Abstract

The impact of the substitution of wheat flour with 20, 40 and 60% of wheat resistant starch (WRS type III) and corn resistant starch (CRS type III) on noodle properties was investigated by means of X-ray diffraction, textural profile analysis, physico-chemical properties and microstructure evaluation. The kinetic data of amylose at different concentration of WRC and CRS during baking were investigated in terms of zero order model (ZOM), first-order model (FOM), and parabolic diffusion model (PDM). Furthermore, the kinetic data of crystallinity were fitted to the pseudo-first-order (PFOM), pseudo-second-order model (PSOM), and intra-particle diffusion models (IDM). A ZOM satisfactorily described the experimental data of amylose at different concentration of resistant starch, whereas crystallinity data was ideally fitted to PFOM. According to X-ray pattern, crystallinity of noodle containing CRS and WRS had increasing trend with wheat flour substitution. The hardness, cohesiveness and adhesiveness of the dough diminished remarkably as the resistant starch content increases. With the augment in resistant starch level, the finest noodle cooking time was reduced and furthermore, the noodle cooking loss was significantly increased, while the water uptake and the time needs for cooking the samples, decreased.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Plants are a significant source of proteins, carbohydrates, fats, vitamins, minerals, and water. These are the nutrients that are essential for sustaining life and contribute to the caloric content of the body. The basic factor vital in the selection of plants for systematic classification, nutritive value, and plant improvement programs are the quality and proportion of proteins in the seed [1,2,3,4,5]. Resistant starch (RS) is defined as the starch and starch hydrolyzed products that endure digestion in human intestine. Being a source of dietary fiber, RS has been categorized in functional foods which has attracted a lot of attention over the past two decades owing to its functional properties. Such kind of starch does not affect enzymatic digestion, therefore it cannot produce glucose in the body. Producing gas and short chain fatty acids, bacterial microflora, however, can ferment resistant starch in the colon, hence the fact that the effects of RS can be compared with dietary fiber. RS increases the chances to prevent the health problems related to the strong consumption of high caloric foods [6]. Compared with traditional fiber sources, RS entails fewer influences on the food sensory profile, and provides satisfying water-binding capacity, viscosity, swelling power and gel formation, hence its application in a variety of foods [7, 8]. RS impact on several cereal derived products has further been investigated [9,10,11,12,13].

The noodle sales in the world is growing at a rate of 5% per year, an increase due to its low price and high easy consuming, and the fact that they can be prepared quickly [14]. In particular, in Asia, noodles are the most wheat foods consumed [15,16,17].

Baking could increase RS content. The objective of the present work was to investigate X-ray pattern, amylose and crystallinity kinetics at different concentrations (20, 40 and 60%) of corn resistant starch (CRS) and wheat resistant starch (WRS) (before and after of baking) in wheat flour. Ultimately, noodles were made with CRS and WRS to be compared with each other in different parameters such as SEM analysis, textural and physicochemical properties of noodles.

Materials and methods

Dough and noodle preparation

Different amounts of wheat and corn resistant starch (20%, 40%, 60% w/w) and sodium chloride (8%) were added to wheat flour and mixed thoroughly (Table 1). The dough was prepared by mixing flour and distilled water (40 °C) in a Hobart mixer (Model N-50, Richmond Hill, Ontario, Canada) at a speed of 1 (60 rpm) for 5 min to make water distribution more homogenous. Using laboratory noodle machine (La Monferrina, model Dolly, Asti, Italy), noodle strands with 1 mm diameter die was formed from the prepared dough (500 g), were dried at room temperature (25 °C) for 4 h and stored in a polyethylene package, where the physicochemical and textural analyses were conducted Pourmohammadi et al. [18].

Evaluation of the dried noodle quality

X-ray diffraction and amylose content

X-ray diffractograms of dried noodles contain CRS and WRS were obtained with an X-ray diffractometer (X’Pert MPD, Phillips, Eindhoven, Netherlands). Dried noodles were tightly packed into the sample holder. Diffraction data were collected over an angular range from 4 to 40 (2θ). The X-ray patterns were visually compared with the peak characteristics of a theoretical diffractogram given by Pourmohammadi et al. [18]. Amylose content was determined based on method reported by Pourmohammadi et al. [18].

