Abstract

The current study aimed to achieve the enhanced phytase production from Aspergillus niger NT7 using the statistical method in solid-state fermentation to diminish their cost significantly for commercial purposes. The six different variables — the substrate’s amount, temperature, incubation time, pH, the concentration of mannitol, and ammonium sulfate — identified as critical parameters from the one variable at a time (OVAT) approach, were further modeled and optimized in solid-state fermentation using response surface methodology (RSM). Increased phytase production (521 ± 28.16 Ugds−1) by RSM was attained with 5-g wheat bran supplemented with 2% mannitol, 0.5% ammonium sulfate, and pH 4.3 at 35 °C after five days of fermentation. The phytase production was enhanced by 6.8- and 2.5-fold after statistical optimization compared to unoptimized culture conditions and OVAT methodology, respectively. Further, dephytinization of maize bran using crude phytase preparation resulted in ameliorated nutritional status with the release of phosphorous, reducing sugars, proteins, and minerals (Mn, Fe, Mg, Zn, and Ca). To the best of our knowledge, this is the first report showing the nutritional enhancement of maize bran and the analysis of released minerals by ICP-MS using crude enzyme preparation. The current study successfully demonstrates the potential application of A. niger NT7 phytase for mitigating the antinutrient nature of phytate molecules in feed supplementation.

Graphical abstract

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

Microbial phytases (EC 3.1.3.8) are promising effective candidates for removing antinutrients from plant-based foodstuffs due to their natural function of hydrolyzing the phospho-monoester bonds present in the phytic acid [1,2,3,4]. As a result, the market for feed and food enzymes is growing at a rate of 6 − 8% each year [5].

Microbial sources for phytase production are much more desirable than other plant sources as they are more thermostable, protease resistant, and have broad pH tolerance. This proved to be the boom of the food industry [4, 6, 7]. However, the global demand for phytase is not met due to its higher operational and production costs. Solid-state fermentation (SSF)’s simple operational and economic nature favors phytase production over submerged fermentation (SmF) [8, 9]. Among different fungi, Aspergillus spp. are the predominant producers of phytase with GRAS (generally recognized as safe) status with the potential application in the animal feed industry [10,11,12,13,14,15,16,17]. The laborious steps and time-consuming features are associated with the OVAT (one variable at a time). Statistical-based modeling and optimization is the ideal approach for enhanced yields with the design of experiment (DOE), model development, and analysis skills [18, 19].

Moreover, the statistical approach includes implementing mathematical and statistical models for significant experimental validation of parameters selected for optimization studies. Response surface methodology (RSM) has been successfully employed for the multivariate optimizations of different biological processes towards enhanced yields [19, 20]. Multiple factors for optimization and interaction between them could be studied simultaneously by 2-D and 3-D contour plots with less time consumption [18, 19]. Previous studies also reported that the statistical approach resulted in an augmentation in extracellular phytase production using SSF methodology [13, 15, 21, 22]. RSM resulted in a 2.07-fold enhanced phytase production by Sporotrichum thermophile [22], 3.08-fold by Aspergillus niger National Collection of Industrial Microorganisms (NCIM) 563 [23], 10.83-fold by Thermomyces lanuginosus [24], and 11.6-fold enhanced production by Sporotrichum thermophile [25].

Plant-based food materials, mainly pulses and flour, are rich protein sources in a vegan diet rich in essential amino acids [2]. The major limitation in plant-based food formulation is the presence of antinutrient factors (ANF), majorly in the form of phytic acid, oxalates, polyphenols, saponins, and enzyme inhibitors [26]. The phytic acid, either as free form or as in complex form with salts, metal ions (Fe2+, Zn2+, and Ca2+), carbohydrates, tannins, and digestive enzymes, proved to be arduous for the digestive system of monogastric animals due to deprivation of phytic acid degrading enzymes [27]. ANF present in food is one of the major underlying causes of malnutrition in children and anemia in women in developing countries [28]. ANF contents can be removed by conventional methods, such as germination, fermentation, and soaking, but not to a reasonable extent. Phytase formulation is extensively used in the feed and food industries to remove the phytic acid content and ameliorate the nutritional content of feed and food [3, 16]. Phosphorus is added to poultry and aquaculture animals’ diets to meet their nutritional needs, adding additional cost constraints to the livestock industry. Undigested phosphorous is released into the environment as such through their excreta, which leads to environmental pollution. The phytase application in the feed enhances overall nutritional contents (phosphorous content, metal ions, total proteins, and carbohydrates) and reduces pollution [29, 30].

