [1] criterion of superabsorbency, as given earlier, it is well known that water can be easily squeezed from fluff pulp. To understand why fluff pulp takes up water so readily, it can be useful to consider the layered structure of natural fibers in wood, as illustrated in Fig. 3.

The mechanical ability of kraft fibers to increase their radial dimensions when exposed to aqueous solution can be understood based on the directionality of cellulose macromolecules and microfibrils within the dominant (S2) sublayer of the cell wall [83]. Within that layer, the chains are oriented not far from a parallel alignment (often deviating by 10–15°) from the fiber axis. Since the stiffness and crystalline content of the fibrils prevents them from stretching much in the lengthwise direction, most expansion resulting from immersion in water occurs perpendicular to the fiber length. Within intact wood such swelling is limited by three factors, namely, (a) the presence of a stiff, relatively hydrophobic lignin-rich zone (the middle lamella) that joins the fibers to each other; (b) the presence of an S1 layer, in which the cellulose macromolecules and microfibrils essentially wrap around the fiber circumferences, thus constraining their outward expansion; and (c) the close integration of the cellulose microfibrils with densely packed matrix materials, mainly lignin and hemicellulose. Eriksson et al. [44] showed that selective removal of lignin from solid wood greatly increased the uptake of water. Chemical pulping, employing such reagents as NaOH and Na2S, can effectively remove lignin and a part of the hemicellulose, thus rendering the material porous within a range of about 2–100 nm [84]. The mesoporous nature can be regarded as a first step in enabling subsequent internal delamination and swelling of the fibers.

Delamination and swelling of delignified fibers is further enabled if and when the fibers are subjected to mechanical refining, which is an almost universal practice when preparing the fibers for papermaking. Common refining practices entail passage of a 4–8% solid suspension of fibers between a rotor and stator having raised rectangular “bar” areas, which repeatedly compress and shear bunches of the fibers. Even a relatively short application of refining, especially after delignification, is able to break up and remove both the primary (P) layer and the S1 sublayer, such that the remaining material in the S2 layer is no longer impeded from expanding outward from the fiber axis. The shearing action of refining also tends to open up spaces between fibrils within the S2 layer, causing partial delamination. Concurrently, the fibers become increasingly swollen with water.

At this point in the discussion, a reality check may be helpful. Although an ordinary paper towel can take up about 5–10 times its mass of water [85], this is only a minor fraction of what is expected for modern superabsorbent materials, e.g., an absorbency mass ratio of 100–1000. While kraft fibers may constitute a major component of such products as disposable diapers, it is clear that they do not account for the majority of the absorbency. Fluff pulp fibers, which are about 3 mm long and about 30–50 μm thick, provide three main functions within highly absorbent products: providing a place for the SAP to be contained, serving as channels for the wicking of liquid so that it can reach all the SAP quickly, and providing structure to the highly absorbent garment.

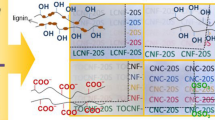

2.3.3 Nanofibrillated Cellulose (NFC)

Very extensive mechanical refining of cellulosic fibers, such as from kraft pulps, cotton, and other plant sources, will eventually yield a highly swollen, gelatinous mass that is mostly water but highly viscous [86, 87]. The solid material within such gelatinous mixtures is highly fibrillated cellulose, in which the individual strands may have diameters in the range of 20–60 nm [88]. Rather than consisting of individual fibrils, most published images of NFC (or microfibrillated cellulose, a term often used when the material has not yet been reduced to nano-dimensions), the material is usually described as a network, or “highly branched,” or a “weblike structure” [88]. Although the term “cellulose nanofibrils” (CNF) is widely used in the literature for the products of such preparations, that term does not appear to be well suited to describing the highly branched and networked structures most often described in the studies that were considered when preparing this chapter. Equipment used for production of NFC includes not only conventional refiners, of the type used by papermakers, but also “micro-grinders,” in which the pulp is passed multiple times through the gap between a rotor and stator with abrasive mineral surfaces [89]. Alternatively, as shown in Fig. 4a, NFC can be produced by multiple passes through a high-pressure homogenizer, where the suspended material is forced through a narrow gap, within which the solids impinge on a hard surface [90]. In another type of device, the microfluidizer, jets of cellulose suspension are made to impinge upon each other, bringing about mutual fibrillation with less wear of the equipment (Fig. 4b) [91]. In a patented approach, highly fibrillated cellulose also can be prepared by co-grinding in the presence of a suspension of calcium carbonate particles [92].

The production of NFC by mechanical action alone requires a high input of energy [88]. For instance, 70,000 kWh may be required to prepare NFC by homogenization [44]. Such a high consumption of energy is not only environmentally unfavorable, but it also tends to reduce the chance that NFC would be employed as a component in future highly absorbent products. To reduce the required energy, several approaches involving chemical treatments have been demonstrated. Selective oxidation with (2,2,6,6-tetramethylpiperidin-1-yl)oxyl (TEMPO) has been shown to be particularly effective in promoting fibrillation of cellulose with much less energy. Such treatment was found to decrease the required mechanical energy to product NFC by as much as a factor of 100 [93]. The much reduced energy of processing of the oxidized pulp has been attributed to the ionic charges of the –COO− groups (especially at pH values above about 4), which promote swelling, fibrillation, and internal delamination. The water retention value of NFC, produced by such treatment, can be in the range 1700% [94]. The oxidation reaction is diagrammed in Fig. 5. As shown, the TEMPO-mediated oxidation selectively forms carboxylic acid groups at the C6 position, while having only a minor effect on the anhydroglucose rings of the macromolecule [93]. Similar effects have been achieved by treatments with periodate/chlorite oxidation [95, 96] and by carboxymethylation [97].

Another promising approach consists of an optimized treatment with cellulase enzyme [98]. Such treatments must be performed with careful attention to concentrations, temperatures, treatment times, etc., since the enzymes preferentially attack noncrystalline and nanoscale fibrillar parts of the cellulose. Thus, excessive treatment can be expected to break down and solubilize the class of material that one is attempting to form. Pääkkö et al. [98] showed that the optimized use of cellulase, in combination of mechanical energy, can make it possible to produce NFC with less energy consumed.

2.3.4 Cellulose Nanocrystals (CNCs)

Digestion of cellulosic material in strong acid, under optimized conditions, gives rise to cellulose nanocrystals, which also can be considered as a component in certain highly absorbent materials. The technology of producing CNC has been reviewed [99, 100]. Briefly stated, the strong acid treatment preferentially hydrolyzes the noncrystalline or defect areas in the material, leaving behind crystals having thickness dimensions in the size range of about 4–70 nm [99, 101]. Though the acid eventually would also hydrolyze the crystals, the rate of hydrolysis is sufficiently slower so that it is possible to isolate suspensions of highly uniform crystals. Cheng et al. [102] reported a water retention value of 3.4–3.5 g/g for a water suspension of CNC.