Kinetic studies

Zero order model (ZOM), first-order model (FOM), and parabolic diffusion model (PDM) were used to fit the data of WRS and CRS for amylose. Also, the kinetic data of crystallinity were fitted to the pseudo-first-order (PFOM), pseudo-second-order model (PSOM), and intra-particle diffusion models (IDM) [19, 20].

-

1.

ZOM

A ZOM can be expressed as follow Eq. (1):

$$ {\text{q}}_{{\text{t}}} = {\text{q}}_{{\text{e}}} - {\text{k}}_{0} {\text{t}} $$(1)where qt and qe are the amounts of crystallization loss (%) at time t of baking (0, 6, 12, 18, 24 and 30 min of baking process) and equilibrium crystallization loss (%), respectively, and k0 is the zero-order rate constant.

-

2.

FOM

A FOM can be expressed as follow Eq. (2):

$$ {\text{lnq}}_{{\text{t}}} = \ln {\text{q}}_{{\text{e}}} - {\text{k}}_{1} t $$(2)where k1 is the first-order rate constant.

-

3.

PDM

A PDM can be formulated as:

$$ {\text{q}}_{{\text{t}}} = {\text{q}}_{{\text{e}}} - {\text{k}}_{{\text{p}}} {\text{t}}^{0.5} $$(3)where kp is the diffusion rate constant.

-

4.

PFOM

A PFOM is formulated as:

$$ \frac{{{\text{dq}}}}{{{\text{dt}}}} = k_{1} \left( {{\text{q}}_{{\text{e}}} - {\text{q}}} \right) $$(4)where qt and q are the amounts of crystallization loss (%) at time t of baking (0, 6, 12, 18, 24 and 30 min of baking process) and equilibrium crystallization loss (%), respectively, and k1 is the rate constant of PFOM (min−1). After integration with the suitable boundary condition (i.e. qe − q = 0 at t = 0) Eq. 5 can be written as:

$$ {\text{q}}_{{\text{t}}} = {\text{q}}_{{\text{e}}} - \exp \left( {{\ln}\left( {{\text{q}}_{{\text{e}}} } \right) - {\text{k}}_{1} {\text{t}}} \right) $$(5)The constant parameters consisting of \( {\text{k}}_{1}\) and \( {\text{q}}_{{\text{e}}}\) can be determined using the nonlinear optimization techniques.

-

5.

PSOM

A PSOM is formulated as follows:

$$ \frac{{{\text{dq}}}}{{{\text{dt}}}} = k_{2} \left( {{\text{q}}_{{\text{e}}} - {\text{q}}} \right)^{2} $$(6)where \( {\text{k}}_{2}\) is the rate constant of PSOM (g mg−1 min−1). By integration and using boundary conditions (t = 0 to t = t and q = 0 to q = qt) Eq. 7 becomes:

$$ \frac{{\text{t}}}{{\text{q}}} = \frac{1}{{{\text{k}}_{2} {\text{q}}_{{\text{e}}}^{2} }} + \frac{t}{{{\text{q}}_{{\text{e}}} }} $$(7)The constant parameters including \( {\text{k}}_{2}\) and \( {\text{q}}_{{\text{e}}}\) can be determined using the nonlinear optimization techniques.

-

6.

IDM

Experimental data were also fitted to the Weber and Morris intraparticle diffusion model (IDM):

$$ q_{t} = k_{p} (t)^{0.5} + I $$(8)where kp is the IDM rate constant, t is the time (min), and C is the intercept.

Cooking time, cooking loss and water uptake

The optimal cooking time was estimated as the time at which when the noodle pushed between two pieces of glass, the white center of the noodle vanished completely [21]. The cooking loss was specified via the ratio of noodle weight remained in the cooking water (residue) to the dry weight of the noodle. Cooking loss was calculated by Eq. (9) through collecting the cooking water following the drainage of the noodles and drying 5 ml of that at 105 °C. The dried residue was weighed and the results were expressed as a proportion of the uncooked noodles [21]. Water uptake was determined by immerging 100 g of noodles in 300 ml of boiling water for an appropriate time until the noodles were cooked. The noodles were then drained, cooled for 5 min in room temperature, and finally weighed. Water uptake was calculated through subtracting the cooked noodle weight from the initial noodle weight [22].

