Abstract

Improvement of swell and dispersive characteristics of problematic soils which are present at various places in the world is an important topic of research in engineering applications. In recent years, industrial side products are often used to improve engineering features of problematic clay soils and both environmentalist and economic benefits are obtained. In the present study, it is aimed to improve the high plasticity clay soil, which is determined to have both high swelling potential and dispersive features, by using silica fume (SF) as a by-product material and lime (L). The minimum lime quantity that is required for the pozzolanic reaction is fixed as 3% and experiments are made with SF additive mixtures of increasing percentages (0, 1, 3, 5, 10, 15, and 20%). Within this context, the swell percentage, swell pressure, crumb, pinhole, and unconsolidated–undrained (UU) triaxial compression tests with different curing periods were conducted on the soil samples that are prepared by compressing at compaction characteristics that are specified at each additive level at standard proctor energy. In addition to these tests, in order to examine the changes caused by additives on soil structure, scanning electron microscopy (SEM) analyses were performed. As a result of this study, it is found out that swelling and dispersive features of the clay soil improved and that curing period of first 7 days was more effective on the strength improvement and optimum stabilization was achieved at an addition of 3% lime combined with 10% silica fume.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Improvement of undesired features of clay soils such as dispersibility and swelling has an important place in engineering applications. Dispersive and expansive soils are considered problematic, and these soil properties cause serious problems for many engineering structures (Sherard et al. 1976; Chen 1988; Basma et al. 1995; Yong and Warkentin 1996; Abdullah et al. 1999; Goodarzi and Salimi 2015; Qi and Vanapalli 2015; Hassanlourad et al. 2017). Dispersive soils are thought to be the cause of internal erosion in earthen structures (NRC 1983), and expansive soils are thought to be the main cause of problems in light structures (Nelson and Miller 1992).

Although not life-threatening or cataclysmic as compared to other natural events, expansive soils are certainly a natural hazard. In fact, expansive soil damage exceeds the average annual damage caused by floods, hurricanes, earthquakes, and tornados combined (Buhler and Cerato 2007). Expansive soils are frequently overlooked as a major problem because they take years to cause extensive damage. However, in reality, expansive soils are a widespread and costly natural hazard. This damage to engineering structures results in significant financial losses. The annual cost of damage to facilities and infrastructures caused by these types of soils is estimated at £150 million in UK, $1000 million in the United States, and several billions of dollars worldwide (Qi and Vanapalli 2015). The annual cost of damage to the engineering structures has also been reported in other studies (Chen 1988; Basma et al. 1995; Abdullah et al. 1999; Dua et al. 1999; Al-Rawas et al. 2002; Shi et al. 2002; Huang and Wu 2007; Phanikumar 2009; Turkoz and Tosun 2011; Djellali et al. 2017).

Dispersive clays are those clays that are confronted with erosion due to their individual colloidal clay particles flowing slowly and creating suspension even in still water. This erosion process is related to the physical–chemical situation of clay fraction of a soil. This situation causes for individual clay particles to push each other in free water existence. Chemistry of water is very important at this stage (Sherard et al. 1976; Yong and Warkentin 1996; Penner and Lagaly 2001).

While dispersive clays are widely present in nature until recent years, they were not defined as problematic soils. Earlier, it was considered that dispersive soils were only related to arid or semi-arid lands and alkali soils. In recent times, it is found out that similar problems caused by dispersive clays have existed in moist climates in various places in the world. In the water projects which are present in various places in Australia, South Africa, India, Iran, Thailand, Middle East, and South America, big problems are experienced with dispersive clays. Problems associated with dispersive soils are reported from many parts of the world. A number of earthen dams, hydraulic structures, and roadway embankments have suffered damage or collapsed due to erosion problems (NRC 1983; Indraratna et al. 1991; Umesha et al. 2009; Abbasi and Nazifi 2013; Goodarzi and Salimi 2015; Hassanlourad et al. 2017).

Studies are being made for improving swelling and dispersive soils which are observed in various countries in the world, by using additives such as cement, lime, gypsum, natural pozzolana, industrial wastes, magnesium chloride solution, and fly ash with different contents (Ouhadi and Goodarzi 2006; Murty and Praveen 2008; Yilmaz and Civelekoglu 2009; Harichane et al. 2010; Vakili et al. 2013; Turkoz et al. 2014; Latifi et al. 2016; Hassanlourad et al. 2017; Moravej et al. 2018).

In recent years, in order to improve engineering features of problematic clay soils, industrial by-products are used frequently. Usage of additives such as volatile ash, rice husk, and silica fume for stabilization purposes provides both environmentalist and economic benefits. On the other hand, it is observed that usage of these additives together with lime turned out to be more effective rather than when used alone. Lime improves the efficiency of stabilization considerably. Some researchers (El-Aziz et al. 2004; Fattah et al. 2015a; Savas 2016; Alrubaye et al. 2017) have stated that after usage of additives together, swell and dispersive features of problematic soils have improved and that their shear strength parameters and workability have significantly improved. For example, in the study conducted by Savas (2016) on the stabilization of dispersive soils, it has been shown that with the addition of 3% of natural pozzolanic additive to 2% lime content, both swelling potential and compressibility of soils were reduced, and similarly Alrubaye et al. (2017) have shown that shear strength parameters of soils gave bigger values with soil + lime + silica fume mixture series when compared with lime + soil and silica fume + soil mixture series.

