Abstract

A simple, fast and reliable spectrophotometric method for the determination and microextraction of trace amounts of uranium using chromotrope 2R as a chelating agent and 1-butyl-3-methylimidazolium hexafluorophosphate ionic liquid (IL) was used as an extractant solvent. Influence variables such as pH, volume of ligand and IL were inspected by full factorial design. In the view of Pareto chart a contour plot was studied to examine the significant variables and their interactions. The detection limit and the preconcentration factor were found to be 0.87 and 50 μg L−1, respectively. The developed method was successfully applied to ore samples.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Uranium and its compounds are known as one the dangerous radioactive element [1] and it can be harmful because of its toxicity. It occurs naturally in soil, rock and water at low level and is commercially extracted from uranium-bearing minerals such as uraninite [2]. The quantitative determination of uranium in igneous rocks is of great interest and important for geological investigation [3]. However the small amount of radioactive element can cause acute toxicological effects in humans and animals [4, 5].

Several methods have been developed for the determination of uranium such as instrumental neutron activation analysis (INAA) [6], inductively coupled plasma mass spectrometry (ICP-MS) [7, 8], capillary zone electrophoresis (CZE) [9], alpha spectrometry [10, 11] and spectrophotometry [12]. Although all these techniques have also some drawbacks such as high level of sensitivity, lack of selectivity, presence of complex matrix, poor precision and accuracy, because it requires well-controlled experimental conditions, and presence of complex matrix.

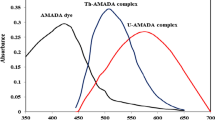

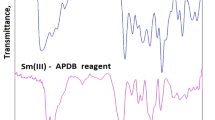

Spectrophotometric methods are widely used for the determination of trace U, due to its simplicity, rapidity, inexpensive and reliable accuracy [13]. A number of chromogenic reagents were used such as chromazurol [14], 4-(2-pyridylazo) resorcinol [15], 8-quinolinol [16], Arsenazo III [17], and Chromotrope 2R [18].

Multivariate technique has been widely used in analytical chemistry for heavy metal determination. In the multivariate technique a full factorial design (FFD) is well established in preconcentration and separation techniques [19–21].

In this study, an ionic liquid (IL) based dispersive liquid–liquid microextraction (IL-DLLME) procedure has been developed for the determination of uranium in ore sample using chromotrope 2R as a chelating agent. The optimization of procedure was carried out through a multivariate approach. The three factors [pH (P), ligand volume (LV) and IL volume] were selected as effective parameters for the extraction of U with two levels for each one. A FFD was applied to identify the effects of main variables on the % recovery of U and finding out possible interactions between the main factors.

Materials and methods

Apparatus

A Hitachi Model 150–20 UV–Vis double beam spectrophotometer carrying a 10 mm optical path cell was used for the measurement of U. A model Nel pH 900 (Ankara-Turkey) with glass electrodes was used for the pH adjustment.

Chemicals and reagents

Chemicals and reagents were used of high purity analytical grades (Merck, Darmstadt, Germany). Nitric acid (HNO3-65 %), perchloric acid (HClO4-60 %), hydrogen flouride (HF-38–40 %) and 1-butyl-3-methylimidazolium hexafluorophosphate [C4MIM] [PF6] IL were used and obtained from Merck, (Darmstadt, Germany). A stock standard solution (1,000 µg mL−1) of U was also purchased (Merck, Darmstadt, Germany). While working standards of corresponding metal ion was prepared from the dilution of stock standard solution with distilled water. A solution of chromotrope 2R (Fluka, Buchs, Switzerland) was prepared with the addition of an appropriate amount of 0.1 g of the reagent in 100 mL distilled water.

Ionic liquid based dispersive liquid–liquid microextraction procedure

For the preconcentration of U(VI), 20 mL of aliquots containing 100 μg L−1 U(VI) were taken into 50 mL conical bottom vials. The pH of the solution was adjusted at desired pH value of 8.0 by the addition of HCl (0.01 mol L−1) and NaOH (1.0 mol L−1). After adjusting of pH, 100–500 µL of LV, and 50–200 µL of IL was added into mixtures. The mixture solutions were diluted up to 20 mL with distilled water and were kept at room temperature for the formation of U chelates. Afterward, the solution was centrifuged for 3 min at 3,000 rpm. After centrifugation, the aqueous layer was decanted and the sample solution containing uranium(VI) was diluted with 400 µL of ethanol and finally was determined by UV–Vis spectrophotometer.

