Abstract

Phytase production by Aspergillus niger NCIM 563 was optimized by using wheat bran in solid state fermentation (SSF). An integrated statistical optimization approach involving the combination of Placket–Burman design (PBD) and Box–Behnken design (BBD) was employed. PBD was used to evaluate the effect of 11 variables related to phytase production, and five statistically significant variables, namely, glucose, dextrin, NaNO3, distilled water, and MgSO4·7H2O, were selected for further optimization studies. The levels of five variables for maximum phytase production were determined by a BBD. Phytase production improved from 50 IU/g dry moldy bran (DMB) to 154 IU/g DMB indicating 3.08-fold increase after optimization. A simultaneous reduction in fermentation time from 7 to 4 days shows a high productivity of 38,500 IU/kg/day. Scaling up the process in trays gave reproducible phytase production overcoming industrial constraints of practicability and economics. The culture extract also had 133.2, 41.58, and 310.34 IU/g DMB of xylanase, cellulase, and amylase activities, respectively. The partially purified phytase was optimally active at 55°C and pH 6.0. The enzyme retained ca. 75% activity over a wide pH range 2.0–9.5. It also released more inorganic phosphorus from soybean meal in a broad pH range from 2.5 to 6.5 under emulated gastric conditions. Molecular weight of phytase on Sephacryl S-200 was approximately 87 kDa. The K m and V max observed were 0.156 mM and 220 μm/min/mg. The SSF phytase from A. niger NCIM 563 offers an economical production capability and its wide pH stability shows its suitability for use in poultry feed.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Phosphorus is an essential constituent of life like nitrogen, but, unlike nitrogen, phosphorus does not have a cycle to constantly replenish its supply. All animal diets must contain adequate amounts of this element. So to meet their phosphorus requirements, inorganic phosphorus especially dicalcium phosphate is supplemented in the diet of livestock and poultry animals. This has made phosphorus the third most expensive nutrient in poultry production after energy and protein. At the current extraction and usage rate, the existing phosphate reserves will be exhausted in next 80 years [35].

Bound phosphorus (18–88% of total phosphorus content) in fact exists as phytate which is already present in animal feed. But this phytate phosphorus is not utilized by monogastric animals like poultry and pigs due to lack of intrinsic phytase in their gastrointestinal tracts. Phytate in addition acts as an antinutrient by chelating various cations such as Ca2+, Fe2+, Zn2+, and Mg2+ and thereby reducing their bioavailability. This unutilized phytate is the origin of phosphorus pollution as it builds up in areas of livestock production leading to eutrophication and algal blooms [22].

So use of phytase in animal feed will stop the antinutritional effects of phytate, decrease environmental pollution, increase availability of starch, protein, amino acids, calcium, and phosphorus, and abolish the need for addition of inorganic phosphate in animal feed. Phytases are also imminent candidates for production of special isomers of different lower phosphate esters of myo-inositol, some of which are considered to be pharmacoactive and important intracellular secondary messengers [33].

The US Food and Drug Administration (FDA) has approved a “generally recognized as safe (GRAS)” petition for use of phytase in food, and phytase has been marketed as an animal feed enzyme in the US since 1996 [17]. All these factors have concurrently made phytase the third largest feed enzyme in terms of annual consumption [28].

There are various reports on phytase production by bacteria, yeast, and fungi among which fungal phytases are widely employed in animal feed due to their acid tolerance and higher yield [34]. The existing commercial microbial phytases produced by submerged fermentation (Smf) conditions are expensive because of diluted product, production using recombinant strains, and high product recovery costs [15]. SSF provides a more economic alternative for enzyme production and application as compared with Smf.

There is no defined medium for optimum production of phytase from different microbial sources especially fungi because each fungus has its own special conditions and specific substrates for maximum enzyme production especially in SSF. Krishna and Nokes studied the effect of culture conditions, particularly inoculum age, media composition (wheat bran and full-fat soybean flour), and duration of SSF, on the phytase production by A. niger [15]. Bogar et al. reported phytase production by A. ficcium NRRL 3135, M. racemosus NRRL 1994, and R. oligosporous NRRL 5905 using various substrates such as canola meal, cracked corn, soybean meal, and wheat bran [2]. But such reports are nevertheless few because of the low productivities and difficulties associated with operating and up-scaling SSF conditions [3].