The lengths of CNCs vary widely, depending on both the source material employed and the conditions of preparation [99, 101]. It is possible to shorten the crystals after their preparation by crushing them in the presence of liquid nitrogen [103]. The longest CNC particles, up to several micrometers, have been reported for tunicate cellulose, obtained from the protective spines of marine animals [99, 101]. Lengths of CNCs obtained from wood (after delignification) are typically in the range 100–250 nm [99].

3 Absorbency Mechanisms

The uptake of aqueous solution by cellulose-based products is affected by the chemical groups and structural factors discussed in the previous two sections. As has been described in more detail elsewhere [5, 104,105,106,107,108,109,110], one can envision there being competition between certain chemical factors tending to solubilize and swell the material and various structural contributions that prevent complete dissolution and may limit the amount of swelling in a specific case. The chemical factors will be considered here first.

3.1 Hydrophilicity

As was mentioned in Sect. 2.2.1, the formation of a hydrogen bond between a water molecule and an available –OH group on a cellulosic surface releases approximately 5 kcal/mole of energy. This implies that the wetting of dry cellulosic material is favored by the ability to form such bonds with water. One of the greatest uncertainties, when trying to estimate the relative importance of hydrogen bond formation as a contributor to the uptake of water by cellulosic materials, is the fact that only a fraction of the –OH groups on cellulose chains may be available to participate in such interactions. In such materials as wood and cotton, roughly 70% of the cellulose may be in crystalline form, and it has been shown that crystalline regions are essentially impenetrable to water molecules [60]. On the other hand, typical plant-derived cellulose is likely to contain hemicellulose (except in the case of certain dissolving pulps and cotton), and the hemicellulose remains amorphous and much more able to interact with water molecules. A search of the literature did not indicate any work to estimate the density of water-to-cellulose hydrogen bonds formed upon the immersion of common cellulosic materials. Thus, this would appear to be an excellent area to proposed future research. In particular, it is reasonable to expect that measures to reduce the crystallinity of cellulose, e.g., by chemical derivatization or ball milling [111], would be expected to increase the amount of water-to-cellulose hydrogen bonds in a given mass of material.

The interaction of a water molecule with an ideal cellulosic surface, creating a monolayer coverage, will be energetically favored by hydrogen bonding, but what about subsequent layers of water? Studies of the energetics of water sorption, at a molecular level, indicate that the adsorption of a first and possibly a second layer of water can involve different amounts of energy, compared to the energy of water association with itself in the bulk of solution [112]. However, such differences tend to become unimportant after about five molecular layers of water [113]. This is a key point if one’s goal is to achieve superabsorbency. Even if the cellulose-based material has been transformed in a way to make every –OH group available for interaction with water (essentially solubilizing the material), the hydrogen bonds subsequently formed with one, two, or even three layers of water molecules surrounding each cellulosic –OH group (including those from hemicellulose, if present) might not be enough to achieve superabsorbent behavior.

3.2 Dissociation

Another large contribution to the energy of interaction between water molecules and a cellulosic surface can come from ionized groups. As noted in Sect. 2.2.2, the energy of solvation of an individual ionic group in water is about 4 kcal/mole. Whether this is enough to make an important contribution depends not only on how many such groups are present, but also on whether or not the groups are in their charged form. As mentioned earlier, although native cellulose is essentially uncharged, there can be up to about 1000–3000 μeq of carboxylic acid groups per gram the hemicellulose component in typical papermaking pulps [114]. This amount will depend on the type of hemicellulose and whether or not acetyl groups have been hydrolyzed during processing to convert them to –COOH or –COO− groups [61]. Salam et al. [115] showed that increased absorbency can be achieved by incorporating additional carboxylate groups into hemicellulose.

Carboxylic acid groups can undergo dissociation reactions of the type shown in Eq. 1. In its protonated form, though the carboxylic acid group is capable of participating in hydrogen bond formation [116], it is uncharged. Reaction with one mole of alkali converts the group to its charged, carboxylate form. In the discussion that immediately follows, it will be tentatively assumed that sufficient base is present that the groups are at least mostly in their charged form.

In order for there to be a sufficient density of ionic groups to meet the requirements of superabsorbent materials, the carboxylic acid content has to be much higher than what is found in natural cellulosic materials. Most research for the development of highly absorbent cellulose-based materials have been based on carboxymethylation [3]. Superabsorbent materials with water uptake ratios in the range 20–800 have been achieved with the use of carboxymethylcellulose (CMC) [18, 19, 63, 64, 67, 68]. Even higher levels of water uptake have been achieved with copolymers of CMC and acrylic acid or related monomers [25, 117,118,119,120,121,122,123,124,125,126,127,128,129]. In such cases, the level of carboxymethylation is typically in the range of 0.64–2.2 substitutions per anhydroglucose unit. Water absorption capacities in the range 40–1400 g/g have been reported with SAPs based on ordinary CMC.

3.3 Osmotic Pressure

Bound ionic charges within a polymeric material, when it is placed in pure water, create an imbalance of ionic charges vs. location. Because the bound charges cannot move away from the polymer segments, the counterions to the bound groups will be constrained to remain nearby, and there will be a higher concentration of ions in the neighborhood of the polymer segments compared to the bulk of solution. To rectify the imbalance, water molecules will spontaneously diffuse into the charged polymeric material, swelling it, thus increasing the average distance between adjacent charges. Since the range of electrostatic effects can extend to several nanometers, especially in relatively pure water, such effects can involve high ratios of water mass to solid mass, leading to high swelling ratios. Related theories have been applied to hydrogels, including cellulose-based materials [104, 109, 130,131,132,133,134].

The contribution of charged groups to the swelling of a charged polymeric material in water can be expressed in terms of an osmotic pressure, as given by Eq. 2 [109].

In the equation, Φ is the osmotic coefficient of the external solution, and ϕ is the corresponding quantity for the gel phase. Likewise, \( \overline{C_i} \) is the concentration of the ith species in the gel phase, and Ci is the corresponding value in the bulk phase. In principle, the material will continue to expand until there is a balance between the osmotic pressure and a restraining pressure, which may be related to the strength of the material or the manner in which it may be attached together. For example, cross-linking of the macromolecular material may limit its ability to stretch past a certain extent. Alternatively, one might model the solid material in terms of mechanical springs, which represent the resistance to swelling. Scallan and Tigerström [135] showed that such reasoning can be used to estimate the elastic modulus of absorbent cellulosic material in its water-swollen state. Other contributions to net swelling of a hydrogel are contributed by the entropy of mixing and hydrogen-bonding effects [3].

