Abstract

This study aims to assess the suitability of micro-silica (MS) as an industrial waste to modify the hydro-mechanical behavior of expansive soil in comparison with the use of lime as a traditional stabilizer. Due to limitations associated with soil treatment with calcium-based materials, the effect of lime–micro-silica (LMS) on stabilization of expansive clay was also studied with the aim of reducing the amount of lime consumption. The clay was stabilized with different percentages of lime alone (3% and 5%), MS alone (10% and 20%) and mixtures of LMS (3–10%, 5–10%, 3–20% and 5–20%). Experimental study performed on treated and untreated specimens included the reactivity tests measuring the pozzolanicity of the additives, compaction characteristics and Atterberg limits of mixtures, one-dimensional swell, compressibility, shrinkage, unconfined compressive strength of compacted specimens of different mixtures, as well as X-ray diffraction, scanning electron microscopy and wet chemistry analysis to study the mineralogy, microstructure and chemical composition of specimens. The results showed that the addition of MS alone did not have a significant effect on the stabilization of expansive soil, whereas stabilization with LMS achieved promising results with 10% MS + 3% lime mixture, hence achieving the goals of recycling MS as well as minimizing the amount of lime used. This combination was effective in improving the hydro-mechanical behavior of the clay due to formation of cementitious compounds resulting from pozzolanic reactions between Ca2+ of lime and SiO2 of micro-silica.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

Stabilization of expansive clays is an effective method to modify the hydro-mechanical behavior of these problematic soils in order to improve their performance. High swell-shrinkage potential of expansive soils makes them susceptible to moisture changes due to seasonal climatic conditions. Change in water table level or broken underground drains may result in considerable damage to structures. Foundation settlements, subsidence and bulging of roads, cracking in pavements and buildings are some of the structural failures that may be associated with expansive soils. Therefore, it is very important to study the expansive soil characteristics and mitigate its properties in order to achieve the desired engineering requirements for any civil engineering project [27, 39, 44, 59, 74, 76].

One of the methods of soil stabilization is the use of natural, chemical or by-product materials as additives in the soil [31, 40, 44, 47, 50, 56]. Utilization of waste materials as stabilizing agents grew more interest among civil engineers in the recent years to manage waste. Whether the source of the waste materials is industrial, such as micro-silica, fly ash, or agricultural, such as rise husk ash, oyster shells, olive seed, or from construction wastes (calcined clay), it is rapidly becoming a priority for geotechnical engineers to utilize these materials in order to enhance the soil properties, while achieving an effective and sufficient method of waste management [1,2,3,4, 8, 10, 21, 32, 34, 37, 42, 44, 46, 53, 55, 57, 68,69,70].

In the previous studies, the effect of traditional soil stabilizers such as hydrated lime, limestone dust and cement has been studied [1, 2, 28, 38, 58, 60, 75]. Schanz and Elsawy [64] studied the effect of limestone and hydrated lime on the behavior of expansive soil. Their results indicated that while both calcium-based additives positively affected the swelling potential of soils, due to more abundant calcium ions in hydrated lime (Ca(OH)2), the effect of hydrated lime on reduction of swelling pressure was much more significant than limestone (CaCO3). Also, the result of their study showed that limestone negatively affected strength, while hydrated lime increased the strength of expansive soil. These results affirm that the chemical composition of different types of lime plays an important role in effectiveness of reaction of lime with soil. Therefore, hydrated lime is clearly a better choice for expansive soil stabilization. Another factor that closely influences the result of soil treatment with lime is the amount of added lime. Previous researches have documented expansive soil treatment with different variations of lime content (from 1 up to 10%). According to Bell [23], the optimum amount of lime required to achieve maximum modification of soil is between 1 and 3% of lime added by weight. Up to this point which is known as lime fixation point, the addition of lime only satisfies the affinity of the diffuse double layer of clay particles for lime’s divalent Ca2+ ions. Therefore, the positive ions that are adsorbed by clay particles are not available to participate in other reactions, and they only affect the plasticity of the soil due to cation exchange between surface of negatively charged clay platelets and calcium ions. It is only after this point that the further addition of lime can participate in pozzolanic reaction with soil. However, Schanz and Elsawy [64] found that increasing lime content of up to 5% and more has positive effects on swell pressure and swell time. Generally, it is observed that increasing the lime content and curing period positively affects soil strength, swelling and Young’s modulus [23, 25, 29, 58, 64].

However, there are limitations associated with calcium-based additives for stabilization of expansive soils. Considerable costs are necessary for the repair and renovation of damages regarding sulfate-induced heaves that occurs after stabilization. There is limited information available in the literature on how to eliminate the problems associated with expansive soil treatment with such materials. The findings from literature review indicate that in recent years the addition of waste materials, such as micro-silica, to clay soils and their effect on swelling potential, hydraulic conductivity, volume change, development of desiccation cracks and unconfined compressive strength have been investigated. The results show that the addition of pozzolanic waste materials such as micro-silica improves these properties of expansive soils.

Micro-silica (MS), also known as silica fume or condensed silica, is a by-product of calcium silicon, ferrosilicon alloys and silicon metal production, which results from the reduction process of high purity quartz, and therefore does not need any further processing. Hence, from environmental perspective, using micro-silica as a stabilizer saves energy, because its production does not consume any extra energy [4, 9, 11, 33, 41, 44, 46]. MS is composed of mostly amorphous silicon dioxide (SiO2), and due to its extremely small particle size, it has low unit weight. These characteristics combined with large surface area of the particles places MS in the category of highly reactive pozzolanic materials [11, 61, 73]. MS has been successfully used to enhance the durability, strength and electrical resistivity of concrete [9, 21, 30]. Others investigated the performance of micro-silica on expansive soil [8, 22, 24, 43,44,45]. Kalkan [44] studied the effect of micro-silica on swell behavior of expansive soils subjected to wetting–drying cycles and showed that both swell pressure and swell potential decreased with the increase in the cycles. It was also observed that micro-silica contents of up to 20% reduced the swell potential, thus swelling pressure, whereas no significant effect occurred with higher amounts of micro-silica. Kalkan [43] has observed that micro-silica contents of 0–25% reduced the development of desiccation cracks, whereas higher micro-silica contents did not have any considerable effect on the extent of development of desiccation cracks.