There is need for intensive research on SSF to develop a commercial process for phytase production with techno-economic feasibility. The intricacies in SSF technology can be understood through modeling, kinetics of growth of microbes, control of parameters, optimization, scale-up and commercialization of the process for application. Before carrying out these studies it is, however, necessary to increase the phytase production and this can become significant by employing statistical optimization techniques rather than the conventional one variable at a time approach. This is because statistical optimization gives the optimum media formulation with minimum number of experiments in a short time while also considering the interaction between selected components [30].

Earlier, we reported phytase production by A. niger NCIM 563 under SSF using wheat bran with no additional nutrients [19]. The same fungus produces two dissimilar phytases under Smf [31]. In this paper, our objective is to evaluate the application of statistical methods to increase the phytase activity under SSF, partial characterization, and up-scaling to tray fermenters.

Materials and methods

Chemicals

Phytic acid sodium salt was purchased from Sigma Chemical Company (St Louis, MO, USA). All other chemicals used were of analytical grade. Various agriculture residues were purchased from a local market.

Fungi and inoculum preparation

Aspergillus niger NCIM 563 used in the present study was from NCIM Resource Center, Pune, India. The stock cultures were maintained on potato dextrose agar (PDA) slants and stored at 4°C. Spores from 7-day-old PDA slants were harvested by using sterile distilled water containing 0.01% Tween 80 to obtain 5 × 107 spores/ml and used as inoculum for SSF.

SSF in Erlenmeyer flasks

The unoptimized medium contained 10 g of agricultural residue moistened with 10 ml distilled water in a 250-ml Erlenmeyer flask sterilized at 121°C for 30 min (Table 1). On cooling fermentation medium was inoculated with 1% spore suspension and incubated for 7 days at 30°C. The optimized fermentation medium for SSF contained 10 g of wheat bran in a 250-ml Erlenmeyer flask plus glucose 3 g, dextrin 1.25 g, sodium nitrate 0.2 g, magnesium sulfate 0.3 g moistened with 20 ml distilled water and sterilized by autoclaving at 121°C for 30 min. On cooling fermentation medium was inoculated with 1% spore suspension and incubated for 4 days at 30°C. Enzyme production was expressed as enzyme activity IU/g DMB. All experiments were carried out in triplicates.

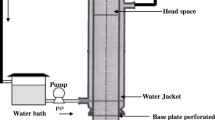

SSF in trays

Wheat bran (50, 100, 200, and 1,000 g) was moistened with the optimized medium mentioned in “SSF in Erlenmeyer flasks” in enamel-coated metallic trays having dimensions 28 × 24 × 4 cm, 45 × 30 × 4 cm, and 80 × 40 × 4 cm. The trays were covered with aluminum foil and sterilized at 121°C for 20 min. The cooled substrate was inoculated with 1% spore suspension of A. niger and incubated for 5 days at 30°C. Samples were withdrawn aseptically each day from different parts of the tray to obtain representative composite samples.

Analytical methods

Phytase activity was measured at 50°C as described earlier [19]. One unit of phytase activity (IU) was expressed as the amount of enzyme that liberates 1 μmol phosphorus per min under standard assay conditions.

Filter paper cellulase and xylanase activities were determined as reported earlier [11]. α-Amylase activity was determined by McCleary and Sheehan’s method [21]. The reducing sugars were determined by using dinitrosalicylic acid (DNS) [20]. One unit of enzyme activity was defined as the amount of enzyme that produces 1 μmol of xylose, glucose, or galacturonic acid/min under the assay conditions. Protein concentration in the culture filtrate was determined by the method of Lowry et al. using bovine serum albumin as a standard [18]. Biomass determination was carried out by measuring the glucosamine content resulting from acid hydrolysis of the fermented substrate [32]. Glucosamine was determined by the method of Reissig and the dry mycelial weight was calculated by assuming a mycelia glucosamine content of 139 mg of glucosamine/g of dry mycelium [29].

