Abstract

Mesoporous carbon foam (MCF) was prepared by via the Pechini method which is facile and template-free. The MCF was characterized by field emission scanning electron microscopy, transmission electron microscopy, X-ray diffraction and BET surface area analysis. Afterwards, the MCF was dispersed in the natural hydrogel salep to give a composite. Finally, myoglobin was immobilized on the composite and then placed on a glassy carbon electrode (GCE). The modified GCE gives a distinct quasi-reversible redox peak during electroreduction of hydrogen perxide (H2O2). The estimated electron transfer coefficient (α) and the heterogeneous electron transfer rate constant (ks) for redox process of Mb are 0.54 and 2.25 s−1, respectively. The sensor, best operated at −0.2 V (vs. Ag/AgCl), responds to H2O2 in the 1.0 to 80 μM H2O2 concentration range, with a 180 nM limit of detection (at S/N ratio of 3). The technique was applied to the determination of H2O2 in spiked fetal bovine serum samples.

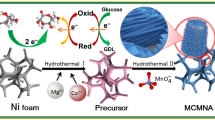

Mesoporous carbon foam (MCF) synthesis, dispersion in Salep solution, preparing the Salep-MCF composite (S-MCF), immobilizing the Mb at S-MCF and preparing Mb/S-MCF composite, Casting the Mb/S-MCF on electrode surface to prepare Mb/S-MCF/GCE and electrochemical behavior of biosensor.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

The direct electron transfer between proteins and electrode surface has been widely considered since the first reports about immobilization of cytochrome c on tin-doped indium oxide electrodes [1]. Myoglobin (Mb is an essential oxygen-transporter in mammalian skeleton and muscle structures [2]. Mb has been applied as an ideal model system for research on direct electron-transfer (DET) of hemoproteins and enzymes owning to its commercial availability, well- known structure and enzyme-like performance [2, 3]. It is worthwhile to select a substrate on which these proteins ca be immobilized and as a result, the DET between these molecules and electrode surface is facilitated.

Carbon based nanocomposites have been applied as a substrate for the immobilization of hemoproteins on the electrode surface [4, 5]. Among them, mesoporous carbon (MC) has high stability and efficient electronic features. MC possess numerous exclusive characteristics, such as meso-structure, abundant pores, admirable mass transfer, distinct pore size, excessive specific surface area, low dielectric constant and great pore volume [4, 6]. Therefore, MC has been applied as a suitable substrate for Mb immobilization and final application for electrode modification. The electrochemical properties of MC is well studied. The features and capabilities of mesoporous materials, e.g. MC, in electrochemical devices (sensors and biosensors) have been explained in detail in previously published review [7]. Also, large number of procedures for MC fabrication [8,9,10], and its application in sensors and biosensors have been reported [11,12,13].

The use of MC, especially in electrochemical devices, suffers from two main drawbacks. First, MC synthesis requires a special template and second, defect is the low dispersity of pristine MC in aqueous medium. In order to tackle these unresolved issues, there is a need for simple synthesis method of MC with low cost and template-free features. Moreover, an appropriate medium with high ability to disperse the pristine MC without covalent functionalization is required since the covalent functionalization results in broking the MC structure. Subsequently depletes the applicable properties of this material, is really desirable.

Pechini method is introduced to synthesize MC to enhance compositional homogeneousness [14, 15]. This method has been extensively applied in the nanocrystals synthesis owning its low cost, non-toxicity, simplicity and template-free characteristics features compared to other methods [15]. Pechini method is carried out by a rigorous mixing of positive ions with a solution, organized conversion of the blend into a polymeric compound, and finally elimination of the polymer background and progress of a homogenous oxide precursor.