The present study aimed to enhance the extracellular phytase production from A. niger NT7 in SSF using wheat bran through a statistical approach. Phytase enzyme could be used as a crude form for feed supplementation due to the GRAS status of microorganisms. In addition, the dephytinization potential was also investigated against maize bran to establish its major application as feed supplements.

2 Materials and methods

2.1 Raw material

Wheat bran was collected from local vendors of Solan, Himachal Pradesh (H.P.) India. The wheat bran was first passed through a sieve with a pore size of 600 microns (BSS 25 IS46-1962) to obtain medium-sized bran particles dried at 55 °C in a hot air oven to remove all the retained moisture. This medium-sized, moisture-free bran was then used for further experiments [17].

2.2 Chemicals

Sodium phytate was purchased from HiMedia Private Limited, Mumbai, India. All other additional chemicals and reagents were of analytical grades.

2.3 Microorganism and inoculum preparation

The fungal isolate A. niger NT7 was previously isolated from the rhizosphere of Zea mays agricultural field of Hamirpur, Himachal Pradesh, India, and identified as a potential phytase producer [17]. The culture was preserved on potato dextrose agar (PDA) slants and stored at 4 °C and repeatedly subcultured to maintain viability. Three-day-old inoculum harvested in normal saline subsequently counted by hemocytometer to a level of 12 × 107 spores per ml to carry out fermentation.

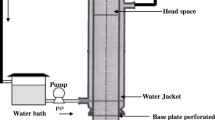

2.4 Phytase production through SSF

SSF was set up on previously optimized parameters carried out with 5-g wheat bran in a 250-ml Erlenmeyer flask moistened with a 10-ml distilled water (1 (wheat bran): 2 (moistening agent)) supplemented with mannitol (0.5%) and ammonium sulfate (0.5%). The fermentation was carried out for 5 days at a temperature of 35 °C while maintaining the medium at pH 5.

2.4.1 Phytase extraction

Crude phytase from A. niger NT7 was extracted from moldy wheat bran by the previously defined method by Kumari and Bansal [17]. After fermentation, moldy wheat bran was soaked in 0.1% Tween 80 (10 ml per gram of wheat bran) for 1 h under shaking conditions at 30 °C. A cleared mycelium-free supernatant was obtained from solid moldy particles after filtration through the double-layered muslin cloth followed by centrifugation at 7000 rpm for 20 min at 4 °C and used as a crude phytase enzyme.

2.5 Phytase assay

The phytase activity was evaluated spectrophotometrically by measuring inorganic phosphorous release from the substrate sodium phytate at 750 nm. The reaction mixture contains 1 mM sodium phytate prepared in 0.1 M acetate buffer (pH 5.5) and 50-µl crude phytase enzyme. Liberated phosphorous was determined using KH2PO4 as standard [31]. One unit was defined as the amount of enzyme required to liberate 1 µmol of inorganic phosphorous released per minute under the assay conditions. The phytase production was expressed as phytase activity as unit per gram dry substrate (Ugds–1).

2.6 Optimization of phytase production using response surface methodology (RSM)

The phytase production through SSF mainly depends on the process variables, amount of wheat bran (A), temperature (B), incubation time (C), pH (D), the concentration of mannitol (E), and ammonium sulfate (F) [17]. In the present study, three different levels, i.e., lower, mid, and higher, were selected for the design of the experiment (DOE) based on the central composite design (CCD) of RSM. The range of each SSF variable taken for DOE of RSM was tabulated under Table 1. Minitab® version 2016 was used to obtain the predicted values of phytase activities of this DOE and to develop a polynomial response surface model that was further validated experimentally (Table 2).

2.7 Model validation and optimization

The equation was generated and analyzed for lack of fit by R2 and adjusted R2 values. The significance tests and analysis of variance (ANOVA) help analyze the individual, square, and interactive effects between various experimental data set parameters under study. Three-dimensional contour plots based upon the interaction between multiple parameters were generated using Minitab® 2016 software. The optimal microbial phytase production conditions were drawn through the response optimizer function of Minitab® 2016 software and used for experimental testing.

2.8 Amelioration of maize bran by crude phytase from A. niger NT7

In addition to secreting phytase enzyme, crude enzyme formulation of A. niger NT7 expresses other hydrolytic enzymes (amylase, invertase, pectinase, xylanase, and cellulase) in optimized cultural conditions (MS1, Fig. S1). This enzyme cocktail aids in the dephytinization activity of the phytase enzyme [15, 32]. Dephytinization of maize bran occurs when 5-g maize bran is mixed with a 100-ml 0.1 M sodium acetate buffer (pH 4.8) and incubated at 50 °C along with 10 U of crude A. niger NT7 phytase enzyme. The test (with enzyme) and control (without enzyme) samples were both incubated under the same constant shaking conditions. Two-milliliter samples were withdrawn at regular intervals for released nutritional analysis. The amount of phosphorous released was estimated by using the standard Fiske and Subbarow method [31]. Miller’s method was used to calculate the amount of sugar released, and the Bradford method was used to estimate total proteins [33]. The amount of liberated amino acids was determined using a colorimetric assay with ninhydrin reagent [34].

