Abstract

Lime stabilization is an effective way of stabilizing expansive clays, which cause significant environmental problems both as earth and foundation materials. There are considerable environmental benefits in using the in situ lime-stabilized expansive soils in the construction of road pavements, fill or foundations instead of importing valuable granular materials. However, due to high plastic nature of these clays, achieving appropriate pulverization in field applications is a difficult task. This paper presents the results of a laboratory investigation to determine the effects of soil pulverization quality on lime stabilization of a local expansive clay. Effect of mellowing the soil–lime mixtures for 24 h was also studied to find out whether this would compensate for poor pulverization. The clay studied had swelling pressures varying between 300 and 500 kN/m2 and free swell potential as high as 19%. In this study, 3, 6 and 9% lime by dry weight were used for lime-stabilized samples. Unconfined compression strength, failure strain and Secant Elasticity Modulus values were measured through unconfined compression strength testing. The results of the study showed that lime stabilization improved plasticity, workability, compressive strength, elastic moduli and swelling and compressibility behavior of the expansive clay. While mellowing did not have a definite effect on the measured strength and moduli values, soil pulverization quality considerably affected the unconfined compression strength and Secant Elasticity Modulus values. The higher the percentage passing No. 4 sieve, the higher the effectiveness of lime treatment. Based on the data obtained in this study, two original equations were derived to assign Secant Elasticity Modulus based on unconfined compression strength, for different soil pulverization qualities. Microfabric investigations conducted by Environmental Scanning Electron Microscope and Mercury Intrusion Porosimetry exposed the effect of lime stabilization on fabric, porosity and pore size distributions. The results of the study clearly demonstrated that if enough time and effort were not given to soil pulverization process in lime stabilization works in field applications, lower performance and therefore increased environmental problems should be expected.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Expansive soils are highly plastic clays and clay shales that often contain colloidal clay minerals such as montmorillonite. Changes in field environment either from natural conditions or from construction and usage effects may lead to swelling of these soils. Significant variations in climate, such as drought and heavy rains, changes in water table depth, removal of trees due to constructions or inadequate drainage of surface water from the structure are some examples for these environmental changes (UFC 2004). Types of structures that are most often damaged from expansive soils include highways, canals and reservoir linings, retaining walls, foundations and walls of one- or two-story buildings. In a significant number of cases, the structures become unstable. Lime stabilization has been extensively used to stabilize expansive soils, which have been reported to cause more damage to structures, particularly light buildings and pavements, than any other natural hazards including earthquakes and floods (Jones and Holtz 1973).

Soil stabilization techniques are used in most parts of the world for several reasons. In cases where the availability of good aggregates or appropriate soil is a problem, stabilization of available soils to improve the geotechnical properties is an attractive proposition. In industrialized, densely populated countries, such as Great Britain, the demand for aggregates has been reported to come into a sharp conflict with agricultural and environmental aspects, whereas in less developed countries and in remote areas, the availability of good aggregates of consistent quality at economic prices may be limited (Sherwood 1993). In this context, there are considerable environmental benefits in using the in situ lime-stabilized soils in the construction of road pavements, fill or foundation materials instead of importing valuable granular materials.

Based on numerous studies, it is well known that lime stabilization improves the properties of the expansive soils by reducing plasticity and volume change potential and increasing the workability and strength. However, due to high plastic nature of these expansive clays, one of the main problems is to achieve appropriate pulverization in field applications. Effects of soil pulverization in lime stabilization works have not gained enough consideration from researchers. Almost all of the studies considering lime stabilization have been performed on samples prepared with high-quality pulverized samples. Yet, this fine gradation does not accurately reflect the range of pulverization in field applications with expansive soils, where less time and effort may be spent for soil pulverization process resulting in coarser gradations. In many cases, the laboratory and field gradations differ to a great extent. It should be anticipated that different gradations may result in different geotechnical properties.

The purpose of the research (Garaisayev 2008) is to investigate the effects of lime and soil pulverization quality on properties of a locally available expansive soil. Consequences of mellowing the lime–soil mixtures for 24 h prior to compaction process was studied to investigate whether this time period could compensate for poor soil pulverization quality. Effects of soil pulverization quality on unconfined compression strength, failure strain and Secant Elasticity Modulus were determined through unconfined compression strength testing. Tests were also conducted in the consolidometer apparatus to measure the swelling potential and compressibility of natural and lime-treated samples. This study also included intensive microfabric investigations, which were conducted through Environmental Scanning Electron Microscope (ESEM) and pore size distribution analyses through Mercury Intrusion Porosimetry (MIP) testing.

