Abstract

Milling and subsequent air classification can be exploited for production of functional protein-enriched fractions from legumes and grains. Fracture behaviour is of large relevance to optimal disentanglement of protein and starch and is determined by the thermomechanical morphology of the seeds. Thermomechanical properties of peas were explored as a function of temperature and moisture content. Differential scanning calorimetry and thermal mechanical compression tests were carried out on pea protein and starch isolates yielding similar glass transition temperatures. Glass transition lines were successfully constructed using the Gordon–Taylor equation. Subsequently, three regions were identified in the state diagram; starch in the glassy and protein in the rubbery state, both components in the glassy state, and both components in the rubbery state. From single pea fracture experiments, it was found that the completely glassy peas fractured at a smaller critical compression distance compared to the peas in the other two regions. This can be explained by the elastic behaviour of the rubbery protein network, having a detrimental effect on the energy efficiency of milling processes. However, from scanning electron microscopy, it appeared that in rough fracture planes, visible when the protein was in the rubbery state, starch granules were present as more separate identities, suggesting increased disentanglement. Disentanglement of protein and starch by milling would then be optimal when protein is in the rubbery state. The latter can be achieved by milling at increased temperature and/or moisture content, which would be an attractive alternative.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

With the increasing world population and prosperity, the demand for protein-rich foods is expected to double in the coming decades. The transition from a livestock to a plant-based protein supply could lead to a more efficient food production (Aiking 2011). Conventional production methods of plant-derived protein isolates usually involve wet fractionation, which involves copious amounts of water, uses significant amounts chemicals (e.g. for acidification and neutralisation), and often results in large amounts of wastewater. A less common method for production of protein concentrates, especially applicable to pulses and grains, involves dry milling and subsequent air classification. The major advantages of this method are higher energy efficiency and retention of native functionality of the proteins (Schutyser 2010). However, only limited protein concentration can be obtained with this method (e.g. 55 % for field peas) because of the entanglement of the protein and starch. In field peas, the cotyledon, which is the largest part of the seed, consists of starch granules (53 %) tightly embedded in a matrix with protein bodies (22 %; de Almeida Costa 2006; Boye 2010). Since milling enables protein bodies and starch granules to be disentangled, it is a critical step in the process of separation of these compounds. Essential to the success of dry fractionation is thus knowledge about the structural properties of the cotyledon and its corresponding milling behaviour (Tyler 1981, 1984; Bergthaller 2001; Naguleswaran 2010).

The milling behaviour of legumes varies strongly with the mechanical properties of the seed and its constituents since these determine the fracture behaviour. Structural tissue properties, such as cell morphology or presence of tissue layers, affect the fracture behaviour. This behaviour is also influenced by microstructural properties of the constituents, which are a function of the temperature and the moisture content. In dried pulses, starch granules and protein bodies are in the glassy state (Ballesteros 2011), which is a non-equilibrium solid state (Abiad 2009). Adding water or increasing temperature causes starch and proteins to change to the rubbery state. However, as proteins and starch exhibit different glass transitions, a region exists where proteins are in the rubbery state, while the starch granules are still glassy.

Numerous analysis methods can be used to measure glass transition in food ingredients. These methods can be classified into thermal (differential scanning calorimetry), mechanical (thermo mechanical analysis, dynamic mechanical analysis), spectroscopic (electron spin resonance, nuclear magnetic resonance) and electrical (dielectric measurements) methods (Seyler 1994). With differential scanning calorimetry (DSC), the glass transition temperature is derived from the change in heat capacity between the glassy and the rubbery states. The mechanical and dielectric techniques measure a change in mobility of molecules around the glass transition. The spectroscopic techniques determine the glass transition based on information on chemical bonding and molecular mobility (Roos 2010). The most common method is DSC because it is an easy, rapid and reliable method. Several authors reported that DSC may not accurately measure the glass transition temperature (T g ) in complex food systems (Boonyai 2007; Shrestha 2007; Sablani 2010). For high molecular weight protein and carbohydrates, the change in specific heat capacity is small during glass transition. This small change causes broad and indistinct transitions. For these materials, detecting changes in the mechanical properties has proven to be more sensitive. A relatively new and promising test to measure this is the thermal mechanical compression test (TMCT), which is described by Boonyai (2007). The test is relatively easy and was shown to give accurate values for the glass transition in various dry food systems. It uses a probe, which applies a constant force on the sample under continuous heating. The T g is then characterised by displacement of the probe, resulting from increased mobility of materials in the rubbery state. The TMCT method has been compared with DSC and thermal mechanical analysis and successfully applied to various dry food systems, such as skimmed milk powder (Boonyai 2007), pasta (Rahman 2011) and rice (Thuc 2010).