4 Factors Affecting Swelling Extent

The extent of swelling and absorption capacity of cellulose-based materials, including cellulosic fibers and various kinds of hydrogels, depends on many factors, some of which involve the nature of the absorbent materials, and others that depend mainly on what is in the aqueous environment. It will be assumed here, for the sake of discussion, that some form of cross-linking usually will provide the main resistance to swelling. As pointed out by Scallan [104], similar reasoning can be applied to other situations, such as when diffusion of a charged polymeric material is constrained by a semipermeable membrane.

4.1 Cross-Link Density

As outlined in an earlier review [3], several different kinds of cross-linking agent have been employed in published studies of cellulose-based hydrogel materials. Typically, when considering cross-links, one is interested in compounds capable of forming pairs of covalent bonds, thus connecting polymeric segments to each other. In addition, it is important to also consider the role of nanocellulose, which has been shown in some studies to produce effects that have similarities to those of cross-linking agents.

4.1.1 Conventional Links

As illustrated in Fig. 6, with increasing density of cross-linking among the polymeric chains of the material, there is less and less distance that the adjacent chains can move away from each other, on average, before they reach their limit. Studies of cellulose-based hydrogels generally have shown strong correlations between cross-link density and absorption capacity [18, 19, 26, 64, 136, 137]. The highest absorption capacities reported tend to be observed at the lowest cross-link densities considered [19]. One needs to be cautious, however, since the lower limit of practical cross-link density may be governed by how much cross-linking is needed to avoid mechanical failure or outright dissolution of the gel material [138]. At the limit of low cross-linking density, the molecular mass of the charged polymer needs to be high, thus ensuring that most of the chains are bound by at least one covalent link to the rest of the material. A higher molecular mass has been shown to lead to higher absorption capacity of cross-linked CMC hydrogels [26].

4.1.2 Cellulose-Based Links

Some studies have shown that inclusion of nanocellulose within hydrogel formulations tends to reduce the uptake of water [2, 139,140,141,142,143]. In such cases, the role of the cellulosic material appears to be similar, in some respects, to that of cross-linking agents. Since no covalent bonding is suspected in most such cases, other explanations must be considered. One such possibility is to regard the nanocellulose as a reinforcement within a kind of composite, where superabsorbent polymer may play the role of matrix. There are many examples in which the presence of fibrillar nanocellulose tends to increase the modulus of elasticity of the continuous phase in cellulosic nanocomposite systems [144]. It also has been proposed that the presence of ordinary cellulose fibers within conventional disposable diapers and related products will tend to limit the swelling due to the fibers’ resistance to tensile expansion [134]. The high aspect ratios of a cellulose nanofibril, as long as it is intimately associated with the swellable material, are assumed to be important relative to the restraint of swelling.

4.2 Aqueous Conditions

Water can be regarded as a uniquely effective medium for absorbing into and swelling up materials that are inherently hydrophilic and subject to the development of bound ionic charges, i.e., the kinds of highly absorbent materials being considered here. One reason why water is such a welcome guest within hydrogel materials is that it has a high dielectric constant, ε, thus making it an excellent solvent and stabilizer for ionic materials. But changes in the ionic composition of aqueous solutions can have very large effects on uptake by cellulose-based hydrogels and other absorbent materials. Three key factors to be considered in this section are pH, salt concentration, and the presence of multivalent cations.

4.2.1 pH

The proportion of charged carboxylic acid groups on cellulosic materials of various kinds is known to be a strong function of pH. The same principles apply to kraft fibers, CMC, and even to poly(acrylic acid). Kraft fibers, especially if they are rich in carboxylic acid groups, exhibit increased swelling as the pH is raised from acidic to neutral values [145, 146]. A similar trend, but with much higher levels of swelling, has been reported for CMC and for copolymers of CMC and acrylic acid [30, 63, 125, 126, 129, 147, 148].

Effects of pH can be understood based on Eq. 1, which can be rearranged as shown in Eq. 3 to define the acid dissociation constant Ka.

The pKa value can be defined by taking the logarithms of the terms in Eq. 3, where [A−] is the concentration of the conjugate base, [H+] is the concentration of the hydronium ion, and [HA] is the concentration of the associated form of the carboxylic acid.

In general, there will be an equal number of charged and uncharged carboxyl groups when the pH is equal to the pKa value, which is approximately 4.4 in the case of CMC [149].

Based on Eq. 4, one might predict that the relative amount of dissociated –COO− groups ought to increase from 1% to 99% within the pH range of one less than pKa to one more than pKa. That would be true if all of the carboxyl groups were equal and noninteracting. But the dissociation of one carboxyl group on a polyelectrolyte chain changes the electrical field in that part of the molecule and tends to discourage the subsequent dissociation of neighboring carboxyl groups [150]. The situation is analogous to the dissociation of citric acid, a compound with three carboxylic acid groups, along with three values of pKa corresponding to the first, second, and third dissociation. The consequence, in the case of a relatively high-charge-density polycarboxylic acid compound such as CMC or polyacrylic acid, is that the charge-pH curve will tend to be spread out over a wider pH range compared to what would be expected for a simple monomeric compound such as acetic acid. On the other hand, once the pH is as high as 7 or higher, most of the carboxyl groups will be in their charged form.

Investigators sometimes claim that their hydrogels are “smart” due to their ability to respond to pH [151]. For instance, hydrogels that contain carboxylic acid groups tend to remain unswollen in the stomach, which is a highly acidic environment, but they become highly swollen (perhaps releasing a medical agent) in the alkaline environment of the intestine [152,153,154,155]. Such behavior is consistent with the dissociation of carboxyl groups when the pH is raised.

4.2.2 Salts

The presence of simple salts such as NaCl tends to limit the range over which electrostatic forces are able to act within aqueous media. The effect can be expressed as Eq. 5, where zi is the valence of ions opposite to that of the charged body of interest, ni is the concentration of that ion, e is the electron charge, ε is the dielectric constant of water, k is the Boltzmann constant, and T is the absolute temperature [156].

The quantity κ−1 is proportional to the distance over which electrostatic forces maintain a given level of influence. It follows from Eq. 5 that osmotic effects, especially those that involve high ratios of water uptake to the mass of absorbent materials, ought to be diminished by the presence of increasing concentrations of salt. Indeed, there is ample evidence of the ability of salts to repress swelling, including such evidence in the case of cellulose-based superabsorbent hydrogels [128, 129, 157]. Many researchers are especially interested in comparing pure water to physiological saline, which is intended to represent typical electrolyte concentrations in human bodily fluids, e.g., the liquid within cells. In that case, various studies have observed an approximately 50% reduction in the amount of water taken up by CMC-based hydrogels with the addition of that amount of salts [3].