Background

Lime stabilization is a widely used means of stabilizing unstable soils and transforming them into sound construction foundations. There are many studies in literature, which investigated the effect of lime on soil properties. These numerous studies (Eades and Grim 1966; Locat et al. 1990; Basma and Tuncer 1991; Sherwood 1993; Little 1995, 1999; Nalbantoglu and Tuncer 2001; Tonoz et al. 2003; Kavak and Akyarli 2007) showed that the improvement in soil–lime mixtures was dependent on many variables such as soil type, lime content, type of lime, curing time and method, water content, unit weight.

Research has shown that there are four mechanisms associated with the addition of lime to clayey materials (Little 1995). These mechanisms are: cation exchange, flocculation and aggregation, carbonation and pozzolanic reaction. Cation exchange, flocculation and aggregation are closely interrelated phenomena and occur in the short term and influence the mechanical, hydraulic and swelling properties of the soils. In contrast, the pozzolanic reaction is a slow process, which is responsible for strength development in soil–lime composites and for improved strength. During the pozzolanic process, calcium silicate hydrates and calcium aluminate hydrates are formed. In this context, the most obvious improvement in a soil through lime stabilization is strength gain. These mechanisms have been proven to have occurred by numerous researches. Most of these studies were conducted by electron microscopy analyses (Little 1991; Rajasekaran and Rao Narasimha 2002). Lime stabilization also causes important changes in porosity and pore size distribution of the samples; however, changes in pore size distribution have been studied to a lesser extent. One of the few studies was conducted by Wild et al. (1987), who stated that formation and growth of the gel led to a general refinement of the pore structure.

Soil pulverization quality is an important parameter in lime stabilization, however, it has not been studied to a greater extent. Degree of pulverization has been stated by Petry and Little (2002) to be an important constructional factor, which affected the quality of chemical stabilization. One of very few studies conducted on the effects of soil pulverization on lime stabilization was conducted by Petry and Wohlegemuth (1988). The authors stated that inclusion of large clay lumps in stabilized soils was considered detrimental to the stabilization process and to the corresponding strength and durabilities. They emphasized that this was a less important problem for granular soils and light clays, which could be easily pulverized. On the other hand, pulverization of heavy, highly plastic soils to meet the specifications was difficult and therefore the specifications could not be met. Their results showed that as the gradations became smaller, stabilizing effects increased and the materials gained strength and durability. The authors reported that poor pulverization resulted in less effective stabilization due to the presence of large clods or aggregations of highly active clay particles that were relatively left untreated. Little (1995) recommended that for heavy clays, preliminary mixing may be followed by 24–48 h (or more) of moist curing prior to final mixing. During this process, a more intimate mixing of the lime and the clay would occur, resulting in more complete stabilization.

Unconfined compression strength value is a most frequently measured property for lime-stabilized soils. Based on the unconfined compressive strength, the designer can assign other important parameters, such as modulus, tensile and flexural strength (Little 1999). In this context, unconfined compression strength values have been used as a primary control check in many stabilization studies; however, Secant Elasticity Modulus, which is defined as linear slope of the change in stress versus strain, is a less widely calculated parameter. Modulus properties are important in pavement design, where lime stabilization is widely used for improving the properties of the soils. Increased stiffness of the base provides a better support for the surface, reducing the potential to fatigue crack or deform (Little 1995). Modulus properties also affect the amount of deformations in lime-stabilized materials. Therefore, not only unconfined compression strength, but also Secant Elasticity Modulus at maximum stress was determined in this study.

Methodology

Materials

Soil

The soil used in this study is a locally available highly expansive soil in Istanbul, Turkey. The soil belonged to Gürpinar unit, which is a part of Danismen formation (Ozgul 2005). Danişmen formation has a lithology including green-gray claystone, sandstone, conglomerate, tuff and lignite. Gürpinar unit consists of green-gray fissured, overconsolidated clays occasionally interbedded with sand layers.

Initial tests of the study consisted of defining index properties of this soil. Specific gravity (ASTM D854-06 2006), Atterberg Limits (ASTM D4318-05 2005), grain size and hydrometer analyses (ASTM D421-85 2007; ASTM D422-63 2007) were conducted on natural soil. The results of the testing on natural soil presented in Table 1 revealed that the soil is inorganic high plastic clay (CH). The results of chemical analysis are given in Table 2. XRD analysis of the natural soil given in Fig. 1, exposed that the clay mineral was montmorillonite with the chemical formula; Na0.3(AlMg)2Si4O10OH2!6H2O.

Soluble sulfate content is also an important parameter for lime stabilization of clays since it is deleterious in the long term. The analysis conducted in this context revealed that soluble sulfate content (SO4) was 0.17%, which was less than the critical value of 0.3%. Soluble sulfate analysis was conducted according to TS EN-1744-1(2000).