In order to synthesize mesoporous carbon (MC) using the Pechini method, polymeric compound is required to prepare the stable suspension. Hydrophilic polymers such as sodium alginate and chitosan are frequently used for MC synthesis due to theirs high ability as dispersant to create stable carbon materials suspensions [16, 17]. We introduced Salep for the first time as a dispersant for epinephrine detection previously [18]. Salep is a hydrophilic polymer, similar to sodium alginate and chitosan in structure and properties, with advantageous properties such as cheapness, high availability, non-toxicity and gelling possessions [19]. Salep is preferred over chitosan and sodium alginate due to its higher availability and lower price. In the previous work we introduced MCF as a new modifier, but in this work MCF was used as a novel substrate for Mb immobilization [18]. This work show that MCF can act as a suitable substrate for stabilizing myoglobin and facilitating its electron transport. A biosensor was developed in this work, but in the previous work, an electrochemical sensor was established. It is important that a substrate be able to immobilize a biomolecule, this can be a new platform for improving biosensors.

MC foam (MCF) with spread surface area and appropriate distribution of pore size is prepared here via template-free Pechini method. The method is improved compare to traditional Pechin method as a matter of some basically changes especially in metal precursor and final stage. The metallic production is removed and instead of metallic production, polymeric and chelating agents were used in final step of pechini method. As a result, the MCF is mixed with Salep and a composite of S-MCF is fabricated with admirable dispersion. Finally, Mb was immobilized on or into S-MCF composite and resultant hybrid was casted on the GCE surface to design a novel biosensor (S-MCF/Mb/GCE). The biosensor displayed a fast DET, and also noticeable catalytic activity toward H2O2 reduction with extensive linear range and low detection limit.

Materials and methods

Chemicals

Salep was purchased from local source (ShahreKord, Iran). All other reagents were in analytical grade and were purchased from Merck (http://www.merck.com) or Fluka (http://www.sigmaaldrich.com) and applied without further purification. The phosphate buffer (0.1 M, pH 7.0) was used as supporting electrolyte and doubly distilled water was used during the all of investigations.

Apparatus and measurements

All electrochemical analysis were performed by means of an potentiostat/galvanostat (AUTOLAB PGSTAT-100, metrohm-autolab, Switzerland) with a typical three-electrode association composed of an Ag/AgCl (3 M KCl) reference electrode, a platinum auxiliary electrode, and Mb/S-MCF/GCE as working electrode. The morphology of MCF were investigated through trans-mission electron microscopy (TEM) tool (JEM-1200 EX/S) and field emission-scanning electron microscopy (FE-SEM) device (JSM-6700F FE-SEM, JEOL Ltd., Japan). XRD analysis were carried out by means of a Bruker AXS (D8 Advance) (www.bruker.com) X-ray diffractometer. N2 adsorption–desorption was established by Brunanuer–Emmett–Teller (BET) tests using Micromeritics Tristar 3000 gas adsorption analyzer. The distributions of pore size were estimatedvia BET theory and the Barrett–Joyner–Halenda (BJH) technique, the MCF were heated at 433 K in vacuum condition for about 5 h.

Biosensor fabrication

Mesoporous carbon foam (MCF) was prepared via the Pechini method [14] as described in the Electronic Supporting Material (ESM).

Then the GCE was polished with 1.0, 0.3 and 0.05 μm alumina slurry subsequently, then cleaned in bath sonication for 10 min and finally rinsed with distilled water. Afterwards, the MCF (2 mg) and Salep (2 mg) were mixed in water (1 mL) and the resulted mixture was sonicated for 30 min at room temperature to achieve a homogeneous and stable suspension containing 2.0 mg mL−1 MCF. Then, 4 mg Mb was dissolved in 1 mL phosphate buffer at pH 5.0 (the iso-electric point of Mb is at pH around 6.8 [20]), this biomolecule was positively charged inside the applied buffer (pH 5.0). Mb is adsorbed on the MCF surface essentially via electrostatic interactions. The resultant suspension was stirred at 4 °C for about 100 min which caused the Mb to adsorb on the MCF surface. For the fabrication of biosensor, 5 μL of suspension was casted on the cleaned GCE surface and dried in air. The biosensor (Mb/S-MCF/GCE) were washed with doubly distilled water and dried for 2 h at 4 °C. As a control, the similar protocols were applied to immobilize Mb on the bare GCE and electrode was modified with only Salep without presence of MCF.