Moreover, dephytinization resulted in the release of divalent metal ions, quantified by ICP-MS (inductively coupled plasma mass spectrometry). One gram of untreated maize bran was oven dried and then acidically treated (HNO3:HClO4, i.e., 1:4) at 120 °C until a clear solution formed. The cleared untreated maize bran is used as a control and is valued at 100%. After a 24-h period, test samples were collected from the previously mentioned dephytinization setup for metal ion analysis. All the experiments were performed in triplicate, and the average values are represented along with the standard deviation.

3 Results and discussions

3.1 Optimization of phytase production using RSM in SSF

Previously, A. niger NT7 produced 208.30 ± 0.22 Ugds−1 of phytase in SSF (5-g wheat bran, distilled water as moistening agent (1:2), 0.5% mannitol, and 0.5% ammonium sulfate) optimized by OVAT approach at temperature 30 °C, pH 5.0 after 4 days. Hence, the current study was carried out to boost the additional phytase production by further optimizing the critical factors (medium components, temperature, pH, and incubation time) using a statistical approach. Therefore, RSM was used to establish the relationship between multiple process variables with obtained responses (phytase activity) more effectively than a traditional design. A set of 53 experiments were executed based on CCD using the process variables of SSF, i.e., amount of wheat bran (g), temperature (°C), incubation time (days), pH, and the concentration of mannitol and ammonium sulfate (% w/w) as input variables to develop a design of experiments (DOE) (Table 2). The range of each input variable was selected using the experimental acquaintance of the OVAT approach [17].

These responses were examined by feeding data to Minitab® software version 16, which also develops a polynomial response surface model. The model was further validated experimentally (Table 2). The highest phytase production (438.35 Ugds−1) was observed with run order number 14 using 5-g wheat bran as substrate supplemented with 2% (w/w) mannitol, 0.5% ammonium sulfate, pH 5, and incubated at 35 °C for 5 days to carry out SSF. A regression equation was obtained for experimental data, which predicts the optimal phytase production with selected parameters as follows:

Phytase activity (Ugds−1) (Y) = − 1476.66 + 152.930 × SC (g) + 134.686 × ITemp (°C) + 125.387 × IT (day) − 198.445 × pH − 1144.00 × mannitol (%) + 782.743 × amm. sulfate (%) − 18.4703 × SC (g) × SC (g) − 2.13776 × ITemp (°C) × ITemp (°C) − 14.4111 × IT (day) × IT (day) + 12.2509 × pH × pH + 494.608 × mannitol (%) × mannitol (%) − 571.810 × amm. sulfate (%) × amm. sulfate (%) + 0.477802 × SC (g) × ITemp (°C) − 0.441245 × SC (g) × IT (day) − 1.59156 × SC (g) × pH + 4.07652 × SC (g) × mannitol (%) + 26.2063 × SC (g) × amm. sulfate (%) + 0.568593 × ITemp (°C) × IT (day) + 2.88293 × ITemp (°C) × pH − 3.64606 × ITemp (°C) × mannitol (%) − 5.88287 × ITemp (°C) × amm. sulfate (%) − 0.216263 × IT (day) × pH − 5.08617 × IT (day) × mannitol (%) + 9.00875 × IT (day) × amm. sulfate (%) − 22.0579 × pH × mannitol (%) − 31.0886 × pH × amm. sulfate (%) − 74.7557 × mannitol (%) × amm. sulfate (%).

Here, SC is the substrate (wheat bran) concentration, ITemp the incubation temperature, IT the incubation time, and amm. sulfate the ammonium sulfate.

This regression equation represents all linear and interaction among parameters under study.

3.1.1 Analysis of variance (ANOVA) results

Analysis of variance (ANOVA) for the model is presented in Table 3. The model’s P value of 0.000 reflects the significance of the model and efficacy for optimization. Coefficient of determination (R2) 98.07% and correlation coefficient (adjusted R2) 95.99% also suggest the model’s aptness and adequacy. The R2 value approaches 1.0, indicating the model’s ability to predict optimization of the parameter under consideration. This showed our model’s feasibility and suggested the following of our experimental data set. The linear and square interactions seemed to be effective (P < 0.05) except for the square interaction of pH.