4.2.3 Complexation

A much greater repression of swelling can be expected if the aqueous solution contains multivalent cations [25, 125, 131, 151, 159,160,161]. The term “complexation” is often used when describing such interactions due to the fact that two or more carboxylate functions within the absorbent material may approach one multivalent positive ion simultaneously, thus forming a reversible bridge. Even in the case of divalent ions, such as Ca2+, the effect can be strong enough to be able to prepare strongly bonded “wet wipes,” which can be redispersed as fibers only when they become highly diluted with water of much lower Ca2+ content when they are flushed [162]. Even stronger deswelling effects have been reported when adding water-soluble aluminum products [151, 158]. Coagulant mixtures based on aluminum are known to contain ions such as Al3+ and [Al12(OH)24AlO4(H2O)12]7+ [163, 164]. The bottom line is that multivalent positive ion concentrations ought to be low when the goal is to achieve high levels of water uptake.

4.3 Temperature

The temperature can have various effects on water uptake capacities, and in some cases the effects can be dramatic. For instance, hydrogels prepared with poly-(N-isopropylacrylamide) (iPAM) have been reported to abruptly lose 80–90% of their capacity to absorb water when heated over a range of about 20 °C [165, 166]. Such effects have been attributed to changes in the elastic properties of the hydrogels [167]. In the case of typical CMC-based hydrogels, moderate increases in sorption capacity with temperature have been observed [64].

5 Factors Affecting Rates of Uptake

In many applications of superabsorbent hydrogels, one needs to be concerned not only with the amount of water taken up but also the rate of sorption. The topic of absorption rates by highly absorbent materials has been considered by others [110, 129, 168]. Although ordinary SAP materials can have very high capacity to take up water, they sometimes can be very effective for blocking the flow of water. For instance, if a disposable diaper gets flushed by mistake, it can easily swell up and obstruct a drain pipe. Once a mass of SAP has become swollen with water, it has been observed that flow from one side to the other, even when encouraged by pressure, can essentially stop [106]. As implied by the word “gel,” the material behaves as an elastic material, despite its high content of water. Flow through a compressed, water-swollen mass of SAP can be very slow indeed, sometimes making it difficult for the contained liquid to migrate to parts of the products where dry SAP particles may still be present. So one of the big challenges faced by producers of highly absorbent items has been to allow flow to take place readily within a partly wetted mass of superabsorbent material . One solution to this problem is to create some kind of channels within the material.

5.1 Diffusion

Before considering the possible roles of cellulosic materials with respect to flow within a highly absorbent product, this section will consider factors affecting the diffusion of water through a hydrogel. In particular, engineers need to optimize the size and shapes of SAP phases so that water can diffuse all the way to the core within a practical length of time, depending on the application.

The characteristic time required for diffusion to occur over a distance L can be computed by the Stokes-Einstein version of the equation for diffusion [169].

In Eq. 6, τ is the characteristic time for diffusion to take place over a distance L, η is the viscosity of the medium, a is the radius of the diffusing object (modeled as a sphere), kB is the Boltzmann constant, and T is the absolute temperature. Related calculations have been developed to deal with various geometries of interest, such as diffusion into either spherical or cylindrical SAP bodies [109]. Models are set up on the assumption that water needs to diffuse through a swollen layer in order to reach a core of still-dry SAP. In general, such analyses have emphasized that SAP phases ought to be relatively small and interspersed by zones in which bulk flow can take place. Such predictions are consistent with the work of Tanaka and Fillmore [170], who found that the time constant for swelling of poly(acrylic acid) gels was proportional to the square of the final radius of the SAP.

5.2 Channels

5.2.1 Cellulose-Enabled Channels

A primary role of softwood kraft fibers (fluff pulp) in typical highly absorbent products appears to be to provide wicking of liquids throughout the structure [106]. The ability of cellulose fibers to facilitate the wicking of water can be appreciated if one looks with a microscope at highly wettable paper that has been printed with aqueous ink-jet ink. Letters printed on such paper will appear ragged, with “feathered” edges. It has been proposed that a related process occurs when fluff pulp fibers are included in a mixture of SAP particles [106]. In other words, the edges of the fibers are expected to provide relatively unobstructed passage of aqueous fluids so that all of the available SAP, as needed, can participate in the absorption. To enhance the effect, fibers can be designed with a lobe structure, which is claimed to provide especially efficient channeling of water. In summary, whereas before about 1960, cellulosic fibers served as the main absorbent material in diaper materials [8], now, in disposable absorbent products, one of their main roles appears to be to provide wicking.

5.2.2 Other Channels through Hydrogels

Progress also continues to be made with respect to the preparation of acrylic-based SAPs, and researchers have shown that the wicking role of fibers can be replaced by forming channels in a completely different way [171]. Instead of relying on fibers, the SAP itself is formulated with gas addition in a way that preserves a network of channels.

6 Strategies to Promote Absorbency

Increasing the accessibility and placement of functional groups onto cellulosic materials are both primary strategies that have been used to increase the water-sorptive capacity of cellulosic materials. Sometimes these two goals are connected. For instance, high levels of chemical derivatization of cellulose can be instrumental in bringing about solubilization of the macromolecular chain , thus exposing the material to water in a more intimate manner.

6.1 TEMPO-Mediated Oxidation

The option of TEMPO-mediated oxidation merits special mention, relative to water-sorptive properties, since it can be used in combination with mechanical processing to achieve not only a reduction in the need for mechanical energy but also a strong contribution to absorbency [172, 173]. For instance, Brodin et al. [173] showed that TEMPO-mediated oxidation of kraft pulp, as a pretreatment before freeze-drying, resulted in highly porous material having a sorption capacity of 21–65 g/g. Especially in cases where the goal is to achieve high levels of absorbency without reliance on complete solubilization of the cellulose, it has been shown that high levels of water uptake can be obtained by TEMPO-mediated oxidation of nanofibrillated cellulose, followed by freeze-drying [98, 174,175,176].