Results and discussion

Choice of material

Salep is a flour made from the tubers of the orchid genus Orchis. It is widely consumed in beverages and desserts [19]. Carbon baesd nanocomposites, specially with biopolymers such as sodium alginate, chitosan and nafion, show high performance in electrochemical sensors and biosensors. Salep is similar to sodium alginate and chitosan in structure and properties, has advantageous properties such as cheapness, high availability, non-toxicity and gelling possessions. Salep is more preferred in comparison with chitosan and sodium alginateare due to its higher availability and lower price. Salep is available in many stores, confectioneries or even at some houses. MCF disperses in salep soloution homogeneusly. This composite, S-MCF, can provide an appropriate matrix for biomolecules immobilization.

Characterization of the mesoporous carbon foam

Morphology and size distribution of the MCF were characterized by means of TEM and FE-SEM methods. Figure 1a shows TEM image of the MCF in low. TEM image display the distinct pores with three dimensional channel organizations. TEM image with higher magnification is also shon in Fig. 1S (see ESM). Figure 1b, FE-SEM images of the MCF, shows the gritty with a three-dimensional and porous structure of the MCF. This porous structure of MCF, observed by TEM and SEM studies, can create an advanced substrate for entrapment of proteins and enzymes which is suitable material to be applied for biosensor area.

The XRD methods was applied for additional investigation of synthesized MC. Figure 2a indicated that the wide diffraction peak located at about 23°, a characteristic of carbon based materials, disclosed an amorphous nature for the MCF. This peak is in good agreement with previously published XRD reports for the carbon materials [28, 30].

Figure 2b shows the N2 adsorption–desorption isotherms for MCF sample. Isotherm curves displayed characteristic IV shapes which is in accordance to the IUPAC arrangement. This curves confirms the mesoporous structure for prepared carbon structure [28]. According to isotherms and corresponding BET data, the estimated specific surface area and pore volume were obtained about 1435.65 m2 g−1 and 1.2 cm3 g−1 respectively. The average pore diameter of 6 nm was obtained from BJH method, which is in agreemnt with the TEM results.

The MC needs to be dispersed in aqueous or organic media to be used for biosensor application. MC drastically has tendency to aggregate in aqueous medium due to its poor interaction with water molecules. In contrast, MC can form homogeneous and stable suspension in Salep solution (see Fig. 2S). The binding between MC and nonpolar side-chains of hydrophilic biopolymers produced a stable dispersions of these nanoparticles in water which results in stable black suspension (stable more than 20 h) [16]. The mechanism is explained by breaking the MC aggregations as a result of forming complex with salep. It has proper biocompatibility which donates superior biocompatibility to the S-MCF composite. Furthermore, salep provided a suitable surface for immobilizing the Mb molecules and it is efficient dispersant for carbon materials.

Direct electrochemistry of Mb/S-MCF/GCE

Figure 3 illustrates the cyclic voltammograms of Mb/S-MCF/GCE, Mb/S/GCE and Mb/GCE in N2 saturated 0.1 M phosphate buffer at pH 7.0. There are no clear redox signals for Mb/GCE (Fig. 3a) and Mb/Salep modified electrode (Fig. 3b). Figure 3a shows the cyclic voltammogram of Mb/S-MCF/GCE at the sweep rate of 100 mVs−1 that represents a distinct and quasi-reversible redox peak at −0.32 V (Epc) and −0.23 V (Epa), and the peak-to-peak separation is found to be around 90 mV. These results corresponds to the characteristics of Mb Fe(III)/Fe(II) redox center [21], which show a fast DET for Mb enmeshed into the composite film. The improved DET of Mb incorporated in S-MCF composite film compared to Mb/S/GCE and Mb/GCE can arise from the critical role of MCF as a promoter component to facilities DET between Mb and electrode surface. This results confirms that the (i) MCF has an absolute influence on the kinetics of biosensor, (ii) MCF provides a suitable matrix for electron transfer of Mb and (iii) MCF creates a promising mesoporous environment to prevent denaturation of Mb [20, 21]. In addition, the anodic and cathodic peaks are closely symmetric and the oxidation and reduction signal heights are approximately equal (see, Fig. 3c). These results indicate the fully transformation of Fe(III) species in center of Mb to Fe(II) species in the reverse scan rate confirming an ideal behavior for immobilized hemoprotein.