Lime

Commercially available hydrated lime was used in the experiments. Properties of the lime are given in Table 3. In this study, 3, 6 and 9% lime were used for the preparation of lime-stabilized samples.

Experiments

Definition of soil pulverization qualities and mellowing conditions

In order to simulate the wide range of pulverization qualities that could be obtained in field applications, pulverization process was carried out in three different quality levels after the samples were air dried. These levels were chosen as High, Average and Poor. To standardize the soil pulverization quality levels, time spent for the pulverization process was defined for each quality level as presented in Table 4. Soil gradation curves were achieved after pulverization, prior to sample preparation process so that consistency could be checked (Fig. 2). In high-quality pulverization, all the material passed through No. 4 sieve (4.75 mm), whereas in poor quality pulverization only 40% passed this sieve. Photographs of soil samples pulverized in different quality levels are given in Fig. 3.

Changes in pH values, Atterberg Limits, grain size distributions and compaction characteristics of lime-stabilized samples were investigated using high-quality pulverized soils, since these tests are always conducted in this manner in laboratory scales.

Effects of mellowing were investigated using two different groups of samples. After the soil was pulverized to the required degree, it was mixed with lime in dry form. All the samples were prepared at optimum water contents so necessary amount of water was added to the soil–lime mixture and mixed thoroughly. The mixture was then wrapped with nylon and left for 1 h for “Not Mellowed, NM” samples and for 24 h for “Mellowed, M” samples. After this time period, compaction was carried out.

Eades and Grim pH test

It has been shown by Eades and Grim (1966) that, a pH value of 12.4 is needed so that silica in the clay mineral can dissolve in order to react with calcium ions released from lime. If the amount of lime used is below the percentage needed for cementation, the soil will merely be modified, which means that the plastic behavior will be altered, but that substantial strength development will not take place. In this study, Eades and Grim pH testing was carried out to see how the selected lime contents (3, 6 and 9%) changed the pH value. Five different lime percents (2, 3, 6, 8 and 9%) by dry weight of soil contents were used.

Atterberg Limit and hydrometer tests

Atterberg Limit testing was conducted on lime stabilized soils after 1 h following mixing and after 28 days of curing at 22°C in the curing tank. Hydrometer testing was carried out to determine the effect of lime stabilization on particle size distribution. The experiments were conducted on lime-stabilized soils, which were cured for 3 months and effect of extended curing on particle size was measured.

Compaction tests and preparation of samples

Compaction tests were carried out to determine the effect of lime on optimum moisture content and maximum dry unit weight of natural and lime-stabilized soils. Standard Proctor Compaction energy was used in all compaction tests as this is an expected energy level to be used in a wide range of field applications.

Samples for unconfined compression strength and swelling potential testing were prepared with soils with different levels of soil pulverization qualities. Appropriate amount of lime was added in dry form and molding water contents were selected as optimum water contents for the lime content used. The soil–lime–water mixtures were compacted in compaction molds using Standard Proctor Compaction energy. Samples were then extruded from the compaction mold using appropriate instruments.

Testing of swelling and compressibility behavior

Although there are different definitions for measuring swelling potential, the technique developed by Seed et al. (1962) was used in this study to define swelling potential of the samples. Seed et al. (1962) defined swelling potential as the percentage of swell of a laterally confined specimen after soaking in water under a confining pressure of 6.9 kN/m2.

Tests were conducted on both pure samples and 3, 6 and 9% lime-stabilized samples cured for 7 and 28 days. Swelling and compressibility behavior were measured in consolidation apparatus on 5-cm diameter and 2-cm high samples. After the samples were placed in the consolidometer, 6.9 kN/m2 of surcharge pressure was applied and the samples were then submerged in water and allowed to expand. After equilibrium was achieved in dial readings, consolidation tests with the load increment ratio equal to unity were conducted on the specimens. Swelling pressures were recorded as the pressures at which the initial dial readings were reached. Most of the samples were loaded up to 400 or 800 kN/m2. 6% lime added samples which were loaded up to 3,200 kN/m2, provided an interesting insight into the yield pressures of lime-stabilized soils, where yield pressures were defined as the apparent preconsolidation pressures.

Unconfined compression strength testing

Unconfined compression strength tests were conducted on cylindrical samples which were 3.5 cm in diameter and 7–9 cm in length. Lime stabilized samples were tested after 7 and 28 days of curing at 22°C in the curing tank, respectively. Tests were conducted following ASTM D2166-06 (2006).

ESEM and MIP analyses

ESEM analyses were conducted under low vacuum and water vapor pressure, so that the samples need not to be sputtered with gold or carbon. The possibility of the investigation of humid materials without pre-drying is the most important advantage of the ESEM analyses. Energy Dispersive X-ray analysis (EDX) was also used during ESEM testing. This analysis was used for the quantitative measurement of the chemical composition of small-surface regions.