Goodarzi et al. [41] studied the effect of lime–micro-silica on highly expansive smectite clay. They indicate that although addition of micro-silica has positive effect on soil properties, the addition of micro-silica and lime combination to highly expansive soil improves soil strength, swelling and permeability more than the addition of lime or micro-silica alone. They also found that combination of micro-silica and lime enhances the soil strength with lower amount of lime and shorter curing time in comparison with samples that are treated with lime alone. Moayyeri et al. [53] examined the effect of lime–micro-silica mixture on geotechnical properties of low plasticity gypsiferous clay soil. Their results show that addition of lime and micro-silica increases the stability against soaking and compressive strength of gypsiferous soil. Alrubaye et al. [6, 7] investigated the effect of lime–micro-silica mixture on soft kaolin clay. Their results show that addition of lime and micro-silica reduces the degree of permeability and coefficient of consolidation and increases the shear strength of kaolin soil.

According to ASTM C 618 standard, micro-silica is considered as a pozzolanic material. The reaction between reactive silica and alumina oxides of the pozzolan and the calcium oxide present in lime develops pozzolanic reaction in the presence of water. Calcium silicate hydrates (CSH) and calcium aluminate hydrates (CAH) are the cementitious compounds resulting from pozzolanic reaction. The mechanism of pozzolanic reaction can be explained as in Eqs. (1) and (2):

Hydration of lime with water liberates (OH)− ions which will increase the pH of the soil solution. This will increase the solubility potential of silica and alumina and leads to pozzolanic reaction.

The pozzolanic reaction can be separated into two phases: in the first phase with the addition of lime an immediate cation exchange will occur in the soil in which the high valance cations of the lime like Ca2+ instantly isolate the clay anions from other monovalent ions in order to attach to the negatively charged surface of the clay. This reaction reduces the thickness of the diffuse double layer which will cause flocculation and reduction in the plasticity of the soil [52]. In the second phase, the cementing compound (CSH and CAH) gradually bonds the clay particles together. Therefore, this phase takes place over long time scale. These pozzolanic compounds improve the mechanical behavior of the soil by binding the soil particles together. Also, since the pozzolanic reaction uses some of the pore water, it will make the soil stiffer and reduce the swell and shrinkage potential [12, 13, 54, 59, 62, 65, 75].

The present research aims to investigate the reutilization of a waste material in the field of geotechnics. To achieve this, the effect of micro-silica as an industrial waste on modifying the engineering characteristics of expansive soils was investigated. As inferred from previous works, the use of MS–lime combination in expansive soils is quite scarce and usually does not cover study of shrinkage behavior, as well as durability of the suggested cementing mixture over prolonged time. Therefore, shrinkage behavior, which is important in the study of swelling clays in semiarid climates, is included in this study. Durability of the cemented soil is also an important issue which was investigated up to 28 days in previous research. 90 days of curing period for unconfined compressive strength specimens has been incorporated in this study, in order to assess the sustainability of the method over a longer time period. The experimental study included tests on swell-shrinkage behavior, compressibility and unconfined compressive strength. The twofold purpose of using MS, to stabilize a local expansive soil, as well as recycling it, is assessed together with lime addition required for pozzolanic reaction, yet a reduced amount of lime to eliminate the undesirable effects when used alone.

2 Materials and methods

2.1 Materials

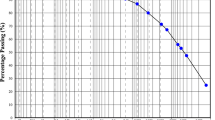

The expansive soil was collected from Famagusta, Cyprus. According to the Unified Soil Classification System [16], it is classified as clay with high plasticity (CH) consisting of mostly clay particles with an appreciable amount of silt. Physical properties of the soil are presented in Table 1. Mineralogical composition of soil was determined by X-ray diffraction (XRD), and the results are illustrated in Fig. 1 depicting that the expansive soil includes calcite, illite, montmorillonite, quartz, kaolinite and albite which are clay minerals as well as non-clay minerals of calcite.

The micro-silica (MS) used in this study is a white ultrafine powder which was obtained from Semra Ltd. Company in Northern Cyprus. It contains more than 95% purity of silicon dioxide. Based on hydrometer test, MS has 52% clay size particles and 20.8% silt size particles. Table 2 presents the chemical composition of the soil and micro-silica obtained from wet chemistry analysis. The total percentage of SiO2, Al2O3 and Fe2O3 in micro-silica is more than 70%, which is an indicator of pozzolanicity according to ASTM [13].

2.2 Methods

The expansive soil was oven-dried at 50 °C, pulverized and was separately mixed with different percentages of micro-silica, lime and combinations of both under dry conditions. The amounts of micro-silica were selected to be 10% and 20% of the dry mass of the expansive soil and was mixed with 3% and 5% lime as a secondary additive. The dry mixtures were then blended with the required amount of water for each combination to reach the optimum moisture content (Fig. 3). Soil mixtures were left to mellow for 24 h to ensure a homogeneous distribution of moisture and were then compacted according to ASTM [19]. Based on different requirements for each test, the samples were wrapped and placed in desiccators for different curing periods.

Reactivity of the pozzolan (micro-silica) was studied in accordance with the method proposed by Luxán et al. [49].