In this study, it is investigated whether specific combinations of moisture contents and temperature could provide different mechanical properties to starch and protein (e.g. due to glass transition) and thus lead to different fractures through cotyledon cells. This fracture behaviour is relevant for dry fractionation purposes, which requires complete disentanglement of protein bodies and starch granules. It is anticipated that the results support the design of optimal pretreatment and milling procedures. We report on freeze and glass transition lines of the cotyledon tissue constituents of field peas based on DSC and TMCT analyses of pea starch and protein isolates. Moreover, the measured glass transition temperatures are compared to the calculations following the Gordon–Taylor equation (Gordon 1952; Sun 1997). The data on glass transition are combined with experimental data on single pea fracture behaviour as characterised by stress–strain curves and scanning electron microscopic (SEM) images. It should be emphasised that these single pea fracture experiments are only indicative for fracture during actual milling processes, as the forces and deformation rates applied during milling are of a different order of magnitude. Finally, it is discussed how single pea fracture behaviour is influenced by the microstructural properties at different temperatures and moisture contents. This discussion provides a basis for the further systematic exploration of milling and the dry fractionation process.

Materials and Methods

Materials

Pre-dried dehulled yellow peas, Pisum sativum, were purchased from Alimex (The Netherlands). Pea protein isolate (NUTRALYS® F85G) and pea starch isolate (PEA STARCH N—735) were obtained from Roquette (France). These isolates have been produced from pea flour via a wet fractionation process, in which a slurry is prepared from pea flour. The starch is then recovered by cyclone separation and subsequently dried. The pea proteins are coagulated from the slurry and spray dried.

Sample Preparation

The moisture content of pea protein and starch isolates were varied to obtain glass transition data (5–20 % w/w) and to obtain freeze transition data (20–80 % w/w). Based on the DSC results, moisture contents were selected in combination with a specific temperature to obtain peas with protein and starch in rubbery and/or glassy states. Following, fracture experiments of these peas were carried out with a Texture Analyser. Peas and isolates were brought to the target moisture content (10–80 %) by addition of water followed by equilibration overnight. Peas and isolates with a target moisture content below 10 % were placed in a climate chamber at 20 °C with a relative humidity of 5 %. The relative humidity in the climate chamber was set according to the isotherm of the isolates. The isotherm was determined with the Dynamic Vapour Sorption Advantage apparatus (Surface Measurement Systems NA, Allentown, PA, USA). The final moisture content of all samples was determined in duplicate by measuring the weight loss after overnight drying at 105 °C.

Thermal Transition by DSC

DSC measurements were performed using a Diamond DSC (PerkinElmer). The glass transition temperature was measured for pea protein isolates and pea starch isolates at various moisture contents. About 20–25 mg of sample was weighed in a DSC stainless steel pan. The DSC analyser was calibrated using indium, and an empty stainless steel pan was used as a reference. During the measurement, nitrogen was used as carrier gas. Samples were cooled to −60 °C at a rate of 100 °C/min followed by a heating ramp of −60 to 160 °C at a rate of 10 °C/min. The heating rate was chosen based on literature (Casey 1982; Bora 1994; Ratnayake 2001; Simsek 2009). A second cooling step at a rate of 100 °C/min to −60 °C and a second heating step from −60 to 160 °C were applied to obtain a clearer glass transition. Each sample was prepared in duplicate and each of these duplicates was measured twice. Measurements were analysed for the glass transition midpoint using Start Pyris Software.