6.2 Specialized Drying

Once cellulose has been processed to achieve high levels of fibrillation and water retention ability, it often would make sense to be able to store and ship such material in dry form. Unfortunately, such drying ordinarily will tend to irreversibly decrease the water swellability of the material, when it is subsequently placed in water [84, 146, 177]. An irreversible reduction in the ability of the cellulosic material to take up water again, after it has been dried, has been attributed to strong capillary forces, causing the material to be drawn together to molecular distances; at that point a highly regular pattern of hydrogen bonding can take place between the cellulosic surface [178]. To some degree, such effects can be overcome if there is a sufficiently high density of carboxylate groups, in their dissociated form [146]. For example, Butchosa and Zhou [179] showed that treatment of NFC with CMC could help preserve the ability of the nanocellulose to act as a thickener, even after it had been dried. Other promising strategies include the addition of salt before drying [180], though such a strategy can have disadvantages in various potential applications.

Promising results have been achieved in the preparation of highly absorbent aerogels from nanocellulose [181, 182]. Some such compositions have exhibited superabsorbent characteristics [183, 184]. One of the advantages of such materials is that, in principle, one can achieve high absorbency with products that consist mainly of air and cellulose, such that many potential uses can be considered, including food and medical applications.

7 Conclusion

In view of the publications considered in this review chapter, much progress appears to have been made in the development of highly absorbent materials based on carboxymethylcellulose and other forms of cellulose. Ordinary cellulosic fluff pulp fibers, as well as various kinds of nanocellulose, can be used to adjust the properties of such absorbent materials. Factors affecting absorption capacities, as well as rates of wicking, appear to be in line with what is known about the individual components, as well as concepts of absorbency.

8 Future Scope

The subject of cost will be an important area of focus for future research related to cellulose-based highly absorbent products. Because various aspects of cellulose-based superabsorbents have been well demonstrated [3], the fact that such materials have not yet gained an appreciable market share suggests that costs must be unfavorable relative to acrylic-based SAPs. It may be useful in future studies also to consider costs that presently are not fairly distributed in the economy. Such a study could investigate how the relative costs would change if each producer of disposable materials had to arrange for or to directly pay the costs of disposal. Such a study could estimate the impact on costs if bio-based, sustainable technologies were given favorable economic treatment, for instance, through tax policies. Though many readers of this chapter are likely to be more interested in questions concerning chemistry, it will be important to collaborate with researchers attuned to issues of economics, logistics, and ethical issues related to highly absorbent products.

There appears to be a critical need for fresh thinking and research concerning the best way to dispose of used items containing superabsorbent materials. It has been widely assumed, in published articles, that the cellulose-based products, being inherently biodegradable, are therefore ecologically preferable to petroleum-based SAPs and related absorbent products. But the use of disposable diapers, in particular, places challenges on the already heavily burdened system for solids waste collection and disposal. Studies have shown that even quite highly “biodegradable” materials can take a long time to degrade under typical landfilling conditions [185, 186]. When degradation does eventually occur, usually under anaerobic conditions, one has to worry about the efficiency with which the released methane is collected [187]. The ecological implications of such a system needs to be compared against state-of-the art wastewater treatment systems [188], as well as options such as composting [32, 33, 39]. A well-planned and regulated program of manufacture, collection after use, and composting of highly absorbent products made with 100% compostable components appears to be an attractive option that merits further research attention.

References

Kabiri K, Omidian H, Zohuriaan-Mehr MJ, Doroudiani S (2011) Superabsorbent hydrogel composites and nanocomposites: a review. Polym Compos 32(2):277–289

Laftah WA, Hashim S, Ibrahim AN (2011) Polymer hydrogels: a review. Polym-Plast Technol Eng 50(14):1475–1486

Hubbe MA, Ayoub A, Daystar JS, Venditti RA, Pawlak JJ (2013) Enhanced absorbent products incorporating cellulose and its derivatives: a review. Bioresources 8(4):6556–6629

Matushek M (2008) The history of super absorbent chemistry. M2 Polymer Technologies, Inc. http://www.m2polymer.com/html/history_of_superabsorbents.html

Zohuriaan-Mehr MJ, Kabiri K (2008) Superabsorbent polymer materials: a review. Iran Polym J 17(6):451–477

Field CB, Behrenfeld JM, Randerson JT, Falkowski P (1998) Primary production of the biosphere, integrating terrestrial and oceanic components. Science 281(5374):237–240

Parham R, Hergert H (1980) Fluff pulp: a review of its development and current technology. Pulp Pap 54(3):110–115. 121

Buchholz FL, Graham AT (2005) Modern superabsorbent polymer technology. Wiley-VCH, New York

Green Facts. Facts on health and the environment. https://www.greenfacts.org/en/forests/l-2/6-forest-wood-timber-food.htm#1

FAO (2010) Pulp and paper capacities. Survey 2009–2014, ISSN 0255–7665

Smithers PIRA (2015) The future of global fluff pulp to 2020. http://www.smitherspira.com/industry-market-reports/paper/the-future-of-fluff-pulp-to-2020

CISION (2015) Global superabsorbent polymers market drive by top 6 companies at 80% SAP manufacturing capacity. http://www.prnewswire.com/news-releases/global-sap-superabsorbent-polymers-market-driven-by-top-6-companies-at-80-sap-manufacturing-capacity-520573382.html

Nazmi Afshar BA (2014) Chemical profile: CMC. TranTech Consultants. http://chemplan.biz/?AspxAutoDetectCookieSupport=1

Askari F, Nafisi S, Omidian H, Hashemi SA (1993) Synthesis and characterization of acrylic-based superabsorbents. J Appl Polym Sci 50(10):1851–1855

Theis T, Tomkin J. Sustainability: a comprehensive foundation. http://legacy.cnx.org/content/col11325/1.43/

Ress BB, Calvert PP, Pettigrew CA, Barlaz MA (1998) Testing anaerobic biodegradability of polymers in a laboratory scale simulated landfill. Environ Sci Technol 32(6):821–827

Wang XM (2014) Biodegradability of forest products in laboratory- and field-scale municipal solid waste (MSW) landfills. PhD dissertation, North Carolina State University

Fei B, Wach RA, Minomo H, Yoshii F, Kume T (2000) Hydrogel of biodegradable cellulose derivatives. I radiation-induced crosslinking of CMC. J Appl Polym Sci 78(2):278–283

Wach RA, Mitomo H, Yoshii F, Kume T (2001) Hydrogel of biodegradable cellulose derivatives. II effect of some factors on radiation-induced crosslinking of CMC. J Appl Polym Sci 81(12):3030–3037

Lionetto F, Sannino A, Maffezzoli A (2005) Ultrasonic monitoring of the network formation in superabsorbent cellulose based hydrogels. Polymer 46(6):1796–1803

Sahoo PK, Mohapatra R, Sahoo A, DebSarkar N, Swain SK (2005) Characterization, biodegradation, and water absorbency of chemically modified tossa variety jute fiber via pulping and grafting with acrylamide. Int J Polym Anal Charact 10(3–4):153–167