Specific gravity [20] tests were conducted for expansive soil, micro-silica and lime.

The effect of different additives on Atterberg limits was investigated as a basis for the assessment of mechanical properties for each soil-additive mixture [17].

One-dimensional swell test was performed according to ASTM [18] followed by consolidation test [15].

Shrinkage test was conducted on samples confined in the consolidation rings of 75 mm diameter and 15 mm height. After full swell was achieved in one-dimensional swell, the samples were placed in a temperature-controlled room to dry. Mass, diameter and height of the samples were continuously measured at different time intervals until measurements showed no change in volume.

Unconfined compressive strength (UCS) tests were performed according to ASTM [14], on non-cured and cured (1, 28 and 90 days) specimens of 38 mm diameter and 76 mm height with compression rate of 0.76 mm/min.

The X-ray diffraction (XRD) analysis was carried out using Bruker D8 XRD instrument with a copper sealed tube X-ray source producing Cu. Samples were first milled into fine powder and then scanned with a 2θ value ranging from 5.0° to 90.02° with the step time of 1 s at a temperature of 25 °C.

Scanning electron microscopy (SEM) analysis was performed on treated and untreated samples for further assessment of the interactions between different additives and clay particles. The SEM analysis was carried out using Philips XL30 scanning electron microscope, with high vacuum pressure. Air-dried samples collected from mixed batches prior to compaction test were used for XRD and SEM analyses.

3 Experimental results and discussions

3.1 Reactivity of pozzolan

The pozzolanicity of clay, micro-silica and their combinations was evaluated by the method presented by Luxan et al. [49]. According to this method variation in conductivity within the first 2 min is taken as a measure of pozzolanic activity. Materials possess good pozzolanicity when this variation is greater than 1.2 mS/cm, variable pozzolanicity between 0.4 and 1.2 mS/cm and non-pozzolanic below 0.4. The results presented in Fig. 2a, b show that micro-silica and its combinations with clay have higher pozzolanicity than clay, which indicates that it has more dissolved silica and consequently governs a stronger pozzolanic reaction.

3.2 Compaction characteristics

The compaction curves obtained by standard Proctor compaction test are illustrated in Fig. 3. It can be observed that the addition of 10% and 20% MS has an insignificant effect on optimum water content and maximum dry density, whereas addition of 3% and 5% lime changed the optimum water content from 25 to 34% and 35.5% and maximum dry density from 1.52 to 1.31 g/cm3 and 1.35 g/cm3, respectively. A significant change was observed in maximum dry density, from 1.52 to 1.25 kg/m3 when minimum amount of additives, 10% MS + 3% lime, was added to the soil, with optimum water content changing from 25 to 27%. Addition of the maximum quantity of additives, 20% MS + 5% lime, changed the optimum water content from 25 to 38% and maximum dry density from 1.52 to 1.23 kg/m3.

3.3 Atterberg limits

The effect of additives on plasticity index of natural and stabilized clay samples is presented in Fig. 4. It is observed that the addition of micro-silica has a very small effect on plasticity index (PI). However, when 3% and 5% lime were introduced to the soil-pozzolan mixtures, PI decreased by 65% and 72%, respectively, compared to untreated sample (PI = 34.5%). However, it was observed that while 5% lime has the lower plasticity index, almost the same results can be seen in samples with lower percentage of lime when combined with micro-silica. For example, the plasticity index of samples containing 10% + 3% lime micro-silica decreased by 70% compared to the untreated soil. This reduction is due to the occurrence of pozzolanic reaction which takes place in higher pH environment in the soil solution that is formed by addition of (OH)− ions to the soil. Therefore, by the addition of lime–micro-silica (LMS) mixtures to the soil the concentration of soil solution increases also, because of instantaneous cation exchange rate of clay minerals in the soil, cations with higher valance like additional Ca2+ ions substitute the monovalent ions and attach to the negatively charged surface of the clay almost immediately. This will ultimately lead to reduction of diffuse double layer thickness. Therefore, as the water retention capacity of the soil declines, the plasticity of the soil also decreases.

3.4 Volume change

3.4.1 One-dimensional swell

Figure 5 depicts the effect of different quantities of lime and micro-silica on the swelling potential of treated specimens. As presented in the figure, expansive soil possesses a high swell potential of 4.86%. The results show that the addition of 3% and 5% lime reduced the swell potential by 87% and 89% to 0.61% and 0.56%, respectively. This shows that the increase in additive in lime treatment significantly reduces the swell capacity of the expansive soil. These results are in good agreement with the findings of Atterberg limits tests which showed that lime treatment of expansive soil leads to reduction of water uptake potential due to the increase in the ion concentration and instantaneous cation exchange which eventually results in reduction of the swelling potential.

Figure 5 shows that addition of 10% and 20% MS reduces the swell potential. However, based on Snethen [66] classification, the soil still possesses high swell potential. The results indicate that specimens containing combination of lime and MS show a substantially lower swelling capacity. It is also observed that the addition of MS to the mixture not only could reduce the consumption of lime, but also yields lower swelling potential. For example, swell potential of specimens treated with 5% lime is 0.56%, whereas when the mixtures of 10% MS + 3% lime and 10% MS + 5% lime are added to the natural soil, the swell potential reduces to 0.41% and 0.45%, respectively. Therefore, utilization of LMS mixture has a better effect on overcoming the swelling tendency of the expansive soil compared with lime alone. This behavior can be explained by the pozzolanic reaction between lime and silica taking place after the separation of silica from clay minerals, which takes a longer time for pozzolanic compounds to develop and bind the particles together. On the other hand, when a higher concentration of silica is introduced to the soil through the addition of micro-silica, the reaction between Ca2+ of lime and SiO2 of micro-silica takes place at a higher rate. Consequently, CSH compound developed immediately begins to coat and bind the soil particles together. Hence, a higher reduction in swell potential is obtained from LMS-treated samples compared to lime-treated ones.