TMCT Method

The TMCT device is composed of a concentric cylinder (20 mm diameter, 40 mm height) with a water chamber in the sidewalls and a solid bottom (Fig. 1) for temperature control. A ramp of 5 to 80 °C was created by connecting the water chamber to a water bath (Julabo FP50-HE, Julabo, Seelbach, Germany). A heating rate of 3 °C/min was used. The temperature in the bottom of the cylinder was continuously recorded (Testo 175 T3, Testo GmbH & Co., Lenzkirch, Germany). A 15 mm cylindrical probe attached to a Texture Analyser (Instron-5564Series-Table-Model-Systems-Twin-column-design, Canton USA) equipped with a 2000 N load cell, exerted a constant force of 30 N on 2 g of sample. The force–displacement curve was measured with the Bluehill 2 Texture Profile Analysis software. For each sample, the force-displacement curve was corrected for thermal expansion of the equipment by subtracting the force–displacement curve of maltodextrin (Aldrich Chemical Co.; dextrose equivalent, 13–17), which was chosen as reference because it has a high T g value (T g > 180 °C), and it is physically and chemically stable. Skim milk powder (Sigma-Aldrich) was used to compare the setup with the Thermal Mechanical Compression Test designed by Boonyai (2007). Each sample was measured at least in duplicate.

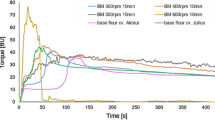

Fracture Behaviour Analysis

The mechanical properties of pea cotyledons were determined with the same Texture Analyser and sample holder as used for the TMCT measurements (Fig. 1). The temperature was controlled by connecting the water chamber to a water bath (Julabo FP50-HE, Julabo, Seelbach, Germany). A dehulled and split cotyledon, flat-side down, was compressed between the cylindrical probe and the bottom-plate at a crosshead speed of 20 mm/min till breakage occurred. The force-deformation curve was recorded with the Bluehill 2 Texture Profile Analysis software. For each treatment, ten cotyledons were randomly selected and the average critical compression distances leading to fracture were reported.

Microscopic Analysis with SEM

The SEM images of yellow peas broken by Texture Analyser at various moisture contents and temperatures were obtained in a high-resolution field emission scanning electron microscope (Magellan 400 FEI, Eindhoven, The Netherlands). Conductive carbon cement (Plano GmbH, Wetzlar, Germany) was used to fix the samples on SEM sample holders and to increase the electron conducting at the interface. After the solvent evaporated, the dry samples were sputter coated with platinum (Jeol JFC 1200 fine coater Tokyo, Japan). The samples were analysed at 2 kV room temperature and the images were contrast enhanced with Photoshop CS5.

Results and Discussion

Thermomechanical Characterization of Pea Protein and Starch

DSC thermal curves for pea protein and starch isolates were measured at a dry matter content of 20 % (w/w) up to 95 % (w/w). The curves of both isolates showed a glass transition region instead of a sharp glass transition point. An explanation is that both protein and starch are not pure components, but a mixture of components, which exhibit a distribution of glass transition temperatures (Cuq 2003). The glass transition temperature midpoint was determined and plotted in the state diagram given in (Fig. 2). The glass temperature decreases as the moisture content increases due to the plasticizing effect of water. Water works as a plasticizer because it increases the mobility of polymer chains (Levine 1986). Peas that have a moisture content and temperature corresponding to the region below the glass transition points are in the glassy state. This means that dried peas at room temperature are glassy, as their dry matter content is typically around 90 %. Peas are biologically in this quiescent state to survive dormancy (Ballesteros 2011). At higher moisture contents peas are in the rubbery state at room temperature. Increasing the moisture content or the temperature induces a glass transition for both protein and for starch, but faster for the protein. This difference has been recorded for several sources of protein and starch in the literature (Cuq 2003). The glass transition temperature for pea starch at similar moisture content is higher compared to pea protein because the molecular weight of starch is larger than that of protein, which is in line with the data from Fig. 2 (Colonna 1984; Owusu-Ansah 1991). A difference in T g for pea protein and pea starch is interesting as it means that the pea cotyledon has a state in which protein is already in the rubbery state while starch is still in the glassy state. At a dry matter content below 0.8 (in kilograms dry matter per kilogram total) the phase transition (freezing) of the water present in the samples gives more pronounced peaks than the glass transition peaks and thus no data could be obtained on glass transition (Sman 2007; Ballesteros 2011).