Analysis of ore samples

The ore samples were collected from Kayseri, Turkey. A 0.2 g of triplicate ore samples were weighed in 100 mL of beaker and added 10 mL of HNO3 followed by heating on hot plate for 2 h at 90 °C. After that 5 mL of HClO4 was added to this mixture and then left the sample solution for overnight. Thereafter, HNO3 (10 mL) and HClO4 (5 mL) were added into the mixture and was heated overnight at 90 °C. After cooling, the resulting solutions were filtered through a 0.45 μm pore size membrane filter (Millipore Corporation, Bedford, MA, USA) into a 25 mL conical bottom flask and were diluted with distilled water. Afterwards, adjusted pH of digested ore samples to desired pH and then were subjected to developed procedure as described in “IL based dispersive liquid–liquid microextraction procedure” section and subsequent determination of uranium(VI) by UV–Vis spectrophotometer.

Statistical software

A FFD was used for experimental design analysis and to evaluate the results by using of computer program Minitab 13.2 (Minitab Inc., State College, PA, USA).

Experimental design

For the optimization of proposed procedure, a two level factorial design was carried out [22, 23]. A FFD was used for sequential experimentation and gives the practical information about the imperative factors. Thus the three most significant factors such as P, IL and LV were evaluated by FFD in which eight experiments were performed to optimize above discussed three variables versus % recovery of U. For further assessment of optimal conditions of variables and their significant interactions were studied by Pareto chart.

Results and discussion

Optimization strategy by full factorial design

In preliminary experiments, FFD was performed involving 8 experimental runs. The variables at low (−) and high (+) levels are listed in Table 1. This design was used for the screening of the main variables such as P, IL and LV which influencing on the analytical signal of U and estimation of the corresponding response surface by a proposed procedure based on the advantages of standardized testing [24]. From the results of the FFD (Table 2), it was clearly seen that the high P(+), IL and high amount of ligand provided significantly high extraction efficiency for U. In the present study, pH plays a very important role in metal chelate formation and the consequent extraction efficiency of analytes [25–33]. The results showed that the analytical signal of uranium(VI) increased with the increasing of pH and whereas remaining factors were at low (−) level. At high pH, % recovery was achieved 85.6 % and whereas other factors LV and IL were at low level (−) (experiment 2).

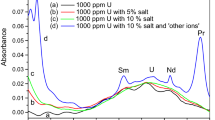

The selected three significant variables P, LV and IL (experiment 8) showed optimum % recovery of U at high level of each factors, 8.0, 500 and 200 µL, respectively. Therefore, U(VI) CT-2R complex will become stronger at high pH 8.0. However, in the present study FFD with eight experiments were performed to explore the significant variables and their interactions versus % recovery of U as summarized in Table 2 and their interactions can be visualized by Pareto chart using standardized effect at 0.05 P values (Fig. 1). According to the Pareto chart, the effect of P and IL were shown to be most significant at P values of 0.05. Since there were eight experiments were performed at two levels for optimization of recovery and estimation of the corresponding response surface. Figures 2 and 3 represented the contour diagram of the estimated response surface. The figure clearly indicates the significance of P and IL at high levels and its interaction.

Interferences study

Due to the “Matrix Effects” are an important problem in the instrumental detection of analytes at trace levels [31, 34–39], the effect of interference ions on analytical response of U was studied under optimized conditions. The solution containing 100 µg L−1 and different concentrations of alkali, alkaline earth metals and some metal ions were prepared separately and then was applied the proposed procedure as illustrated in “IL based dispersive liquid–liquid microextraction procedure” section. The results showed that the proposed method was fairly free from foreign interfering species as shown in Table 3.

Analytical figure of merit

Under the optimized conditions, the analytical performance of the developed procedure was evaluated. The linear range was 0.5–10 μg mL−1 with the correlation coefficient (R) of 0.998. The preconcentration factor (PF) was 50 when sample volume 20 mL and final volume 400 μL. The limit of detection (LOD) was calculated as equivalent of three times of standard deviation of blank signals was 0.87 μg L−1. The limit of quantification (LOQ), ten times of the standard deviation of the blank signals was 2.90 μg L−1.