Three-dimensional graphs (3-D plots) were plotted to show the interaction between various parameters (Fig. 1a–e) where phytase activity was plotted on the y axis and two independent variables were plotted on the x axis and z axis. The shape and peak of 3-D plots suggest the optimum phytase production for two interactive parameters. Figure 1a represents an intermediate peak with maximal phytase production and suggests the positive interactive effect of substrate concentration (wheat bran) with incubation temperature. It showed the maximal enzymatic production at 35 °C with 5-g wheat bran (Fig. 1a). While going outside, these peak values do not increase phytase production levels. Wheat bran provides physical support and has all the nutrient ingredients to carry out SSF efficiently. The optimum substrate quantity is a must since there may be competition for nutrients and physical support while carrying out fermentation. Interaction between incubation days and mannitol concentration suggests increasing the mannitol concentration with optimal incubation period, resulting in enhanced enzymatic activity (Fig. 1b).

Response surface plots of phytase activity (Ugds−1) where the phytase activity is plotted on the y axis and two independent variables plotted on the x axis and z axis: effect of a SC (g) and ITemp (°C), b IT (day) and mannitol (%), c ITemp (°C) and pH, d pH and mannitol (%), and e mannitol (%) and amm. sulfate (%)

The interaction between pH and incubation temperature means that optimal phytase production was recorded at 35 °C with pH 5. Further, going beyond these optimal values for parameters brings about dropped enzymatic production (Fig. 1c). Interaction between mannitol and pH suggests the highest phytase activity achieved at low pH and higher mannitol concentration (2%) (Fig. 1d). While increasing the mannitol (2%) and (0.5%) decreasing ammonium sulfate resulted in an interactive way to have an optimal C/N ratio to get maximum phytase production (Fig. 1e).

3.1.2 Optimized SSF variables for enhanced phytase production

The response optimizer suggested a phytase activity of 442.50 Ugds−1, utilizing the SSF variables of 5-g wheat bran, supplemented with 1.97% (w/w) mannitol and 0.44% (w/w) ammonium sulfate, and pH 4.38 at 35 °C for 5 days resulted in predicted phytase production. To prove the response optimizer’s accuracy, the predicted optimal SSF variables have been utilized to execute laboratory experiments in triplicates. Experimental authentication from triplicate experiments resulted in a phytase activity of 521.29 ± 28.16 Ugds−1 phytase production. A 2.5-fold enhancement has been brought by utilizing the statistical approach compared with the OVAT approach (208.30 ± 0.22 Ugds−1), whereas 6.8-fold enhanced phytase productivity with a counterpart of unoptimized cultural conditions (76.34 ± 0.99 Ugds−1) [17]. The improved phytase production observed in the present study is compared with other fungal phytase sources in Table 4.

Earlier studies have already validated an effective economic 10.80-fold improved phytase production using the Minitab® software package for medium optimization [24, 46]. Statistical optimization of Pichia anomala phytase using CCD enhanced the enzyme yield when 2% glucose and 0.5% beef extract concentration were used [47]. Thermomyces lanuginosus phytase attained a 10.38-fold increased enzyme production using four factors (culture temperature, initial pH, aeration area, age of seeding culture) for CCD of RSM [24]. RSM tremendously enhances the phytase production from a fungal isolate, Hypocrea lixii SURT01 [43]. RSM significantly boosts the phytase yield of Aspergillus ficuum by optimizing three parameters (concentration of glucose, ammonium sulfate, and moisture content) [37]. Bhavsar et al. testified the improved phytase production, i.e., a 3.08-fold enhancement, using 10-g wheat bran as SSF substrate complemented with 3 g glucose, 1.25 g dextrin, 0.2 g NaNO3, and 0.3 g MgSO4 moistened with a 20-ml distilled water with a 4-day incubation period with the aid of the RSM approach [38]. A. ficuum NTG-23 displayed a remarkable 7.34-fold enhanced phytase production using waste vinegar as an energy source [36]. Another concluded that A. niger NRF9 showed a 2.9-fold rise in enzyme production in SSF using wheat bran as substrate compared to the conventional approach [46]. Recent studies have also employed this approach not only for phytase enzyme production but also for other hydrolytic enzymes from A. niger [48]. Some currently carried out studies also explored the RSM approach for other potential phytase-producing candidates such as Penicillium purpurogenum GE1, Sporotrichum thermophile, and Williopsis saturnus NCIM 3298, resulting in 2.6-, 11.6-, 5.8-fold augmentation, respectively, as compared to the initial production stage [25, 44, 49]. Aspergillus niger NCIM 563 phytase production upsurged from 15 to 550 IU/gds by statistical optimization [16]. Most recent studies show that the statistical optimization of Pholiota adiposa resulted in an overall 3.15 improved phytase production using water hyacinth as a cheap agricultural substrate in SSF [42].