The influence of scan rate on the signals was examined to explore the features of Mb at the Mb/S-MCF/GCE by using various sweep rates (please see ESM). More investigates have been performed to study the effect of pH on the electrochemical behavior of Mb/S–MCF/GCE. The cyclic voltamograms of Mb/S-MCF/GCE recorded in buffers for pH ranging from 3.0 to 9.0. Reslts indicated that both reduction and oxidation potential peaks shift negatively when the pH increases (See Fig. 3S in ESM). This consequences proves that the process is along with the proton transfer. Moreover, the slopes of Epa and Epc vs. pH are −51.8 mV. pH −1 and −50.3 mV. pH −1 respectively. The obtained slopes for Epa and Epc are very close to the Nernstian slope of −59 mV for electrochemical procedures involving the equal number of electrons and protons [22]. The slope of −59 mV represented the process of single-electron transfer combined with one proton as follows [23]: Mb [Fe (III) + e− + H+ ↔ Mb [H+-Fe (II)].

From Fig. 3S it can be understood that the biosensor shows better behavior in pHs of 3 and 7 compared to other pHs. So, pH 7.0 (pH of biological medium) was used in all experiments.

Electro-catalytic reduction of H2O2 at Mb/S-MCF/GCE

The DET of Mb was improved at the S-MCF nanocomposite substrate as entrapped Mb into the S-MCF composite possess the enzymatic performance. The Mb/S-MCF provides a suitable platform for fabricating the third-generation of biosensor for H2O2 detection since the heme is perfectly recognized as an effective electro-catalyst toward H2O2 reduction. The behavior of biosensor to electro-reduction of H2O2 was studied here to further explore the activity of entrapped Mb into S-MCF composite film.

Figure 4 displays the cyclic voltammogram of Mb/S-MCF/GCE in the presence of H2O2 (Fig. 4a) and the absence of H2O2 (Fig. 4b and c). The evaluation of these curves reveals that after adding H2O2, the reduction current increases accompanied by decreasing oxidation peak. These performance confirms the electro-catalytic activity of the immobilized Mb on S-MCF toward the reduction of H2O2 [5, 20]. Additionally, this result might be explained by bio-activity of the immobilized Mb on the S-MCF medium which exhibits suitable catalytic performance to the H2O2 electro-reduction. The electro-reduction mechanism can be explained as follows [24]:

Analytical performance of the Mb/S-MCF/GCE toward determination of H2O2

The Mb/S-MCF/GCE was applied to detect H2O2 concentration. For this purpose, the amperometric experiments were accomplished in an electrochemical cell containing 0.1 M phosphate buffer, stirred at 1000 rpm in the applied potential of −0.2 V. Figure 5 displays the amperometric signals of Mb/S-MCF/GCE to the additions of H2O2 concentrations. The reaction at the surface of biosensor reaches to a dynamic steadiness rapidly within the time period of 2–5 s (immediately after each addition of the H2O2). As it is presented in inset of Fig. 5, the linear range is from 1.0 to 80.0 μM and the linear equation was obtained as follow: I (μM) = −0.3774 CHydrogen peroxide (μM) − 1.8454 (R2 = 0.9994). The limit of detection for the methode is about 180 nM (S/N = 3). Also, the RSD was realized to be about 2.9%, which demonstrate the repeatability/reproducibility of the method. The sensitivity was estimated to be 2.2 μA. μM. cm-2. Compared to the other electrochemical H2O2 sensors and biosensors, the Mb/S-MCF/GCE shows acceptable performance (Table 1).

Amperometric responses of Mb/S-MCF/GCE to stepwise addition of H2O2 (1.0 to 80 μM) in 0.1 M phosphate buffer solution (pH 7.0) in the conditions of −0.2 V constant potential and rotation speed of 1000 rpm. Inset a is the plot of current against H2O2 concentration. (Inset b) Currenttime responsesof the Mb/S-MCF/GCE to 10 μM H2O2 (first and last additions) and 0.1 mMAA, Dp, UA, Glu, CA and L-Tyr under the conditions of −0.2 V applied potential and rotation speed of 1000 rpm

The Michaelis-Menten constant (KM) can be estimated from the Line weaver-Burk equation (Iss = Imax - KM (Iss/Css), where Iss is the steady-state current, Css is the concentration of analyte, and Imax is the determined signal measured in saturated H2O2 concentration. The KM for Mb/S-MCF/GCE was calculated to be about 0.22 mM confirmaing the high affinity of the biosensor to H2O2 [35].