It is also illustrated in Fig. 5 that secondary swell rate is dramatically reduced in the specimens treated with LMS mixture. Overall, based on the results of swelling test, it can be concluded that stabilization of expansive clay with LMS significantly improves the swelling characteristics. These findings are in good agreement with the observations from SEM micrographs to be described in later sections, which show formation of flocculated structure due to LMS addition and development of cementitious compound. As mentioned before, MS is a waste product that is produced all around the world; therefore, utilization of it is greatly beneficial for the environment. It is also found that by addition of MS, lesser amount of lime is required for the pozzolanic reaction. Based on the results of this study, 3% lime addition would be sufficient to achieve low swell potential. Therefore, the risks associated with lime stabilization, such as formation of ettringite and sulfate-induced heaves, are also reduced [26, 36, 48, 63].

3.5 Compressibility

In order to better understand the compressibility behavior of treated samples, a normalization method was applied to the one-dimensional consolidation test results. Normalization method helps to create the same initial condition for specimens treated with different additives. Figure 6 demonstrates the normalized one-dimensional consolidation curves which account for the variation in initial void ratio prior to loading. As observed from the results, addition of MS alone does not have a considerable effect on compressive behavior of the soil; however, compressibility was reduced upon the addition of LMS mixtures. The reduction in compressibility is 45% and 70% after the addition of 10% MS + 3% lime and 10% MS + 5% lime, respectively.

The rebound index (Cr) and preconsolidation pressure (\(\sigma_{\text{p}}^{\prime }\)) are also calculated from void ratio versus logarithm of effective stress graphs and presented in Table 3, which depicts that rebound index of the soil decreased by 43% after the addition 10% MS + 3% lime. This improvement is also attributed to the formation of pozzolanic compounds which binds the clay particles together. Also, preconsolidation pressure increased by threefold after the addition of 10% MS + 3% lime, which confirms that the addition of LMS develops cementitious bonds, rapidly occupying the clay voids and enhancing the strength of the soil.

Consolidation test results were also used to determine coefficient of consolidation (cv) and coefficient of volume compressibility (mv). These parameters were used in Eq. (3) to determine the saturated hydraulic conductivity (ksat) under 7 different ranges of consolidation pressures.

where \(\gamma_{\text{w}}\) is the unit weight of water.

Saturated hydraulic conductivity values under different ranges of consolidation pressure are illustrated in Fig. 7. The results show that after the addition of lime–pozzolan mixtures to the expansive soil, saturated hydraulic conductivity increases. 20% MS + 3% lime mixture shows the highest ks value at all pressure ranges. This can be attributed to the formation of flocculated structure of clay particles at short curing time which increases the size of voids between clay particles [41]. The selected optimum combination required to produce a notable effect on the swell-shrink potential, 10% MS + 3% lime, however, yielded approximately a threefold increment in hydraulic conductivity within stress range of 7–220 kPa, whereas higher increments are observed at higher stresses with respect to the hydraulic conductivity value of clay alone.

3.6 Shrinkage

Figure 8 presents the results of shrinkage tests in terms of diametral (∆D/D0), axial (∆H/H0) and volumetric (∆V/V0), shrinkage strains of different mixtures. The addition of 10% MS does not have a significant effect on volumetric shrinkage strain though 20% MS reduced the volumetric shrinkage strain by 38.9% from 0.18 to 0.11. Also, 39% and 61% reduction in volumetric shrinkage strain was achieved when 10% MS + 3% lime and 20% MS + 5% lime was added to the mixture, respectively. This can be attributed to the formation of pozzolanic compounds that binds the particles together and reduces the volume change in dry seasons.

In addition, the hyperbolic model by Fredlund et al. [35] given in Eq. (4) was used to model volumetric shrinkage test results.

here w is gravimetric water content, e(w) is the void ratio at a given water content, ash is minimum void ratio, bsh is shrinkage limit, and csh is curvature of the hyperbola.

Shrinkage curves are shown in Fig. 9, and fitting parameters are presented in Table 4. The results show that the addition of MS increased the shrinkage limit (bsh parameter); however, when lime was introduced to the mixture, a higher increase in shrinkage limit was observed. For example, the addition of 20% MS increased the shrinkage limit by 42.8%, after the addition of 20% MS + 5% lime the shrinkage limit increased by 157.1%. The same trend was observed with the final void ratio (ash parameter), the addition of MS and LMS increased the void ratio by 38.5% and 130.7%, respectively, affirming the considerable reduction in volumetric shrinkage.

3.7 Unconfined compressive strength

Figure 10 demonstrates the unconfined compressive strength (UCS) test results for untreated and treated samples cured for 28 and 90 days. The results indicate that the addition of MS alone does not have a considerable effect on enhancing the strength regardless of the curing time. Addition of 3% and 5% lime increases the unconfined compressive strength by 127% and 129%, respectively, after 90 days of curing. Samples containing 20% MS + 5% lime show the highest strength value after 28 days with UCS of 1245.8 kPa, followed by only 14.9% strength increment to 1431.5 kPa after 90 days. On the other hand, 10% MS + 5% lime mixtures demonstrate 81.5% increase in strength from 940.7 kPa after 28-day curing to 1707.8 kPa after 90 days of curing exhibiting the highest strength after long-term curing which is due to long-term pozzolanic reaction and development of cementitious pozzolanic compounds [65, 73]. This behavior can be attributed to the microstructural changes observed in micrographs obtained from SEM tests as explained in the next section. The flocculated structure is observed to occur after the addition of LMS which binds the soil particles together and results in higher strength in the soil. These results show that higher percentage of MS increases the amount of soluble silica which accelerates the pozzolanic reaction rate [59]. However, if the amount of MS is more than the required amount for pozzolanic reaction, after the reaction has established, the excess amount of silica will no longer affect the microstructural changes of the soil.