Each experiment was carried out in triplicate and the values reported are the mean of three such experiments.

Partial purification of phytase

The enzyme extraction from Koji was done as mentioned by Mandviwala [19]. The filtrate obtained was subjected to ammonium sulfate precipitation (95% saturation) with constant stirring. The precipitate was collected by centrifugation (15,000×g, 20 min) and dissolved in minimum volume of acetate buffer (100 mM, pH 6.0). The enzyme was desalted by passing it through a Sephadex G-25 column and fractions were estimated for phytase activity.

Electrophoresis

Native polyacrylamide gel electrophoresis (PAGE) (8%) was performed at room temperature and 200 V for 2–3 h [6]. Protein bands were visualized by silver staining [7].

Molecular weight determination by gel filtration

The molecular weight of native enzyme was estimated by gel filtration on a Sephacryl S-200 (1 × 100 cm) column equilibrated with 20 mM acetate buffer, pH 5.5 using cytochrome C (12.4 kDa), carbonic anhydrase (29 kDa), bovine serum albumin (66 KDa), alcohol dehydrogenase (150 kDa), and β-amylase(200 kDa) as standard proteins by the method of Andrews [1].

Characterization of phytase

The enzyme precipitated by ammonium sulfate and desalted by Sephadex G-25 was used for characterization of partially purified phytase. The optimum pH was determined by measuring the activity between pH 2.0 and 10.0 using 200 mM buffers: glycine–HCl (pH 2.0–3.0), sodium acetate (pH 4.0–6.0), Tris–HCl (pH 7.0–8.0), and glycine–NaOH (pH 9.0–10.0) at 50°C. Stability assay was performed by incubating the partially purified enzyme at 30°C for 24 h in 50 mM buffers of different pH values: glycine–HCl (pH 2.0–3.0), sodium acetate (pH 4.0–6.0), Tris–HCl (pH 7.0–8.0), and glycine–NaOH (pH 9.0–10.0). The residual activity was then assayed under standard assay conditions considering enzyme activity at zero time as 100%. The optimum temperature was determined over the temperature range 45–60°C. The thermal stability was studied up to 60°C and the residual enzyme activity was determined by using standard assay conditions and compared with the control without incubation.

To check the effect of metal ions, the enzyme was incubated in the presence of 1 mM and 5 mM of various metals ions for 30 min at 50°C under standard assay conditions along with control which is phytase reaction without metal ion.

The kinetic constants V max and K m were determined with sodium phytate as substrate using a Lineweaver–Burk plot [16].

Hydrolysis of soybean meal phytate in simulated gastric fluid

One gram soybean meal was dissolved in 9 ml simulated gastric fluid (SGF) [0.25 M glycine–HCl containing 2.0 mg/ml NaCl and 3.2 mg/ml pepsin] and pH was adjusted with HCl or NaOH to a final pH of 1.5, 2.0, 2.5, 3.5, 5.5, or 6.5. The solutions were incubated with agitation at 37°C for 30 min, and pH was adjusted to the corresponding values again. Then 1 ml partially purified enzyme was added to the solutions and incubated by agitation at 37°C for 60 min. The amount of released phosphorus was determined by a modified ammonium molybdate method as described in “Analytical methods”.

Optimization using response surface methodology

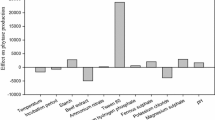

The PBD was employed to identify the key ingredients and the conditions for the best yield of enzyme production [26]. Phytase production is influenced by media components, especially carbon and nitrogen sources, metal ions, and physical variables such as pH, temperature, inoculum density, and incubation time. The choice of variables was made on the basis of studies employing Smf [31]. In the present study PBD was used to screen various variables, viz., glucose (A), dextrin (B), NaNO3 (C), distilled water (D), MgSO4·7H2O (E), FeSO4·7H2O (F), KCl (G), incubation period (H), inoculum level (J), Triton X (K), and MnSO4 (L). The total number of trials to be carried out was n + 1 where n is the number of variables. Each independent variable was tested at two levels, a high (1) level and a low (2) level. Table 2 shows the variables and their levels used in the experimental design constructed by using Design-Expert software (DES) version 7.1.2 (Stat-Ease, Minneapolis, MN, USA). The variables with more percent contribution were considered to influence phytase activity. Percentage values were calculated by adding the total sum of squares and then taking each term’s sum of squares and dividing by the total.

