Abstract

Purpose

The analysis of the engineering properties of food and agricultural products is necessary to design processing, sorting, handling, sizing, and other postharvesting equipment.

Methods

The engineering properties of psyllium seeds (PSs) as a function of moisture content (MC, 4.32–20.38% d.b.) were assessed. The regression linear and polynomial models with high coefficients of determination were also fitted to the data to explain the significant effect of moisture content on different engineering properties.

Results

An increase in axial dimensions with increasing MC led to a significant increase in volume (1.27–1.45 mm3), surface area (4.51–4.98 mm2), and sphericity (51.7–52.5%) of PSs. However, the bulk (654.16–601.35 kg/m3) and true (1265.1–1074.7 kg/m3) densities and porosity (48.29–44.04%) were reduced by increasing MC. Increasing the MC led to a significant increase in repose angle (32.30–39.61°) and terminal velocity (1.51–2.41 m/s). The galvanized iron sheet (0.423–0.519) had the highest static friction coefficients compared to glass (0.261–0.332), stainless steel (0.369–0.426), and plywood (0.393–0.458) surfaces. The rupture force was significantly decreased by increasing MC. Under the vertical loading orientation, PSs required less compressive force to rupture compared to the horizontal loading orientation. The specific heat (1.56–3.12 kJ/kg K°) and thermal conductivity (0.235–0.322 W/m K°) were increased by increasing MC, while the thermal diffusivity (2.3–1.7 × 10−4 m2/s) decreased.

Conclusions

Since MC had a key role in changing engineering properties of PSs, the resulted regression equations can be applied for extracting mucilaginous polysaccharides from PSs grown in other geographical areas with different weather conditions.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

The knowledge of the morphology and size distribution of crops is fundamental to design the cleaning, grading, and separation equipment accurately. Gravimetric properties are essential in the design of processing systems related to aeration, drying, storage, and transport (Mohsenin 1986). Bulk density determines the capacity of storage and transport systems, while true density is practical in separation systems. The porosity of seeds can control the resistance to airflow during aeration and drying processes (Altuntas and Özkan 2008). Engineers recognize the frictional properties such as repose angle and coefficients of external friction as important properties involved in the rational design of bins and other storage structures such as the compressibility and flow behavior of food and agricultural materials (Gharibzahedi et al. 2012a). Aerodynamic properties (such as terminal velocity) are beneficial for air conveying or pneumatic separation of materials, so the air velocity lifts the particles when this factor is higher than the terminal velocity (Akharume and Aregbesola 2019). Furthermore, the fracture properties of seeds are necessary for a rational design of high-efficient grinding systems, as well as the optimization of processing parameters involved in the extraction and development of food products and ingredients (Gharibzahedi et al. 2012c; Jan et al. 2019). Understanding the food transformation, e.g., the evolution of Biot number, along the process that affects the heating kinetics inside the particle is not possible without the calculation of thermal properties such as specific heat capacity, thermal conductivity, and thermal diffusivity. These factors have a vital role in different food processes like heating, blanching, freezing, thawing, cooking, drying, frying, and cooling (Gharibzahedi et al. 2012d; Gharibzahedi et al. 2014b).

Psyllium (Plantago ovata Forsk) as an annual plant is mainly cultivated in India. Therefore, this country dominates the world market (≥ 85%) in the production and export of psyllium. The husk of psyllium seeds (PSs) is rich in white fibrous mucilage, which is obtained by mechanical milling/grinding of their outer layer (Guo et al. 2009). The colorless mucilaginous gel of this seed has high absorbing water and can be used in dairy, beverage, and gluten-free bakery and pasta formulations to improve the structural stability, organoleptic attributes, antistaling properties, and the product yield (Guo et al. 2009; Gharibzahedi et al. 2013c; Hashemi et al. 2015; Amini et al. 2018; Gao et al. 2018). Apart from mucilage components in psyllium, this seed contains fatty oil in the endosperm (~ 40% linoleic acid), phenolic compounds (e.g., acteoside and isoacteoside), and minerals (e.g., calcium, manganese, and sodium) (Chong et al. 2019; Ziemichód et al. 2019). It has a high potential in the improvement of antioxidant capacity through reactive oxygen species scavenging activities (Chong et al. 2019; Patel et al. 2019). Psyllium seeds because of the presence of mucilaginous polysaccharide components and other bioactives have many medical applications such as treating constipation (Jalanka et al. 2019), diarrhea (Lertpipopmetha et al. 2018), diabetes (Soltanian and Janghorbani 2019), inflammatory bowel diseases (Zhou et al. 2019), obesity (Pal et al. 2019), and high cholesterol levels (Sadeghian et al. 2018). The optimal extraction of mucilages from plant tissues (e.g., seeds and fruit bodies) is needed to the knowledge and understanding the changes of engineering properties of polysaccharide-rich sources as a function of moisture content (MC) (Rostami and Gharibzahedi 2017).