4 Dephytinization of maize bran

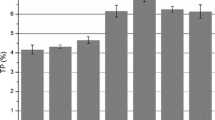

Maize bran is the major byproduct formed after processing maize grains and used as feed. The phytic acid content of maize bran undergoes successful hydrolysis with phytase of A. niger NT7. The process resulted in the liberation of inorganic phosphate and reaches a maximum after 24 h (1723.04 ± 45.32 µg/ml) of treatment afterwards, gradually downfalls probably due to protein denaturation or end-product inhibition/inhibitory effects [22]. Previous studies also showed the successful dephytinization potential of phytase from A. niger NCIM 563 [40], A. niger NT7 [17] against wheat bran, and A. oryzae [15] against maize bran, resulting in the liberation of phosphorous. In our study, maximum liberation of bounded reducing sugar (3210.9 ± 56.35 µg/ml), total proteins (956.4 ± 4.30 µg/ml), and amino acids (250.87 ± 10.04 µg/ml) from phytate were detected after 24 h of treatment (Fig. 2). Afterwards, a progressively declining phase was observed because of the inhibitor actions of end products of reactions and denaturation of released proteins and amino acids [25]. The findings reported in the present study are corroborated in previous phytase studies of Rhizopus oligosporus MTCC 556 [50], Aspergillus aculeatus APF1 [51], recombinant phytase (rSt-Phy) of thermophilic mold Sporotrichum thermophile [52], and Hemicola nigrescnes [50, 51, 53], showing the release of bound nutrients (phosphorous, reducing sugar, protein).

ICP-MS analysis revealed that dephytinization results in the significant release of various minerals in the ascending order of Ca < Zn < Mn < Mg < P < Fe as compared to untreated maize bran (Fig. 3). More than 100% mineral release was observed in Mg, P, and Fe, whereas ≤ 50% release was detected in Mn and Zn compared to untreated maize bran. The current study showed that the lowest percent release was observed in Ca (Fig. 3). According to one study, phytase from Aspergillus niger NCIM 563 releases more than 50% of minerals from soybean flour [16]. Phytic acid content proved to be declined after the dephytinization activity of A. niger NT7 phytase, therefore, resulting in the liberation of all bound nutrients. The crude mixture is a cocktail of hydrolytic enzymes and helps to synergistically enhance the nutritional status of feed [32, 54]. The current results represent the applicability of A. niger NT7 for ameliorating nourishment of maize bran and auxiliary; it could be used on a commercial scale as a feed supplement.

5 Conclusions

A. niger NT7 has been proven to be a potential candidate for high phytase activity through the SSF with the aid of statistical modeling and optimization. Overall, the RSM approach with the validated nonlinear regression model resulted in 2.5- and 6.8-fold enhanced phytase production when compared to OVAT and unoptimized cultural conditions, respectively. Supplementation of crude enzyme preparation of A. niger NT7 in maize bran improved the significant release of reducing sugars; soluble proteins; and various minerals, including phosphorus. Also, the crude formulation demands no purification step, which further keeps the feed additive cost at a lower side. Therefore, the crude preparation of A. niger NT7 appears to be a promising feed additive to improve the nutritional properties.

Data availability

All data and related materials are with the authors wherever needed; the same may be provided.

Abbreviations

- SSF:

-

Solid-state fermentation

- ANF:

-

Antinutrient factor

- GRAS:

-

Generally recognized as safe

- OVAT:

-

One variable at a time approach

- RSM:

-

Response surface methodology

- CCD:

-

Central composite design

- DOE:

-

Design of experiment

- ANOVA:

-

Analysis of variance

- ICP-MS:

-

Inductively coupled plasma mass spectrometry

References

Gupta RK, Gangoliya SS, Singh NK (2015) Reduction of phytic acid and enhancement of bioavailable micronutrients in food grains. J Food Sci Technol 52:676–684. https://doi.org/10.1007/s13197-013-0978-y

Rosa-Sibakov N, Re M, Karsma A et al (2018) Phytic acid reduction by bioprocessing as a tool to improve the in vitro digestibility of faba bean protein. J Agric Food Chem 66:10394–10399. https://doi.org/10.1021/acs.jafc.8b02948

Song H-Y, El Sheikha AF, Hu D-M (2019) The positive impacts of microbial phytase on its nutritional applications. Trends Food Sci Technol 86:553–562. https://doi.org/10.1016/j.tifs.2018.12.001