There are many studies carried out for the purpose of studying the impacts of silica fume additive on the problematic clay soil properties (Abd El-Aziz et al. 2004; Al-Zairjawi 2009; Fattah et al. 2015a, 2015b; Bharadwaj and Trivedi 2016; Goodarzi et al. 2016). In these studies, not only the swelling and dispersive properties of the soil but also their physical and strength parameters have been examined. In the study conducted by Abd El-Aziz et al. (2004), lime and silica fume together have been used as stabilizers. It was found that the engineering properties of soil have been improved by adding lime (L) in the range of 5–9% combined with a 10% silica fume (SF). The plasticity index decreased from 40% to 19% when subjected to an L-SF blend of 11–15%. At L-SF 5–10%, the angle of internal friction concerning shear strength parameters would increase from 5.80° to 24.75°.

In the study carried out by Al-Zairjawi (2009), the impact of a cement and silica fume additive on the compaction characteristics and strength of a high plasticity clayey soil was examined. Test results showed that 8% cement + 6% silica fume decreased the maximum dry density from 1.64 to 1.55 g/cm3 and increased the optimum water content from 19 to 23%. In addition, it has been observed that the curing time has a positive effect on the unconfined compressive strength of the soil.

Goodarzi et al. (2015) also studied the effect of micro silica–lime admixture on geotechnical properties on the expansive soils and concluded that highly expansive clayey soils can be stabilized satisfactorily by a large amount of lime (at least 10%) and following adequate curing due to development of the pozzolanic reaction. Also, with a further increase in the lime content, the pozzolanic activity cannot continuously occur and the excessive addition of lime alone causes a reduction in the mechanical capacity. Moreover, it is found that the addition of silica fume (SF) alone, even up to 30%, has less effect on the engineering parameters of Na-smectite. On the other hand, adding lime–silica fume mixture is very effective and improves the soil behavior with a lower percentage of lime.

In the investigation performed by Bharadwaj and Trivedi (2016), a series of laboratory experiments have been conducted on samples with 0, 5, 10, and 15% of silica fume by weight of dry soil. The test results showed a significant change in consistency limits of samples containing silica fume. Also, the differential free swell decreased from 48.46 to 9% showing an appreciable decrease in swelling behavior. It is seen that swelling potential decreased with an increase in percent silica fume treatment. Amina and Rani (2017) used hydrated lime (Ca (OH)2) and silica fume as a by-product material for stabilizing the dispersive soil. They concluded that the addition of suitable additives such as lime and lime + silica fume caused a significant decrease in the dispersive characteristics of the soil. From the modified free swell test, crumb test, and double hydrometer test, it was observed that 5% lime and 2% lime + 12% silica fume decreased the dispersive characteristics of the soil.

Silica fume (SF) is a by-product material produced in large amounts throughout the world from the manufacture of silicon or ferrosilicon on alloys. The proper disposal of SF, as an industrial waste, is one of the major issues for environmentalists since leaving it directly in the environment may cause severe health problems (Zhang et al. 2016).

Silica fume which is obtained as a by-product in the production of silicon and ferrosilicon alloys has got very small spherical particles and as it contains 90% of amorphous silica, it is a substance having high pozzolanic value. Silica fume is obtained by degrading quartz at 2000 °C in an open electrical arc furnace. SiO, which turns into gas under high temperature, are accumulated as SiO2 grains as they are oxidized during the cooling process. SiO2, which does not crystallize due to sudden cooling process, is formed as very small grains in an amorphous structure.

Total annual silica fume production in the world is around 1 million tons. Moreover, 130,000 tons of this amount are being produced in the USA and 120,000 tons are being produced in Norway. In North America, there are 13 plants where silicon, silica fume, and ferrosilicon are being produced. Silica fume can also be obtained from other production ways which release silicon such as ferrochromium (FeCr), ferromanganese (FeMn), ferromagnesium (FeMg), and calcium silicon. Silica fume has very small grains and as it has nearly 93% of SiO2 in its structure, it is a very powerful pozzolanic substance (Papworth 1997). Silica fume (SF), which has low unit weight, low compactibility, and high pozzolanic activity, is widely used for the improvement of problematic soils (Goodarzi et al. 2015).

Each feature in the literature associated with the improvement of the dispersive and swell properties of clay soil with additives was separately evaluated. In this study, the effects of lime additive mixed with different proportions of silica fume on swelling potential, dispersive, and strength characteristics of a natural clay soil were investigated.