In the past, the physical (e.g., black cumin, quinoa, finger millet, red lentil, and sesame seeds) (Gharibzahedi et al. 2009; Gharibzahedi et al. 2010b; Ramashia et al. 2018; Jan et al. 2019), mechanical (e.g., sesame, rapeseed, Sericea lespedeza, hemp, and lentil seeds) (Gharibzahedi et al. 2011a; Taheri-Garavand et al. 2012; Gharibzahedi et al. 2014a; Ropelewska et al. 2017; Mahapatra et al. 2019), and thermal (e.g., Nigella oxypetala Boiss., Sericea lespedeza, red lentil, chia, kaniwa, triticale, and farro seeds) (Gharibzahedi et al. 2012d; Gharibzahedi et al. 2014b; Mahapatra et al. 2019; Suleiman et al. 2015) properties of many small-size seeds were determined as a function of MC. Concerning PSs, Ahmadi et al. (2012) earlier determined the physical and mechanical properties of PSs at a constant MC of 7.2% (w.b.). As a result, not only there is a research gap on the evaluation of other engineering properties of these nutritious seeds but also the effect of different MCs on these industrial-related characteristics has not yet investigated. Hence, this study aimed to assess moisture-dependent engineering properties of PSs for facilitating the design calculations of harvesting, handling, and processing systems.

Materials and Methods

Seeds Preparation and Moisture Conditioning

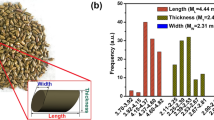

Psyllium seeds (P. ovata Forsk, Fig. 1) were purchased from the local market in Shahrekord (Chaharmahal and Bakhtiari Province, Iran) in April 2019. The seeds in polyethylene bags were transferred to the Food Processing Laboratory. All foreign materials (e.g., dust, dirt, stones, external grains, and chaff) and immature and broken PSs were removed by hand. An oven drying (103 ± 2 °C, 24 h) was utilized to assess the initial MC of PSs (4.32% d.b.). Other desired MCs to evaluate the different engineering properties were obtained by adding various quantities of water to PSs and estimated based on Eq. (1) (Table 1) (Gharibzahedi et al. 2011b). After that, moisturized PSs were packed in the tightly sealed bags and maintained at 4 °C for 7 days to homogenously distribute moisture throughout the seeds. Samples before doing experiments were placed in the ambient temperature (23 °C) for 90 min. Three MCs of 8.72, 14.53, and 20.38% d.b. along with the initial MC (4.32% d.b.) were determined to evaluate the engineering properties in a relative humidity of 56 ± 3%. Although most PSs collected in producing countries have an MC of 4–20% d.b., an MC between 10 and 20% d.b. can provide a possibility to increase the seed storability and mucilage extractability (Ahmadi et al. 2012).

Physical Characteristics

One hundred PSs were randomly picked to assess the mean size dimensions (length, width, and thickness) using a digital caliper with an accuracy of 0.01 mm (Fig. 2). An electronic balance with an accuracy of 0.001 g was applied to measure the one thousand seed mass (m1000). The calculation of arithmetic and geometric mean diameters of PSs were respectively carried out using Eqs. (2) and (3) (Table 1) (Mohsenin 1986). The sphericity, volume, and surface area of PSs also were determined using formulas 4–6 (Table 1) (Mohsenin 1986; Jain and Bal 1997). The bulk density was measured by filling an empty glass container of predetermined volume and net weight with PSs by pouring from a constant height, striking off the top level, and weighing. The bulk density was expressed as the mass and volume ratio (Tavakoli et al. 2010). The toluene displacement method was used to the true density because PSs, to a lesser extent, absorb this chemical agent. Besides, toluene has a low surface tension, so that it fills even shallow dips in seed, and its dissolution power is low (Gharibzahedi et al. 2013b). Equation (7) (Table 1) was applied to calculate the porosity of PSs based on the data of bulk and true densities (Mohsenin 1986). An apparatus consisting of a plywood box of 140 × 160 × 35 mm and two plates of fixed and adjustable were applied to determine the emptying angle of repose (EAR). The box was filled with PSs, and then the adjustable plate was inclined, gradually, allowing PSs to flow and assume a natural slope; this was measured as EAR (Fig. 3A) (Tavakoli et al. 2010).