The porosity value and distribution of the voids is an important property of the soil fabric and porosity (n t) is defined as the ratio of void volume (V v) to total volume (V t) in a sample as given in Eq. 1;

In this study, porosities and volumetric pore size distributions were determined using MIP analyses. In spite of some limitations, pore size distribution determined by the mercury intrusion method can provide useful information about factors influencing fabric and fabric–property interrelationships (Mitchell and Soga 2005).

Results

Eades and Grim pH test results

Addition of 2 and 3% lime increased the pH value to 11.5 and 12.0, respectively, which were less than the critical value of 12.4 needed for long-term stabilization. pH values exceeding the critical value of 12.4 were obtained for lime contents greater than 6%. Based on the results, it should be expected that 3% lime used in this study would not cause increases in strength values, only modification would be possible. For lime percents higher than 6%, cementation and strength gain should be expected.

Atterberg Limit test results

Results of the Atterberg Limit testing are given in Table 5. Significant changes in Atterberg Limits occurred with lime addition both immediately and after the curing period of 28 days. Liquid Limit values decreased and Plastic Limit values increased with the addition of lime. As a result of these changes, Plasticity Index (PI) decreased considerably. Even 3% lime was enough to cause considerable changes in plasticity behavior. Tests conducted after 28 days of curing exposed that changes in Atterberg Limits continued. As the pozzolanic reactions began to take effect, the plasticity changed still further. For example, for this curing period, 9% lime addition made the soil behave as a non-plastic material.

With lime addition, the soil class changed even after 1 h of curing; and addition of lime caused the soil to behave as a silty soil. This means that if the soil in the field were mixed with lime and left to cure for only 1 h, the workability of the soil would increase considerably and the problems of dealing with a highly expansive soil would be overcome even for 3% lime addition.

Hydrometer test results

Hydrometer testing conducted after 3 months of curing for lime-stabilized samples revealed that particle size changed considerably during this curing period. As seen in Fig. 4, soil gradation curves moved towards left, which indicated coarsening of the particles. Percent of clay sized particles (<0.002 mm) decreased with lime addition.

Compaction tests results

Figure 5 presents the results of the compaction tests conducted on natural and lime-stabilized soils after 1 h of mellowing period. Due to high plastic behavior associated with natural soil, compaction tests were carried out with great difficulty on natural soil. Especially, on dry side, it was nearly impossible to obtain a smooth compaction curve, and the results scattered to a great extent. This was an indication of the difficulties that should be expected with this expansive soil in natural form in field applications.

Addition of even 3% lime by dry weight increased the workability of the natural soil, so compaction could be performed effectively. This increased efficiency resulted in higher maximum dry unit weights for this lime content. Optimum water content increased with respect to that of natural soil, which was attributed to flocculation due to lime addition. Further increase of lime contents to 6 and 9% caused increased optimum water contents and decreased maximum dry unit weights.

Swelling and compressibility test results

Samples prepared with different soil pulverization qualities and mellowing conditions revealed swelling potential values ranging between 9 and 19%, which corresponded to very high swelling potential. Swell pressures for these samples ranged between 300 and 500 kN/m2. Effect of pulverization on swelling pressures and swelling potential values could not be determined, since there was no definite trend. This may be due to the fact that original fabric was destroyed during swelling behavior; therefore, effects of soil pulverization quality were offset.

Tests conducted on lime-treated samples showed that all lime percents including 3% lime, eliminated swell potential and swell pressures. This was valid even for 7 days of curing. The results revealed that lime stabilization was able to improve swelling behavior of expansive soils for all soil pulverization qualities. It seems that lime addition eliminated the water affinity of clayey particles regardless of soil pulverization quality. Lime addition also changed the compressibility behavior and decreased compressibility considerably. Most of the lime-stabilized samples were loaded up to 800 kN/m2, and for all lime percents compressibility up to this pressure were about one-tenth of natural samples. Soil pulverization quality did not modify the compressibility behavior in a definite way.

Some of the 6% lime-treated samples were loaded up to 3,200 kN/m2 in order to measure the yield pressure values, where the slope of the curve increased considerably. Yield pressures were in the range of 70–80 kN/m2 for natural samples. 6% lime-treated samples revealed a yield pressure of about 1,200 kN/m2 for 7 days curing and 1,600 kN/m2 for 28 days curing (Fig. 6). These are very high pressure values when compared with natural soils and are attributed to cementation that occurred. Due to limited number of samples loaded beyond yield pressures, effects of pulverization on yield pressures could not be measured. The graphs also yielded interesting results on effects of curing on compressibility behavior. For the 6% lime-treated sample cured for 7 days, compressibility up to yield pressure was less than those of pure samples, associated with cementation. However, beyond the yield pressure, compressibility increased and became nearly equal to that of pure samples. For 28 days curing, this was not the case and compressibility values were significantly lower than natural samples. It seems that, extended curing helped in obtaining a more stable fabric, which can be destroyed only to some extent even under very high pressures.