Materials

Soil

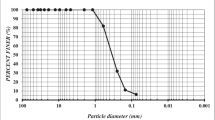

The soil sample considered in this study was taken from the Afyon province located in the Central Anatolia Region of Turkey. Sieve analysis, hydrometer analysis (ASTM D 422-63), consistency limits (ASTM D 4318-00), and specific gravity (ASTM D 854-00) tests were performed to characterize the soil sample. Based on the identification test results, the sample was classified as CH (high plasticity clay) according to the Unified Soil Classification System (USCS) (ASTM D 2487-00). The grain-size distribution, physical properties, and some chemical compositions of the soil sample are presented in Fig. 1 and Table 1, respectively. The engineering properties of the clay sample were measured according to American Society for Testing and Materials methods (ASTM 1994). X-ray diffraction (XRD) analysis was carried out on the clay sample in Anadolu University Material Science Laboratory (Fig. 2). According to the result of XRD analysis, it could be said that illite is the dominant clay mineral.

Chen (1988) classified a plasticity index over 35 as a very high swell potential, 29–35 as high, 10–35 as moderate, and 0–15 as low. On the basis of the physical properties, the swell potential of the sample can be classified as very high.

It is seen from Table 1 that the values of Na (%), ESP, and SAR, which are shown as the reason for dispersive soil behavior, are significantly high. According to Knodel’s (1991) classification based on the exchangeable sodium percentage (ESP), he has stated that soils with an ESP value higher than 10 can be classified as dispersive soils. For this reason, this soil sample also has dispersive characteristics.

Additives

In this study, two additives which are hydrated lime and silica fume have been used. Silica fume is obtained from Antalya Elektrometalurji A.Ş. Silica fume is collected with dust catchers having special filters in ferrosilicium (FeSi) and silicoferrochromium (SiFeCr) furnaces at Antalya Elektrometalurji A.Ş. factory as a by-product in Turkey. Lime obtained from standard manufacturers is used for the treatment of the studied soil. The chemical properties of the additives used in this study are shown in Table 2. Table 2 shows a significantly high content of amorphous SiO2 in SF, with small amounts of alumina, iron, calcium, and alkali oxides. Lime contains a lower SiO2 and a higher CaO when compared to SF.

Percentage of lime that is added to a soil can vary depending on whether it is used to improve stabilization of soil or its workability. While small percentages are sufficient to improve workability, an adequate quantity of lime percentage is needed to improve stabilization. For determining the minimum percentage of lime required for stabilization of soil, pH experiment which is recommended by Eades and Grim (1966) has been conducted. In this experiment, when pH value of soil and lime mixture reaches up to 12.4, the percentage of lime required for the reaction is determined. When lime with a ratio of 3% is added to the soil, pH has reached to 12.4 and in increased percentages of lime, no significant change was observed in pH value (Fig. 3).

Methods

Sample preparation

The soil sample used in the study has firstly been dried for 24 h at 105 °C in an oven, and after that, it has been ground and passed through a No. 4 sieve to obtain a uniform distribution. Different amounts of the silica fume (0, 1, 3, 5, 10, 15, and 20% by dry weight of the soil) and lime (3% by dry weight of the soil) were added and mixed into the prepared soil samples. Soil–additive mixtures were prepared for each soil sample by mixing in an optimum amount of water, which was determined at the standard Proctor energy level (ASTM D 698). As a result, compaction characteristics needed to prepare the samples for use in swell percentage, swell pressure, crumb, pinhole, and strength tests for each additive level were determined.

Experimental study

Swell potential referred to the swell percentage and swell pressure of clays is best determined through direct measurements (Nelson and Miller 1992). The swell percentage and swell pressure tests were performed using direct methods. Swell percentage test determines the amount of vertical heave that will occur when the soil is wetted. This test is performed on specimens prepared by compressing in the desired density and water content. The swell percentage is defined as the ratio between the starting length of the sample and the final deformation of the sample after being soaked in water under 7 kPa pressure for 24 h or until swelling is complete (ASTM D 4829). Modified potential volume change (PVC) meter equipment that is developed by Turkoz et al. (2014) was used to determine the swell pressure. There is no standard procedure for the PVC meter test, so the method recommended by Lambe (1960) was used. The PVC meter test involves determining the pressure arising from the inhibited swell deformation that develops after saturating the compacted soil sample with water. Immediately after, the samples placed in equipment were soaked in water, and the swell percentage and swell pressure were measured at a series of time intervals (0, 0.17, 0.33, 0.50, 0.67, 0.83, 1, 2, 4, 8, 15, 30, 60, 120, 240, 360, … min) using digital deformation meters connected to the data logger. Swell percentage and swell pressure tests were performed on the soil specimens prepared by compression in a ring with a height of 2 cm and a diameter of 7 cm.

To determine the dispersive characteristics of the samples, pinhole and crumb tests were performed following the standard procedures of the United States Bureau of Reclamation (USBR) (USBR 5400 1989; USBR 5410 1989). The crumb test yields good qualitative results and is used to determine the potential erodibility of clay soils.