Frictional Characteristics

The static friction coefficients (SFCs) were evaluated against different surfaces of the glass (GS), stainless steel (SS), plywood (PW), and galvanized iron sheet (GIS). With the resting cylinder (75 mm diameter and 50 mm depth) filled with PSs on the surface, the surface was gradually raised until the filled cylinder just started to slide down (Fig. 3B) (Gharibzahedi et al. 2013a).

Aerodynamic Characteristics

An air column system was applied to assess the terminal velocity of PSs (Fig. 4a). Briefly, a sample was dropped into the air stream from the top of the air column, up which air was blown to suspend the material in the air stream. A hot-wire anemometer (A TES-1341, Taiwan; Fig. 4b) with an at least accuracy of 0.01 m/s was utilized to measure the air velocity near the location of the seed suspension (Akinci et al. 2004).

Mechanical Characteristics

A universal Instron machine (Santam, STM-20, Tehran, Iran) with accuracy 0.001 N and 0.001 mm, respectively, in force and deformation was used to assess the fracture resistance characteristics of PSs (Fig. 5a). This system was equipped with a 50 kg compression load cell and integrator. A rupture point (as the maximum compression force) in the force-deformation curve was obtained when the individual moisturized PS was compressed along with thickness between two parallel plates (Fig. 5b). The loading of 10 mm/min was stopped when the rupture point appeared. The average rupture force and energy at horizontal and vertical orientations were triplicates evaluated at all the MCs. For the definition of the loading orientation, the seed was horizontally situated with the major axis of the seed being normal to the direction of loading, or lengthwise. In contrast, the major axis of the seed was parallel to the loading direction under the vertical loading (Fig. 6). The rupture energy was calculated based on the area under the force-deformation curve using the Eq. (8) (Table 1) (Gharibzahedi et al. 2012b).

Thermal Characteristics

A copper calorimeter placed inside a flask by the method of mixtures was used to evaluate the amount of specific heat of PSs (Fig. 7a). The seeds with a certain weight and temperature were transferred into a calorimeter containing water with the known weight and temperature. A copper stirrer was applied to blend the mixture until the equilibrium temperature. According to Eq. (9) (Table 1), the sample-specific heat was determined (Gharibzahedi et al. 2012d). Also, an assembled heating device with a source, a calorimeter, and a simple Dewar vessel type equipped to a probe was used to measure the thermal conductivity of the bulk PSs under steady-state conditions (Fig. 7b). The sample tube filled with the compacted PSs was provided to two thermocouples penetrated into PSs. These thermocouples were placed between the clamp and the heat source by embedded holes. A thermostat was used to control the maximum temperature of the seed bulk. The amount of heat absorbed by water was determined to estimate the thermal conductivity of the seed bulk. Since there was no radial heat transfer, the temperature read by the thermocouple at the cross-section was considered. Using Eq. (10) in Table 1, the thermal diffusivity was calculated based on the bulk density, specific heat, and thermal conductivity data (Gharibzahedi et al. 2012d; Gharibzahedi et al. 2014b).

Statistical Analysis

Data were expressed as mean ± standard deviation. The results were subjected to analysis of variance (ANOVA) followed by Duncan’s multiple range test using the SPSS software package version 20.0 (SPSS Inc., Chicago, IL, USA) at a significant level of p < 0.05. The best model among linear, power, polynomial, exponential, and logarithmic equations was fitted between MC and data of each engineering property according to the highest regression coefficient (R2).