Biosensor reproducibility, repeatability, and stability

The investigation of reproducibility, repeatability and stability of a biosensor are actually essential for its application in real sample analysis. Therefore, these parameters in the optimal conditions need to be examined for the biosensor. Reproducibility of the Mb/S-MCF/GCE was estimated in 0.1 M phosphate buffer at pH 7 containing 10 μM H2O2 for four detections. The relative standard deviation (RSD) was found to be about 2.6%. Moreover, to obtain repeatability of the biosensor, three independent Mb/S-MCF/GCE were applied to estimate the concentration of 10 μM H2O2. The RSD was found to be about 3.1%, which reveals the outstanding repeatability for biosensor production method. To observe the long-term stability of Mb/S-MCF/GCE, firstly the response of biosensor was obtained in 10 μM H2O2 solution and then the electrode was washed with doubly distilled water and reserved in 0.1 M buffer at pH 7. After 1 and 3 weeks, the decreased signal were found to be about 2.1% and 5.9% respectively. These results proves that this biosensor has respectable stability, repeatability, and reproducibility.

Interference studies and real sample analysis

Some compounds possibly presented in biological samples were explored for their interference on the amperometric detection of 10 μM H2O2. Ascorbic acid (AA), dopamine (Dp), uric acid (UA), Glucose (Glu), salicylic acid (SA), and L-tyrosine (L-Tyr) interfering effects on the amperometric signal of H2O2 was observed and represented in insert b of Fig. 5. The biosensor displays no amperometric current toward 0.1 mM of each cited species. Nevertheless, a distinct signal was appeared after addition of 10 μM H2O2. The selectivity of this biosensor were aroused from the low applied potential (−0.2 V) in amperometric experiments.

To end, disinfected fetal bovine serum (FBS) was used as real sample in order to evaluate the capability of the biosensor in biological sample analysis. FBS was pretreated using an arrangement of membrane filtration and centrifugation. The filtration process performs through the application of three sterilizing grade membrane filters (0.1 μm), serially. Next, the solution of methanol (5% (v/v)) was added to the treated samples and centrifuged under 7500 rpm for around20 min. Each sample was diluted with 0.1 M buffer (pH 7) and spiked with the standard solutions of H2O2 ranging from 1.0 to 10.0 μM. Amperometric method was used for evaluation of H2O2 content in samples. The consequences have been reported in Table 2.The average recovery was calculated to be around 97.3%. Above results suggest that the S-MCF composite performs as an ideal substrate for immobilizing Mb and the biosensor is reliable and effective in determination of H2O2 in biological samples.

Conclusion

The salep solution shows high ability to disperse MCF produced via Pechini technique. This carbon nanocomposite is an appropriate matrix for Mb immobilization. MCF dispersing in salep increased its biocompatibility and considerably assisted the bio-electrochemical capability of MCF. The DET of Mb entrapped into S-MCF composite film was principally improved.The biosensor productively sensed H2O2 with short response time (2–5 s), extensive linear range and low detection limit. This biosensor reveals good sensitivity, standing stability, also acceptable repeatability and reproducibility. In overal, the bio-device organized in this assay is promising for the future development of sensors and biosensors. Perhaps the storage conditions of the biosensor is one of its limitations, which is done by placing it in a buffer and holding in the refrigerator.