Unconsolidated–undrained (UU) test method was used to evaluate the shear strength parameters of the samples with additives (ASTM D 2850). The samples were prepared in stainless steel tubes so that the ratio of their height to their diameter was 2 (76 mm height and 38 mm diameter) and compressed to the desired compaction characteristics of each additive level. The samples were removed from the tubes, placed in plastic bags, and cured for 7 and 28 days in vacuum desiccators. These tests were performed under confining pressures of 100, 200, and 300 kPa, prior to curing and then after curing for 7 and 28 days.

Finally, in addition to these experiments, in order to investigate the impact of additives on soil structure, SEM analyses are conducted. In the analysis, ZEISS branded SUPRA 50 VP model Scanning Electron Microscope (SEM) has been used.

Results and discussions

Atterberg limits

Atterberg limits tests were performed on each soil–additive mixture (ASTM D 4318). Figure 4 shows the effect of additive contents on Atterberg limits. It can be noticed that there is a decrease in liquid limit and plasticity index with the addition of silica fume. Liquid limit (LL) value has decreased from 69 to 67% with 3% lime additive and it has reduced to 60% with 3% L + 10% SF additives. No significant reduction in LL was observed with increasing lime + silica fume additive percentages. Plastic Limit (PL) value has increased from 32 to 34% with 3% lime additive and it has risen to 37% with 3% L + 10% SF additive levels, while PL has not changed with increased percentages of silica fume. Plasticity index (PI) value, which is defined as the difference between LL and PL water content, has shown an important reduction by decreasing from 37 to 23% especially with the additive level of 3% L + 10% SF. The decrease in plasticity index indicated an improvement of the soil characteristics. In the study conducted by Harichane et al. (2018) for the same soil class by only using the lime additive, it was seen that with 10% lime additive, the liquid limit has decreased from 84.8 to 76.4%. Attoh-Okine (1995) has stated that LL value of clay soils with high plasticity decreased with increasing quantity of lime.

Figure 5 shows the changing caused by additive content on the soil class. Soil class has gradually changed in the arrow direction depending on the increase in the additive content. As mentioned by Abd El-Aziz et al. (2004), SF coats and binds all clay particles which possess little cementitious value and large particles which called the pozzolanic reaction between SF and aluminous material. According to the soil classification system, the soil class has changed as MH (high plasticity silt). Similar results have been seen in the studies conducted by Kalkan (2011) and Harichane et al. (2018).

Compaction test

In order to determine the compaction characteristics used in the preparation of the soil samples with additives, experiments were made at Standard Proctor energy level. Compaction curves which were obtained as a result of compaction experiment that was conducted depending on additive content are shown in Fig. 6 and changes in optimum water content (OWC) and maximum dry density (MDD) values are shown in Table 3. As can be seen in Fig. 6 and Table 3, the MDD value decreases while the OWC value increases with increasing percentage of additives. A remarkable reduction in MDD value was observed at 3% L + 10% SF additive level. MDD value of 1.448 Mg/m3 without additive has reduced to 1.376 Mg/m3 at 3% L + 10% SF additive level and it has not changed significantly with increasing percentage of additives. The decrease in MDD value was caused by additional gap volume that has developed due to low specific gravity (Gs) of samples with additives and grain dimensions. The 3% L additive was effective in the increase in OWC, whereas this increase was limited to increasing SF additive percentages. Due to flocculation and agglomeration, lime and silica fume additives around clay grain surfaces reduce the specific surface area and they require more water for pozzolanic reaction.

Swell potential test

Changes in swell percentage–time and swell pressure–time relations with the additive content are shown in Figs. 7 and 8, respectively. From Figs. 7 and 8, it is seen that both the swell percentage and the swell pressure values reached a final value at a longer time in the case of no addition of the additive. These variables reach their final values sooner together with the addition of additives. It can be stated that this kind of behavior could provide a big advantage with regard to application. Especially in fillings which are constructed by compressing in layers, providing stabilization in a short time can be evaluated as superiority.

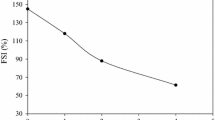

Table 4 presents the changes in swelling potential as a whole. From Table 4, it is observed that both swell percentage and swell pressure decreased depending on increasing additive content. At 3% L additive level, while there is a reduction of 32% in swell percentage and a reduction of 29.2% in swell pressure, this reduction has become more apparent in the silica fume additive percentages combined with lime. Especially, at 3% L + 10% SF additive level, there has been a reduction of 95% in swell percentage and a reduction of 94% in swell pressure. No significant changes have occurred in SF additive percentages higher than 10%. The reason for this situation has been evaluated such that silica fume is a pozzolanic substance and that there is no sufficient amount of lime to activate a binding feature of silica with increasing silica fume percentages.

