Abstract

This study reported for the first time the simultaneous production of hydrolytic enzymes by Aspergillus niger under solid state fermentation using chicken feather meal as substrate. The effect of some culture parameters for production of protease, lipase, phytase and keratinase enzymes was evaluated using a central composite rotatable design. The results obtained demonstrated that the independent variables initial moisture of the culture medium and incubation temperature presented as highly significant on the enzymes production. The production of protease and lipase followed a similar profile, in which the highest values of enzymatic activities were detected after 48 h of fermentation. The conduction of the fermentative process using an initial moisture of 50%, 30 °C as incubation temperature and supplementation of the feather meal with 15% wheat bran resulted in higher yields of protease (> 300 U g−1) and lipase (> 90 U g−1) after 48 h and satisfactory values of phytase activity (> 70 U g−1) after 72 h. No significant effects of the independent variables on keratinase production were observed. However, under the selected conditions for the other enzymes, keratinase production reached values higher than 13 U g−1 after 72 h fermentation. Thus, our work contributed to the proposal of an alternative process for the simultaneous production of proteases, lipases, phytases and keratinases in a single and simplified process using chicken feather meal.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Brazil is the world’s second largest producer of chicken meat with a production of 12.9 million tons in 2016 [1]. The poultry industry also produces a large amount of waste. In the period 2010–2014, an annual average of 528 thousand tons of feather meal was produced [2].

The wastes from poultry industry are usually directed to the production of inputs for animal feed, fertilizers or simply discarded into the environment. Feather meal, for example, if discarded improperly can result in environmental pollution. Thus, the development of efficient methods for the use and transformation of these wastes in higher value-added products, such as hydrolytic enzymes, becomes a viable alternative [3,4,5].

Hydrolytic enzymes are of great importance in the food industry and in animal nutrition. Proteases can be used in several processes, such as beer production, cheese production, meat brewing, reduction of protein allergenicity and production of protein hydrolysates with higher digestibility and biological activity [6]. Lipases present great relevance in reactions of hydrolysis and synthesis, with highlight being the obtaining of lipids with better nutritional characteristics [7]. Phytases have been widely used as adjuvants in animal feed, as it acts on phytate, reducing this antinutritional factor and releasing phosphorus [8]. Keratinases are proteolytic enzymes that attack peptide bonds in the keratin structure, present in chicken feathers, to convert it to simplified forms, which makes these enzymes potentially applicable in several sectors and industrial processes, such as agroindustry, food, animal feed, chemical, pharmaceutical, leather and textile industries [4, 9, 10].

Thus, this work aimed to study the simultaneous production of hydrolytic enzymes (protease, lipase, phytase and keratinase) by solid state fermentation using Aspergillus niger as a bioconversion agent and chicken feather meal as substrate.

Materials and Methods

Microorganism and Substrate for Solid State Fermentation (SSF)

The microorganism used in this study was A. niger LBA 02 from the culture collection of the Laboratory of Food Biochemistry, School of Food Engineering, University of Campinas, Brazil. Chicken feather meal was kindly provided by Adoro Alimenticia e Comercial Ltda (Varzea Paulista, Sao Paulo, Brazil).

Evaluation of the Effects of Some Factors on Enzymes Production Using Response Surface Methodology

Chicken feather meal was used as substrate for protease, lipase, phytase and keratinase production by A. niger LBA 02 under SSF using 250 mL Erlenmeyer flasks. The substrate was prepared to a final amount of 20 g medium according to the initial moisture and composition as shown in Table 1. The culture media were sterilized and inoculated with a suspension of A. niger LBA 02 spores at 107 spores g−1. Enzymes production was tested at 48, 72 and 96 h fermentation. The crude extract contained the hydrolytic enzymes was obtained by the addition of 100 mL distilled water, homogenized and kept at rest for 1 h. Then, the solution was filtered through a filter membrane (Whatman® qualitative filter paper no. 1) to obtain a crude enzyme solution free of any solid material.

A central composite rotatable design (CCRD) with 17 runs was applied to verify the effects of some factors (independent variables) on enzymes production as well as to establish the mathematic models. The three variables used in this study were initial moisture of the solid substrate (%) (x1), incubation temperature (°C) (x2) and supplementation of the chicken feather meal with wheat bran (%) (x3) while the dependent variables were protease, lipase, phytase and keratinase activities (Table 1).