References

Yeh P, Kuwana T (1997) Reversible electrode reaction of cytochrome c. Chem Lett 6:1145

Yagati AK, Lee T, Min J, Choi JW (2013) An enzymatic biosensor for hydrogen peroxide based on CeO2 nanostructure electrodeposited on ITO surface. Biosens Bioelectron 47:385

Liu H, Weng L, Yang C (2017) A review on nanomaterial-based electrochemical sensors for H2O2, H2S and NO inside cells or released by cells. Microchim Acta 184:1267

Habibi B, Jahanbakhshi M (2015) Direct electrochemistry of hemoglobin in a renewable mesoporous carbon ceramic electrode: a new kind of hydrogen peroxide biosensor. Microchim Acta 182:957

Wang Y, Han M, Ye X, Wu K, Wu T, Li C (2017) Voltammetric myoglobin sensor based on a glassy carbon electrode modified with a composite film consisting of carbon nanotubes and a molecularly imprinted polymerized ionic liquid. Microchim Acta 184:195

Lu X, Xiao Y, Lei Z, Chen J, Zhang H, Ni Y, Zhang Q (2009) A promising electrochemical biosensing platform based on graphitized ordered mesoporous carbon. J Mater Chem 19:4707

Walcarius A (2013) Mesoporous materials and electrochemistry. Chem Soc Rev 42:4098

Jun S, Joo SH, Ryoo R, Kruk M, Jaroniec M, Liu Z, Ohsuna T, Terasaki O (2000) Synthesis of new, nanoporous carbon with hexagonally ordered mesostructure. J Am Chem Soc 122:10712

Shi X, Chen Y, Lai Y, Zhang K, Li J, Zhang Z (2017) Metal organic frameworks templated sulfur-doped mesoporous carbons as anode materials for advanced sodium ion batteries. Carbon 123:250

Tian M, Cui X, Yuan M, Yang J, Ma J, Dong Z (2017) Efficient chemoselective hydrogenation of halogenated nitrobenzenes over an easily prepared γ-Fe2O3-modified mesoporous carbon catalyst. Green Chem 19:1548

Habibi B, Jahanbakhshi M (2014) A novel nonenzymatic hydrogen peroxide sensor based on the synthesized mesoporous carbon and silver nanoparticles nanohybrid. Sensors Actuators B Chem 203:919

Walcarius A (2017) Recent trends on electrochemical sensors based on ordered mesoporous carbon. Sensors 17(8):1863

Ni Y, Liao Y, Zheng M, Shao S (2017) In-situ growth of Co3O4 nanoparticles on mesoporous carbon nanofibers: a new nanocomposite for nonenzymatic amperometric sensing of H2O2. Microchim Acta 184:3689

Pechini M., US patent no. 3330697, July

Hassanzadeh-Tabrizi S (2012) Synthesis and luminescence properties of YAG: Ce nanopowder prepared by the Pechini method. Adv Powder Technol 23:324

Zhao H, Zheng W, Meng ZX, Zhao HM, XX X, Zheng YF (2009) Bioelectrochemistry of hemoglobin immobilized on a sodium alginate-multiwall carbon nanotubes composite film. Biosens Bioelectron 24:2352

Zhang Z, Fu X, Li K, Liu R, Peng D, He L, Wang M, Zhang H, Zhou L (2016) One-step fabrication of electrochemical biosensor based on DNA-modified three-dimensional reduced graphene oxide and chitosan nanocomposite for highly sensitive detection of hg (II). Sensors Actuators B Chem 225:453

Jahanbakhshi M (2017) Mesoporous carbon foam, synthesized via modified Pechini method, in a new dispersant of Salep as a novel substrate for electroanalytical determination of epinephrine in the presence of uric acid. Mater Sci Eng C 70:544

Rezanejade Bardajee G, Hooshyar Z (2014) One-pot synthesis of biocompatible superparamagnetic iron oxide nanoparticles/hydrogel based on salep: characterization and drug delivery. Carbohydr Polym 101:741

Zhan T, Guo Y, Xu L, Zhang W, Sun W, Hou W (2012) Electrochemistry and electrocatalysis of myoglobin intercalated in mg 2 Al–Cl layered double hydroxide and ionic liquid composite material. Talanta 94:189

Palanisamy S, Karuppiah C, Chen SM, Emmanuel R, Muthukrishnan P, Prakash P (2014) Direct electrochemistry of myoglobin at silver nanoparticles/myoglobin biocomposite: application for hydrogen peroxide sensing. Sensors Actuators B Chem 202:177