Textural analysis

The noodle texture was evaluated using a texture analyzer (A/LKB-F, Stable Micro Systems, Surrey, UK) [23]. The texture profile analysis (TPA) of the noodle doughs was performed by a texture analyzer (Model LFRA 4500, Brukfield, USA). Dough formatted to 2 cm diameter and 2 mm thick disks was employed in TPA tests conducted according to Bourne [24, 25]. The analyser was set at two compression cycles, a speed of 1 mm s−1, a distance of 10 mm and a relaxation time of 2 s between the two compressions. The recorded force–time plots were analyzed for the following: (1) dough hardness (g), height of compression peak (2) dough cohesiveness, the ratio of the areas of the two resistance peaks (A2/A1) (3) springiness, which is length 2/ length 1, and (4) adhesiveness, the area of adhesion peak.

Determination of the morphology

The microstructure of dough and noodle formulated with CRS and WRS in raw and cooked products was studied by means of a scanning electron microscope (SEM) at 20 kV (Leica, Cambridge, United Kingdom).

Color and sensory analysis

The most favorable time for cooking the noodles in soup is 13 min, therefore, for sensory evaluation, 20 g of dried noodles were cooked in 500 ml water for 13 min. Next, 20 panelists (10 males, 20–40 years) evaluated the noodles at room temperature (27 ± 1 °C). The panelists evaluated the samples for their color, odor, taste, flavor, texture, and overall acceptability on a five-point hedonic scale, ranging from 5 = desirable enormously to 3 = neither like nor dislike and 1 = not desirable enormously) [18]. Color parameters of the dried noodles were investigated by use of a hunter lab colorimeter [26].

Statistical analysis

Results are reported as mean values and their standard deviations. Analysis of variance (ANOVA) was carried out on data and the significance of differences between the means was specified via Duncan’s new multiple range test (P < 0.05). Data analysis was performed using the SPSS software version 24.0 (SPSS Inc., Chicago, IL, USA).

Results and discussion

The effect of resistant starch content on amylose content and crystal patterns of noodles

Table 2 and Fig. 1 reports the amylose content of the samples and the crystallinity levels at various concentration of resistant starch before and after of baking process, estimated as the ratio of X-ray diffraction peak area and total X-ray diffraction. Corn and wheat resistant starch showed the maximum diffraction peak in the region of (15.21°, 17.05°, 20.45° and 22.42° 2θ) and (15.3°, 17°, 20.3° and 23.35° 2θ) peaks, respectively, which is consistent with the amylose content by Cheetham and Tao [27].

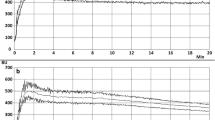

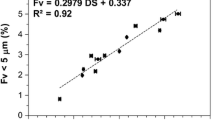

Twelve regression equations were obtained to investigate the association between amylose content and crystallinity in samples with different concentrations of dough contains resistant starches, before and the noodles after cooking (Table 3). A negative linear relationship between crystallinity and amylose content was found. The amylose content in dough of CRS and WRS was (22.2 ± 0.2 to 16.9 ± 0.4) and (21.3 ± 0.4 to 16.5 ± 0.2) which reduced to (18.8 ± 0. 2 to 13.1 ± 0.2) and (17.4 ± 0.2 to 9.9 ± 0.4) after baking process, respectively. The percent of crystallinity in dough containing CRS and WRS increased from 27.4 ± 0.5 to 35.0 ± 0.6 and 28.7 ± 0.8 to 40.3 ± 0.6, respectively. Cooking had positive effect on the formation of crystallinity. According to the result of Cheetham and Tao [27], when amylose content increases from 40 to 84%, crystallinity also decreases. These results showed that amylopectin, due to its double helices formation, it is positive correlated to the crystallinity level in a usual cereal starch ( < 28% amylose). The kinetic data of amylose at different concentration of WRC and CRS during baking were investigated in terms of ZOM, FOM, and PDM and the results are reported in Table 4 and Fig. 2. Also, the kinetic data of crystallinity at different concentration of WRS and CRS during baking were fitted to the IDM (Fig. 2a, b), PSOM (Fig. 2c, d) and PFOM (Fig. 2e, f). The results are reported in Table 5. The results indicated that the ZOM better fitted the amylose kinetic data (R2 > 0.94) compared to the FOM, and PDM (Table 4). The zero-order rate constants (k0) were found between 0.241 and 0.312. As can be seen (Table 5), the PSOM appeared to be the best-fitting model than IDM and PFOM (R2 > 0.89) for crystallinity kinetic data. The highest equilibrium crystallization loss (%) for WRC and CRS was found at 60%. The predicted constants of PSOM at different concentration of WRC and CRS during baking were close to the average amounts, confirming that this model is indeed superior when it comes to the description of the kinetics of the amounts of crystallization loss. The experimental data and predicted values of amylose at different concentration of WRC and CRS during baking were investigated in Fig. 2 which shows the ZOM is ideally describe the kinetic data. As Fig. 3 indicates, the plots of crystallinity at different concentration of WRC and CRS during baking were not linear in the overall time demonstrating that this model is not appropriate in the kinetic modeling. The relationship between t/q versus time for crystallinity at different concentration of CRS and WRS (Fig. 3c, d) by PSOM is linear, indicating that this model is ideally applicable to describe the data. The relationship between (qe − q) versus time for crystallinity at different concentration of CRS and WRS (Fig. 3 e, f) by PFOM is linear over the entire time range.