Mrudula Vasudevan U, Jaiswal AK, Krishna S, Pandey A (2019) Thermostable phytase in feed and fuel industries. Bioresour Technol 278:400–407. https://doi.org/10.1016/j.biortech.2019.01.065

Castaneda JPL (2021) Characterization of indigestible fiber in diets based on corn and soybean meal or corn, soybean meal, and distiller dried grains with solubles and in feces from pigs fed these diets. PhD Thesis, University of Illinois at Urbana-Champaign

Balwani I, Chakravarty K, Gaur S (2017) Role of phytase producing microorganisms towards agricultural sustainability. Biocatal Agric Biotechnol 12:23–29. https://doi.org/10.1016/j.bcab.2017.08.010

Pires EBE, de Freitas AJ, Souza FF e et al (2019) Production of fungal phytases from agroindustrial byproducts for pig diets. Sci Rep 9:9256. https://doi.org/10.1038/s41598-019-45720-z

Pandey A (2003) Solid-state fermentation. Biochem Eng J 13:81–84. https://doi.org/10.1016/S1369-703X(02)00121-3

de Castro RJS, Sato HH (2015) Enzyme production by solid state fermentation: general aspects and an analysis of the physicochemical characteristics of substrates for agro-industrial wastes valorization. Waste Biomass Valori 6:1085–1093. https://doi.org/10.1007/s12649-015-9396-x

Bogar B, Szakacs G, Pandey A et al (2003) Production of phytase by Mucor racemosus in solid-state fermentation. Biotechnol Prog 19:312–319. https://doi.org/10.1021/bp020126v

Chadha BS, Harmeet G, Mandeep M et al (2004) Phytase production by the thermophilic fungus Rhizomucor pusillus. World J Microbiol Biotechnol 20:105–109. https://doi.org/10.1023/B:WIBI.0000013319.13348.0a

Ramachandran S, Roopesh K, Nampoothiri KM et al (2005) Mixed substrate fermentation for the production of phytase by Rhizopus spp. using oilcakes as substrates. Process Biochem 40:1749–1754. https://doi.org/10.1016/j.procbio.2004.06.040

Rani R, Ghosh S (2011) Production of phytase under solid-state fermentation using Rhizopus oryzae: novel strain improvement approach and studies on purification and characterization. Bioresour Technol 102:10641–10649. https://doi.org/10.1016/j.biortech.2011.08.075

Bhavsar K, Buddhiwant P, Soni SK et al (2013) Phytase isozymes from Aspergillus niger NCIM 563 under solid state fermentation: biochemical characterization and their correlation with submerged phytases. Process Biochem 48:1618–1625. https://doi.org/10.1016/j.procbio.2013.08.001

Sapna SB (2014) Phytase production by Aspergillus oryzae in solid-state fermentation and its applicability in dephytinization of wheat bran. Appl Biochem Biotechnol 173:1885–1895. https://doi.org/10.1007/s12010-014-0974-3

Buddhiwant P, Bhavsar K, Kumar VR, Khire JM (2016) Phytase production by solid-state fermentation of groundnut oil cake by Aspergillus niger: a bioprocess optimization study for animal feedstock applications. Prep Biochem Biotechnol 46:531–538. https://doi.org/10.1080/10826068.2015.1045606

Kumari N, Bansal S (2021) Production and characterization of a novel, thermotolerant fungal phytase from agro-industrial byproducts for cattle feed. Biotechnol Lett 43:865–879. https://doi.org/10.1007/s10529-020-03069-8

Khuri AI, Mukhopadhyay S (2010) Response surface methodology. Wiley Interdiscip Rev Comput Stat 2:128–149. https://doi.org/10.1002/wics.73

Myers RH, Montgomery DC, Anderson-Cook CM (2016) Response surface methodology: process and product optimization using designed experiments, 4th edn. John Wiley & Sons

Chauhan M, Garlapati VK (2014) Modeling embedded optimization strategy for the formulation of bacterial lipase-based biodetergent. Ind Eng Chem Res 53:514–520. https://doi.org/10.1021/ie401357h

Vohra A, Satyanarayana T (2003) Phytases: microbial sources, production, purification, and potential biotechnological applications. Crit Rev Biotechnol 23:29–60. https://doi.org/10.1080/713609297

Singh B, Satyanarayana T (2006) Phytase production by thermophilic mold sporotrichum thermophile in solid-state fermentation and its application in dephytinization of sesame oil cake. Appl Biochem Biotechnol 133:239–250. https://doi.org/10.1385/ABAB:133:3:239