Pinhole and crumb tests

Crumb and pinhole tests were conducted separately for each additive level with the aim to analyze the change in dispersibility characteristic of the soil sample. Crumb test results are collectively given in Fig. 9. The colloidal clouding, which is an indicator of the dispersive nature of the soil sample without additive, was densely observed, and the crumb test class was determined as K3. As can be seen from Fig. 9, silica fume and lime additive reduced clouding. Colloidal clouding decreased and crumb class was determined as K2 at 3% lime additive. At 3% lime additive and the addition of increased amounts of silica fume, colloidal clouding was almost completely eliminated and crumb test class was defined as K1.

However, it was understood that the more than 10% of the silica fume was not able to bind with the soil and lime because silica fume transmitted its color to water at the rates of 3% L + 15% SF and 3% L + 20% SF. When this situation is evaluated with respect to crumb tests, it can be seen that 3% L + 10% SF additive ratios are sufficient to reduce dispersion.

Figure 10 shows the time–flow rate graphic obtained from pinhole test that is conducted depending on the percentage of the additive. According to the pinhole test results, it can be observed that the soil sample shows dispersive (D2) properties. With increasing amounts of additives, the dispersibility properties have changed. It exhibited intermediate-dispersive soil (ND3) behaviors at the additive percentages of 3% L and 3% L + 1% SF and it was classified as non-dispersive soil (ND2) at the additive percentages of 3% L + 3% SF and 3% L + 5% SF. Finally, it demonstrated features of a non-dispersive soil (ND1) at the 3% L + 10% SF additive level and increased SF additive percentages. The changes of dispersive properties of the soil sample are given in Table 5. In Table 5, it can be seen that dispersive features of the sample have improved depending on increasing amounts of additives. By using silica fume together with lime, dispersibility of sample has considerably decreased.

Unconsolidated–undrained test

The unconsolidated–undrained (UU) triaxial compression test was used to evaluate the shear strength parameters of the sample with and without the additive. These tests were performed under confining pressures of 100, 200, and 300 kPa prior to curing and then after curing for 7 and 28 days. The effects of the additive content and the curing time on the shear strength parameters of the sample are presented in Table 6. It is observed that internal friction angle (Ø) and especially cohesion (c) values increased depending on additive ratios and curing periods. This situation reveals the positive impact of increased additive amounts and curing period on strength. In the study conducted by Turkoz and Vural (2013), it is mentioned that curing period was more effective on increase of strength especially in clays with high plasticity. The impact of curing period on cohesion and internal friction angle can be more clearly seen in Figs. 11 and 12, respectively. In clay soils, the cohesion has a strong influence on the shear strength, and increasing cohesion is assumed to correspond to increasing shear strength (Turkoz et al. 2014).

It is seen that there is a gradual increase in cohesion value with the increasing additive percentages (Fig. 11). While the increase starting at 3% L additive does not change much at additive percentages up to 3% L + 5% SF additive level, it has a new increasing tendency at 3% L + 10% SF level and it has not changed much at additive percentages within the interval up to 3% L + 20% SF level. The cohesion value of 81.7 kPa in the state without additives reached 169.2, 253.9, and 280 kPa in 3% L, 3% L + 10% SF, and 3% L + 20% SF additives levels, respectively, after 7 days of curing. For the same additive levels, after a curing period of 28 days, cohesion has reached to the values of 202.2, 298, and 325 kPa. As can be seen from these values, a significant increase in cohesion value has occurred at the level of 3% L + 10% SF after a curing period of 7 days. As it was stated in the study conducted by Latifi et al. (2016), curing on first 7 days had significant importance on the increase of strength for clays with high plasticity. This result is due to the pozzolanic reaction between the lime and silica fume, which is more effective with soil particles (Alrubaye et al. 2017).

As can be seen in Fig. 12, the value of the internal friction angle varied in a narrow range depending on the increasing percentage of additive and curing time. There was no significant change in the value of the internal friction angle (22.1° to 24.2°) especially without curing. This value was partially increased as a result of the pozzolanic reaction that was accompanied by the increased cure time.

Scanning electron microscopy (SEM) analysis

To determine the microstructural changes in the soil, SEM analyses were performed on the natural samples, an additive content of 3% lime, and 3% lime + 10% silica fume. The 3% lime + 10% silica fume additive content was chosen because it produced the optimal results in swell, dispersibility, and strength tests.