For the determination of the most suitable process conditions for simultaneous production of the hydrolytic enzymes, the results generated from CCRD were adjusted to second order polynomial equations, as shown in Eq. 1:

where Y is the estimated response for enzymes activities, i and j take value from 1 to the number of variables (n = 3 in our study), β0 is the constant coefficient, βi and βij values are the linear and quadratic coefficients, respectively, while xi and xj are the coded factors. The quality of fit of the second-order model equations was verified using the coefficient of determination (R2) and F test (analysis of variance-ANOVA). The software Statistica 13.3 from TIBCO Software Inc. (Palo Alto, California, USA) was employed for the design of experiments, effects analysis and model building.

Determination of Protease Activity

The protease activities were determined according to the methodology described by De Castro et al. [11]. The amount of enzyme that promoted a difference of 0.01 in absorbance at 428 nm, result of azo dye release, per minute of reaction between the blank reaction and the sample was defined as one unit of protease activity (U). The final values of protease activity were expressed as U per gram of dried substrate (U g−1).

Determination of Lipase Activity

Lipase activity was measured according to the method described by Silva et al. [12]. The amount of lipase required to liberate 1 μmol of fatty acid per minute per mL of the enzyme solution under the assay conditions was defined as one unit of lipase activity (U). The final result of lipase activity was expressed as U per gram of dried substrate (U g−1).

Determination of Phytase Activity

Phytase activity was determined according to the method described by Bhavsar et al. [8]. The amount of enzyme required to release 1 μmol of inorganic phosphorus per minute per mL of enzyme extract under the reaction conditions was defined as one unit of phytase activity (U). The final result of phytase activity was expressed as U per gram of dried substrate (U g−1).

Determination of Keratinase Activity

Keratinase activity was determined according to the method described by Sahoo et al. [13] using keratin azure as an insoluble substrate. The amount of enzyme required to produce a difference of 0.01 in absorbance at 280 nm per minute of reaction between the blank reaction and the sample was defined as one unit of keratinase activity (U). The final values of keratinase activity were expressed as U g−1.

Results and Discussion

Effects of the Independent Variables on Enzymes Production Using a CCRD

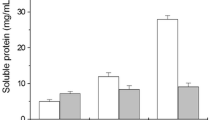

The CCRD matrix for protease, lipase, phytase and keratinase production after 48, 72 and 96 h fermentation using chicken feather meal as solid substrate with the results from the experimental runs was shown in Table 2. The kinetics of fermentation showed a profile change over time, but in general, the best results for protease and lipase production were observed at 48 h, while for phytase and keratinase enhancement, the highest values were detected at 72 h. The protease production at 48 h reached a minimum value of 5.98 U g−1 (run 8) and a maximum value of 387.85 U g−1 (run 13). The lipase production at 48 h on the other hand was found ranging from 13.70 (run 6) to 111.85 U g−1 (run 13). For phytase production at 72 h, 41.93 (run 1) and 117.16 U g−1 (run 7) were the lowest and the highest values detected, respectively. Results ranging from 0.50 (run 3) to 31.60 U g−1 (run 5) were observed for keratinase production at 72 h. The high variation of the results between the runs performed in CCRD is a strong indication of the relevance of the studied factors on the enzymes production.

The multiple regression analysis technique included in the CCRD was applied to estimate the model’s coefficients. Final reduced models in terms of coded values to predict the maximal enzymes activities, namely: protease and lipase production at 48 h fermentation and phytase production at 72 h fermentation, were showed in Table 3.

From Table 3, the independent variables moisture (x1), temperature (°C) (x2) and their interactions have the most significant effects on the resulting responses (p < 0.10). The insignificant term coefficients were excluded from the model equations. For protease production at 48 h, the linear and quadratic term of moisture (x1) had negative effects, while the linear and quadratic terms of temperature (°C) (x2) had positive and negative effects, respectively. The estimated coefficients for lipase production at 48 h fermentation showed positive and significant effects for the linear terms of moisture (x1) and temperature (°C) (x2) and negative and significant effects for the quadratic terms of the same variables. On the other hand, phytase production at 72 h fermentation was the only response that was significantly affected by the incorporation of wheat bran into the culture medium (x3), in which the interaction of this variable with the moisture (x1x3) and temperature (x2x3) exerted negative effects on the production of the enzyme. The results of regression analysis for keratinase production showed that the independent variables had no significant effects on enzyme production, so the model was not considered statistically adequate to predict values for this response.