Bhavsar K, Gujar P, Shah P et al (2013) Combinatorial approach of statistical optimization and mutagenesis for improved production of acidic phytase by Aspergillus niger NCIM 563 under submerged fermentation condition. Appl Microbiol Biotechnol 97:673–679. https://doi.org/10.1007/s00253-012-3965-8

Berikten D, Kivanc M (2014) Optimization of solid-state fermentation for phytase production by Thermomyces lanuginosus using response surface methodology. Prep Biochem Biotechnol 44:834–848. https://doi.org/10.1080/10826068.2013.868357

Kumari A, Satyanarayana T, Singh B (2016) Mixed substrate fermentation for enhanced phytase production by thermophilic mould Sporotrichum thermophile and its application in beneficiation of poultry feed. Appl Biochem Biotechnol 178:197–210. https://doi.org/10.1007/s12010-015-1868-8

Kaur S, Sharma S, Singh B, Dar BN (2015) Effect of extrusion variables (temperature, moisture) on the antinutrient components of cereal brans. J Food Sci Technol 52:1670–1676. https://doi.org/10.1007/s13197-013-1118-4

Vats P, Banerjee UC (2004) Production studies and catalytic properties of phytases (myo-inositolhexakisphosphate phosphohydrolases): an overview. Enzyme Microb Technol 35:3–14. https://doi.org/10.1016/j.enzmictec.2004.03.010

Swaminathan S, Hemalatha R, Pandey A et al (2019) The burden of child and maternal malnutrition and trends in its indicators in the states of India: the Global Burden of Disease Study 1990–2017. Lancet Child Adolesc Health 3:855–870. https://doi.org/10.1016/S2352-4642(19)30273-1

Cao L, Wang W, Yang C et al (2007) Application of microbial phytase in fish feed. Enzyme and Microb Technol 40:497–507. https://doi.org/10.1016/j.enzmictec.2007.01.007

Bedford MR, Walk CL, Masey O’Neill HV (2016) Assessing measurements in feed enzyme research: phytase evaluations in broilers. J Appl Poult Res 25:305–314. https://doi.org/10.3382/japr/pfv073

Fiske CH, Subbarow Y (1925) The colorimetric determination of phosphorus. J Biol Chem 66:375–400. https://doi.org/10.1016/S0021-9258(18)84756-1

Dahiya S, Kumar A, Singh B (2020) Enhanced endoxylanase production by Myceliophthora thermophila using rice straw and its synergism with phytase in improving nutrition. Process Biochem 94:235–242. https://doi.org/10.1016/j.procbio.2020.04.032

Miller GL (1959) Use of dinitrosalicylic acid reagent for determination of reducing sugar. Anal Chem 31:426–428. https://doi.org/10.1021/ac60147a030

Yemm EW, Cocking EC, Ricketts RE (1955) The determination of amino-acids with ninhydrin. Analyst 80:209–214. https://doi.org/10.1039/AN9558000209

Spier MR, Scheidt GN, Portella AC et al (2010) Increase in phytase synthesis during citric pulp fermentation. Chem Eng Commun 198:286–297. https://doi.org/10.1080/00986445.2010.493115

Wang Z-H, Dong X-F, Zhang G-Q et al (2011) Waste vinegar residue as substrate for phytase production. Waste Manag Res 29:1262–1270. https://doi.org/10.1177/0734242X11398521

Shahryari Z, Fazaelipoor MH, Setoodeh P et al (2018) Utilization of wheat straw for fungal phytase production. Int J Recycl Org Waste Agricult 7:345–355. https://doi.org/10.1007/s40093-018-0220-z

Bhavsar K, Ravi Kumar V, Khire JM (2011) High level phytase production by Aspergillus niger NCIM 563 in solid state culture: response surface optimization, up-scaling, and its partial characterization. J Ind Microbiol Biotechnol 38:1407–1417. https://doi.org/10.1007/s10295-010-0926-z

Chen L, Vadlani PV, Madl RL (2014) High-efficiency removal of phytic acid in soy meal using two-stage temperature-induced Aspergillus oryzae solid-state fermentation. J Sci Food Agric 94:113–118. https://doi.org/10.1002/jsfa.6209

Mandviwala TN, Khire JM (2000) Production of high activity thermostable phytase from thermotolerant Aspergillus niger in solid state fermentation. J Ind Microbiol Biotech 24:237–243. https://doi.org/10.1038/sj.jim.2900811

Sapna SB (2015) Biocatalytic potential of protease-resistant phytase of Aspergillus oryzae SBS50 in ameliorating food nutrition. Biocatal Biotransfor 33:167–174. https://doi.org/10.3109/10242422.2015.1076215