Validation of proposed methodology

In order to validation of IL-DLLME methodology, the accuracy of the proposed method was evaluated by standard addition recovery/test method to determine U in ore samples. The proposed procedure was applied on four replicates of ore samples as discussed in “IL based dispersive liquid–liquid microextraction procedure” section. Under the optimized experimental conditions, the spiking of ore samples was performed with a known amount of 2.0, 4.0 and 8.0 µg g−1, respectively. The results are listed in Table 4. A good agreement exists between the results of the proposed method and can be applied successfully to real samples.

Comparison of IL-DLLME with other analytical methodologies

A comparison of developed IL-DLLME procedure with the other reported analytical methodologies is summarized in Table 5 [40–49]. Our method has comparatively low detection limit.

Conclusion

A two-level FFD was used for the screening of the main variables which affect extraction efficiency of U(VI). Thus the effects of significant variables versus the % recovery of U were evaluated by FFD. Moreover, pareto chart was used to identify important variables and their interactions between the significant variables. The developed procedure was really more effective, rapid, and environmental friendly. This technique provides good repeatability and reproducibility with high LODs and PF and could be successfully applied for determination of U in ore samples without interfering ions.

References

Amin AS, Mohammed TY (2001) Simultaneous spectrophotometric determination of thorium and rare earth metals with pyrimidine azo dyes and cetylpyridinium chloride. Talanta 54:611–620

Shi Y, Chatt A (2014) Simultaneous determination of inorganic As(III), As(V), Sb(III), Sb(V), and Se(IV) species in natural waters by APDC/MIBK-NAA. J Radioanal Nucl Chem 299:867–877

Sen Gupta JG, Bertrand NB (1995) Direct ICP-MS determination of trace and ultratrace elements in geological materials after decomposition in a microwave oven I. Quantitation of Y, Th, U and the lanthanides. Talanta 42:1595–1607

US public health service (2000) Agency for toxic substances and disease registry. Chapman and Hall, New York

Al-Dayel OAF (2002) Uranium contents in wheat samples of Saudi Arabia. Asian J Chem 14:1307–1310

Abdul-Hadi A, Al-Qadhi W, El-Zeen E (2011) Determination of uranium, thorium and potassium contents of rock samples in Yemen. J Radioanal Nucl Chem 290:261–266

Aydin FA, Soylak M (2007) Solid phase extraction and preconcentration of uranium(VI) and thorium(IV) on Duolite XAD761 prior to their inductively coupled plasma mass spectrometric determination. Talanta 72:187–192

Joannon S, Telouk P, Pin C (1997) Determination of U and Th at ultra-trace levels by isotope dilution inductively coupled plasma mass spectrometry using a geyser-type ultrasonic nebulizer: application to geological samples. Spectrochim Acta Part B 52:1783–1789

Liu B, Liu L, Cheng J (1998) Separation and determination of thorium, uranium and mixed rare-earth elements as their UV/Vis absorbing complexes by capillary zone electrophoresis. Talanta 47:291–299

Rathore DPS (2008) Advances in technologies for the measurement of uranium in diverse matrices. Talanta 77:9–20

Benedik L, Vasile M, Spasova Y, Watjen U (2009) Sequential determination of 210 Po and uranium radioisotopes in drinking water by alpha-particle spectrometry. Appl Radiat Isot 67:770–775

Shah F, Soylak M, Kazi TG, Afridi HI (2013) Development of an extractive spectrophotometric method for uranium using MWCNTs as solid phase and arsenazo(III) as chromophore. J Radioanal Nucl Chem 296:1239–1245

Khan MH, Hasany SM, Khan MA, Ali A (1994) Spectrophotometric determination of microamounts of thorium with disodium salt of 2-(2-hydroxy-3,6-disulfo-1-naphthylazo)-benzenearsonic acid (thorin) as a chromogenic reagent. J Radioanal Nucl Chem 188:341–353

Leong CL, Florence TM, Farrar Y (1973) Spectrophotometric determination of uranium(VI) with chromazurol S and cetylpyridinium bromide. Anal Chem 45:201–203

Florence TM, Farrar YJ (1963) Spectrophotometric determination of uranium with 4-(2-pyridylazo) resorcinol. Anal Chem 35:1613–1616