On the other hand, the addition of 10% MS + 5% lime improves the soil strength by threefold after 28 days compared to untreated sample while the required curing time for 5% lime treated specimens to reach to the similar strength is 90 days. This again shows that by addition of reactive silica to the soil in the form of MS, Ca2+ ion in the lime and silica immediately engage in pozzolanic reaction. Therefore, the rate of pozzolanic compounds formation increases, whereas when there are no additional reactive silica and/or alumina, development of the pozzolanic reaction only starts as silica or alumina dissociate from clay particles.

As inferred from the results, 10% MS + 5% lime mixture demonstrates 311% increase in strength from 415.6 to 1707.8 kPa after 90 days, addition of 10% MS + 3% lime also increased the strength by 144% from 415.6 to 1013.5 kPa exhibiting a satisfactory result [67]. Therefore, it can be concluded that even though the mixture of 10% SF + 5% lime gives the highest result, 10% MS + 3% lime is selected as the optimal amount of additive for the intended expansive clay. Figure 11 demonstrates the relationship between the additive content and unconfined compressive strength.

The stiffness of treated and untreated samples was determined by calculating the secant modulus (E50). The variation of secant modulus for different mixtures after two curing periods (28 days and 90 days) is presented in Table 5. It can be noted that the addition of 10% MS + 5% lime has the highest effect on the stiffness in both curing times. With this mixture, secant modulus increased by threefolds after 90 days of curing. However, a satisfactory result was also achieved with lesser amount of lime with the addition of 10% MS + 3% lime which led to a 257% increase in secant modulus after 90 days of curing.

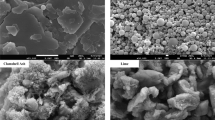

3.8 Scanning electron microscopy analysis

In order to further assess the interactions between different additives and clay particles, scanning electron microscopy (SEM) analysis was performed on treated and untreated samples.

The SEM micrographs of untreated expansive clay, 5% lime and combination of 20% MS + 5% lime are presented in Fig. 12a–c, respectively. As observed from the figures, clay SEM micrograph demonstrates thin sheets and dispersed structure. Although the particles appear more integrated after the addition of lime, cementitious compounds formed from pozzolanic reaction are more significantly observed in LMS-stabilized sample. This structural transformation of clay particles results in higher compressive strength and improvement of swell potential of treated soil. These findings are in good agreement with Goodarzi et al. [41], Kalkan [44] and Kalkan and Akbulut [45].

3.9 The X-ray diffraction (XRD) analysis

XRD results of untreated expansive clay and combination of 20% MS + 5% lime are presented in Fig. 13. The results indicate that the cementitious pozzolanic are formed after the addition of 20% MS and 5% lime. A careful comparison of the XRD patterns shows the presence of reflections in the range 2θ 20.0°–31.0° that could be attributed to calcium aluminate hydrate (CAH) phase. Also, XRD pattern reveals a reflection at 2θ 11.0°–12.0° assigned to a calcium silicate hydrate (CSH) phase [5, 51, 71, 72].

4 Conclusions

On the basis of the results obtained from this research it can be concluded that:

-

1.

Stabilization of expansive clay with a combination of 10% MS + 3% lime reduced the swell potential by 92% from 4.86 to 0.41%, Therefore, selecting the optimum mixture not only would result in lower swelling potential but also would reduce the consumption of lime.

-

2.

Hydraulic conductivity values of samples treated with 10% MS + 3% lime yielded approximately threefold increment in hydraulic conductivity values compared to untreated clay, under stresses of 7–220 kPa.

-

3.

Maximum volumetric shrinkage results showed that although the addition of MS increased the shrinkage limit, due to the formation of pozzolanic compounds which bind the particles together, when lime was introduced to the mixture, a higher increase in shrinkage limit was observed.

-

4-

10% MS + 3% lime mixture demonstrated 144% increase in strength after 90 days and was selected as the optimal amount of additive for the intended expansive clay. Consequently, addition of 10% MS + 3% lime increased the stiffness, demonstrated by secant modulus (E50), by 257% after 90 days of curing.

It is finally concluded that while the addition of micro-silica (MS) alone has less effect on the engineering parameters of expansive clay, the addition of lime–micro-silica (LMS) provided promising results in stabilization of expansive soil. According to different tests, reaction between Ca2+ of lime and SiO2 of micro-silica and the formation of a cementitious pozzolanic compound bind the clay particles together. Therefore, by stabilizing the soil with LMS not only the pozzolanic reaction takes place at a faster pace, but a lower percentage of lime is required which lowers the risks associated with lime stabilization, such as formation of ettringite and sulfate-induced heaves. Therefore, utilization of MS, which is an industrial waste, enhances the engineering properties of soils as well as providing an application for recycling against degradation of the environment.