Effects of WRS and CRS on the textural properties of the dough and noodles

TPA results (hardness, adhesiveness, cohesiveness, springiness and gumminess) found for noodles are tabulated in Fig. 4. Both starch and proteins play crucial parts in governing the textural properties of noodles. However, the influence of proteins on textural properties is well reflected by TPA parameters [28]. Specifying the hardness of the cooked noodles (Fig. 4) revealed that as the cooking time increased, the hardness of the samples decreased from 916 ± 81 to 519 ± 56 for WRS and from 454 ± 34 to 272 ± 21 for CRS substitution. The softer texture of the samples is the result of absorbing water by gluten and starch gelatinization while cooking. Furthermore, with the increase in the resistant starch content, the noodle hardness was observably reduced, which can be associated with the decrease of gluten content in these samples. A positive correlation has been reported between hardness and gluten level in noodles [22, 29]. In general, adding starch lead to softer noodle [30, 31], which was corroborated by the downward trend of hardness in the present study? Comparatively, Zhou et al. [12], showed that noodles formulated with 10% CLWMS were to some extent more rigid than the controls, certainly chemical cross-linking, increased starch–protein interaction and lead to a strong network of coagulated gluten proteins, and made the texture harder [12]. Intra- and inter-molecular bonds introduced by cross-linking were able to stabilize and strengthen starch granules, which would then minimize the disruption of granule and increase starch granular rigidity under high-temperature shearing, resulting in greater resistance to the breakdown of the swollen granules, which accounted for the higher pasting viscosities during heating and holding. Cohesiveness is an indicator of how noodle texture maintains its ingredients together during cooking. With the increase in the resistant starch levels, the cohesiveness of all samples decreased, except for those containing 20% and 40% of WRS. A positive correlation between the cohesiveness of spaghetti and noodles and the gluten content of the flour was reported [22, 29]. Providing adequate hydration and heat, hot water regularly goes through the noodles, and hydrates gluten and gelatinizes starch granules during cooking. As a result, by rising the cooking time, a powerful network is created and the cohesiveness of the noodles is augmented. Nevertheless, substituting wheat flour with RS, the gluten level was reduced, leading to less cohesive noodles. Zhou et al. [12] showed that CLWMS negatively affected the noodle texture, with samples treated with CLWMS at different concentrations resulting similar to each other and exhibiting lower cohesiveness [12]. The reducing trend of the cohesiveness is possibly due to less amylose leaching from the granules, which is in agreement with the present research. Adhesiveness is an indication of noodle stickiness, which is due to the release of amylose and amylopectin from the noodle throughout cooking [10]. The results showed that increasing the RS level, the samples adhesiveness was remarkably reduced from 8.9 ± 1 to 1.1 ± 0.6 for WRS and from 3.1 ± 0.7 to 1.5 ± 0.2 for CRS substitution (Fig. 4). Preventing amylose and amylopectin from leaching the noodles, the cross-link between hydrated gluten and gelatinized starch during cooking may decrease the adhesiveness and stickiness. Since gluten level resulted positively correlated to adhesiveness [8, 22], the decrease in the adhesiveness of the resistant starch noodles could be mainly explained by the reduce gluten content of the samples associated to the adding of RS. Owing to the cross-linked bridges among its bonds, resistant starch does not let amylose to leach, hence the noodle adhesiveness decrease. Zhou et al. did not report significant differences between CLWMS samples and controls, as far as adhesiveness parameters are concerned [12].