The TMCT was used to confirm the T g values measured with the DSC. The TMCT curves of pea protein (moisture, 13.9 %) and starch (moisture, 13.5 %) isolates are shown in (Fig. 3). These curves were obtained by subtracting the compression of the reference from the compression of each sample, the reference being a material that remains in the glassy state. This reference will also undergo compression due to normal relaxation in the powder bed due to rearrangement of the powder particle. By subtracting this from the compression behaviour of the actual sample, the compression due to changes in its state is obtained. When the reference is compressed less during heating than a sample, the TMCT curve shows an increase. The reference can be compressed less compared to a sample because the reference remains in the glassy state during the measurement while the sample undergoes a state transition. More compression is expected of a rubbery sample since molecules in the rubbery state have a higher mobility than molecules in the glassy state (Slade 1991). In Fig. 3, pea starch showed more compression than the reference: the curve increases with increasing temperature. This is the behaviour that is usually found with relatively simple materials (Boonyai 2007; Rahman 2011). The curve of pea protein isolate, however, shows first a compression, followed by an extension. The glass transition temperature of pea protein isolate coincides with the bending point of compression. We speculate that this unexpected behaviour is because of relaxation of the powder particles above the glass transition. The protein isolate particles are spray dried, and hence are quite porous. As soon as the particles become rubbery, the pores will collapse under the compression, and the sample will compress considerably. Thus, it is reasonable to assume that the region where the sample curves start to deviate from zero is the glass transition region.

TMCT curves of pea protein and starch isolates. The extension of the probe, which applies a force of 30 N on a sample, is plotted as a function of the increasing temperature of pea protein isolate (black curve; moisture, 13.9 %; T g , 25 °C) and pea starch isolate (grey curve; moisture, 13.5 %; T g , 59 °C)

Figure 4 gives a comparison between the T g values measured with DSC and TMCT. The isolates that were expected to have a T g between 20 and 60 °C were measured. In this range, the TMCT set-up was able to detect the T g . For each measurement, a new sample was made; therefore, samples tested by DSC and TMCT did not have exactly the same moisture content. The measurements of the TMCT strengthen the results obtained with the DSC. TMCT results can however differ from DSC results, because DSC monitors the sudden enthalpic and heat capacity change during glass–rubber transition whereas TMCT determines the exact point of mechanical deformation. Therefore, the T g from TMCT can be expected closer to the stickiness point, which is usually several degrees higher than the T g from DSC (Shrestha 2007). As the TMCT measures changes at the particle surface, the test can give lower T g values than DSC (Boonyai 2007). No differences were however found for the pea protein and starch isolates.

The Gordon–Taylor equation is fitted to the measured glass transition temperatures of pea protein and starch isolates. This equation is commonly used to describe the effect of the water content on the glass transition temperature, T g , of a specific component. Several other equations exist that can be used like, the Couchman–Karasz equation or the Kwei equation. The Gordon–Taylor equation is chosen because it has least parameters and has been successfully applied to seeds (Sun 1997). DSC results are used for this purpose because the measured data range was larger than for TMCT. The Gordon–Taylor equation can be written as:

where T g1 and T g2 are the glass transition temperatures of the water and pea isolates, respectively. T g1 is the glass transition of pure water and is taken to be 136 K. This value is, however, subject of discussion (Velikov 2001; Yue 2004). Further, w 1 and w 2 are the weight fractions of water and pea isolates in the blend; k is a fitting parameter. Parameter k can be related to the strength of interactions of the sample components (Gordon 1952).

The values of the parameters k and T g2 for the Gordon–Taylor equation were obtained by minimising the sum of squares of the differences between the measured T g and the predicted T g . The nonlinear regression routine was implemented in Matlab®. It is noted that only dry matter contents above 0.8 (kg dry matter/kg total) were included for this because at lower dry matter contents, the freezing line of water interferes with the results. The freezing line of water is obtained by plotting a line through the freezing points of the water in the samples. The parameters and the state diagram are given in (Table 1 and Fig. 5, respectively). The values of the parameters of the pea protein and starch isolates found are in the same order of magnitude as those found for other plant-derived components (Table 1).