Results and Discussion

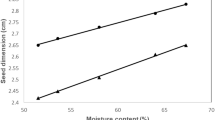

Table 2 shows all the geometrical and gravimetrical characteristics of PSs as a function of MC in the range of 4.32–20.38% d.b. With an increase in axial dimensions, the arithmetic and geometric mean diameter ranged from 1.49 to 1.55 and 1.29 to 1.36 mm as the moisture content increased from 4.32 to 20.38% d.b., respectively (p < 0.05). These data are significant in determining aperture size to design the handling machinery of seeds. They also can be useful in the ease separation of extraneous materials from the particle during cleaning by pneumatic systems (Fos’ hat et al. 2011; Hamdani et al. 2014). In addition, the presence of impurities may accelerate spoilage rate due to the growth of microorganisms and insects and reduce the quality and quantity of extracted mucilages (Rostami and Gharibzahedi 2017). The sphericity increased from 51.7 to 52.5% by increasing MC in the studied range. The moisture absorption could approach the shape of PSs to sphere owing to the differential dimensional changes of the major dimensions. Similar results were reported by Taheri-Garavand et al. (2012) for hemp seeds; Dak et al. (2014) for dried pomegranate arils; and Yurtlu et al. (2010) for bay laurel seeds. The volume and surface area significantly increased from 1.27 to 1.45 mm3 and from 4.51 to 4.98 mm2, respectively (Table 2). These results were lower than the volume (1.47 mm3) and surface area (5.02 mm2) measured by Ahmadi et al. (2012) for PSs at the MC of 7.2% w.b. The m1000 also increased from 1.241 to 1.503 g (p < 0.05). As this parameter is useful in determining the equivalent diameter, it can be applied to theoretically estimate the seed volume in cleaning systems using aerodynamic forces (Varnamkhasti et al. 2008). The bulk density decreased from 654.16 to 601.35 kg/m3 as the MC increased from 4.32 to 20.38% d.b. (p < 0.05). The decrease of bulk density by increasing MC shows that the mass increase in the result of the moisture gain of PSs is lower than the accompanying volumetric expansion of the bulk. Also, the true density decreased from 1265.1 to 1074.7 kg/m3 by increasing MC in the studied range. An increase in MC also led to a decrease in true density of sugarbeet (Dursun et al. 2007), ajwain (Zewdu 2011), and barbunia bean (Cetin 2007) seeds. The porosity significantly reduced from 48.29 to 44.04% by increasing MC from 4.32 to 20.38% d.b. (Table 2). The reverse association between porosity and MC may be explained based on the volumetric expansion of PSs, which proportionally decreased in pore space (Dak et al. 2014). The EAR of PSs increased from 32.30 to 39.61° with an increase in MC from 4.32 to 20.38 d.b. (p < 0.01). The seeds tend to stick together at higher MCs, because of the plasticity effect (stickiness) over the surface of the seeds, leading to better stability and less flowability, thereby increasing the EAR (Gharibzahedi et al. 2010b; Taheri-Garavand et al. 2012). The obtained data of EAR is valuable to design hoppers and storage bins in different countries with diverse weather conditions, providing the optimal processing strategy and quality control of extracted PS-based products (Jan et al. 2019). The increased terminal velocity was observed at high MCs so that this factor increased from 1.51 to 2.41 m/s by increasing MC from 4.32 to 20.38 d.b. (p < 0.05, Table 3). The terminal velocity of PSs was lower than that of black cumin seed (5.7 m/s) (Gharibzahedi et al. 2010b), ackee apple seed (9.95 m/s) (Omobuwajo et al. 2000), pine nut (8.67–8.83 m/s) (Gharibzahedi et al. 2010a), and dill seed (2.24–2.91 m/s) (Singh et al. 2016). Table 3 also reveals the SFCs against GS, SS, PW, and GIS surfaces at the different MCs. At all MCs, the SFC was greatest against GIS (0.423–0.519), followed by PW (0.393–0.458) and SS (0.369–0.426), and least for GS (0.261–0.332). The increased SFCs with an increase in MC on all surfaces can be attributed to the increased adhesion between PSs and the applied surface at higher moisture values (Gharibzahedi et al. 2010a). Frictional coefficients can determine the best surface to increase or decrease the flow speed of seeds during operation units for their preparation to extract bioactive carbohydrate mucilages. This character is a vital parameter to calculate the compressibility degree and flow behavior rate of materials applied to design bins and other storage equipment of PSs (Ahmadi et al. 2012). The linear regression correlations with R2 values more than 0.94 were obtained between all the physical properties and MC (Tables 2 and 3).

Fig. 8A shows the required force to rupture PSs under two loading orientations (vertical and horizontal) at the different MCs. A significant decrease in rupture force with an increase in MC was determined at vertical and horizontal loading orientations (p < 0.05). This reduction may be as a result of becoming softer of PS tissue at higher MCs. Dak et al. (2014) found that the hardness and toughness of dried pomegranate arils decreased with an increase in MC from 7 to 28% d.b. A reduction in rupture force hemp seeds (Taheri-Garavand et al. 2012) and red bean grains (Kiani Deh Kiani et al. 2008) was earlier reported when the MC increased. Moreover, the PS rupture at the vertical position required less force and yielded the best mucilage extraction quality. Therefore, this investigation can be beneficial in determining mechanical energy required for designing postharvest systems to do accurate unit operations such as handling, sorting/separating, grinding, and processing. Therefore, the loading orientation had a stronger effect than MC on the rupture force. Table 4 demonstrates that the linear regression equations are adequately fitted to the moisture-dependent rupture force data under two loading orientations. It was also reported that the required force to rupture cumin seed decreased from 50 to 40 N and 31 to 20.3 N by increasing MC from 7 to 13% d.b., for the horizontal and vertical orientations, respectively (Singh and Goswami 1998). Fig. 8B depicts the absorbed energy by PSs at rupture point as a function of MC at two loading orientations. An increase in MC led to an increase in rupture energy. This parameter increased from 0.703 to 1.125 mJ and 1.04 to 1.43 mJ by increasing MC from 4.32 to 20.38% d.b., for the horizontal and vertical orientations, respectively (Fig. 8B). An adverse result in rupture energy compared to the rupture force was obtained (Fig. 8A and B). Based on the Eq. (8) (Table 1), two parameters of force and deformation up to rupture point directly affect the energy absorbed at seed rupture. It seems that PSs at low MCs required to the more force to be ruptured with low deformation. In contrast, the rupture force and deformation respectively were low and high at high MCs. Therefore, the energy required to rupture PSs during compressive loading increases with an increase in their MC (Gharibzahedi et al. 2014b). Thus, it is necessary to use of drying systems before extracting high-quality mucilage from PSs. The regression analysis showed that two linear and polynomial models were suitable to be fitted to the data of rupture energy at horizontal and vertical orientations (Table 4).