The effects of different factors on enzymes production using chicken feather as substrate were reported by several studies. Bhari et al. [4] investigated the capacity of 73 bacterial strains isolated from poultry dump sites and selected an isolate that showed high keratinase activity, namely as Bacillus aerius NSMk2. Sequentially, the authors evaluated the effect of different sources of carbon and nitrogen and of three process variables (feather concentration, pH and temperature) on keratinase production using a CCRD under submerged fermentation. In the first step of optimization study, the supplementation of the culture medium with beef extract (2.5%) and fructose (2.0%) were defined as the optimal conditions for keratinase production by Bacillus aerius NSMk2. The maximum keratinase production (127.63 U mL−1) was achieved after 48 h fermentation using feather concentration of 1.375%, pH 7.5 and incubation temperature of 35 °C. Similar to the observed in our study for protease and lipase production, it was verified that the linear term of the temperature showed a positive and significant (p < 0.05) effect on keratinase production, while the quadratic term of this factor was significantly negative [4]. This result corroborates that the increase in incubation temperature favors the production of these enzymes up to a certain point, from which this effect is negative and results in a decrease in the enzymes production. Although the models for keratinase production were not statistically significant in our study, it was possible to observe that the highest enzyme activities were detected at temperatures ranging from 24 to 30 °C.

Another fact worth mentioning in other studies that evaluated the production of enzymes using chicken feathers as substrate is the need to supplement the culture media with carbon and nitrogen sources. In our study, wheat bran, a low-value by-product, was used for this purpose. Although no significant or positive effects of wheat bran supplementation on the feather meal medium were observed, preliminary studies performed in our research group (data not shown) demonstrated that the presence of wheat bran anticipates the peak production of the enzymes by A. niger LBA02, reducing the fermentation time required to achieve high levels of production. Several studies have reported the use of wheat bran as a suitable substrate for the production of enzymes by solid-state fermentation [11, 14,15,16].

The enzymes production under SSF can be affected by several cultivation factors and specific chemical components present in the substrates. The presence of protein sources can induce the protease secretion by the microorganism, for example. It was expected that chicken feathers would be excellent substrates for induction of the production of proteolytic enzymes by the high content of protein (approximately 80%) [3]. However, the extensive cross-linking by cysteine disulfide bonds, hydrogen binding and hydrophobic interactions of keratin, present in large quantities in chicken feather, make its degradation very slowly in nature and hinders the growth of microorganisms [17]. The supplementation of chicken feather meal with nutrient sources more assimilable by the microorganisms allows for a faster initial development accompanied by a considerable increase of biomass, facilitating the colonization of the substrate and consequently the synthesis of the enzymatic support necessary for the degradation of the feathers. This strategy was used by several studies on keratinase production using chicken feather as substrate [4, 17,18,19].

Mazotto et al. [20] studied the keratinase production by Aspergillus niger mutants under submerged and solid-state fermentation (SSF). Their results showed that the keratinase production by A. niger 3T5B8 strain cultivated under SSF was seven times greater. Keratinase production by strains of the genus Aspergillus under solid-state fermentation was rarely described in scientific studies. In this sense, the development of bioprocesses to assess the ability of Aspergillus niger strains to produce keratinases, could contribute to the development of a biotechnological process for the degradation of feather waste [20]. Additionally, papers reporting the production of other hydrolytic enzymes using chicken feathers as substrate are also scarce. Thus, our work also contributes to the proposal of an alternative process for the simultaneous production of proteases, lipases, phytases and keratinases in a single and simplified process.