Fracture Behaviour of Single Peas in Relation to Protein-Starch Disentanglement

The constructed state diagram of pea protein and pea starch was used to analyse fracture behaviour of peas in different states. Based on the state diagram, the state of starch and protein in peas was changed by increasing the moisture content and/or the temperature. Figure 6 shows the effect of temperature (lower right graph) and dry matter content (upper right graph) on the critical compression distance leading to fracture. An increase in temperature or an increase in moisture content led to an increase in compression distance, which is in agreement with the literature and is explained by the elastic properties of the material (Dijkink 2002; Altuntas 2007; Łysiak 2007). Peas with a low moisture content and /or low temperature showed one clear fracture line in the stress–strain curves obtained with the Texture Analyser (results not shown). Peas with a high moisture content and/or high temperature showed several small fracture lines in these curves as compression advanced. The critical compression distance was found to change between a dry matter content of 0.85 and 0.90 (kilograms of dry matter per kilogram total). This was also reported by Dijkink (2002) and Łysiak (2007). Around a dry matter content of 0.87 (kilograms of dry matter per kilogram total), the glass transition of pea protein takes place. The compression of peas containing rubbery protein and glassy starch proceeds differently from that of peas having glassy protein and glassy starch, which is explained by the appearance of the protein as a network around the starch granules. During the transition between the glassy and rubbery state for the starch, no influence was observed on the critical compression distance. Results of experiments with peas with a dry matter content lower than 0.83 (kilograms of dry matter per kilogram total) are not shown because no fracture occurred, but only plastic deformation.

State diagram of peas. The circles in the state diagram represent the points in which samples are taken (black curve protein, grey curve starch). On the right side, the Texture Analyser results are plotted in which the critical compression distance is a function of temperature or moisture content (error bars standard deviation)

As could be expected, it was observed that completely glassy peas showed clearly brittle fracture behaviour; with one impact the cotyledon was broken along a flat fracture surface. Rubbery peas showed more elastic fracture behaviour, indicating that during compression the cells were gradually torn apart. These mechanical properties are very relevant for the efficiency of a milling process. The energy input for size reduction of elastic materials is much higher than for brittle materials. In addition, creating smaller and smaller particles will become progressively more difficult because the weakest flaws will have been eliminated as the size is reduced, and the many microscopic fractures act as an energy sink during deformation (Coulson 2002). Therefore, it is expected that ultrafine grinding of rubbery peas will be difficult or impossible during impact or jet milling. Instead, cryogenic milling is referred to as a method to increase brittleness of particles and thus grind materials more easily into an ultrafine powder (Hemery 2011). However, if the fracture behaviour of the rubbery peas is such that the protein and starch are more disentangled, it could be acceptable that more energy is consumed for milling. This may for example coincide with the ambient milling of wheat bran, where ambient milling has been found to provide more tissue disentanglement of constituent layers with corresponding mechanical properties compared to cryogenic milling (Hemery 2011). Still, it should be investigated whether the size reduction that can be achieved is also sufficient.

Subsequently, we investigated the fracture surface of the peas broken with the Texture Analyser using SEM. Images were taken of the cells of the inner pea cotyledon. These cells were selected to obtain uniformity and a representative view because the chemical composition and the microstructure of the inner and outer layers differs (Kosson 1994; Otto 1997).

The microstructure of the fracture surface of dried glassy peas is shown in (Fig. 7a). Irregularly shaped cells form a compact matrix. Inside the cells, starch granules (53 %) are tightly embedded in a matrix with protein bodies (22 %). The typical size of a pea starch granule is 15 μm and the typical size of a pea protein body is 2 μm (Whitaker 1977). In these cells, both protein and starch were in the glassy state. The chemical bonding between starch granules and the protein matrix has been reported to be relatively weak in dry pea cotyledon cells (Parker 2008). Fracture was therefore assumed to follow these contact lines, which was confirmed by parts of the granules emerging from of or by empty holes remaining in the fractured surface (Fig. 7a). Fracture, however, also occurred in between cells.