Unconfined compression strength test results

Unconfined compression strength and failure strain values are tabulated in Tables 6 and 7, respectively.

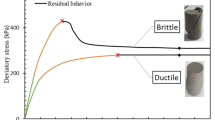

Stress–strain behavior of natural and lime stabilized samples

Stress–strain graphs of the tested specimens for natural and lime-stabilized samples cured for 7 and 28 days are presented in Fig. 7. It is evident from the graphs that lime addition changed the stress–strain behavior of the soil for all lime contents. Ductile failure behavior of natural samples was replaced by brittle behavior for lime-stabilized samples. As seen in Table 7, samples prepared with natural soil failed at considerably high strain values (about 4–5%) when compared to their treated counterparts (about 1–2%). The difference was about five-fold for most of the samples.

Effects of mellowing on unconfined compression strength

The results did not indicate an improvement in strength values due to mellowing. This was valid for all the lime contents used, as well as natural samples. Therefore, for the soil tested, and for 24 h of mellowing, no beneficial effects of mellowing were observed. It was anticipated that this might be due to very high consistency limits associated with the clay studied (LL of 118%). These results indicated that longer mellowing times (more than 24 h) for such heavy clays might be needed to break down the clods and reduce the material to finer gradations before compaction.

Effects of lime and pulverization quality on unconfined compression strength and failure strain values

Unconfined compression strength (q u) for specimens prepared with natural soil ranged between 307 and 432 kN/m2. Pulverization quality did not have a definite effect on unconfined compression strength values for natural samples.

The 3% lime addition did not cause any considerable changes on unconfined compression strength values for both 7 and 28 days of curing. This finding was consistent with the results of the Eades and Grim pH test conducted in this study. It should be noted that, this lime content was enough to change the plasticity of the natural soil considerably as seen in Table 5. Since strength increase with lime was not considerable, effect of soil pulverization quality was not investigated for this lime content. The interesting point about 3% lime addition was how the failure strains decreased considerably (Table 7) despite insignificant changes in strength values. This was associated with lowered plasticity, which had also affected swelling behavior considerably.

The addition of 6% lime increased unconfined compression strength values considerably for both 7 and 28 days of curing. For this lime content, unconfined compression strength of the samples ranged between 384 and 896 kN/m2 for 28 days of curing. The highest value (896 kN/m2) was obtained for the sample prepared with high-quality pulverized soil, whereas the lowest value (384) was obtained from poorly pulverized soil. This was a significant difference of more than two-fold. It was worth noting that with the same soil and lime percent, poor pulverization might result in half strength values. The results were similar for even 7 days of curing. The results were also interesting with 9% lime addition. With this lime content, strength values increased significantly for all pulverization qualities, when compared with the natural soil. The highest strength value belonged to the sample prepared with high-quality pulverized soil and this value was as high as 1,529 kN/m2, whereas the lowest value of 850 kN/m2 belonged to the sample prepared with poorly pulverized soil.

Figures 8 and 9 present the variations in strength values for different pulverization qualities with 6% and 9 lime additions, respectively. The graphs on the right side are averaged values for different pulverization qualities using the results obtained from mellowed (M) and not mellowed (NM) samples. As evident from the graphs, there was a decreasing trend in strength values for both lime contents, as pulverization quality moved from “high” to “poor”. It should still be noted that, for 9% lime, the results obtained with average and poor pulverization were closer when compared to the results obtained for 6% lime. It was anticipated that if higher lime percents were used, strength values for average and poor pulverizations might converge, however, they would not be able to reach the very high strength values (1,529 kN/m2) that could be obtained only with high-quality soil pulverization.

Figure 10 was prepared to demonstrate the effect of lime, curing and soil pulverization in a single graph. Average strength values of mellowed and non-mellowed samples were used for each pulverization quality. The trends in the graphs exposed clearly that strength values increased with increasing lime contents for all pulverization qualities. However, the rate of increase in strength values; in other words effectiveness of lime treatment increased with increasing soil pulverization quality; highest for high-quality and lowest for poor-quality pulverization. Average pulverization resulted in strengths in between.

Figure 11 presents failure strain values for 6 and 9% lime-stabilized samples cured for 28 days. Pulverization effect was also substantial for strain values. Poor-quality soil pulverization revealed higher failure strain values than their better pulverized counterparts. This is an indication of less effective stabilization obtained with poor pulverization.