Figure 13 shows the images obtained from the analyses of natural clay (Fig. 13a), of the clay sample with an additive content of 3% lime (Fig. 13b), and of the clay sample with an additive content of 3% lime + 10% silica fume (Fig. 13c) taken at the same magnification. The natural sample shows a more disperse and dense structure (Fig. 13a). In case of 3% L additive content, it exhibits a more aggregated structure (Fig. 13b). The 3% L + 10% SF additive content caused the particles to reorganize and the structural integrity to increase (Fig. 13c). The resultant agglomeration reduces the interactions between the surface areas and water, which in turn changes the engineering properties. This finding can be explained by the increased silica concentration caused by the addition of silica fume and the subsequent increase in particle size due to the rapid flocculation of particles. With the addition of silica fume, the arrangement of the clay particles transforms from a dispersed structure to a flocculated structure and some new cementing compounds are formed. The surfaces of particles have been generally coated by the hydration gels, and the soil pores have been mainly filled. Besides, the flocculated condition is almost invisible and a large quantity of cementitious matter appeared on the L + SF treatment (Fig. 13c), as stated by Goodarzi et al. (2016). Such changes can be referred to the beneficial effects of L + SF on the additional formation of cementing phase. The superior influences of L + SF are ascribed to the immediate growth of silicate gel and to extend synthesis of the new cementitious compound (i.e., CSH) which is mainly formed by Ca+2 of lime and SiO2 of silica fume. This can rapidly block off the soil voids and greatly interlock the clay particles together, resulting in the continuous development of soil geotechnical properties as the additive content increases (Goodarzi and Salimi 2015). The grain sizes have increased due to enlargement of soil structure and agglomeration of the material (Fig. 13c). On treatment with lime, clays aggregate to form a more coherent mass due to pozzolanic reaction and cation exchange reactions. In further treatment with silica fume along with lime, the cementitious compounds are formed and the silica fume imparts a mechanical bonding which forms well-developed floccules and shows a more porous nature. Thus, this type of aggregation and improvement in porosity brings the desired improvement in the engineering properties of the soil (Amina and Rani 2017).

Thus, depending on increasing grain size and dimensions of aggregation, higher values were obtained with series having 3% lime + 10% silica fume additives when compared with those having 3% lime additives in strength experiments.

Conclusion

It is determined that lime and silica fume additives have a significant impact on dispersibility, swell potential, and strength of the soil sample revealing swell and dispersive features. On the other hand, it was seen that using silica fume, which is a waste material, together with lime rather than being used alone, has been much more effective and it has successfully improved the engineering features of this soil having high plasticity. In this study, the following conclusions were reached:

-

1.

In the increased L + SF additive ratios, the plasticity index decreased as a result of the decrease in the liquid limit value and the increase in the plastic limit value. As a result, the workability of the soil has improved and the soil class has changed.

-

2.

The optimum water content value of the soil increased and the maximum dry density value (MDD) decreased with increasing the amount of silica fume added to the mixture while keeping the 3% lime ratio constant. Significant reduction in MDD value was observed at 3% L + 10% SF additive level.

-

3.

At 3% L + 10% SF additive level, a reduction of 95% was observed in swell percentage and a reduction of 94% was observed in swell pressure. No significant changes have occurred in silica fume additive percentages that were more than 10%.

-

4.

When the test results were compared in terms of dispersibility, an improvement was seen in the dispersive properties of the soil sample at silica fume additive level of 10%, with 3% lime content. The expected effect was not observed when the additive percentage was increased due to the presence of free silica fume, which is unable to react with adequate lime.

-

5.

Depending on improved structural integrity and dimension being observed as a result of SEM analysis, higher values revealed with series having 3% lime + 10% silica fume additives when compared with those having 3% lime additives in strength experiments.

As the population increases, and with it the number of built structures, the dimensions of the swelling and dispersive soil problems will also grow. The combination of silica fume and lime can be successfully utilized as an additive to increase the efficiency of soil stabilization from the economic, technical, and environmental point of views.

References

Abbasi N, Nazifi MH (2013) Assessment and modification of Sherard chemical method for evaluation of dispersion potential of soils. Geotech Geol Eng 31:337–346. https://doi.org/10.1007/s10706-012-9573-7

Abd El-Aziz MA, Abo-Hashema MA, and El-Shourbagy M (2004) The effect of lime–silica fume stabilizer on engineering properties of clayey subgrade. Fourth Mansoura International Engineering Conference (4th IEC), Faculty of Engineering, Mansoura University, Egypt, Paper No. 96

Abdullah WS, Alshibli KA, Al-Zou’bi MS (1999) Influence of pore water chemistry on the swelling behavior of compacted clays. Appl Clay Sci 15:447–462. https://doi.org/10.1016/S0169-1317(99)00034-4

Al-Rawas AA, Taha R, Nelson J, Al-Shap B, Al-Siyabi H (2002) A comparative evaluation of various additives used in the stabilization of expansive soils. Geotech Test J 25(2):199–209. https://doi.org/10.1520/GTJ11363J

Alrubaye AJ, Hasan M, Fattah MY (2017) Stabilization of soft kaolin clay with silica fume and lime. Int J Geotech Eng 11(1):90–96. https://doi.org/10.1080/19386362.2016.1187884

Al-Zairjawi MK (2009) Effect of adding cement and silica fume with cement on compaction properties and shear strength of clayey soil. Al-Qadisiyah Journal for Engineering Sciences 2(2):253–261