Figure 7b and c show the fracture surface of peas with protein in the rubbery state. The fracture plane was rougher and irregular compared to that of peas that were completely in the glassy state. Moreover, the starch granules seemed to be more disentangled from the protein matrix. Figure 7d and e show the break surface of pea cells in the rubbery state. Also in these images, the starch granules are more separate from the protein matrix compared to completely glassy cells. The fracture lines in these cells did not coincide with the contact lines between starch granules and protein matrix, but were throughout the whole cell. Similar fracture behaviour was observed for cowpeas after a heat treatment of 50–90 °C (Hung 1990). Another observation from the SEM images was that cells in the rubbery state were less tightly ordered than cells in the glassy state. The cell wall of these rubbery cells had loosened, due to heating and the addition of water.

The upper row images of Fig. 7a, b, d contained 10 % (w/w) moisture, but were fractured at different temperatures. The SEM images indicate that an increase in temperature led to more disentanglement between protein and starch. However, because the single pea breakage experiments are not completely representative for fracture behaviour during impact or jet milling, further investigation is required to find out whether the increased disentanglement is effective under more realistic conditions. Moreover, it should be evaluated if the rubbery state of the proteins does not affect the overall size reduction process, which again could have a negative effect because the peas cannot be milled to sufficiently small particles for subsequent separation.

Conclusions

Mechanistic insight in fracture behaviour of peas supports design of optimal milling and dry fractionation procedures for production of pea protein concentrates. To provide a basis for understanding fracture behaviour leading to complete disentanglement, thermomechanical morphology of peas was investigated as a function of moisture content and temperature. A state diagram was constructed for pea protein and starch based on DSC results and confirmed by thermal mechanical compression tests. The T g curves were obtained by describing experimental results with the Gordon–Taylor equation. Three regions existed in the relevant area in the state diagram of peas: glassy protein and starch, rubbery protein and glassy starch and, rubbery protein and starch. Based on this insight, peas were analysed for their fracture behaviour in the three regions. Glassy peas were observed to fracture at a smaller critical compression distance compared to rubbery peas. Elastic compression behaviour was observed for peas in the rubbery state. The latter is expected to have negative impact on the size reduction process. SEM analysis further indicated that the fracture plane of glassy peas is more smooth, while in the fracture plane of rubbery peas separate starch granules can be seen, indicating that more disentanglement of protein and starch has taken place. It can be concluded that more energy is needed to break rubbery peas, however also more disentanglement upon fracture takes place. Further investigations on milling behaviour of peas at increased temperature and/or moisture content should reveal whether peas with only protein in the rubbery state could provide more pure protein fractions or that the overall size reduction of this material is insufficient for adequate further dry fractionation.

References

Abiad, M. G., Carvajal, M. T., & Campanella, O. H. (2009). A review on methods and theories to describe the glass transition phenomenon: applications in food and pharmaceutical products. Food Engineering Review, 1, 105–132.

Aiking, H. (2011). Future protein supply. Trends in Food Science & Technology, 22, 112–120.

Altuntas, E., & Yıldız, M. (2007). Effect of moisture content on some physical and mechanical properties of faba bean (Vicia faba L.) grains. Journal of Food Engineering, 78, 174–183.

Ballesteros, D., & Walters, C. (2011). Detailed characterization of mechanical properties and molecular mobility within dry seed glasses relevance to the physiology of dry biological systems. The Plant Journal, 68, 607–619.

Bergthaller, W., Dijkink, B. H., Langelaan, H. C., & Vereijken, J. M. (2001). Protein from pea mutants as a co-product in starch separation—isolates from wet and dry separation: yield, composition and solubility. Nahrung / Food, 45(6), 390–392.

Boonyai, P., Howes, T., & Bhandari, B. (2007). Instrumentation and testing of a thermal mechanical compression test for glass–rubber transition analysis of food powders. Journal of Food Engineering, 78, 1333–1342.