Bond AM (1980) Modern polarographic methods in analytical chemistry, CRC Press Vol: 4

Sun YX, Wang SF (2007) Direct electrochemistry and electrocatalytic characteristic of heme proteins immobilized in a new sol–gel polymer film. Bioelectrochemistry 71:172

Canbay E, Sahin B, Kiran M, Akyilmaz E (2015) MWCNT–cysteamine–Nafion modified gold electrode based on myoglobin for determination of hydrogen peroxide and nitrite. Bioelectrochemistry 101:126

Wang J, Wang Y, Cui M, Xu S, Luo X (2017) Enzymeless voltammetric hydrogen peroxide sensor based on the use of PEDOT doped with Prussian blue nanoparticles. Microchim Acta 184:483

Kafi AKM, Wali Q, Jose R, Biswas TK, Yusoff MM (2017) A glassy carbon electrode modified with SnO2 nanofibers, polyaniline and hemoglobin for improved amperometric sensing of hydrogen peroxide. Microchim Acta 184:4443

Chen TW, Palanisamy S, Che SM (2016) Non-enzymatic sensing of hydrogen peroxide using a glassy carbon electrode modified with a composite consisting of chitosan-encapsulated graphite and platinum nanoparticles. Microchim Acta 183:2861

Chen J, He P, Bai H, Lei H, Zhang G, Dong F, Ma Y (2016) A glassy carbon electrode modified with a nanocomposite consisting of carbon nanohorns and poly(2-aminopyridine) for non-enzymatic amperometric determination of hydrogen peroxide. Microchim Acta 183:3237

Mei L, Zhang P, Chen J, Chen D, Quan Y, Gu N, Zhang G, Cui R (2015) Non-enzymatic sensing of glucose and hydrogen peroxide using a glassy carbon electrode modified with a nanocomposite consisting of nanoporous copper, carbon black and nafion. Microchim Acta 183:1359

Zhang C, Zhang Y, Du X, Chen Y, Dong W, Han B, Chen Q (2016) Facile fabrication of Pt-Ag bimetallic nanoparticles decorated reduced graphene oxide for highly sensitive non-enzymatic hydrogen peroxide sensing. Talanta 159:280

Turunc E, Binzet R, Gumus I, Binzet G, Arsalan H (2017) Green synthesis of silver and palladium nanoparticles using Lithodora hispidula (Sm.) Griseb. (Boraginaceae) and application to the electrocatalytic reduction of hydrogen peroxide. Mater Chem Phys 202:310

Deac AR, Muresan LM, Cotet LC, Baia L, Turdean GL (2017) Hybrid composite material based on graphene and polyhemin for electrochemical detection of hydrogen peroxide. J Electroanal Chem 802:40

Huang B, Wang Y, Lu Z, Du H, Ye J (2017) One pot synthesis of palladium-cobalt nanoparticles over carbonnanotubes as a sensitive non-enzymatic sensor for glucose andhydrogen peroxide detection. Sensors Actuators B Chem 252:1016

Baccarin M, Janegitz BC, Berte R, Vicentini FC, Banks CE, Fatibello-Filho O, Zucolotto V (2016) Direct electrochemistry of hemoglobin and biosensing for hydrogen peroxide using a film containing silver nanoparticles and poly(amidoamine) dendrimer. Mater Sci Eng C 58:97

Mehta A, Patil S, Bang H, Cho HJ, Seal S (2007) A novel multivalent nanomaterial based hydrogen peroxide sensor. Sens Actuators A 134:146

Acknowledgements

The author is grateful to the Young Researchers and Elite Club, Islamic Azad University of ShahreKord, ShahreKord, Iran.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

The author(s) declare that they have no competing interests.

Electronic supplementary material

ESM 1

(DOCX 332 kb)

Rights and permissions

About this article

Cite this article

Jahanbakhshi, M. Myoglobin immobilized on mesoporous carbon foam in a hydrogel (selep) dispersant for voltammetric sensing of hydrogen peroxide. Microchim Acta 185, 121 (2018). https://doi.org/10.1007/s00604-017-2654-9

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s00604-017-2654-9