Amina SM, Rani V (2017) Control of dispersivity of soil using lime and silica fume. International Journal for Research in Applied Science & Engineering Technology 5(5):386–391

ASTM (1994) Annual book of ASTM standards. Soil and rock, vol. 0 4.08. American Society for Testing and Materials, Philadelphia

Attoh-Okine NO (1995) Lime treatment of laterite soils and gravels-revisited. Constr Build Mater 9(5):283–287. https://doi.org/10.1016/0950-0618(95)00030-J

Basma AA, Al-Hamoud AS, Husein A (1995) Laboratory assessment of swelling pressure of expansive soils. Appl Clay Sci 9:355–365. https://doi.org/10.1016/0169-1317(94)00032-L

Bharadwaj S, Trivedi MK (2016) Impact of micro silica fume on engineering properties of expansive soil. International Journal of Science Technology & Engineering 2(12):435–440

Buhler R, and Cerato AB (2007) Stabilization of Oklahoma expansive soils using lime and class C fly ash. GeoDenver: New Peaks in Geotechnics. GSP 162: Problematic Soils and Rocks and In Situ Characterization. Denver, CO, Feb. 18–21, 2007. CD Proceedings

Chen FH (1988) Foundation on expansive soils. Elsevier, Amsterdam, the Netherlands

Djellali A, Houam A, Saghafi B (2017) Indirect estimation of swelling pressure of clayey subgrade under pavement structures. Arab J Sci Eng 42(9):3991–3999. https://doi.org/10.1007/s13369-017-2546-7

Dua Y, Lib S, Hayashic S (1999) Swell–shrinkage properties and soil improvement of compacted expansive soil, Ning-Liang highway, China. Eng Geol 53:351–358. https://doi.org/10.1016/S0013-7952(98)00086-6

Eades JL, Grim RE (1966) A quick test to determine lime requirements for lime stabilization. Highw Res Rec 139:61–72

El-Aziz A, Abo-Hashema M, and El-Shourbagy M (2004) The effect of lime silica fume stabilizer on engineering properties of clayey subgrade. Paper presented at the Engineering Conference of Mansoura University Faculty, Sharm: 96–104

Fattah MY, Al-Saidi AA, Jaber MM (2015a) Improvement of bearing capacity of footing on soft clay grouted with lime–silica fume mix. Geomech Eng 8(1):113–132. https://doi.org/10.12989/gae.2015.8.1.000

Fattah MY, Al-Saidi AA, Jaber MM (2015b) Characteristics of clays stabilized with lime–silica fume mix. Ital J Geosci 134(1):104–113. https://doi.org/10.3301/IJG.2014.36

Goodarzi AR, Goodarzi SH, Akbari HR (2015) Assessing geo-mechanical and micro-structural performance of modified expansive clayey soil by silica fume as industrial waste. Transactions of Civil Engineering 39(C2):333–350

Goodarzi A, Salimi M (2015) Stabilization treatment of a dispersive clayey soil using granulated blast furnace slag and basic oxygen furnace slag. Appl Clay Sci 108:61–69. https://doi.org/10.1016/j.clay.2015.02.024

Goodarzi R, Akbari HR, Salimi M (2016) Enhanced stabilization of highly expansive clays by mixing cement and silica fume. Appl Clay Sci 132-133:675–684. https://doi.org/10.1016/j.clay.2016.08.023

Harichane K, Ghrici M, Missoum H (2010) Effect of the combination of lime and natural pozzolana on the durability of clayey soils. European J. Geotech. Eng. 15:1194–1210

Harichane K, Ghrici M, Kenai S (2018) Stabilization of Algerian clayey soils with natural pozzolana and lime. Periodica Polytechnica Civil Engineering 62(1):1–10. https://doi.org/10.3311/PPci.9229

Hassanlourad M, Rokni MN, Hassanlo M, Badrlou A (2017) Dispersive clay stabilised by alum and lime. International Journal of GEOMATE 12(29):156–162. https://doi.org/10.21660/2017.29.93287

Huang R, Wu L (2007) Stability analysis of unsaturated expansive soil slope. Earth Science Frontiers 14(6):129–133. https://doi.org/10.1016/S1872-5791(08)60007-X

Indraratna B, Nutalaya P, Kuganenthira N (1991) Stabilization of a dispersive soil by blending with fly ash. Q J Eng Geol Hydrogeol 24(3):275–290. https://doi.org/10.1144/GSL.QJEG.1991.024.03.03

Kalkan E (2011) Impact of wetting–drying cycles on swelling behavior of clayey soils modified by silica fume. Appl Clay Sci 52(4):345–352. https://doi.org/10.1016/j.clay.2011.03.014

Knodel PC (1991) Characteristics and problems of dispersive clay soils. United States Department of the Interior Bureau of Reclamation, Materials Engineering Branch, Denver, USA, R91-09, p.17

Lambe TW (1960) The character and identification of expansive soils. Soil PVC Meter, Federal Housing Administration, Technical Studies Program, FHA 701