Yoshimura T, Uchikoshi I, Yoshiura Y, Fujioka R (2005) Synthesis and characterization of novel biodegradable superabsorbent hydrogels based on chitin and succinic anhydride. Carbohydr Polym 61(3):322–326

Yoshimura T, Matsuo K, Fujioka R (2006) Novel superabsorbent hydrogels derived from cotton cellulose and succinic anhydride: synthesis and characterization. J Appl Polym Sci 99(6):3251–3256

Wang D, Song ZQ, Shang SB (2008) Characterization and biodegradability of amphoteric superabsorbent polymers. J Appl Polym Sci 107(6):4116–4120

Feng H, Li JA, Wang LJ (2010) Preparation of biodegradable flax shive cellulose-based superabsorbent polymer under microwave irradiation. Bioresources 5(3):1484–1495

Kono H, Fujita S (2012) Biodegradable superabsorbent hydrogels derived from cellulose by esterification crosslinking with 1,2,3,4-butanetetracarboxylic dianhydride. Carbohydr Polym 87(4):2582–2588

Xie LH, Liu MZ, Ni BL, Wang YF (2012) Utilization of wheat straw for the preparation of coated controlled-release fertilizer with the function of water retention. J Agric Food Chem 60(28):6921–6928

Pohland FG, Cross WH, King LW (1993) Codisposal of disposable diapers with shredded municipal refuse in simulated landfills. Water Sci Technol 27(2):209–223

Dutkiewicz JK (2002) Superabsorbent materials from shellfish waste – a review. J Biomed Mater Res 63(3):373–381

Sannino A, Nicolais L (2005) Concurrent effect of microporosity and chemical structure on the equilibrium sorption properties of cellulose-based hydrogels. Polymer 46(13):4676–4685

Wilske B, Bai M, Lindenstruth B, Bach M, Rezaie Z, Frede HG, Breuer L (2014) Biodegradability of a polyacrylate superabsorbent in agricultural soil. Environ Sci Pollut Res 21(16):9453–9460

Colon J, Mestre-Montserrat M, Puig-Ventosa I, Sanchez A (2013) Performance of compostable baby used diapers in the composting process with the organic fraction of municipal solid waste. Waste Manag 33(5):1097–1103

Espinosa-Valdemar RM, Sotelo-Navarro PX, Quecholac-Pina X, Garcia-Rivera MA, Beltran-Villavicencio M, Ojeda-Benitez S, Vazquez-Morillas A (2014) Biological recycling of used baby diapers in a small-scale composting system. Resour Conserv Recycl 87:153–157

Nonaka H, Kobayashi A, Funaoka M (2014) Enzymatic hydrolysis of carboxymethyl cellulose and filter paper by immobilized cellulases on lignophenols. J Wood Chem Technol 34(3):169–177

Glasser WG, McCartney BK, Samaranayake G (1994) Cellulose derivatives with low degree of substitution. 3. The biodegradability of cellulose esters using a simple enzyme assay. Biotechnol Prog 10(2):214–219

Vizcarra AT, Lo KV, Liao PH (1994) A life-cycle inventory of baby diapers subject to Canadian conditions. Environ Toxicol Chem 13(10):1707–1716

Mirabella N, Valentina C, Serenella S (2013) Life cycle assessment of bio-based products: a disposable diaper case study. Int J Life Cycle Assess 18:1036–1047

Hubbe MA, Nazhad M, Sánchez C (2010) Composting as a way to convert cellulosic biomass and organic waste into high-value soil amendments: a review. Bioresources 5(4):2808–2854

Colon J, Ruggieri L, Sanchez A, Gonzalez A, Puig I (2011) Possibilities of composting disposable diapers with municipal solid wastes. Waste Manag Res 29(3):249–259

Torrijos M, Sousbie P, Rouez M, Lemunier M, Lessard Y, Galtier L, Simao A, Steyer JP (2014) Treatment of the biodegradable fraction of used disposable diapers by co-digestion with waste activated sludge. Waste Manag 34(3):669–675

Sotelo-Navarro PX, Poggi-Varaldo HM, Turpin-Marion SJ, Vazquez-Morillas A, Beltran-Villavicencio M, Espinosa-Valdemar RM (2017) Biohydrogen production from used diapers: evaluation of effect of temperature and substrate conditioning. Waste Manag Res 35(3):267–275

Yeh Y-C, Ogawa M, Ogai H, Sakiyama K (2006) Model development of disposable diapers disposal process. SICE-ICASE International Joint Conference, Busan

Hallac BB, Ragauskas AJ (2011) Analyzing cellulose degree of polymerization and its relevancy to cellulosic ethanol. Biofuels Bioprod Biorefin 5(2):215–225

Eriksson I, Haglind I, Lidbrandt O, Salmén L (1991) Fiber swelling favoured by lignin softening. Wood Sci Technol 25:135–144

Hubbe MA, Gardner DJ, Shen W (2015) Contact angles and wettability of cellulosic surfaces: a review of proposed mechanisms and test strategies. Bioresources 10(4):8657–8749

Obataya E, Shibutani S, Minato K (2007) Swelling of acetylated wood II: effects of delignification on solvent adsorption of acetylated wood. J Wood Sci 53(5):408–411

Back EL, Allen L (2000) Pitch control, wood resin and deresination. TAPPI Press, Atlanta, p 392

Alén R (2000) Chap. 1: Structure and chemical composition of wood. In: Stenius P (ed) Forest products chemistry, Papermaking science and technology series. Fapet Oy, Jyväskyl, pp 12–57

Wakelyn PJ, Bertoniere NR, French AD, Thibodeaux DP, Triplett BA, Rousselle M-A, Goynes WR, Edwards JV, Hunter L, McAlister DD, Gamble GR (2007) Cotton fiber chemistry and technology. CRC Press, Boca Raton

Biermann CJ (1996) Handbook of pulping and papermaking. Academic Press, Elsevier, San Diego

Hansen CM (2007) Hansen solubility parameters: a user’s handbook, 2nd edn. CRC Press, Boca Raton

Handgraaf J-W, van Erp TS, Meijer EJ (2003) Ab initio molecular dynamic study of liquid methanol. Chem Phys Lett 367(5–6):617–624

Drost-Hansen W (1969) Structure of water near solid interfaces. Ind Eng Chem 61(11):10–47

Berthold J, Rinaudo M, Salmen L (1996) Association of water to polar groups; estimations by an adsorption model for ligno-cellulosic materials. Colloids Surf A Physicochem Eng Asp 112(2–3):117–129