The results of hardness in noodles (Fig. 4) revealed a decrease of the Young’s moduli due to the addition of resistant starch. The hardness of noodles containing WRS and CRS varied from 2412 ± 341 to 1150 ± 221 Pa and 2510 ± 256 to 1530 ± 170 Pa, respectively. This probably indicates that by increasing the level of resistant starch, the dried noodles broke easily. With considering the amount of flour used in the noodle formulation it can be noted that by increasing the level of gluten proteins, the noodle strength increased obviously [29]. By increasing the amount of WRS and CRS, the firmness of the noodles decreased notably, which could be due to the reducing of viscoelastic properties of the noodle dough. The addition of resistant starch dilute wheat proteins (gluten), rendering them weaker, and making them lose their viscoelastic properties. Therefore, the increase in the resistant starch reduces the gluten content, entailing a weaker noodle structure [15]. As seen in Fig. 4, WRS and CRS noodle samples have significant differences in only 60% substitution; moreover, in lower levels (20%, 40%) of replacement, there is no observable difference among samples.

Effects of WRS and CRS on the cooking characteristics of the noodles

In the situation where starch, gluten and water exist, and also heating occurs, starch granules and gluten absorb water and gluten is denatured and starch granules go through gelatinization. As shown in Fig. 5a, with the increase in resistant starch levels, the optimum cooking time significantly reduced from 196 ± 46 to 171 ± 38 for WRS and from 239 ± 41 to 162 ± 25 for CRS substitution. This can be attributed to the lower thermal properties of starch in comparison with flour [15], which probably indicates that, compared with wheat flour, for WRS and CRS gelatinization, lower cooking process were required. This may further be the reason for the shorter cooking time associate to higher RS content. Resistant starch may decrease the phase transition temperature range and the melting enthalpy of starch crystallites, unstabilizing the structure of the granules during heating [32] and decreasing the cooking time. Cooking time reduction observed with the increase in resistant starch levels may be the result of the dilution of gluten network. Weakening the gluten network, the resistant starch would decrease the cooking time. Nevertheless, cooking time for all the samples was less than 13 min, which is the best cooking time for Iranian noodles [15]. With the increase in the resistant starch level, the cooking loss of noodles further augmented noticeably from 5.2 ± 0.2 to 7.0 ± 0.8 for WRS and from 5.4 ± 0.5 to 7.4 ± 0.7 for CRS substitution (Fig. 5b). Majzoobi et al. [22] have reported a negative correlation between the gluten content and the cooking loss in spaghetti. Therefore, higher cooking loss observed in samples containing resistant starch, may be the result of the reduction of the gluten content due to the flour replacement with RS. Zhou et al. [12] revealed that the excessive replacement with flours not containing gluten limits the gluten strength and softens the whole structure, promoting a higher loss of solids into the cooking medium [12]. As salt strength the gluten network, cooking noodles in salted water would lead to lower cooking loss of the samples. Accordingly, by weakening the gluten network, resistant starch increases the cooking loss [22].

Figure 5c shows that cooking time absolutely influences the water absorption of the noodles. The augment in the water absorption of the noodles throughout cooking is essentially owing to the water absorbtion of gluten and starch granules in the course of gelatinization [8, 22, 33]. The increase in WRS and CRS levels noticeably decreased the water absorption from 8.5 ± 0.8 to 5.1 ± 1.2 for WRS and from 8.4 ± 1.2 to 7.3 ± 0.9 for CRS replacement. This may be caused by the gluten dilution of the samples in consequence of resistant starch substitution with wheat flour. Furthermore, the differences in the sample water uptake could be attributed to the differences between starch and flour in terms of physicochemical and thermal characteristics [15]. Accordingly, due to their gluten network, the control samples have higher water absorption than noodle samples containing resistant starch. Zhou et al. [12] showed that as CLWMS increased, water absorption increased gradually. It has been reported that water absorption has negative correlation with amylose content of flours [13]. Moreover, this trend seems to be associated to the existence of mostly amylopectin, which let more water to penetrate the structure [12].