The most important thermal parameters are specific heat, thermal conductivity, and thermal diffusivity. Specific heat is the critical property to determine the level of energy required to change the temperature of a product, whereas the two other parameters are involved in estimating the heat transfer rate for designing process and equipment (Aviara et al. 2008). The thermal properties of PSs were evaluated as a function of MC (Fig. 9). An increase in MC (from 4.32 to 20.38% d.b.) led to a significant increase in specific heat (1.56–3.12 kJ/kg K°) and thermal conductivity (0.235–0.322 W/m K°), while the thermal diffusivity decreased significantly at higher MCs (p < 0.05). The mean value of thermal diffusivity decreased non-linearly from 2.3 × 10−4 to 1.7 × 10−4 m2/s in the moisture range from 4.32 to 20.38% d.b. Table 5 also shows that the data of specific heat and thermal conductivity can be expressed as a linear model (R2 = 0.960–0.981), whereas the thermal diffusivity data were acceptably fitted to the polynomial model (R2 = 0.968). An increase in specific heat of pistachio nuts at 7.5–39% w.b. (Hsu et al. 1991); coffee beans at 9.9–30.6% w.b. (Chandrasekar and Viswanathan 1999); red lentil seeds at 9.1–21.1% w.b. (Gharibzahedi et al. 2014b); and chia, kaniwa, triticale, and farro seeds at 10–20% d.b. (Suleiman et al. 2015) was reported by increasing the MC range. Also, an increase in thermal conductivity with increasing MC was observed for minor millet grains and flours (Subramanian and Viswanathan 2003), stored canola seeds (Yu et al. 2015), and Persian walnut kernels (Mamani 2015). Increasing the MC also led to a significant reduction in thermal diffusivity of red lentil seeds (Gharibzahedi et al. 2014b), cassia bark (Ghodki et al. 2016), and guna seeds (Aviara et al. 2008).

Conclusions

In this study, some engineering characteristics of PSs were evaluated in the MC range of 4.32–20.38% d.b. The geometrical, frictional, and aerodynamic properties were significantly increased by increasing MC. The gravimetrical results showed that the porosity and bulk and true densities were reduced scientifically by increasing MC from 4.32 to 20.38% d.b. More moisture absorption could significantly lead to a significant decrease in the force required to rupture PSs. A substantial increase in the specific heat and thermal conductivity and a remarkable reduction in thermal diffusivity were found by increasing MC. All the studied engineering properties of PSs showed an excellent correlation to their MC. The obtained data would be instrumental in harvesting, transportation, classification, sorting, extraction, hydrothermal processes, and packaging in the industry.

Abbreviations

- PSs:

-

psyllium seeds

- MC:

-

moisture content (% w.b.)

- EAR:

-

emptying angle of repose (°)

- SFCs:

-

static friction coefficients

- GS:

-

glass

- SS:

-

stainless steel

- PW:

-

plywood

- GIS:

-

galvanized iron sheet

References

Ahmadi, R., Kalbasi-Ashtari, A., & Gharibzahedi, S. (2012). Physical properties of psyllium seed. International Agrophysics, 26(1), 91–93.

Akharume, F., & Aregbesola, O. A. (2019). Moisture dependent physico-mechanical and aerodynamic properties of roselle calyxes (Hibiscus sabdariffa). Journal of Postharvest Technology, 7(1), 84–92.

Akinci, I., Ozdemir, F., Topuz, A., Kabas, O., & Canakci, M. (2004). Some physical and nutritional properties of Juniperus drupacea fruits. Journal of Food Engineering, 65(3), 325–331.

Altuntas, E., & Özkan, Y. (2008). Physical and mechanical properties of some walnut (Juglans regia L.) cultivars. International Journal of Food Engineering, 4(4), 1–16.