Yang ZZ, Wu Y, Zhao DX (2004) Atom-bond electronegativity equalization method fused into molecular mechanics. I a seven-site fluctuating charge and flexible body water potential function for water clusters. J Chem Phys 120(6):2541–2557

Poletto M, Zattera AJ, Santana RMC (2012) Structural differences between wood species: evidence from chemical composition, FTIR spectroscopy, and thermogravimetric analysis. J Appl Polym Sci 126(S1):E337–E343

Luzar A, Chandler D (1996) Hydrogen-bond kinetics in liquid water. Nature 379(6560):55–57

Nishiyama Y, Langan P, Chanzy H (2002) Crystal structure and hydrogen-bonding system in cellulose 1 beta from synchrotron X-ray and neutron fiber diffraction. J Am Chem Soc 124(31):9074–9082

Ahvenainen P, Kontro I, Svedstrom K (2016) Comparison of sample crystallinity determination methods by X-ray diffraction for challenging cellulose I materials. Cellulose 23(2):1073–1086

Bergenstrahle M, Wohlert J, Larsson PT, Mazeau K, Berglund LA (2008) Dynamics of cellulose-water interfaces: NMR spin-lattice relaxation times calculated from atomistic computer simulations. J Phys Chem B 112(9):2590–2595

Alén R (2000) Chap. 2: Basic chemistry of wood delignification. In: Stenius P (ed) Forest products chemistry, Papermaking science and technology series. Fapet Oy, Jyväskyl, pp 59–104

Herrington TM, Petzold JC (1992) An investigation into the nature of charge on the surface of papermaking woodpulps. 2. Analysis of potentiometric titration data. Colloids Surf 64:109–118

Barbucci R, Magnani A, Consumi M (2000) Swelling behavior of carboxymethyl cellulose hydrogels in relation to cross-linking, pH, and charge density. Macromolecules 33(20):7475–7480

Liu P, Peng J, Li J, Wu J (2005) Radiation crosslinking of CMC-Na at low dose and its application as substitute for hydrogel. Radiat Phys Chem 72(5):635–638

Chawla B, Ahluwalia JC (1975) Enthalpies and heat-capacities of dissolution of some sodium carboxylates in water and hydrophobic hydration. J Solut Chem 4(5):383–389

Sixta H, Iakovlev M, Testova L, Roselli A, Hummel M, Borrega M, van Heiningen A, Froschauer C, Schottenberger H (2013) Novel concepts of dissolving pulp production. Cellulose 20(4):1547–1561

Liu P, Zhai M, Li J, Peng J, Wu J (2002) Radiation preparation and swelling behavior of sodium carboxymethylcellulose hydrogels. Radiat Phys Chem 63(3–6):525–528

Bao Y, Ma JZ, Sun YG (2012) Swelling behaviors of organic/inorganic composites based on various cellulose derivatives and inorganic particles. Carbohydr Polym 88(2):589–595

Gurdag G, Guclu G, Ozgumus S (2001) Graft copolymerization of acrylic acid onto cellulose: effects of pretreatments and crosslinking agent. J Appl Polym Sci 80(12):2267–2272

Margutti S, Vicini S, Proietti N, Capitani D, Conio G, Pedemonte E, Segre AL (2002) Physical-chemical characterization of acrylic polymers grafted on cellulose. Polymer 43(23):6183–6194

Beck S, Bouchard J (2014) Auto-catalyzed acidic desulfation of cellulose nanocrystals. Nord Pulp Pap Res J 29(1):6–14

Zhang J, Jiang N, Dang Z, Elder TJ, Ragauskas AJ (2008) Oxidation and sulfonation of cellulosics. Cellulose 15(3):489–496

TAPPI (1981) Water retention value (WRV), useful test method. UM 256. TAPPI Press, Atlanta

Brandes R, Carminatti C, Mikowski A, Al-Qureshi H, Recouvreux D (2017) A mini-review on the progress of spherical bacterial cellulose production. J Nanopart Res 45:142–154

Lenz J, Schurz J (1990) Fibrillar structure and deformation-behavior of regenerated cellulose fibers 1 methods of investigation and crystallite dimensions. Cellul Chem Technol 24(1):3–27

Witter R, Sternberg U, Hesse S, Kondo T, Koch FT, Ulrich AS (2006) C-13 chemical shift constrained crystal structure refinement of cellulose I-alpha and its verification by NMR anisotropy experiments. Macromolecules 39(18):6125–6132

Sethaphong L, Haigler CH, Kubicki JD, Zimmer J, Bonetta D, DeBolt S, Yingling YG (2013) Tertiary model of a plant cellulose synthase. Proc Nat Acad Sci USA 110(18):7512–7517

Guerriero G, Fugelstad J, Bulone V (2010) What do we really know about cellulose biosynthesis in higher plants? J Integr Plant Biol 52(2):161–175

Ioelovich M (2008) Cellulose as a nanostructured polymer: a short review. Bioresources 3(4):1403–1418

Nishiyama Y, Kim UJ, Kim DY, Katsumata KS, May RP, Langan P (2003) Periodic disorder along ramie cellulose microfibrils. Biomacromolecules 4(4):1013–1017

Heiner AP, Kuutti L, Teleman O (1998) Comparison of the interface between water and four surfaces of native crystalline cellulose by molecular dynamics simulations. Carbohydr Res 306(1–2):205–220

Kocherbitov V, Ulvenlund S, Kober M, Jarring K, Arnebrant T (2008) Hydration of microcrystalline cellulose and milled cellulose studied by sorption calorimetry. J Phys Chem B 112(12):3728–3734

Barnett JR, Bonham VA (2004) Cellulose microfibril angle in the cell wall of wood fibres. Biol Rev 79(2):461–472

Stone J, Scallan A (1966) Influence of drying on the pore structures of the cell wall. In: Bolam F (ed) Consolidation of the paper web. Transactions of the symposium held at Cambridge, September 1965, vol 1. Technical Section British Paper & Board Makers’ Association, London, pp 145–174

Beuther PD, Veith MW, Zwick KJ (2010) Characterization of absorbent flow rate in towel and tissue. J Eng Fibers Fabr 5(2):1–7

Naderi A, Lindstrom T (2016) A comparative study of the rheological properties of three different nanofibrillated cellulose systems. Nord Pulp Pap Res J 31(3):354–363

Nechyporchuk O, Belgacem MN, Pignon F (2016) Current progress in rheology of cellulose nanofibril suspensions. Biomacromolecules 17(7):2311–2320

Lavoine N, Desloges I, Dufresne A, Bras J (2012) Microfibrillated cellulose – its barrier properties and applications in cellulosic materials: a review. Carbohydr Polym 90(2):735–764