Jatuwong K, Suwannarach N, Kumla J et al (2020) Bioprocess for production, characteristics, and biotechnological applications of fungal phytases. Front Microbiol 11:188. https://doi.org/10.3389/fmicb.2020.00188

Thyagarajan R, Narendrakumar G, Kumar VR, Namasivayam SKR (2016) Comparison of response surface methodology and artificial neural networks for optimization of medium constituents for enhancement of phytase production from Hypocrea lixii SURT01. Res J Pharm Technol 9:430. https://doi.org/10.5958/0974-360X.2016.00079.2

Awad GEA, Helal MMI, Danial EN, Esawy MA (2014) Optimization of phytase production by Penicillium purpurogenum GE1 under solid state fermentation by using Box-Behnken design. Saudi J Biol Sci 21:81–88. https://doi.org/10.1016/j.sjbs.2013.06.004

Chadha BS, Harmeet G, Mandeep M et al (2004) Phytase production by the thermophilic fungus Rhizomucor pusillus. World J Microb Biot 20:105–109. https://doi.org/10.1023/B:WIBI.0000013319.13348.0a

Gupta RK, Gangoliya SS, Singh NK (2014) Isolation of thermotolerant phytase producing fungi and optimisation of phytase production by Aspergillus niger NRF9 in solid state fermentation using response surface methodology. Biotechnol Bioproc E 19:996–1004. https://doi.org/10.1007/s12257-014-0175-5

Vohra A, Satyanarayana T (2002) Statistical optimization of the medium components by response surface methodology to enhance phytase production by Pichia anomala. Process Biochem 37:999–1004. https://doi.org/10.1016/S0032-9592(01)00308-9

de Oliveira CC, de Souza AKS, de Castro RJS (2019) Bioconversion of chicken feather meal by Aspergillus niger: simultaneous enzymes production using a cost-effective feedstock under solid state fermentation. Indian J Microbiol 59:209–216. https://doi.org/10.1007/s12088-019-00792-3

Pable AA, Shah S, Ravi Kumar V, Khire JM (2019) Use of Plackett-Burman design for enhanced phytase production by Williopsis saturnus NCIM 3298 for applications in animal feed and ethanol production. 3 Biotech 9:237. https://doi.org/10.1007/s13205-019-1764-y

Suresh S, Radha KV (2015) Effect of a mixed substrate on phytase production by Rhizopus oligosporus MTCC 556 using solid state fermentation and determination of dephytinization activities in food grains. Food Sci Biotechnol 24:551–559. https://doi.org/10.1007/s10068-015-0072-5

Saxena A, Verma M, Singh B et al (2019) Characteristics of an acidic phytase from Aspergillus aculeatus apf1 for dephytinization of biofortified wheat genotypes. Appl Biochem Biotechnol 191:679–694. https://doi.org/10.1007/s12010-019-03205-9

Ranjan B, Singh B, Satyanarayana T (2015) Characteristics of recombinant phytase (rSt-Phy) of the thermophilic mold Sporotrichum thermophile and its applicability in dephytinizing foods. Appl Biochem Biotechnol 177:1753–1766. https://doi.org/10.1007/s12010-015-1851-4

Bala A, Sapna, Jain J et al (2014) Production of an extracellular phytase from a thermophilic mould Humicola nigrescens in solid state fermentation and its application in dephytinization. Biocatal Agric Biotechnol 3:259–264. https://doi.org/10.1016/j.bcab.2014.07.002

Maller A, Vici AC, Facchini FDA et al (2014) Increase of the phytase production by Aspergillus japonicus and its biocatalyst potential on chicken feed treatment. J Basic Microbiol 54:S152–S160. https://doi.org/10.1002/jobm.201300315

Acknowledgements

The authors acknowledge Dr. V. K. Garlapati, Jaypee University of Information Technology Waknaghat, Solan, India, and Prof. Bishwajit Kundu, Indian Institute of Technology, New Delhi, for their valuable feedback during the present studies.

Funding

The authors acknowledge the Jaypee University of Information Technology Waknaghat, India, for providing basic infrastructure and financial support for carrying out the present work.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Ethics approval

Not applicable.

Consent for publication

All authors agree to publish the manuscript in the said journal.

Conflict of interest

The authors declare no competing interests.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Kumari, N., Bansal, S. Statistical modeling and optimization of microbial phytase production towards utilization as a feed supplement. Biomass Conv. Bioref. 13, 8339–8349 (2023). https://doi.org/10.1007/s13399-021-01672-x

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13399-021-01672-x