References

Abdi MR, Askarian A, Gonbad MSS (2019) Effects of sodium and calcium sulphates on volume stability and strength of lime-stabilized kaolinite. Bull Eng Geol Environ 79:1–17. https://doi.org/10.1007/s10064-019-01592-1

Abdi MR, Chehregosha A, Farzalizadeh R (2019) Effects of miscellaneous plasticity on behavior of lime-treated kaolinites. Int J Geotech Eng. https://doi.org/10.1080/19386362.2019.1677401

Abo-El-Enein SA, Heikal M, Amin MS, Negm HH (2013) Reactivity of dealuminated kaolin and burnt kaolin using cement kiln dust or hydrated lime as activators. Constr Build Mater 47:1451–1460. https://doi.org/10.1016/j.conbuildmat.2013.06.078

Akbulut S, Saglamer A (2004) Modification of hydraulic conductivity in granular soils using waste materials. Waste Manag 24(5):491–499. https://doi.org/10.1016/j.wasman.2004.01.002

Al-Mukhtar M, Lasledj A, Alcover JF (2010) Behaviour and mineralogy changes in lime-treated expansive soil at 20 °C. Appl Clay Sci 50(2):191–198. https://doi.org/10.1016/j.clay.2010.07.023

Alrubaye AJ, Hasan M, Fattah MY (2017) Stabilization of soft kaolin clay with silica fume and lime. Int J Geotech Eng 11(1):90–96. https://doi.org/10.1080/19386362.2016.1187884

Alrubaye AJ, Hasan M, Fattah MY (2018) Effects of using silica fume and lime in the treatment of kaolin soft clay. Geomech Eng 14(3):247–255. https://doi.org/10.12989/gae.2018.14.3.247

AL-Soudany KY (2018) Improvement of expansive soil by using silica fume. Kufa J Eng 9(1):222–239. https://doi.org/10.30572/2018/kje/090115%20%20%20%20

Amin MS, Hashem FS (2011) Hydration characteristics of hydrothermal treated cement kiln dust–sludge–silica fume pastes. Constr Build Mater 25(4):1870–1876. https://doi.org/10.1016/j.conbuildmat.2010.11.073

Asl FN, Asgari HR, Emami H, Jafari M (2019) Combined effect of micro silica with clay, and gypsum as mulches on shear strength and wind erosion rate of sands. Int Soil Water Conserv Res 7(4):388–394. https://doi.org/10.1016/j.iswcr.2019.03.003

ASTM C1240-15 (2015) Standard specification for silica fume used in cementitious mixtures. ASTM International, West Conshohocken. https://doi.org/10.1520/C1240-15

ASTM C593-06 (2011) Standard specification for fly ash and other pozzolans for use with lime for soil stabilization. ASTM International, West Conshohocken. https://doi.org/10.1520/C0593-06R11

ASTM C618-19 (2019) Standard specification for coal fly ash and raw or calcined natural pozzolan for use in concrete. ASTM International, West Conshohocken. https://doi.org/10.1520/C0618-19

ASTM D2166/D2166M-16 (2016) Standard test method for unconfined compressive strength of cohesive soil. ASTM International, West Conshohocken. https://doi.org/10.1520/D2166_D2166M-16

ASTM D2435/D2435M-11 (2011) Standard test methods for one-dimensional consolidation properties of soils using incremental loading. ASTM International, West Conshohocken. https://doi.org/10.1520/D2435_D2435M-11

ASTM D2487-17 (2017) Standard practice for classification of soils for engineering purposes (unified soil classification system). ASTM International, West Conshohocken. https://doi.org/10.1520/D2487-17

ASTM D4318-17e1 (2017) Standard test methods for liquid limit, plastic limit, and plasticity index of soils. ASTM International, West Conshohocken. https://doi.org/10.1520/D4318-17E01

ASTM D4546-14e1 (2014) Standard test methods for one-dimensional swell or collapse of soils. ASTM International, West Conshohocken. https://doi.org/10.1520/D4546-14E01

ASTM D698-12e2 (2012) Standard test methods for laboratory compaction characteristics of soil using standard effort (12,400 ft-lbf/ft3 (600 kNm/m3)). ASTM International, West Conshohocken. https://doi.org/10.1520/D0698-12E02

ASTM D854-14 (2014) Standard test methods for specific gravity of soil solids by water pycnometer. ASTM International, West Conshohocken. https://doi.org/10.1520/D0854-14

Barbhuiya SA, Gbagbo JK, Russell MI, Basheer PAM (2009) Properties of fly ash concrete modified with hydrated lime and silica fume. Constr Build Mater 23(10):3233–3239. https://doi.org/10.1016/j.conbuildmat.2009.06.001

Bharadwaj S, Trivedi MK (2016) Impact of micro silica fume on engineering properties of expansive soil. Int J Sci Technol Eng 2:435–440

Bell FG (1996) Lime stabilization of clay minerals and soils. Eng Geol 42(4):223–237. https://doi.org/10.1016/0013-7952(96)00028-2

Borsadiya AK (2018) Improvement of compressive strength of clayey soil with microsilica (Doctoral dissertation, Texas A&M University-Kingsville)

Bozbey I, Garaisayev S (2010) Effects of soil pulverization quality on lime stabilization of an expansive clay. Environ Earth Sci 60(6):1137–1151. https://doi.org/10.1007/s12665-009-0256-5

Buttress AJ, Grenfell JA, Airey GD (2015) Accelerated swell testing of artificial sulfate bearing lime stabilised cohesive soils. Mater Struct 48(11):3635–3655. https://doi.org/10.1617/s11527-014-0428-y

Chen R, Ding X, Ramey D, Lee I, Zhang L (2016) Experimental and numerical investigation into surface strength of mine tailings after biopolymer stabilization. Acta Geotech 11(5):1075–1085. https://doi.org/10.1007/s11440-015-0420-x

Cristelo N, Glendinning S, Fernandes L, Pinto AT (2013) Effects of alkaline-activated fly ash and Portland cement on soft soil stabilisation. Acta Geotech 8(4):395–405. https://doi.org/10.1007/s11440-012-0200-9