Bora, P. S., Brekke, C. J., & Powers, J. R. (1994). Heat induced gelation of pea (Pisum sativum) mixed globulins, vicilin and legumin. Journal of Food Science, 59(3), 594–596.

Boye, J., Zare, F., & Pletch, A. (2010). Pulse proteins: processing, characterization, functional properties and applications in food and feed. Food Research International, 43, 414–431.

Casey, R., Sharman, J. E., Wright, D. J., Bacon, J. R., & Guldager, P. (1982). Quantitative variability in Pisum seed globulins: its assessment and significance. Plant Foods for Human Nutrutrition, 31, 333–346.

Colonna, P., & Mercier, C. (1984). Macromolecular structure of wrinkled- and smooth-pea starch components. Carbohydrate Research, 126(2), 233–247.

Coulson, J. M., & Richardson, J. F. (2002). Chemical engineering: Particle technology and separation processes. Oxford: Butterworth-Heinemann.

Cuq, B., Abecassis, J., & Guilbert, S. (2003). State diagrams to help describe wheat bread processing. International Journal of Food Science and Technology, 38, 759–766.

de Almeida Costa, G. E., da Silva Queiroz-Monici, K., Machado Reis, S. M. P., & Costa de Oliveira, A. (2006). Chemical composition, dietary fibre and resistant starch contents of raw and cooked pea, common bean, chickpea and lentil legumes. Food Chemistry, 94(3), 327–330.

Dijkink, B. H., & Langelaan, H. C. (2002). Milling properties of peas in relation to texture analysis. Part 1. Effect of moisture content. Journal of Food Engineering, 51, 99–104.

Gordon, M., & Taylor, J. (1952). Ideal copolymers and the second-order transitions of synthetic rubbers. 1 non-crystalline copolymers. Journal of Applied Chemistry, 2(9), 493–500.

Goula, A. M., & Adamopoulos, K. G. (2008). Effect of maltodextrin addition during spray drying of tomato pulp in dehumidified air: I. drying kinetics and product recovery. Drying Technology, 26, 714–725.

Hemery, Y., Chaurand, M., Holopainen, U., Lampi, A. M., Lehtinen, P., Piironen, V., et al. (2011). Potential of dry fractionation of wheat bran for the development of food ingredients, part I: influence of ultra-fine grinding. Journal of Cereal Science, 53(1), 1–8.

Hung, Y. C., McWaiters, K. H., Phillips, R. D., & Chinnan, M. S. (1990). Effects of pre-decortication drying treatment on the microstructure of cowpea products. Journal of Food Science, 55(3), 774–776.

Kosson, R., Czuchajowska, Z., & Pomeranz, Y. (1994). Smooth and wrinkled peas. 2. distribution of protein, lipid, and fatty acids in seed and milling fractions. Journal of Agricultural and Food Chemistry, 42, 96–99.

Lazou, A., & Krokida, M. (2011). Thermal characterisation of corn–lentil extruded snacks. Food Chemistry, 127, 1625–1633.

Levine, H., & Slade, L. (1986). A polymer physico-chemical approach to the study of commercial starch hydrolysis products (SHPs). Carbohydrate Polymers, 6, 213–244.

Łysiak, G. (2007). Fracture toughness of pea: Weibull analysis. Journal of Food Engineering, 83, 436–443.

Micard, V., & Guilbert, S. (2000). Thermal behavior of native and hydrophobized wheat gluten, gliadin and glutenin-rich fractions by modulated DSC. International Journal of Biological Macromolecules 27, 229–236.

Naguleswaran, S., & Vasanthan, T. (2010). Dry milling of field pea (Pisum sativum L.) groats prior to wet fractionation influences the starch yield and purity. Food Chemistry, 118, 627–633.

Otto, T., Baik, B. K., & Czuchajowska, Z. (1997). Microstructure of seeds, flours, and starches of legumes. Cereal Chemistry, 74(4), 445–451.

Owusu-Ansah, Y. J., & McCurdy, S. M. (1991). Pea proteins: a review of chemistry, technology of production, and utilization. Food Reviews International, 7(1), 103–134.

Parker, M. L., Kirby, A. R., & Morris, V. J. (2008). In situ imaging of pea starch in seeds. Food Biophysics, 3, 66–76.