Amini, S., Yousefi, S., & Moghari, A. A. (2018). Development and quality characterization of liquid Kashk by incorporating psyllium (Plantago ovata Forsk) hydrocolloid gel. Journal of Food Measurement and Characterization, 12(3), 1669–1677.

Aviara, N. A., Haque, M. A., & Ogunjimi, L. A. O. (2008). Thermal properties of guna seed. International Agrophysics, 22(4), 291–297.

Cetin, M. (2007). Physical properties of barbunia bean (Phaseolus vulgaris L. cv. ‘Barbunia’) seed. Journal of Food Engineering, 80(1), 353–358.

Chandrasekar, V., & Viswanathan, R. (1999). Physical and thermal properties of coffee. Journal of Agricultural Engineering Research, 73(3), 227–234.

Chong, R. W. W., Ball, M., McRae, C., & Packer, N. H. (2019). Comparing the chemical composition of dietary fibres prepared from sugarcane, psyllium husk and wheat dextrin. Food Chemistry, 298, 125032.

Dak, M., Jaaffrey, S. N. A., & Gupta, R. B. (2014). Moisture-dependent physical properties of dried pomegranate arils. Journal of Food Measurement and Characterization, 8(3), 234–240.

Dursun, I., Tuğrul, K. M., & Dursun, E. (2007). Some physical properties of sugarbeet seed. Journal of Stored Products Research, 43(2), 149–155.

Fos'hat, M., Etemad, V., Gharibzahedi, S. M. T., & Ghahderijani, M. (2011). Physical, mechanical and aerodynamic properties of acorn (Quercus suber L.) as potentials for development of processing machines. Australian Journal of Crop Science, 5(4), 473–478.

Gao, Y., Janes, M. E., Chaiya, B., Brennan, M. A., Brennan, C. S., & Prinyawiwatkul, W. (2018). Gluten-free bakery and pasta products: Prevalence and quality improvement. International Journal of Food Science & Technology, 53(1), 19–32.

Gharibzahedi, S. M. T., Mousavi, S. M., & Razavi, S. H. (2009). Evaluation of physical, mechanical and nutritional properties of sesame seed (Sesamum Indicum L.) in different moisture contents for the optimization of the processing operation. Electronic Journal of Food Processing and Preservation, 1(3), 101–118.

Gharibzahedi, S. M. T., Etemad, V., & Mirarab-Razi, J. (2010a). Study on some engineering attributes of pine nut (Pinus pinea) to the design of processing equipment. Research in Agricultural Engineering, 56(3), 99–106.

Gharibzahedi, S. M. T., Mousavi, S. M., Moayedi, A., Garavand, A. T., & Alizadeh, S. M. (2010b). Moisture-dependent engineering properties of black cumin (Nigella sativa L.) seed. Agricultural Engineering International: CIGR Journal, 12(1), 194–202.

Gharibzahedi, S. M. T., Ghasemlou, M., Razavi, S. H., Jafarii, S. M., & Faraji, K. (2011a). Moisture-dependent physical properties and biochemical composition of red lentil seeds. International Agrophysics, 25(4), 343–347.

Gharibzahedi, S. M. T., Mousavi, S. M., & Ghahderijani, M. (2011b). A survey on moisture-dependent physical properties of castor seed (Ricinus communis L.). Australian Journal of Crop Science, 5(1), 1–7.

Gharibzahedi, S. M. T., Mousavi, S. M., Ghahderijani, M., & Dadashpour, A. (2012a). Assessment of physical and chemical aspects of new Persian walnut cultivars to optimize process conditions. International Journal of Food Engineering, 8(1), 12.

Gharibzahedi, S. M. T., Mousavi, S. M., Hamedi, M., & Khodaiyan, F. (2012b). Comparative analysis of new Persian walnut cultivars: Nut/kernel geometrical, gravimetrical, frictional and mechanical attributes and kernel chemical composition. Scientia Horticulturae, 135, 202–209.

Gharibzahedi, S. M. T., Mousavi, S. M., Hamedi, M., Khodaiyan, F., & Dadashpour, A. (2012c). Mechanical behavior of Persian walnut and its kernel under compression loading: An experimental and computational study. Journal of Food Processing and Preservation, 36(5), 423–430.

Gharibzahedi, S. M. T., Mousavi, S. M., Jouki, M., & Ghahderijani, M. (2012d). Analysis of physicochemical and thermo-mechanical characteristics of Iranian black seed (Nigella oxypetala Boiss). International Journal of Food Engineering, 8(3), 14.

Gharibzahedi, S. M. T., Ansarifard, I., Hasanabadi, Y. S., Ghahderijani, M., & Yousefi, R. (2013a). Physicochemical properties of Moringa peregrina seed and its oil. Quality Assurance and Safety of Crops & Foods, 5(4), 303–309.