Analysis of Variance (ANOVA)

The statistical adequacy and significance of the quadratic models was further verified by analysis of variance (ANOVA). Test F (F-ratio), coefficient of determination (R2) and p values of the final reduced models for protease and lipase production at 48 h and phytase at 72 h by A. niger LBA02 and chicken feather meal as solid substrate were evaluated for validity and accuracy of the proposed models (Table 3). The high R2 values, which were above 0.80, Fcalculated > Ftabulated (F-ratio > 1) and the obtained p values < 0.05 showed that the equations were well fitted to the experimental data and can be used successfully to predict the variance occurrence in protease, lipase and phytase production by A. niger LBA02 using chicken feather meal supplemented with wheat bran as substrate (Table 3).

Interpretation of Contour Plots and Validation Tests

Figures 1, 2 and 3 show the contour plots for protease, lipase and phytase production, respectively, as function of the independent variables used in the CCRD and the fitted line plots between the observed and predicted values by the equation model. These figures are the best way to clearly present the relationships between the independent variables besides showing how the quadratic equations of the responses fit to the experimental data [21].

In general, protease (Fig. 1) and lipase (Fig. 2) yields were favored under the culture conditions at the CCRD center points, where the initial moisture of the medium was 50%, the incubation temperature was 30 °C and the culture medium containing feather meal was supplemented with 15% wheat bran. However, phytase production was affected differently from the other enzymes. In this case, higher values of initial moisture, incubation temperature and supplementation of the feather meal with wheat bran resulted in higher yields of phytase production (Fig. 3).

Although the culture conditions of the microorganism were not the same for the simultaneous production of the enzymes, the use of the independent variables in the values set at the central point of the experimental design allowed the synthesis of high values of protease and lipase and intermediate values of phytase. Also, in this context, it is important to remember that although the results for keratinase production did not generate statistically significant models, in the aforementioned conditions, high production values were also detected for this enzyme.

Validation assays were performed to verify the accuracy of the mathematic models obtained for the protease, lipase and phytase production with three assays. The values of relative standard deviation between the experimental and predicted responses by the equations ranged from 0.63 to 11.69%, thereby confirming the statistical adequacy of the quadratic models (Table 4).

An alternative way to use chicken feather meal as substrate for simultaneous production of protease, lipase, phytase and keratinase by A. niger LBA02 under SSF was provided in this study. More specifically, these results can contribute to the availability of data on the production of fungal keratinases, which are still known in the literature.

References

ABPA - Associação Brasileira de Proteína Animal (2018) http://www.abpa-br.com.br/. Accessed 11 Aug 2018

ABRA - Associação Brasileira de Reciclagem Animal (2018) http://abra.ind.br/. Accessed 18 Aug 2018

Tesfaye T, Sithole B, Ramjugernath D, Chunilall V (2017) Valorisation of chicken feathers: characterisation of chemical properties. Waste Manag 68:626–635. https://doi.org/10.1016/j.wasman.2017.06.050

Bhari R, Kaur M, Singh RS, Pandey A, Larroche C (2018) Bioconversion of chicken feathers by Bacillus aerius NSMk2: a potential approach in poultry waste management. Bioresour Technol Rep 3:224–230. https://doi.org/10.1016/j.biteb.2018.07.015

Cheong CW, Lee YS, Ahmad SA, Ooi PT, Phang LY (2018) Chicken feather valorization by thermal alkaline pretreatment followed by enzymatic hydrolysis for protein-rich hydrolysate production. Waste Manag 79:658–666. https://doi.org/10.1016/j.wasman.2018.08.029

Tavano OL (2013) Protein hydrolysis using proteases: an important tool for food biotechnology. J Mol Catal B Enzym 90:1–11. https://doi.org/10.1016/j.molcatb.2013.01.011

Angajala G, Pavan P, Subashini R (2016) Lipases: an overview of its current challenges and prospectives in the revolution of Biocatalysis. Biocatal Agric Biotechnol 7:257–270. https://doi.org/10.1016/j.bcab.2016.07.001

Bhavsar K, Buddhiwant P, Soni SK, Depan D, Sarkar S, Khire JM (2013) Phytase isozymes from Aspergillus niger NCIM 563 under solid state fermentation: biochemical characterization and their correlation with submerged phytases. Process Biochem 48:1618–1625. https://doi.org/10.1016/j.procbio.2013.08.001