Nair SS, Zhu JY, Deng YL, Ragauskas AJ (2014) Characterization of cellulose nanofibrillation by micro grinding. J Nanopart Res 16(4):article 2349

Lee SY, Chun SJ, Kang IA, Park JY (2009) Preparation of cellulose nanofibrils by high-pressure homogenizer and cellulose-based composite films. J Ind Eng Chem 15(1):50–55

Naderi A, Lindstrom T, Sundstrom J, Pettersson T, Flodberg G, Erlandsson J (2015) Microfluidized carboxymethyl cellulose modified pulp: a nanofibrillated cellulose system with some attractive properties. Cellulose 22(2):1159–1173

Husband JC, Svending P, Skuse DR, Motsi T, Likitalo M, Coles A (2011) Paper filler method. US Patent 8,231,764

Isogai A, Saito T, Fukuzumi H (2011) TEMPO-oxidized cellulose nanofibers. Nanoscale 3(1):71–85

Alcala M, Gonzalez I, Boufi S, Vilaseca F, Mutje P (2013) All-cellulose composites from unbleached hardwood Kraft pulp reinforced with nanofibrillated cellulose. Cellulose 20(6):2909–2921

Kim U, Kuga S (2002) Functionalization of cellulose by periodate oxidation. Cell Commun 56(1):7–10

Liimatainen H, Visanko M, Sirvio JA, Hormi OEO, Niinimaki J (2012) Enhancement of the nanofibrillation of wood cellulose through sequential periodate-chlorite oxidation. Biomacromolecules 13(5):1592–1597

Naderi A, Lindstrom T, Sundstrom J (2015) Repeated homogenization, a route for decreasing the energy consumption in the manufacturing process of carboxymethylated nanofibrillated cellulose? Cellulose 22(2):1147–1157

Pääkkö M, Vapaavuori J, Silvennoinen R, Kosonen H, Ankerfors M, Lindström T, Berglund LA, Ikkala O (2008) Long and entangled native cellulose I nanofibers allow flexible aerogels and hierarchically porous templates for functionalities. Soft Matter 4:2492–2499

Brinchi L, Cotana F, Fortunati E, Kenny JM (2013) Production of nanocrystalline cellulose from lignocellulosic biomass: technology and applications. Carbohydr Polym 94(1):154–169

Habibi Y (2014) Key advances in the chemical modification of nanocelluloses. Chem Soc Rev 43:1519–1542

Eichhorn SH (2011) Cellulose nanowhiskers: promising materials for advanced applications. Soft Matter 7:303–315

Cheng QZ, Wang JX, McNeel JF, Jacobson PM (2010) Water retention value measurements of cellulosic materials using a centrifuge technique. Bioresources 5(3):1945–1954

Lenze CJ, Peksa CA, Sun WM, Hoeger IC, Salas C, Hubbe MA (2016) Intact and broken cellulose nanocrystals as model nanoparticles to promote dewatering and fine-particle retention during papermaking. Cellulose 23(6):3951–3962

Scallan AM (1983) The effect of acid groups on the swelling of pulps: a review. TAPPI J 66(11):73–75

Brannon-Peppas L, Peppas NA (1990) The equilibrium swelling behavior of porous and non-porous hydrogels. In: Brannon-Peppas L, Harland RS (eds) Absorbent polymer technology, Studies in polymer science series 8. Elsevier, Amsterdam

Schuchardt DR, Berg JC (1991) Liquid transport in composite cellulose-superabsorbent fiber networks. Wood Fiber Sci 23(3):342–357

Wiryana S, Berg JC (1991) The transport of water in wet-formed networks of cellulose fibers and powdered superabsorbent. Wood Fiber Sci 23(3):457–464

Kazanskii KS, Dubrovskii SA (1992) Chemistry and physics of agricultural hydrogels. Adv Polym Sci 104:97–133

Ganji F, Vasheghani-Farahani S, Vasheghani-Farahani E (2010) Theoretical description of hydrogel swelling: a review. Iran Polym J 19(5):375–398

Zohuriaan-Mehr MJ, Omidian H, Doroudiani S, Kabiri K (2010) Advances in non-hygienic applications of superabsorbent hydrogel materials. J Mater Sci 45(21):5711–5735

Zhao HB, Kwak JH, Wang Y, Franz JA, White JM, Holladay JE (2006) Effects of crystallinity on dilute acid hydrolysis of cellulose by cellulose ball-milling study. Energy Fuel 20(2):807–811

Park S, Venditti RA, Jameel H, Pawlak JJ (2006) Hard to remove water in cellulose fibers characterized by high resolution thermogravimetric analysis – methods development. Cellulose 13(1):23–30

Heiner AP, Teleman O (1997) Interface between monoclinic crystalline cellulose and water: breakdown of the odd/even duplicity. Langmuir 13(3):511–518

Hubbe MA, Sundberg A, Mocchiutti P, Ni Y, Pelton R (2012) Dissolved and colloidal substances (DCS) and the charge demand of papermaking process waters and suspensions: a review. Bioresources 7(4):6109–6193

Salam A, Pawlak JJ, Venditti RA, El-tahlawy K (2011a) Incorporation of carboxyl groups into xylan for improved absorbency. Cellulose 18(4):1033–1041

Gavezzotti A (2008) Hydrogen bond strength and bond geometry in cyclic dimers of crystalline carboxylic acids. Acta Crystallogr Sec B Struct Sci 64:401–403

Pourjavadi A, Mahdavinia GR (2005) Superabsorbency and swelling behaviour of partially hydrolyzed carboxymethylcellulose-g-PAAm hydrogels. J Polym Mater 22(3):235–243

Pourjavadi A, Ghasemzadeh H (2006) CMC-g-poly (sodium acrylate)/kaolin superabsorbent hydrogel composites: synthesis, characterization and swelling behavior. Polym Polym Compos 14(7):701–712

Abd El-Mohdy HL (2007) Water sorption behavior of CMC/PAM hydrogels prepared by gamma-irradiation and release of potassium nitrate as agrochemical. React Funct Polym 67:1094–1102

Ibrahim SM, El Salmawi KM, Zahran AH (2007) Synthesis of crosslinked superabsorbent carboxymethyl cellulose/acrylamide hydrogels through electron-beam irradiation. J Appl Polym Sci 104(3):2003–2008

Pourjavadi A, Zohuriaan-Mehr MJ, Ghasernpoori SN, Hossienzadeh H (2007) Modified CMC. V. Synthesis and super-swelling behavior of hydrolyzed CMC-g-PAN hydrogel. J Appl Polym Sci 103(2):877–883