Gharibzahedi, S. M. T., Mousavi, S. M., Hamedi, M., & Khodaiyan, F. (2013b). Engineering characterization of Persian walnut and its kernel (Juglans regia L.) for obtaining high quality produce. Quality Assurance and Safety of Crops & Foods, 5(2), 145–156.

Gharibzahedi, S. M. T., Razavi, S. H., & Mousavi, S. M. (2013c). Psyllium husk gum: An attractive carbohydrate biopolymer for the production of stable canthaxanthin emulsions. Carbohydrate Polymers, 92(2), 2002–2011.

Gharibzahedi, S. M. T., Emam-Djomeh, Z., Razavi, S. H., & Jafari, S. M. (2014a). Mechanical behavior of lentil seeds in relation to their physicochemical and microstructural characteristics. International Journal of Food Properties, 17(3), 545–558.

Gharibzahedi, S. M. T., Ghahderijani, M., & Lajevardi, Z. S. (2014b). Specific heat, thermal conductivity and thermal diffusivity of red lentil seed as a function of moisture content. Journal of Food Processing and Preservation, 38(4), 1807–1811.

Ghodki, B. M., Tangirala, A. S., & Goswami, T. K. (2016). Moisture dependent thermal properties of cassia. Cogent Food & Agriculture, 2(1), 1227110.

Guo, Q., Cui, S. W., Wang, Q., Goff, H. D., & Smith, A. (2009). Microstructure and rheological properties of psyllium polysaccharide gel. Food Hydrocolloids, 23(6), 1542–1547.

Hamdani, A., Rather, S. A., Shah, A., Gani, A., Wani, S. M., Masoodi, F. A., & Gani, A. (2014). Physical properties of barley and oats cultivars grown in high altitude Himalayan regions of India. Journal of Food Measurement and Characterization, 8(4), 296–304.

Hashemi, F. S., Gharibzahedi, S. M. T., & Hamishehkar, H. (2015). The effect of high methoxyl pectin and gellan including psyllium gel on Doogh stability. RSC Advances, 5(53), 42346–42353.

Hsu, M. H., Mannapperuma, J. D., & Singh, R. P. (1991). Physical and thermal properties of pistachios. Journal of Agricultural Engineering Research, 49, 311–321.

Jain, R. K., & Bal, S. (1997). Properties of pearl millet. Journal of Agricultural Engineering Research, 66(2), 85–91.

Jalanka, J., Major, G., Murray, K., Singh, G., Nowak, A., Kurtz, C., Silos-Santiago, I., Johnston, J., de Vos, W., & Spiller, R. (2019). The effect of psyllium husk on intestinal microbiota in constipated patients and healthy controls. International Journal of Molecular Sciences, 20(2), 433.

Jan, K. N., Panesar, P. S., & Singh, S. (2019). Effect of moisture content on the physical and mechanical properties of quinoa seeds. International Agrophysics, 33(1), 41–48.

Kiani, M. K. D., Minaei, S., Maghsoudi, H., & Varnamkhasti, M. G. (2008). Moisture dependent physical properties of red bean (Phaseolus vulgaris L.) grains. International Agrophysics, 22(3), 231–237.

Lertpipopmetha, K., Kongkamol, C., & Sripongpun, P. (2018). Effect of psyllium fiber supplementation on diarrhea incidence in enteral tube-fed patients: A prospective, randomized, and controlled trial. Journal of Parenteral and Enteral Nutrition., 43, 759–767. https://doi.org/10.1002/jpen.1489.

Mahapatra, A. K., Ekefre, D. E., Degala, H. L., Punnuri, S. M., & Terrill, T. H. (2019). Moisture-dependent physical and thermal properties of Sericea lespedeza seeds. Applied Engineering in Agriculture, 35(3), 389–397.

Mamani, I. (2015). Modeling of thermal properties of Persian walnut kernel as a function of moisture content and temperature using response surface methodology. Journal of Food Processing and Preservation, 39(6), 2762–2772.

Mohsenin, N. N. (1986). Physical properties of plant and animal materials. New York: Gordon and Breach science publishers.

Omobuwajo, T. O., Sanni, L. A., & Olajide, J. O. (2000). Physical properties of ackee apple (Blighia sapida) seeds. Journal of Food Engineering, 45(1), 43–48.

Pal, S., McKay, J., Jane, M., & Ho, S. (2019). Using Psyllium to prevent and treat obesity comorbidities. In Nutrition in the Prevention and Treatment of Abdominal Obesity (pp. 245–260). Academic Press.