Effects of WRS and CRS on SEM analysis

The effect of the cooking process (before and after cooking) and various concentrations (40 and 60%) of RS on WRS40 (a and b), WRS60 (c and d), CRS40 (e and f), CRS60 (g and h) samples were investigated by SEM analysis (Fig. 6). The increasing in the RS content of dough and noodles would be attributed to a growing CRS/WRS replacement (from 40 to 60%), which has correlation with the results of crystallinity % (Table 2). Cooking could be cause to enhance the RS level of noodles in comparison with those in dough owing to increase in recrystallization of amylose and small chain of amylopectin leaching out the granules (b and d; f and h). Similarly to what found by Pourmohammadi et al. [18] for biscuits, gelatinization and retrogradation could have significant effects on the RS level in dough and noodles formulations [18]. It can be noted that small granules of wheat and corn were melted during production of dough (a, c, e, and g), nevertheless were improved after cooking process (b, d, f, and h). These results are in perfect agreement with Pourmohammadi et al. [18].

Effects of WRS and CRS on the color and sensory analysis of the noodles

Color is an important feature of noodles as consumer’s first opinion of noodle is, more often than not, derived from evaluation of the appearance [9]. The preferred color of customary white salted noodles is to some extent creamy. Table 6 shows that there exists a significant difference between the samples. With the increase up to 60% in the amount of wheat and corn resistant starch, the L value of the samples observably augmented from 75.403 to 89.593, and 86.123 to 92.803, respectively. On the other hand, samples containing 20% of WRS were significantly different from the controls in terms of lightness. The a* and b* in WRS had no specified trends in the overall samples, while in CRS, resistant starch up to 40% had a diminishing effect on a* and b* values, meaning that the redness and yellowness of the noodles were reduced. Zhou et al. [12] revealed that the addition of CLWMS (cross-linked waxy maize starch) considerably affect the color of noodles. Noodles became notably lighter with the increase in the CLWMS content from 10 to 30%. Such results is in going with the recent research in Asia, where potato starch, tapioca starch or modified starch are employed to make noodles bright [12]. Park and Baik [13] showed that the escalation of L* in noodles was in accordance with their results that protein contents had negative associations with lightness (L*) of instant noodles [13]. Moreover, a notable point is that water absorption is positively associated with brightness [34]. The increase in the amount of resistant starch dilutes protein (gluten) and enhances the lightness of the noodles.

Sensory analysis results showed that the thickness of the soup containing WRS and CRS decreased by increasing the level of resistant starch in the noodles (Table 7). Decreasing the thickness of the soup was not pleasing, since the panelist gave lower scores to the thinner samples (60% CRS and 60%WRS). The thickness of noodles containing of CRS was significantly (P < 0.05). Even though the sample prepared with 20% resistant starch noodle obtained a little higher score in all the samples containing WRS (4.80 ± 0.12) and CRS (3.70 ± 0.08 and 3.80 ± 0.12). The assessment of the noodles overall acceptability exposed that those made with 40% resistant starch received the highest scores and noodles made with 60% resistant starch obtained the lowest grade in both WRS and CRS.

Conclusion

The incorporation of WRS and CRS into the formulation of noodles leads to considerable modifications in rheological, textural and cooking characteristics. A negative linear relationship between crystallinity and amylose content was found. The results indicated that the ZOM better fitted the amylose kinetic data (R2 > 0.94) while the PSOM appeared to be the best-fitting model (R2 > 0.89) for crystallinity kinetic data. The results of the hardness in noodles revealed a noticeable reduction of the Young’s modulus of the noodle samples. Increasing the resistant starch level in the noodle formulation, augmented the cooking loss marginally. Conversely, with the increase in the amount of corn and wheat resistant starch, the water uptake and noodle cooking time decreased. In conclusion, resistant starch resulted appropriate for increasing the noodle fiber content.