Latifi N, Meehan C, Majid MZA, Horpibulsuk S (2016) Strengthening montmorillonitic and kaolinitic clays using a calcium-based non-traditional additive: a micro-level study. Appl Clay Sci 132-133:182–193. https://doi.org/10.1016/j.clay.2016.06.004

Moravej S, Habibagahi G, Nikooee E, Niazi A (2018) Stabilization of dispersive soils by means of biological calcite precipitation. Geoderma 315:130–137. https://doi.org/10.1016/j.geoderma.2017.11.037

Murty VR, Praveen GV (2008) Use of chemically stabilized soil as cushion material below light weight structures founded on expansive soils. J Mater Civ Eng 20(5):392–400. https://doi.org/10.1061/(ASCE)0899-1561(2008)20:5(392)

NRC (1983) Safety of existing dams, evaluation and improvement. National Research Council, National Academy Press

Nelson JD, and Miller JD (1992) Expansive soils—problems and practice in foundation and pavement engineering. J. Wiley and Sons, New York

Ouhadi VR, Goodarzi AR (2006) Assessment of the stability of a dispersive soil treated by alum. Eng Geol 85:91–101. https://doi.org/10.1016/j.enggeo.2005.09.042

Papworth HF (1997) Production of silica fume. M.I.E. (Australia) Civil Engineering

Penner D, Lagaly G (2001) Influence of anions on the rheological properties of clay mineral dispersions. Appl Clay Sci 19:131–142. https://doi.org/10.1016/S0169-1317(01)00052-7

Phanikumar BR (2009) Effect of lime and fly ash on swell, consolidation and shear strength characteristics of expansive clays: a comparative study. Geomech Geoeng 4(2):175–181. https://doi.org/10.1080/17486020902856983

Qi S, Vanapalli SK (2015) Hydro-mechanical coupling effect on surficial layer stability of unsaturated expansive soil slopes. Comput Geotech 70:68–82. https://doi.org/10.1016/j.compgeo.2015.07.006

Savas H (2016) Consolidation and swell characteristics of dispersive soils stabilized with lime and natural zeolite. Sci Eng Compos Mater 23(6):589–598. https://doi.org/10.1515/secm-2014-0202

Sherard JL, Dunnigan LP, Decker RS (1976) Identification and nature of dispersive soils. J Geotech Eng Div 102(4):287–301

Shi B, Jiang H, Liu Z, Fang Y (2002) Engineering geological characteristics of expansive soils in China. Eng Geol 67:63–71. https://doi.org/10.1016/S0013-7952(02)00145-X

Turkoz M, Tosun H (2011) A GIS model for preliminary hazard assessment of swelling clays, a case study in Harran plain (SE Turkey). J Environ Earth Sciences 63:1343–1353. https://doi.org/10.1007/s12665-010-0805-y

Turkoz M, Vural P (2013) The effects of cement and natural zeolite additives on problematic clay soils. Sci Eng Compos Mater 20(4):395–405. https://doi.org/10.1515/secm-2012-0104

Turkoz M, Savas H, Acaz A, Tosun H (2014) The effect of magnesium chloride solution on the engineering properties of clay soil with expansive and dispersive characteristics. Appl Clay Sci 101:1–9. https://doi.org/10.1016/j.clay.2014.08.007

Umesha TS, Dinesh SV, Sivapullaiah PV (2009) Control of dispersivity of soil using lime and cement. International Journal of Geology 1(3):8–16

USBR 5400 (1989) Determining Dispersibility of Clayey Soils by the Crumb Test Method, Earth Manual II, United States Department of the Interior Bureau of Reclamation: 414–418

USBR 5410 (1989) Determining Dispersibility of Clayey Soils by the Pinhole Test Method. Earth Manual II, United States Department of the Interior Bureau of Reclamation: 425–437

Vakili AH, Selamat MR, Moayedi H (2013) Effects of using pozzolan and Portland cement in the treatment of dispersive clay. Hindawi Publishing Corporation The Scientific World Journal, 10 pages, https://doi.org/10.1155/2013/547615

Yilmaz I, Civelekoglu B (2009) Gypsum: an additive for stabilization of swelling clay soils. Appl Clay Sci 44:166–172. https://doi.org/10.1016/j.clay.2009.01.020

Yong and Warkentin BP (1996) Introduction to soil behavior. In: Chapter, vol 7. Macmillan, New York, pp 151–175

Zhang Z, Zhang B, Yan P (2016) Comparative study of effect of raw and densified silica fume in the paste, mortar and concrete. Constr Build Mater 105:82–93. https://doi.org/10.1016/j.conbuildmat.2015.12.045

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Türköz, M., Savaş, H. & Tasci, G. The effect of silica fume and lime on geotechnical properties of a clay soil showing both swelling and dispersive features. Arab J Geosci 11, 735 (2018). https://doi.org/10.1007/s12517-018-4045-x

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s12517-018-4045-x