Patel, M. K., Tanna, B., Gupta, H., Mishra, A., & Jha, B. (2019). Physicochemical, scavenging and anti-proliferative analyses of polysaccharides extracted from psyllium (Plantago ovata Forsk) husk and seeds. International Journal of Biological Macromolecules, 133, 190–201.

Ramashia, S. E., Gwata, E. T., Meddows-Taylor, S., Anyasi, T. A., & Jideani, A. I. O. (2018). Some physical and functional properties of finger millet (Eleusine coracana) obtained in sub-Saharan Africa. Food Research International, 104, 110–118.

Ropelewska, E., Zapotoczny, P., Budzyński, W. S., & Jankowski, K. J. (2017). Discriminating power of selected physical properties of seeds of various rapeseed (Brassica napus L.) cultivars. Journal of Cereal Science, 73, 62–67.

Rostami, H., & Gharibzahedi, S. M. T. (2017). Mathematical modeling of mucilage extraction kinetic from the waste hydrolysates of fruiting bodies of Zizyphus jujuba mill. Journal of Food Processing and Preservation, 41(4), e13064.

Sadeghian, F., Rahmanian, S., & Jahromi, H. K. (2018). Impact of aqueous extract of Plantago ovata fork (psyllium) fruit on the improvement of non-alcoholic fatty liver disease among male rats. Asian Journal of Pharmaceutics, 12(1), S173–S178.

Singh, K. K., & Goswami, T. K. (1998). Mechanical properties of cumin seed (Cuminum cyminum Linn.) under compressive loading. Journal of Food Engineering, 36(3), 311–321.

Singh, R. K., Vishwakarma, R. K., Vishal, M. K., Goswami, D., & Mehta, R. S. (2016). Moisture dependent physical properties of dill. Journal of Agricultural Engineering, 53(1), 33–40.

Soltanian, N., & Janghorbani, M. (2019). Effect of flaxseed or psyllium vs. placebo on management of constipation, weight, glycemia, and lipids: A randomized trial in constipated patients with type 2 diabetes. Clinical Nutrition ESPEN, 29, 41–48.

Subramanian, S., & Viswanathan, R. (2003). Thermal properties of minor millet grains and flours. Biosystems Engineering, 84(3), 289–296.

Suleiman, R. A., Xie, K., & Rosentrater, K. A. (2015). Physical and thermal properties of chia, kaniwa, triticale and farro as a function of moisture content. In 2015 ASABE Annual International Meeting (p. 1). American Society of Agricultural and Biological Engineers.

Taheri-Garavand, A., Nassiri, A., & Gharibzahedi, S. M. T. (2012). Physical and mechanical properties of hemp seed. International Agrophysics, 26(2), 211–215.

Tavakoli, M., Tavakoli, H., Rajabipour, A., Ahmadi, H., & Gharib-Zahedi, S. M. T. (2010). Moisture-dependent physical properties of barley grains. International Journal of Agricultural and Biological Engineering, 2(4), 84–91.

Varnamkhasti, M. G., Mobli, H., Jafari, A., Keyhani, A. R., Soltanabadi, M. H., Rafiee, S., & Kheiralipour, K. (2008). Some physical properties of rough rice (Oryza sativa L.) grain. Journal of Cereal Science, 47(3), 496–501.

Yu, D. U., Shrestha, B. L., & Baik, O. D. (2015). Thermal conductivity, specific heat, thermal diffusivity, and emissivity of stored canola seeds with their temperature and moisture content. Journal of Food Engineering, 165, 156–165.

Yurtlu, Y. B., Yesiloglu, E., & Arslanoglu, F. (2010). Physical properties of bay laurel seeds. International Agrophysics, 24, 325–328.

Zewdu, A. D. (2011). Moisture-dependent physical properties of ajwain (Trachyspermum ammi L.) seeds. Philippine Agricultural Scientist, 94(3), 278–284.

Zhou, Y. Q., Xu, R. Y., & Wan, Y. P. (2019). The role of dietary factors in inflammatory bowel diseases: New perspectives. Journal of Digestive Diseases, 20(1), 11–17.

Ziemichód, A., Wójcik, M., & Różyło, R. (2019). Seeds of Plantago psyllium and Plantago ovata: Mineral composition, grinding, and use for gluten-free bread as substitutes for hydrocolloids. Journal of Food Process Engineering, 42(1), e12931.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of Interest

The author declares that he/she has no conflict of interest.

Rights and permissions

About this article

Cite this article

Hashemifesharaki, R. Moisture-Dependent Engineering Characterization of Psyllium Seeds: Physical, Frictional, Aerodynamic, Mechanical, and Thermal Properties. J. Biosyst. Eng. 45, 374–384 (2020). https://doi.org/10.1007/s42853-020-00077-4

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s42853-020-00077-4