Motojima K, Yoshida H, Izawa K (1960) Spectrophotometric determination of small amounts of uranium with 8-quinolinol. Anal Chem 32:1083–1085

Khan MH, Warwick P, Evans N (2006) Spectrophotometric determination of uranium with arsenazo-III in perchloric acid. Chemosphere 63:1165–1169

Gholivand MB, Omidi M, Khodadadian M (2012) Cloud point extraction and spectrophotometric determination of uranium (VI) in water samples after mixed micelle-mediated extraction using chromotrope 2R as complexing agent. Croat Chem Acta 85:289–295

Eisapour M, Keshtkar A, Moosavian MA, Rashidi A (2013) Bioleaching of uranium in batch stirred tank reactor: process optimization using Box–Behnken design. Ann Nucl Energy 54:245–250

Golshani T, Jorjani E, Chelgani S, Chehrehb, Shafaei SZ, Heidari NY (2013) Modeling and process optimization for microbial desulfurization of coal by using a two-level full factorial design. Int J Mining Sci Technol 23:261–265

Hashemi P, Bagheri S, Fathi MR (2005) Factorial design for optimization of experimental variables in preconcentration of copper by a chromotropic acid loaded Q-Sepharose adsorbent. Talanta 68:72–78

Massart DL, Vandeginte BGM, Buydens LMC, de jong S, Lewi PJ, Smeyers-Verbek J (2003) Handbook of chemometrics and qualimetrica Part A. Elsevier, Amstermdam

Lundstedt T, Seifert E, Abramo L, Thelin B, Nystrom A, Petersen J, Bergman R (1998) Experimental design and optimization. Chemometr Intell Lab 42:3–40

Santos JS, Teixeira LSG, Araujo RGO, Fernandes AP, Korn MGA, Ferreira SLC (2011) Optimization of the operating conditions using factorial designs for determination of uranium by inductively coupled plasma optical emission spectrometry. Microchem J 97:113–117

Ghaedi M, Pakniat M, Mahmoudi Z, Hajati S, Sahraei R, Daneshfar A (2014) Synthesis of nickel sulfide nanoparticles loaded on activated carbon as a novel adsorbent for the competitive removal of methylene blue and safranin-O. Spectrochim Acta 123A:402–409

Saracoglu S, Soylak M, Elci L (2003) Preconcentration of Cu (II), Fe(III), Ni (II), Co (II) and Pb(II) ions in some manganese salts with solid phase extraction method using chromosorb-102 resin. Acta Chim Slov 50:807–814

Narin I, Soylak M, Elci L, Dogan M (2001) Separation and enrichment of Chromium, copper, nickel and lead in surface sea water samples on a column filled with amberlite XAD-2000. Anal Lett 34:1935–1947

Roosta M, Ghaedi M, Daneshfar A, Sahraei R (2014) Experimental design based response surface methodology optimization of ultrasonic assisted adsorption of safaranin O by tin sulfide nanoparticle loaded on activated carbon. Spectrochim Acta 122A:223–231

Elci L, Soylak M, Uzun A, Buyukpatir E, Dogan M (2000) Determination of trace impurities in some nickel compounds by flame atomic absorption spectrometry after solid phase extraction using Amberlite XAD-16 Resin. Fresenius J Anal Chem 368:358–361

Goodwin WE, Rao Raghu R, Chatt A (2013) Reversed-phase extraction chromatography-neutron activation analysis (RPEC-NAA) for copper in natural waters using Amberlite XAD-4 resin coated with 1-(2-thiazolylazo)-2-naphthol. J Radioanal Nucl Chem 296:489–494

Soylak M, Sahin U, Elci L (1996) Spectrophotometric determination of molybdenum in steel samples utilising selective sorbent extraction on Amberlite XAD-8 Resin. Anal Chim Acta 322:111–115

Zolfonoun E, Salahinejad M (2013) Preconcentration procedure using vortex-assisted liquid–liquid microextraction for the fast determination of trace levels of thorium in water samples. J Radioanal Nucl Chem 298:1801–1807

Senturk HB, Gundogdu A, Bulut VN, Duran C, Soylak M, Elci L, Tufekci M (2007) Separation and enrichment of gold(III) from environmental samples prior to its flame atomic absorption spectrometric determination. J Hazard Mater 149:317–323