On the basis of analysis of PBD results, five variables, viz., glucose (A), dextrin (B), NaNO3 (C), distilled water (D), and MgSO4.7H2O (E), were chosen for further optimization by response surface methodology (RSM) using BBD. BBD is a good design for RSM studies because it permits estimation of the best fit parameters of the quadratic model, building of sequential designs, and detection of lack of fit of the model [4]. The number of experiments (N) required for the development of BBD is defined as N = 2k (k − 1) + C o (where k is number of variables and C o is the number of central points). This was used to develop a mathematical correlation between five variables on production of phytase. Each variable was studied at three levels (1, 2, and 3). The values for each component at three levels studied in the BBD are shown in Table 3. The design matrix was constructed by using DES to generate the response surface plot and optimum values for media formulation. The optimum values of the variables and the behavior of the system were studied by using the quadratic equation model in DES. All experiments were carried out in triplicates and their mean values are presented.

Results and discussion

Phytase production using agricultural residues

Wheat bran gave the highest phytase production of 50 IU/g DMB on the 7th day of fermentation as compared with groundnut cake, coconut cake, cotton cake, and rice bran (Table 1). As wheat bran is a cheaper substrate, economical, and supported maximum phytase production, it was selected for optimization experiments.

Optimization of phytase production by RSM

The 11 chosen variables (Table 2) likely to be influencing phytase production were optimized by using PBD. The PBD design matrix for experimental design of the 11 selected variables is shown in Table 4 along with their responses on phytase production. Maximum phytase production of 110 IU/g DMB was observed in trial number 11. The variables showing high percent contribution were considered as significant variables, influencing phytase production, by fitting to a linear model assuming the absence of interactions. Thus it was found that phytase production was influenced by glucose (A), dextrin (B), NaNO3 (C), distilled water (D), and MgSO4·7H2O (E) as seen from the analysis of half normal plot and the total sum of squares and percent contribution respectively (Table 5). The remaining variables were observed to have small percent contribution and they were therefore considered insignificant. Vohra and Satyanarayana [34] also identified magnesium sulfate as an important variable for phytase production by the thermophilic mold Sporotrichum thermophile by using PBD. Moisture content of the medium in SSF is very important for the growth of microorganisms, production of enzyme, and for enzyme activity [27]. It was found that distilled water (DW) contributed the most to phytase production as observed from the analysis of PBD results. The best fit linear regression model used for modeling gave a model F value of 5.75. This implies that there is only 0.01% chance that this “model F value” could occur due to noise. The coefficient of determination was obtained as R 2 = 0.873 and shows that the model used for analyzing the data is significant.

The five medium components (Table 3), identified above as significant variables for phytase production by PBD, were further optimized by RSM using BBD. Table 6 represents the design matrix of the five significant variables in coded levels, and reports the experimentally obtained phytase activity. It may be seen that trial number 20 showed the highest phytase activity. The experimental results obtained for phytase production were fed into the DES and analysis was carried out using backward elimination regression. The calculated regression equation for the optimization of medium components showed the phytase activity (Y) as a function of these variables. By applying multiple regression analysis on the experimental data, the following quadratic model was found to explain phytase production:

where Y is the predicted response and A–E are variables.

The results were analyzed by using ANOVA as appropriate to the experimental design used. The quality of the model was checked by using various criteria. The coefficient of determination (R 2) is 0.9499 for phytase production, suggesting that 94.99% of the variability is explained in the model. The value of correlation coefficient (predicted R 2) for phytase production was 0.8685, which suggests a strong agreement between the experimental and predicted values of phytase production. The model F value of 37.94 and values of P > F (<0.0001) indicated that the model terms are significant. For phytase production, A, D, AC, AD, AE, BC, CE, DE, B 2, C 2, D 2, and E 2 are significant model terms. The results of the ANOVA study are presented in Table 7.