Effects of lime and soil pulverization quality on Secant Elasticity Modulus values

Secant Elasticity Modulus for maximum stress values are given in Table 8 and displayed in Fig. 12 for 6 and 9% lime contents. For all lime contents, modulus values increased considerably. For both natural and lime-treated soils, higher modulus values were always associated with better pulverized soils and poor quality pulverization in all cases resulted in lowest modulus values.

Figure 13 revealed that modulus values could be approximated from unconfined compression values; however, they depended strongly on soil pulverization quality. Poor soil pulverization resulted in significantly lower modulus values than better pulverized counterparts for the same unconfined compression strength value. Based on the results, two original formulas were derived so that Secant Modulus at maximum stress values can be assigned from unconfined compression strength values. Equation 2 is valid for high- and average-quality soil pulverizations and Eq. 3 for poor-quality soil pulverizations.

Based on these equations, it seems obligatory to take effect of soil pulverization quality into consideration in pavement design, when using unconfined compression strength value to assign other important structural properties, such as modulus. The authors think that conversions to flexural strength and tensile strength or resilient modulus also warrant research in this context, because in the current state of the art soil pulverization quality is not included in the equations as a parameter and unconfined compression value is the only parameter considered (Thompson 1966; Little 1995).

Microfabric investigations

Mercury intrusion porosimetry analyses

Mercury intrusion porosimetry analyses were conducted for 15 samples. The results were evaluated in terms of total porosities and pore size distributions. Pore size distribution analyses gave evidences of differences in pore sizes for different lime percentages, pulverization qualities and curing times as given through Figs. 14 and 15. It should be emphasized that pore refinement is a dynamic process, and curing for longer periods is expected to cause further changes in these values.

Porosimetry results did not reveal any consistent trends between porosity values and soil pulverization qualities. Total porosity of the samples prepared with natural soil ranged between 15 and 20%. On the other hand, lime-stabilized samples had higher porosities, ranging between 24 and 37%. In other words, about one-third of the total volume consisted of voids for lime-stabilized samples. The increased porosities were attributed to flocculation of soil particles, which also caused coarsening of the pore structure and grain sizes as seen in Fig. 4.

Porosimetry analyses gave important insights into the pore refinement process of lime-stabilized soils. As lime percent increased from 0 to 3%, pore size distribution graphs moved upwards as an indication of increased pore volumes as can be seen in Fig. 14a. Increase in pore sizes greater than 100 nm was noticeable. This was attributed to formation of a more porous structure and insufficient amount of cementation with this lime content.

Figure 14b compares the results for natural and 9% lime added samples cured for 7 and 28 days. For 28 days cured sample, lime addition increased pore volumes for a wide range of pore diameters when compared with natural soil. However, for pore diameters greater than about 20,000 nm, it revealed lower pore volumes than natural sample, which indicated that pozzolanic material was formed to precipitate in these large pores. On the other hand, 7 days curing resulted in higher pore volumes than 28 days curing for a wide range of pore diameters. Probably, 7 days of curing was not sufficient for the cementation to occur and close these pores.

The analyses also indicated that soil pulverization quality affected pore size distribution of the samples as presented in Fig. 15. The results belonged to 6% lime-stabilized samples, prepared with high and poor soil pulverization qualities, respectively. For larger pore diameters (>10,000 nm), samples prepared with poor pulverized soil revealed significantly higher pore volumes than their better pulverized counterparts. These results were important evidences of lower strengths and modulus values associated with poor soil pulverization.

Environmental scanning electron microscope analyses

ESEM analyses revealed significant differences in soil fabric and proved flocculation, aggregation and formation of pozzolanic crystals and gels due to lime addition. This supported the findings of mercury intrusion porosimetry tests. Some typical examples are given below.

Figure 16 shows the ESEM micrographs of natural and 3% lime-treated samples taken at the same magnification. The natural sample displayed typical morphology of the montmorillonite clay, which consisted thin wavy sheets. On the other hand, 3% lime-treated sample had a more porous structure when compared with the natural sample. The flocculation and agglomeration events were evident; the sizes of the soil flocs were as big as 20 μm. These micrographs also provided visual evidences of increased particle sizes and pore radii, which were also displayed by hydrometer and porosimetry tests (see Figs. 4, 14a).

During ESEM testing, pozzolanic crystals developed due to lime addition were also observed and for some samples chemical analyses were conducted via EDX method. Lime-treated samples revealed considerable pozzolanic developments in the form of hydration crystals and hydration coatings. Micrograph and EDX analysis of a 9% lime-treated sample prepared with high-pulverized soil are given in Fig. 17. It is anticipated that formation of new cementitous materials which were visualized as spiny hydration crystals led to development of network of reinforcement and eventually to increases in strength and stiffness values. This micrograph also revealed that the voids were being filled with these new crystals. EDX chemical analyses conducted on the same sample displayed evidences of calcium silicate hydrate (C-S-H) and calcium aluminate hydrate (C-A-H) formations.