Tuzen M, Saygi KO, Soylak M (2008) Novel solid phase extraction procedure for gold(III) on Dowex M 4195 prior to its flame atomic absorption spectrometric determination. J Hazard Mater 156:591–595

Soylak M (1998) Determination of trace amounts of copper in metallic aluminium samples after separation and preconcentration on an activated carbon column. Fresenius Environ Bull 7:383–387

Khan S, Soylak M, Kazi G (2013) Room temperature ionic liquid-based dispersive liquid phase microextraction for the separation/preconcentration of trace Cd2+ with 1-(2-pyridylazo)-2-naphthol (PAN) complex from environmental and biological samples using and determined by FAAS. Biol Trace Elem Res 156:49–55

ALOthman ZA, Yilmaz E, Habila M, Soylak M (2013) Development of a dispersive liquid–liquid microextraction combined with flame atomic absorption spectrometry using a microinjection system for the enrichment, separation and determination of nickel in water samples. Desalin Water Treat 51:6770–6776

Chen JH, Ding-Qiang L, Chen B (2013) Removal of U(VI) from aqueous solutions by using MWCNTs and chitosan modified MWCNTs. J Radioanal Nucl Chem 295:2233–2241

Divrikli U, Soylak M, Elci L (2003) Separation and enrichment of gallium (III) as 4-(2-thiazolylazo) resorcinol (TAR) complex by solid phase extraction on Amberlite XAD-4 adsorption Resin. Anal Lett 36:839–852

Praveen RS, Metilda P, Daniel S, Prasada Rao T (2005) Solid phase extractive preconcentration of uranium(VI) using quinoline-8-ol anchored chloromethylated polymeric resin beads. Talanta 67:960–967

Greene PA, Copper CL, Berv DE, Ramsey JD, Collins GE (2005) Colorimetric detection of uranium(VI) on building surfaces after enrichment by solid phase extraction. Talanta 66:961–966

Sadeghi S, Sheikhzadeh E (2009) Solid phase extraction using silica gel modified with murexide for preconcentration of uranium (VI) ions from water samples. J Hazard Mater 163:861–868

Yousefi SR, Ahmadi SJ, Shemirani F, Jamali MR, Salavati-Niasari M (2009) Simultaneous extraction and preconcentration of uranium and thorium in aqueous samples by new modified mesoporous silica prior to inductively coupled plasma optical emission spectrometry determination. Talanta 80:212–217

Jain VK, Pandya RA, Pillai SG, Shrivastav PS (2006) Simultaneous preconcentration of uranium (VI) and thorium(IV) from aqueous solutions using a chelating calix[4]arene anchored chloromethylated polystyrene solid phase. Talanta 70:257–266

Liu M, Dong F, Yan X, Zeng W, Hou L, Pang X (2010) Biosorption of uranium by Saccharomyces cerevisiae and surface interactions under culture conditions. Bioresour Technol 101:8573–8580

Lad SN, Mohite BS (2014) Column chromatographic separation of Ce(III) from U(VI) and other elements in hippuric acid medium as an analytical application of poly[dibenzo-18-crown-6]. J Radioanal Nucl Chem 299:501–507

Nilchi A, Dehaghan T, Garmarodi S, Rasouli S (2013) Solid phase extraction of uranium and thorium on octadecyl bonded silica modified with Cyanex 302 from aqueous solutions. J Radioanal Nucl Chem 295:2111–2115

Nisa QU, Ali A, Khan MH (2013) FI-spectrophotometric determination of uranium after preconcentration on an anion exchange resin. J. Radioanal Nuc Chem 295:2203–2214

Fangting C, Xiaolin W, Xiong J (2013) Polyvinyl alcohol fibers with functional phosphonic acid group: synthesis and adsorption of uranyl (VI) ions in aqueous solutions. J Radioanal Nucl Chem 296:1331–1340

Acknowledgments

Nusrat Jalbani is thankful to the Scientific and Technological Research Council of Turkey (TUBITAK) under “2216 Research Fellowship Programme for Foreign Citizens” for financial support.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Jalbani, N., Soylak, M. Spectrophotometric determination of uranium using chromotrope 2R complexes. J Radioanal Nucl Chem 301, 263–268 (2014). https://doi.org/10.1007/s10967-014-3132-z

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10967-014-3132-z