References

D. Altindal, N. Altindal, Int. J. Agric. For. Life Sci. 2(2), 87–92 (2018)

V. Okatan, Folia Horticulturae 30(1), 93–101 (2018)

S. Sonmez, T. Akar, E. Demir, Int. J. Agric. For. Life Sci. 2(2), 180–184 (2018)

A. Rehman, M. Adnan, Pak. J. Bot. 50(1), 287–300 (2018)

M.S. Haider, I.A. Khan, M.J. Jaskani, S.A. Naqvi, S. Mateen, U. Shahzad, H. Abbas, Pak. J. Bot. 50(3), 1069–1076 (2018)

S. Ashraf, F.M. Anjum, M. Nadeem, Pakistan. J. Food Sci. 22, 90–95 (2012)

T. Sanz, A. Salvador, S.M. Fiszman, Eur. Food Res. Technol. 227, 813–819 (2008)

N. Sozer, A.C. Dalgic, A. Kaya, J. Food Eng. 8, 476–484 (2007)

A.L. Choy, B.K. May, M.D. Small, Food Hydrocolloids. 26, 2–8 (2012)

J.E. Dexture, R.R. Matsuo, B.C. Morgan, J. Food Sci. 48, 1545–1599 (1983)

S.J. Heo, S.M. Lee, I.Y. Bae, H.G. Park, Food Bioprocess Technol. 6, 553–560 (2013)

M. Zhou, M. Xiong, Z. Cai, J.H. Xiong, Starch. 67, 1035–1043 (2015)

C.S. Park, B.K. Baik, Cereal Chem. 82, 159–164 (2004)

K. Kubomura, Cereal Foods World. 34, 194–197 (1998)

M. Majzoobi, B. Layegh, A. Farahnaky, J. Food Process Preserv. 74, 35–41 (2012)

Q.Y. Lu, S.Y. Guo, S.B. Zhang, Food Res. Int. 42, 226–230 (2009)

L.J. Yu, M.O. Ngadi, J. Sci. Food Agric. 86, 544–548 (2006)

K. Pourmohammadi, E. Abedi, SH. Farahmandi, M.R. Mahmoudi, S.M.B. Hashemi, L. Torri, J. Food Process Eng. (2018) (in Press)

M.J.D. Low, Kinetics of chemisorption of gases on solids. Chem. Rev. 60, 267–312 (1960)

K. Jouppilaav, J. Kansikasb, Y.H. Roos, Carbohydr. Polym. 36, 143–149 (1998)

AACC, Approved Methods of the American Association of Cereal Chemists, 10th edn. (The Association, St. Paul, 2000).

M. Majzoobi, R. Ostovan, A. Farahnaky, J. Texture Stud. 42, 20–30 (2011)

J.F. Steffe, Rheological Methods in Food Process Engineering, (Freeman Press, New York, 1996), pp. 10–30, and 73–75.

M. Bourne, Food Texture and Viscosity: Concept and Measurement, 2nd edn. (Academic Press, New York, 2002), pp. 182–188

E. Abedi, M. Majzoobi, A. Farahnaky, K. Pourmohammadi, M.R. Mahmoudi, Int. J. Biol. Macromol. 120, 2035–2047 (2018)

E. Abedi, M. Sahari, M.A. Barzegar, M.H. Azizi, Int. J. Food Sci. Technol. 50, 857–863 (2015)

N.W.H. Cheetham, L. Tao, Carbohydr. Polym. 36, 277–284 (1998)

B.K. Baik, Z. Czuchajowska, J. Pomeranz, Cereal Chem. 71, 314–320 (1994)

S.B. Zhang, Q.Y. Lu, D.D. Meng, Cereal Chem. 88, 296–301 (2011)

L. Wang, G. Hou, Y.H. Hsu, J. Cereal Sci. 54, 506–512 (2011)

I.S.M. Zaidul, N.A.N. Norualaini, A.K.M. Omar, H. Yamauchi, T. Noda, Carbohydr. Polym. 69, 784–791 (2007)

C.G. Biliaderis, I. Arvanitoyannis, M.S. Izydorczyk, D.J. Prokopowich, Starch. 49, 278–283 (1997)

N.M. Edwards, M.S. Izydorczyk, J.E. Dexter, C.G. Biliaderis, Cereal Chem. 70, 122–126 (1993)

D.W. Hatcher, J.E. Kruger, M.J. Anderson, Cereal Chem. 76, 566–572 (1999)

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare that there are no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Pourmohammadi, K., Abedi, E., Amiri, M.J. et al. The effect of thermal processing and different concentrations of resistant starch on X-ray pattern, crystallization kinetics and morphological properties of noodles supplemented with wheat and corn resistant starch. Food Measure 13, 3149–3161 (2019). https://doi.org/10.1007/s11694-019-00238-w

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11694-019-00238-w