Dash SK, Hussain M (2015) Influence of lime on shrinkage behavior of soils. J Mater Civ Eng 27(12):04015041. https://doi.org/10.1061/(ASCE)MT.1943-5533.0001301

Dotto JMR, De Abreu AG, Dal Molin DCC, Müller IL (2004) Influence of silica fume addition on concretes physical properties and on corrosion behaviour of reinforcement bars. Cem Concr Compos 26(1):31–39. https://doi.org/10.1016/S0958-9465(02)00120-8

Eberemu AO (2013) Evaluation of bagasse ash treated lateritic soil as a potential barrier material in waste containment application. Acta Geotech 8(4):407–421. https://doi.org/10.1007/s11440-012-0204-5

Fasihnikoutalab MH, Pourakbar S, Ball RJ, Unluer C, Cristelo N (2019) Sustainable soil stabilisation with ground granulated blast-furnace slag activated by olivine and sodium hydroxide. Acta Geotech 15:1–11. https://doi.org/10.1007/s11440-019-00884-w

Fattah MY, Al-Saidi AA, Jaber MM (2015) Improvement of bearing capacity of footing on soft clay grouted with lime–silica fume mix. Geomech Eng 8(1):113–132. https://doi.org/10.12989/gae.2015.8.1.000

Firoozi AA, Olgun CG, Firoozi AA, Baghini MS (2017) Fundamentals of soil stabilization. Int J Geo-Eng 8(1):26. https://doi.org/10.1186/s40703-017-0064-9

Fredlund MD, Wilson GW, Fredlund DG (2002) Representation and estimation of the shrinkage curve. In: Proceedings of 3rd international conference on unsaturated soils, UNSAT 2002, pp 145–149. Retrieved July 19, 2019, from http://hdl.handle.net/1783.1/13621

Gadouri H, Harichane K, Ghrici M (2017) Effect of calcium sulphate on the geotechnical properties of stabilized clayey soils. Period Polytech Civ Eng 61(2):256–271. https://doi.org/10.3311/PPci.9359

Ghorbani A, Hasanzadehshooiili H, Karimi M, Daghigh Y, Medzvieckas J (2015) Stabilization of problematic silty sands using microsilica and lime. Baltic J Road Bridge Eng 10(1):61–70. https://doi.org/10.3846/bjrbe.2015.08

Giridharan A, Bharathan R, Saranya P (2017) Soil stabilization using silica fume and cement. SSRG Int J Civ Eng 17(1):78–82

Golhashem MR, Uygar E (2019) Improvement of internal stability of alluvial clay from Famagusta Bay, Cyprus, using copolymer of butyl acrylate and styrene. Environ Eng Geosci 25:1–12. https://doi.org/10.2113/EEG-2205

Golhashem MR, Uygar E (2020) Volume change and compressive strength of an alluvial soil stabilized with butyl acrylate and styrene. Constr Build Mater 255:119352. https://doi.org/10.1016/j.conbuildmat.2020.119352

Goodarzi AR, Goodarzi SH, Akbari HR (2015) Assessing geo-mechanical and micro-structural performance of modified expansive clayey soil by silica fume as industrial waste. Iran J Sci Technol Trans Civ Eng 39(C2):333–350. https://doi.org/10.22099/ijstc.2015.3138

James J, Pandian PK (2016) Industrial wastes as auxiliary additives to cement/lime stabilization of soils. Adv Civ Eng. https://doi.org/10.1155/2016/1267391

Kalkan E (2009) Influence of silica fume on the desiccation cracks of compacted clayey soils. Appl Clay Sci 43(3–4):296–302. https://doi.org/10.1016/j.clay.2008.09.002

Kalkan E (2011) Impact of wetting–drying cycles on swelling behavior of clayey soils modified by silica fume. Appl Clay Sci 52(4):345–352. https://doi.org/10.1016/j.clay.2011.03.014

Kalkan E, Akbulut S (2004) The positive effects of silica fume on the permeability, swelling pressure and compressive strength of natural clay liners. Eng Geol 73(1–2):145–156. https://doi.org/10.1016/j.enggeo.2004.01.001

Koteng DO, Chen CT (2015) Strength development of lime–pozzolana pastes with silica fume and fly ash. Constr Build Mater 84:294–300. https://doi.org/10.1016/j.conbuildmat.2015.03.052

Latifi N, Marto A, Eisazadeh A (2016) Physicochemical behavior of tropical laterite soil stabilized with non-traditional additive. Acta Geotech 11(2):433–443. https://doi.org/10.1007/s11440-015-0370-3

Little DN, Nair S (2009) Recommended practice for stabilization for sulfate rich subgrade soils. National Highway Cooperative Research Program, Transportation Research Board of the National Academies, Washington, DC. https://doi.org/10.17226/22997

Luxán MD, Madruga F, Saavedra J (1989) Rapid evaluation of pozzolanic activity of natural products by conductivity measurement. Cem Concr Res 19(1):63–68. https://doi.org/10.1016/0008-8846(89)90066-5

Malekzadeh M, Bilsel H (2014) Use of posidonia oceanica ash in stabilization of expansive soils. Mar Georesour Geotechnol 32(2):179–186. https://doi.org/10.1080/1064119X.2012.728685

Maubec N, Deneele D, Ouvrard G (2017) Influence of the clay type on the strength evolution of lime treated material. Appl Clay Sci 137:107–114. https://doi.org/10.1016/j.clay.2016.11.033

Mitchell JK, Soga K (2005) Fundamentals of soil behavior, vol 3. Wiley, New York

Moayyeri N, Oulapour M, Haghighi A (2019) Study of geotechnical properties of a gypsiferous soil treated with lime and silica fume. Geomech Eng 17(2):195–206. https://doi.org/10.12989/gae.2019.17.2.195