The results show a strong agreement between the predicted and the experimental response. The optimum values of the tested variables are obtained as glucose 3 g, dextrin 1.25 g, NaNO3 0.2 g, MgSO4·7H2O 0.3 g moistened with 20 ml distilled water per 10 g of wheat bran with the rest of the variables kept at mean value of the corresponding ranges in PBD. The enzyme production behavior was then studied under optimized fermentation conditions by monitoring in time for 6 days. An unoptimized medium showed a phytase production of 50 IU/g DMB on the 7th day, whereas optimization studies gave phytase production of 154 IU/g DMB on the 4th day. The rapid growth of fungus is corroborated by the corresponding increase in the mycelial weight (Fig. 1). Thus the phytase activity is increased by 3.08 times with a simultaneous reduction of fermentation from 7 to 4 days. The three-dimensional (3D) plots showing the optimal levels and nonlinear interactions among the variables for enzyme production are presented in Fig. 2a, b. The maximum predicted value for phytase production was 123.14 IU/g DMB, while the experimental response was 139.53 IU/g DMB (run number 20 in Table 6). It may also be noted that optimization using PBD and central composite design in the case of A. ficcium gave phytase activity of only 15 IU/g using wheat bran [2].

The optimized results show a productivity of 38,500 IU/kg/day which is the highest as compared with other reported SSF using spore inoculum. Our experiments for phytase production using vegetative inocula did not give significant increase in production (data not included) but our productivity of 38,500 IU/kg/day is 8.3-fold more as compared with 4,667 IU/kg/day reported for A. niger by Krishna and Nokes (Table 8). Moisture content in SSF plays a crucial role as can be seen from the above response surface analysis. But increasing the moisture content leading to semi-solid conditions did not enhance the activity any further. Thus the above optimized variables using response surface analysis gave the best conditions for maximum phytase production.

A recommended 400 IU/kg feed supplementation would require only 2.59 kg crude SSF enzyme of A. niger NCIM 563 to be added to each metric ton (MT) of feed which presently requires 16 kg crude SSF enzyme of A. ficcium NRRL 3135. At present all available commercial phytase preparations are produced by recombinant strains using Smf. But they are costly as it requires concentration of diluted enzyme, extensive downstream procedures, and treatment of generated effluents that do not make the process eco-friendly. All this restricts the use of Smf phytase in animal feed [25]. In contrast, as compared with Smf, the SSF enzyme as shown here is produced in large quantity along with hydrolytic enzymes and its application involves minimum downstream processing because the product can now be easily mixed with other ingredients in a feed ration [24]. So the process economy of the SSF enzyme appears to be favorable and eco-friendly. In this case a high productivity is achieved with a natural wild strain, and thus the possibility for genetic improvisation is also very good.

Up-scaling and SSF in trays

SSF was performed in stationary trays analogous to conditions in a traditional Koji reactor as mentioned in “SSF in trays”. The procedure was scaled up from 10 g wheat bran in 250-ml Erlenmeyer flasks to 1,000 g wheat bran in 80 × 40 × 4-cm trays (Table 1). By scaling up from flasks to stationary trays, activities of 154 IU/g DMB were reproducibly obtained. These results are therefore encouraging for optimization under pilot scale conditions.

Production of accessory enzymes

The culture extract in addition to phytase consists of 133.2, 41.58, and 310.34 IU/g DMB of xylanase, cellulase, and amylase, respectively (Table 1). The supplementation of these enzymes along with phytase decreases viscosity, amount of loose droppings, and increases mass gain, feed conversion, and egg production [36]. The starch and nonstarch fractions of feed are efficiently hydrolyzed by hydrolytic enzymes improving prebiotic functional properties [23].