Brandelli A, Sala L, Kalil SJ (2015) Microbial enzymes for bioconversion of poultry waste into added-value products. Food Res Int 73:3–12. https://doi.org/10.1016/j.foodres.2015.01.015

Gopinath SCB, Anbu P, Lakshmipriya T, Tang TH, Chen Y, Hashim U, Ruslinda AR, Arshad MK (2015) Biotechnological aspects and perspective of microbial keratinase production. Biomed Res Int 2015:1–10. https://doi.org/10.1155/2015/140726

De Castro RJS, Nishide TG, Sato HH (2014) Production and biochemical properties of proteases secreted by Aspergillus niger under solid state fermentation in response to different agroindustrial substrates. Biocatal Agric Biotechnol 3:236–245. https://doi.org/10.1016/j.bcab.2014.06.001

Silva EB, Ohara A, Fernandes CM, Barbosa PPM, Macedo GA (2015) Screening of filamentous fungi from Brazilian rainforests for enzyme production. Afr J Microbiol Res 9:332–342. https://doi.org/10.5897/AJMR2014.7234

Sahoo DK, Das A, Thatoi H, Mondal KC, Mohapatra PK (2012) Keratinase production and biodegradation of whole chicken feather keratin by a newly isolated bacterium under submerged fermentation. Appl Biochem Biotechnol 167:1040–1051. https://doi.org/10.1007/s12010-011-9527-1

Aljammas HA, Fathi HA, Alkhalaf W (2018) Study the influence of culture conditions on rennin production by Rhizomucor miehei using solid-state fermentations. J Genet Eng Biotechnol 16:213–216. https://doi.org/10.1016/j.jgeb.2017.10.004

Cunha MC, Silva LC, Sato HH, De Castro RJS (2018) Using response surface methodology to improve the l-asparaginase production by Aspergillus niger under solid-state fermentation. Biocatal Agric Biotechnol 16:31–36. https://doi.org/10.1016/j.bcab.2018.07.018

Zhao G, Ding LL, Pan ZH, Kong DH, Hadiatullah H, Fan ZC (2019) Proteinase and glycoside hydrolase production is enhanced in solid-state fermentation by manipulating the carbon and nitrogen fluxes in Aspergillus oryzae. Food Chem 271:606–613. https://doi.org/10.1016/j.foodchem.2018.07.199

Fakhfakh-Zouari N, Haddar A, Hmidet N, Frikha F, Nasri M (2010) Application of statistical experimental design for optimization of keratinases production by Bacillus pumilus A1 grown on chicken feather and some biochemical properties. Process Biochem 45:617–626. https://doi.org/10.1016/j.procbio.2009.12.007

Reddy MR, Reddy KS, Chouhan YR, Bee H, Reddy G (2017) Effective feather degradation and keratinase production by Bacillus pumilus GRK for its application as bio-detergent additive. Bioresour Technolol 243:254–263. https://doi.org/10.1016/j.biortech.2017.06.067

Bagewadi ZK, Mulla SI, Ninnekar HZ (2018) Response surface methodology based optimization of keratinase production from Trichoderma harzianum isolate HZN12 using chicken feather waste and its application in dehairing of hide. J Environ Chem Eng 6:4828–4839. https://doi.org/10.1016/j.jece.2018.07.007

Mazotto AM, Couri S, Damaso MCT, Vermelho AB (2013) Degradation of feather waste by Aspergillus niger keratinases: comparison of submerged and solid-state fermentation. Int Biodeterior Biodegrad 85:189–195. https://doi.org/10.1016/j.ibiod.2013.07.003

Sulaiman NS, Hashim R, Amini MHM, Danish M, Sulaiman O (2018) Optimization of activated carbon preparation from cassava stem using response surface methodology on surface area and yield. J Clean Prod 198:1422–1430. https://doi.org/10.1016/j.jclepro.2018.07.061

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

de Oliveira, C.C., de Souza, A.K.S. & de Castro, R.J.S. Bioconversion of Chicken Feather Meal by Aspergillus niger: Simultaneous Enzymes Production Using a Cost-Effective Feedstock Under Solid State Fermentation. Indian J Microbiol 59, 209–216 (2019). https://doi.org/10.1007/s12088-019-00792-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12088-019-00792-3