Another interesting EDX analysis was conducted on a 9% lime-treated sample prepared with poorly pulverized soil. Micrograph and EDX analysis are given in Fig. 18 and EDX values are given in Table 9. EDX analysis showed the presence of carbonation on this sample. This insoluble carbonate is detrimental to the stabilization because it depletes the system of the free calcium needed in the stabilization process. It seems possible that unreacted lime particles in poorly pulverized soils may result in formation of carbonation in case it reacts with air.

Evaluations for effect of soil pulverization quality in lime stabilization

Based on the results obtained in this study, effects of pulverization on lime-stabilized soils were summarized below;

-

The lime–clay reaction is controlled by the surface area and dissolution of the clay material. Therefore, it is anticipated that large clay clods allied with poor pulverization result in lower surface areas and the clay material inside these clods cannot dissolve to the required degree. Therefore. lime cannot react with all the clay material present in the matrix. This concept may be defined as the “passivation of reactive clay material in soil clods due to poor quality pulverization”. Passivation of the reactive clay surfaces of clay minerals were also observed by Muller (2005), but it was through the overgrowth of the pozzolanic reaction products. Diffusion of lime into the inner parts of the clods may be expected in the long term; however, this will be a very slow process, because lime has to diffuse through the clods.

-

Poor soil pulverization may result increases in larger pore diameters (Fig. 15).

-

Some amount of lime may be trapped in the neighborhood of the large clods and therefore cannot disseminate properly within the soil matrix in poor pulverized soils. If these lime particles react with air, carbonation can occur, which inhibits further pozzolanic reactions (Fig. 18; Table 9).

Evaluation of the results from an environmental point of view

The results of this study revealed that lime stabilization improved the workability characteristics of the highly expansive soil used in the study. The expansive behavior was eliminated and compressibility was improved to a greater extent. Soil strength increased significantly with 6 and 9% lime additions. This means that environmental problems associated with this soil in native form were eliminated by lime addition. If used in foundations of structures, this would mean elimination of risks from swell, increased bearing capacity and decreased settlements. If used in pavement construction, increased geotechnical properties implied reduced pavement thickness requirements, reduced use of imported aggregates and future savings associated with delays in pavement rehabilitation and reductions in the frequency and amount of pavement maintenance.

However, the results of unconfined compression test conducted in this study highlighted the importance of soil pulverization quality so that the above-mentioned benefits could be realized at maximum level. The experiences obtained in this study showed that soil pulverization is a problem for expansive soils, which have high plasticity and tend to form hard clods. Based on the results of unconfined compression strength tests, it is clear that enough time and effort should be given to soil pulverization quality in field applications. The higher the percentage passing No. 4 sieve, the higher the effectiveness of lime treatment. In this context, soil pulverization quality can be as important as lime percent selected and it should not be overlooked in quality control studies in field applications.

These results are also important due to their implications in pavement design, where thickness of the layers is selected based on their stiffness properties. Lower modulus values associated with poor soil pulverization may result in weak subgrade support layers in field applications. This is an environmental problem, because it will eventually lead to excessive deformations and damages in pavements. Rehabilitation of these pavements is another problem in terms of economy and environment because valuable and limited resources have to be used once more.

Conclusions

The results are summarized below;

-

A highly expansive local clay in Istanbul was used in the tests. Lime stabilization improved workability, swelling, compressibility, strength and modulus properties.

-

Effects of mellowing for 24 h did not have a positive effect on any measured or calculated geotechnical property. It was anticipated that 24 h was not sufficient to break down the clods associated with poor pulverization. Longer mellowing periods might be needed, however, this subject should be investigated further.

-

Improvements in strength and modulus values depended strongly on soil pulverization quality. Benefits of lime stabilization could not be realized at maximum level, unless high-quality soil pulverization was provided.

-

Two original formulas were derived for assigning Secant Elasticity Modulus from unconfined compression strength values for different pulverization qualities. This brings important considerations for current conversion equations.

-

MIP tests and ESEM analyses provided valuable evidences of differences in pore sizes for different lime percentages, pulverization qualities and curing times.

-

It may be anticipated that longer curing periods may be necessary for specimens prepared with poorly pulverized soils. On the other hand, longer curing times may mean that traffic delays are associated with using the pavement and therefore significant environmental problems.

-

There is a need for further research on soil pulverization quality effect on durability and long-term performance of lime-stabilized soils. In this context, testing on samples cured for very long times as well as field testing are also recommended.