Partial purification and characterization of phytase

The ammonium sulfate precipitation and desalting by Sephadex G-25 procedure resulted in 69% enzyme recovery with purification of 2.5 fold and specific activity of 49.83 IU/mg of protein. The highest phytase activity was observed at pH 6.0. The enzyme retained ca. 75% activity over a wide pH range, 2.0–9.5 (Table 1). The pH optima and pH stability profile of phytase determines its ability to act efficiently in the crop and stomach of the digestive tract of poultry [9]. Fungal phytase acts efficiently in stomach (pH 2–5) and needs reactivation to maintain activity in the crop (pH 4–5) of poultry and bacterial phytases act vice versa [17]. The catalytic efficiency of A. niger NCIM 563 phytase will be more in both the crop and stomach of poultry because it retains activity over a wide pH range (2–9.5) and will not require reactivation.

The maximum phytase activity was at 55°C and declined thereafter (Table 1). Phytases from various Aspergilli show optimum temperature in the range 40–65°C [32]. Thermostability studies are performed to predict the stability of phytase during the dry pelleting process employed presently for commercial phytase produced under submerged conditions. At 45°C the phytase enzyme exhibited 90% of its original activity after 60 min. At 60°C the enzyme exhibited 80% activity after 5 min and 20% activity after 60 min (Table 1). Phytase from E. coli (which is considered a candidate for commercial phytase) has also been reported to retain only 24% activity at 60°C for 1 h [10]. This solid state product is therefore more efficient and cost effective than E. coli phytase. Because it does not require downstreaming such as pelleting at high temperature and product formulation, the entire fermented product can be dried and ground and this also does not require high temperature. Therefore the step of pelleting at high temperature can be avoided and the dried product from food grade fungus can be sold as animal feed enzyme.

Phytase activity was moderately stimulated in the presence of 5 mM Ca2+, Fe2+, Fe3+, Ba2+, and Pb2+ and inhibited in the presence of 1 mM Hg2+, Ni2+, Zn2+, Cu2+, and Ag2+ (Table 1). The enzyme retained 63 and 43% activity in the presence of Zn2+ and Cu2+ in contrast to most phytate-degrading enzymes that are greatly inhibited by Cu2+ and Zn2+ [14]. Actually the influence of zinc, iron, copper, and calcium is potentially significant from an applied perspective with respect to phytase in animal feed. Retention of phytase activity in the presence of Pb2+ (125% for 5 mM) and Ag2+ (50% for 1 mM) provides an opportunity for phytate hydrolysis in soils contaminated with heavy metals. The partially purified phytase when subjected to gel filtration chromatography on Sephacryl S-200 along with standard markers showed its native molecular weight 87 kDa (Table 1). The K m and V max were 0.156 mM and 220 μm/min/mg using a Lineweaver–Burk plot. These values fall well within the range previously reported for microbial phytases [35]. The partially purified phytase exhibited single band on nondenaturing PAGE and is detected by activity staining (Fig. 3).

Phytase exhibited high efficacy in phytate hydrolysis at different pH releasing 50, 562.8, 797.8, 470,776, and 733 mg inorganic phosphorus/kg soybean meal at pH 1.5, 2.0, 2.5, 3.5, 5.5, and 6.5, respectively, under emulated gastric conditions (Fig. 4). Phytase from Yersinia rhodei hydrolyzes phytate phosphorus only up to pH 5.5 [13]. But phytase from A. niger NCIM 563 was more resistant to pepsin and released more inorganic phosphorus from soybean meal under emulated gastric conditions over a much broader pH range. This determines the efficacy of A. niger NCIM 563 phytase and is exceptional.

Hydrolysis efficacy of phytate phosphorus in simulated gastric fluid at different pHs. Released inorganic phosphorus (mg/kg soybean) (filled squares). The degradation of phytate was measured after digestion at pH 1.5, 2.0, 2.5, 3.5, 5.5, and 6.5. Hydrolysis efficacy was calculated as the quantity of released inorganic phosphorus from soybean meal. All experiments are carried out in triplicates and their mean values are presented