Rahman, M. S., Senadeera, W., Al-Alawi, A., Truong, T., Bhandari, B., & Al-Saidi, G. (2011). Thermal transition properties of spaghetti measured by differential scanning calorimetry (DSC) and thermal mechanical compression test (TMCT). Food and Bioprocess Technology, 2011(4), 1422–1431.

Ratnayake, W. S., Hoover, R., Shahidi, F., Perera, C., & Jane, J. (2001). Composition, molecular structure, and physicochemical properties of starches from four field pea (Pisum sativum L.) cultivars. Food Chemistry, 74, 189–202.

Roos, Y. H. (2010). Glass transition temperature and its relevance in food processing. Annual Review of Food Science and Technology, 1, 469–496.

Sablani, S. S., Syamaladevi, R. M., & Swanson, B. G. (2010). A review of methods, data and applications of state diagrams of food systems. Food Eng Rev, 2, 168–203.

Schutyser, M., & van der Goot, A. J. (2010). The potential of dry fractionation processes for sustainable plant protein production. Trends in Food Science & Technology, 22(4), 154–164.

Seyler, R. J. (1994). Assignment of the glass transition. Philadelphia, PA: American Society for Testing and Materials.

Shrestha, A. K., Ua-arak, T., Adhikari, B. P., Howes, T., & Bhandari, B. R. (2007). Glass transition behavior of spray dried orange juice powder measured by differential scanning calorimetry (DSC) and thermal mechanical compression test (TMCT). International Journal of Food Properties, 10(3), 661–673.

Simsek, S., Tulbek, M. C., Yao, Y., & Schatz, B. (2009). Starch characteristics of dry peas (Pisum sativum L.) grown in the USA. Food Chemistry, 115, 832–838.

Slade, L., & Levine, H. (1991). Beyond water activity: recent advances based on an alternative approach to the assessment of food quality and safety. Critical Reviews in Food Science and Nutrition, 30(2–3), 115–360.

Sman, R. G. M. V. D., & van der Goot, A. J. (2007). The science of food structuring. Soft Matter, 5, 501–510.

Sun, W. Q. (1997). Glassy state and seed storage stability: the WLF kinetics of seed viability loss at T>Tg and the plasticization effect of water on storage stability. Annals of Botany, 79, 291–297.

Thuc, T. T., Fukai, S., Truong, V., & Bhandari, B. (2010). Measurement of glass–rubber transition temperature of rice by thermal mechanical compression test (TMCT). International Journal of Food Properties, 13, 176–183.

Toufeili, I., Lambert, I. A., & Kokini, J. L. (2002). Effect of glass transition and cross-linking on rheological properties of gluten: development of a preliminary state diagram. Cereal Chemistry 79(1), 138–142.

Tyler, R. T. (1984). Impact milling quality of grain legumes. Journal of Food Science, 49, 925–930.

Tyler, R. T., Youngs, C. G., & Sosulski, F. W. (1981). Air classification of legumes. I. separation efficiency yield, and composition of the starch and protein fractions. Cereal Chemistry, 58(2), 144–148.

Velikov, V., Borick, S., & Angell, C. A. (2001). The glass transition of water, based on hyperquenching experiments. Science, 294, 2335–2338.

Whitaker, J. R., & Tannenbaum, S. R. (1977). Food proteins. Westport, CT: Avi Publishing.

Yue, Y., & Austen Angell, C. (2004). Clarifying the glass-transition behaviour of water by comparison with hyperquenched inorganic glasses. Nature, 427, 717–720.

Acknowledgments

The authors thank The PEAS Foundation and ISPT for financial support through the Intensified Protein Structuring project. We also thank Desiree Nieuwenhuijse for her support by performing experimental work and Herman de Beukelaer for his help with interpretation of the DSC results.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Pelgrom, P.J.M., Schutyser, M.A.I. & Boom, R.M. Thermomechanical Morphology of Peas and Its Relation to Fracture Behaviour. Food Bioprocess Technol 6, 3317–3325 (2013). https://doi.org/10.1007/s11947-012-1031-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11947-012-1031-2