-

The results showed that there are considerable environmental benefits in using the in situ lime-stabilized expansive soils in construction of road pavements, fill or foundations instead of importing valuable granular materials. However, if enough time and effort is not given to soil pulverization process in lime stabilization works in field applications, lower performance and therefore increased environmental problems should be expected.

References

ASTM D2166-06 (2006) Standard test method for unconfined compressive strength of cohesive soil. ASTM International, West Conshohocken

ASTM D421-85 (2007) Standard test method for dry preparation of soil samples for particle size analysis and determination of soil constants. ASTM International, West Conshohocken

ASTM D422-63 (2007) Standard test method for particle size analysis of soils. ASTM International, West Conshohocken

ASTM D4318-05 (2005) Standard test method for liquid limit, plastic limit and plasticity index of soils. ASTM International, West Conshohocken

ASTM D854-06 (2006) Standard test method for specific gravity of soil solids by water pycnometer. ASTM International, West Conshohocken

Basma AA, Tuncer ER (1991) Effect of lime on volume change and compressibility of expansive clays. Transportation Research Record No. 1295, pp 52–61

Eades JL, Grim RE (1966) A quick test to determine lime requirements for lime stabilization. Highway Research. Record 139

Garaisayev S (2008) Chemical stabilization of expansive soils. M.Sc. thesis, Institute of Sciences, Istanbul University, 170 p (in Turkish)

Jones DR, Holtz WG (1973) Expansive soils—the hidden disaster. Civ Eng 43:49–51

Kavak A, Akyarli A (2007) A field application for lime stabilization. Environ Geol 51(6):987–997

Little DN (1991) X Ray Diffraction, energy dispersive spectra and scanning electron microscopic evaluation of stabilized Denver clay soils containing sulfates. Report to Chemical Lime Company, Fort Worth, Texas

Little DN (1995) Handbook for stabilization pavement subgrades and base courses with lime, prepared for APG lime company. Hunt Publishing Company, Kendal

Little DN (1999) Evaluation of structural properties of lime stabilized soils and aggregates, vol 1. Summary and findings. Prepared for National Lime Association

Locat J, Bérube MA, Choquette M (1990) Laboratory investigation on the lime stabilization of sensitive clays: shear strength development. Can Geotechnol J 27:294–304

Mitchell JK, Soga K (2005) Fundamentals of soil behavior, 3rd edn. Wiley, New York

Muller CJ (2005) Pozzolanic activity of natural clay minerals with respect to environmental geotechnics. Doctor of Technical Science, Swiss Federal Institute of Technology, Zurich

Nalbantoğlu Z, Tuncer ER (2001) Compressibility and hydraulic conductivity of a chemically treated expansive clay. Can Geotechnol J 38:154–160

Ozgul N et al (2005) General geology of Istanbul City, Istanbul Municipality (in Turkish)

Petry TM, Little DN (2002) Review of stabilization of clays and expansive soils in pavements and lightly loaded structures—History, practice and future. ASCE J Mater Eng 14(6):447–460

Petry TM, Wohlegemuth SK (1988) Effects of pulverization on the strength and durability of highly active clay soils stabilized with lime and Portland cement, Transportation Research Board 1190, 0-309-04758-7, pp 38–45

Rajasekaran GR, Rao Narasimha SN (2002) Permeability characteristics of lime treated marine clay. Ocean Eng 29:113–127

Seed HB, Woodward RJ, Lundgren R (1962) Prediction of swelling potential for compacted clays. J Soil Mech Found Div Am Soc Civ Eng 88(SM3)

Sherwood PT (1993) Soil stabilization with cement and lime, Transport Research Laboratory, State of the art review. HMSO

Thompson, MR (1966) Shear strength and elastic properties of lime soil mixtures. Transportation Research Record No. 139

Tonoz M, Gokceoglu C, Ulusay R (2003) A laboratory-scale experimental investigation on the performance of lime columns in expansive Ankara (Turkey) clay. Bull Eng Geol Environ 62(2):91–106

TS EN 1744-1 (2000) Tests for chemical properties of aggregates—Part 1: Chemical analysis, Institute of Turkish Standards

UFC Unified Facilities Criteria (2004) Foundations in expansive soils, US Army Corps of Engineers, UFC-3-220-07

Wild S, Arabi M, Rowlands GO (1987) Relation between pore size distribution, permeability, and cementitous gel formation in cured clay–lime systems. Mater Sci Technol 3:1005–1011

Acknowledgments

This study was supported by Research Fund of the Istanbul University, Project Number: 2128.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Bozbey, I., Garaisayev, S. Effects of soil pulverization quality on lime stabilization of an expansive clay. Environ Earth Sci 60, 1137–1151 (2010). https://doi.org/10.1007/s12665-009-0256-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12665-009-0256-5