Conclusion

The present work demonstrates that using response surface optimization employing PBD and BBD gave a high level of phytase production of 154 IU/g DMB along with accessory enzymes in SSF. Among the 11 chosen variables for optimization by PBD glucose, dextrin, NaNO3, distilled water, and MgSO4·7H2O were found to influence phytase production more significantly. Some fungi are known to produce phytase and accessory enzymes by SSF but their low productivities are not comparable with the highest phytase productivity of 38,500 IU/kg/day by A. niger NCIM 563 as shown by studies here. Tray fermentation studies for up-scaling also gave promising results from an industrial point of view. The process can be improved by using advanced bioreactors that provide accurate moisture and temperature control, as well as optimized O2 mass transfer [8]. The partial characterization of phytase enzyme as studied here reveals some exclusive biochemical properties that bring out its potential for use as an animal feed additive. Among them are stability over broad pH range, high efficacy in hydrolyzing phytate phosphorus under emulated gastric conditions, and phytate hydrolysis of heavy metal contaminated soils. Instead of low yield, high cost Smf, SSF by A. niger NCIM 563 for phytase production emerges as a more efficient, less costly, and a more directly applicable process. All these factors corroborate the commercial potential and industrial application of phytase produced by A. niger NCIM 563 as a solid state culture product.

References

Andrews P (1964) Estimation of molecular weight of proteins by Sephadex gel filtration. Biochem J 92:222–223

Bogar B, Szakacs G, Tengerdy RP, Linden JC, Pandey A (2003) Optimization of phytase production by solid substrate fermentation. J Ind Microbiol Biotech 30:183–189

Bogar B, Szakacs G, Pandey A, Abdulhameed S, Linden J, Tengerdy R (2003) Production of phytase by Mucor racemosus in solid state fermentation. Biotechnol Prog 19:312–319

Box GEP, Hunter JS (1957) Multifactor experimental design for exploring response surfaces. Ann Math Stat 28:95–241

Chadha BS, Gulati H, Mandeep M, Saini SH, Singh N (2004) Phytase production by the thermophilic fungus Rhizomucor pusillus. World J Microbiol Biotechnol 20:105–109

Davis BJ (1964) Disc electrophoresis II. Method and application to human serum proteins. Ann N Y Acad Sci 121:404–427

Deutscher MP (1990) Guide to protein purification, methods enzymology, vol 182. Academic, Toronto, p 430

Durand D, Broise D, Blachere H (1988) Laboratory scale bioreactor for solid state process. J Biotechnol 8:59–66

Garrett JB, Kretz KA, O’Donoghue E, Kerovuo J, Kim W, Barton NR, Hazlewood GP, Short JM, Robertson DE, Gray KA (2004) Enhancing the thermal tolerance and gastric performance of a microbial phytase for use as a phosphate-mobilizing monogastric-feed supplement. Appl Environ Microbiol 70:3041–3046

Gilati HK, Chadha BS, Saini HS (2007) Production of feed enzymes (phytase and plant cell wall hydrolyzing enzymes) by Mucor indicus MTCC 6333: purification and characterization of phytase. Folia Microbiol 52:491–497

Gokhale DV, Puntambekar US, Deobagkar DN, Peberdy JF (1988) Production of cellulolytic enzymes by mutants of Aspergillus niger NCIM 1207. Enzy Microbiol Technol 10:442–445

Gunashree BS, Venkateswaran G (2008) Effect of different cultural conditions for phytase production by Aspergillus niger CFR 335 in submerged and solid-state fermentations. J Ind Microbiol Biotechnol 35:1587–1596

Huoqing H, Huiying L, Wang Y, Fu D, Shao N, Wang G, Yang P, Yao B (2008) A novel phytase from Yersinia rohdei with high phytate hydrolysis activity under low pH and strong pepsin conditions. Appl Microbiol Biotechnol 80:417–426

Konietzny U, Greiner R (2002) Molecular and catalytic properties of phytate-degrading enzymes (phytases). Int J Food Sci Technol 37:791–812

Krishna C, Nokes SE (2001) Predicting vegetative inoculum performance to maximize phytase production in solid-state fermentation using response surface methodology. J Ind Microbiol Biotechnol 26:161–170

Lineweaver H, Burk D (1934) Determination of enzyme dissociation constants. J Am Chem Soc 56:658–666