Nalbantoğlu Z (2004) Effectiveness of class C fly ash as an expansive soil stabilizer. Constr Build Mater 18(6):377–381. https://doi.org/10.1016/j.conbuildmat.2004.03.011

Ok YS, Lim JE, Moon DH (2011) Stabilization of Pb and Cd contaminated soils and soil quality improvements using waste oyster shells. Environ Geochem Health 33(1):83–91. https://doi.org/10.1007/s10653-010-9329-3

Öncü Ş, Bilsel H (2018) Utilization of waste marble to enhance volume change and strength characteristics of sand-stabilized expansive soil. Environ Earth Sci 77(12):461. https://doi.org/10.1007/s12665-018-7638-5

Park CG, Yun SW, Baveye P, Yu C (2015) Effect of industrial by-products on unconfined compressive strength of solidified organic marine clayey soils. Materials 8(8):5098–5111. https://doi.org/10.3390/ma8085098

Pandey A, Rabbani A (2017) Soil stabilization using cement. Int J Civ Eng Technol 8(6):316–322

Pham PV (2012) Utilization of rice husk ash in geotechnology: applicability and effect of the burning conditions. Retrived June 10, 2019, from http://resolver.tudelft.nl/uuid:1400389f-c643-4d44-af41-580c7209e7bb

Quiroga AJ, Thompson ZM, Muraleetharan KK, Miller GA, Cerato AB (2017) Stress–strain behavior of cement-improved clays: testing and modeling. Acta Geotech 12(5):1003–1020. https://doi.org/10.1007/s11440-017-0529-1

Sami A, Rashid I, Bilal M (2018) Improvement in behaviour of expansive soil by adding lime and silica fume. Ned Univ J Res 15(3):101–110

Sargent P (2015) The development of alkali-activated mixtures for soil stabilisation. In: Handbook of alkali-activated cements, mortars and concretes. Woodhead Publishing, Sawston, pp 555–604. https://doi.org/10.1533/9781782422884.4.555

Saussaye L, Boutouil M, Baraud F, Leleyter L, Abdo J (2013) Influence of chloride and sulfate ions on the geotechnical properties of soils treated with hydraulic binders. Road Mater Pavement Des 14(3):551–569. https://doi.org/10.1080/14680629.2013.779303

Schanz T, Elsawy MB (2015) Swelling characteristics and shear strength of highly expansive clay–lime mixtures: a comparative study. Arab J Geosci 8(10):7919–7927. https://doi.org/10.1007/s12517-014-1703-5

Seco A, Ramirez F, Miqueleiz L, Urmeneta P, García B, Prieto E, Oroz V (2012) Types of waste for the production of pozzolanic materials—a review. In: Industrial waste. IntechOpen. https://doi.org/10.5772/36285

Snethen DR (1984) Evaluation of expedient methods for identification and classification of potentially expansive soils. In: Fifth international conference on expansive soils 1984: preprints of papers. Institution of Engineers, Barton, p 22. Retrieved June 15, 2019, from https://search.informit.com.au/documentSummary;dn=826036288566026;res=IELENG

Terzaghi K, Peck RB, Mesri G (1996) Soil mechanics in engineering practice. Wiley, New York. https://doi.org/10.1086/625679

Thakare SW, Chauhan P (2016) Stabilization of expansive soil with micro silica, lime and fly ash for pavement. Int J Eng Res 5(1):9–13. https://doi.org/10.17950/ijer/v5i1/003

Tiwari N, Satyam N (2020) An experimental study on the behavior of lime and silica fume treated coir geotextile reinforced expansive soil subgrade. Eng Sci Technol Int J. https://doi.org/10.1016/j.jestch.2019.12.006

Türköz M, Savaş H, Tasci G (2018) The effect of silica fume and lime on geotechnical properties of a clay soil showing both swelling and dispersive features. Arab J Geosci 11(23):735. https://doi.org/10.1007/s12517-018-4045-x

Vitale E, Deneele D, Paris M, Russo G (2017) Multi-scale analysis and time evolution of pozzolanic activity of lime treated clays. Appl Clay Sci 141:36–45. https://doi.org/10.1016/j.clay.2017.02.013

Wu Z, Deng Y, Liu S, Liu Q, Chen Y, Zha F (2016) Strength and micro-structure evolution of compacted soils modified by admixtures of cement and metakaolin. Appl Clay Sci 127:44–51. https://doi.org/10.1016/j.clay.2016.03.040

Yarbaşi N, Kalkan E, Akbulut S (2007) Modification of the geotechnical properties, as influenced by freeze–thaw, of granular soils with waste additives. Cold Reg Sci Technol 48(1):44–54. https://doi.org/10.1016/j.coldregions.2006.09.009

Yuan S, Liu X, Sloan SW, Buzzi OP (2016) Multi-scale characterization of swelling behaviour of compacted Maryland clay. Acta Geotech 11(4):789–804. https://doi.org/10.1007/s11440-016-0457-5

Zhang X, Mavroulidou M, Gunn MJ (2017) A study of the water retention curve of lime-treated London Clay. Acta Geotech 12(1):23–45. https://doi.org/10.1007/s11440-015-0432-6

Zhao NF, Ye WM, Chen B, Chen YG, Cui YJ (2019) Modeling of the swelling–shrinkage behavior of expansive clays during wetting–drying cycles. Acta Geotech 14(5):1325–1335. https://doi.org/10.1007/s11440-018-0718-6

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

GhavamShirazi, S., Bilsel, H. Characterization of volume change and strength behavior of micro-silica and lime-stabilized Cyprus clay. Acta Geotech. 16, 827–840 (2021). https://doi.org/10.1007/s11440-020-01060-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11440-020-01060-1