Lei X, Stahl CH (2001) Biotechnological development of effective phytases for mineral nutrition and environmental protection. Appl Microbiol Biotechnol 57:474–481

Lowry OH, Rosebrough NJ, Farr AL, Randall RL (1951) Protein measurement with the Folin phenol reagent. J Biol Chem 193:265–275

Mandviwala TN, Khire JM (2000) Production of high activity thermostable phytase from thermotolerant Aspergillus niger in solid-state fermentation. J Ind Micrbiol Biotechnol 24:237–243

Miller GL, Lorenz G (1959) Use of dinitrosalicylic acid reagent for determination of reducing sugar. Anal Chem 31:426–428

McCleary BV, Sheehan H (1987) Measurement of cereal alpha amylase: a new assay procedure. J Cereal Sci 6:237–251

Ole K, Torben VB, Claus CF (2002) Industrial enzyme applications. Curr Opinion Biotechnol 13:345–351

Omogbenigun FO, Nyachoti CM, Slominski BA (2004) Dietary supplementation with multienzyme preparations improves nutrient utilization and growth performance in weaned pigs. J Anim Sci 82:1053–1061

Pandey A, Selvakumar P, Soccol CR, Nigam P (1999) Solid state fermentation. Proc Biochem 35:397–402

Pandey A, Szakacs G, Soccol CR, Rodriguez-Leon JA, Soccol VT (2001) Production, purification and properties of microbial phytases. Bioresour Technol 77:203–214

Plackett RL, Burman JP (1946) The design of optimum multifactor experiments. Biometrika 33:305–325

Prabhakar A, Krishnaiah K, Janaun J, Bono A (2005) An overview of engineering aspects of solid state fermentation. Malaysian J Microbiol 1:10–16

Raboy V (2001) Seeds for a better future: “low phytate” grains help to overcome malnutrition and pollution. Trend Plant Sci 6:458–462

Reissig JL, Stromiger JL, Leloir LF (1955) A modified colorimetric method for the estimation of N-acetylamino sugars. J Biol Chem 217:959–966

Singh B, Satyanarayan T (2006) A marked enhancement in phytase production by a thermophilic mould Sporotricum thermophile using statistical designs in a cost effective cane molasses medium. J Appl Microbiol 101:344–352

Soni SK, Khire JM (2007) Production and partial characterization of two types of phytase from Aspergillus niger NCIM 563 under SF conditions. World J Microbiol Biotechnol 23:1585–1593

Terebiznik MR, Pilosof AMR (1999) Biomass estimation in solid state fermentation by modeling dry matter weight loss. Biotech Tech 13:215–221

Vats P, Banerjee UC (2004) Production studies and catalytic properties of phytases (myoinositolhexakisphosphate phosphohydrolases): an overview. Enzy. Microbiol Technol 35:3–14

Vohra A, Satyanarayana T (2003) Phytases: microbial sources, production, purification and potential biotechnological applications. Crit Rev in Biotech 23:29–60

Wodzinski RJ, Ullah AHJ (1996) Phytase. Adv Appl Microbiol 42:263–302

Wu YB, Ravindran V, Thomas DG, Birtles MJ, Hendricks WH (2004) Influence of phytase and xylanase, individually or in combination, on performance, apparent metabolizable energy, digestive tract measurements and gut morphology in broilers fed wheat-based diets containing adequate level of phosphorus. Brit Poultry Sci 45:76–84

Acknowledgments

One of the authors, Ms Kavita Bhavsar, thanks Council of Scientific and Industrial Research, Government of India for the financial assistance. We also gratefully acknowledge support and facilities provided by the Center of Excellence in Scientific Computing, National Chemical Laboratory, India.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Bhavsar, K., Ravi Kumar, V. & Khire, J.M. High level phytase production by Aspergillus niger NCIM 563 in solid state culture: response surface optimization, up-scaling, and its partial characterization. J Ind Microbiol Biotechnol 38, 1407–1417 (2011). https://doi.org/10.1007/s10295-010-0926-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10295-010-0926-z